Abstract

The potential application of the digital twins concept and its principles to all industries, including agriculture, has recently been the subject of considerable research interest. Since livestock farming is one of the mainstays of the agricultural industry, contributing to food security as well as employment and income generation, digital twins appear to be a promising technology to address issues related to the intensive nature of livestock production systems, which are typically characterized by high levels of input and output. The objective of this study is to identify and analyze the latest scientific and technological contributions in the field of digital twins technology, with a view to its adoption and assimilation in livestock production systems in the context of Agriculture 5.0. In particular, the aim of this study is to synthesize the existing research and identify the opportunities and open issues related to the implementation of digital twins in livestock production systems. The results derived in the literature review indicate that digital twins is still in the early stages of development in livestock farming, but it has the potential to transform the industry. As Agriculture 5.0 evolves and the digital twins technology matures, it is expected to play an increasingly important role in the livestock farming industry.

1. Introduction

Food insecurity is a pervasive and pressing global issue that has far-reaching consequences for individuals, communities, and nations. Given that the world population in 2022 reached almost 8 billion and is expected to exceed 10 billion by the later part of the 21st century [1], the Food and Agriculture Organization (FAO) of the United Nations predicts that the production of food commodities needs to increase by at least 50% compared to 2012 [2]. On top of that, food insecurity is exacerbated by the intensification of occurrences of unusually severe weather events due to climate change and the economic crises, as well as ongoing armed conflicts like the Russo–Ukrainian war or other contingent circumstances, for instance, the COVID-19 pandemic [3]. Therefore, it seems imperative to ensure food security through higher agricultural productivity without compromising the long-term sustainability and resilience of agro-ecosystems [4]. In this sense, agricultural production systems face the challenge of meeting a rising food demand along with climate change-related conditions, the deterioration of natural resources due to their uncontrolled exploitation, the loss of biodiversity, and the increased food waste caused by the deficiencies in the agri-food supply chain while remaining profitable [5].

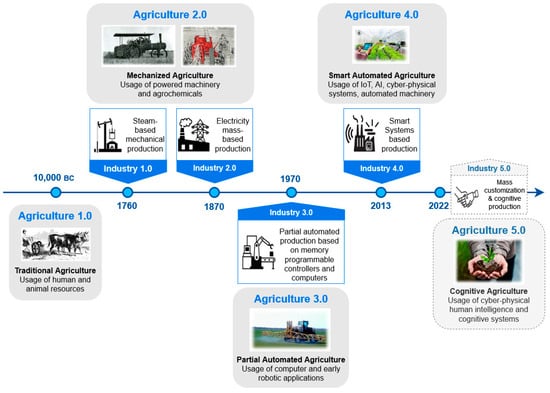

Considering the importance of the agricultural production system as a main pillar of the primary sector of industry, various scientific and technological approaches have been devised and implemented over time to increase the efficiency of their outputs [6]. Indeed, the agricultural sector has evolved throughout history, alongside the technological developments of all industrial revolutions, as illustrated in Figure 1, from the first agricultural revolution under the term “Agriculture 1.0” to the current agricultural revolution, attributed as “Agriculture 5.0” [5,7], which represents the emerging trend that the agricultural sector is going to adopt in the upcoming years. In particular, the concept of Agriculture 5.0 focuses on transforming agricultural production systems through the integration of the recent advancements in smart technologies [8] so as to enhance their efficiency while making them environmentally sustainable [9].

Figure 1.

Timeline of industrial and agricultural revolutions.

Rapid progress in the application of leading-edge technologies, such as wireless sensor networks (WSNs) and real-time sensing [10], artificial intelligence (AI) [11] and machine learning (ML) [12], edge computing [13], big data analytics and the Internet of Things (IoT) [14] as part of Agriculture 4.0 [15], are enabling agricultural production systems to be fully data-driven in the context of Agriculture 5.0 [16] and, therefore, raise attention in the digital twins (DTs) concept and their feasible applications in the agricultural sector to achieve the objectives of sustainable development [17]. Actually, based on the integrated farm management (IFM) approach [18], an agricultural production system is potent at adapting to dynamic changes [19] as it is updated on a continuous basis and in real time based on data feedback from sensors and devices that collect the parameters related to the properties of its physical entities and environment, as well as the system itself [8,20]. In this respect, the DTs concept enables the virtual replication of physical entities with corresponding digital ones that are accurate and “live” [21], bridging them according to a cyber-physical architecture under which any change that occurs in the physical entities simultaneously and continuously modifies their virtual twins [22].

The potential of applying the DTs concept and the principles it represents to all industrial sectors, including the agricultural one, has lately gained great research interest, as reported in the recent literature [22,23,24,25,26,27], concerning the case of arable agriculture in particular. In this area, DTs represent virtual representations of extensive fields. These digital replicas enable farmers to accurately understand critical factors, such as soil health, moisture levels, and crop growth [28]. This approach goes beyond conventional practices, offering targeted interventions and resource optimization through the ability to rapidly adapt to evolving conditions and ensure resilience against uncertainties [29].

Likewise, considering that livestock farming is one of the leading sectors of the agricultural industry, adding to food safety [30], as well as creating work opportunities and income, DTs may emerge as a promising technology for addressing issues related to the intense nature of livestock production systems [30], which are typically characterized by high levels of input and output per farming unit [31]. To this end, by creating virtual counterparts of livestock and the environment, DTs can facilitate the real-time monitoring of individual animals, providing farmers with insights into feeding patterns, stress factors, and optimal breeding strategies, allowing for a proactive approach to health management as well as disease prevention, thereby ensuring not only productivity but also the welfare of the livestock [32].

Despite the prominent benefits that derive from the integration of the DTs technology into livestock production systems, the number of works in the literature that review recent advances in DTs technology (with a focus on their applications in livestock production systems) has been, to the best of our knowledge, rather limited to date. Therefore, this study is prompted by the objective of tracking the latest research works in the literature related to the application of the DTs technology in livestock production systems in the context of Agriculture 5.0, as well as to synthesize their outcomes in order to identify the opportunities and challenges regarding this topic.

Following the introduction in Section 1, the rest of the paper is structured as follows: In Section 2, the concept of DTs is specified based on the recent definitions reported in the literature, and its integration in livestock farming is also studied. Then, in Section 3, the methodology followed for reviewing the literature is overviewed. The results of the search in the literature are presented in Section 4, along with an analysis of the recent applications of DTs in livestock production systems, and Section 5 discusses the results of this study and identifies the open issues for the implementation of DTs in the livestock sector. Finally, in Section 6, the conclusions of this study are presented, and some directions for future research are proposed.

2. Digital Twins Concept Integration in Livestock Farming

2.1. The Digital Twins Concept

The digital twins (DTs) concept was initially conceptualized by Michael Grieves, referring to the management of the product life cycle in 2003 [33]—a virtual version of a physical product comprising information about the product in question [34]. In a more specific definition, a DT can be attributed as a virtual copy of a product, process, or service that incorporates all of the above features [35]. Miller et al. [36] further extended the definition of the DTs concept as the integration of multiple models within a model-based enterprise. According to this definition, a digital twin can be formed by establishing associations between different models as well as relationships between the data stored in various domains. Stark and Damerau [37] provided a more comprehensive definition of the DTs concept by describing it as “a digital representation of an active unique product (real device, object, machine, service, or intangible asset) or unique product-service system (a system consisting of a product and a related service) that comprises its selected characteristics, properties, conditions, and behaviours by means of models, information, and data within a single or even across multiple life cycle phases”. While the meaning of the DTs concept may seem straightforward, its definition is debated and constantly evolving, as is reported in the literature [38,39,40,41]. The various existing definitions are characterized by specific features deriving from multiple use cases employing the DTs concept. What may be expressed in the simplest terms, is that a DT consists a digital duplicate of an existing physical entity [23].

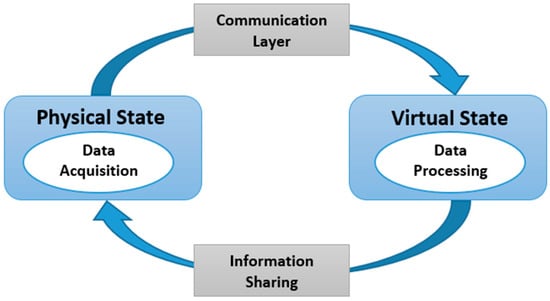

The lack of consistency in the definition of the DTs concept makes the identification of its main components rather challenging. As DTs was first introduced by Grieves [33], it applies to a system constituted of three principal subsystems: (a) the real space with the physical products, (b) the cyberspace with the virtual products, and (c) the interconnection of the virtual and real products via data and information. Based on this structure, the DTs flow is represented as a loop, called twinning, where data are directed from the physical to the virtual state, while information and processes are directed in reverse, as depicted in Figure 2 [26]. This concept has been recently extended by Tao et al. [42] to five components, involving data and services as a part of a DT system, while in [43], verification, validation, and accreditation were also identified as components of a DT system, stating that cyber and physical space are seamlessly integrated.

Figure 2.

The basis of the digital twins concept.

Establishing a commonly accepted definition of the DTs concept constitutes a step forward in the advancement of this technology. By contextualizing future use cases of DTs in a unified notion and terminology, a broad set of the diverse DTs physical entities may be implemented in a way that remains consistent with the DTs paradigm so that its intended benefits can be fully achieved and shared across all sectors.

2.2. The Digital Twins Concept in Livestock Farming

Τhe livestock sector is undergoing rapid development on a worldwide level as a result of the growing demand for animal products, driven by the need for food safety [44] due to population increase and rapid urbanization, as well as stimulating prosperity in the industrialized world and most developing countries [45]. In addition to the potential benefits associated with the growing development of the livestock sector, a number of challenges seem to arise from operational, socio-economic, environmental, and sanitary issues [30].

That which is characteristic of livestock production systems (at present) is their intensive nature, which is associated with both greater volumes of inputs (i.e., farm size, manpower, financial resources, etc.) and outputs per production holding. In this perspective, the number of holdings is declining, while the number of animals reared in closed, environmentally controlled, automated facilities is rising [46]. Moreover, vertical integration is often embedded in the view that a single company can be in charge of the overall production system (e.g., from the feed mill to the processing plant), which is configured to achieve maximum output with all of its components running consistently at full load [47]. Therefore, whatever disorder may occur at any stage of the production chain will lead to a direct impact on both the upstream and downstream levels, with direct implications not just for animal welfare but for humans and the wider environment as well. This fact is aligned with the emergent notion of “One Welfare”, an approach which, as reported in [48], gives recognition to the immediate and implicit associations between animal welfare and the well-being of people and the broader environment.

In response, the entire digitization of livestock production systems is often suggested [17] in the context of Agriculture 4.0 and, consequently, Agriculture 5.0 [5,7]. According to this approach, computationally enabled technologies [8], incorporating smart sensors, WSNs, AI and ML, Edge computing, big data analytics, the IoT, and other cutting-edge technologies, with DTs among them, are considered to be of great importance.

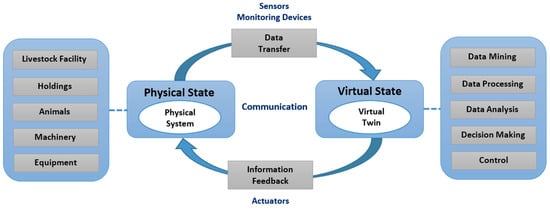

To this end, when integrating the DTs concept in livestock farming, the physical state accounts for a physical system that embodies the composite and dynamic environment of livestock facilities, with the boundaries of the DTs specified [49]. Herein, it has to be noted that the physical system is a fundamental component of a DT since the lack of it implies that the physical state merely represents a model [50]. To this end, the physical system involves the fundamental features of the incorporated physical objects and devices [51]; it can be comprised of an entire object with individual components found in a physical environment, a single component of the object [50], or an individual property of the object that is linked to other objects. In the case of livestock production systems, the physical system may indicatively consist of an entire facility, including animals, holdings, machinery, equipment, and feeding strategies, as well as a number of animals or just an animal body [52]. Finally, monitoring and sensing devices [53] are incorporated into the physical system so as to collect the data required. Accordingly, the virtual state accounts as a representation of the physical state model and data. By involving data mining, processing, and analytics by means of AI and ML techniques, the virtual state provides feedback for supporting decision-making and controlling the physical system so as to foresee any obscure matters and optimize its operation [54]. Finally, the twinning, which enables the interconnection between the physical and virtual state, accounts for the transmission of data from the physical system to its virtual twin, as well as for the reverse information feedback [55] to the livestock production system. The type of techniques incorporated for establishing such interconnection depends on the data volume, type, and source as well as the speed and rate that is required for achieving the minimum accepted delay both of the data transmission and information feedback [52,56]. Based on the aforementioned, Figure 2 has been elaborated upon, resulting in Figure 3, which depicts a schematic of the DTs concept in livestock farming.

Figure 3.

The digital twins concept for livestock farming.

3. Materials and Methods

Herein, the applications of the recently emerged DTs technology in livestock production systems are identified and studied for improving their outputs and enhancing their sustainability [9]. For this, a systematic review was conducted based on the methodology proposed by other systematic and bibliometric reviews, as per [26,57,58] and according to the PRISMA guidelines [59]. Moreover, the methodology introduced in [60] was taken into account since it is considered quite efficient for identifying related research sources based on rigid quality criteria [61]. On such a basis, the review was conducted according to five phases: (a) the determination of the research questions, (b) the selection of the information sources, (c) the planning of the search methodology, (d) the definition of the eligibility criteria, and (e) the selection of contributions.

- Determination of Research Questions. As previously mentioned, the scope of this study is to identify the latest research works in the literature related to the application of the DTs technology in livestock production systems in the context of Agriculture 5.0, as well as to synthesize their outcomes in order to identify the opportunities and challenges regarding this topic. Therefore, these research goals can be summarized in the following research questions (RQs):

- -

- RQ1. What are the later research trends in the application of the DTs technology in livestock production systems?

- -

- RQ2. In which types of livestock production systems have the DTs technology been applied?

- -

- RQ3. In what domains of livestock farming does the DTs technology find application?

- -

- RQ4. What are the potential benefits and current open issues of incorporating the DTs technology in livestock production systems?

- Information Sources Selection. The search was conducted in the Google Scholar, Scopus, and Web of Science (WoS) academic research databases. Contributions indexed in ScienceDirect, IEEE-Xplore, and SpringerLink were indirectly included, as these are also contained in the aforementioned databases.

- Search Methodology Planning. The search of the literature was performed based on a combination of keywords closely related to the determined research questions. The principal keyword selected was the term “digital twin” associated with the key terms “livestock”, “livestock production”, “smart farming”, “application”, “animal”, “dairy”, “cattle”, “swine”, “pig”, “pigsty”, “husbandry”, “welfare”, “energy management”, “environmental control”, “supply-chain”, “meat”, “food supply”, “use case”, and “case study”. These keywords were associated with the Boolean operators “AND” and “OR” so as to provide the most accurate results.

- Eligibility Criteria Definition. Contributions were considered eligible under the following criteria:

- -

- Type of contribution: For the purposes of this review, peer-reviewed journal articles and conference papers published in proceedings that introduce applications of the DTs technology in the livestock farming sector are included. Comparative studies and literature reviews were excluded.

- -

- Year of publication: Given the recent emergence as well as the development of the DTs technology in the livestock sector, a 5-year prospecting period was defined from 2018 to 2023; hence, outdated information that could be irrelevant was excluded.

- -

- Region: Worldwide contributions were included.

- -

- Language: The literature search was limited to contributions in English.

- -

- Status of publication: Only accepted and published contributions in indexed journals and conference proceedings were included.

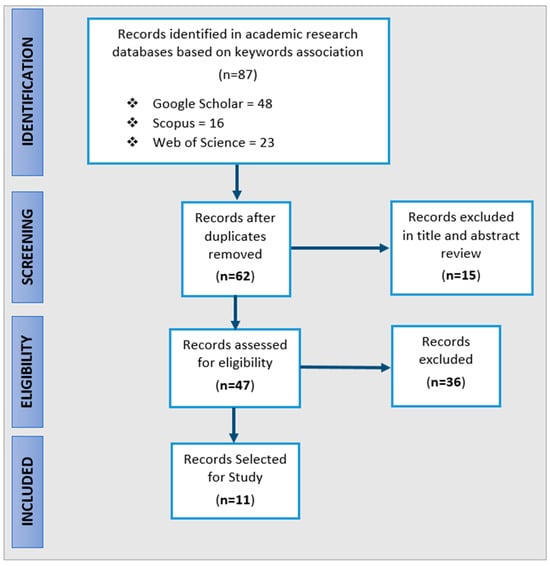

- Contributions Selection. At first, contributions were selected based merely on the digital twins topic, resulting in 334 papers, among which 114 were indexed in Google Scholar, 94 in Scopus, and 126 in the Web of Science. However, considering that the topic in question refers to the application of the DTs in livestock farming, the number of the selected contributions was eliminated in 87 based on the queries generated by the association of the defined keywords. In this respect, this was considered to be the first step of selection, that is, identification. Among the contributions selected during identification, 48 were indexed in Google Scholar, 16 in Scopus, and 23 in the Web of Science. Then, by screening the titles, abstracts, and keywords of these contributions, the duplicate versions, as well as those with almost identical titles and irrelevant or insufficient content related to the main criteria, were omitted. According to this step, all relevant research was narrowed down to 47 contributions, which were individually subjected to further consideration in terms of their contents to assess whether they aligned with the scope of this work and minimize the risk of missing relevant information. Finally, 11 contributions were retained for inclusion in this study based on their scope, the specific field of research, and the eligibility criteria. The schematic representation of the selection process is presented according to the PRISMA flowchart in Figure 4.

Figure 4. PRISMA flowchart of the selection process.

Figure 4. PRISMA flowchart of the selection process.

4. Results

Once the contributions to be reviewed were defined, each one of them was carefully processed so as to extract the information related to the objective of this review.

Analysis of the Selected Studies

Based on the analysis of the 11 contributions on the recent applications of DTs in livestock animal production systems, the majority of them (eight contributions) focused mainly, but not exclusively, on animal welfare and management, while the more particular animal species of interest appeared to be dairy cattle and swine. Some of the contributions also included the application domains of precision livestock farming (PLF), production management, and intelligent livestock monitoring, as well as real-time environmental and energy control—these are strongly related to the animal welfare and management objective.

In this respect, Zhang et al. [60] proposed a novel architecture for DTs of cows that covers their entire lifecycle, aiming to manage dairy cattle production and improve animal welfare. For this, a solution was implemented so as to construct the cows’ digital shadow by utilizing an innovative custom-made intelligent collar incorporating ultra-wideband (UWB) chips and inertial measurement units (IMUs) to collect real-time location and neck movement data from cows categorized in the calf stage, the heifer stage, and the adult stage. According to this solution, the architecture is divided based on the reliability of the data into three levels: barn integration, the pasture agent, and the cloud, while implementation consists of five layers: the integration layer, the data management and information layer, the model and simulation layer, the partial decision-making layer, and the visualization layer. The testing of the DTs solution indicated the robustness and technical feasibility of its architecture, holding considerable reference value for the development of the DTs in the livestock production industry.

Additionally, Han et al. [61] developed a smart DT to model the state of cattle by incorporating a long short-term memory (LSTM) neural network so as to detect and predict a range of the cattle’s behavioral state, such as impending physiological cycles. According to this solution, a DT model of cattle based on deep learning (DL) is generated, utilizing the sensor data acquired from an IoT farm system so as to monitor the physiological cycle of cattle in real time and foresee the state of the next physiological cycle of cattle. Based on the evaluation results, although the accuracy of the DTs model is high in terms of behavioral state for a considerable amount of sample data, it appears to be unsatisfactory when the amount of sampled data is inadequate.

A feasibility study regarding the preliminary design of a smart pig farm incorporating the DTs concept for improving animal welfare was presented by Jo et al. in [62]. In this sense, the framework of smart livestock farms consisting of two layers, namely the digital farm engine and the digital farm framework, is overviewed, while a service scenario of autonomous control in livestock farms, which can be easily deployed, is briefly described so as to showcase the way in which physical livestock farm works with digital livestock farms. As mentioned previously, the design of the smart pig farm was preliminary and was not evaluated by obtaining real results. As an extension of this work, in [63], Jo et al. proposed energy planning for a pigsty so as to provide comfortable feeding conditions. This solution incorporated the DTs concept for establishing an interaction between a physical and a virtual pigsty. Energy consumption comparisons were performed by combining a number of fans with different capacities in the pigsty, resulting in findings that indicated the expected energy usage and the installation guidelines for new fans.

Neethirajan S. [64], as well as Neethirajan and Kemp [52], introduced the reference architecture of a DT system for a smart animal welfare platform so as to predict the behavior of farm animals. The architecture’s structure incorporated interlinked components: (i) remote and wearable sensors for collecting data from the animals; (ii) cloud servers for interacting with the sensors as well as for receiving, storing, and processing the sensory data, resulting in changes in the states of the sensors; (iii) AI models for identifying data patterns and ML models for making predictions; (iv) a user interface through which the users can monitor the information and predictions of the DTs as well as interact with the platform. Particularly, in [64], the sensor-based DTs animal emotion modeling process is presented while the development of the DTs processing pipeline for classifying and estimating affective state and behavior in real-time is overviewed. This solution, however, appears to still be in a theoretical stage and has not yet been evaluated by obtaining real results.

A 3D real-time virtual model of a barn and the animals husbanded in it (showing their exact location) was developed by Plamen and Atanasova [65]. The model was developed based on data collected from IoT devices according to the five-domain model for animal welfare assessment, involving the physical environment, health, mental state, behavioral interactions, and nutrition. AI software was also developed to monitor the collected data and alert when values appear to be outside the preset intervals. In addition, the software provides information on possible problems that may arise from the measured deviations and on the actions that can be taken as soon as possible to solve the problem. Augmented reality (AR) and virtual reality (VR) resources provide faster learning in a safe environment and can be used for different purposes by veterinarians, breeders, and students. This solution, as it appears, has not yet presented any evaluation results.

Finally, Valero et al. [66] presented a conceptual framework for a circular meat supply chain that integrates the key technological aspects of the DTs concept across various areas of the meat supply chain towards “zero-waste”. Animal management, as part of the meat supply chain, is achieved by incorporating DTs, which can provide insights into animal health and welfare by monitoring, predicting, and influencing animal behavior and environmental conditions. In this context, the physical objects of the framework range from those concerning individual animals (e.g., exercise and rest level, grazing patterns, and location) to those about environmental and housing conditions (e.g., temperature, humidity, luminosity, etc.). Since this framework appears to be at a starting point, its implementation, as well as the generation of a simulation model, form part of future research considerations.

Another domain of DTs application in livestock animal production systems appears to be real-time environmental and energy control. In this context, Jeong et al. [67] proposed a DTs framework for supporting real-time environmental control in a pig house and presented several scenarios regarding energy efficiency for a DTs framework deployment. Considering that energy is a major concern in the operation of pig houses while creating a comfortable feeding environment, in this work, a virtual pig house was implemented, and several conditions were simulated by applying actual data so as to find the best possible solutions for energy efficiency. In this regard, a number of entities incorporated in an actual enclosed pig house were modeled in order to develop its digital counterpart. The DT-based dynamic simulation analysis for the pig house indicated not only an energy-efficient solution that can be applied in the design stage but also resulted in information related to the optimal control of the heating, ventilation, and air conditioning (HVAC) system during the actual operation stage.

Moreover, in their work, Mu et al. [68] included DTs insights and applied them to animal husbandry—a brief overview of a case study conducted in the Qinghai Meadow regarding the integration of the DTs concept into the routine pasture—so as to create a supply chain for livestock. The fundamental structure of this approach adopts two main flows, of which the first is related to the horizontal communication between suppliers and consumers, which forms the commercial supply chain, while the second is related to the IT operating system, which is structured into three levels: physical, data, and virtual. According to this structure, the data acquired from different types of sensors in the physical layer are forwarded to the data layer, where they are processed, evaluated, managed, and stored. Consequently, the information generated in the data layer is passed to the virtual layer, which exploits AI and ML to process the information further and provide advanced feedback to the physical layer. The scope of this process is to assist in preventing losses due to catastrophic weather conditions and predicting diseases in the life cycle. To this end, alarms are triggered whenever the system detects abnormal behaviors, whatever the animal or the surrounding environmental may be. This solution, as it appears, has not yet presented any evaluation results.

Conclusively, since the decision making in the supply chain of livestock production systems has always caused concern, Raba et al. [69] proposed a computer-aided system for controlling and optimizing the supply chain of animal feed deliverance to a number of livestock farms under the IoFEED project. For this, a DT-based approach was implemented at the farm level by integrating sensors to monitor the inventories remotely and provide data that were exploited through a combination of biased-randomization techniques along with a simheuristic framework. The results of this work indicate that the feeding operations of the livestock farms were optimized based on the proposed solution.

An overview of the results of the literature review for the recent application of DTs in livestock production systems can be seen in Table 1.

Table 1.

Overview of the recent DTs applications in livestock production systems.

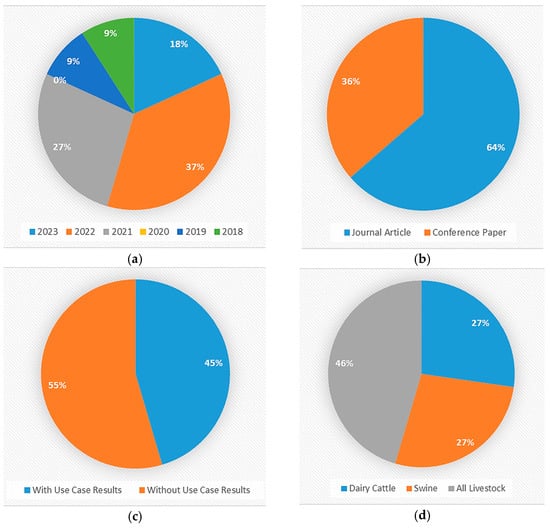

Based on the results that were generated by analyzing the works that were included in the literature review, some interesting outcomes regarding their distribution according to the year of publication, the type of the contribution (journal article or conference paper), the presentation (or not) of use case results, and the animal species of interest are illustrated as diagrams in Figure 5.

Figure 5.

Distribution of the works included in the literature review according to (a) the year of publication, (b) the type of the contribution, (c) the presentation of the use case results, and (d) the animal species of interest.

5. Discussion

As the literature review indicates, the DTs trend that has recently emerged is still in the early stages of development in a number of application domains related to livestock production systems, but due to the increased research interest in this field, they have the potential to transform the industry. By providing farmers with a real-time view of their animals’ health, well-being, and productivity, digital twins can assist farmers in making better decisions about animal care, feed management, and disease prevention. Some of the potential benefits of incorporating the DTs technology in livestock production systems have been identified as follows:

- Improved animal health and welfare: As indicated in [52,60,61,62,63,64,65,66], DTs can be used to monitor animals’ vital signs, feeding behavior, and activity levels. They can also analyze data from multiple sources, such as animal health records, as well as weather and environmental data, to identify patterns and trends that may indicate an increased risk of disease outbreak so that farmers can take preventive action;

- Increased productivity: As indicated in [52,60,61,62,63,64,65,66], DTs can be used to optimize feed rations and feeding schedules and to identify and address environmental factors [67,68] that may be impacting animal productivity;

- Reduced costs: DTs can help farmers to reduce costs by identifying and eliminating inefficiencies in their operations. For example, digital twins can be used to optimize energy use in livestock barns [67,68] and reduce the amount of food waste;

- Improving food safety and quality: DTs can be used to track the movement of animals and food products through the supply chain [69], ensuring that they are safe and of high quality.

- Design and manage more sustainable farming operations: Digital twins can be used to simulate the impact of different farming practices on the environment. This can help farmers to design and manage more sustainable farming operations that reduce their impact on water quality, greenhouse gas emissions, and other environmental factors.

An interesting finding indicated by the literature review was the fact that most of the DTs applications for livestock production systems are still at the concept and prototype stages. This might be due to the agricultural sector being a slow adopter of technology, partly because the advanced technologies in the context of Agriculture 5.0 are growing in complexity. Based on this, what must be highlighted is the need for the interoperability and standardization of the DTs models in the food industry. This challenge is also applicable to livestock production systems, as different farms may incorporate diverse sensors, data formats, and management systems. Standardization efforts are required to ensure seamless integration and data exchange between different digital twin systems.

Another open issue is the ethical implications of digital livestock farming, as discussed in [70]. Responsible technological innovation is crucial to ensure that the benefits of the DTs technology in livestock production are realized while avoiding any unintended consequences that might negatively impact animal welfare and the resilience of the livestock industry. Ethical considerations, such as data privacy, animal welfare, and the social implications of automation, need to be carefully addressed in the development and implementation of digital twin systems.

Further open issues and challenges that must be addressed to realize the full potential of the DTs technology in livestock production systems are identified as follows:

- Data Management and Integration: DTs require vast amounts of data from various sources, including sensors, farm equipment, and animal monitoring systems. Integrating and managing these data efficiently remains a challenge.

- Cost of Implementation: The upfront costs associated with implementing DTs systems in livestock farming can be prohibitive, especially for small-scale farmers. Finding cost-effective solutions and demonstrating a return on investment is crucial to encourage wider adoption.

- Technical Expertise: Operating and maintaining DTs systems demands technical expertise in areas such as data analytics, IoT, and AI. Many farmers and practitioners may lack the necessary skills, highlighting the need for training and support.

- Scale and Scope: DTs are often applied to specific aspects of livestock production, such as health monitoring or environmental control. Expanding their scope to cover all aspects of the production cycle, from breeding to processing, is a complex task.

- Regulatory and Compliance Challenges: Compliance with existing regulations and the development of new regulatory frameworks for DTs applications in livestock farming is a significant challenge. Ensuring that these systems adhere to animal welfare and environmental regulations is critical.

- Resource Constraints: In some regions, limited access to reliable electricity and internet connectivity can impede the implementation of DTs technologies. Addressing these resource constraints is crucial for widespread adoption.

- Data Ownership and Privacy: Determining the ownership of data generated by DTs systems and protecting the privacy of sensitive information, such as animal health records, is a complex issue that requires clear guidelines and regulations.

- Validation and Verification: Ensuring the accuracy and reliability of DTs models is essential, particularly when making critical decisions in livestock farming. Developing robust methods for validation and verification is an ongoing challenge.

- Environmental Impact: While DTs can contribute to sustainability, they also require energy for data processing and maintenance. Assessing and mitigating the environmental impact of digital twin technologies is an open issue.

Consequently, while the DTs technology holds great potential for improving livestock production systems, these open issues and challenges need to be addressed to facilitate their effective implementation. Collaboration among researchers, industry stakeholders, and regulatory bodies is essential to create a framework that ensures the ethical, sustainable, and efficient use of digital twins in livestock farming. Overcoming these challenges will pave the way for a more productive and sustainable future for the livestock industry.

6. Conclusions

As Agriculture 5.0 evolves, DTs is expected to play an increasingly important role in the livestock farming industry. By helping farmers achieve the goals of Agriculture 5.0, DTs can contribute to a more sustainable and resilient food system. Indeed, DTs has the potential to revolutionize livestock production systems by providing real-time monitoring, analysis, and simulation capabilities. By integrating advanced technologies and data-driven decision-making, farmers gain insights into feeding patterns, stress factors, and optimal breeding strategies, thereby ensuring not only productivity but also the welfare of the livestock while promoting sustainable farming practices. Yet, despite their benefits, the applications of DTs in livestock production systems seem to be fragmentary and in the early stages of development, likely due to some open issues that have to be addressed. The initial costs of adoption, concerns regarding data security, and the imperative of educating farmers about these advanced tools necessitate careful consideration. Moreover, issues such as interoperability and ethical considerations need to be addressed for the widespread adoption of digital twins in livestock production systems. Future research should focus on developing standardized models, addressing ethical concerns, and exploring new applications of digital twins in livestock farming. In addition, a concerted effort toward developing user-friendly interfaces and comprehensive training programs is crucial to unlocking the full potential of digital twins in agriculture. As technology advances, DTs are expected to offer increased connectivity and seamless interoperability with other smart farming technologies. The collaboration between technology developers, agricultural experts, and policymakers will be pivotal in shaping a future where DTs play a central role in sustainable, efficient, and resilient agricultural practices.

Author Contributions

Conceptualization, E.S., C.M. and K.G.A.; Data curation, E.S. and C.M.; Methodology, E.S., C.M. and K.G.A.; Supervision, C.M. and K.G.A.; Validation, E.S. and C.M.; Visualization, E.S.; Writing—original draft, E.S.; Writing—review and editing, E.S., C.M. and K.G.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- World Population Trends. Available online: https://www.unfpa.org/world-population-trends#readmore-expand (accessed on 29 October 2023).

- The State of the World’s Land and Water Resources for Food and Agriculture 2021—Systems at Breaking Point; FAO: Rome, Italy, 2022.

- Global Report on Food Crises—2022|World Food Programme. Available online: https://www.wfp.org/publications/global-report-food-crises-2022 (accessed on 29 October 2023).

- Sundstrom, S.M.; Angeler, D.G.; Allen, C.R. Resilience Theory and Coerced Resilience in Agriculture. Agric. Syst. 2023, 206, 103612. [Google Scholar] [CrossRef]

- Fraser, E.D.G.; Campbell, M. Agriculture 5.0: Reconciling Production with Planetary Health. One Earth 2019, 1, 278–280. [Google Scholar] [CrossRef]

- Engås, K.G.; Raja, J.Z.; Neufang, I.F. Decoding Technological Frames: An Exploratory Study of Access to and Meaningful Engagement with Digital Technologies in Agriculture. Technol. Forecast. Soc. Chang. 2023, 190, 122405. [Google Scholar] [CrossRef]

- Saiz-Rubio, V.; Rovira-Más, F. From Smart Farming towards Agriculture 5.0: A Review on Crop Data Management. Agronomy 2020, 10, 207. [Google Scholar] [CrossRef]

- Alwis, S.D.; Hou, Z.; Zhang, Y.; Na, M.H.; Ofoghi, B.; Sajjanhar, A. A Survey on Smart Farming Data, Applications and Techniques. Comput. Ind. 2022, 138, 103624. [Google Scholar] [CrossRef]

- Ragazou, K.; Garefalakis, A.; Zafeiriou, E.; Passas, I. Agriculture 5.0: A New Strategic Management Mode for a Cut Cost and an Energy Efficient Agriculture Sector. Energies 2022, 15, 3113. [Google Scholar] [CrossRef]

- Loukatos, D.; Arvanitis, K.G. Multi-Modal Sensor Nodes in Experimental Scalable Agricultural IoT Application Scenarios. Lect. Notes Data Eng. Commun. Technol. 2021, 67, 101–128. [Google Scholar] [CrossRef]

- Smith, M.J. Getting Value from Artificial Intelligence in Agriculture. Anim. Prod. Sci. 2018, 60, 46–54. [Google Scholar] [CrossRef]

- Benos, L.; Tagarakis, A.C.; Dolias, G.; Berruto, R.; Kateris, D.; Bochtis, D. Machine Learning in Agriculture: A Comprehensive Updated Review. Sensors 2021, 21, 3758. [Google Scholar] [CrossRef]

- Zhang, X.; Cao, Z.; Dong, W. Overview of Edge Computing in the Agricultural Internet of Things: Key Technologies, Applications, Challenges. IEEE Access 2020, 8, 141748–141761. [Google Scholar] [CrossRef]

- Paraforos, D.S.; Griepentrog, H.W. Digital Farming and Field Robotics: Internet of Things, Cloud Computing, and Big Data. In Fundamentals of Agricultural and Field Robotics. Agriculture Automation and Control; Springer: Cham, Switzerland, 2021; pp. 365–385. [Google Scholar] [CrossRef]

- da Silveira, F.; Lermen, F.H.; Amaral, F.G. An Overview of Agriculture 4.0 Development: Systematic Review of Descriptions, Technologies, Barriers, Advantages, and Disadvantages. Comput. Electron. Agric. 2021, 189, 106405. [Google Scholar] [CrossRef]

- Kaklauskas, A. Agriculture 5.0: Smart Agriculture, AI, Iot, Society 5.0, Big Data Analytics, Blockchain, Digital Twins, Robotics, Drones and Immersive Reality. 2018. Available online: http://ir.lib.ruh.ac.lk/xmlui/handle/iruor/13735 (accessed on 1 November 2023).

- Tzachor, A.; Richards, C.E.; Jeen, S. Transforming Agrifood Production Systems and Supply Chains with Digital Twins. NPJ Sci. Food 2022, 6, 47. [Google Scholar] [CrossRef] [PubMed]

- Rose, D.C.; Sutherland, W.J.; Barnes, A.P.; Borthwick, F.; Ffoulkes, C.; Hall, C.; Moorby, J.M.; Nicholas-Davies, P.; Twining, S.; Dicks, L.V. Integrated Farm Management for Sustainable Agriculture: Lessons for Knowledge Exchange and Policy. Land Use Policy 2019, 81, 834–842. [Google Scholar] [CrossRef]

- Talavera, J.M.; Tobón, L.E.; Gómez, J.A.; Culman, M.A.; Aranda, J.M.; Parra, D.T.; Quiroz, L.A.; Hoyos, A.; Garreta, L.E. Review of IoT Applications in Agro-Industrial and Environmental Fields. Comput. Electron. Agric. 2017, 142, 283–297. [Google Scholar] [CrossRef]

- Waleed, M.; Um, T.W.; Kamal, T.; Usman, S.M. Classification of Agriculture Farm Machinery Using Machine Learning and Internet of Things. Symmetry 2021, 13, 403. [Google Scholar] [CrossRef]

- Niederer, S.A.; Sacks, M.S.; Girolami, M.; Willcox, K. Scaling Digital Twins from the Artisanal to the Industrial. Nat. Comput. Sci. 2021, 1, 313–320. [Google Scholar] [CrossRef]

- Jiang, Y.; Yin, S.; Li, K.; Luo, H.; Kaynak, O. Industrial Applications of Digital Twins. Philos. Trans. R. Soc. A 2021, 379, 20200360. [Google Scholar] [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the Art Theory and Practice, Challenges, and Open Research Questions. J. Ind. Inf. Integr. 2022, 30, 100383. [Google Scholar] [CrossRef]

- Stark, R.; Fresemann, C.; Lindow, K. Development and Operation of Digital Twins for Technical Systems and Services. CIRP Ann. 2019, 68, 129–132. [Google Scholar] [CrossRef]

- Ketzler, B.; Naserentin, V.; Latino, F.; Zangelidis, C.; Thuvander, L.; Logg, A. Digital Twins for Cities: A State of the Art Review. Built Environ. 2020, 46, 547–573. [Google Scholar] [CrossRef]

- Agnusdei, G.P.; Elia, V.; Gnoni, M.G. Is Digital Twin Technology Supporting Safety Management? A Bibliometric and Systematic Review. Appl. Sci. 2021, 11, 2767. [Google Scholar] [CrossRef]

- Pylianidis, C.; Osinga, S.; Athanasiadis, I.N. Introducing Digital Twins to Agriculture. Comput. Electron. Agric. 2021, 184, 105942. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Hensel, O. Toward the Next Generation of Digitalization in Agriculture Based on Digital Twin Paradigm. Sensors 2022, 22, 498. [Google Scholar] [CrossRef] [PubMed]

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital Twins in Smart Farming. Agric. Syst. 2021, 189, 103046. [Google Scholar] [CrossRef]

- Busch, G.; Gauly, M.; Spiller, A. Opinion Paper: What Needs to Be Changed for Successful Future Livestock Farming in Europe? Animal 2018, 12, 1999–2001. [Google Scholar] [CrossRef]

- Symeonaki, E.; Arvanitis, K.G.; Piromalis, D.; Tseles, D.; Balafoutis, A.T. Ontology-Based IoT Middleware Approach for Smart Livestock Farming toward Agriculture 4.0: A Case Study for Controlling Thermal Environment in a Pig Facility. Agronomy 2022, 12, 750. [Google Scholar] [CrossRef]

- García, R.; Aguilar, J.; Toro, M.; Pinto, A.; Rodríguez, P. A Systematic Literature Review on the Use of Machine Learning in Precision Livestock Farming. Comput. Electron. Agric. 2020, 179, 105826. [Google Scholar] [CrossRef]

- Grieves, M.W. Product Lifecycle Management: The New Paradigm for Enterprises. Int. J. Prod. Dev. 2005, 2, 71–84. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A Systematic Literature Review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the Digital Twin for Design and Production Engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Miller, A.M.D.; Alvarez, R.; Hartman, N. Towards an Extended Model-Based Definition for the Digital Twin. Comput. Aided Des. Appl. 2018, 15, 880–891. [Google Scholar] [CrossRef]

- Stark, R.; Damerau, T. Digital Twin. CIRP Encycl. Prod. Eng. 2019, 1–8. [Google Scholar] [CrossRef]

- Abramovici, M.; Göbel, J.C.; Dang, H.B. Semantic Data Management for the Development and Continuous Reconfiguration of Smart Products and Systems. CIRP Ann. 2016, 65, 185–188. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Wilking, F.; Schleich, B.; Wartzack, S. Digital Twins—Definitions, Classes and Business Scenarios for Different Industry Sectors. Proc. Des. Soc. 2021, 1, 1293–1302. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.d.J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital Twin-Driven Product Design, Manufacturing and Service with Big Data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Qian, J.; Wu, Z.; Zhu, Y.; Liu, C. One Health: A Holistic Approach for Food Safety in Livestock. Sci. One Health 2022, 1, 100015. [Google Scholar] [CrossRef]

- van der Linden, A.; de Olde, E.M.; Mostert, P.F.; de Boer, I.J.M. A Review of European Models to Assess the Sustainability Performance of Livestock Production Systems. Agric. Syst. 2020, 182, 102842. [Google Scholar] [CrossRef]

- Saitone, T.L.; Sexton, R.J. Agri-Food Supply Chain: Evolution and Performance with Conflicting Consumer and Societal Demands. Eur. Rev. Agric. Econ. 2017, 44, 634–657. [Google Scholar] [CrossRef]

- Robinson, S.; Petrick, M. Sustainable Development Goals and the Livestock Sector in Central Asia: A Course Outline; Universitätsbibliothek Gießen: Gießen, Germany, 2021. [Google Scholar] [CrossRef]

- García Pinillos, R.; Appleby, M.C.; Manteca, X.; Scott-Park, F.; Smith, C.; Velarde, A. One Welfare—A Platform for Improving Human and Animal Welfare. Vet. Rec. 2016, 179, 412–413. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Zheng, X.; Schweiger, L.; Kiritsis, D. A Cognitive Approach to Manage the Complexity of Digital Twin Systems. In Smart Services Summit: Digital as an Enabler for Smart Service Business Development; Springer International Publishing: Cham, Switzelrand, 2021; pp. 105–115. [Google Scholar] [CrossRef]

- Wright, L.; Davidson, S. How to Tell the Difference between a Model and a Digital Twin. Adv. Model. Simul. Eng. Sci. 2020, 7, 13. [Google Scholar] [CrossRef]

- Juarez, M.G.; Botti, V.J.; Giret, A.S. Digital Twins: Review and Challenges. J. Comput. Inf. Sci. Eng. 2021, 21, 030802. [Google Scholar] [CrossRef]

- Neethirajan, S.; Kemp, B. Digital Twins in Livestock Farming. Animals 2021, 11, 1008. [Google Scholar] [CrossRef]

- Fera, M.; Greco, A.; Caterino, M.; Gerbino, S.; Caputo, F.; Macchiaroli, R.; D’amato, E. Towards Digital Twin Implementation for Assessing Production Line Performance and Balancing. Sensors 2019, 20, 97. [Google Scholar] [CrossRef]

- Gámez Díaz, R.; Yu, Q.; Ding, Y.; Laamarti, F.; El Saddik, A. Digital Twin Coaching for Physical Activities: A Survey. Sensors 2020, 20, 5936. [Google Scholar] [CrossRef]

- VanDerHorn, E.; Mahadevan, S. Digital Twin: Generalization, Characterization and Implementation. Decis. Support Syst. 2021, 145, 113524. [Google Scholar] [CrossRef]

- Monteiro, J.; Barata, J.; Veloso, M.; Veloso, L.; Nunes, J. Towards Sustainable Digital Twins for Vertical Farming. In Proceedings of the 2018 Thirteenth International Conference on Digital Information Management (ICDIM), Berlin, Germany, 24–26 September 2018; pp. 234–239. [Google Scholar] [CrossRef]

- Salazar-Moya, A.; Garcia, M.V. Lot Streaming in Different Types of Production Processes: A PRISMA Systematic Review. Design 2021, 5, 67. [Google Scholar] [CrossRef]

- Ahn, E.Y.; Kim, S.Y. Digital Twin Application and Bibliometric Analysis for Digitization and Intelligence Studies in Geology and Deep Underground Research Areas. Data 2023, 8, 73. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, Y.; Gao, M.; Dai, B.; Kou, S.; Wang, X.; Fu, X.; Shen, W. Digital Twin Perception and Modeling Method for Feeding Behavior of Dairy Cows. Comput. Electron. Agric. 2023, 214, 108181. [Google Scholar] [CrossRef]

- Han, X.; Lin, Z.; Clark, C.; Vucetic, B.; Lomax, S. AI Based Digital Twin Model for Cattle Caring. Sensors 2022, 22, 7118. [Google Scholar] [CrossRef]

- Jo, S.K.; Park, D.H.; Park, H.; Kim, S.H. Smart Livestock Farms Using Digital Twin: Feasibility Study. In Proceedings of the 9th International Conference on Information and Communication Technology Convergence: ICT Convergence Powered by Smart Intelligence, ICTC 2018, Jeju, Korea, 17–19 October 2018; Institute of Electrical and Electronics Engineers Inc.: Jeju, Korea, 2018; pp. 1461–1463. [Google Scholar]

- Jo, S.K.; Park, D.H.; Park, H.; Kwak, Y.; Kim, S.H. Energy Planning of Pigsty Using Digital Twin. In Proceedings of the ICTC 2019—10th International Conference on ICT Convergence: ICT Convergence Leading the Autonomous Future, Jeju, Korea, 16–18 October 2019; Institute of Electrical and Electronics Engineers Inc.: Jeju, Korea, 2019; pp. 723–725. [Google Scholar]

- Coleman, K.; Neethirajan, S. Affective State Recognition in Livestock—Artificial Intelligence Approaches. Animals 2022, 12, 759. [Google Scholar] [CrossRef]

- Petrov, P.; Atanasova, T. Digital Twins with Application of AR and VR in Livestock Instructions. Probl. Eng. Robot. 2021, 77, 39–50. [Google Scholar] [CrossRef]

- Valero, M.R.; Hicks, B.J.; Nassehi, A. A Conceptual Framework of a Digital-Twin for a Circular Meat Supply Chain. In Proceedings of the Lecture Notes in Mechanical Engineering; Springer Science and Business Media Deutschland GmbH: Berlin, Germany, 2023; pp. 188–196. [Google Scholar]

- Jeong, D.; Jo, S.-K.; Lee, I.-B.; Shin, H.; Kim, J. Digital Twin Application: Making a Virtual Pig House Toward Digital Livestock Farming. IEEE Access 2023, 11, 121592–121602. [Google Scholar] [CrossRef]

- Mu, M.; Zhou, Y.; Wu, D. Digital Twins on Animal Husbandry: Insights and Application. In Proceedings of the Procedia Computer Science; Elsevier: Beijing, China, 2022; Volume 214, pp. 1182–1189. [Google Scholar]

- Raba, D.; Tordecilla, R.D.; Copado, P.; Juan, A.A.; Mount, D. A Digital Twin for Decision Making on Livestock Feeding. INFORMS J. Appl. Anal. 2021, 52, 267–282. [Google Scholar] [CrossRef]

- Neethirajan, S. The Significance and Ethics of Digital Livestock Farming. AgriEngineering 2023, 5, 488–505. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).