Experimental Analysis and Design of 3D-Printed Polymer Elliptical Tubes in Compression

Abstract

Featured Application

Abstract

1. Introduction

2. Material Testing

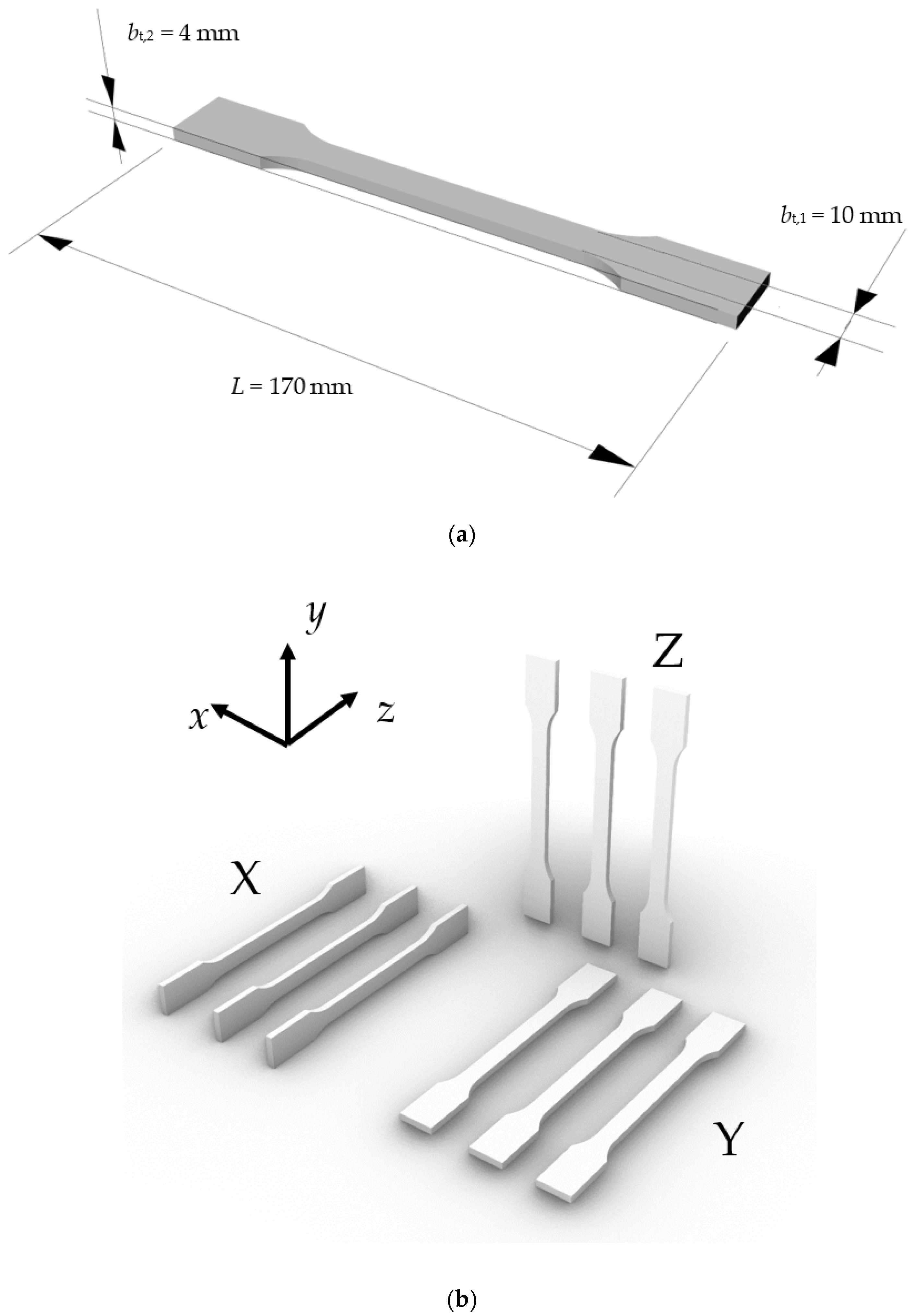

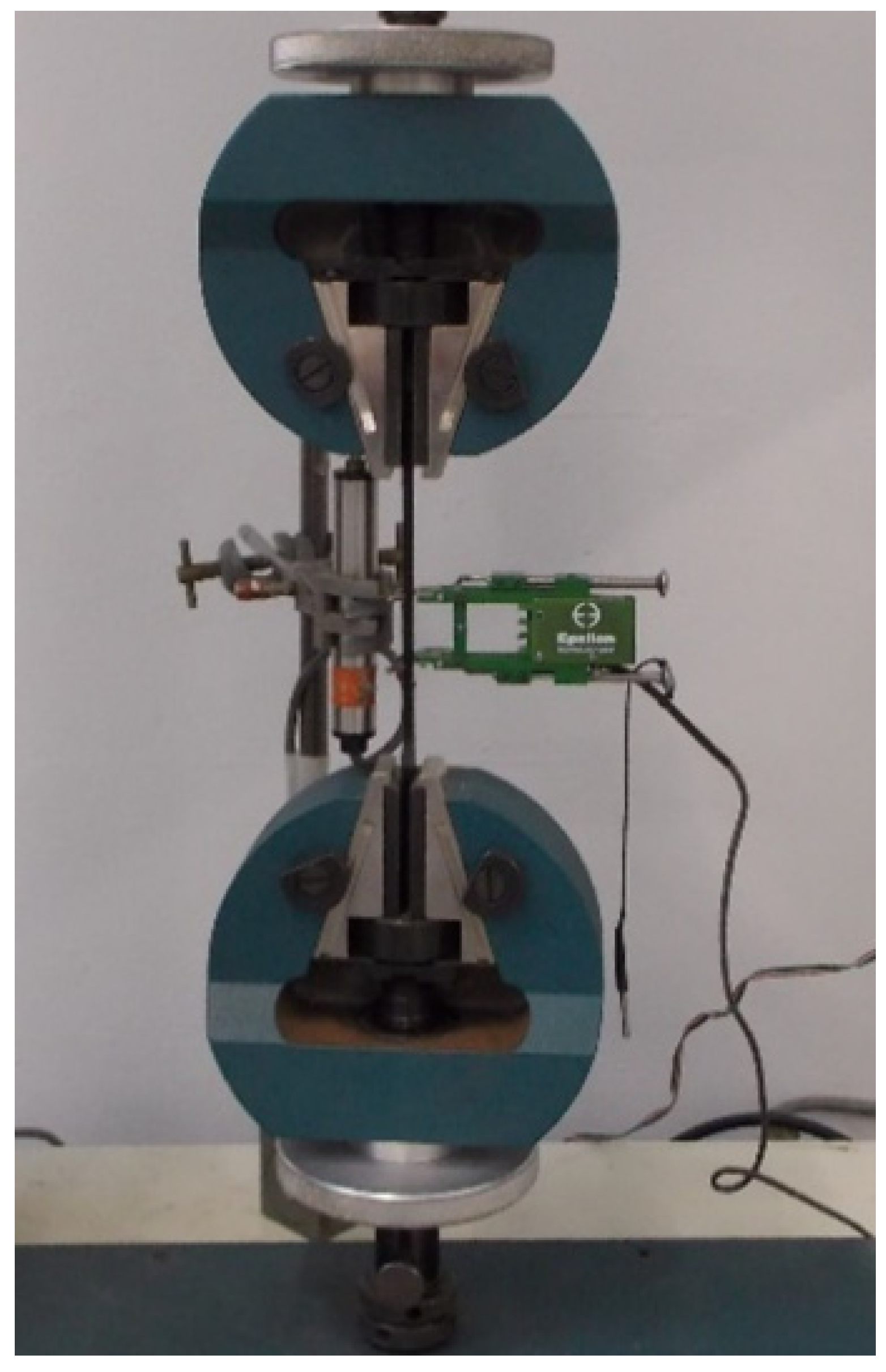

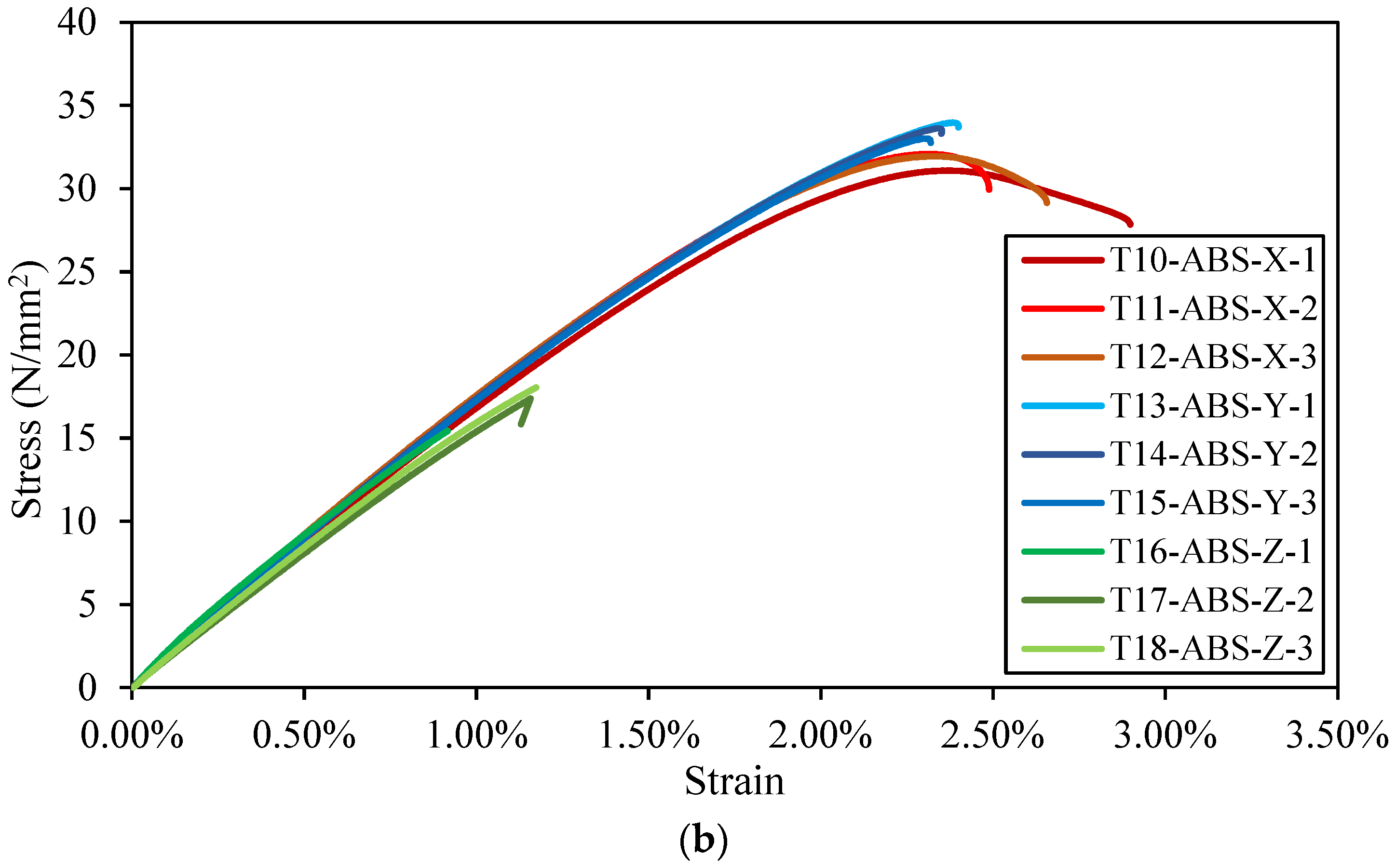

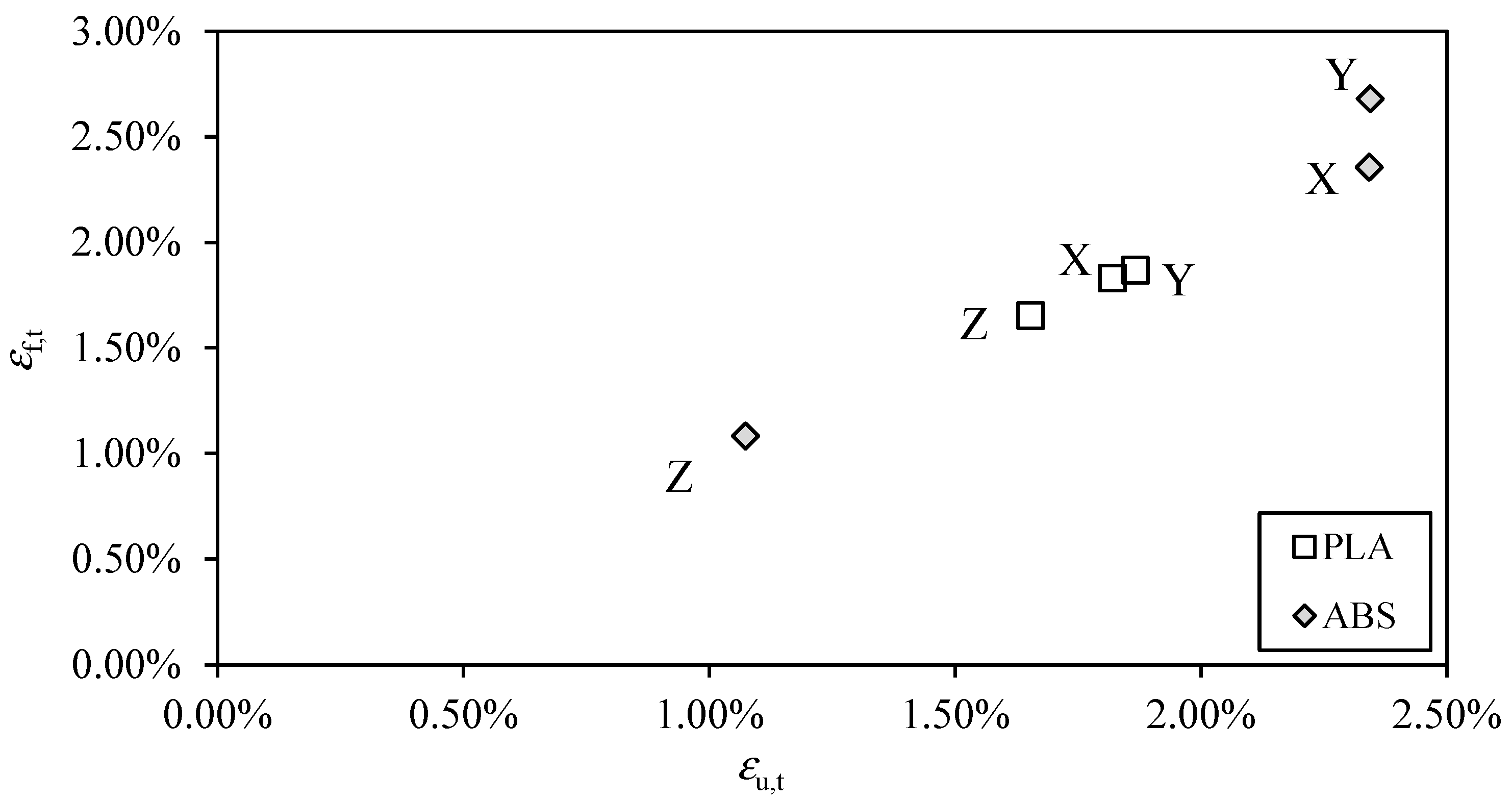

2.1. Tensile Testing

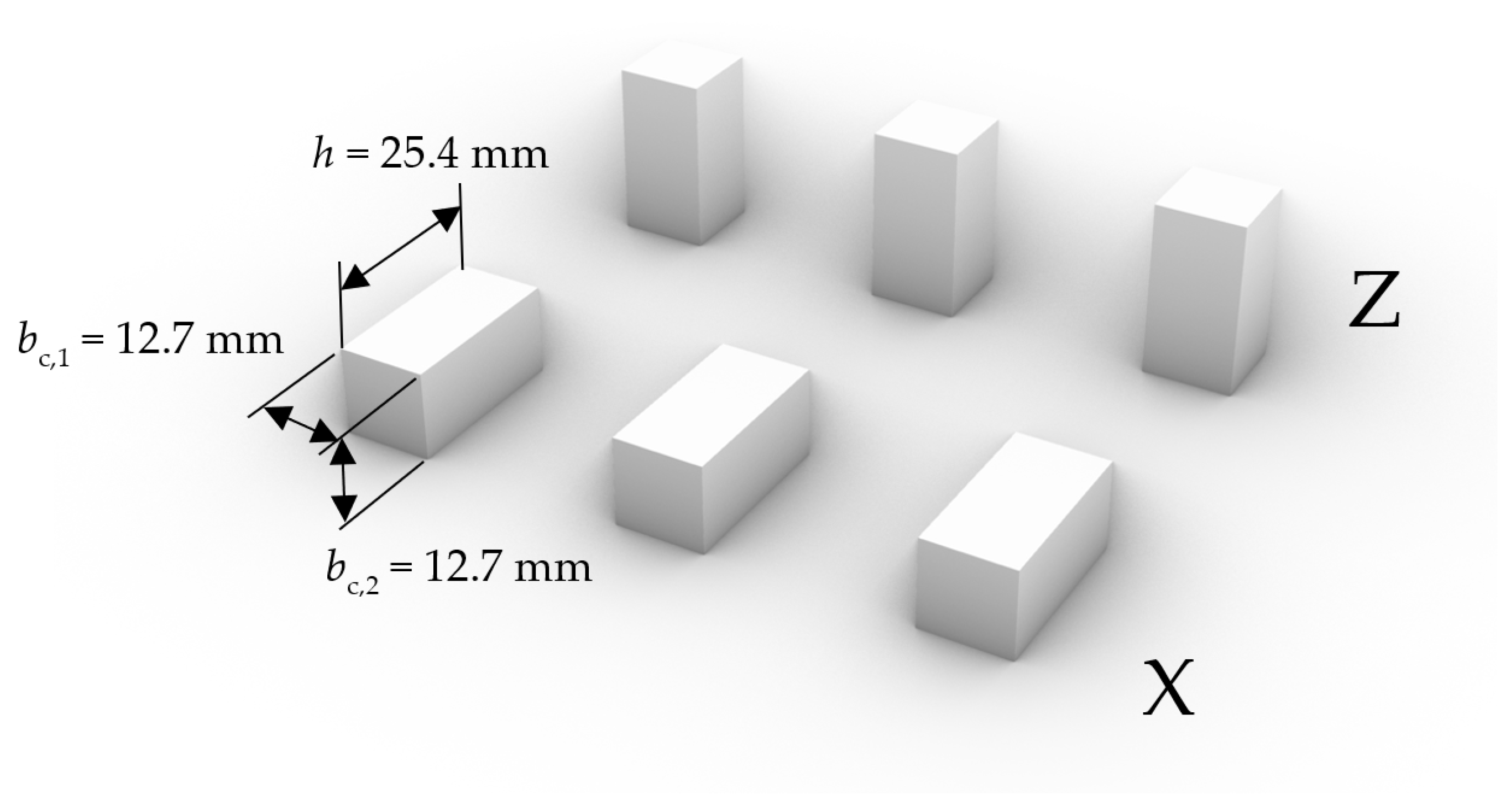

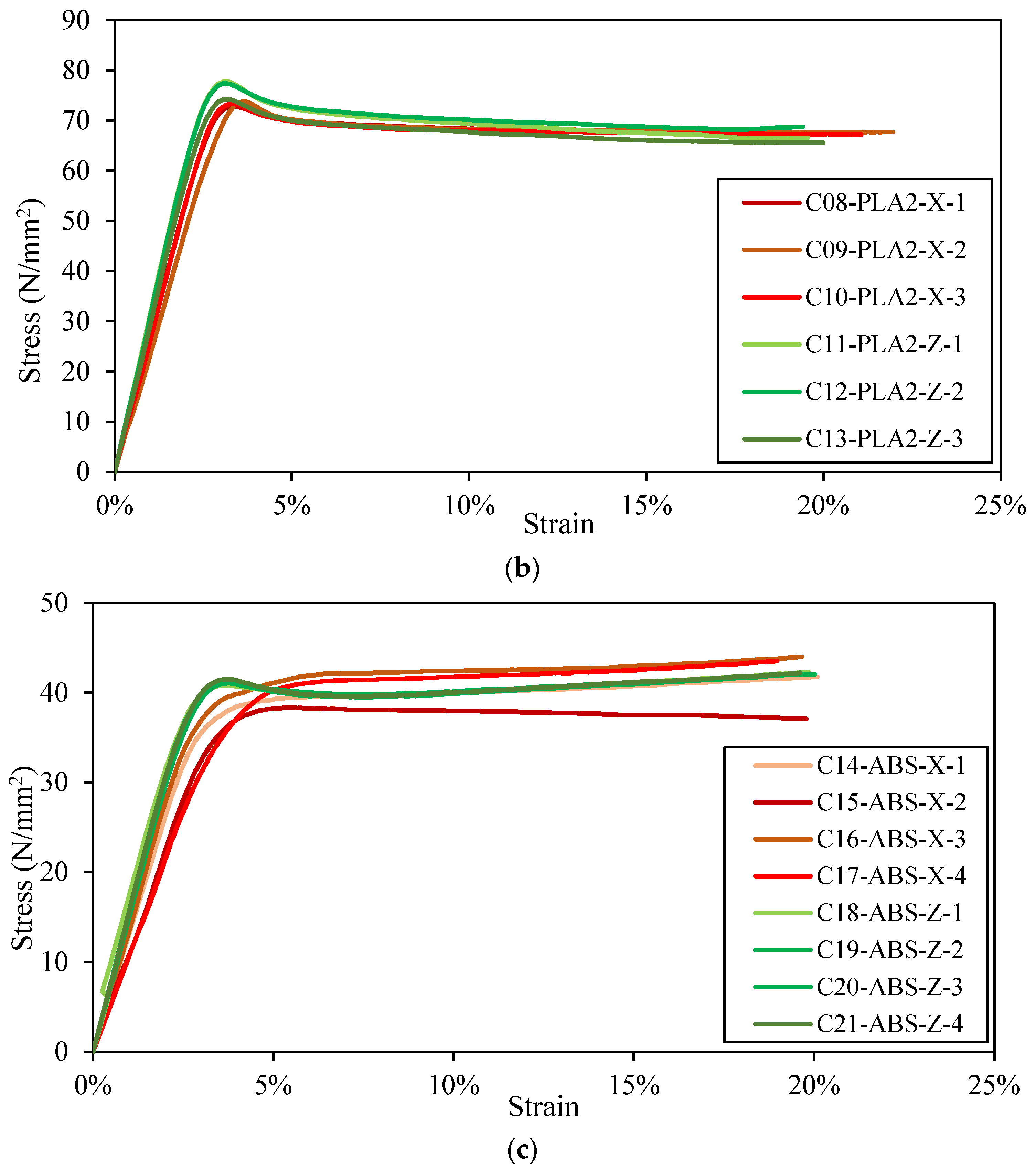

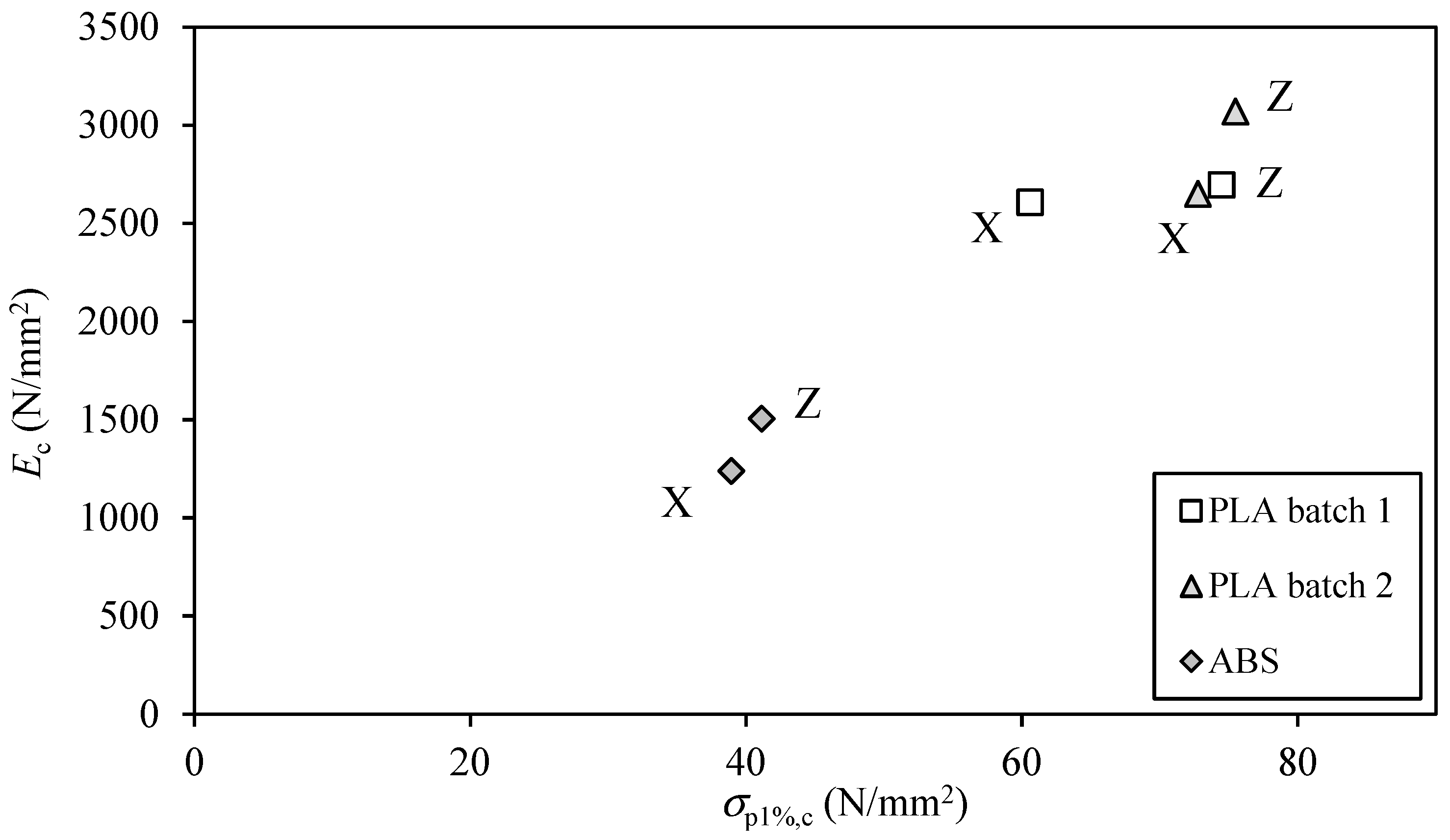

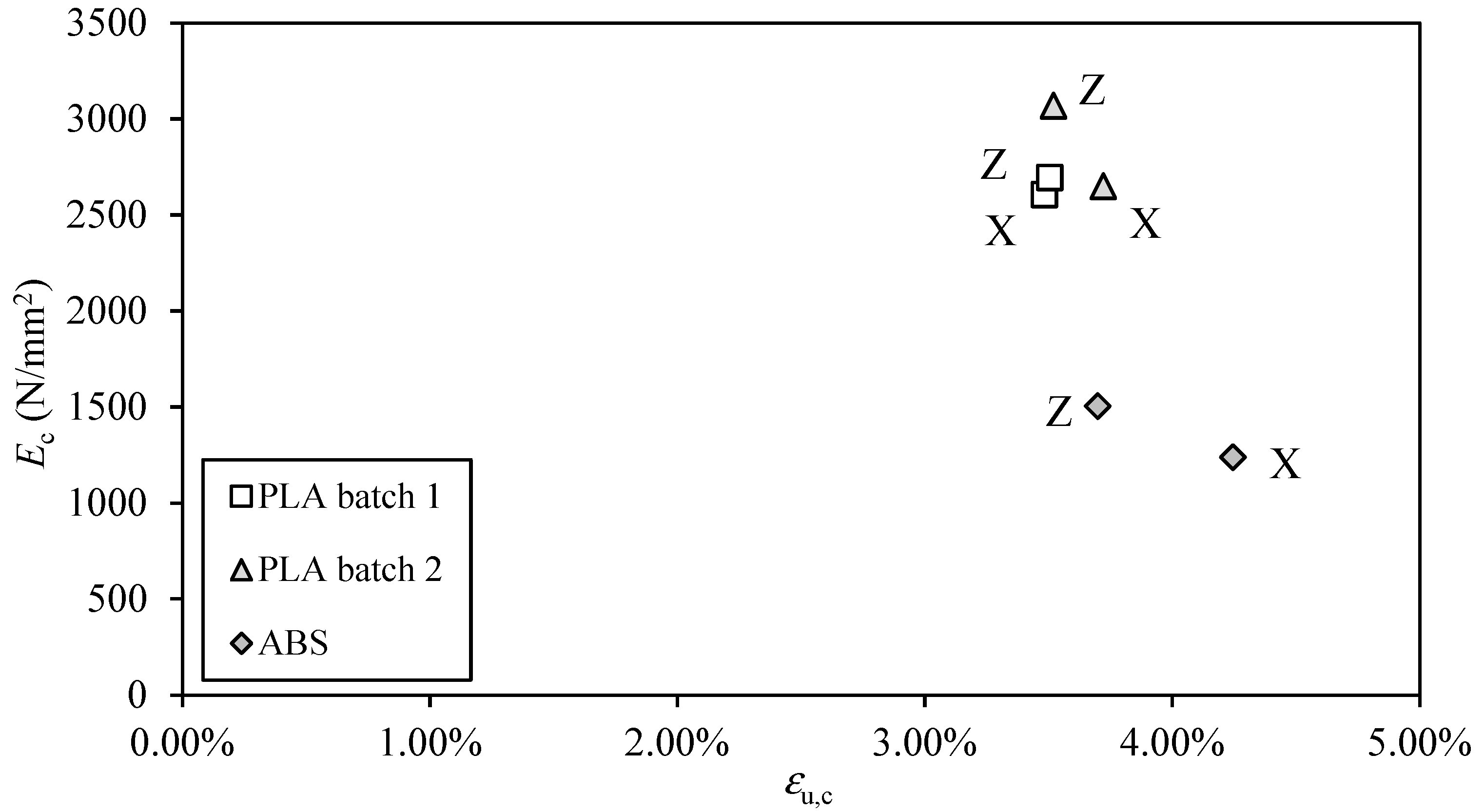

2.2. Compression Testing

2.3. Poisson’s Ratio in Compression

3. Full-Scale Testing

3.1. Elliptical Tube Geometry

3.2. Fabrication and Precision

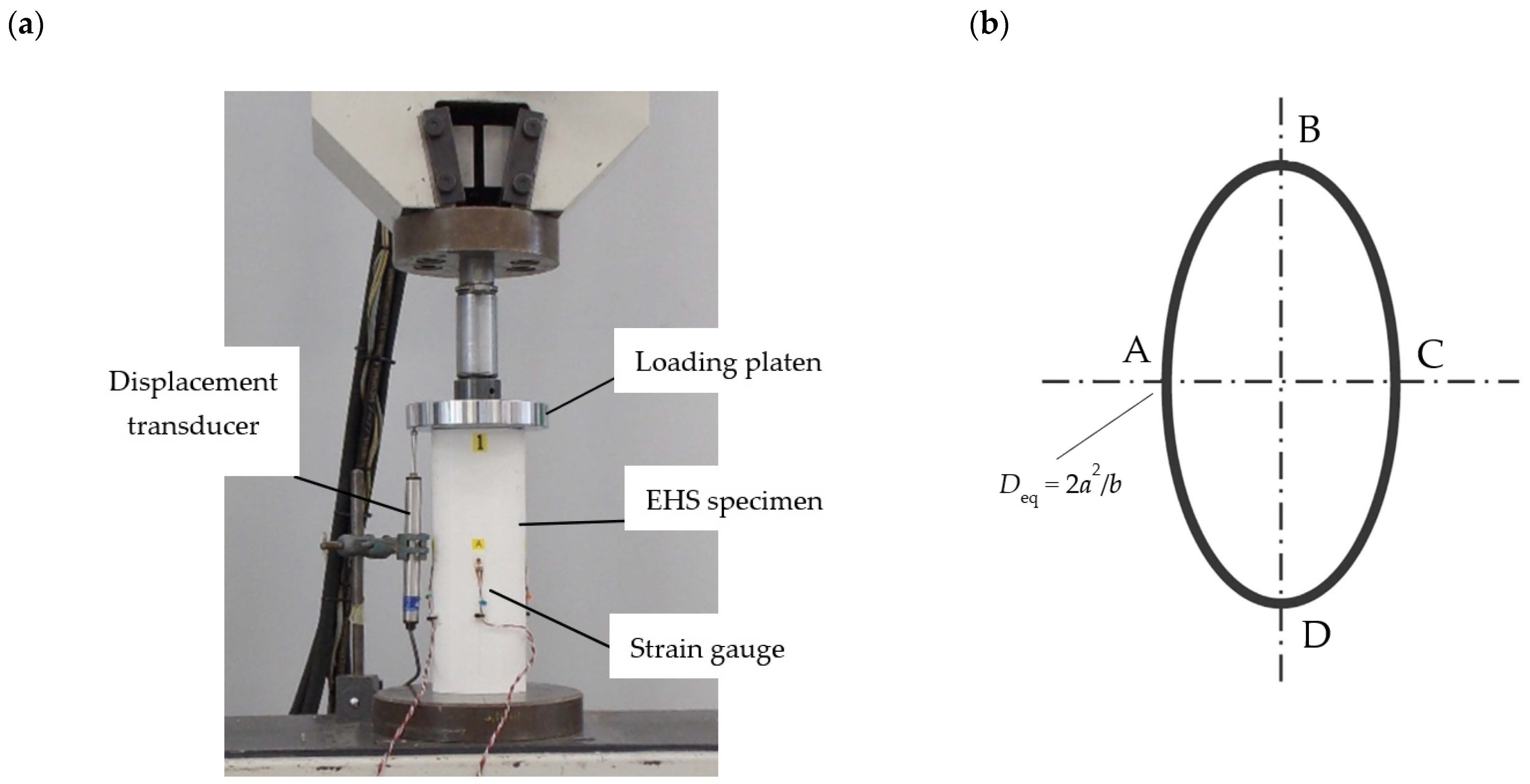

3.3. Test Methodology

3.4. Results

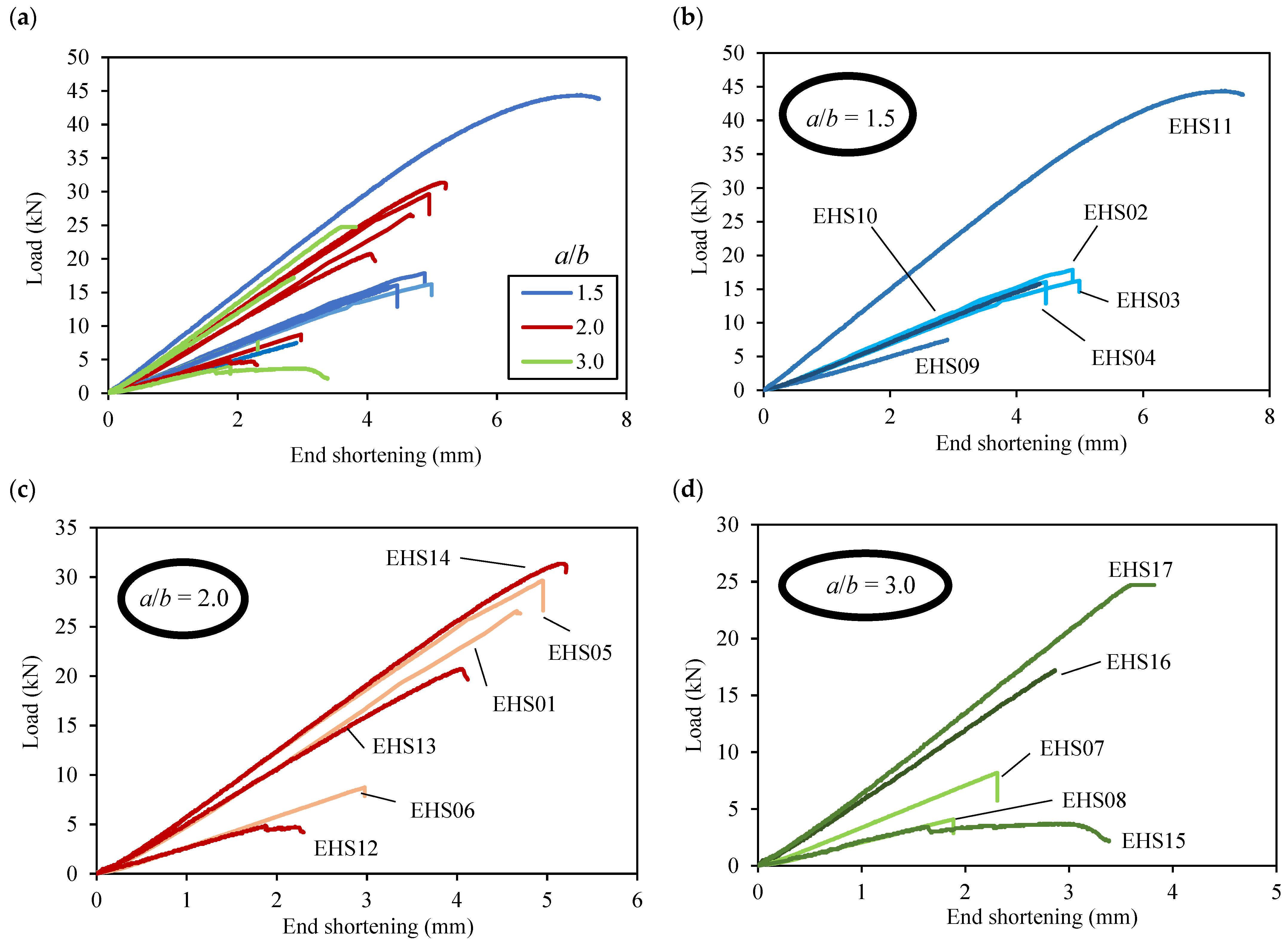

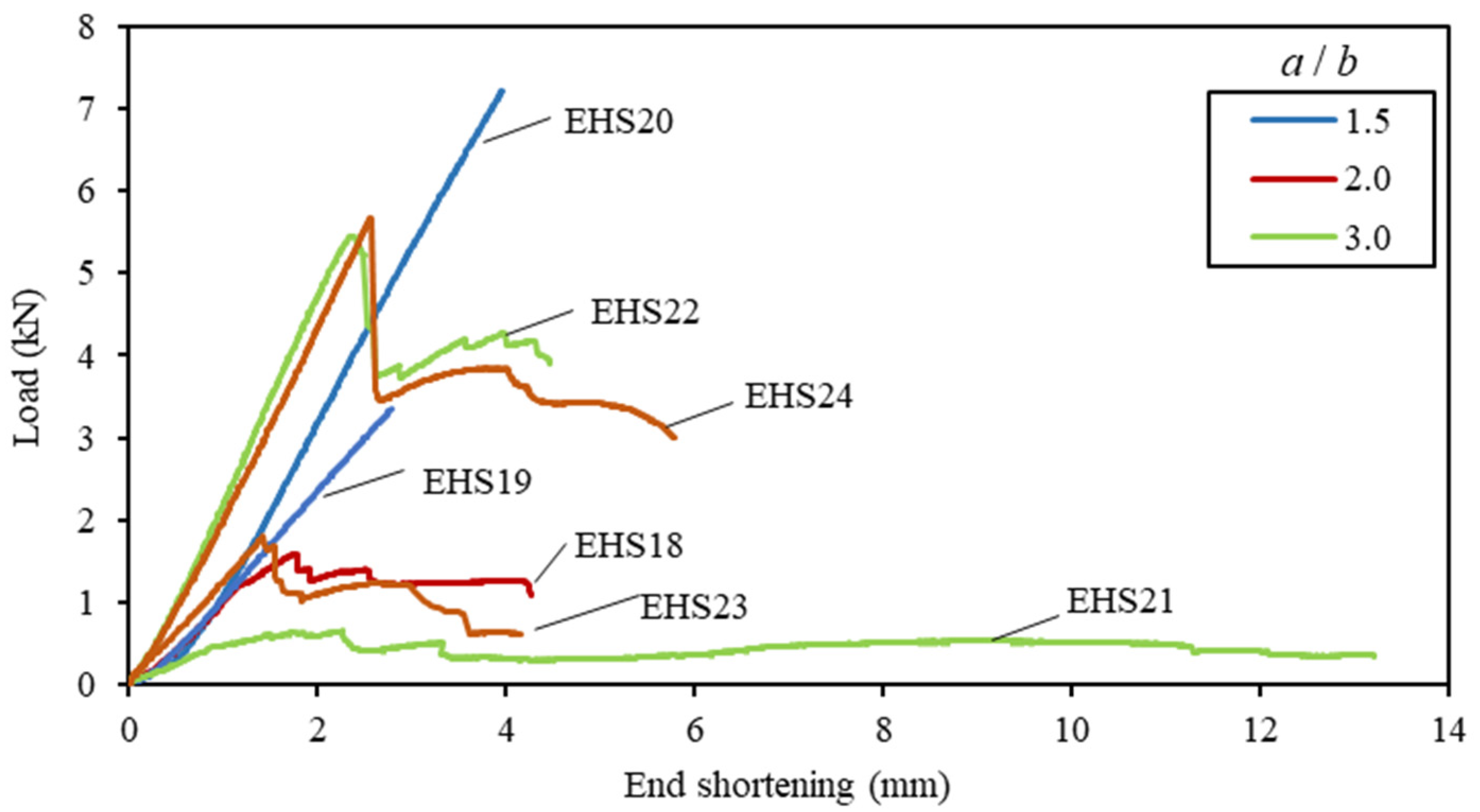

3.4.1. Load–End Shortening Relationships

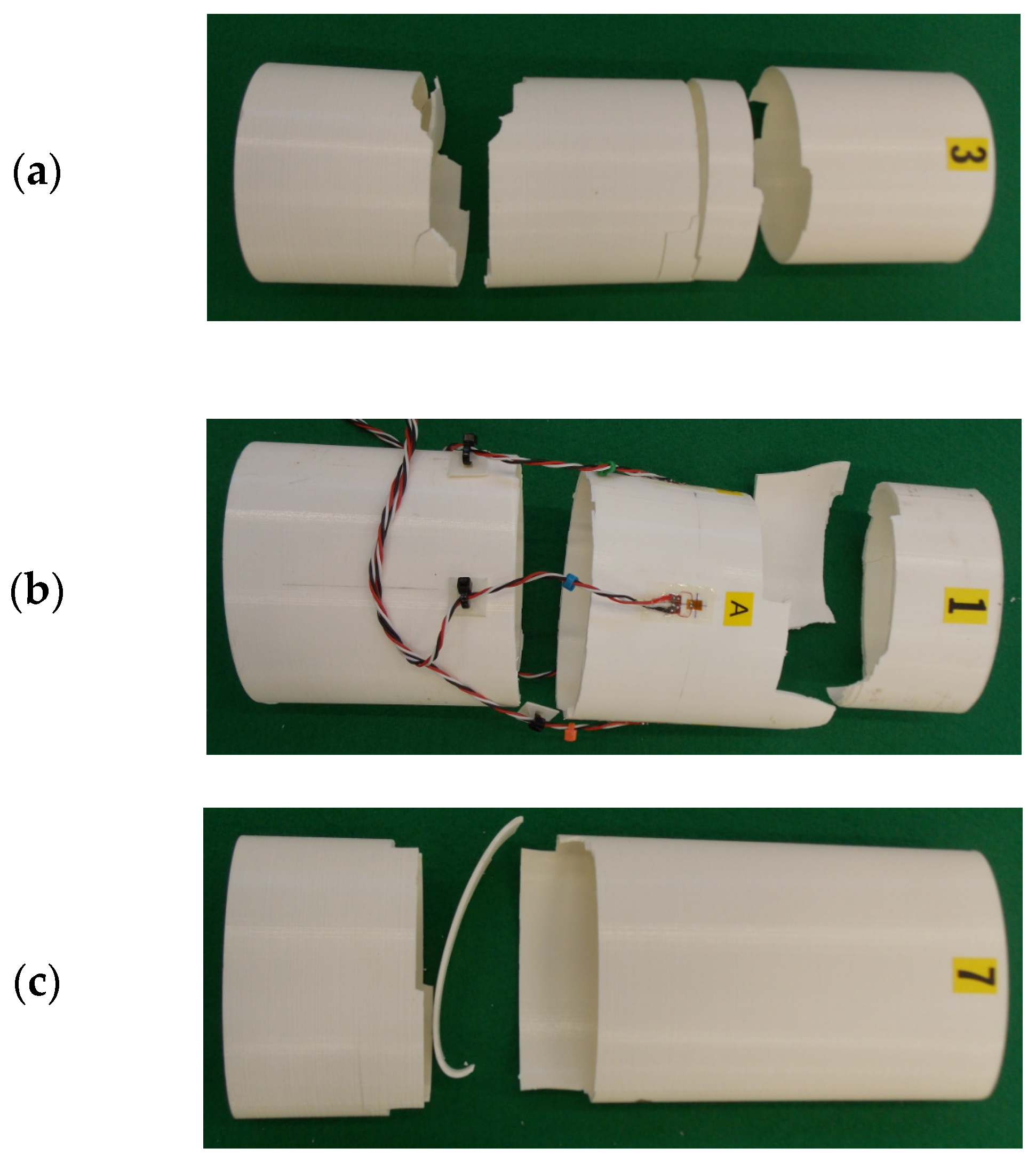

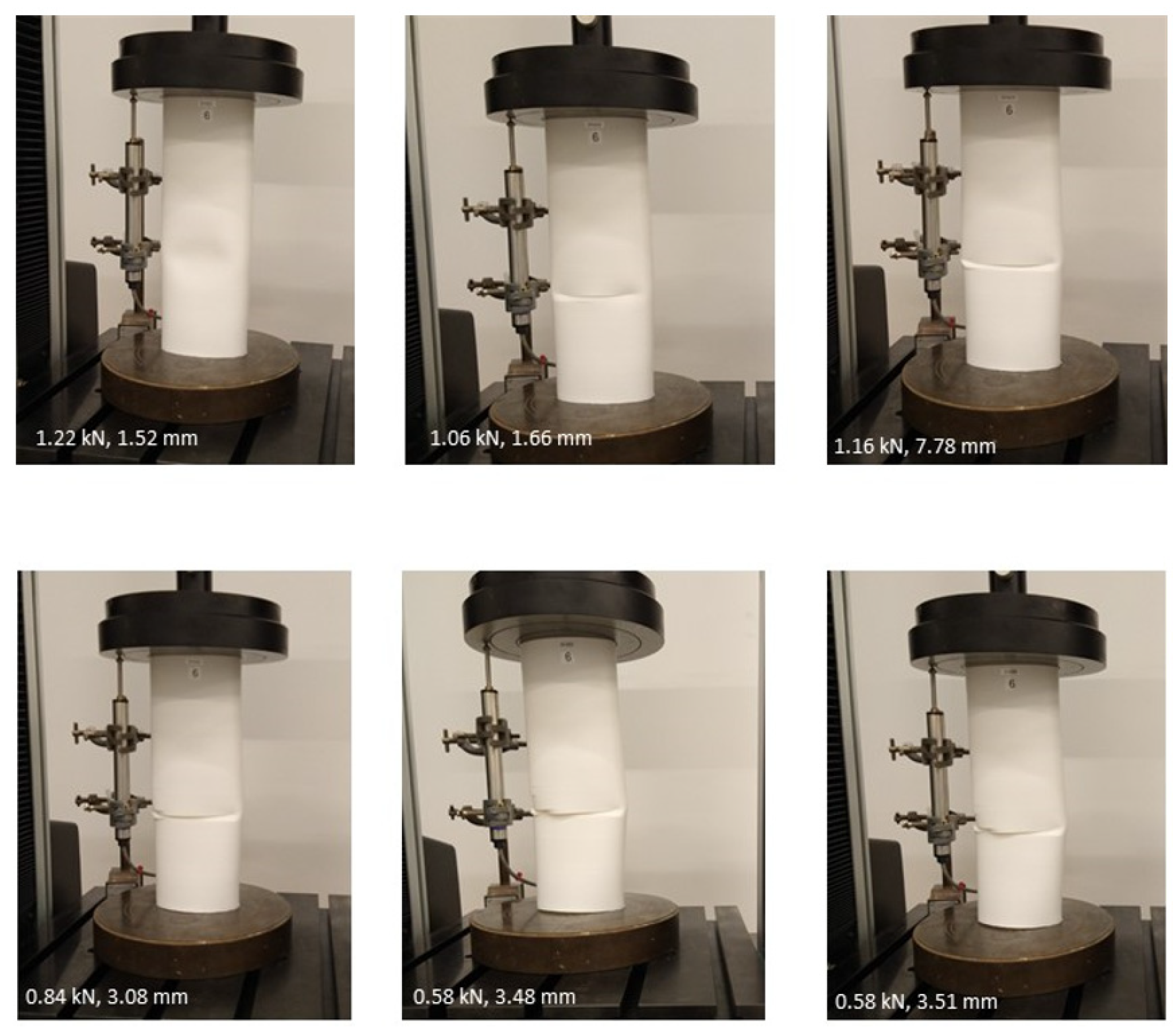

3.4.2. Failure and Deformation Modes

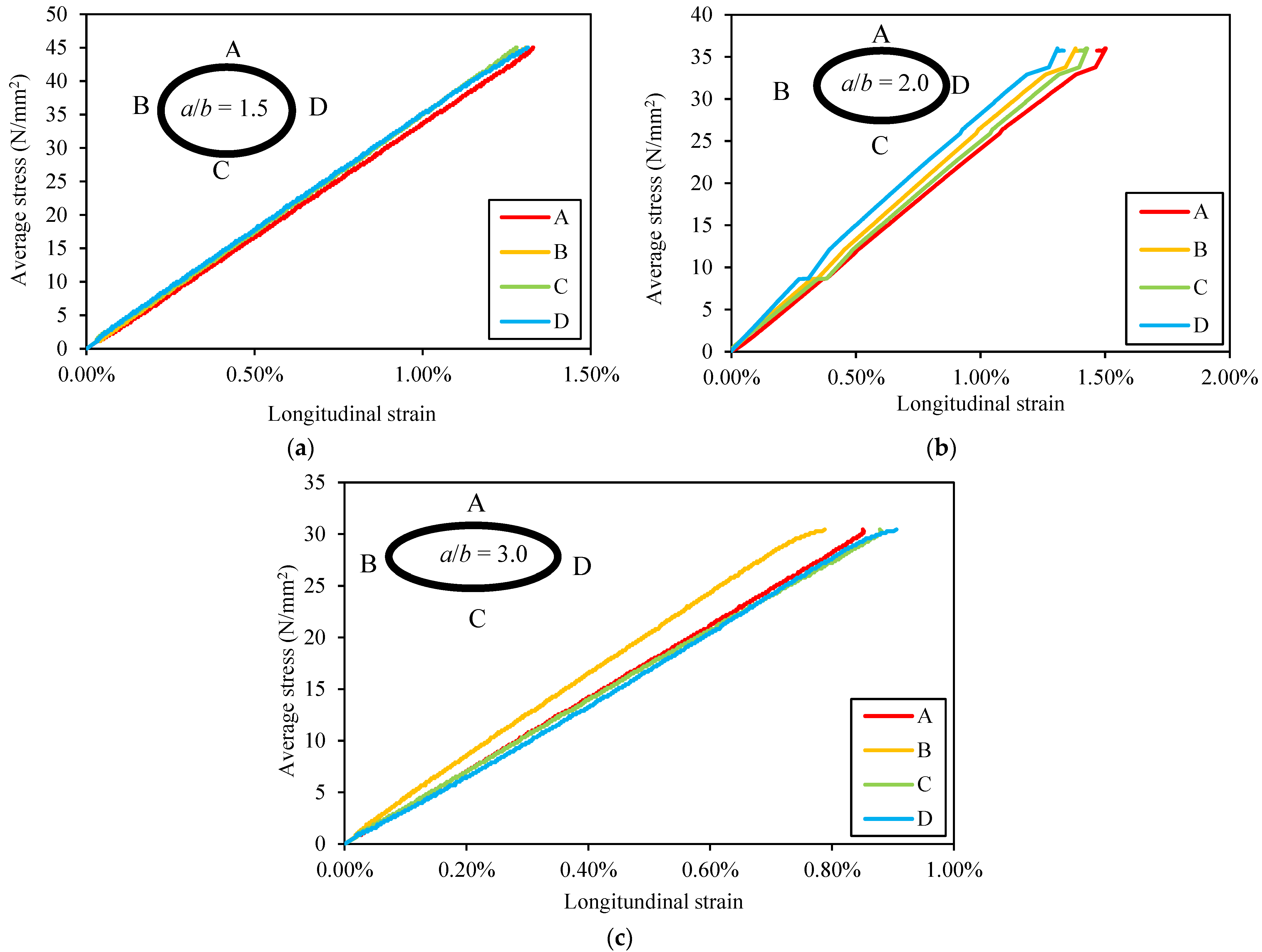

3.4.3. Longitudinal Strains

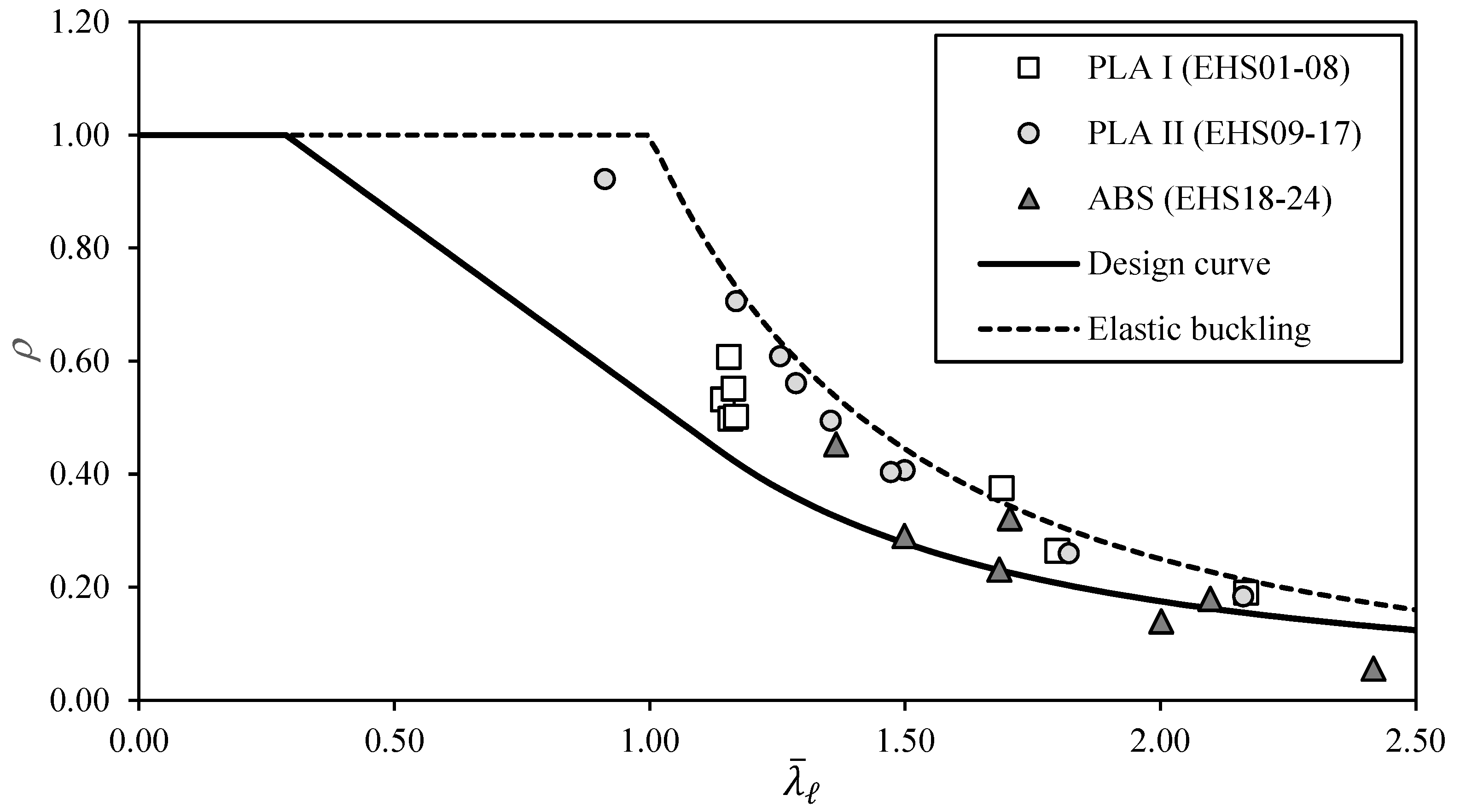

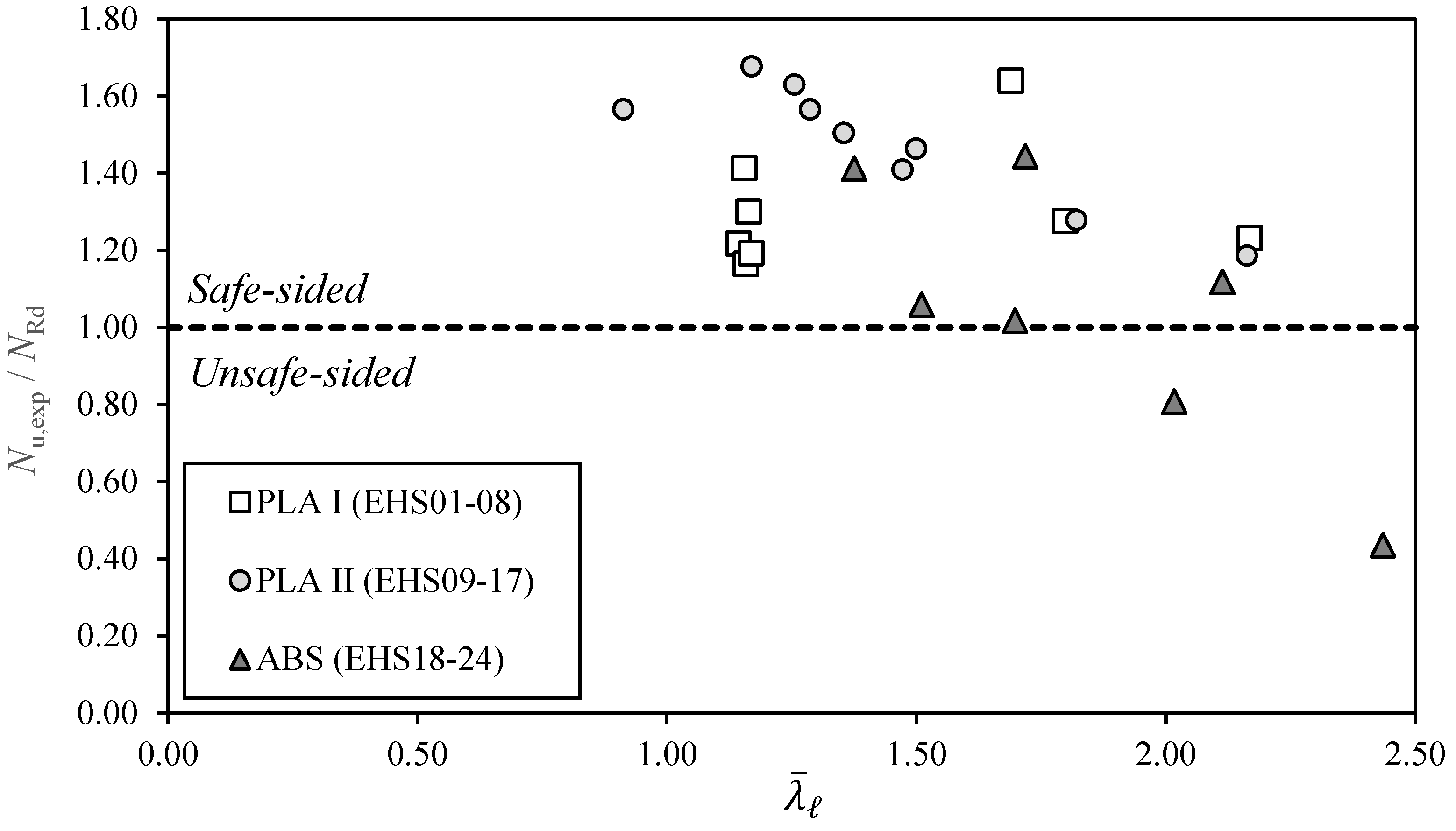

4. Design Method

4.1. Local Buckling of Elliptical Sections

4.2. Design Method for Slender Elliptical Tubes in Compression

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [PubMed]

- Farah, S.; Anderson, D.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Torre, R.; Brischetto, S.; Dipietro, I.R. Buckling developed in 3D printed PLA cuboidal samples under compression: Analytical, numerical and experimental investigations. Addit. Manuf. 2021, 38, 101790. [Google Scholar] [CrossRef]

- Roy, R.; Mukhopadhyay, A. Tribological studies of 3D printed ABS and PLA plastic parts. Mater. Today Proc. 2021, 41, 856–862. [Google Scholar] [CrossRef]

- Hsueh, M.H.; Lai, C.J.; Wang, S.H.; Zeng, Y.S.; Hsieh, C.H.; Pan, C.Y.; Huang, W.C. Effect of printing parameters on the thermal and mechanical properties of 3D-Printed PLA and PETG using Fused Deposition Modeling. Polymers 2021, 3, 1758. [Google Scholar] [CrossRef] [PubMed]

- UM180821 TDS PLA RB V11 Technical Data Sheet PLA; Ultimaker: Zaltbommel, The Netherlands, 2018.

- Technical Data Sheet—ABSX; MCPP: Amsterdam, The Netherlands, 2018.

- Almkvist, G.; Berndt, B. Gauss, Landen, Ramanujan, the Arithmetic-geometric Mean, Ellipses, π, and the Ladies Diary. Amer. Math. Mon. 1988, 95, 585–608. [Google Scholar]

- Zhou, C.; Hu, Y.; Zhang, L.; Fang, J.; Xi, Y.; Hu, J.; Li, Y.; Liu, L.; Zhao, Y.; Yang, L.; et al. Investigation of heat transfer characteristics of deflected elliptical-tube heat exchanger in closed-circuit cooling towers. Appl. Therm. Eng. 2024, 236, 121860. [Google Scholar] [CrossRef]

- Khuda, M.A.; Sarunac, N. A comparative study of latent heat thermal energy storage (LTES) system using cylindrical and elliptical tubes in a staggered tube arrangement. J. Energy Storage 2024, 87, 111333. [Google Scholar] [CrossRef]

- Boiko, A.V.; Demyanko, K.V. On numerical stability analysis of fluid flows in compliant pipes of elliptic cross-section. J. Fluids Struct. 2022, 108, 103414. [Google Scholar] [CrossRef]

- Shi, X.; Alam, M.M.; Zhu, H.; Ji, C.; Bai, H.; Sharifpur, M. Flow three-dimensionality of wavy elliptic cylinder: Vortex shedding bifurcation. Ocean. Eng. 2024, 301, 117527. [Google Scholar] [CrossRef]

- Ruiz-Teran, A.M.; Gardner, L. Elastic buckling of elliptical tubes. Thin-Walled Struct. 2008, 46, 1304–1318. [Google Scholar] [CrossRef]

- Kempner, J.; Chen, Y.N. Large deflections of an axially compressed oval cylindrical shell. In Proceedings of the 11th International Congress of Applied Mechanics, Munich, Germany, 30 August–5 September 1964. [Google Scholar]

- Feinstein, G.; Erickson, B.; Kempner, J. Stability of oval cylindrical shells. Exp. Mech. 1971, 11, 514–520. [Google Scholar] [CrossRef]

- Silvestre, N.; Gardner, L. Elastic local postbuckling of elliptical tubes. J. Const. Steel Res. 2011, 67, 281–292. [Google Scholar] [CrossRef]

- Insausti, A.; Gardner, L. Analytical modelling of plastic collapse in compressed elliptical hollow sections. J. Const. Steel Res. 2011, 67, 678–689. [Google Scholar] [CrossRef]

- Abela, J.M.; Gardner, L. Elastic buckling of elliptical tubes subjected to generalised linearly varying stress distributions. Thin-Walled Struct. 2012, 58, 40–50. [Google Scholar] [CrossRef]

- Yao, Y.; Quach, W.-M.; Young, B. Strength enhancement and stub-column behavior of cold-formed stainless steel elliptical hollow sections. Thin-Walled Struct. 2023, 189, 110939. [Google Scholar] [CrossRef]

- Ge, C.; Gao, Q.; Wang, L.; Hong, Z. Theoretical prediction and numerical analysis for axial crushing behaviour of elliptical aluminium foam-filled tube. Thin-Walled Struct. 2020, 149, 106523. [Google Scholar] [CrossRef]

- Al-saadi, A.U.; Thiru Aravinthan, T.; Lokuge, W. Structural applications of fibre reinforced polymer (FRP)composite tubes: A review of columns members. Compos. Struct. 2018, 204, 513–524. [Google Scholar] [CrossRef]

- McCann, F.; Fang, C.; Gardner, L.; Silvestre, N. Local buckling and ultimate strength of slender elliptical hollow sections in compression. Eng. Struct. 2016, 111, 104–118. [Google Scholar] [CrossRef]

- McCann, F.; Gardner, L. Numerical analysis and design of slender elliptical hollow sections in bending. Thin-Walled Struct. 2019, 139, 196–208. [Google Scholar] [CrossRef]

- Vukasovic, T.; Vivanco, J.F.; Celentano, D.; García-Herrera, C. Characterization of the mechanical response of thermoplastic parts fabricated with 3D printing. Int. J. Adv. Manuf. Technol. 2019, 104, 4207–4218. [Google Scholar] [CrossRef]

- Dundar, M.A.; Dhaliwal, G.S.; Ayorinde, E.; Al-Zubi, M. Tensile, compression, and flexural characteristics of acrylonitrile–butadiene–styrene at low strain rates: Experimental and numerical investigation. Polym. Polym. Compos. 2021, 29, 331–342. [Google Scholar] [CrossRef]

- Ansari, A.A.; Kamil, M. Effect of print speed and extrusion temperature on properties of 3D printed PLA used fused deposition modeling process. Mater. Today Proc. 2021, 45, 5462–5468. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Nabavi-Kivi, A.; Bahrami, B.; Yahya, M.Y.; Khosravani, M.R. The influence of in-plane raster angle on tensile and fracture strengths of 3D-printed PLA specimens. Eng. Fract. Mech. 2020, 237, 107225. [Google Scholar] [CrossRef]

- Kiendl, J.; Gao, C. Controlling toughness and strength of FDM 3D-printed PLA components through the raster layup. Compos. Part B Eng. 2020, 180, 107562. [Google Scholar] [CrossRef]

- Guan, Y.; Virgin, L.N.; Helm, D. Structural behavior of shallow geodesic lattice domes. Int. J. Solids Struct. 2018, 155, 225–239. [Google Scholar] [CrossRef]

- Virgin, L.N.; Guan, Y.; Plaut, R.H. On the geometric conditions for multiple stable equilibria in clamped arches. Int. J. Non-Linear Mech. 2017, 92, 8–14. [Google Scholar] [CrossRef]

- Nomani, J.; Wilson, D.; Paulino, M.; Mohammed, M.I. Effect of layer thickness and cross-section geometry on the tensile and compression properties of 3D printed ABS. Mater. Today Commun. 2020, 22, 100626. [Google Scholar] [CrossRef]

- Grant, A.; Regez, B.; Kocak, S.; Huber, J.D.; Mooers, A. Anisotropic properties of 3-D printed Poly Lactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS) plastics. Results Mater. 2021, 12, 100227. [Google Scholar] [CrossRef]

- EN ISO 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. CEN: Meyrin, Switzerland, 1996.

- Prusa. PrusaSlicer 2.4.0 Manual. 2021. Available online: https://help.prusa3d.com/en/article/general-info_1910 (accessed on 13 December 2021).

- EN ISO 527-1; Plastics—Determination of Tensile Properties—Part 1: General Principles. CEN: Meyrin, Switzerland, 1993.

- ASTM D695; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM: West Conshohocken, PA, USA, 2016.

- Ashby, M.F. The mechanical properties of cellular solids. Metall. Trans. A 1983, 14, 1755–1769. [Google Scholar] [CrossRef]

- Ramberg, W.; Osgood, W.R. Description of Stress–Strain Curves by Three Parameters. Technical Note No. 902; National Advisory Committee for Aeronautics: Washington, DC, USA, 1943. [Google Scholar]

- Ferreira, R.T.L.; Cardoso Amatte, I.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Zou, R.; Xia, Y.; Liu, S.; Hu, P.; Hou, W.; Hu, Q.; Shan, C. Isotropic and anisotropic elasticity and yielding of 3D printed material. Compos. Part B Eng. 2016, 99, 506–513. [Google Scholar] [CrossRef]

- McCann, F.; Rossi, F. Investigating local buckling in highly slender elliptical hollow sections through analysis of 3D-printed analogues. In Proceedings of the 8th International Conference on Coupled Instabilities in Metal Structures, Łodz, Poland, 12–14 July 2021. [Google Scholar]

- Ree, T.; Eyring, H. Theory of Non-Newtonian Flow. I. Solid Plastic System. J. Appl. Phys. 1955, 26, 793–800. [Google Scholar]

- Verbeeten, W.M.H.; Lorenzo-Bañuelos, M.; Arribas-Subiñas, P.J. Anisotropic rate-dependent mechanical behavior of Poly (Lactic Acid) processed by Material Extrusion Additive Manufacturing. Addit. Manuf. 2020, 31, 100968. [Google Scholar] [CrossRef]

- Gardner, L.; Chan, T.M. Cross-section classification of elliptical hollow sections. Steel Comp. Struct. 2007, 7, 185–200. [Google Scholar] [CrossRef]

- Chan, T.M.; Gardner, L. Compressive resistance of hot-rolled elliptical hollow sections. Eng. Struct. 2008, 30, 522–532. [Google Scholar] [CrossRef]

- EN 1993-1-1; Eurocode 3: Design of Steel Structure—Part 1–1: General Rules for Buildings. British Standards Institute. CEN: Meyrin, Switzerland, 2024.

- EN 1993-1-4; Eurocode 3: Design of Steel Structures—Part 1–4: General Rules—Supplementary Rules for Stainless Steels. British Standards Institute. CEN: Meyrin, Switzerland, 2006.

- Tsai, S.W.; Wu, E.M. A general theory of strength for anisotropic materials. In Technical Report AFML-TR-71-12, August 1972; Air Force Materials Laboratory: Dayton, OH, USA, 1972. [Google Scholar]

| Material | Strength (N/mm2) | Elastic Modulus (N/mm2) | Density (kg/m3) | Normalised Strength-to-Weight Ratio (km) |

|---|---|---|---|---|

| Ultimaker PLA [6] | 50 | 2350 | 1248 | 4.08 |

| MCPP ABSX [7] | 39 | 1980 | 1030 | 3.86 |

| S275 steel | 275 | 210,000 | 7850 | 3.57 |

| S355 steel | 355 | 210,000 | 7850 | 4.61 |

| C40 concrete | 40 | 32,100 | 2400 | 1.70 |

| C24 timber | 24 | 10,800 | 550 | 4.45 |

| Specimen | bt,1 | bt,2 | COV(bt,1) | COV(bt,2) | Et | σu,t | εu,t | εf,t |

|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (%) | (%) | (N/mm2) | (N/mm2) | (%) | (%) | |

| PLA | ||||||||

| T01-PLA-X-1 | 9.92 | 4.20 | 0.94 | 6.03 | 2774 | 40.7 | 1.48 | 1.48 |

| T02-PLA-X-2 | 9.95 | 4.20 | 0.59 | 6.23 | 2795 | 51.5 | 1.88 | 1.88 |

| T03-PLA-X-3 | 9.91 | 4.18 | 1.07 | 5.53 | 2834 | 53.1 | 2.10 | 2.13 |

| T04-PLA-Y-1 | 10.91 | 3.98 | 11.11 | 1.30 | 3089 | 53.4 | 1.93 | 1.93 |

| T05-PLA-Y-2 | 10.87 | 3.98 | 10.62 | 1.17 | 3213 | 50.6 | 1.76 | 1.76 |

| T06-PLA-Y-3 | 10.90 | 3.98 | 11.03 | 1.16 | 3231 | 53.9 | 1.90 | 1.91 |

| T07-PLA-Z-1 | 10.35 | 4.35 | 4.33 | 10.84 | 3069 | 37.6 | 1.33 | 1.33 |

| T08-PLA-Z-2 | 10.38 | 4.40 | 4.62 | 12.15 | 3106 | 46.2 | 1.87 | 1.87 |

| T09-PLA-Z-3 | 10.33 | 4.36 | 4.08 | 11.03 | 2968 | 44.9 | 1.76 | 1.76 |

| ABS | ||||||||

| T10-ABS-X-1 | 10.13 | 4.19 | 1.69 | 5.96 | 1692 | 31.1 | 2.38 | 2.90 |

| T11-ABS-X-2 | 9.85 | 4.16 | 1.88 | 4.85 | 1772 | 32.1 | 2.32 | 2.49 |

| T12-ABS-X-3 | 9.86 | 4.17 | 1.76 | 5.23 | 1770 | 31.9 | 2.33 | 2.66 |

| T13-ABS-Y-1 | 10.54 | 3.96 | 6.57 | 1.25 | 1739 | 34.0 | 2.38 | 2.40 |

| T14-ABS-Y-2 | 10.53 | 3.98 | 6.49 | 0.79 | 1737 | 33.6 | 2.34 | 2.35 |

| T15-ABS-Y-3 | 10.59 | 4.01 | 7.27 | 0.43 | 1734 | 33.0 | 2.30 | 2.32 |

| T16-ABS-Z-1 | 10.09 | 4.08 | 1.42 | 2.88 | 1866 | 15.4 | 0.92 | 0.92 |

| T17-ABS-Z-2 | 10.09 | 4.07 | 1.22 | 2.59 | 1599 | 17.4 | 1.13 | 1.16 |

| T18-ABS-Z-3 | 9.93 | 4.16 | 1.21 | 4.86 | 1684 | 18.0 | 1.17 | 1.17 |

| Material Orientation | COV(bt,1) | COV(bt,2) | Et | COV(Et) | σu,t | COV(σt) | εu,t | εf,t |

|---|---|---|---|---|---|---|---|---|

| (%) | (%) | (N/mm2) | (%) | (N/mm2) | (%) | (%) | (%) | |

| PLA | ||||||||

| X orientation | 0.77 | 5.14 | 2801 | 0.98 | 48.4 | 13.9 | 1.82 | 1.83 |

| Y orientation | 9.46 | 1.05 | 3178 | 2.43 | 52.6 | 3.38 | 1.87 | 1.87 |

| Z orientation | 3.77 | 9.83 | 3048 | 2.34 | 42.9 | 10.81 | 1.65 | 1.65 |

| ABS | ||||||||

| X orientation | 1.54 | 4.65 | 1745 | 2.61 | 31.7 | 1.67 | 2.34 | 2.68 |

| Y orientation | 5.88 | 0.77 | 1737 | 0.14 | 33.5 | 1.50 | 2.34 | 2.36 |

| Z orientation | 1.12 | 3.11 | 1716 | 7.95 | 17.0 | 8.04 | 1.07 | 1.08 |

| Specimen | bc,1 | bc,2 | COV(bc,1) | COV(bc,2) | Ec | σp1%,c | σu,c | εu,c |

|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (%) | (%) | (N/mm2) | (N/mm2) | (N/mm2) | (%) | |

| PLA batch 1 | ||||||||

| C01-PLA1-X-1 | 12.84 | 12.56 | 1.32 | 1.32 | 2516 | 58.3 | 58.4 | 3.53 |

| C02-PLA1-X-2 | 12.85 | 12.64 | 1.45 | 0.63 | 2675 | 62.0 | 62.1 | 3.76 |

| C03-PLA1-X-3 | 12.84 | 12.58 | 1.32 | 1.19 | 2782 | 62.9 | 63.6 | 3.25 |

| C04-PLA1-X-4 | 12.93 | 12.60 | 2.46 | 0.93 | 2454 | 59.0 | 59.0 | 3.39 |

| C05-PLA1-Z-1 | 13.01 | 12.98 | 2.71 | 2.99 | 2401 | 72.0 | 73.7 | 3.57 |

| C06-PLA1-Z-2 | 12.76 | 12.78 | 0.94 | 0.68 | 2699 | 75.1 | 75.1 | 3.57 |

| C07-PLA1-Z-3 | 12.72 | 12.73 | 0.33 | 0.30 | 2987 | 76.4 | 76.9 | 3.37 |

| PLA batch 2 | ||||||||

| C08-PLA2-X-1 | 12.51 | 12.72 | 1.80 | 0.24 | 2715 | 72.5 | 72.9 | 3.61 |

| C09-PLA2-X-2 | 12.50 | 12.75 | 1.90 | 0.53 | 2490 | 73.3 | 73.7 | 3.87 |

| C10-PLA2-X-3 | 12.48 | 12.74 | 2.16 | 0.45 | 2747 | 72.5 | 73.3 | 3.68 |

| C11-PLA2-Z-1 | 12.53 | 12.85 | 1.64 | 1.42 | 3135 | 76.5 | 77.7 | 3.55 |

| C12-PLA2-Z-2 | 12.52 | 12.79 | 1.74 | 0.91 | 3108 | 76.1 | 77.4 | 3.59 |

| C13-PLA2-Z-3 | 12.56 | 12.84 | 1.39 | 1.42 | 2968 | 73.8 | 74.3 | 3.42 |

| ABS | ||||||||

| C14-ABS-X-1 | 12.92 | 12.57 | 2.13 | 1.26 | 1301 | 38.5 | - | 4.01 |

| C15-ABS-X-2 | 12.89 | 12.70 | 2.04 | 0.06 | 1174 | 37.5 | - | 4.23 |

| C16-ABS-X-3 | 12.74 | 12.48 | 0.53 | 2.18 | 1420 | 39.6 | - | 3.83 |

| C17-ABS-X-4 | 12.94 | 12.67 | 2.54 | 0.29 | 1060 | 40.1 | - | 4.90 |

| C18-ABS-Z-1 | 12.61 | 12.68 | 0.92 | 0.73 | 1411 | 40.7 | 40.8 | 3.80 |

| C19-ABS-Z-2 | 12.62 | 12.69 | 0.80 | 0.25 | 1492 | 41.1 | 41.1 | 3.77 |

| C20-ABS-Z-3 | 12.62 | 12.59 | 0.87 | 1.12 | 1560 | 41.2 | 41.2 | 3.61 |

| C21-ABS-Z-4 | 12.59 | 12.68 | 1.12 | 0.41 | 1559 | 41.5 | 41.5 | 3.62 |

| Specimen | COV(bc,1) | COV(bc,2) | Ec | COV(Ec) | σp1%,c | COV(σtp1%c) | σu,c | εu,c |

|---|---|---|---|---|---|---|---|---|

| (%) | (%) | (N/mm2) | (%) | (N/mm2) | (%) | (N/mm2) | (%) | |

| PLA batch 1 | ||||||||

| X orientation | 1.45 | 0.90 | 2607 | 5.73 | 60.6 | 3.70 | 60.8 | 3.48 |

| Z orientation | 1.44 | 1.54 | 2696 | 10.87 | 74.5 | 3.03 | 75.2 | 3.51 |

| PLA batch 2 | ||||||||

| X orientation | 1.70 | 0.37 | 2651 | 5.28 | 72.8 | 0.63 | 73.3 | 3.72 |

| Z orientation | 0.82 | 1.12 | 3070 | 2.92 | 75.5 | 1.93 | 76.5 | 3.52 |

| ABS | ||||||||

| X orientation | 1.68 | 1.08 | 1239 | 12.58 | 38.9 | 2.98 | - | 4.25 |

| Z orientation | 0.80 | 0.61 | 1506 | 4.69 | 41.1 | 0.80 | 41.1 | 3.70 |

| Material | ν |

|---|---|

| PLA | |

| X orientation | 0.322 |

| Z orientation | 0.325 |

| ABS | |

| X orientation | 0.341 |

| Z orientation | 0.332 |

| Specimen | 2a | 2b | a/b | Wall Thickness t | Pm | A | |||

|---|---|---|---|---|---|---|---|---|---|

| Nominal | Average | St. Dev | COV | ||||||

| (mm) | (mm) | (mm) | (mm) | (mm) | (%) | (mm) | (mm2) | ||

| EHS01-PLA1-100-50-3.0 | 100.14 | 50.01 | 2.0 | 3.00 | 3.17 | 0.11 | 3.48 | 233 | 737 |

| EHS02-PLA1-90-60-2.0 | 90.17 | 60.09 | 1.5 | 2.00 | 2.07 | 0.08 | 3.96 | 232 | 478 |

| EHS03-PLA1-90-60-2.0 | 90.02 | 60.11 | 1.5 | 2.00 | 2.08 | 0.06 | 2.73 | 232 | 481 |

| EHS04-PLA1-90-60-2.0 | 90.06 | 60.08 | 1.5 | 2.00 | 2.04 | 0.09 | 4.35 | 232 | 473 |

| EHS05-PLA1-100-50-3.0 | 100.04 | 50.05 | 2.0 | 3.00 | 3.10 | 0.12 | 3.93 | 233 | 721 |

| EHS06-PLA1-100-50-1.5 | 100.06 | 50.08 | 2.0 | 1.50 | 1.45 | 0.07 | 5.02 | 238 | 344 |

| EHS07-PLA1-105-35-2.0 | 105.13 | 35.07 | 3.0 | 2.00 | 2.02 | 0.10 | 4.73 | 228 | 459 |

| EHS08-PLA1-105-35-1.5 | 105.08 | 35.01 | 3.0 | 1.50 | 1.39 | 0.15 | 10.91 | 230 | 344 |

| EHS09-PLA2-90-60-1.0 | 90.15 | 59.71 | 1.5 | 1.00 | 1.13 | 0.03 | 2.65 | 234 | 235 |

| EHS10-PLA2-90-60-1.5 | 90.02 | 60.09 | 1.5 | 1.50 | 1.60 | 0.05 | 3.21 | 233 | 350 |

| EHS11-PLA2-90-60-3.0 | 90.03 | 60.01 | 1.5 | 3.00 | 3.03 | 0.05 | 1.63 | 228 | 686 |

| EHS12-PLA2-100-50-1.0 | 100.08 | 50.03 | 2.0 | 1.00 | 1.13 | 0.05 | 4.07 | 238 | 239 |

| EHS13-PLA2-100-50-2.0 | 100.06 | 50.01 | 2.0 | 2.00 | 2.26 | 0.07 | 3.16 | 235 | 472 |

| EHS14-PLA2-100-50-2.5 | 100.03 | 50.04 | 2.0 | 2.50 | 2.73 | 0.06 | 2.19 | 233 | 586 |

| EHS15-PLA2-105-35-1.0 | 105.05 | 35.03 | 3.0 | 1.00 | 1.26 | 0.04 | 3.45 | 230 | 231 |

| EHS16-PLA2-105-35-2.5 | 105.07 | 35.01 | 3.0 | 2.50 | 2.72 | 0.05 | 1.94 | 225 | 566 |

| EHS17-PLA2-105-35-3.0 | 105.02 | 35.01 | 3.0 | 3.00 | 3.20 | 0.07 | 2.03 | 224 | 675 |

| EHS18-ABS-100-50-1.0 | 99.70 | 50.65 | 2.0 | 1.00 | 1.21 | 0.05 | 3.71 | 239 | 239 |

| EHS19-ABS-90-60-1.0 | 90.16 | 59.98 | 1.5 | 1.50 | 1.16 | 0.07 | 5.67 | 235 | 235 |

| EHS20-ABS-90-60-1.5 | 90.07 | 60.14 | 1.5 | 1.00 | 1.79 | 0.05 | 2.87 | 233 | 464 |

| EHS21-ABS-105-35-1.0 | 105.42 | 35.61 | 3.0 | 2.00 | 1.32 | 0.20 | 15.42 | 231 | 231 |

| EHS22-ABS-105-35-2.5 | 105.23 | 35.12 | 3.0 | 1.00 | 2.75 | 0.07 | 2.43 | 226 | 566 |

| EHS23-ABS-100-50-1.0 | 99.60 | 50.15 | 2.0 | 2.50 | 1.11 | 0.04 | 3.36 | 238 | 239 |

| EHS24-ABS-100-50-2.0 | 99.86 | 50.31 | 2.0 | 2.00 | 2.19 | 0.08 | 3.57 | 236 | 472 |

| Specimen | a/b | Deq | Deq/tε2 | σcr | σu,exp | ρexp | ρd | Nu,exp | NRd | Nu,exp/NRd | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (N/mm2) | (N/mm2) | (kN) | (kN) | |||||||

| EHS01-PLA1-100-50-3.0 | 2.0 | 201 | 1419 | 51.8 | 36.0 | 1.14 | 0.53 | 0.44 | 26.59 | 21.84 | 1.22 |

| EHS02-PLA1-90-60-2.0 | 1.5 | 135 | 1470 | 50.0 | 37.3 | 1.16 | 0.55 | 0.42 | 17.88 | 13.75 | 1.30 |

| EHS03-PLA1-90-60-2.0 | 1.5 | 135 | 1456 | 50.5 | 33.7 | 1.16 | 0.50 | 0.43 | 16.23 | 13.94 | 1.16 |

| EHS04-PLA1-90-60-2.0 | 1.5 | 135 | 1483 | 49.5 | 34.0 | 1.17 | 0.50 | 0.42 | 16.08 | 13.50 | 1.19 |

| EHS05-PLA1-100-50-3.0 | 2.0 | 200 | 1447 | 50.8 | 41.1 | 1.15 | 0.61 | 0.43 | 29.68 | 21.00 | 1.41 |

| EHS06-PLA1-100-50-1.5 | 2.0 | 200 | 3096 | 23.7 | 25.4 | 1.69 | 0.38 | 0.23 | 8.76 | 5.34 | 1.64 |

| EHS07-PLA1-105-35-2.0 | 3.0 | 315 | 3509 | 20.9 | 17.9 | 1.80 | 0.26 | 0.21 | 8.22 | 6.44 | 1.28 |

| EHS08-PLA1-105-35-1.5 | 3.0 | 315 | 5100 | 14.4 | 12.9 | 2.17 | 0.19 | 0.15 | 4.10 | 3.33 | 1.23 |

| EHS09-PLA2-90-60-1.0 | 1.5 | 136 | 2440 | 31.0 | 28.3 | 1.50 | 0.41 | 0.28 | 7.50 | 5.12 | 1.46 |

| EHS10-PLA2-90-60-1.5 | 1.5 | 135 | 1710 | 44.2 | 42.3 | 1.26 | 0.61 | 0.37 | 15.77 | 9.68 | 1.63 |

| EHS11-PLA2-90-60-3.0 | 1.5 | 135 | 904 | 83.6 | 64.2 | 0.91 | 0.92 | 0.59 | 44.39 | 28.35 | 1.57 |

| EHS12-PLA2-100-50-1.0 | 2.0 | 200 | 3597 | 21.0 | 18.1 | 1.82 | 0.26 | 0.20 | 4.87 | 3.81 | 1.28 |

| EHS13-PLA2-100-50-2.0 | 2.0 | 200 | 1797 | 42.0 | 39.0 | 1.29 | 0.56 | 0.36 | 20.73 | 13.25 | 1.57 |

| EHS14-PLA2-100-50-2.5 | 2.0 | 200 | 1484 | 50.9 | 49.1 | 1.17 | 0.71 | 0.42 | 31.34 | 18.69 | 1.68 |

| EHS15-PLA2-105-35-1.0 | 3.0 | 315 | 5075 | 14.9 | 12.8 | 2.16 | 0.18 | 0.15 | 3.70 | 3.12 | 1.19 |

| EHS16-PLA2-105-35-2.5 | 3.0 | 315 | 2352 | 32.1 | 28.1 | 1.47 | 0.40 | 0.29 | 17.23 | 12.23 | 1.41 |

| EHS17-PLA2-105-35-3.0 | 3.0 | 315 | 1992 | 37.9 | 34.4 | 1.35 | 0.49 | 0.33 | 24.72 | 16.44 | 1.50 |

| EHS18-ABS-100-50-1.0 | 2.0 | 196 | 4413 | 9.44 | 5.28 | 2.00 | 0.14 | 0.17 | 1.53 | 1.89 | 0.80 |

| EHS19-ABS-90-60-1.0 | 1.5 | 136 | 3202 | 13.01 | 12.18 | 1.71 | 0.32 | 0.23 | 3.30 | 2.29 | 1.43 |

| EHS20-ABS-90-60-1.5 | 1.5 | 135 | 2052 | 20.31 | 17.13 | 1.36 | 0.45 | 0.32 | 7.15 | 5.06 | 1.39 |

| EHS21-ABS-105-35-1.0 | 3.0 | 312 | 6434 | 6.48 | 2.13 | 2.42 | 0.06 | 0.13 | 0.65 | 1.49 | 0.43 |

| EHS22-ABS-105-35-2.5 | 3.0 | 315 | 3126 | 13.33 | 8.74 | 1.68 | 0.23 | 0.23 | 5.44 | 5.35 | 1.00 |

| EHS23-ABS-100-50-1.0 | 2.0 | 198 | 4846 | 8.60 | 6.79 | 2.10 | 0.18 | 0.16 | 1.80 | 1.61 | 1.11 |

| EHS24-ABS-100-50-2.0 | 2.0 | 198 | 2475 | 16.84 | 11.00 | 1.50 | 0.29 | 0.28 | 5.66 | 5.35 | 1.05 |

| Material Batch | σc,eff |

|---|---|

| (N/mm2) | |

| PLA batch 1 | 67.7 |

| PLA batch 2 | 69.6 |

| ABS | 37.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

McCann, F.; Rossi, F.; Sultan, S.D. Experimental Analysis and Design of 3D-Printed Polymer Elliptical Tubes in Compression. Appl. Sci. 2024, 14, 7673. https://doi.org/10.3390/app14177673

McCann F, Rossi F, Sultan SD. Experimental Analysis and Design of 3D-Printed Polymer Elliptical Tubes in Compression. Applied Sciences. 2024; 14(17):7673. https://doi.org/10.3390/app14177673

Chicago/Turabian StyleMcCann, Finian, Federico Rossi, and Shahzada Danyal Sultan. 2024. "Experimental Analysis and Design of 3D-Printed Polymer Elliptical Tubes in Compression" Applied Sciences 14, no. 17: 7673. https://doi.org/10.3390/app14177673

APA StyleMcCann, F., Rossi, F., & Sultan, S. D. (2024). Experimental Analysis and Design of 3D-Printed Polymer Elliptical Tubes in Compression. Applied Sciences, 14(17), 7673. https://doi.org/10.3390/app14177673