Surface Evolution and Optimizing Strategy for Polishing Natural Heterogeneous Marble Using Sol-Gel Diamond Pad

Abstract

1. Introduction

2. Experimental Details

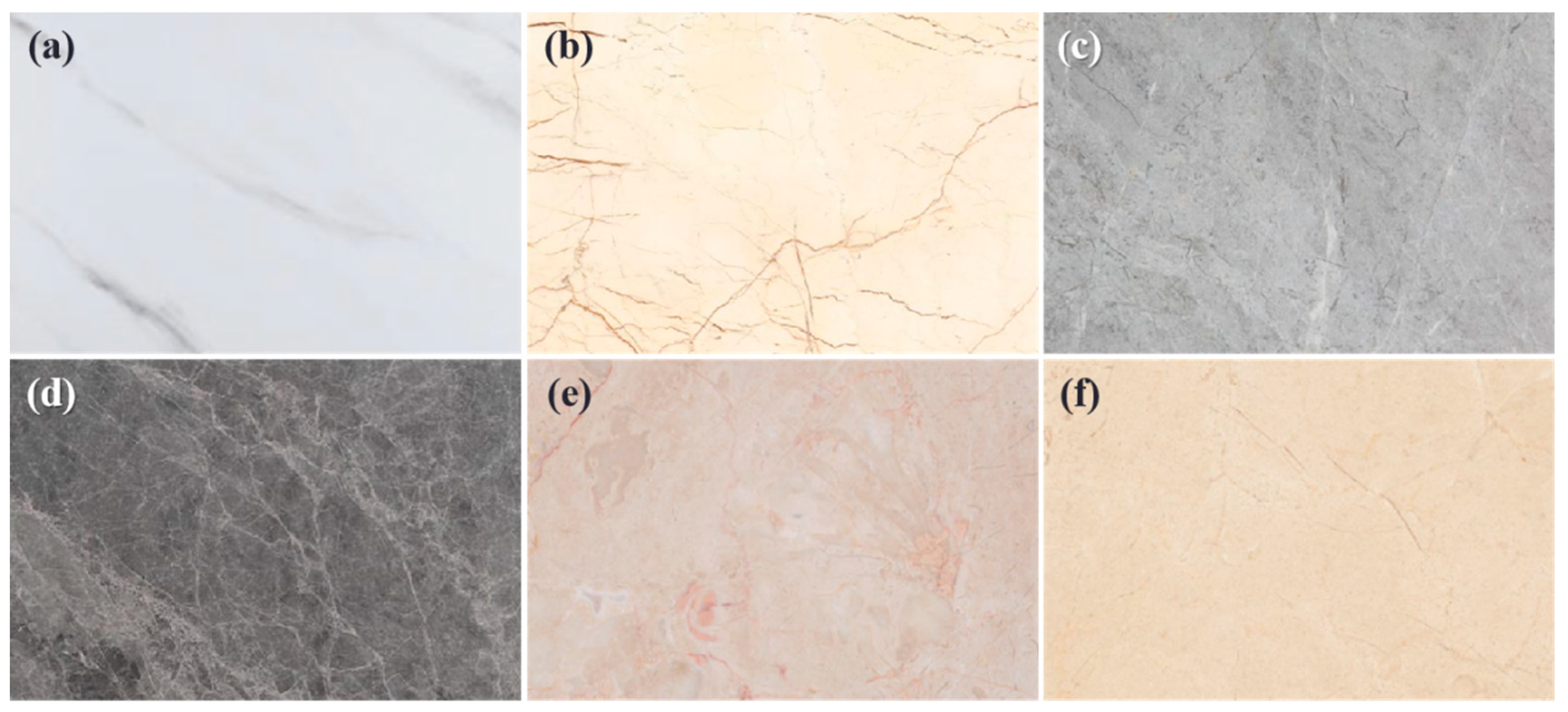

2.1. Materials

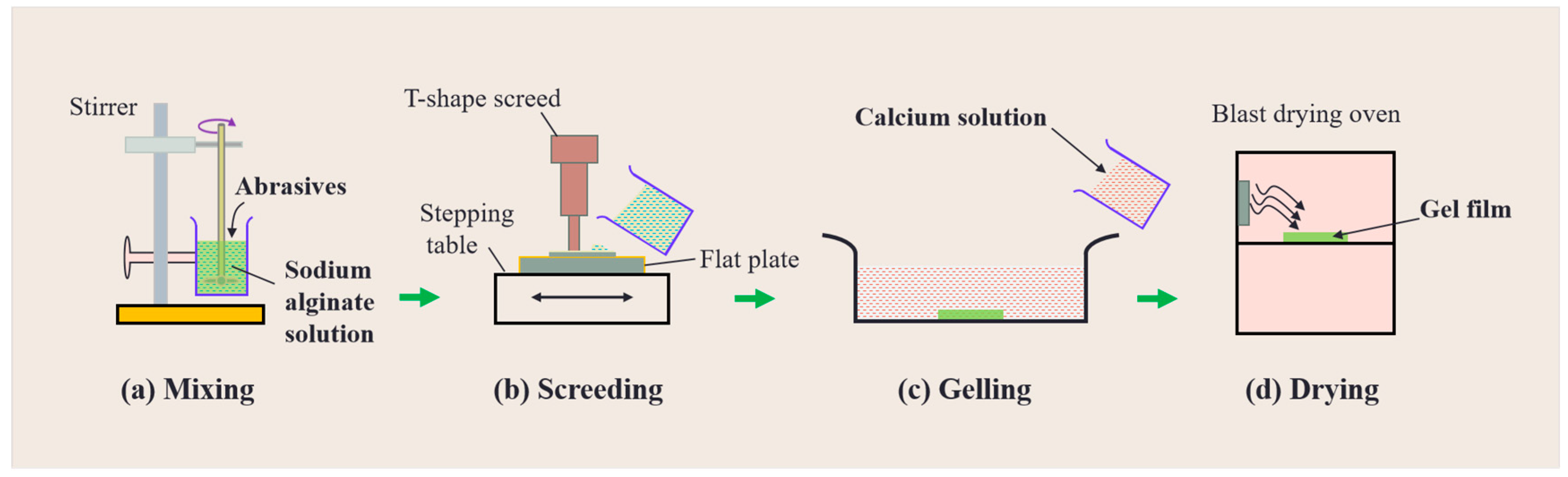

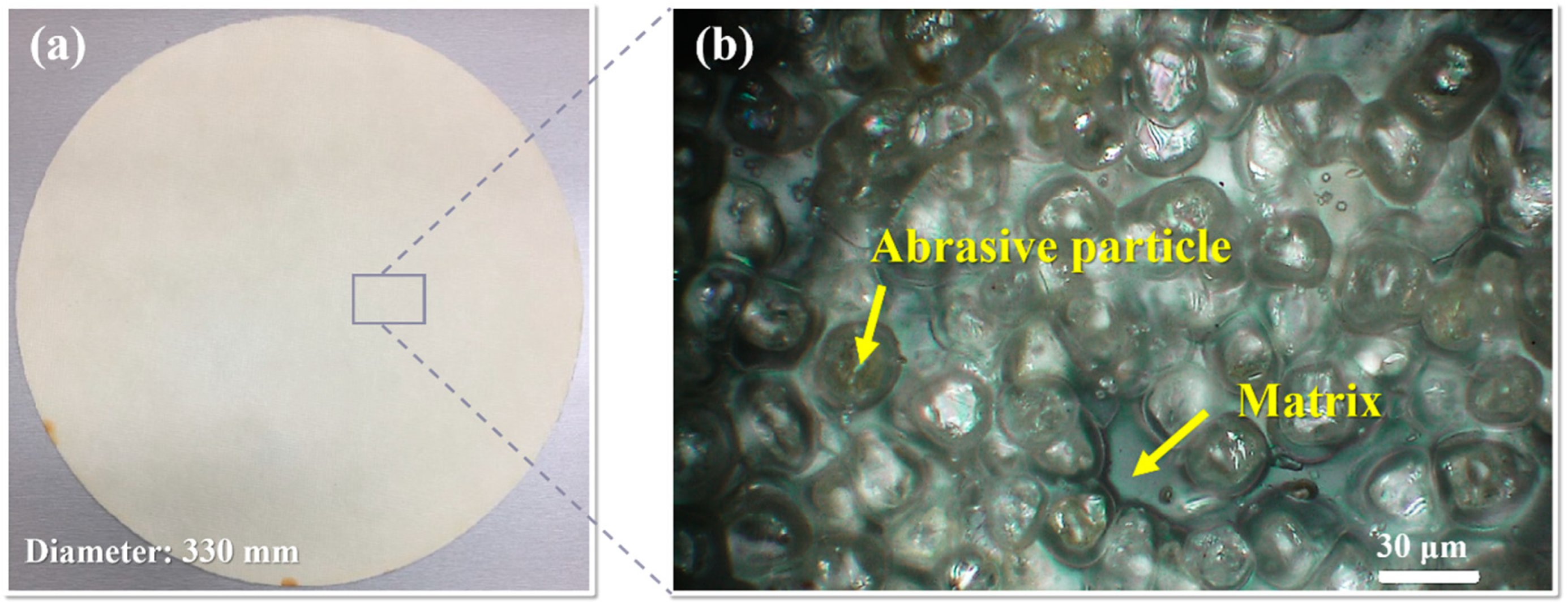

2.2. Fabrication of SG Polishing Pads

2.3. Hardness Measurement

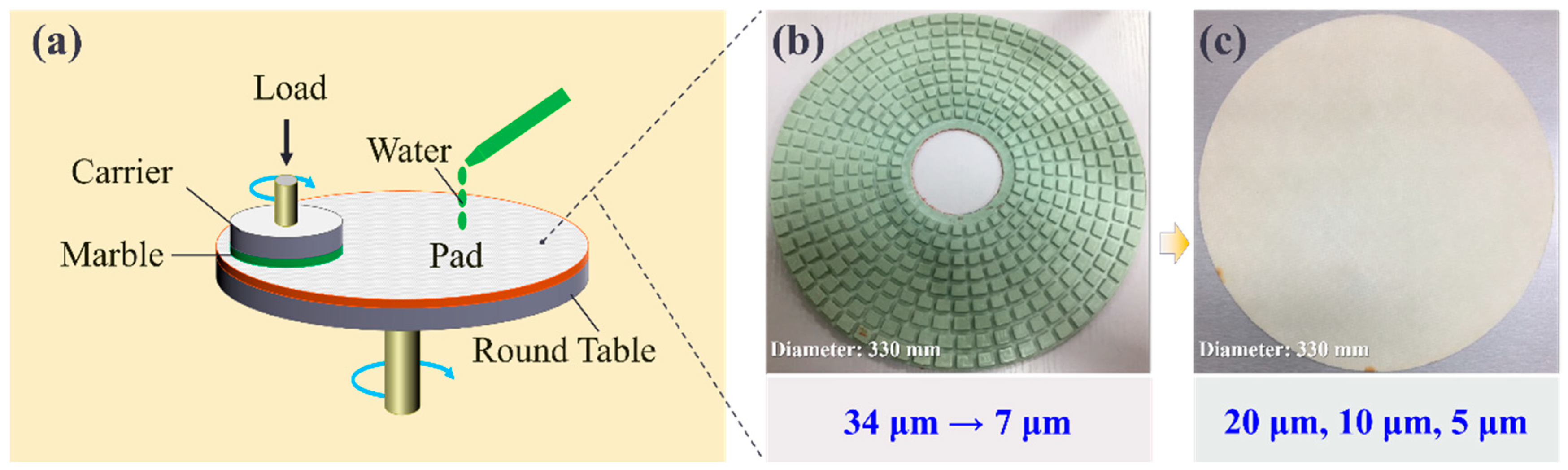

2.4. Polishing Experiment

2.5. Polished Surface Evaluation

3. Results and Discussion

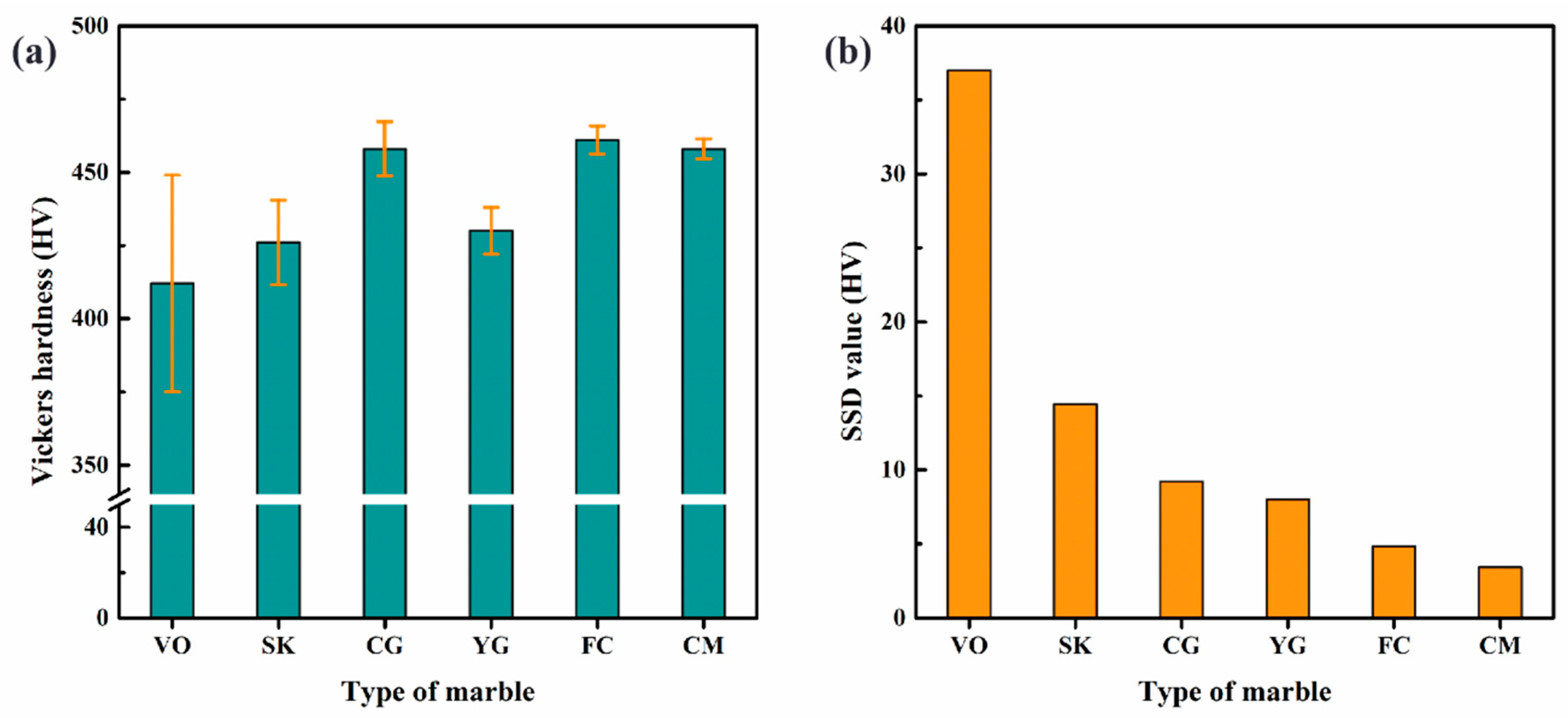

3.1. Hardness of Marbles

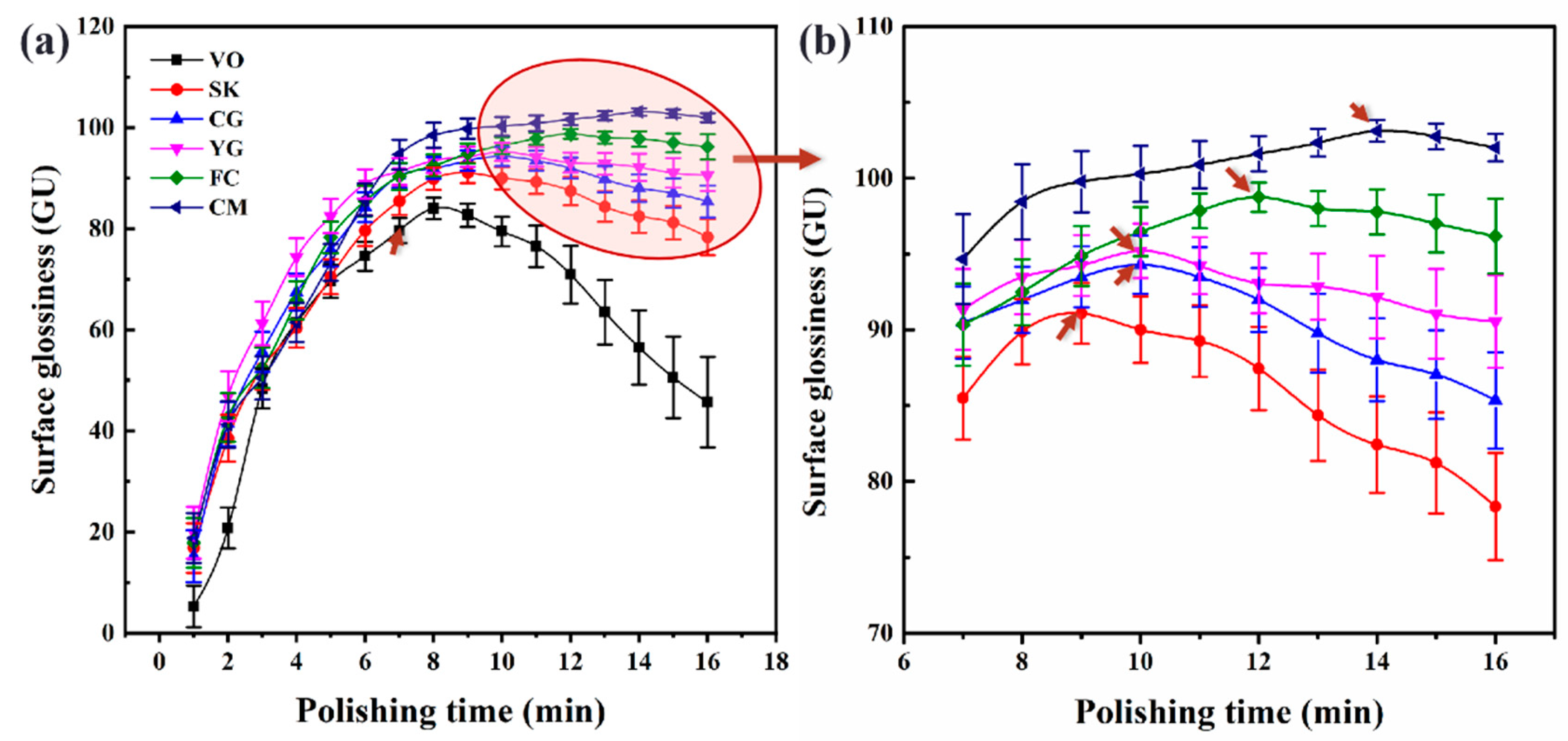

3.2. Influence of Marble Hardness Distribution on Surface Glossiness

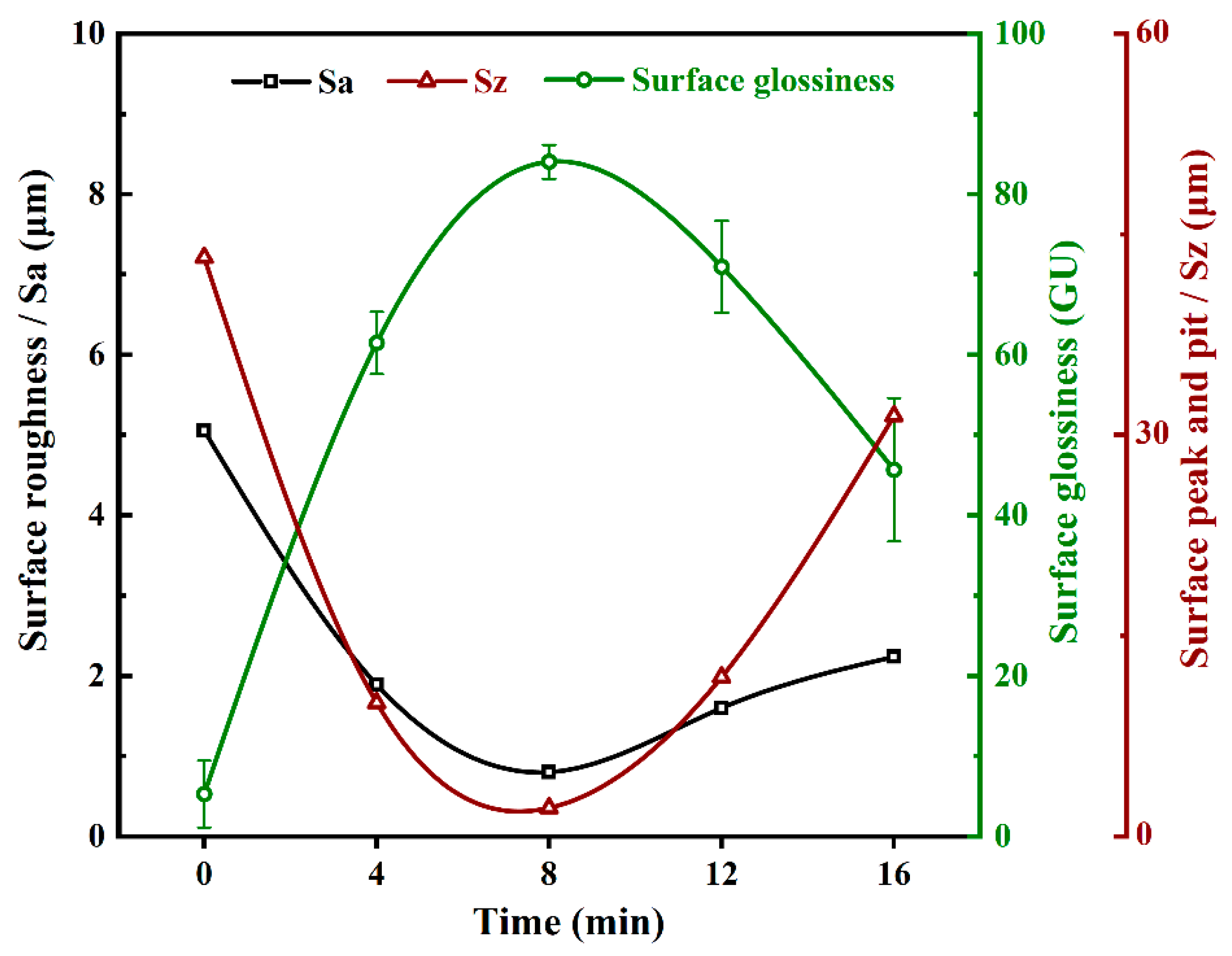

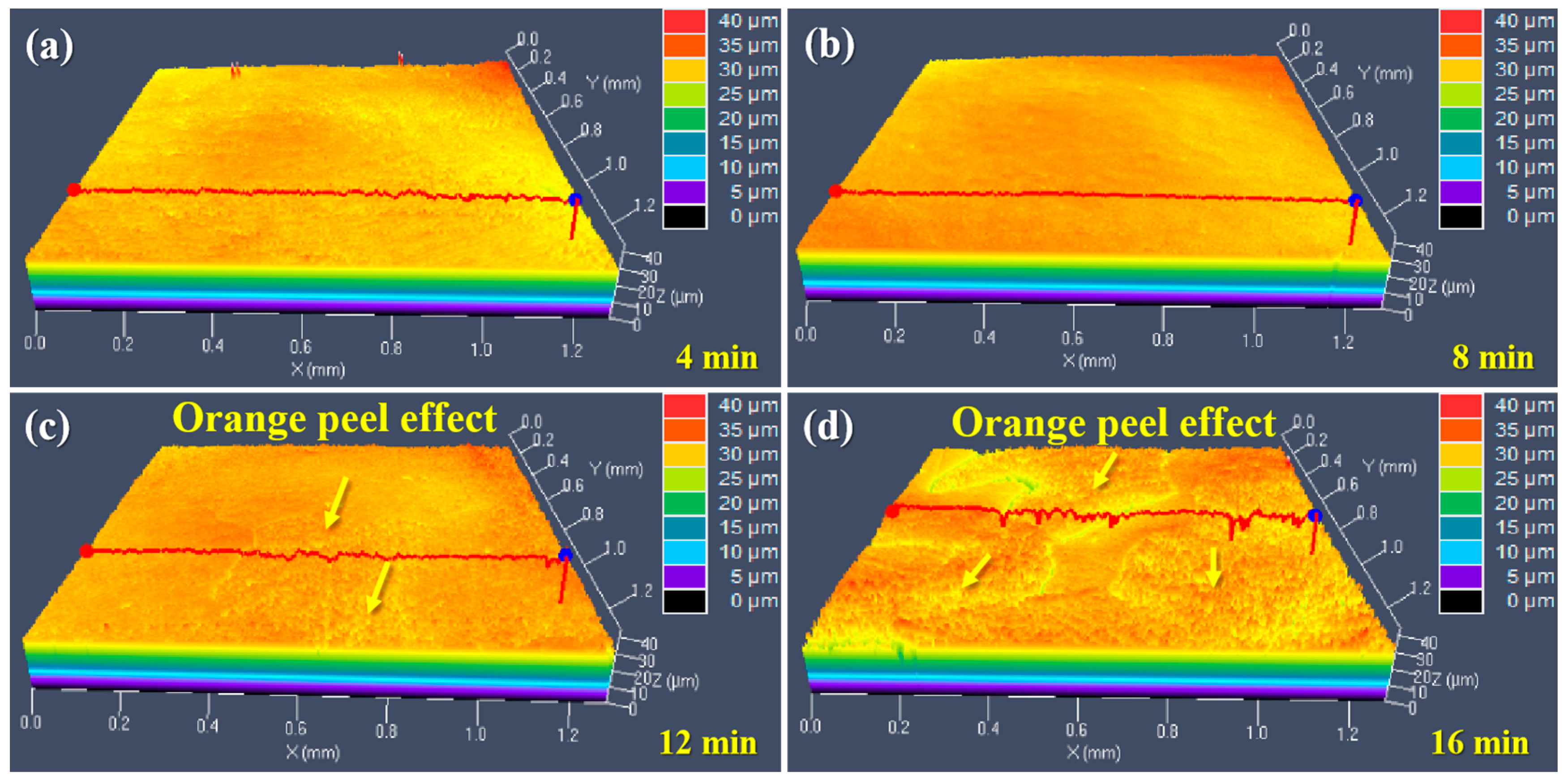

3.3. Surface Evolution Mechanism during Polishing

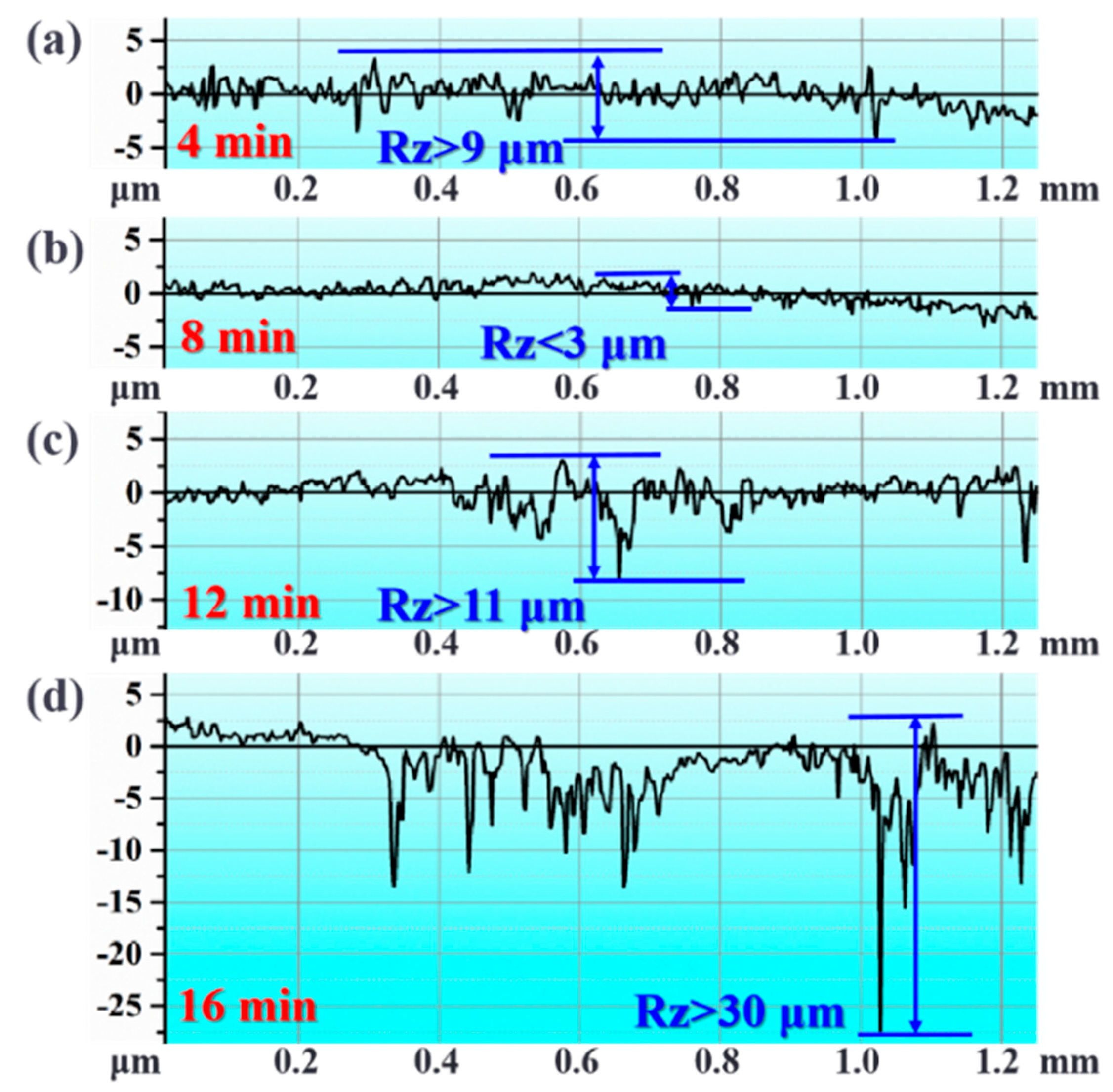

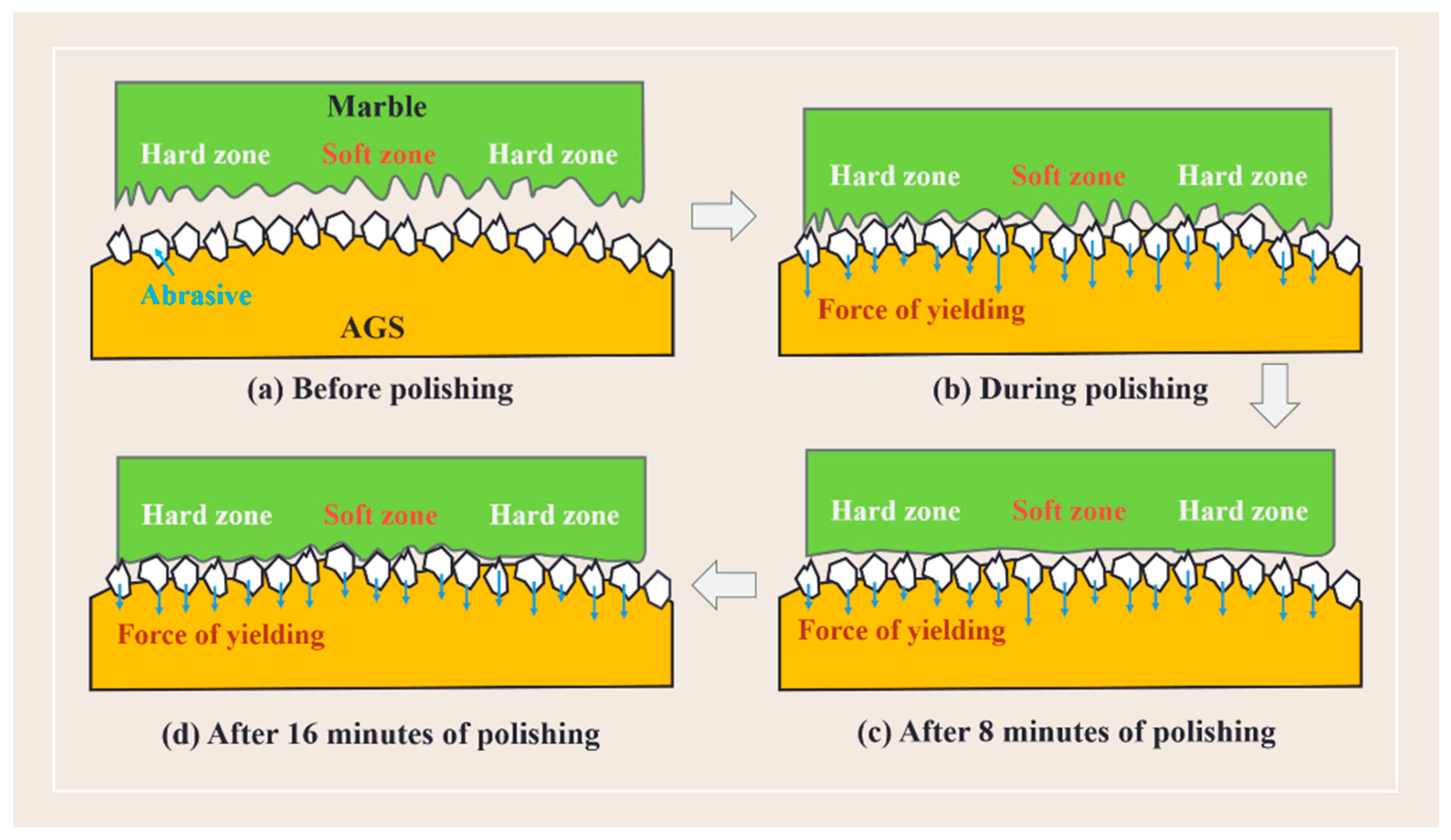

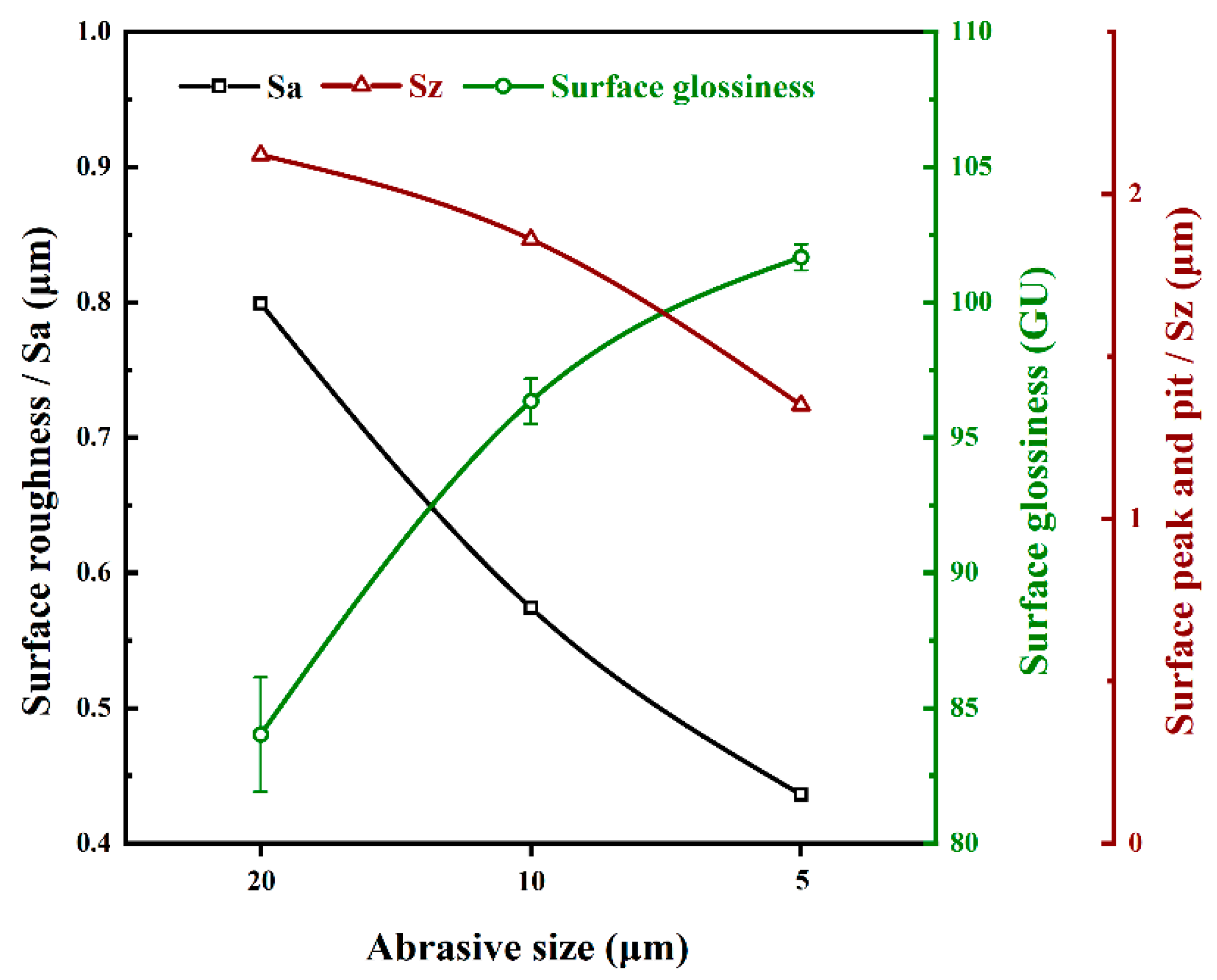

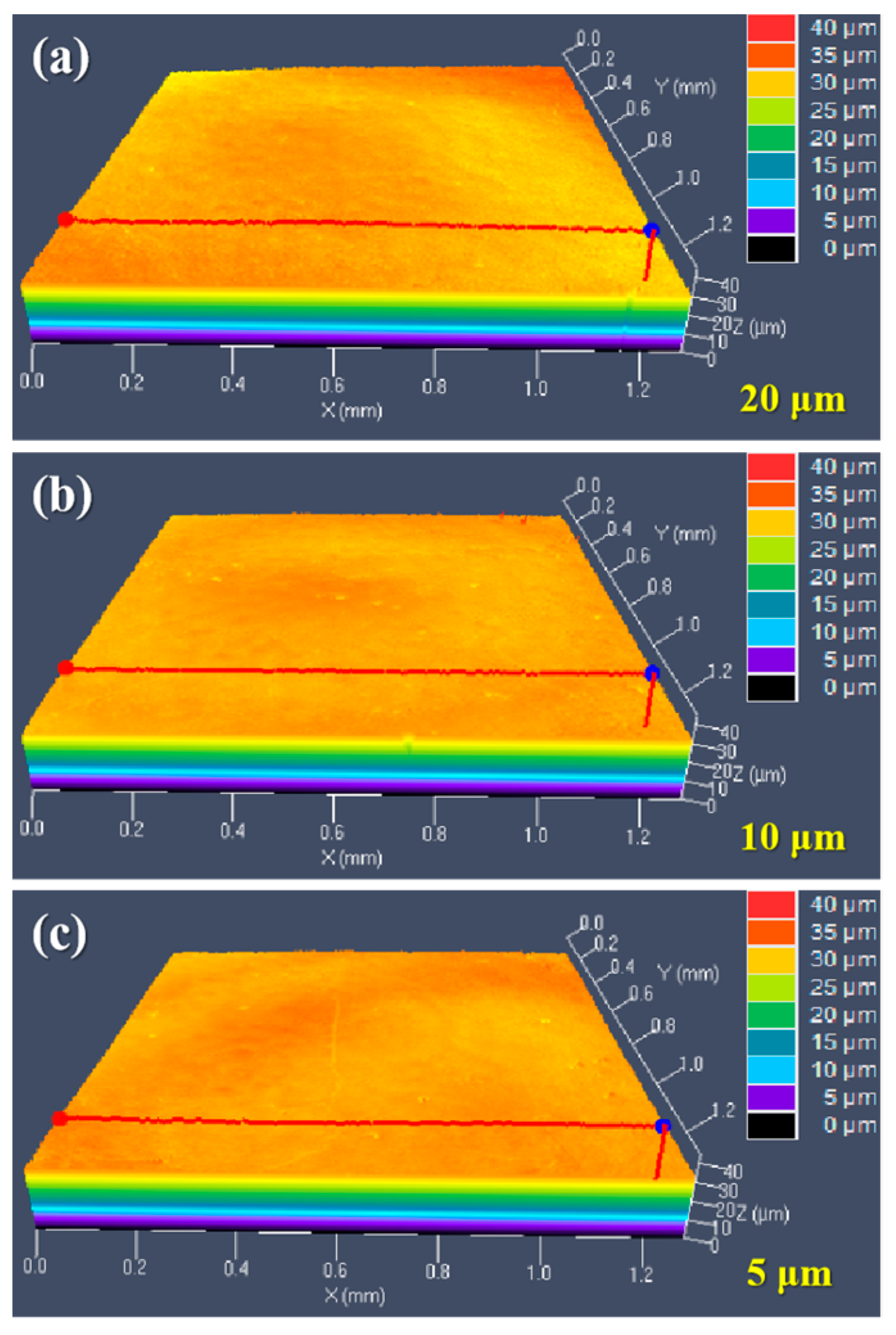

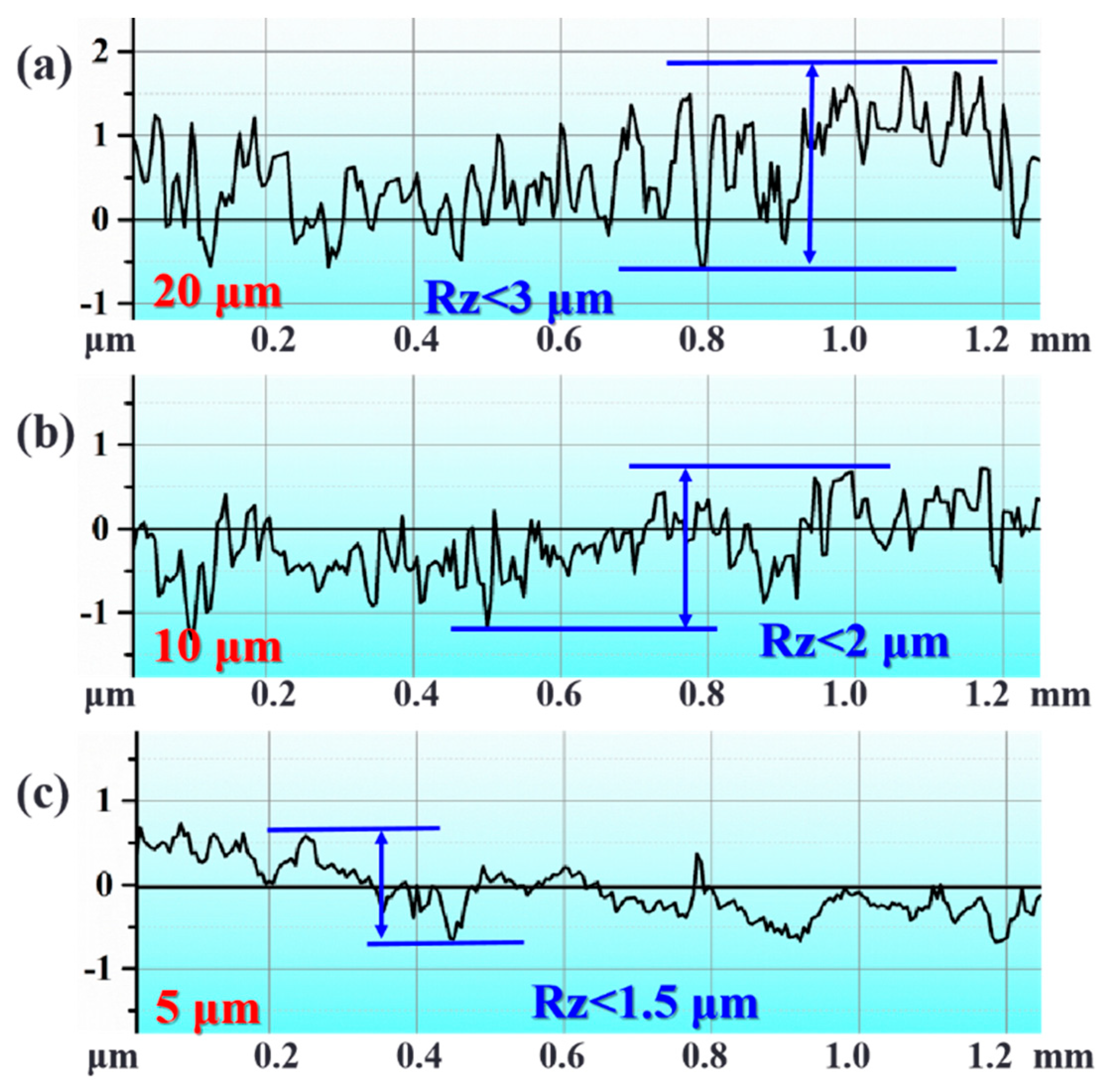

3.4. Optimization of the Polishing Process Based on the Surface Evolution Mechanism

4. Conclusions

- (1)

- The ease of polishing order is VO > SK > CG > YG > FC > CM according to the curve of surface glossiness with time.

- (2)

- The key factor determining the difficulty of polishing is the hardness value deviation rather than the hardness value itself. The larger the SDD of the hardness of the marble, the more difficult it is to obtain a better surface quality.

- (3)

- The essence of the orange peel effect is caused by the inconsistent material removal rates of heterogeneous materials in local areas. The orange peel effect will become more apparent when the polishing is continued after the optimal polishing time.

- (4)

- The optimal polishing time has a good logarithmic relationship with the SDD of the hardness of different kinds of marbles. The established polishing model can be used for other heterogeneous natural marbles and provide theoretical basis guidance for other heterogeneous composite materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohammed, A.A.A.; Fener, M.; Comakli, R.; İnce, İ.; Balci, M.C.; Kayabalı, K. Investigation of the relationships between basic physical and mechanical properties and abrasion wear resistance of several natural building stones used in Turkey. J. Build. Eng. 2021, 42, 103084. [Google Scholar] [CrossRef]

- Martínez-Martínez, J.; Benavente, D.; Pérez-Huerta, A.; Cueto, N.; García-del-Cura, M.A. Changes on the Surface Properties of Foliated Marbles at Different Cutting Orientations. Constr. Build. Mater. 2019, 222, 493–499. [Google Scholar] [CrossRef]

- Kouam, J.; Songmene, V.; Bahloul, A.; Samuel, A.M. Characterization of Si and SiO2 in Dust Emitted during Granite Polishing as a Function of Cutting Conditions. Materials 2022, 15, 3965. [Google Scholar] [CrossRef] [PubMed]

- Bahri, H.; Songmene, V.; Kouam, J.; Samuel, A.M.; Samuel, F.H. CNC Edge Finishing of Granite: Effect of Machining Conditions on Part Quality, Cutting Forces, and Particle Emissions. Materials 2021, 14, 6496. [Google Scholar] [CrossRef] [PubMed]

- Görgülü, K.; Ceylanoǧlu, A. Evaluation of Continuous Grinding Tests on Some Marble and Limestone Units with Silicon Carbide and Diamond Type Abrasives. J. Mater. Process. Technol. 2008, 204, 264–268. [Google Scholar] [CrossRef]

- Cserta, E.; Gyurika, I.G. Effects of the granite-forming minerals on the surface roughness in the milling processes. Int. J. Adv. Manuf. Technol. 2021, 112, 3041–3052. [Google Scholar] [CrossRef]

- Karaca, Z. Relationship between the Mechanical Properties and the Surface Roughness of Marble. Int. J. Mater. Res. 2012, 103, 633–637. [Google Scholar] [CrossRef]

- Cevheroǧlu Çira, S.; Daǧ, A.; Karakuş, A. Application of Response Surface Methodology and Central Composite Inscribed Design for Modeling and Optimization of Marble Surface Quality. Adv. Mater. Sci. Eng. 2016, 2016, 2349476. [Google Scholar] [CrossRef]

- Farhadian, A.; Ghasemi, E.; Hoseinie, S.H.; Bagherpour, R. Development of a new test method for evaluating the abrasivity of granite building stones during polishing process based on weight loss of abrasive tool. Constr. Build. Mater. 2021, 303, 124497. [Google Scholar] [CrossRef]

- Cevheroǧlu Çira, S.; Daǧ, A.; Karakuş, A. Investigation of the Effects of Marble Material Properties on the Surface Quality. Adv. Mater. Sci. Eng. 2018, 2018, 6514785. [Google Scholar] [CrossRef]

- Ribeiro, R.P.; Paraguassú, A.B.; Moreiras, S.T.F. Factors Affecting Slab Surface Roughness of Siliceous Dimension Stones. Bull. Eng. Geol. Environ. 2011, 70, 625–631. [Google Scholar] [CrossRef]

- Sousa, F.J.; Alarcon, O.E.; Weingärtner, W.L.; Fredel, M.C.; Vázquez, M.F.; Vilches, E.S. Evaluation of texture distribution during the industrial polishing process of porcelain stoneware tiles. J. Eur. Ceram. Soc. 2013, 33, 3369–3378. [Google Scholar] [CrossRef]

- Coelho, A.; Pereira, J.C.G.; Amaral, P.M.; Rosa, L.G. Gloss and Modelling Studies of Stone Polishing Using Linear Polishing Machines with Rotating Heads. Appl. Sci. 2022, 12, 7521. [Google Scholar] [CrossRef]

- Huang, S.; Lu, J.; Chen, S.; Huang, H.; Xu, X.; Cui, C. Study on the Surface Quality of Marble Tiles Polished with Sol-Gel Derived Pads. J. Sol-Gel Sci. Technol. 2019, 91, 485–495. [Google Scholar] [CrossRef]

- Luo, Q.; Lu, J.; Xu, X. Study on the processing characteristics of SiC and sapphire substrates polished by semi-fixed and fixed abrasive tools. Tribol. Int. 2016, 104, 191–203. [Google Scholar] [CrossRef]

- Lei, Y.; Feng, M.; Wu, K.; Chen, J.; Ji, J.; Yuan, J. Investigation on the Basic Characteristics of Semi-Fixed Abrasive Grains Polishing Technique for Polishing Sapphire (α-Al2O3). Materials 2022, 15, 3995. [Google Scholar] [CrossRef]

- Lu, J.; Deng, A.; Xiao, P. Preparation and Application of Sol-Gel Polishing Pad for Polishing CVD Single Crystal Diamond at High Speed. IEEE Trans. Semicond. Manuf. 2022, 35, 318–323. [Google Scholar] [CrossRef]

- Wang, W.; Yu, Y.; Hu, Z.; Fang, C.; Lu, J.; Xu, X. Removal Characteristics of Sapphire Lapping using Composite Plates with Consciously Patterned Resinoid-Bonded Semifixed Diamond Grits. Crystals 2020, 10, 293. [Google Scholar] [CrossRef]

- Luo, Q.; Lu, J.; Li, Z.; Wang, J. Fabrication of a sol–gel polishing tool for green manufacturing of the seal stone. J. Sol-Gel Sci. Technol. 2020, 96, 576–588. [Google Scholar] [CrossRef]

- Lin, Y.; Lu, J.; Tong, R.; Luo, Q.; Xu, X. Surface Damage of Single-Crystal Diamond (100) Processed Based on a Sol-Gel Polishing Tool. Diam. Relat. Mater. 2018, 83, 46–53. [Google Scholar] [CrossRef]

- Lu, J.; Xu, Y.; Zhang, Y.; Xu, X. The Effects of SiO2 Coating on Diamond Abrasives in Sol-Gel Tool for SiC Substrate Polishing. Diam. Relat. Mater. 2017, 76, 123–131. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, J.; Xu, X.; Chen, C.C.A.; Lin, Y. Study on High Efficient Sapphire Wafer Processing by Coupling SG-Mechanical Polishing and GLA-CMP. Int. J. Mach. Tools. Manuf. 2018, 130–131, 12–19. [Google Scholar] [CrossRef]

- Amiril, S.A.S.; Sousa, F. The effect of pressure gradient and abrasive tool wear when polishing ceramic tiles. Mater. Today Proc. 2020, 46, 1770–1777. [Google Scholar] [CrossRef]

- Jin, M.; Wang, L.; Ye, S.; Qi, H.; Kang, J.; Hong, T.; Fang, Z.; Dong, X. A Novel Functionally Graded Lapping and Polishing Method for the Improvement of Material Removal Uniformity. J. Manuf. Process. 2020, 50, 102–110. [Google Scholar] [CrossRef]

- Ulusay, R. The ISRM Suggested Methods for Rock Characterization. In Testing and Monitoring, 2007–2014; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Pan, G.; Gong, H.; Gu, Z.; Zou, C.; Chen, G. Investigation on defect control for final chemical mechanical polishing of aluminum alloy. Proc. Inst. Mech. Eng. Part J-J. Eng. Tribol. 2014, 228, 1151–1158. [Google Scholar] [CrossRef]

- Trum, C.J.; Sitzberger, S.; Rascher, R. Improved performance of chemo-mechanical polishing CMP processes through targeted adjustment of polishing slurry and polishing pad. In Proceedings of the Optical Manufacturing and Testing XII, San Diego, CA, USA, 19–23 August 2018; p. 107420. [Google Scholar] [CrossRef]

| Type of Marble | Density (g/cm3) | Water Absorption (%) | Tensile Strength (MPa) | Uniaxial Compressive Strength (MPa) |

|---|---|---|---|---|

| Volakos (VO) | 2.76 | 0.28 | 18.1 | 140.0 |

| Sofitel King (SK) | 2.71 | 0.13 | 7.5 | 121.2 |

| Castle Gray (CG) | 2.66 | 0.15 | 14.0 | 168.6 |

| Yinding Gray (YG) | 2.65 | 0.22 | 11.4 | 72.7 |

| Focus Cream (FC) | 2.68 | 0.11 | 14.8 | 166.0 |

| Crema Marfil (CM) | 2.72 | 0.45 | 12.7 | 125.6 |

| Abrasive Size | Optimum Polishing Time (min) | |||||

|---|---|---|---|---|---|---|

| VO | SK | CG | YG | FC | CM | |

| 20 μm | 8 | 9 | 10 | 10 | 12 | 14 |

| 10 μm | 7 | 8 | 9 | 9 | 11 | 12 |

| 5 μm | 5 | 6 | 8 | 8 | 10 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Lu, J.; Xu, X.; Cui, C. Surface Evolution and Optimizing Strategy for Polishing Natural Heterogeneous Marble Using Sol-Gel Diamond Pad. Appl. Sci. 2024, 14, 8314. https://doi.org/10.3390/app14188314

Huang S, Lu J, Xu X, Cui C. Surface Evolution and Optimizing Strategy for Polishing Natural Heterogeneous Marble Using Sol-Gel Diamond Pad. Applied Sciences. 2024; 14(18):8314. https://doi.org/10.3390/app14188314

Chicago/Turabian StyleHuang, Shengui, Jing Lu, Xipeng Xu, and Changcai Cui. 2024. "Surface Evolution and Optimizing Strategy for Polishing Natural Heterogeneous Marble Using Sol-Gel Diamond Pad" Applied Sciences 14, no. 18: 8314. https://doi.org/10.3390/app14188314

APA StyleHuang, S., Lu, J., Xu, X., & Cui, C. (2024). Surface Evolution and Optimizing Strategy for Polishing Natural Heterogeneous Marble Using Sol-Gel Diamond Pad. Applied Sciences, 14(18), 8314. https://doi.org/10.3390/app14188314