Optimization of Formula for Chromium-Free Zinc–Aluminum Coatings Based on Extension Analytic Hierarchy Process

Abstract

1. Introduction

2. Methods

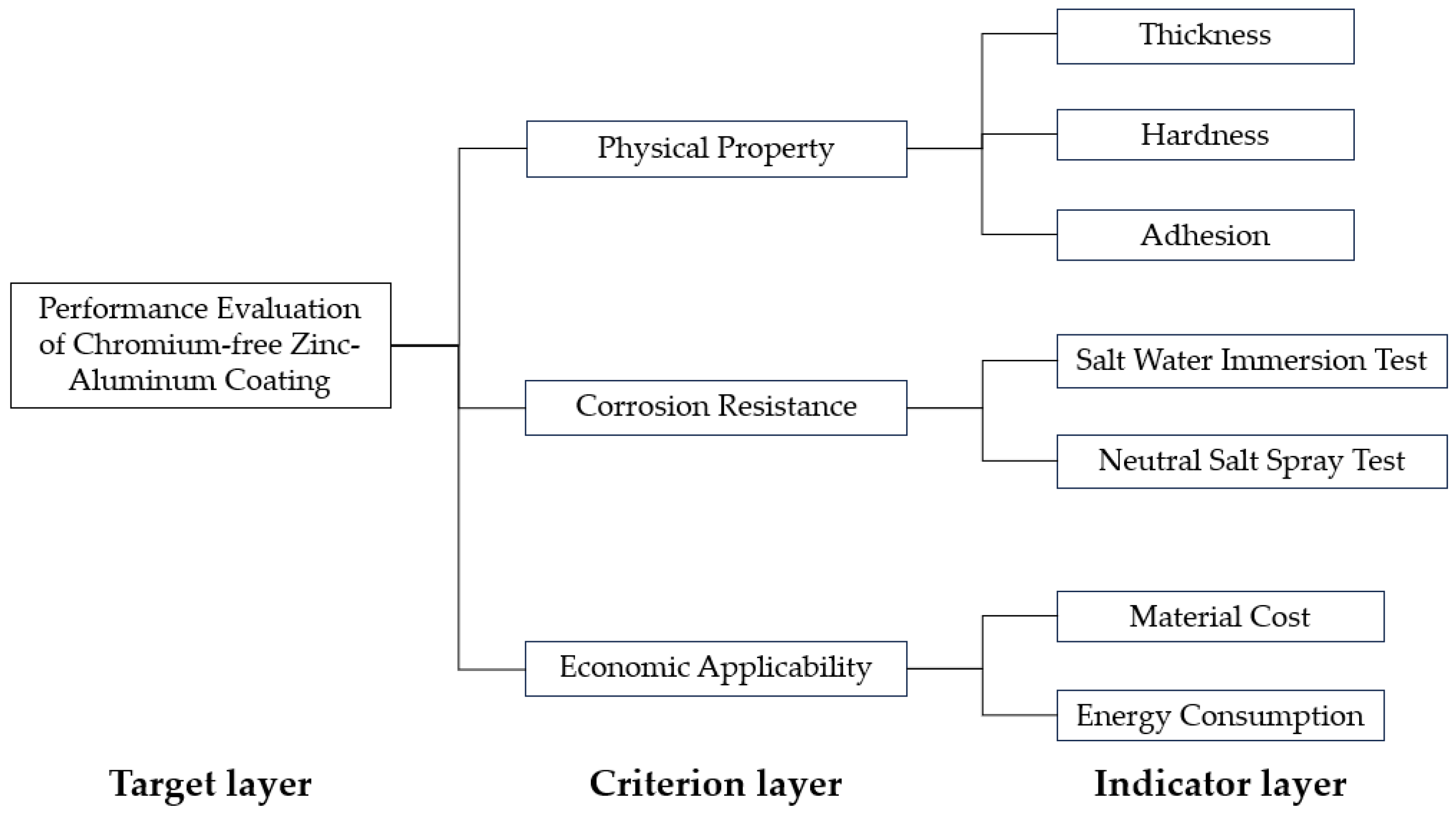

2.1. Establishment of Coating Performance Evaluation System

2.2. Extension Analytic Hierarchy Process

2.2.1. Constructing an Extensible Interval Number Judgment Matrix

2.2.2. Calculate the Weight of Extensible Interval Numbers

- Eigenvector calculation

- Consistency check

- Weight calculation

2.2.3. Interval Weight Univalued

2.2.4. Calculate the Total Ranking Weight of the Hierarchy

2.3. Grading and Scoring of Evaluation Indicators

2.3.1. Evaluation Index Grading Method

2.3.2. Scoring Method for Evaluation Indicators

3. Results and Discussion

3.1. Paint Formulation Design

3.2. Calculation of Evaluation Index Weights

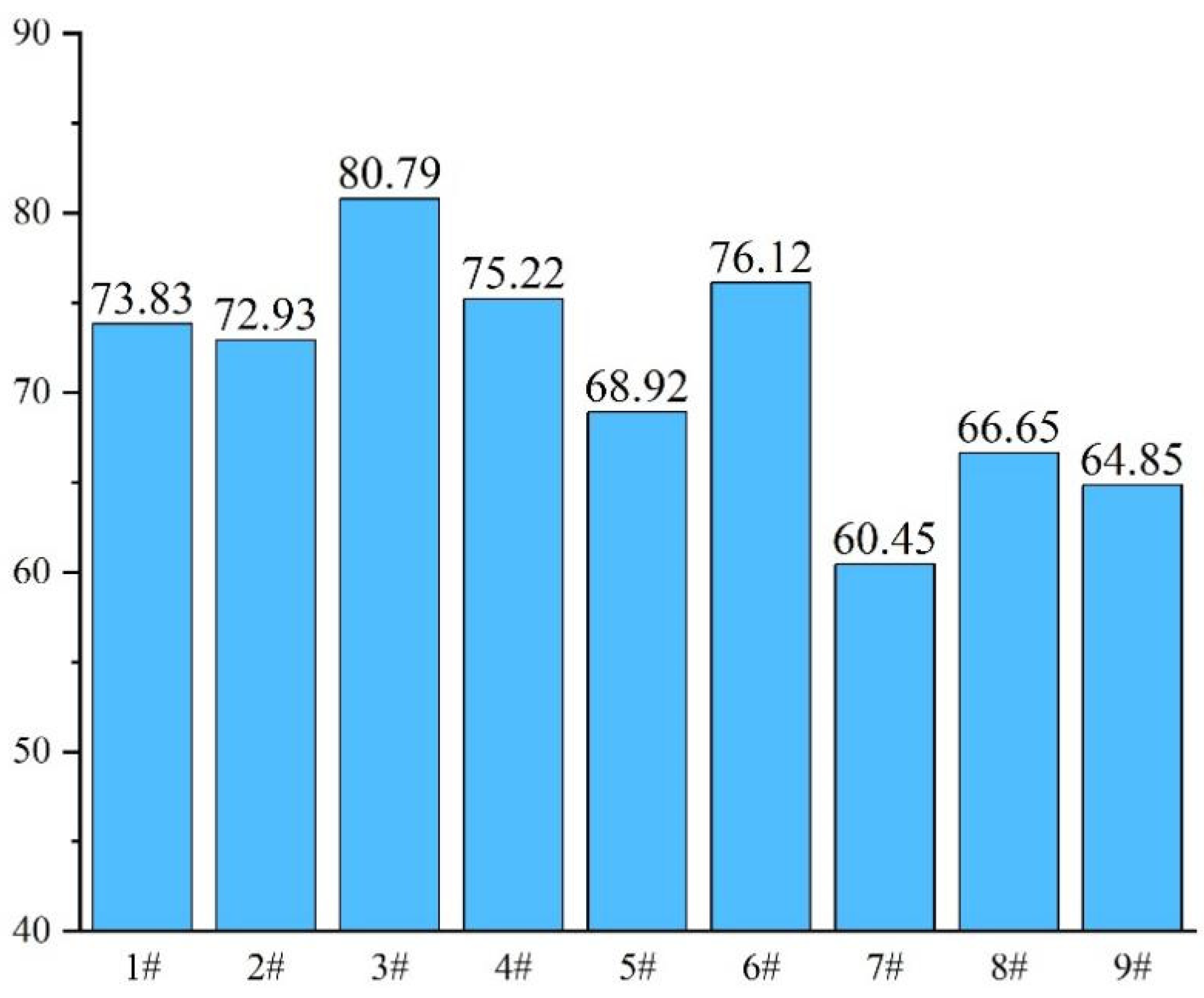

3.3. Performance Evaluation of Chromium-Free Zinc–Aluminum Coating

4. Conclusions

- The extension theory, which introduces the concept of “domain”, has transformed the manner in which point values in the judgment matrix are treated as interval numbers. This has led to more effective combinations in consistency testing and weight vector solving, avoiding time-consuming calculations and eliminating the influence of subjective factors. As a result, the weight of evaluation indicators can be determined with greater speed and accuracy;

- The service performance indicators of chromium-free zinc–aluminum coatings were expressed as dimensionless values, thereby eliminating the differences in numerical values that would otherwise have been caused by different orders of magnitude. A method for grading and scoring the service performance evaluation indicators of chromium-free zinc–aluminum coatings was proposed, which effectively simplified the analysis process;

- Based on the analytic hierarchy process (AHP), formulation 3# was identified as the optimal formulation for chromium-free zinc–aluminum coatings. This method was deemed to be the most practical, reliable, reasonable, and convenient.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, M.; Xie, F.; Wu, X.; Wang, S.; Lu, C.; Yao, X. The Development of Chromium-free Zinc-Aluminum Coating. Mater. Rep. 2021, 35, 11. [Google Scholar] [CrossRef]

- Cui, Y. Application Development of Non-Chromium Dacromet Technology. Mater. Prot. 2018, 51, 5. [Google Scholar] [CrossRef]

- Cai, J.; Shi, X.; Song, J.; Song, J.; Jing, F.; Xiao, Q. Comprehensive performance test and analysis of graphene-enhanced chromium-free Dacromet coating. Corros. Rev. 2020, 38, 445–461. [Google Scholar] [CrossRef]

- Li, C.; Wei, J.; Chen, M.; Guan, X.; Yang, X.; Li, Z.; Ma, C.; Ye, X. Ultralow-temperature fabrication of chromium-free zinc-aluminum coatings based on polysilazane. Mater. Chem. Phys. 2022, 278, 125608. [Google Scholar] [CrossRef]

- Li, H.; Zhao, J.; Dai, G.; Han, J.; Li, X. Impact of Sodium Molybdate Content on Properties of Chromium-free Zinc-Aluminum Coatings. Mater. Rep. 2020, 34, 2105–2109. [Google Scholar] [CrossRef]

- Li, X.; Hui, H.; Zhao, J.; Wu, G.; Dai, G. Effect of MWCNTs Content on Corrosion Resistance of Chromium-free Zinc-aluminum Coatings. J. Chin. Soc. Corros. Prot. 2022, 42, 324–330. [Google Scholar] [CrossRef]

- Li, X.; Wang, T.; Wei, G.; Zhang, J.; Ning, K.; Wang, J. Dispersion of Carbon Nanotubes and its Research Progress in Anti-corrosion Coatings. Paint. Coat. Ind. 2022, 52, 68–76. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, Y.; Zheng, X.; Lai, X.; Jia, R.; Yuan, X. Graphene oxide modified by zirconium dioxide to enhance the corrosion resistance of Zinc/Aluminum coatings—ScienceDirect. Diam. Relat. Mater. 2020, 108, 107868. [Google Scholar] [CrossRef]

- Wang, N.; Liu, C.; Wang, Y.; Chen, H.; Chu, X.; Gao, J. Effect of Process Parameters on Properties of Cold-Sprayed Zn-Al Composite Coatings. Materials 2022, 15, 7007. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P. Electrochemical Investigation of the Synergistic Effect Between Molybdate and Tungstate on Surface Passivation of Carbon Steel. Int. J. Electrochem. Sci. 2021, 16, 151027. [Google Scholar] [CrossRef]

- Li, H.; Bai, X.; Zhai, X.; Zhao, J.; Zhu, X.; Li, C.; Liu, K.; Wang, Q. Research on extension evaluation method of mudslide hazard based on analytic hierarchy Process–Criteria importance through intercriteria correlation combination assignment of game theory ideas. Water 2023, 15, 2961. [Google Scholar] [CrossRef]

- Geping, W.; Haojie, R.; Cheng, Q.; Wei, F.; Gongjin, Y.; Guangyu, W. Assessment method for wind-resistance resilience of power grid based on extension analytic hierarchy process. Int. J. Ind. Syst. Eng. 2021, 38, 116949. [Google Scholar] [CrossRef]

- Jing-Song, X.U. Seismic risk evaluation for a planning mountain tunnel using improved analytical hierarchy process based on extension theory. J. Mt. Sci. 2020, 17, 244–260. [Google Scholar] [CrossRef]

- Wei, W. Kinematics Simulation Modeling and Implementation of Cnc Machine Tool Based on Fuzzy Extension Analytic Hierarchy Process. In Proceedings of the 2019 International Conference on Information Science, Medical and Health Informatics(ISMHI 2019), Paris, France, 21–23 November 2019; p. 6. [Google Scholar] [CrossRef]

- Shi, J.; Li, W.; Zhu, Y.; Xv, L. Safety evaluation for cascade dams based on fuzzy extension analytic hierarchy process. Yellow River 2022, 53, 228–234. [Google Scholar] [CrossRef]

- Cheng, P.; Wang, L.; Zeng, T. Stability Analysis of Rock Slope in the Hydro-Fluctuation Bel Based on AHP-Extension Theory. Yellow River 2020, 42, 123–128+150. [Google Scholar] [CrossRef]

- Guo, Y.; Gong, S.; Kang, S.; Tao, X.; Lin, L.; Wu, D. Disease Evaluation of Existing Tunnel Lining Based on AHP-Extenics Model. Tunn. Constr. 2020, 40, 115–122. [Google Scholar] [CrossRef]

- Meng, J.; Lu, J.; Fan, J.; Lin, L.; Yang, G.; Gong, M. Comparison of corrosion between chromium-containing and chromium-free Zn–Al coatings in the existence of sulfate-reducing bacteria. Electroplat. Finish. 2022, 41, 1745–1753. [Google Scholar] [CrossRef]

- Li, H. Present Situation and Research Progress of Environment-friendly Dacromet Treatment Technology. Surf. Technol. 2023, 52, 115–123+140. [Google Scholar] [CrossRef]

- Chen, L.; Liu, X.; Gao, Q.; Zhong, M.; Bai, Y. Stability Evaluation of Bedding Rock Cutting Slope based on Ideal Point-extension Cloud Model. Highway 2023, 68, 38–45. [Google Scholar]

- Huang, R.; Tian, Z.; Lv, Y. Research on the Consistency of Interval Rough Number Reciprocal Judgment Matrix. Fuzzy Syst. Math. 2019, 33, 124–133. [Google Scholar]

- Du, X.; Nie, Y.; Lv, Y.; Qiu, S. A Method to Determine Weight of Decision Experts Based on Weighted Bidirectional Projection. Control Eng. China 2023, 30, 83–89. [Google Scholar] [CrossRef]

- Saaty, T.L.; Zhang, L. The Need for Adding Judgment in Bayesian Prediction. Int. J. Inf. Technol. Decis. Mak. 2016, 15, 733–761. [Google Scholar] [CrossRef]

- Mao, B. Study on the Preparation and Performance of Zinc-Aluminum Anticorrosive Coating on the Surface of Metal Parts. Master’ Thesis, Dalian University of Technology, Dalian, China, 2021. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, J.; Zhang, W.; Wang, D.; Huai, X.; Zhang, L. Impact of Zinc-aluminum Powder Content on Performance of Chrome-free Zinc-aluminum Coatings. Paint. Coat. Ind. 2023, 53, 14–19+26. [Google Scholar] [CrossRef]

- Wang, B.; Yu, J.; Wang, Y.; Jia, J.; Li, D.; Xiong, J. Effect of the modified zinc/aluminum powder on the corrosion resistance of chromium-free Dacromet coating. J. Beijing Univ. Chem. Technol. (Nat. Sci. Ed.) 2024, 51, 48–56. [Google Scholar] [CrossRef]

| Scale Value | Meaning |

|---|---|

| 1 | Both are equally important when compared. |

| 3 | The former is slightly more important than the latter when compared. |

| 5 | The former is significantly more important than the latter when compared. |

| 7 | The former is markedly more important than the latter when compared. |

| 9 | The former is exceedingly more important than the latter when compared. |

| Level | I | II | III | IV | V |

|---|---|---|---|---|---|

| Thickness (μm) | >10 | 9.5~10 | 9~9.5 | 8.5~9 | 8~8.5 |

| Hardness (H) | 9 | 8 | 7 | 6 | 5 |

| Spalling Area (%) | <5 | 5~15 | 15~35 | 35~65 | >65 |

| Saline Soaking Time (d) | <35 | 30~35 | 25~30 | 20~25 | <20 |

| Neutral Salt Fog Time (h) | >1200 | 1100~1200 | 1000~1100 | 900~1000 | <900 |

| Cost ($/kg) | <8.41 | 8.41~9.11 | 9.11~9.81 | 9.81~10.51 | >10.51 |

| Energy consumption (kw·h) | <230 | 230~240 | 240~250 | 250~260 | >260 |

| Level | I | II | III | IV | V |

|---|---|---|---|---|---|

| Score | 90~100 | 75~90 | 60~75 | 40~60 | 0~40 |

| Factor (%) | Zn-Al Powder (A) | PEG-400 (B) | KH-560 (C) | Molybdate (D) | |

|---|---|---|---|---|---|

| Level | |||||

| 1 | 25 | 15 | 10 | 2 | |

| 2 | 30 | 20 | 15 | 3 | |

| 3 | 35 | 25 | 20 | 4 | |

| Serial Number | Thickness (μm) | Hardness (H) | Spalling Area (%) | Saltwater Soak (d) | Salt Spray (h) | Cost ($/kg) | Energy Consumption (kw·h) |

|---|---|---|---|---|---|---|---|

| 1# | 9.6 | 7 | 3 | 32 | 1052 | 9.73 | 255.8 |

| 2# | 10.3 | 7 | 7 | 29 | 1040 | 10.35 | 251.4 |

| 3# | 10 | 8 | 9 | 32 | 970 | 9.39 | 236.2 |

| 4# | 9.9 | 7 | 4 | 31 | 1086 | 9.66 | 255.9 |

| 5# | 9.5 | 8 | 10 | 28 | 982 | 10.54 | 240.8 |

| 6# | 10.4 | 7 | 9 | 31 | 1050 | 10.03 | 248.6 |

| 7# | 8.1 | 8 | 8 | 29 | 1105 | 10.13 | 259 |

| 8# | 8.4 | 8 | 6 | 33 | 1003 | 9.58 | 253.1 |

| 9# | 8.8 | 7 | 6 | 29 | 974 | 9.82 | 233.6 |

| O-A | A1 | A2 | A3 | Weight |

|---|---|---|---|---|

| A1 | <1, 1> | <2, 4> | <5, 7> | 3.517 |

| A2 | <0.250, 0.500> | <1, 1> | <1, 6> | 3.529 |

| A3 | <1.393, 1.700> | <3.167, 6> | <7, 14> | 1.000 |

| A1-C | C1 | C2 | C3 | Weight |

|---|---|---|---|---|

| C1 | <1, 1> | <1.500, 2.500> | <3, 5> | 6.500 |

| C2 | <0.400, 0.667> | <1, 1> | <2, 4> | 7.600 |

| C3 | <0.200, 0.333> | <0.250, 0.500> | <1, 1> | 1.000 |

| A2-C | C4 | C5 | Weight |

|---|---|---|---|

| C4 | <1, 1> | <1, 8> | 2.921 |

| C5 | <0.125, 1> | <1, 1> | 1.000 |

| A3-C | C6 | C7 | Weight |

|---|---|---|---|

| C6 | <1, 1> | <2, 8> | 5.937 |

| C7 | <0.125, 0.500> | <1, 1> | 1.000 |

| O-A | A1-C | A2-C | A3-C | ||||

|---|---|---|---|---|---|---|---|

| x− | x+ | x− | x+ | x− | x+ | x− | x+ |

| 0.688 | 0.585 | 0.557 | 0.542 | 0.694 | 0.694 | 0.778 | 0.778 |

| 0.213 | 0.296 | 0.316 | 0.328 | 0.306 | 0.306 | 0.222 | 0.222 |

| 0.099 | 0.119 | 0.128 | 0.131 | ||||

| O-A | A1-C | A2-C | A3-C | |

|---|---|---|---|---|

| k | 0.819 | 0.916 | 0.782 | 0.882 |

| m | 1.155 | 1.011 | 1.179 | 1.106 |

| Thickness | Hardness | Spalling Area | Saltwater Soak | Salt Spray | Cost | Energy Consumption | |

|---|---|---|---|---|---|---|---|

| Weight | 0.188 | 0.220 | 0.029 | 0.327 | 0.112 | 0.106 | 0.018 |

| 1# | 78.00 | 67.50 | 94.00 | 81.00 | 67.80 | 62.70 | 48.40 |

| 2# | 100.00 | 67.50 | 87.00 | 72.00 | 66.00 | 46.00 | 52.70 |

| 3# | 100.00 | 82.50 | 84.00 | 81.00 | 54.00 | 69.90 | 80.70 |

| 4# | 87.00 | 67.50 | 92.00 | 78.00 | 72.90 | 64.20 | 48.20 |

| 5# | 75.00 | 82.50 | 82.50 | 69.00 | 56.40 | 40.80 | 60.30 |

| 6# | 100.00 | 67.50 | 84.00 | 78.00 | 67.50 | 55.20 | 62.10 |

| 7# | 8.00 | 82.50 | 85.50 | 72.00 | 75.75 | 52.40 | 41.50 |

| 8# | 32.00 | 82.50 | 88.50 | 84.00 | 40.60 | 66.00 | 50.53 |

| 9# | 52.00 | 67.50 | 88.50 | 72.00 | 54.80 | 60.90 | 84.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, F.; Xin, Y.; Tian, W.; Tang, Y.; Hou, L.; Gao, Y. Optimization of Formula for Chromium-Free Zinc–Aluminum Coatings Based on Extension Analytic Hierarchy Process. Appl. Sci. 2024, 14, 7476. https://doi.org/10.3390/app14177476

Zhu F, Xin Y, Tian W, Tang Y, Hou L, Gao Y. Optimization of Formula for Chromium-Free Zinc–Aluminum Coatings Based on Extension Analytic Hierarchy Process. Applied Sciences. 2024; 14(17):7476. https://doi.org/10.3390/app14177476

Chicago/Turabian StyleZhu, Fu, Yu Xin, Wei Tian, Yan Tang, Lin Hou, and Yuhang Gao. 2024. "Optimization of Formula for Chromium-Free Zinc–Aluminum Coatings Based on Extension Analytic Hierarchy Process" Applied Sciences 14, no. 17: 7476. https://doi.org/10.3390/app14177476

APA StyleZhu, F., Xin, Y., Tian, W., Tang, Y., Hou, L., & Gao, Y. (2024). Optimization of Formula for Chromium-Free Zinc–Aluminum Coatings Based on Extension Analytic Hierarchy Process. Applied Sciences, 14(17), 7476. https://doi.org/10.3390/app14177476