Digital Twin-Based Clamping Sequence Analysis and Optimization for Improved Geometric Quality

Abstract

1. Introduction

1.1. Variation Simulation

1.2. Influence of Clamping Process in Quality Assurance

1.3. Geometry Assurance Digital Twin

1.4. Scope of the Paper

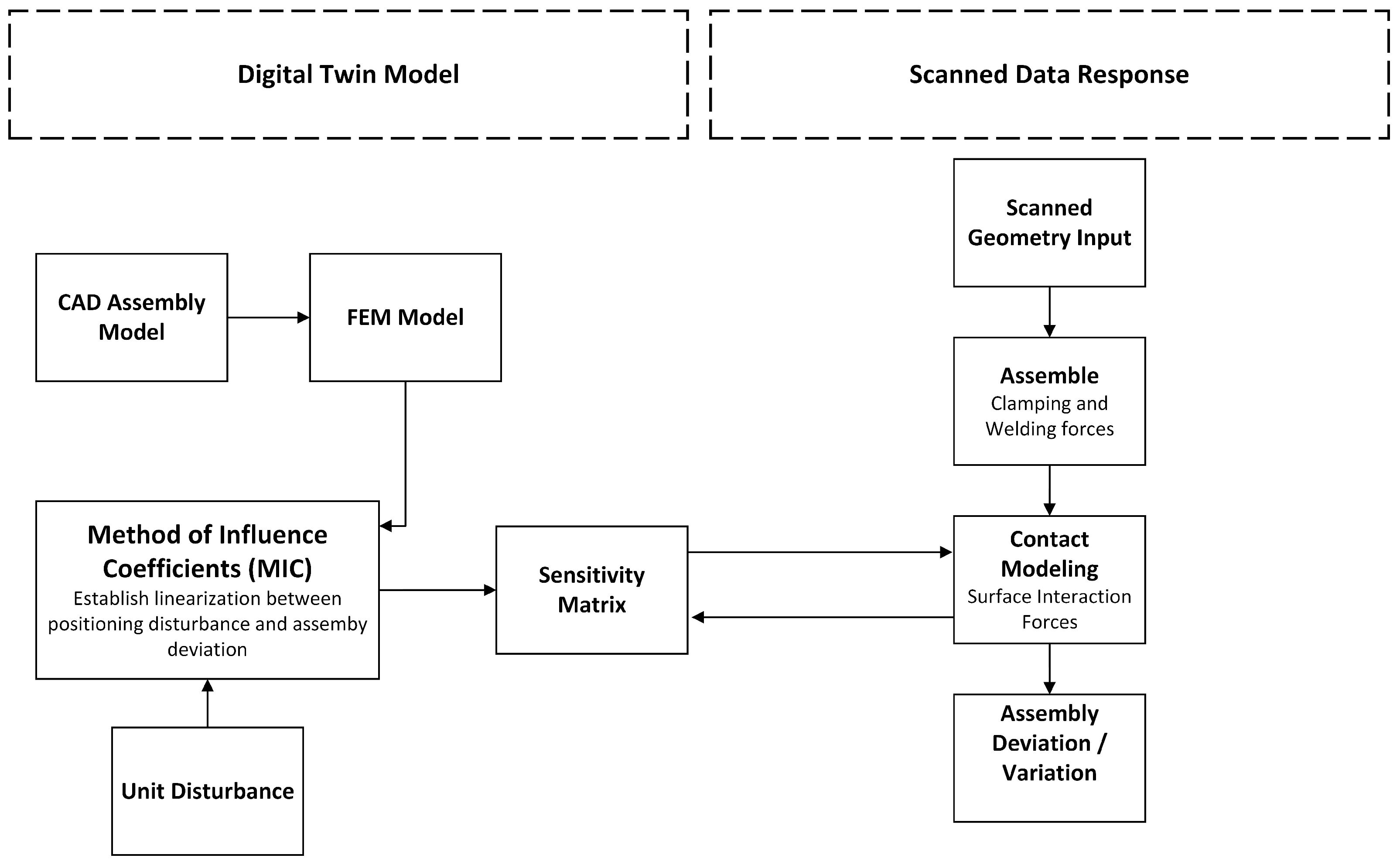

2. Method

2.1. Proposed Clamping Sequence Model

2.2. Sequence Optimization

| Algorithm 1 Stepwise clamp sequence optimization. |

|

3. Reference Assemblies

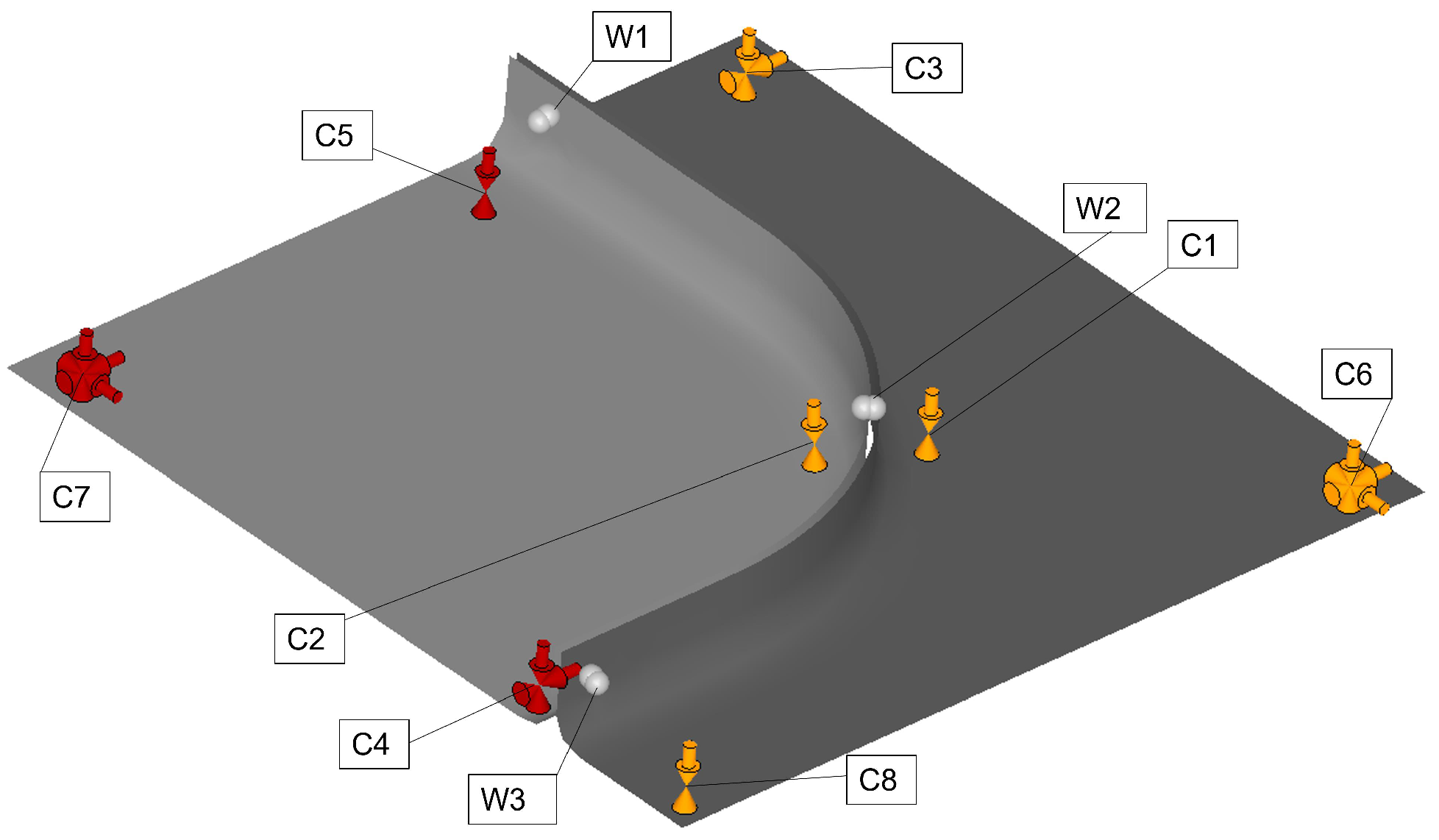

3.1. Assembly I

3.2. Assembly II

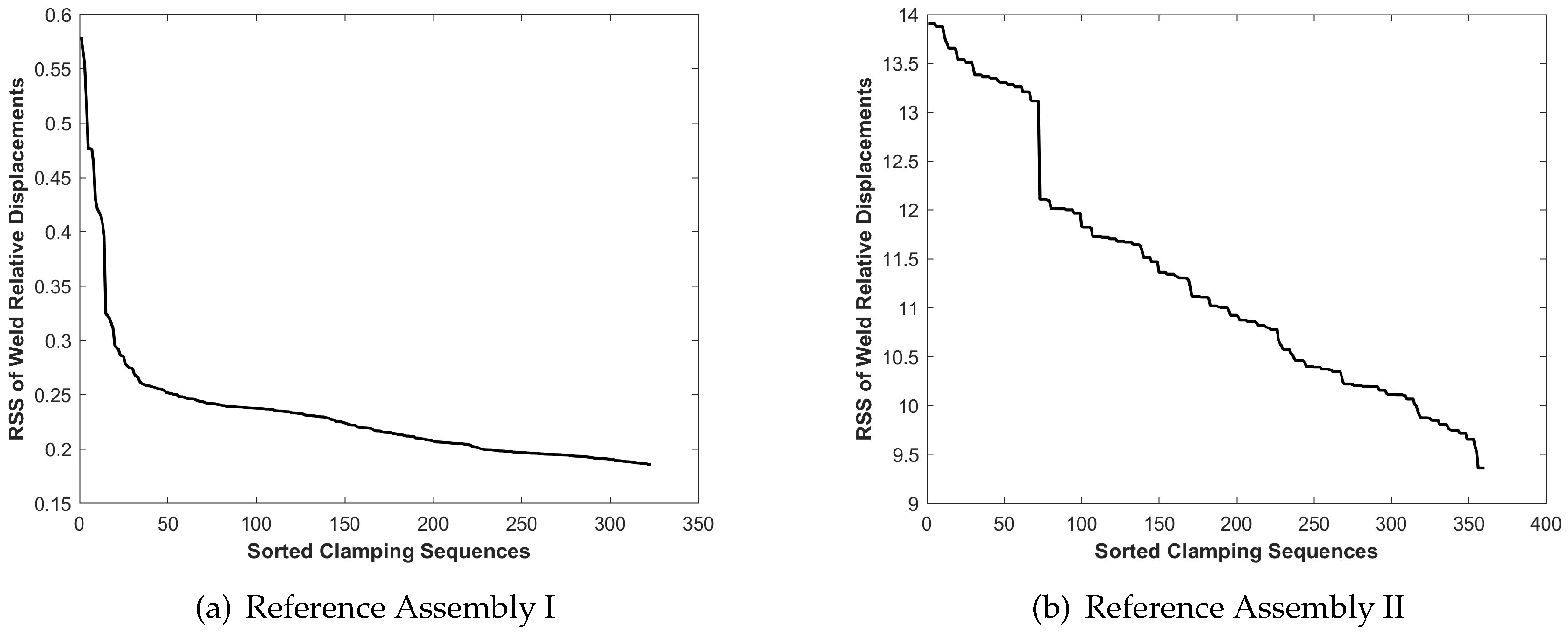

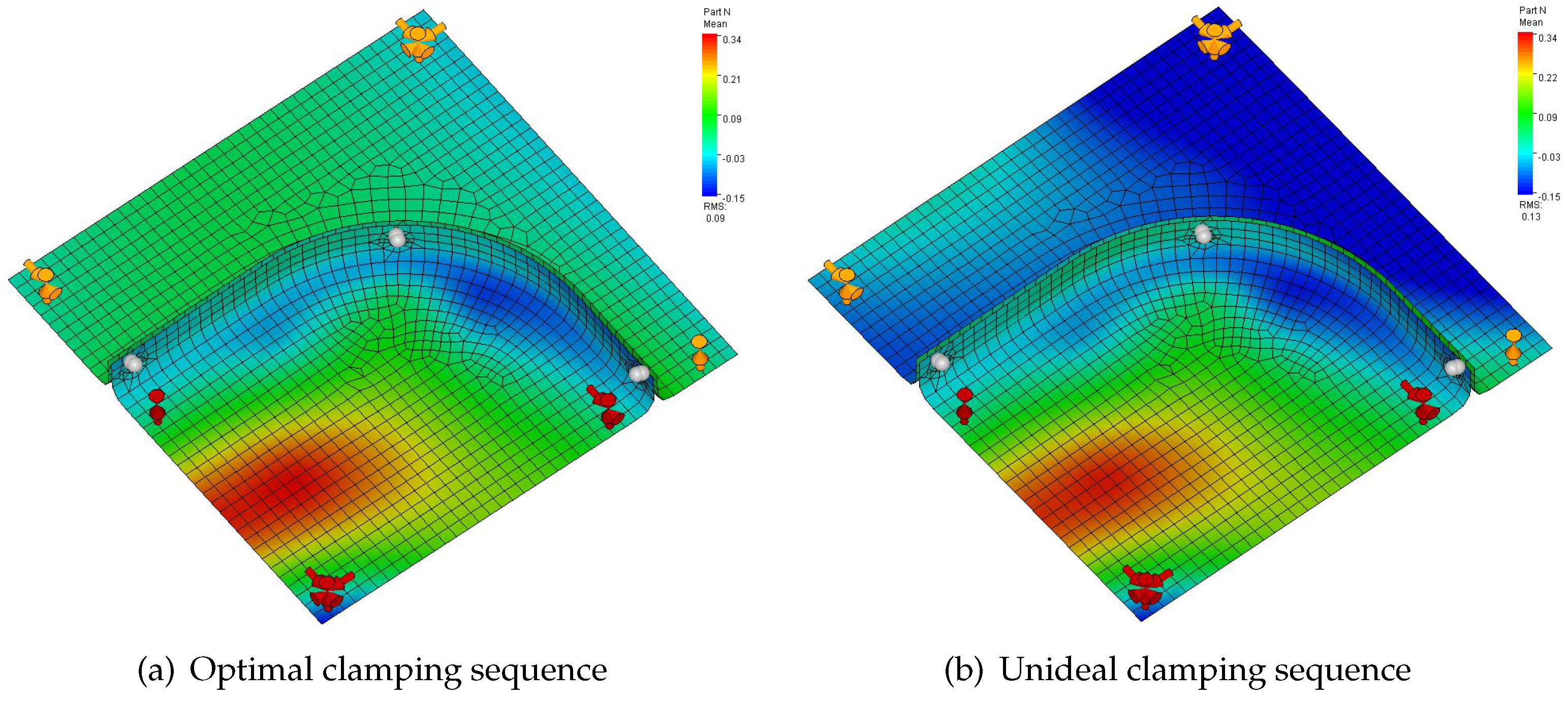

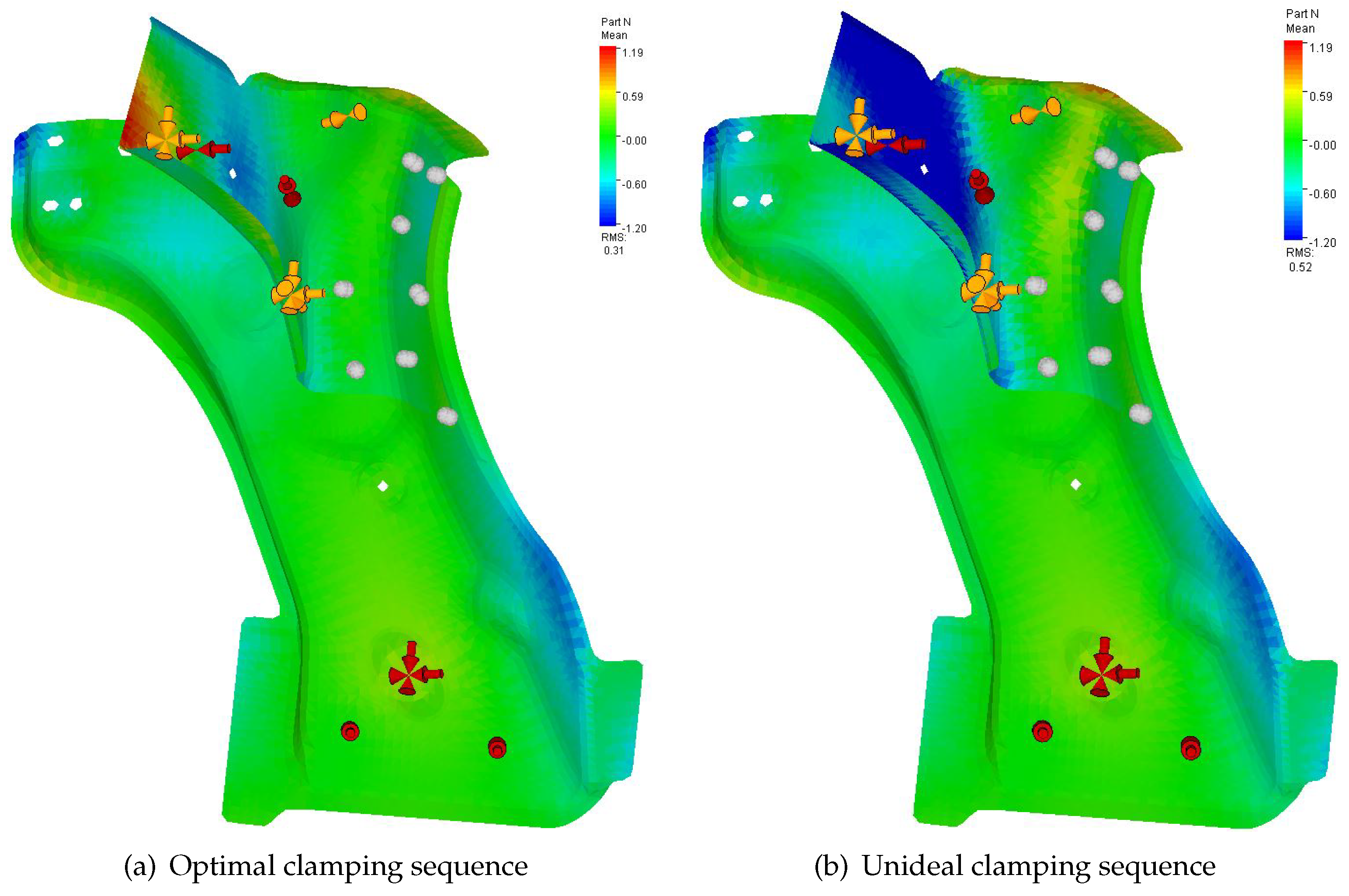

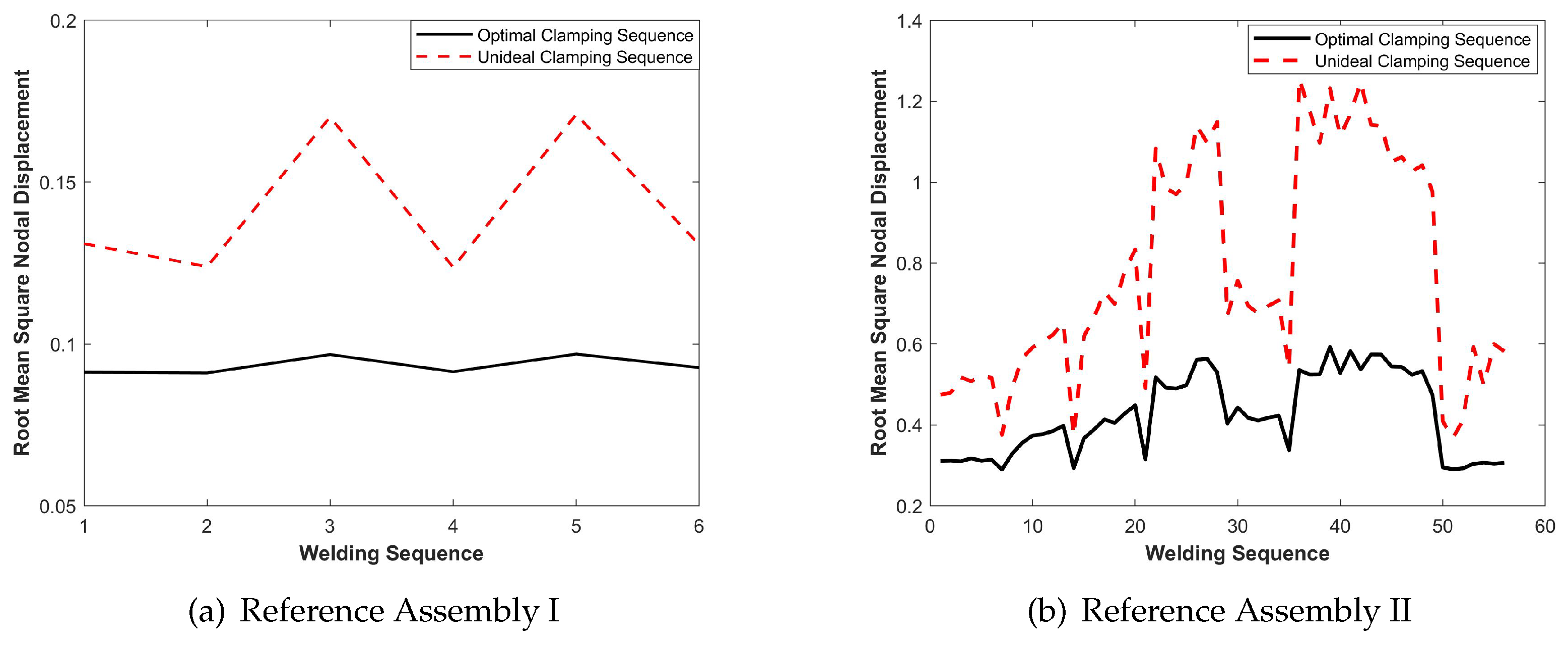

4. Results

- Positioning the non-nominal parts in a rigid fixture.

- Locking the in-plane translation and rotations.

- Applying the clamping points in a sequence.

- Capturing the weld relative displacements after clamping.

- Optimizing the clamping sequence according to the objective above.

- Performing spot welding with the optimal clamping sequence.

- Optimizing the welding sequence with respect to the assembly displacements.

- Releasing the assembly from the fixture and evaluating the assembly springback.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, M.; Lin, Z.; Lai, X.; Ni, J. Simulation and analysis of assembly processes considering compliant, non-ideal parts and tooling variations. Int. J. Mach. Tools Manuf. 2001, 41, 2233–2243. [Google Scholar] [CrossRef]

- Shen, Z.; Ameta, G.; Shah, J.J.; Davidson, J.K. A Comparative Study of Tolerance Analysis Methods. J. Comput. Inf. Sci. Eng. 2005, 5, 247–256. [Google Scholar] [CrossRef]

- RD&T Technology. Robust Design and Tolerancing Software RD&T. 2023. Available online: https://www.rdnt.se/ (accessed on 5 October 2023).

- 3DSC. Dimensional Control System 3DCS. 2023. Available online: https://www.3dcs.com/ (accessed on 5 October 2023).

- Liu, S.C.; Hu, S.J. Variation simulation for deformable sheet metal assemblies using finite element methods. J. Manuf. Sci. Eng. 1997, 119, 368–374. [Google Scholar] [CrossRef]

- Chang, M.; Gossard, D. Modeling the assembly of compliant, non-ideal parts. Comput.-Aided Des. 1997, 29, 701–708. [Google Scholar] [CrossRef][Green Version]

- Camelio, J.; Hu, S.J.; Ceglarek, D. Modeling variation propagation of multi-station assembly systems with compliant parts. J. Mech. Des. 2003, 125, 673–681. [Google Scholar] [CrossRef]

- Anwer, N.; Ballu, A.; Mathieu, L. The skin model, a comprehensive geometric model for engineering design. Cirp Ann. 2013, 62, 143–146. [Google Scholar] [CrossRef]

- Cai, W.; Hu, S.J.; Yuan, J.X. A Variational Method of Robust Fixture Configuration Design for 3-D Workpieces. J. Manuf. Sci. Eng. 1997, 119, 593–602. [Google Scholar] [CrossRef]

- Maropoulos, P.G.; Vichare, P.; Martin, O.; Muelaner, J.; Summers, M.; Kayani, A. Early design verification of complex assembly variability using a Hybrid–Model Based and Physical Testing–Methodology. Cirp Ann. 2011, 60, 207–210. [Google Scholar] [CrossRef]

- Yao, S.; Luan, Y.; Ceccarelli, M.; Carbone, G. Optimization Method of the Clamping Force for Large Cabin Parts. Appl. Sci. 2023, 13, 12575. [Google Scholar] [CrossRef]

- Raghu, A.; Melkote, S.N. Analysis of the effects of fixture clamping sequence on part location errors. Int. J. Mach. Tools Manuf. 2004, 44, 373–382. [Google Scholar] [CrossRef]

- Li, B.; Melkote, S.N. Improved workpiece location accuracy through fixture layout optimization. Int. J. Mach. Tools Manuf. 1999, 39, 871–883. [Google Scholar] [CrossRef]

- Matuszyk, T.; Cardew-Hall, M.; Rolfe, B. The effect of clamping sequence on dimensional variability in sheet metal assembly. Virtual Phys. Prototyp. 2007, 2, 161–171. [Google Scholar] [CrossRef]

- Tabar, R.S.; Lorin, S.; Cromvik, C.; Lindkvist, L.; Wärmefjord, K.; Söderberg, R. Efficient spot welding sequence simulation in compliant variation simulation. J. Manuf. Sci. Eng. 2021, 143, 071009. [Google Scholar] [CrossRef]

- Choi, W.; Chung, H. Variation simulation of compliant metal plate assemblies considering welding distortion. J. Manuf. Sci. Eng. 2015, 137. [Google Scholar] [CrossRef]

- Zheng, H.; Litwa, F.; Bohn, M.; Paetzold, K. Tolerance optimization for sheet metal parts based on joining simulation. Procedia Cirp 2021, 100, 583–588. [Google Scholar] [CrossRef]

- Moos, S.; Vezzetti, E. Compliant assembly tolerance analysis: Guidelines to formalize the resistance spot welding plasticity effects. Int. J. Adv. Manuf. Technol. 2012, 61, 503–518. [Google Scholar] [CrossRef]

- Tabar, R.S.; Lindkvist, L.; Wärmefjord, K.; Söderberg, R. Efficient joining sequence variation analysis of stochastic batch assemblies. J. Comput. Inf. Sci. Eng. 2022, 22, 040905. [Google Scholar] [CrossRef]

- Lu, C.; Zhao, H.W. Fixture layout optimization for deformable sheet metal workpiece. Int. J. Adv. Manuf. Technol. 2015, 78, 85–98. [Google Scholar] [CrossRef]

- Qin, G.; Zhang, W.; Wan, M. Analysis and Optimal Design of Fixture Clamping Sequence. J. Manuf. Sci. Eng. 2005, 128, 482–493. [Google Scholar] [CrossRef]

- Yu, H.; Xu, X.; Zheng, B.; Lai, X. Welding-induced buckling prediction for large thin-walled cylindrical structures with non-uniform stress fields by friction stir welding. Int. J. Adv. Manuf. Technol. 2019, 103, 4635–4647. [Google Scholar] [CrossRef]

- Xie, L.S.; Hsieh, C. Clamping and welding sequence optimisation for minimising cycle time and assembly deformation. Int. J. Mater. Prod. Technol. 2002, 17, 389–399. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, S.; Chen, Z. Automated modular fixture planning based on linkage mechanism theory. Robot.-Comput.-Integr. Manuf. 2008, 24, 38–49. [Google Scholar] [CrossRef]

- Wu, Y.; Rong, Y.; Ma, W.; LeClair, S.R. Automated modular fixture planning: Accuracy, clamping, and accessibility analyses. Robot.-Comput.-Integr. Manuf. 1998, 14, 17–26. [Google Scholar] [CrossRef]

- Jeng, S.L.; Chen, L.G.; Chieng, W.H. Analysis of minimum clamping force. Int. J. Mach. Tools Manuf. 1995, 35, 1213–1224. [Google Scholar] [CrossRef]

- Hajimiri, H.; Abedini, V.; Shakeri, M.; Siahmargoei, M.H. Simultaneous fixturing layout and sequence optimization based on genetic algorithm and finite element method. Int. J. Adv. Manuf. Technol. 2018, 97, 3191–3204. [Google Scholar] [CrossRef]

- Schenk, T.; Richardson, I.; Kraska, M.; Ohnimus, S. A study on the influence of clamping on welding distortion. Comput. Mater. Sci. 2009, 45, 999–1005. [Google Scholar] [CrossRef]

- Gonzalo, O.; Seara, J.M.; Guruceta, E.; Izpizua, A.; Esparta, M.; Zamakona, I.; Uterga, N.; Aranburu, A.; Thoelen, J. A method to minimize the workpiece deformation using a concept of intelligent fixture. Robot.-Comput.-Integr. Manuf. 2017, 48, 209–218. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems; Springer: Berlin/Heidelberg, Germany, 2017; pp. 85–113. [Google Scholar]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. Cirp Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Franciosa, P.; Sokolov, M.; Sinha, S.; Sun, T.; Ceglarek, D. Deep learning enhanced digital twin for Closed-Loop In-Process quality improvement. Cirp Ann. 2020, 69, 369–372. [Google Scholar] [CrossRef]

- Polini, W.; Corrado, A. Digital twin of composite assembly manufacturing process. Int. J. Prod. Res. 2020, 58, 5238–5252. [Google Scholar] [CrossRef]

- Söderberg, R.; Wärmefjord, K.; Carlson, J.S.; Lindkvist, L. Toward a Digital Twin for real-time geometry assurance in individualized production. Cirp Ann. 2017, 66, 137–140. [Google Scholar] [CrossRef]

- Tabar, R.S.; Wärmefjord, K.; Söderberg, R. Optimal part matching and joining sequence in non-rigid assemblies for improved geometric quality. Procedia CIRP 2022, 78, 421–426. [Google Scholar] [CrossRef]

- Aderiani, A.R.; Wärmefjord, K.; Söderberg, R. Evaluating different strategies to achieve the highest geometric quality in self-adjusting smart assembly lines. Robot.-Comput.-Integr. Manuf. 2021, 71, 102164. [Google Scholar] [CrossRef]

- Tabar, R.S.; Wärmefjord, K.; Söderberg, R.; Lindkvist, L. Critical joint identification for efficient sequencing. J. Intell. Manuf. 2021, 32, 769–780. [Google Scholar]

- Tabar, R.S.; Wärmefjord, K.; Söderberg, R. Rapid sequence optimization of spot welds for improved geometrical quality using a novel stepwise algorithm. Eng. Optim. 2021, 53, 867–884. [Google Scholar] [CrossRef]

- Nocedal, J.; Wright, S.J. Numerical Optimization; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

| Assembly I | Clamping Step | Weld Relative Disp. | Welding Step | Nodal Disp. |

|---|---|---|---|---|

| Sequence | RSS (mm) | Sequence | RMS (mm) | |

| Optimal | C8-C5-C1-C3-C4-C7-C2-C6 | 0.228 | W1-W3-W2 | 0.091 |

| Unideal | C3-C8-C7-C4-C6-C2-C5-C1 | 0.579 | W3-W1-W2 | 0.171 |

| Assembly II | ||||

| Optimal | C2-C3-C4-C6-C5-C1 | 9.364 | W8-W1-W7-W6-W5-W4-W3-W2 | 0.290 |

| Unideal | C6-C2-C4-C5-C3-C1 | 13.903 | W3-W8-W7-W6-W5-W4-W2-W1 | 1.255 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadeghi Tabar, R.; Zheng, H.; Litwa, F.; Paetzold-Byhain, K.; Lindkvist, L.; Wärmefjord, K.; Söderberg, R. Digital Twin-Based Clamping Sequence Analysis and Optimization for Improved Geometric Quality. Appl. Sci. 2024, 14, 510. https://doi.org/10.3390/app14020510

Sadeghi Tabar R, Zheng H, Litwa F, Paetzold-Byhain K, Lindkvist L, Wärmefjord K, Söderberg R. Digital Twin-Based Clamping Sequence Analysis and Optimization for Improved Geometric Quality. Applied Sciences. 2024; 14(2):510. https://doi.org/10.3390/app14020510

Chicago/Turabian StyleSadeghi Tabar, Roham, Hanchen Zheng, Frank Litwa, Kristin Paetzold-Byhain, Lars Lindkvist, Kristina Wärmefjord, and Rikard Söderberg. 2024. "Digital Twin-Based Clamping Sequence Analysis and Optimization for Improved Geometric Quality" Applied Sciences 14, no. 2: 510. https://doi.org/10.3390/app14020510

APA StyleSadeghi Tabar, R., Zheng, H., Litwa, F., Paetzold-Byhain, K., Lindkvist, L., Wärmefjord, K., & Söderberg, R. (2024). Digital Twin-Based Clamping Sequence Analysis and Optimization for Improved Geometric Quality. Applied Sciences, 14(2), 510. https://doi.org/10.3390/app14020510