An Innovative Heating Solution for Sustainable Agriculture: A Feasibility Study on the Integration of Phase Change Materials as Passive Heating Elements

Abstract

1. Introduction

2. Materials and Methods

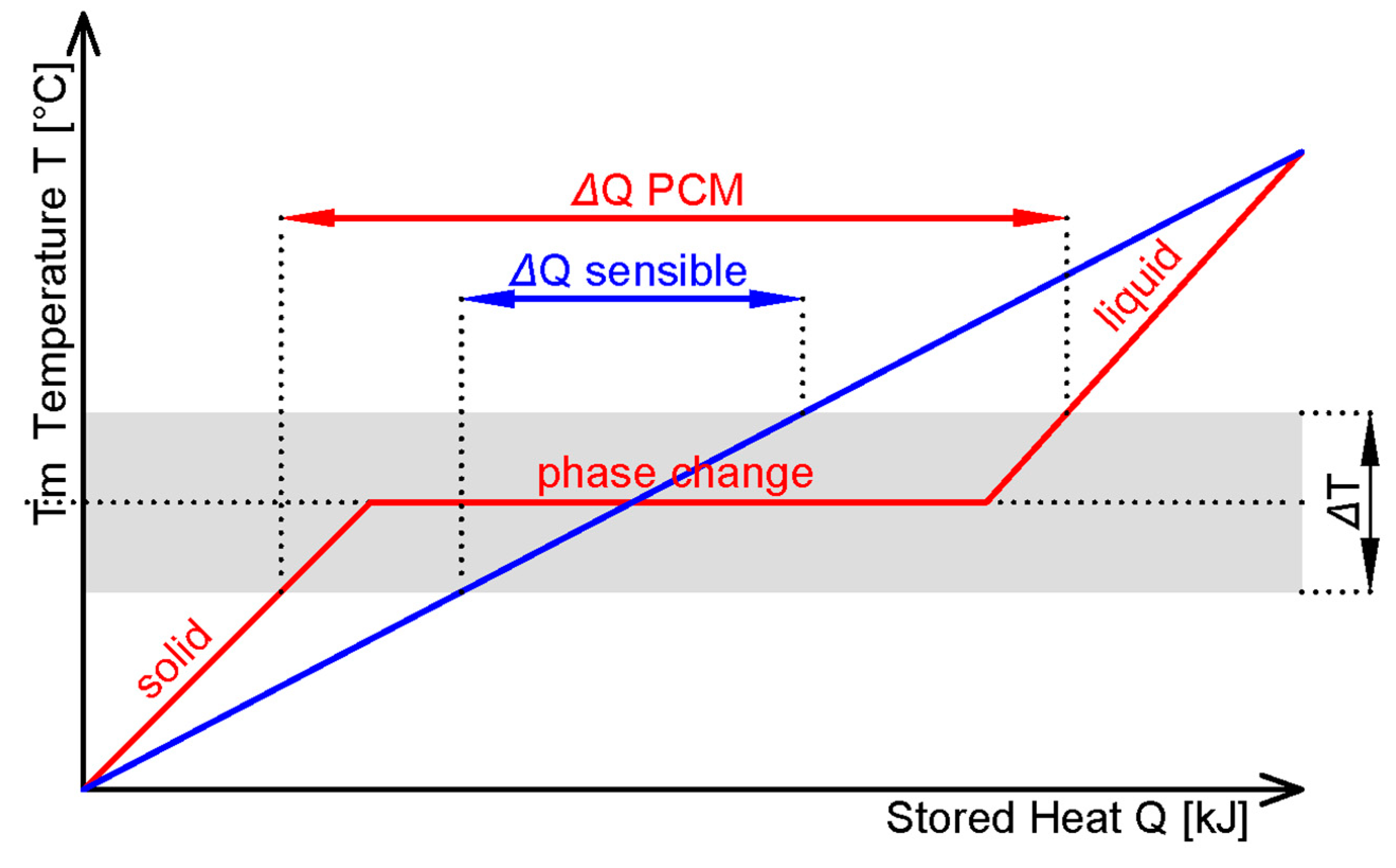

2.1. Phase Change Materials: The Basics

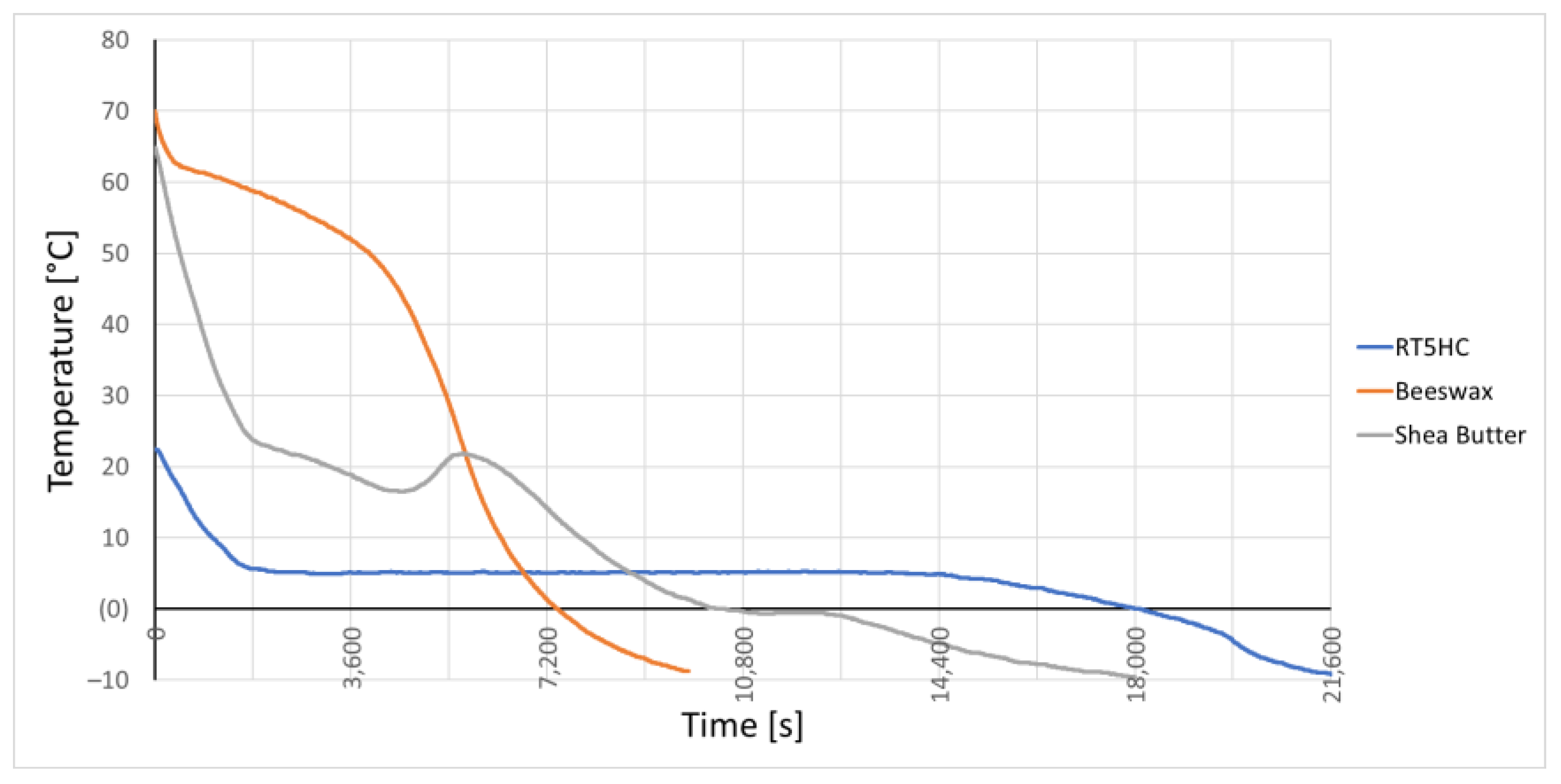

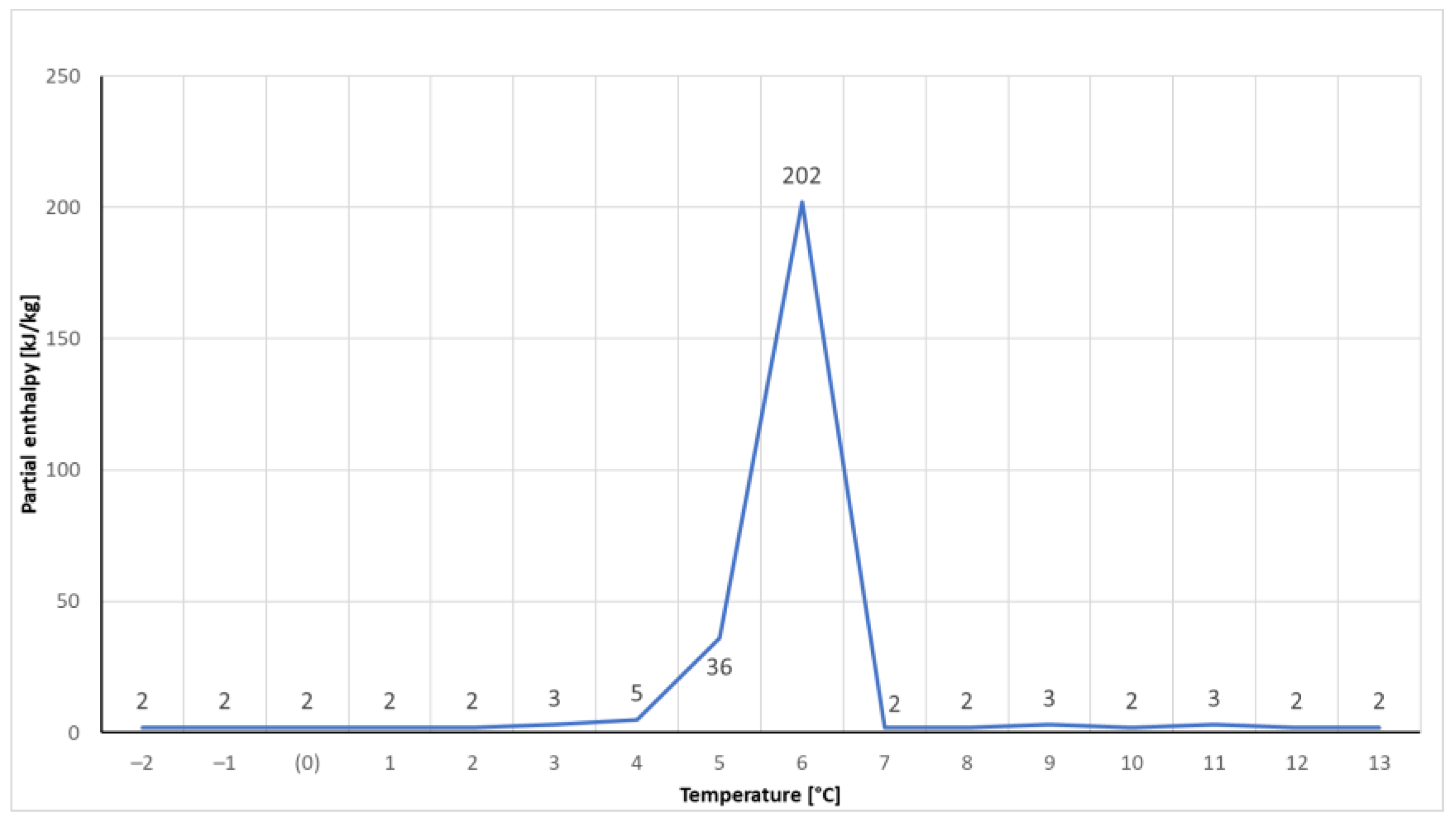

2.2. PCM Selection for Experimental Tests

- Operating temperature range;

- Availability of the material;

- Handling of the material;

- Environmental compatibility of the material.

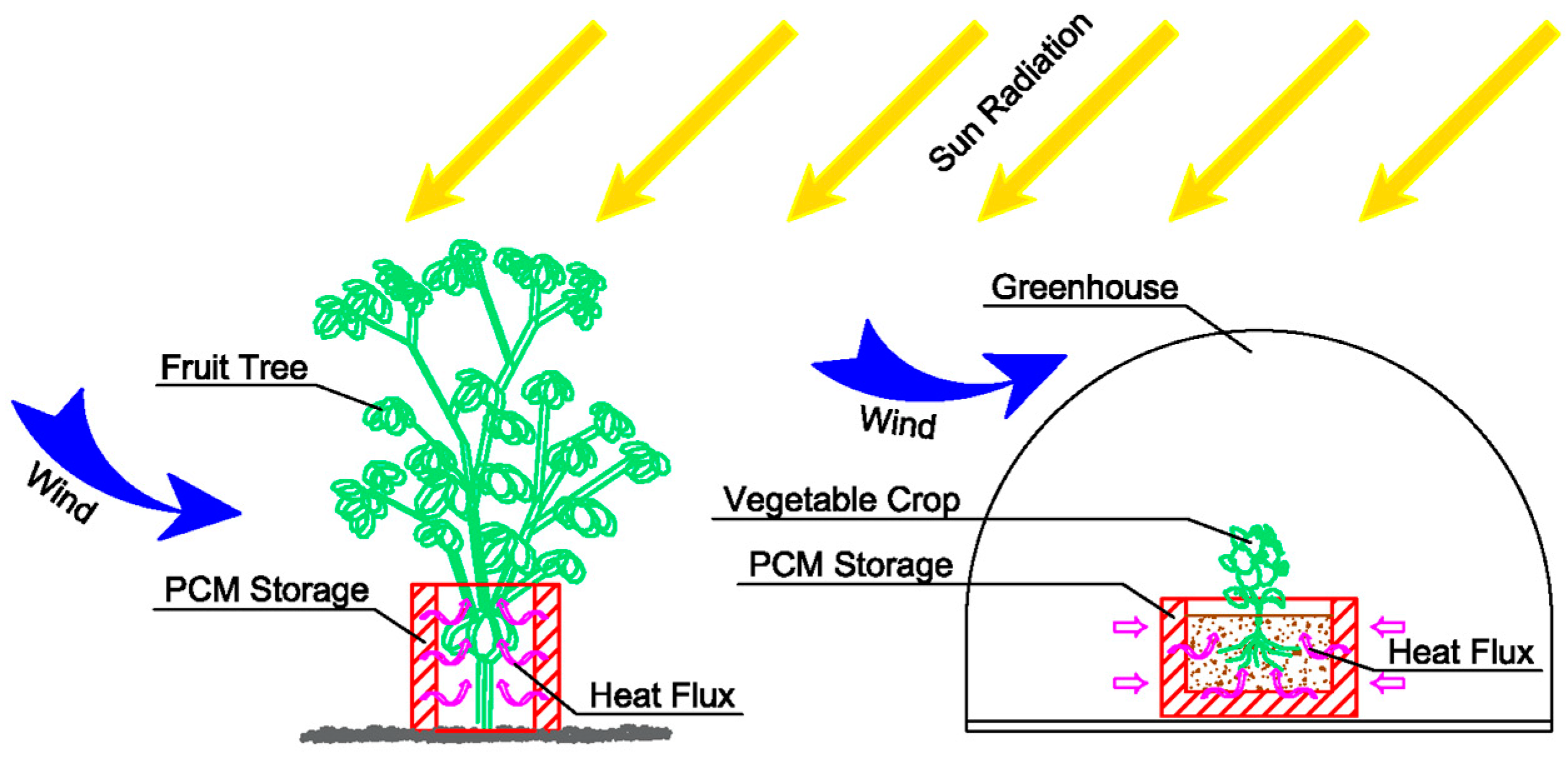

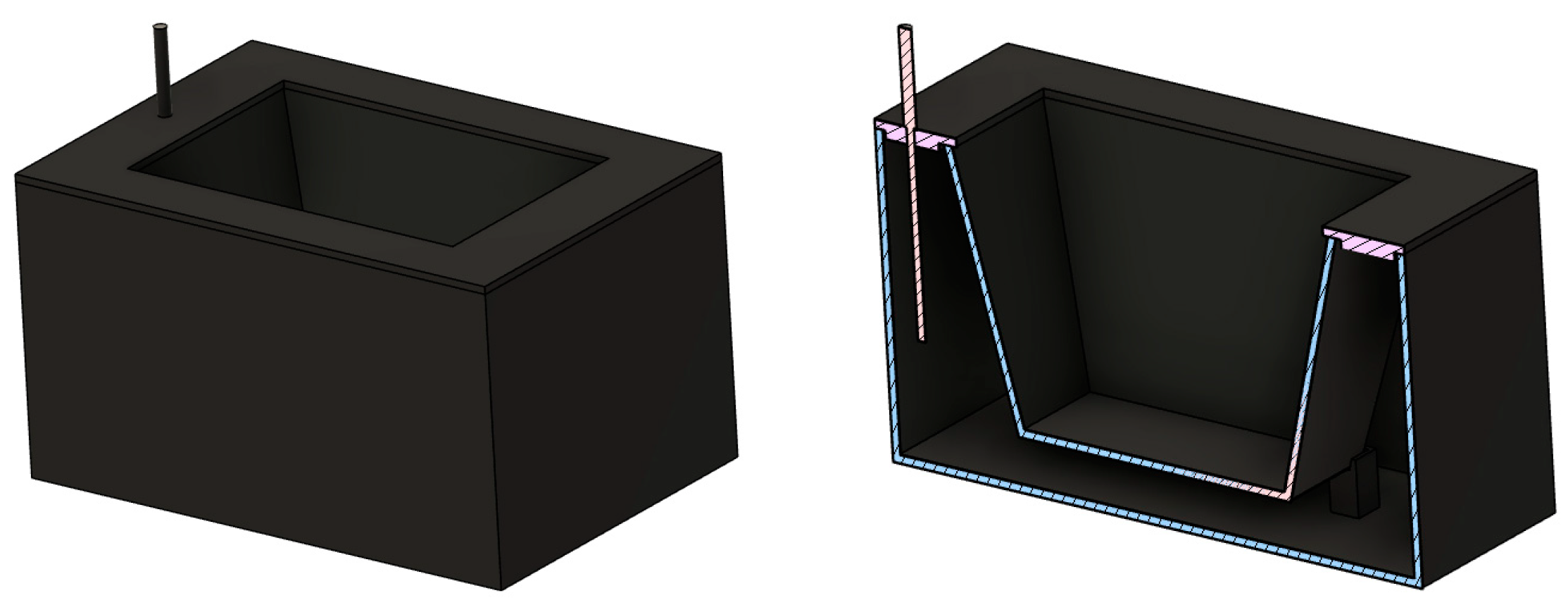

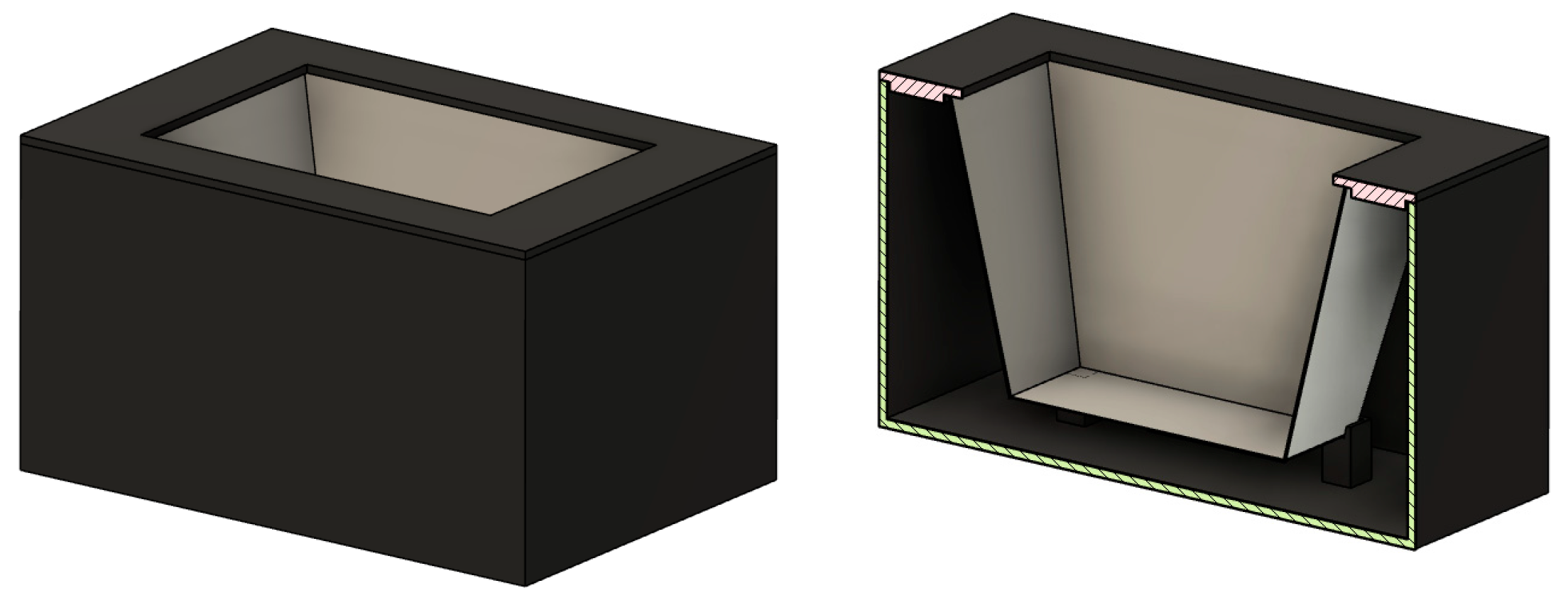

2.3. Movable Passive Heating Elements (Concepts) for Protection against Late Frost Events

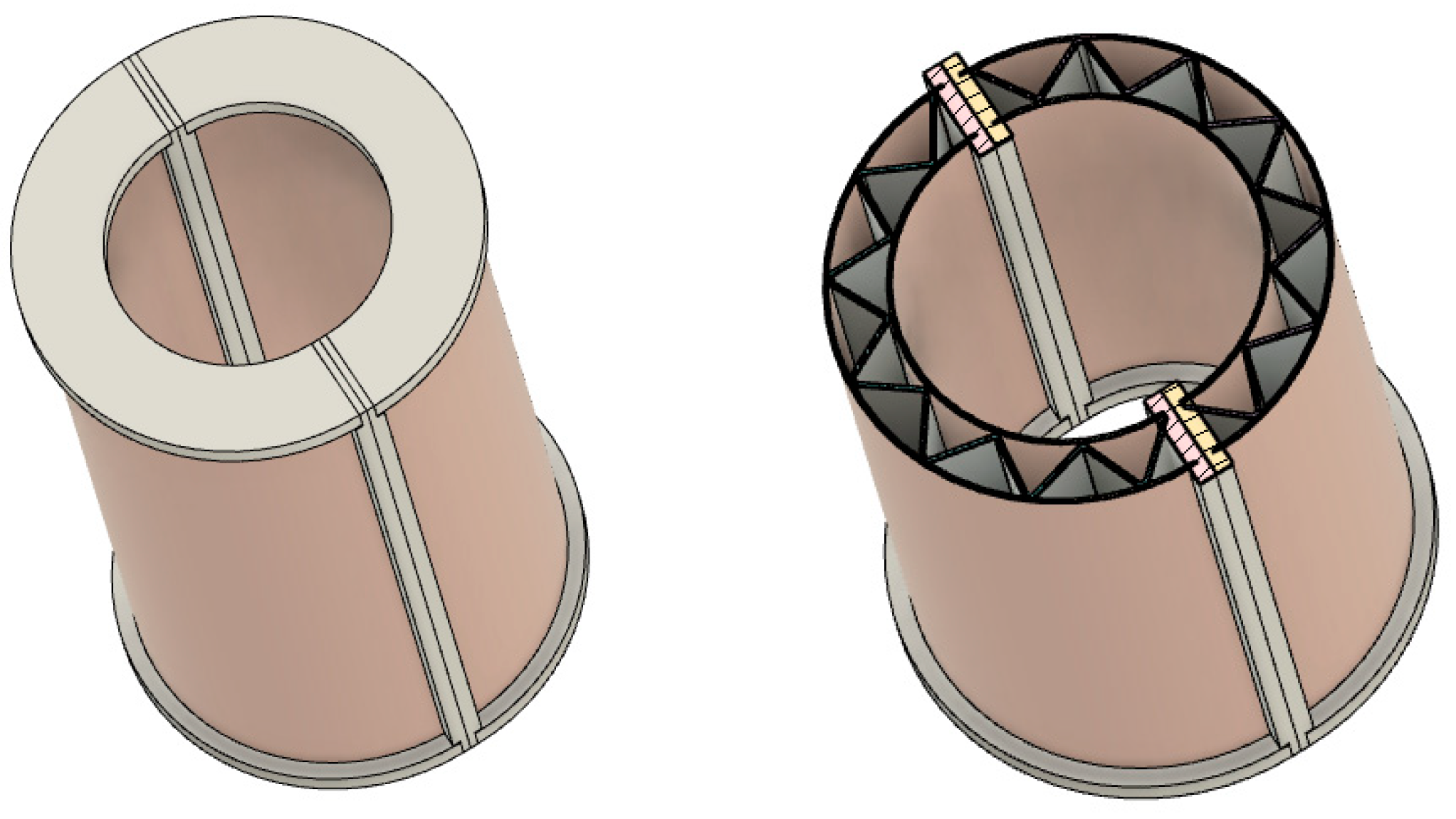

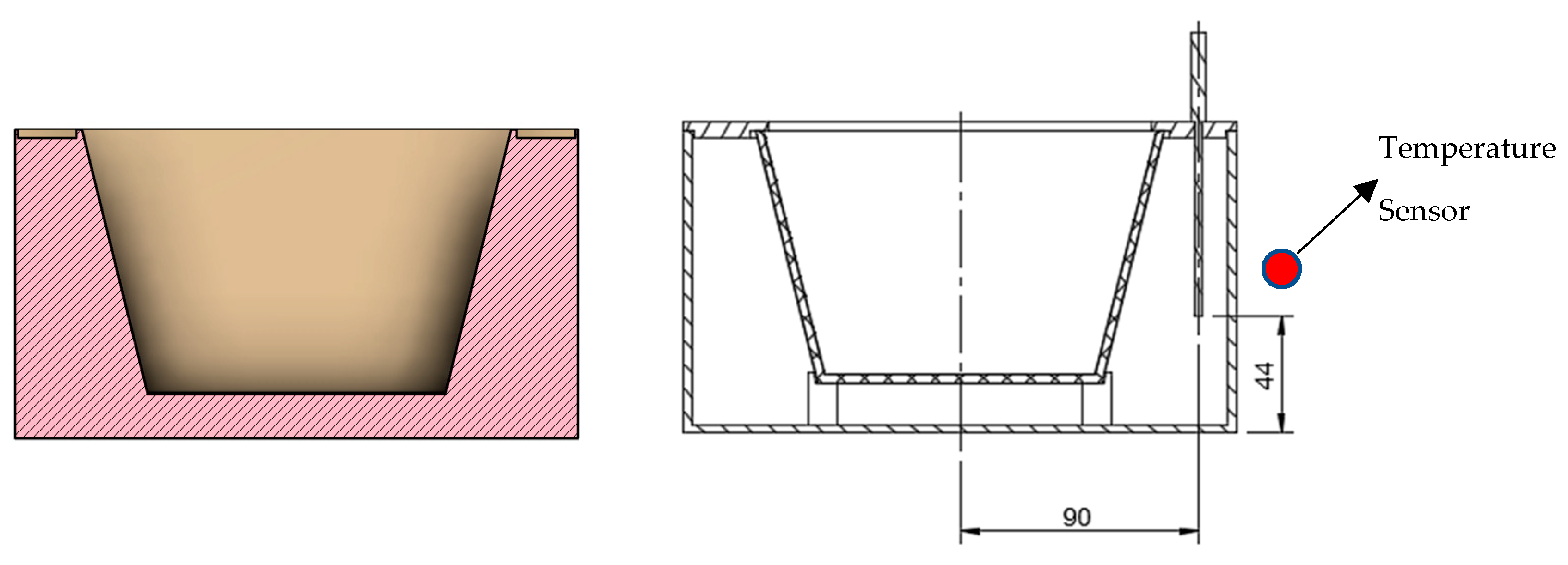

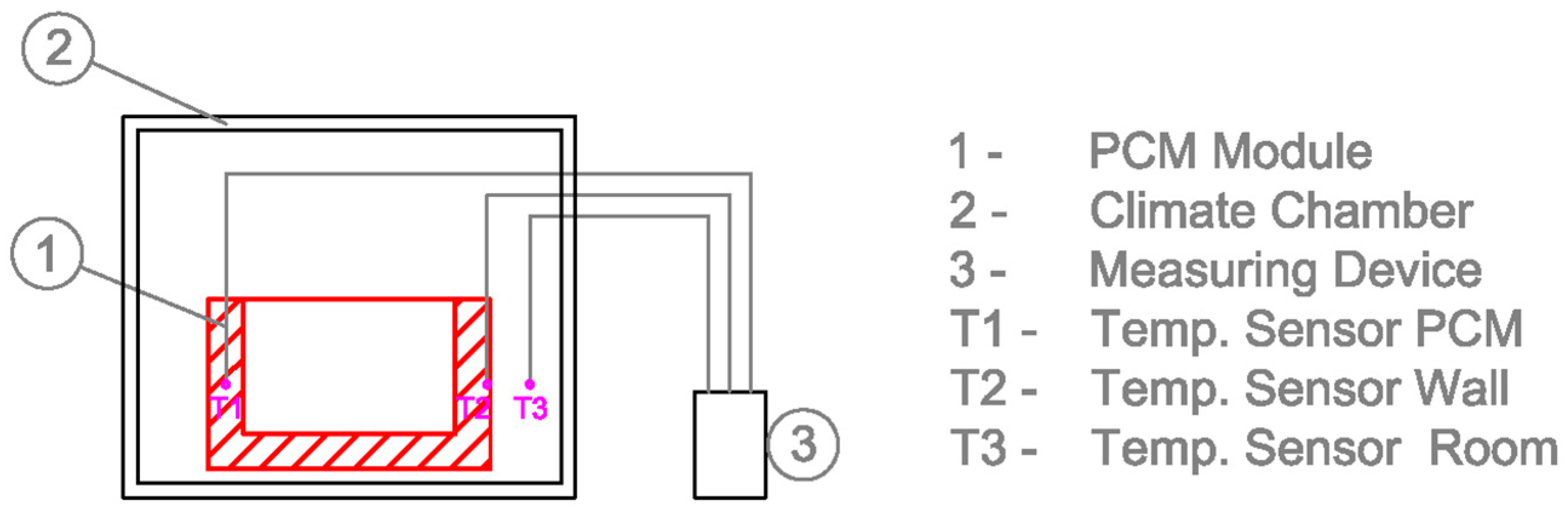

2.4. PCM-Based Temperature Control Module for Potted Plants: Fabrication and Test

3. Results

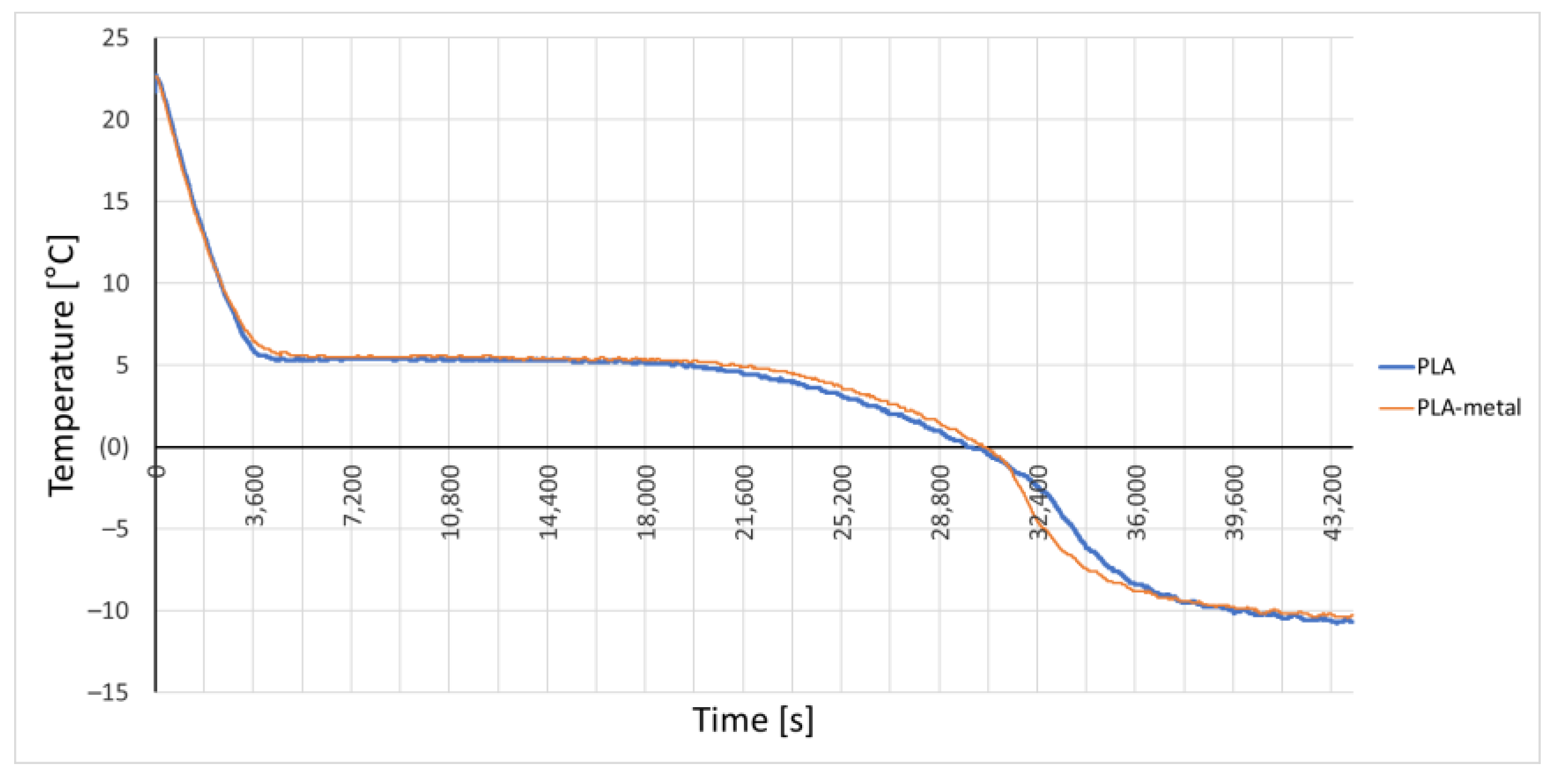

3.1. Potted Plant Protection Modules

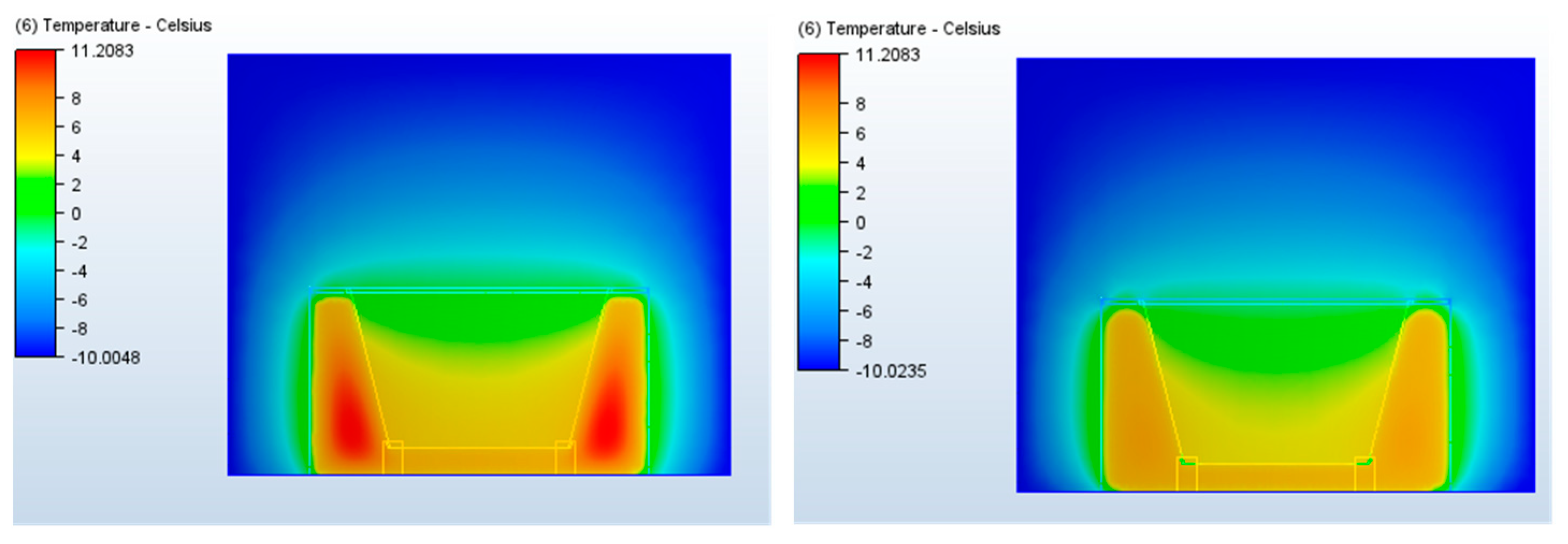

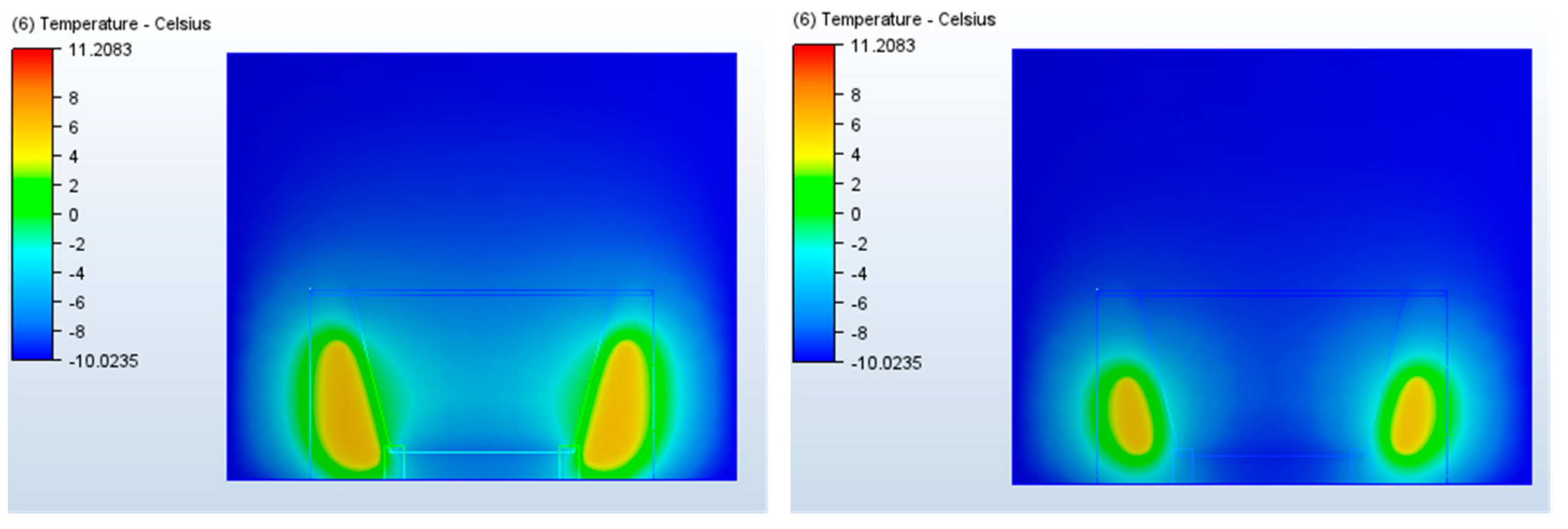

3.2. CFD Simulations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leindl, A.; Böck, M.B.U.E. Energie in Österreich—Zahlen, Daten, Fakten; Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation and Technologie: Wien, Austria, 2023. [Google Scholar]

- IEA. Organisation for Economic Co-Operation and Development. Available online: https://www.oecd.org/publications/harnessing-variable-renewables-9789264111394-en.htm (accessed on 4 June 2024).

- IEA. Global Status Report for Buildings and Construction. 2019. Available online: https://www.iea.org/reports/global-status-report-for-buildings-and-construction-2019 (accessed on 4 June 2024).

- Netafim Deutschland GmbH. Frostschutz Handbuch; Netafim: Frankfurt, Germany, 2017. [Google Scholar]

- Bundesanstalt für Landwirtschaft und Ernährung. Das Bundesinformationszentrum Landwirtschaft (BZL). Available online: https://www.praxis-agrar.de/pflanze/gartenbau/frostschutz-im-obstbau (accessed on 28 March 2024).

- Handschack, M. Komponenten der Ertragsbildung, Ertragsschwankungen and ihre Ursachen, Bekämpfung der Alternanz. In Physiologische Grundlagen des Obstanbaues; Ulmer: Stuttgart, Germany, 2000; pp. 210–227. [Google Scholar]

- Gosselin, A.; Trudel, M. Interactions between root-zone temperature and light levels on growth, development and photosynthesis of Lycopersicon esculentum Mill. cultivar ‘Vendor’. Sci. Hortic. 1984, 23, 313–321. [Google Scholar] [CrossRef]

- Adams, S.R.; Cockshull, K.E.; Cave, C.R.J. Effect of Temperature on the Growth and Development of Tomato Fruits. Ann. Bot. 2001, 88, 869–877. [Google Scholar] [CrossRef]

- Thompson, H.; Langhans, R.; Both, A.; Albright, L. Shoot and Root Temperature Effects on Lettuce Growth in a Floating Hydrophonic System. J. Am. Soc. Hortic. Sci. 1998, 123, 361–364. [Google Scholar] [CrossRef]

- Went, F. The Effect of Temperature on Plant Growth. Annu. Rev. Plant Physiol. 1953, 4, 347–362. [Google Scholar] [CrossRef]

- Wurm, L. Determination of the effictiveness of Frost Busters for frost protection for apricots. In Mitteilung Klosterneuburg, Rebe and Wein, Obstanbau and Früchteverwertung 60; Höhere Bundeslehranstalt and Bundesamt für Wein and Obstanbau Klosterneuburg: Klosterneuburg, Austria, 2010; pp. 106–107. [Google Scholar]

- Tsipouridis, C.; Thomidis, T.; Xatzicharisis, I. Effect of sprinkler irrigation systems on air temperatures and use of chemicals to protect cherry and peach trees from early spring frost. Aust. J. Exp. Agric. 2006, 46, 697–700. [Google Scholar] [CrossRef]

- Beyhan, B.; Paksoy, H.; Dasgan, Y. Root zone temperature control with thermal energy storage in phase change materials for soilless greenhouse applications. Energy Convers. Manag. 2013, 74, 446–453. [Google Scholar] [CrossRef]

- Kooli, S.; Bouadila, S.; Lazaar, M.; Farhat, A. The effect of nocturnal shutter on insulated greenhouse using a solar air heater with latent storage energy. Sol. Energy 2015, 115, 17–228. [Google Scholar] [CrossRef]

- Benli, H.; Durmus, A. Evaluation of ground-source heat pump combined latent heat storage system. Energy Build. 2009, 41, 220–228. [Google Scholar] [CrossRef]

- Kürklü, A. Energy storage applications in greenhouses by means of phase change materials (PCMs): A review. Renew. Energy 1998, 13, 89–103. [Google Scholar] [CrossRef]

- Benli, H.; Durmus, A. Performance analysis of a latent heat storage system with phase change material for new designed solar collectors in greenhouse heating. Sol. Energy 2009, 83, 2109–2119. [Google Scholar] [CrossRef]

- Najjar, A.; Hasan, A. Modeling of greenhouse with PCM energy storage. Energy Convers. Manag. 2008, 49, 3338–3342. [Google Scholar] [CrossRef]

- Berroug, F.; Lakhal, E.; El Omari, M.; Faraji, M.; El Qarnia, H. Thermal performance of a greenhouse with a phase change material north wall. Energy Build. 2011, 43, 3027–3035. [Google Scholar] [CrossRef]

- Llorach-Massana, P.; Pena, J.; Rieradevall, J.; Montero, J.I. Analysis of the technical, environmental and economic potential of phase change materials (PCM) for root zone heating in mediterranean greenhouses. Renew. Energy 2017, 103, 570–581. [Google Scholar] [CrossRef]

- Hauer, A.; Hiebler, S.; Reuß, M. Wärmespeicher; Fraunhofer IRB Verlag: Stuttgart, Germany, 2012. [Google Scholar]

- Rubitherm Technologies GmbH. Available online: https://www.rubitherm.eu/media/products/datasheets/Techdata_-RT5HC_DE_11032024.PDF (accessed on 8 April 2024).

- Rubitherm Technologies GmbH. Available online: https://www.rubitherm.eu/produktkategorien.html (accessed on 8 April 2024).

- Dax, W.; Drozd, N.; Gläse, W.-D.; Kotsch, G.; Kumler, B.; Laier, H.; Slaby, J.; Uhlemann, A.; Weiß, A.; Zeimer, K. Tabellenbuch für Metalltechnik; Verlag Handwerk and Technik GmbH: Hamburg, Germany, 2017. [Google Scholar]

- Snyder, R.; Melo-Abreu, J.P. Frost Protection: Fundamentals, Practice and Economics; Food and Agriculture Organization of the United Nations: Rome, Italy, 2005; Volume 1. [Google Scholar]

| SP15_gel | RT5HC | |

|---|---|---|

| Melting range [°C] | 15–17 | 5–6 |

| Congealing range [°C] | 15–13 | 6–5 |

| Heat storage capacity [kJ/kg] latent-sensible −2 °C to 13 °C | 160 44 | 250 70 |

| Specific heat capacity [kJ/kgK] | 2 | 2 |

| Density solid (at −15 °C) [kg/L] | 1.40 | 0.88 |

| Density liquid (at 20 °C) [kg/L] | 1.30 | 0.76 |

| Heat conductivity [W/mK] | 0.60 | 0.20 |

| Volume extension [%] | 7 | 13 |

| Flashpoint [°C] | - | 115 |

| Max. operation temperature [°C] | 30 | 45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thaler, S.M.; Zwatz, J.; Nicolay, P.; Hauser, R.; Lackner, R. An Innovative Heating Solution for Sustainable Agriculture: A Feasibility Study on the Integration of Phase Change Materials as Passive Heating Elements. Appl. Sci. 2024, 14, 7419. https://doi.org/10.3390/app14167419

Thaler SM, Zwatz J, Nicolay P, Hauser R, Lackner R. An Innovative Heating Solution for Sustainable Agriculture: A Feasibility Study on the Integration of Phase Change Materials as Passive Heating Elements. Applied Sciences. 2024; 14(16):7419. https://doi.org/10.3390/app14167419

Chicago/Turabian StyleThaler, Stephan M., Josef Zwatz, Pascal Nicolay, Robert Hauser, and Roman Lackner. 2024. "An Innovative Heating Solution for Sustainable Agriculture: A Feasibility Study on the Integration of Phase Change Materials as Passive Heating Elements" Applied Sciences 14, no. 16: 7419. https://doi.org/10.3390/app14167419

APA StyleThaler, S. M., Zwatz, J., Nicolay, P., Hauser, R., & Lackner, R. (2024). An Innovative Heating Solution for Sustainable Agriculture: A Feasibility Study on the Integration of Phase Change Materials as Passive Heating Elements. Applied Sciences, 14(16), 7419. https://doi.org/10.3390/app14167419