1. Introduction

In recent years, the need to enhance both seismic performance and energy efficiency in existing buildings has gained increasing recognition, which has been driven by the impact of recent seismic events, climate change and the vulnerabilities of older structures [

1]. Reinforced concrete (RC) buildings, particularly those constructed in the post-war period without seismic considerations, constitute a significant portion of the Italian building stock. These buildings share common characteristics that make them highly vulnerable to seismic activity [

2,

3]. Typically, RC buildings in Italy are composed of frames oriented in only one direction, with hollow brick infill walls lacking thermal insulation. This configuration is particularly susceptible to seismic forces and energy inefficiencies [

4,

5]. Given the prevalence of these structures in urban environments, the need for effective seismic retrofitting solutions is urgent. Traditional methods, such as internal strengthening or the confinement of beam–column joints [

6,

7,

8], though effective, can be invasive, time-consuming and disruptive to building occupants. A promising alternative is the use of external retrofit solutions made of various materials, such as timber, steel, concrete or aluminum alloys. For instance, external CLT timber panels were shown to increase the load bearing and displacement capacity and improve the global seismic response of RC buildings [

9], while steel buckling restrained braces (BRBs) have been used to increase the strength and capacity for sustaining lateral deformations [

10].

Steel exoskeletons offer an innovative solution for seismic retrofitting by providing additional lateral strength and stiffness to existing buildings while allowing for intervening only from the outside of the building, thus minimizing disruptions to the interior activities of occupants. Studies demonstrated the potential of steel exoskeletons to improve the seismic performance of RC buildings while also meeting structural, thermal and architectural requirements [

11]. RC structures retrofitted with steel exoskeletons, at times in combination with local interventions, showed significant improvements in the global structural behavior, while also reducing the number of RC elements affected by brittle failure [

12,

13]. Cold-formed lightweight steel systems offer an effective structural solution, as they combine the advantages of lightweight construction with strong performance during seismic events. Some studies focused on the design of this type of system by conducting both experimental tests and numerical analyses to assess the effect of earthquakes on lightweight structures [

14,

15,

16,

17,

18,

19]. Furthermore, integrated solutions that combine structural and energy retrofitting are nowadays very competitive in the building sector and, therefore, represent an important issue in the research field. Traditional interventions, such as RC shear walls combined with insulation panels, allow for improving the thermal and seismic behaviors of existing RC buildings while also having a low environmental impact [

20]. Innovative solutions, such as the so-called seismic energy coats, integrate various technologies for seismic retrofit and energy requalification using insulating panels, while also granting short execution times and low invasiveness [

21,

22,

23,

24].

This research focused on a multi-story residential building located in northern Italy and was constructed in the late 1970s. It is an RC structure with the typical configuration with frames only in one direction. It was selected as a case study to evaluate the effectiveness of the Resisto 5.9 Tube system developed by the company Progetto Sisma Srl (Fiorano Modenese, MO, Italy). This recent solution for integrated retrofitting combines seismic reinforcement with energy efficiency improvements. Resisto 5.9 Tube features a cold-formed steel exoskeleton for seismic resistance combined with external thermal insulation panels [

25]. This seismic coat is a novel application of traditional exoskeletons because it provides an increase in the existing structure stiffness while maintaining its mass as basically unaltered. By allowing for installation from the building exterior, the system minimizes disruption to occupants and preserves the interior activities during installation phases. This system was investigated under the seismic perspective by means of finite element analysis (FEA) using Pro_Sap software (version 23.6.1). Before implementing the reinforcement in the calculation software, it was designed following a procedure specifically developed for Resisto 5.9 Tube. The purpose of the design procedure was to define the thickness of the bracing elements at each building level in order to optimize the performances of the existing structure to be retrofitted [

26]. Finally, non-linear static analyses were carried out to compare the structural behavior before and after the retrofit by focusing on changes in the seismic safety coefficient and seismic risk classification according to Italian regulations.

2. Materials and Methods

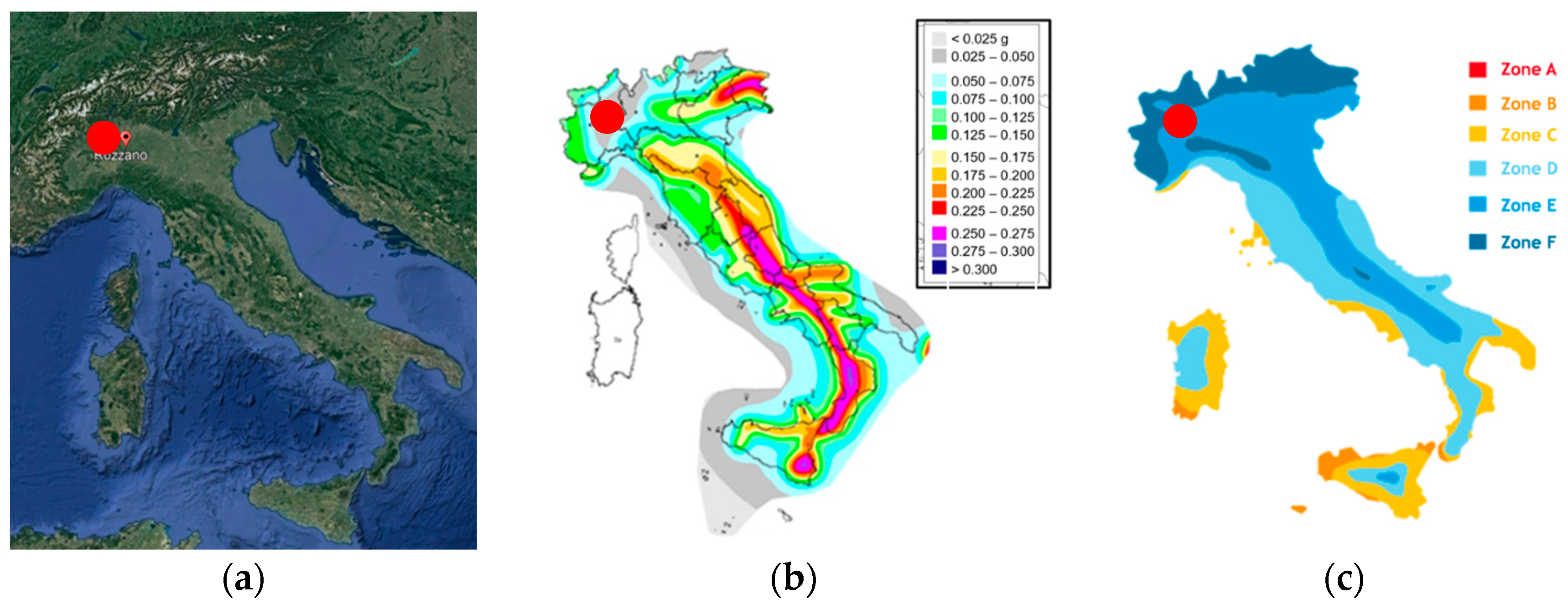

The case study was a multi-story RC residential building located in Rozzano, which is in the province of Milan in Italy. The city of Rozzano is in the northern part of Italy in a low-seismicity area, with a peak ground acceleration (PGA) of 0.075 g and in a climatic zone E, as characterized by 2404 degree-days (

Figure 1).

In this context, the enhancement of the building’s structural performance was the most effective when coupled with improvements in thermal behavior. Resisto 5.9 Tube, which was developed by the Italian company Progetto Sisma Srl, is a retrofit solution designed to simultaneously enhance both the seismic resilience and energy efficiency in existing masonry and reinforced concrete structures. This system can be customized to address the specific needs of each structure by utilizing a design method tailored for this lightweight exoskeleton made of cold-formed steel profiles. The current research aimed to evaluate the effectiveness of this design approach for the seismic retrofitting of a real RC structure. The seismic performance was assessed through nonlinear static analysis performed using finite element software by comparing the structural behavior before and after the application of the retrofit technique.

2.1. Existing RC Building

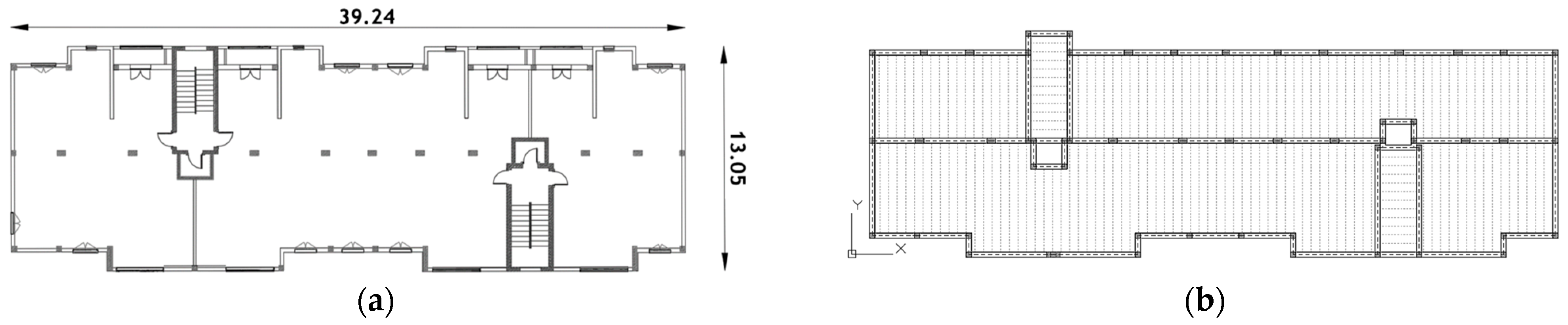

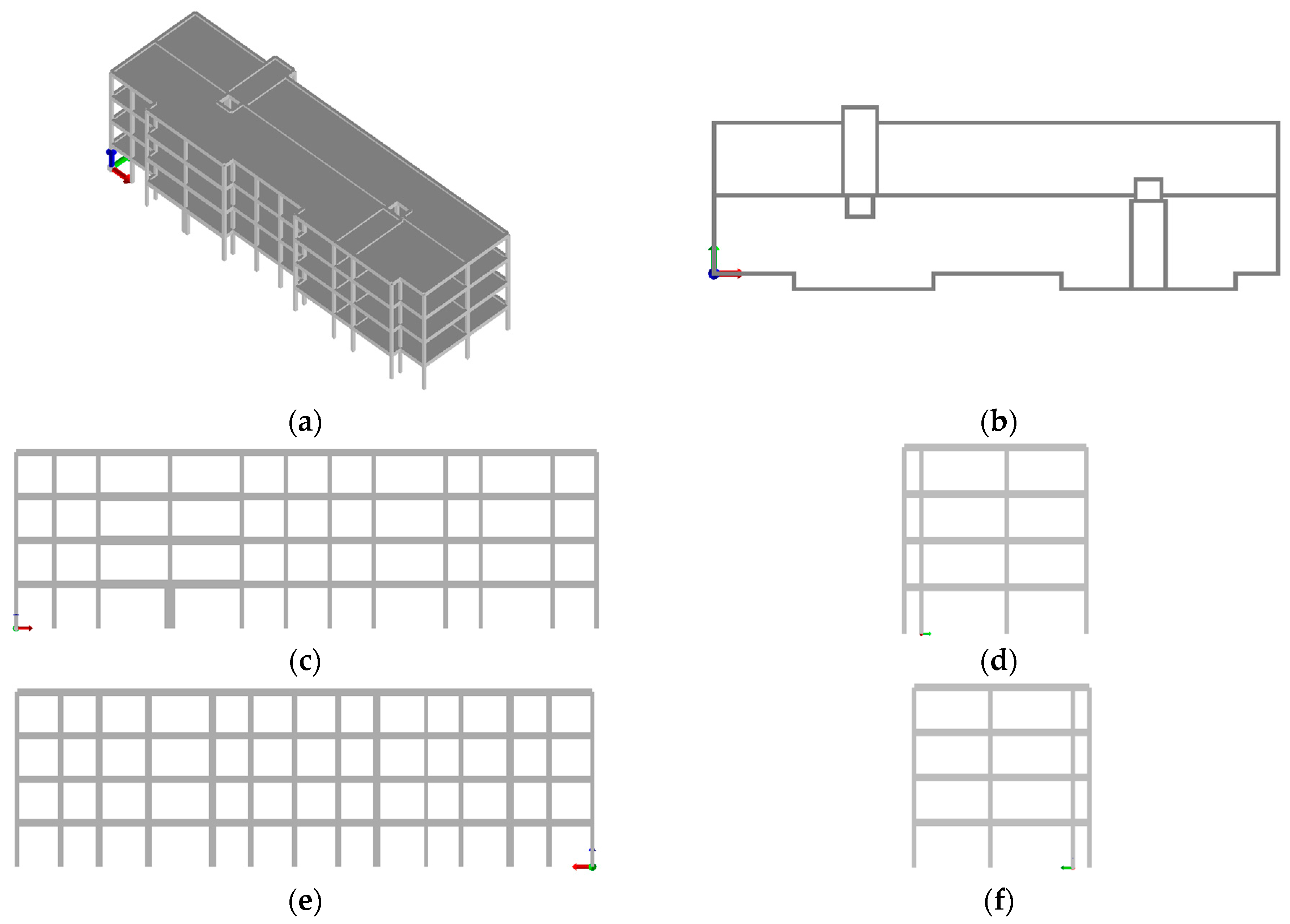

The case study was a multi-story RC structure constructed in the late 1970s. The building had a commercial ground floor and three upper residential levels, with each one characterized by an inter-story height of 3 m. The building’s rectangular plan measured approximately 40 by 13 m, and its structure consisted of RC frames oriented solely in one direction (longitudinal direction X), which were interconnected by the slabs, perimeter beams, and two stair and elevator cores (see

Figure 2).

The building’s façades featured large openings, especially in the longitudinal direction at the ground levels, and the infill walls were made of hollow bricks without thermal insulation (

Figure 3).

The information about the building was gathered through an experimental campaign conducted both on site and in laboratories. This campaign aimed to assess the geometrical configuration, loading conditions and mechanical properties of the structural materials, which were then compared with the existing documentation. According to Italian standards [

27,

28], a normal level of knowledge (KL2) was achieved, which corresponded to a confidence factor (FC) of 1.2 for reducing resistance values.

The RC columns had rectangular cross-sections of varying dimensions (30 × 30 cm, 30 × 40 cm and 30 × 50 cm), with longitudinal bars and stirrups of φ8/30. The RC beams, which were dropped, also had rectangular cross-sections, with dimensions of 30 × 50 cm and 30 × 60 cm, and had stirrups of φ8/20. All structural elements were constructed with C25/30 concrete and were reinforced with B450C steel, as detailed in

Table 1 and

Table 2, respectively.

The infill walls were made of hollow bricks (dead weight γ = 800 kg/m3) with a total thickness of 24 cm.

2.2. Cold-Formed Exoskeleton

The system under investigation was the Resisto 5.9 Tube, which was developed by Progetto Sisma Srl. This innovative solution, which is known as a seismic energy coat, was designed for the integrated retrofitting of existing masonry and reinforced concrete buildings. The system’s seismic-resistant component is a cold-formed steel exoskeleton that features a braced frame that is securely connected to the existing RC columns and beams using chemical anchors. This exoskeleton is installed externally, parallel to the building’s façades, which allows for normal activities within the building to be continued during the assembly process.

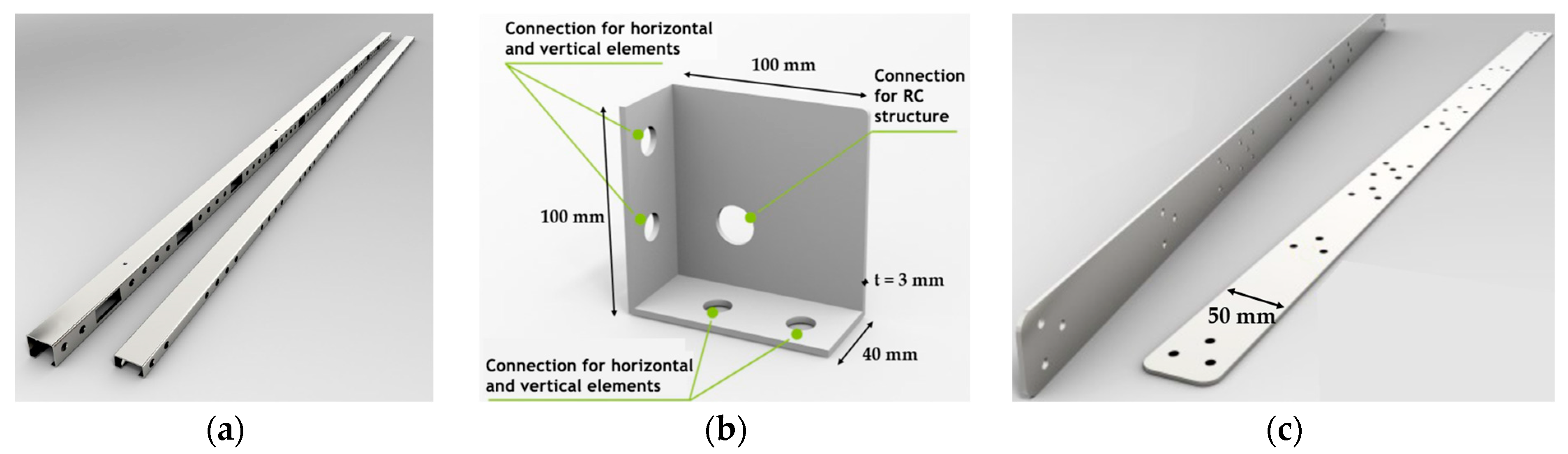

The steel frame consists of horizontal and vertical members, with both having hollow rectangular cross-sections with a thickness of 2 mm, though with varying dimensions. The horizontal members (60 × 25 mm) are inserted into the vertical members (60 × 45 mm) via modular holes (

Figure 4a). The components of the steel frame are connected using gusset plates and bolts, which also attach the diagonal bracings to the frame and secure the connection to the RC structure (

Figure 4b). The diagonal bracings are fastened to the gusset plates with steel rivets, and they have a width of 50 mm, while the thickness is determined by the design specifications (

Figure 4c).

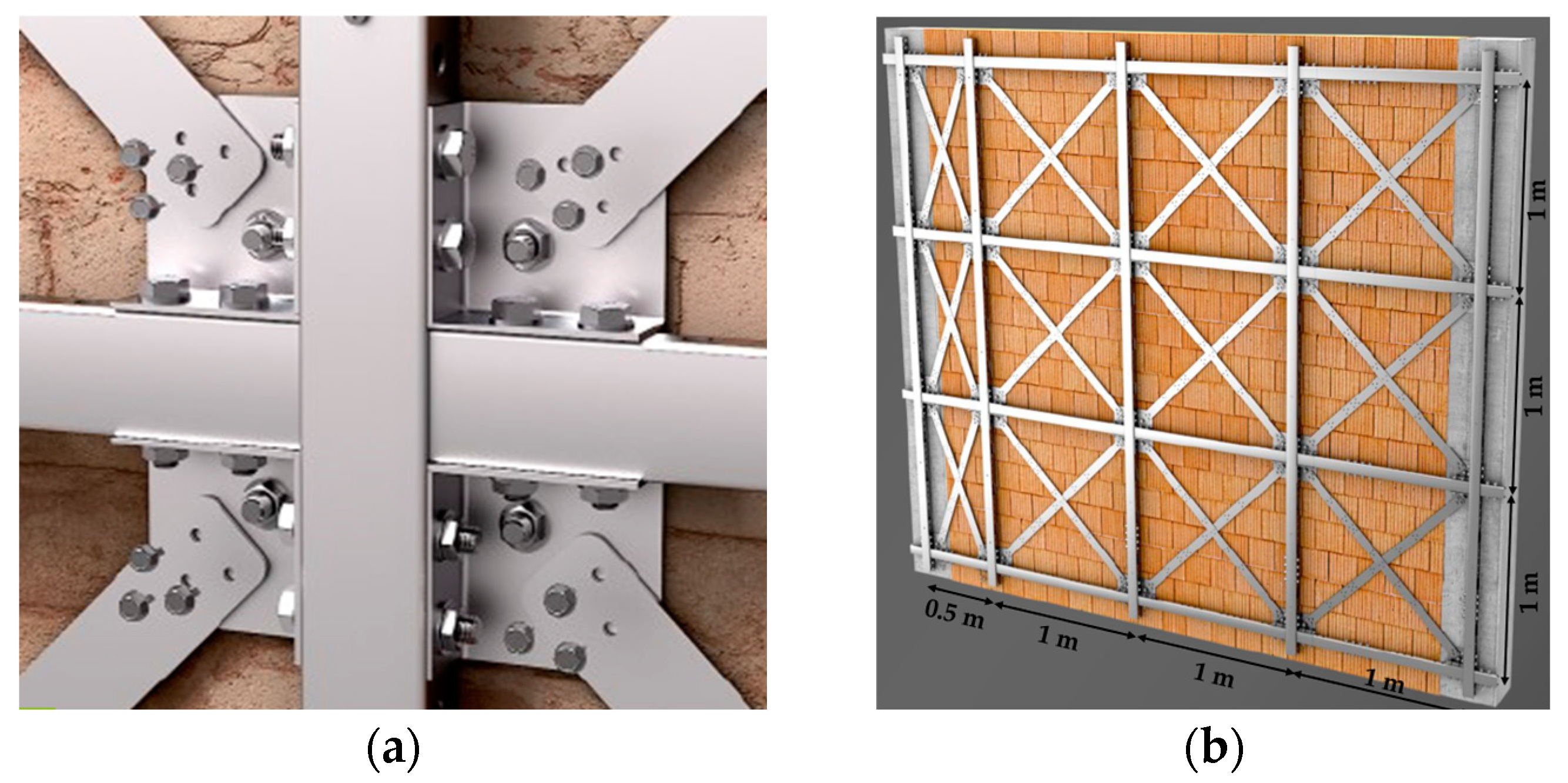

The elements of the exoskeleton were designed with modular holes, which allow for a standardized configuration. The standard module features a spacing of 1 m between horizontal and vertical members, though different dimensions can be used to tailor the retrofit solution to the specific requirements of the structure being reinforced. The reinforcement process is completed with the addition of insulating panels and finishing layers. The final configuration of the system’s seismic-resistant part is illustrated in

Figure 5.

The elements of the Resisto 5.9 Tube system—including the horizontal and vertical members, as well as the diagonal bracings—are constructed from pre-galvanized steel of type S320GD + Z. The anchoring bolts used in the system have a diameter of 12 mm and are of resistance class 8.8. The mechanical properties of the structural materials are summarized in

Table 3 for the steel elements and in

Table 4 for the connectors.

Finally, the improvement in the building’s thermal performance is achieved using expanded polystyrene insulating panels, which are applied at the intended thickness and covered with various types of finishing materials.

2.3. Retrofitted RC Building

Before implementing the design procedure and conducting a seismic analysis on the reinforced structure, it was essential to define the geometric configuration of the reinforcement system. The cold-formed exoskeleton was applied across the entire structure while considering the architectural constraints, such as openings and balconies. A standard module with 1 m spacing between the horizontal and vertical members was used wherever possible. The system was anchored to the ground via a reinforced concrete (RC) foundation beam that was securely attached to the steel vertical members. The new foundation was connected to the existing one using grouted bars. The dimensions of the steel elements match those specified in the standard solution, except for the diagonal bracing thickness, which was calculated using the design procedure to optimize the reinforcement effectiveness. The design procedure was based on pushover analysis, but any analysis method can be employed. The schematic configuration of the Resisto 5.9 Tube system is illustrated in

Figure 6.

2.4. Finite Element Modeling and Analysis

The seismic analysis was conducted using Pro_Sap, which is software developed by the Italian company 2S.I. Software e Servizi per L’Ingegneria S.r.l. (Ferrara, Italy). The case study building was modeled in the software both before and after the installation of the Resisto 5.9 Tube system to assess its contribution to the seismic upgrading of the existing RC structure. The structure was evaluated through nonlinear static analyses, and the seismic safety factor was calculated in accordance with the Italian code. Pushover analysis is the most common method used to investigate the seismic behavior of existing buildings, considering that nonlinear dynamic analyses are more complex procedures that are unknown to many designers. Only mechanical non-linearities were considered. RC members were modeled as bidimensional beam elements with nonlinear properties using a concentrated plasticity model with assigned values for the plastic hinges’ capacities, while steel X-bracings were modeled as non-linear trusses. The values of plastic moments to be considered in the non-linear analysis were automatically assessed by the Pro_Sap software thanks to a linear calculation model called source model. The elastic–plastic behavior of non-linear trusses for X-bracings was considered by assigning tension and compression limits in terms of strength. Notably, the infill walls were not included in the structural model; instead, they were represented as a uniform load distributed along the perimeter beams. Vertical loads were applied to the floors at each level, as specified in

Table 5. The permanent loads on the top floor also included the weight of the roof, which was not directly incorporated into the calculation software. The floors were modeled as rigid slabs with a membrane thickness of 4 cm.

Seismic loads for the nonlinear static analyses were computed using the foundation soil category (C) and topographic category (T1). A standard damping of 5% was applied, while the soil–structure interactions were neglected, as the reinforced concrete and steel vertical elements at ground level were assumed to be fixed at the base. The type of action was calculated at the ultimate limit state (ULS) with different accidental eccentricities (positive, negative and none) for each principal direction (longitudinal X and transverse Y). Two force distributions were considered: a triangular distribution, similar to that used in linear static analysis, and a mass-proportional distribution. The solid view of the existing structure model, as implemented in the Pro_Sap software, is shown in

Figure 7.

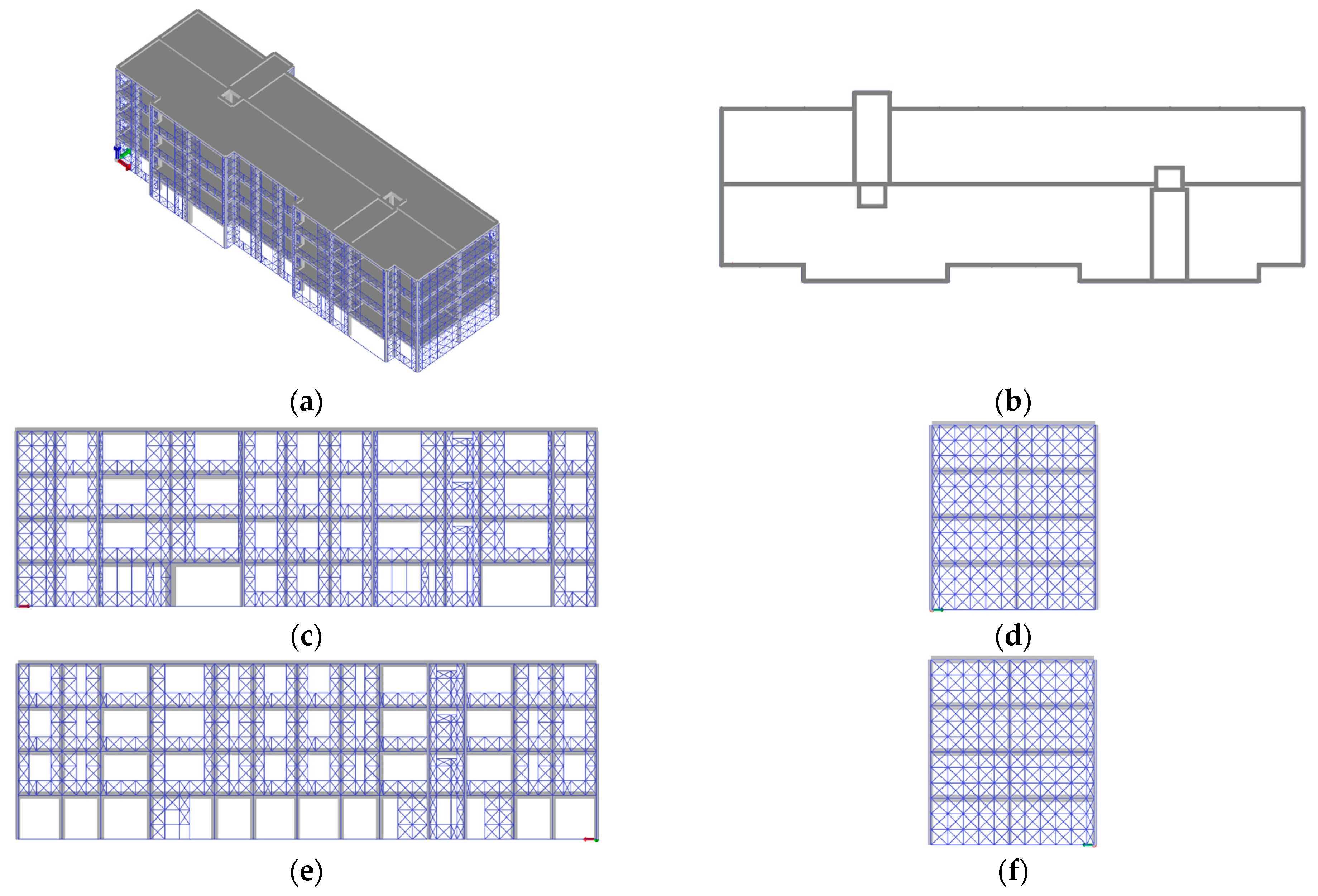

The same loading conditions were applied to the retrofitted model, which was equivalent to the unreinforced structure, but equipped with the cold-formed exoskeleton. The steel elements were incorporated into the structural model as closely as possible to their actual configuration, with some necessary simplifications. Horizontal and vertical profiles were modeled as beam elements with moment releases, which accurately represented the system’s constraint conditions. The diagonal bracings were modeled as nonlinear trusses, which were capable of sustaining only tensile stresses. The connections between the horizontal and vertical members and the RC structure were represented by rigid links, which simulated the presence of the chemical anchors. The solid view of the retrofitted structure model, as implemented in the Pro_Sap software, is shown in

Figure 8.

3. Results and Discussion

The unreinforced and reinforced RC residential buildings were subjected to nonlinear static analysis using the finite element software ProSap. The comparison of the results was conducted by examining the capacity curves of the structures and the seismic safety coefficients, as evaluated according to the Italian Technical Standard. The following sections provide a summary of the key results from the numerical analysis, along with the outcomes of the design procedure.

3.1. Seismic Analysis on the Existing RC Building

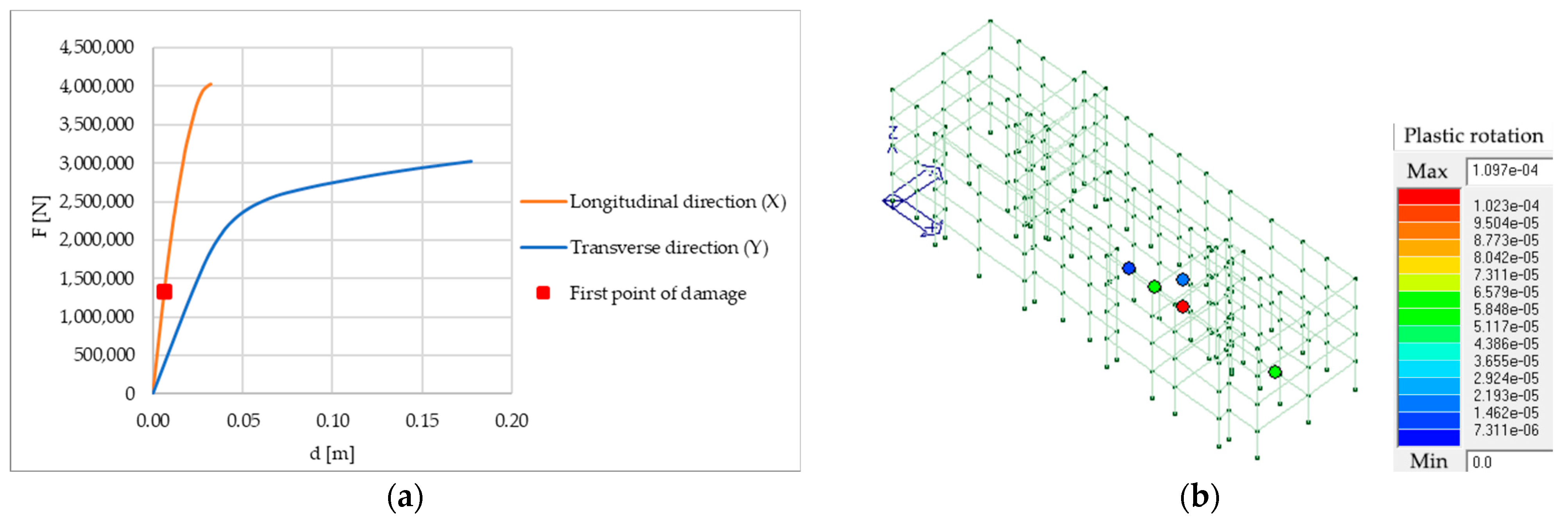

The performance of the numerical analysis on the unreinforced building is crucial not only for assessing the seismic safety and identifying vulnerabilities but also for designing the cold-formed exoskeleton tailored to the building’s capacity and specific needs. The RC building was subjected to pushover analysis in both primary directions, which generated capacity curves for each direction.

Figure 9 presents the pushover curves under the most severe loading conditions for each thrust direction. The red square on the curves marks the point at which the first structural damage occurred, which is a key parameter for seismic design.

The main parameters of the analysis are summarized in

Table 6, which highlights that the structure exhibited greater ductility in the transverse direction (Y) and increased stiffness and strength in the longitudinal direction (X). The initial damage in the structure occurred in the longitudinal direction at a displacement of 0.61 cm, whereas in the transverse direction, the first point of damage corresponded to a displacement of 1.75 cm. In both cases it was represented by the formation of plastic hinges on the columns and beams.

3.2. Seismic Design of the Cold-Formed Exoskeleton

The first instance of damage served as the starting point for the design method, which aimed to determine the thickness of the diagonal members to optimize the retrofitting solution. This initial damage was observed in the longitudinal direction at a displacement of 0.61 cm. The design method, which was based on literature approaches [

30,

31] and adapted for this specific exoskeleton type [

26], began with the assumption that the retrofitted structure should exhibit ductility comparable to that of the unreinforced structure.

The process started by setting a target displacement slightly lower than the displacement at the first point of damage, which was fixed at 0.55 cm. Using the equivalent bilinear curve representation of the structure and the elastic spectrum in the acceleration displacement response spectrum (ADRS) format, an iterative procedure defined the ultimate displacement of the retrofitted structure and, consequently, its stiffness. This iterative process continued until the ductility of the retrofitted structure matched that of the unreinforced one (µ = 2.16). At the end of the procedure, an equivalent bilinear curve representative of the cold-formed exoskeleton was derived by subtracting the design parameters of the retrofitted structure from those of the existing structure. According to the procedure, the design stiffness of the Resisto 5.9 Tube was determined to be 1.039.603 daN/cm. This value represents the total stiffness of the exoskeleton in the longitudinal direction and needed be redistributed across each level and module of the Resisto 5.9 Tube. The distribution of stiffness along the building height was achieved using a proportionality factor r

k, which relates the overall stiffness of the existing structure to that of the Resisto 5.9 Tube. This factor was then applied to the floor stiffnesses of the existing structure to determine the floor stiffnesses of the exoskeleton, as detailed in

Table 7.

To evaluate the regularity in height of the existing structure and determine whether the exoskeleton is needed to redistribute and homogenize the floor stiffnesses, reference to the Italian Code was made. According to the code, for a structure to be considered regular in height, the stiffness of successive floors should fall within the range in Equation (1):

The existing buildings met the requirements for regularity in height; therefore, it was not necessary to use the exoskeleton for redistributing the stiffnesses.

To simplify the design procedure, the floor stiffness was divided by the number of exoskeleton modules in each direction (n

Ri) to determine the stiffness of a single diagonal (k

Ri,s). The design area of the diagonal (A

i) could then be computed using the following Equation (2):

where Li is the average length of diagonal members, E is the elasticity modulus of the material and α is the inclination angle of diagonal members. Knowing the width of the diagonal members (b

i), the design thickness (t

i) for each level could be readily computed.

Table 8 summarizes the results for one of the longitudinal façades, which represents the most severe condition.

Ultimately, it was decided to use the same diagonal member thickness of 1 mm for all levels, except for the first level, where a thicker member (2 mm) was required due to the large number of openings.

3.3. Seismic Analysis on the Retrofitted RC Building

The numerical analysis of the reinforced building aimed to evaluate the effectiveness of the designed retrofitting system in enhancing seismic safety and reducing structural vulnerabilities according to Eurocodes 2, 3 and 8 [

32,

33,

34]. After installing the Resisto 5.9 Tube, the retrofitted RC building was subjected to pushover analysis to derive the capacity curves.

Figure 10 illustrates these curves under the most severe loading conditions for each direction. In these curves, the red square indicates the point where the first damage occurred in the structure reinforced with the cold-formed exoskeleton.

The main parameters of the analysis are summarized in

Table 9, which highlights that the overall behavior of the retrofitted structure remained similar to that of the existing one, with increased ductility in the transverse direction (Y) and enhanced stiffness and strength in the longitudinal direction (X). Even after installing the exoskeleton, the first point of damage in the structure still occurred in the longitudinal direction.

3.4. Comparison of the Results

The comparison of the capacity curves for the structure before and after the application of the Resisto 5.9 Tube (

Figure 11) demonstrates how the cold-formed exoskeleton improved the stiffness, ductility and strength of the existing RC buildings. The percentage variations in the key parameters of the seismic analysis, both before and after the retrofit, are summarized in

Table 10.

The efficacy of the Resisto 5.9 Tube for the seismic upgrading of existing RC buildings was assessed by comparing the seismic safety index ζ

E before and after the retrofit intervention. The seismic safety index was evaluated according to the Italian Technical Standard as a ratio between the capacity and the demand in terms of the peak ground acceleration, as reported in Equation (3):

This index represents the ratio between the seismic action that the building can sustain and the one that is requested for a new structure. To classify a retrofit intervention as seismic upgrading, the code requires that the seismic safety index must increase by at least 0.1. The cold-formed exoskeleton allowed for achieving an increase in ζ

E value of 0.16 and, therefore, the seismic upgrade of the RC building was attained, as summarized in

Table 11.

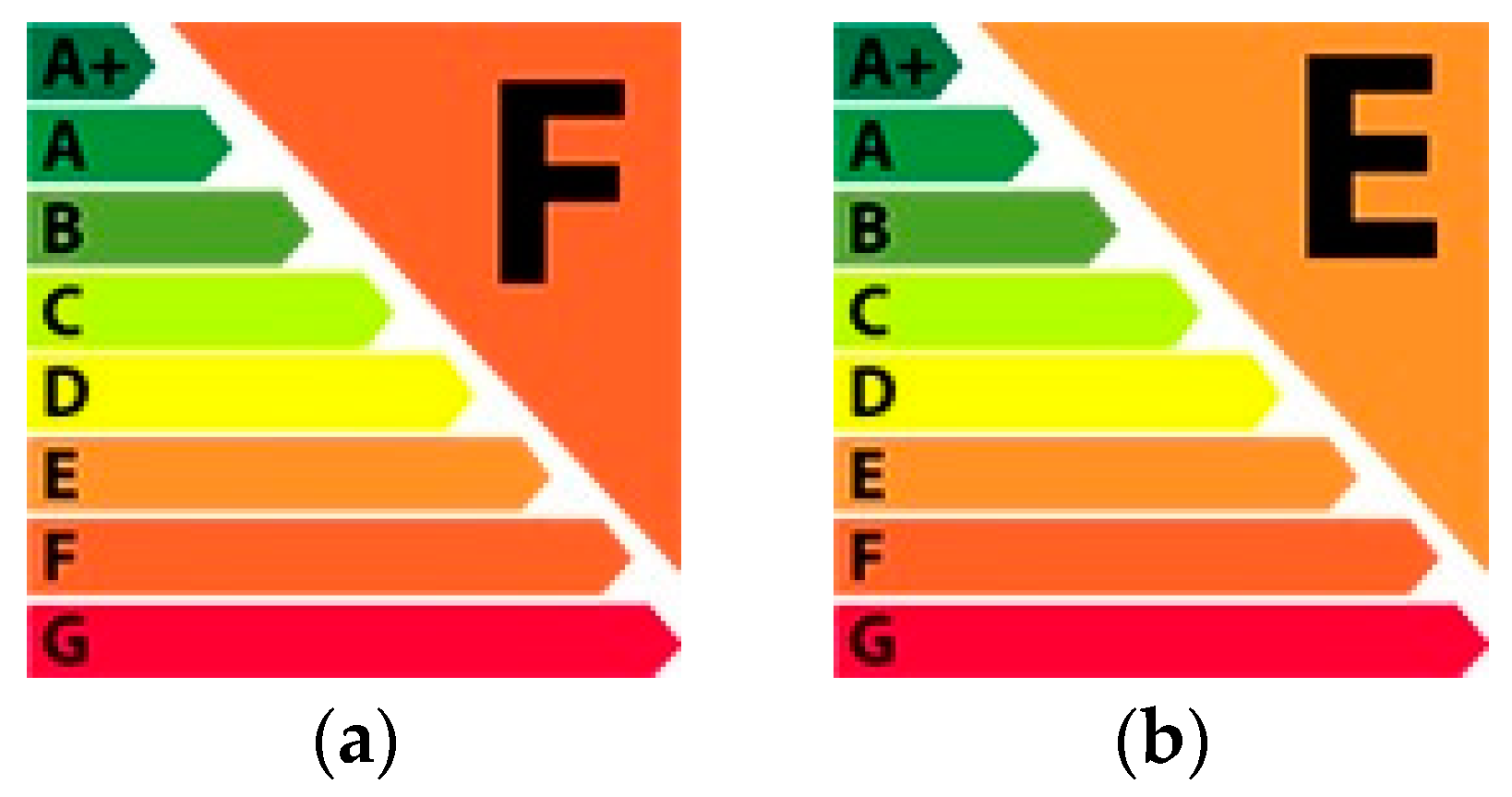

Finally, a comparison was made in terms of the seismic risk classification according to the Italian Guidelines [

35]. The seismic risk class of a building was determined based on two main parameters: the seismic safety index (IS-V), corresponding to the ζ

E index, and the PAM value, which represents the expected annual loss. To each parameter a risk class ranging from A+ to G, with increasing levels of risk, was assigned. The seismic risk of the building was classified according to the lowest class between IS-V class and PAM one. The worst condition was represented by the annual loss (PAM class), which was evaluated as the area under the curve that depicted the direct economic losses as a function of the average annual frequency of an exceedance of the seismic event that causes the structure to reach the life safety limit state.

For the analyzed building, the retrofit intervention led to an improvement by one risk class, from F to E, as shown in

Table 12 and

Figure 12.

In conclusion, based on the results achieved, it is evident that the Resisto 5.9 enhanced the seismic performances of the existing building by improving the global seismic behavior of the bare structure similarly to other exoskeleton solutions [

13,

36].

4. Conclusions

The research focused on applying a cold-formed exoskeleton, known as Resisto 5.9 Tube, to a reinforced concrete (RC) structure for seismic-energy retrofitting. Resisto 5.9 is made of steel-braced frames connected to the existing structure with chemical anchors and integrated with insulation panels for the improvement of the thermal performance. The investigation was addressed to the assessment of the structural behavior of a building before and after the installation of the exoskeleton. The aim of the study was to show the effectiveness of the proposed design procedure to obtain a solution that was able to improve the global seismic behavior of a case study representing a common typology of RC buildings erected in Italy in the 1970s.

The system was initially designed using an iterative procedure that determined the required thickness of the seismic-resistant bracings based on the specific needs of the structure. The design was set on a target displacement that was identified based on the capacity curve of the existing structure before the first instance of damage (d*dam = 0.55 cm). Then, an iterative procedure allowed for determining the required stiffness for the Resisto 5.9 Tube that aimed to obtain a similar ductility of the structure before and after the application of the exoskeleton (µ = 2.16). Due to large openings on the ground floor that limited the application of the exoskeleton, the design specified a bracing thickness of 2 mm for the first level and 1 mm for the upper levels. The effectiveness of the design was evaluated through nonlinear static analysis of the structure both before and after the system application. The results demonstrated that the exoskeleton significantly enhanced the seismic performance of the existing RC buildings. From the comparison of the capacity curves of the structure before and after the retrofit, it was observed that the ultimate and yielding displacements increased in both the longitudinal and transverse directions. The shear strength increased by 18.5% and 27.5% in the longitudinal and transverse directions, respectively, while the initial stiffness increased only in the longitudinal direction with an 8.3% increase. The seismic safety index improved from 0.26 to 0.42, which surpassed the minimum required increase of 0.1, as stipulated by the Italian Technical Standard for seismic upgrading. Additionally, the application of the Resisto 5.9 Tube resulted in a reduction of seismic risk, which advanced the seismic risk class from F to E. In conclusion, the Resisto 5.9 allowed for increasing the strength and the overall base shear of the existing building, and thus, improved the global seismic behavior of the structure consistently with other investigations on external exoskeletons found in literature. The ongoing research aims to further assess the system’s efficacy, including its performance in the presence of infill walls, which were only represented as a uniform load on the perimeter beams in this study. Despite the challenges posed by large openings, the positive impact of the Resisto 5.9 Tube on the case study was confirmed, which demonstrated its effectiveness in improving seismic resilience even when considering complex geometrical configurations. Additional investigations will be performed to take into consideration not only the structural behavior but also the improvement of the energy performances of the building due to the presence of the integrated retrofit system.

Author Contributions

Conceptualization, A.F.; methodology, A.F.; software, E.M.; validation, A.F.; formal analysis, E.M.; investigation, E.M. and A.F.; resources, A.F.; data curation, E.M.; writing—original draft preparation, E.M.; writing—review and editing, A.F.; visualization, A.F.; supervision, A.F.; project administration, A.F.; funding acquisition, A.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors acknowledge the Progetto Sisma Srl company, who patented the Resisto 5.9 system and stipulated a research contract with the Department of Structures for Engineering and Architecture of the University of Naples Federico II (scientist responsible: A. Formisano) to evaluate the system efficacy for retrofitting RC buildings. Also, the DPC-ReLUIS research project, where the current research activity was framed, is gratefully acknowledged. Finally, sincere thanks are also due to 2S.I. Software e Servizi per L’Ingegneria S.r.l., which provided the PRO_SAP software for conducting the numerical analyses.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Besen, P.; Boarin, P. Integrating energy retrofit with seismic upgrades to future-proof built heritage: Case studies of unreinforced masonry buildings in Aotearoa New Zealand. Build. Environ. 2023, 241, 110512. [Google Scholar] [CrossRef]

- Clementi, F.; Quagliarini, E.; Maracchini, G.; Lenci, S. Post-War War II Italian school buildings: Typical and specific seismic vulnerabilities. J. Build. Eng. 2015, 4, 152–166. [Google Scholar] [CrossRef]

- Bartolotti, A.; Smiroldo, F.; Giongo, I. A simplified analytical approach for CLT-based seismic retrofit of existing reinforced concrete structures. Eng. Struct. 2024, 308, 117964. [Google Scholar] [CrossRef]

- Valente, M.; Milani, G. Alternative retrofitting strategies to prevent the failure of an under-designed reinforced concrete frame. Eng. Fail. Anal. 2018, 89, 271–285. [Google Scholar] [CrossRef]

- Braga, F.; Manfredi, V.; Masi, A.; Salvatori, A.; Vona, M. Performance of non-structural elements in RC buildings during the L’Aquila, 2009 earthquake. Bull. Earthq. Eng. 2011, 9, 307–324. [Google Scholar] [CrossRef]

- Ong, C.B.; Chin, C.L.; Ma, C.K.; Tan, J.Y.; Awang, A.Z.; Omar, W. Seismic retrofit of reinforced concrete beam-column joints using various confinement techniques: A review. Structures 2022, 42, 221–243. [Google Scholar] [CrossRef]

- Pohoryles, D.A.; Minas, S.; Melo, J.; Bournas, D.A.; Varum, H.; Rossetto, T. A Novel FRP Retrofit Solution for Improved Local and Global Seismic Performance of RC Buildings: Development of Fragility Curves and Comparative Cost-Benefit Analyses. J. Earthq. Eng. 2024, 28, 1914–1932. [Google Scholar] [CrossRef]

- Huang, H.; Huang, M.; Zhang, W.; Yang, S. Experimental study of predamaged columns strengthened by HPFL and BSP under combined load cases. Struct. Infrastruct. Eng. 2020, 17, 1210–1227. [Google Scholar] [CrossRef]

- Smiroldo, F.; Giongo, I.; Piazza, M. Use of timber panels to reduce the seismic vulnerability of concrete frame structures. Eng. Struct. 2021, 244, 112797. [Google Scholar] [CrossRef]

- Almeida, A.; Ferreira, R.; Proença, J.M.; Gago, A.S. Seismic retrofit of RC building structures with Bucking Restrained Braces. Eng. Struct. 2017, 130, 14–22. [Google Scholar] [CrossRef]

- D’Agostino, D.; Faiella, D.; Febbraro, E.; Mele, E.; Minichiello, F.; Trimarco, J. Steel exoskeletons for integrated seismic/energy retrofit of existing buildings—General framework and case study. J. Build. Eng. 2024, 83, 108413. [Google Scholar] [CrossRef]

- Nigro, F.; Della Corte, G.; Martinelli, E. Assessment of alternative design approaches for seismic upgrading of RC frame structures with steel exoskeletons. Eng. Struct. 2024, 305, 117623. [Google Scholar] [CrossRef]

- Milone, A.; Tartaglia, R.; D’Aniello, M.; Landolfo, R. Seismic upgrade of a non-code compliant multi-storey steel building: A case study. J. Build. Eng. 2024, 95, 110151. [Google Scholar] [CrossRef]

- Bysiec, D.; Maleska, T. Numerical Analysis of Steel Geodesic Dome under Seismic Excitations. Materials 2021, 14, 4493. [Google Scholar] [CrossRef]

- Yang, Z.; Shi, Y.; Cao, W.; Dong, H.; Bian, J. Seismic behavior of lightweight steel frame with thin-walled steel skeleton-lightweight concrete wall. J. Constr. Steel Res. 2024, 222, 109003. [Google Scholar] [CrossRef]

- Bysiec, D.; Maleska, T. Influence of the mesh structure of geodesic domes on their seismic response in applied directions. Arch. Civ. Eng. 2023, 69, 65–78. [Google Scholar] [CrossRef]

- Kang, J.; Xie, L.; Xue, S.; Zhao, Z. Simplified optimization of inerter-enabled tuned mass damper for lightweight-oriented seismic response mitigation of long-span domes. Structures 2023, 58, 105408. [Google Scholar] [CrossRef]

- Fiorino, L.; D’Addesa, V.; Landolfo, R. Seismic design rules for lightweight steel shear walls with wood panel sheathing within the Eurocode format. Thin-Walled Struct. 2024, 204, 112293. [Google Scholar] [CrossRef]

- Campiche, A.; Tartaglia, R.; Fiorino, L.; Landolfo, R. Experimental tests for the evaluation of the seismic performance of the innovative CFS wall. Thin-Walled Struct. 2024, 198, 111681. [Google Scholar] [CrossRef]

- Caruso, M.; Pinho, R.; Bianchi, F.; Cavalieri, F.; Lemmo, M.T. Integrated economic and environmental building classification and optimal seismic vulnerability/energy efficiency retrofitting. Bull. Earthq. Eng. 2021, 19, 3627–3670. [Google Scholar] [CrossRef]

- Pohoryles, D.A.; Bournas, D.A.; Da Porto, F.; Caprino, A.; Santarsiero, G.; Triantafillou, T. Integrated seismic and energy retrofitting of existing buildings: A state-of-the-art review. J. Build. Eng. 2022, 61, 105274. [Google Scholar] [CrossRef]

- Meglio, E.; Longobardi, G.; Formisano, A. Integrated seismic-energy retrofit systems for preventing failure of a historical RC school building: Comparison among metal lightweight exoskeleton solutions. Eng. Fail. Anal. 2023, 154, 107663. [Google Scholar] [CrossRef]

- Ademovic, N.; Formisano, A.; Penazzato, L.; Oliveira, D.V. Seismic and energy integrated retrofit of buildings: A critical review. Front. Built Environ. 2022, 8, 963337. [Google Scholar] [CrossRef]

- Sebastiani, I.; D’Amore, S.; Pinotti, R.; Pampanin, S. Integrated rehabilitation of reinforced concrete buildings: Combining seismic retrofit by means of low-damage exoskeleton and energy refurbishment using multi-functional prefabricated façade. J. Build. Eng. 2024, 15, 110368. [Google Scholar] [CrossRef]

- Progetto Sisma. Available online: https://www.progettosisma.it/ (accessed on 29 July 2024).

- Meglio, E.; Davino, A.; Formisano, A. Design Method of Lightweight Steel Exoskeletons for Seismic-Energy Upgrading of Existing RC Buildings. In Proceedings of the 11th International Conference on Behaviour of Steel Structures in Seismic Areas, Salerno, Italy, 8–10 July 2024. [Google Scholar]

- Ministry of Infrastructure and Transport. Technical Standards for Construction. In Official Gazette; Number 42 of 20 February 2018; Ministry of Infrastructure and Transport: Rome, Italy, 2018. (In Italian) [Google Scholar]

- Ministry of Infrastructure and Transport. Instructions for the Application of the New Technical Code for Constructions. In Official Gazette; Number 7 of 21 February 2019; Ministry of Infrastructure and Transport: Rome, Italy, 2019. (In Italian) [Google Scholar]

- Resisto 5.9 Tube. Progetto Sisma. Available online: https://www.progettosisma.it/wp-content/uploads/2024/04/Resisto_5.9_Tube_ITA.pdf (accessed on 29 July 2024).

- Ponzo, F.C.; Di Cesare, A.; Arleo, G.; Totaro, P. Seismic protection of existing buildings with hysteretic dissipative bracing: Design and execution aspects. Seism. Des. LediJournals 2010, 1, 37–60. [Google Scholar]

- Fajfar, P.; Gašperšič, P. The N2 method for the seismic damage analysis of buildings. Earthq. Eng. Struct. Dyn. 1996, 25, 31–46. [Google Scholar] [CrossRef]

- EN 1992; Eurocode 2: Design of Concrete Structures. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 1993; Eurocode 3: Design of Steel Structures. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 1998; Eurocode 8: Design of Structures for Earthquake Resistance. European Committee for Standardization: Brussels, Belgium, 2004.

- Ministerial Decree n. 65 of 07/03/2017. Ministero delle Infrastrutture e dei Trasporti. Sisma Bonus-Linee Guida per la Classificazione del Rischio Sismico delle Costruzioni e i Relativi Allegati. Modifiche All’articolo 3 del Decreto Ministeriale n. 58 del 28/02/2017. Available online: http://www.mit.gov.it/normativa/decreto-ministeriale-numero-65-del-07032017 (accessed on 18 September 2024). (In Italian)

- Prota, A.; Tartaglia, R.; Di Lorenzo, G.; Landolfo, R. Seismic strengthening of isolated RC framed structures through orthogonal steel exoskeleton: Bidirectional non-linear analyses. Eng. Struct. 2024, 302, 117496. [Google Scholar] [CrossRef]

Figure 1.

Localization of the case study in the Italian territory (a), seismic hazard map (b) and climate zones map (c).

Figure 1.

Localization of the case study in the Italian territory (a), seismic hazard map (b) and climate zones map (c).

Figure 2.

Architectural (a) and structural (b) plan layouts of the case study building (units: m).

Figure 2.

Architectural (a) and structural (b) plan layouts of the case study building (units: m).

Figure 3.

Longitudinal (a) and transversal (b) façades of the case study.

Figure 3.

Longitudinal (a) and transversal (b) façades of the case study.

Figure 4.

Elements of Resisto 5.9 Tube: horizontal and vertical members (

a), connections (

b) and diagonal bracings (

c) [

29].

Figure 4.

Elements of Resisto 5.9 Tube: horizontal and vertical members (

a), connections (

b) and diagonal bracings (

c) [

29].

Figure 5.

Standard configuration of Resisto 5.9 Tube: detail of the connections (

a) and RC structure equipped with the seismic-resistant braced frame (

b) [

29].

Figure 5.

Standard configuration of Resisto 5.9 Tube: detail of the connections (

a) and RC structure equipped with the seismic-resistant braced frame (

b) [

29].

Figure 6.

Schematic configuration of the reinforcement: longitudinal (a) and transversal (b) façades of the retrofitted building.

Figure 6.

Schematic configuration of the reinforcement: longitudinal (a) and transversal (b) façades of the retrofitted building.

Figure 7.

FEM model of the existing structure: 3D view (a), plan layout (b), longitudinal sections (c,e) and transversal sections (d,f).

Figure 7.

FEM model of the existing structure: 3D view (a), plan layout (b), longitudinal sections (c,e) and transversal sections (d,f).

Figure 8.

FEM model of the retrofitted structure: 3D view (a), plan layout (b), longitudinal sections (c,e) and transversal sections (d,f).

Figure 8.

FEM model of the retrofitted structure: 3D view (a), plan layout (b), longitudinal sections (c,e) and transversal sections (d,f).

Figure 9.

Capacity of the existing structure in the most severe condition: pushover curves (a) and location of the first point of damage (b).

Figure 9.

Capacity of the existing structure in the most severe condition: pushover curves (a) and location of the first point of damage (b).

Figure 10.

Capacity of the retrofitted structure in the most severe condition: pushover curves (a) and location of the first point of damage (b).

Figure 10.

Capacity of the retrofitted structure in the most severe condition: pushover curves (a) and location of the first point of damage (b).

Figure 11.

Comparison of the capacity of the existing and retrofitted structures in the most severe condition: longitudinal direction X (a) and transverse direction Y (b).

Figure 11.

Comparison of the capacity of the existing and retrofitted structures in the most severe condition: longitudinal direction X (a) and transverse direction Y (b).

Figure 12.

Seismic risk class of the RC building: before (a) and after (b) the retrofit intervention.

Figure 12.

Seismic risk class of the RC building: before (a) and after (b) the retrofit intervention.

Table 1.

Mechanical properties of concrete.

Table 1.

Mechanical properties of concrete.

| fck, cube 1 [MPa] | E 1 [MPa] | γ 1 [kg/m3] |

|---|

| 30 | 31,447.2 | 2500 |

Table 2.

Mechanical properties of steel.

Table 2.

Mechanical properties of steel.

| ftk 1 [MPa] | fyk 1 [MPa] | E 1 [MPa] | γ 1 [kg/m3] |

|---|

| 540 | 450 | 210,000 | 7850 |

Table 3.

Mechanical properties of steel profiles.

Table 3.

Mechanical properties of steel profiles.

| ftk 1 [MPa] | fyk 1 [MPa] | E 1 [MPa] | γ 1 [kg/m3] |

|---|

| 390 | 320 | 210,000 | 7850 |

Table 4.

Mechanical properties of anchoring bolts.

Table 4.

Mechanical properties of anchoring bolts.

| ftk 1 [MPa] | fyk 1 [MPa] | E 1 [MPa] | γ 1 [kg/m3] |

|---|

| 800 | 640 | 210,000 | 7850 |

Table 5.

Vertical loads applied to the floors.

Table 5.

Vertical loads applied to the floors.

| Level | G1 1 [kg/m2] | G2 1 [kg/m2] | Q 1 [kg/m2] |

|---|

| Intermediate floors | 370 | 120 | 200 |

| Top floor | 500 | - | 120 |

Table 6.

Results of the pushover analysis on the existing building.

Table 6.

Results of the pushover analysis on the existing building.

| Dir. | ddam 1 [cm] | Fdam 1 [kN] | dcu 1 [cm] | Fmax 1 [kN] | d*y 1 [cm] | F*y 1 [kN] | K* 1 [kN/cm] |

|---|

| X | 0.61 | 1323.7 | 3.25 | 4096 | 1.5 | 3008 | 2002 |

| Y | 1.75 | 1100.7 | 17.22 | 3058 | 3.49 | 2102 | 602 |

Table 7.

Design stiffness of the Resisto 5.9 Tube system.

Table 7.

Design stiffness of the Resisto 5.9 Tube system.

| Level | H 1 [m] | d0 1 [cm] | Fi 1 [kN] | Ksi 1 [kN/cm] | rk 1 | KRi 1 [kN/cm] |

|---|

| 4 | 12 | 2.13 | 5074 | 2382.2 | 5.18 | 12,349.6 |

| 3 | 9 | 1.84 | 4428 | 2406.5 | 12,475.9 |

| 2 | 6 | 1.30 | 2952 | 2270.8 | 11,772.1 |

| 1 | 3 | 0.59 | 1478 | 2505.1 | 12,986.8 |

Table 8.

Design thickness of diagonal members.

Table 8.

Design thickness of diagonal members.

| Level | nRi | KRi, s [N/mm] | Li [mm] | Ai [mm2] | bi [mm] | ti [mm] |

|---|

| 4 | 93 | 6639.6 | 1291.4 | 50 | 50 | 0.99 |

| 3 | 93 | 6707.5 | 1291.4 | 50 | 50 | 1.00 |

| 2 | 93 | 6329.1 | 1291.4 | 47 | 50 | 0.94 |

| 1 | 53 | 12,251.7 | 1317.9 | 97 | 50 | 1.93 |

Table 9.

Results of the pushover analysis on the retrofitted building.

Table 9.

Results of the pushover analysis on the retrofitted building.

| Dir. | ddam 1 [cm] | Fdam 1 [kN] | dcu 1 [cm] | Fmax 1 [kN] | d*y 1 [cm] | F*y 1 [kN] | K* 1 [kN/cm] |

|---|

| X | 0.67 | 1579.8 | 3.63 | 4852 | 1.64 | 3562 | 2168 |

| Y | 1.82 | 1242.8 | 18.97 | 4100 | 4.52 | 2679 | 593 |

Table 10.

Comparison of the seismic analysis results: percentage variation in the capacity curve’s parameters due to the application of the Resisto 5.9 Tube system.

Table 10.

Comparison of the seismic analysis results: percentage variation in the capacity curve’s parameters due to the application of the Resisto 5.9 Tube system.

| Dir. | ∆d*y 1 | ∆dcu 1 | ∆Fmax 1 | ∆K* 1 |

|---|

| X | +9.3% | +11.7% | +18.5% | +8.3% |

| Y | +29.5% | +10.2% | +27.5% | −1.5% |

Table 11.

Seismic safety index ζE before and after the retrofit intervention.

Table 11.

Seismic safety index ζE before and after the retrofit intervention.

| ζE Existing Building | ζE Retrofitted Building | ζE Increase |

|---|

| 0.26 | 0.42 | +0.16 |

Table 12.

Seismic risk class of the RC building before and after the retrofit intervention: PAM and IS-V parameters.

Table 12.

Seismic risk class of the RC building before and after the retrofit intervention: PAM and IS-V parameters.

| Status | PAM [%] | PAM Class | IS-V [%] | IS-V Class | Assigned Class |

|---|

| Before retrofit | 5.644 | F | 26 | E | F |

| After retrofit | 4.035 | E | 42 | D | E |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).