Preparation and Performance Characterization of Low-Density 3D-Printed Expanded Perlite–Foam Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Formulation Design and Preparation

2.3. Printing Parameters

2.4. Experimental Methods for Fresh 3DPFC

2.4.1. Flowability and Mini-Slump Testing

2.4.2. Rheological Testing

2.4.3. Constructability Evaluation

2.5. Experimental Plan for Hardened Foam–Perlite Concrete

2.5.1. Compressive Strength and Dry Density

2.5.2. Mercury Intrusion Porosimetry

2.5.3. SEM

2.5.4. Heat Resistance Performance

3. Results and Discussion

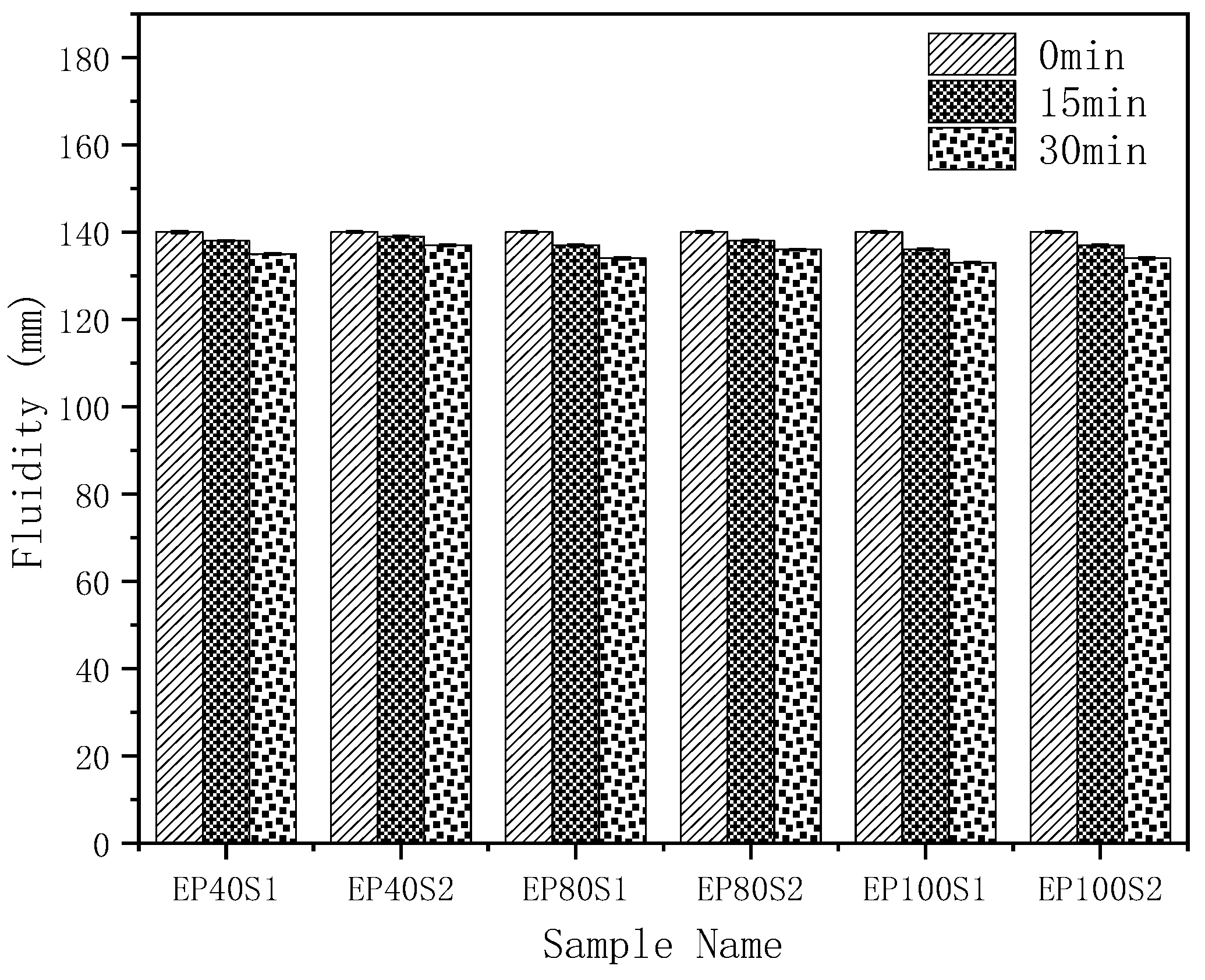

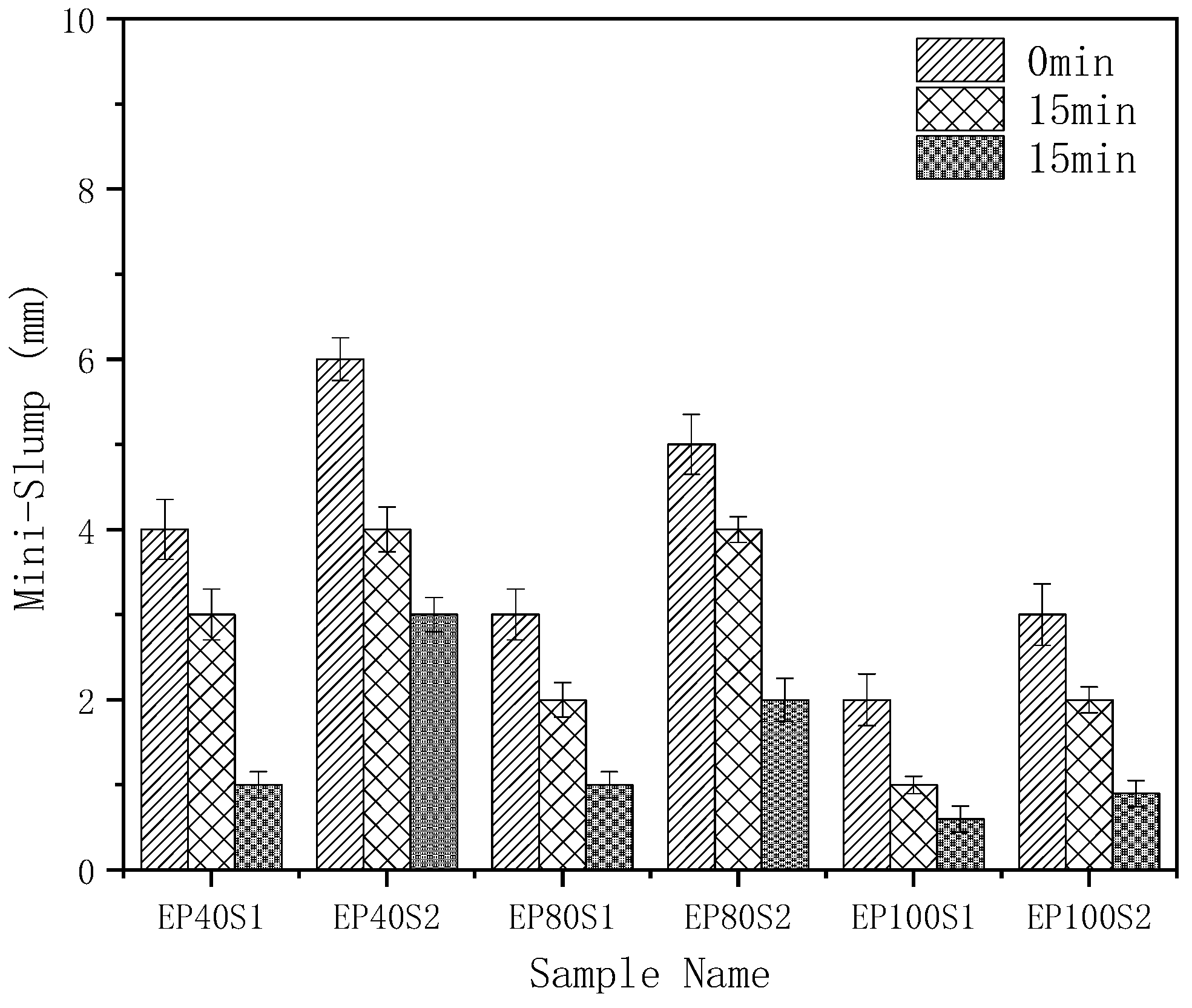

3.1. Flowability and Mini-Slump Testing

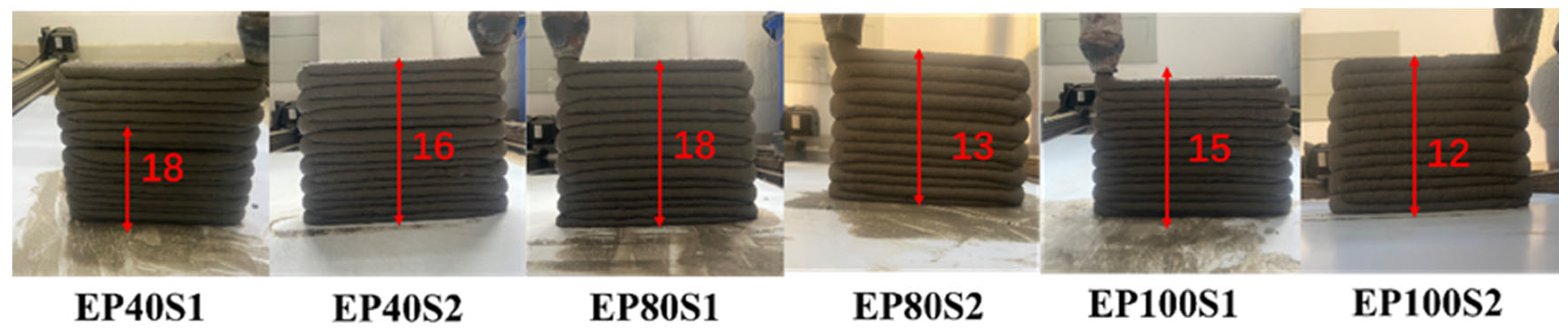

3.2. Constructability Testing

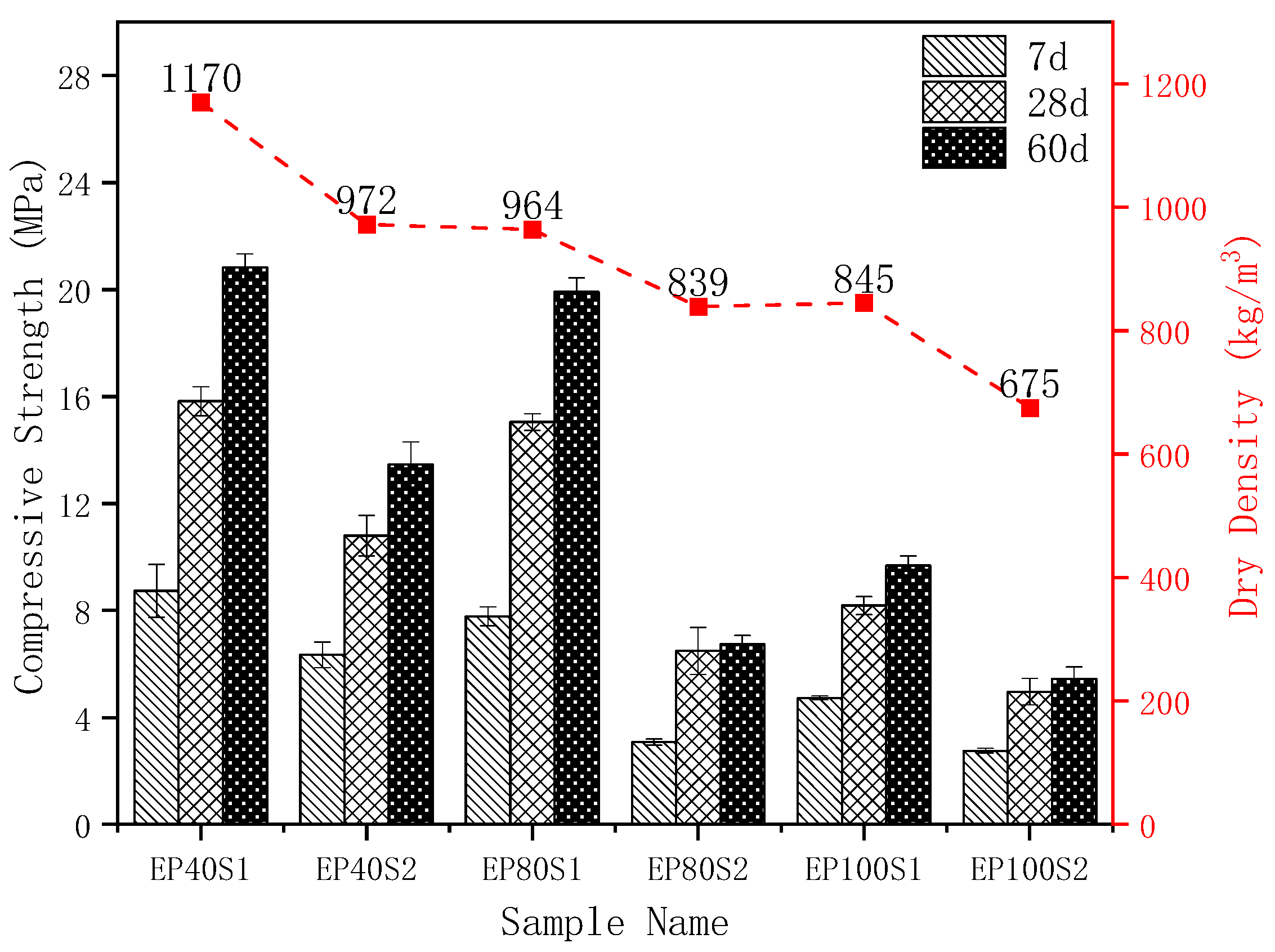

3.3. Compressive Strength and Dry Density

3.4. Heat Resistance Performance Testing

4. Mechanism Analyses

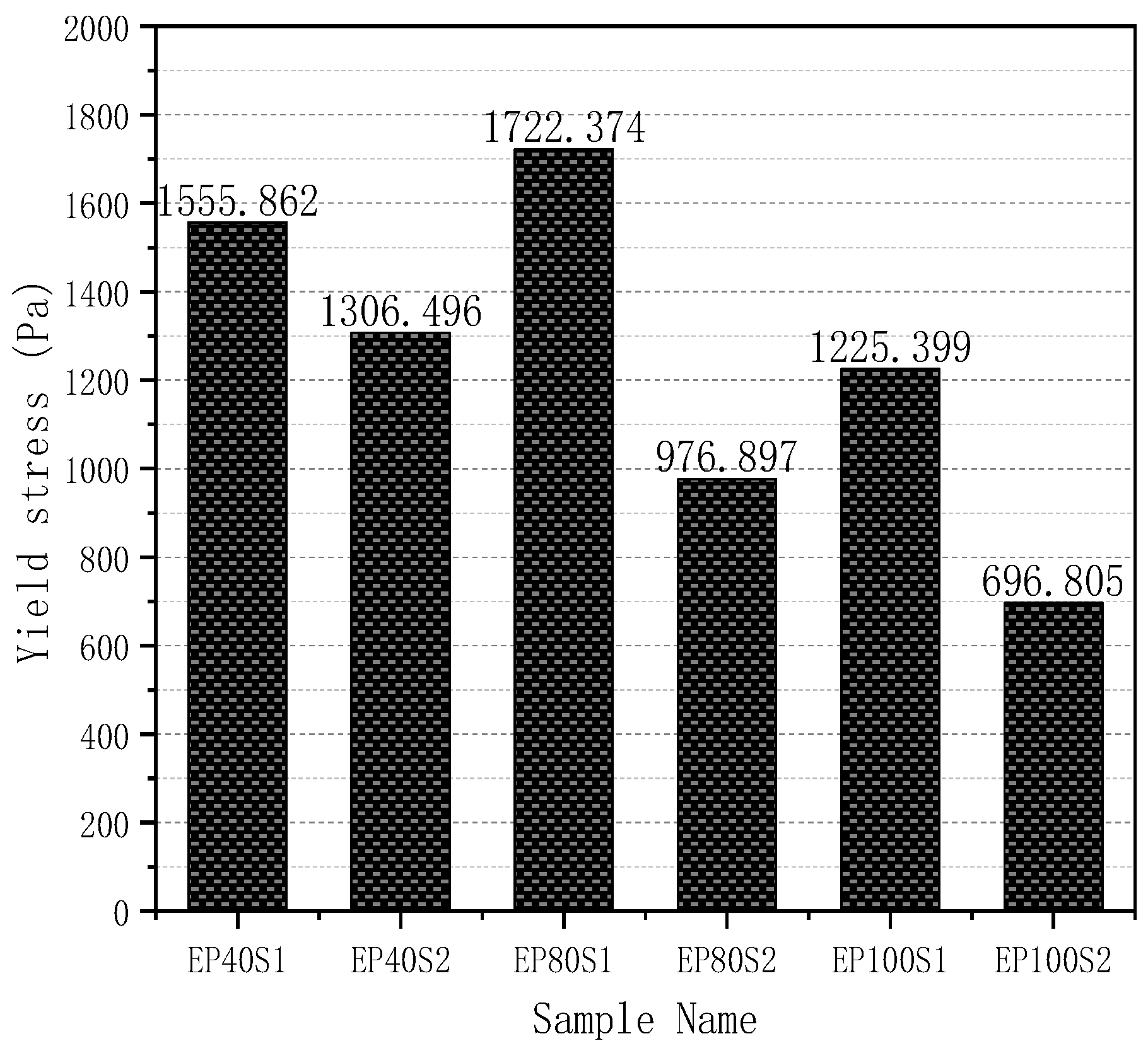

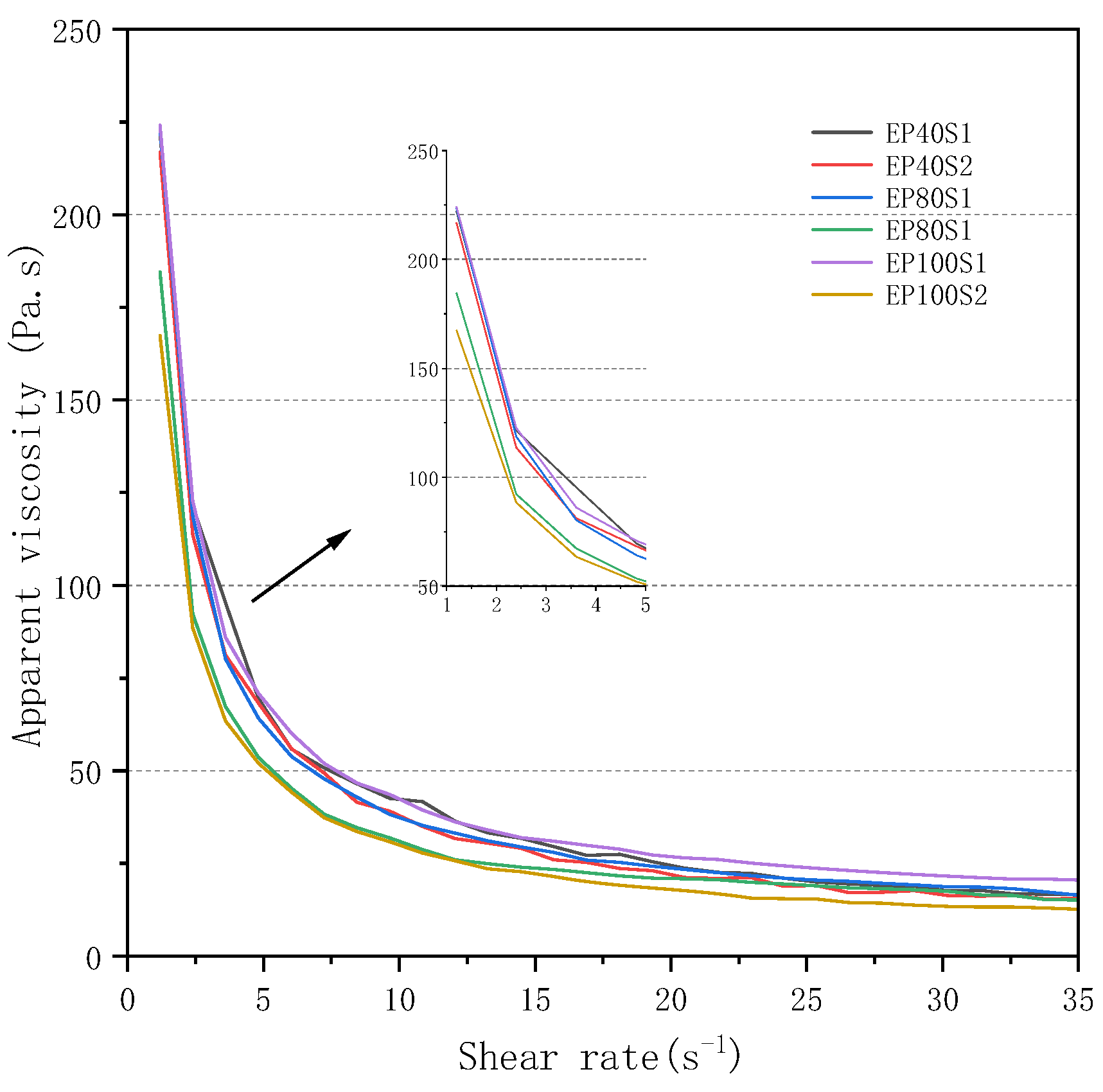

4.1. Rheological Analysis

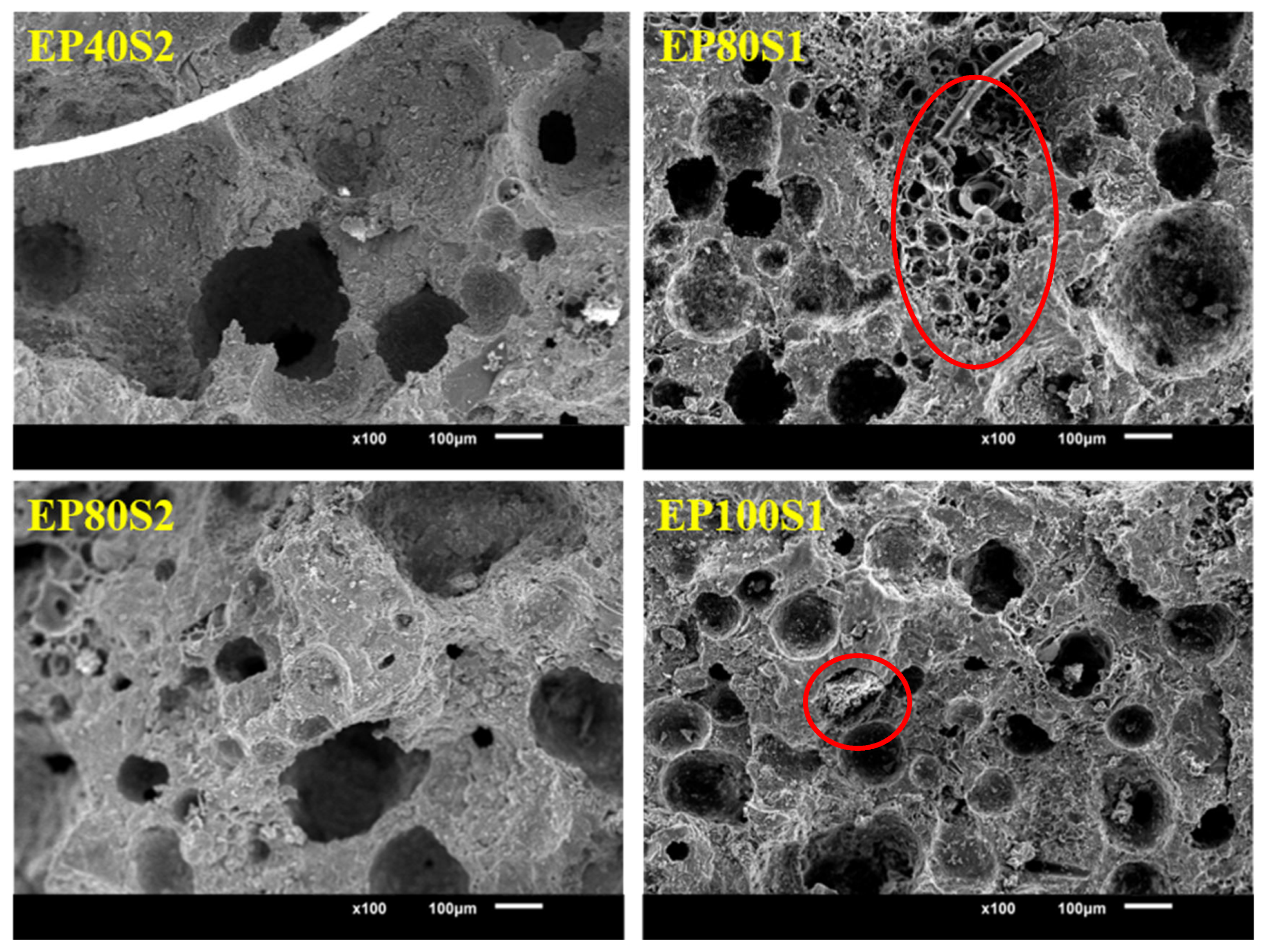

4.2. Pore Structure Analysis

4.3. SEM

5. Conclusions

- Introducing expanded perlite (EP) to replace river sand in 3DFC reduces its dry density and thermal conductivity. Higher perlite replacement ratios lead to superior mechanical performance within a similar density range.

- At similar densities, the group with higher perlite replacement ratios exhibits higher static yield stress and apparent viscosity. The addition of expanded perlite enhances the constructability of 3DFC.

- Higher perlite replacement ratios result in lower porosity and smaller pore sizes at similar densities.

- Expanded perlite reduces foam coalescence, maintaining smaller pore sizes and filling larger pores. This decreases the amount of large pores and the total porosity, thus enhancing strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jindal, B.B.; Sharma, R. The effect of nanomaterials on properties of geopolymers derived from industrial by-products: A state-of-the-art review. Constr. Build. Mater. 2020, 252, 119028. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Batikha, M.; Jotangia, R.; Baaj, M.Y.; Mousleh, I. 3D concrete printing for sustainable and economical construction: A comparative study. Autom. Constr. 2022, 134, 104087. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Dong, S.; Yu, X.; Han, B. A review of the current progress and application of 3D printed concrete. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105533. [Google Scholar] [CrossRef]

- Jindal, B.B.; Jangra, P. 3D Printed Concrete: A comprehensive review of raw material’s properties, synthesis, performance, and potential field applications. Constr. Build. Mater. 2023, 387, 131614. [Google Scholar] [CrossRef]

- Wrobel, R.; Mecrow, B. Additive manufacturing in construction of electrical machines–a review. In Proceedings of the 2019 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Athens, Greece, 22–23 April 2019; pp. 15–22. [Google Scholar]

- Du Plessis, A.; Babafemi, A.J.; Paul, S.C.; Panda, B.; Tran, J.P.; Broeckhoven, C. Biomimicry for 3D concrete printing: A review and perspective. Addit. Manuf. 2021, 38, 101823. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, H.; Ding, T. Finite element analysis on the anisotropic behavior of 3D printed concrete under compression and flexure. Addit. Manuf. 2021, 39, 101712. [Google Scholar] [CrossRef]

- Kruger, J.; du Plessis, A.; van Zijl, G. An investigation into the porosity of extrusion-based 3D printed concrete. Addit. Manuf. 2021, 37, 101740. [Google Scholar] [CrossRef]

- Lowke, D.; Talke, D.; Dressler, I.; Weger, D.; Gehlen, C.; Ostertag, C.; Rael, R. Particle bed 3D printing by selective cement activation–Applications, material and process technology. Cem. Concr. Res. 2020, 134, 106077. [Google Scholar] [CrossRef]

- Liu, Z.; Li, M.; Tay, Y.W.D.; Weng, Y.; Wong, T.N.; Tan, M.J. Rotation nozzle and numerical simulation of mass distribution at corners in 3D cementitious material printing. Addit. Manuf. 2020, 34, 101190. [Google Scholar] [CrossRef]

- Jones, S.Z.; Hipp, J.B.; Allen, A.J.; Gagnon, C.V. Rheology and microstructure development of hydrating tricalcium silicate-implications for additive manufacturing in construction. Cem. Concr. Res. 2022, 152, 106651. [Google Scholar] [CrossRef]

- Narayanan, N.; Ramamurthy, K. Structure and properties of aerated concrete: A review. Cem. Concr. Compos. 2000, 22, 321–329. [Google Scholar] [CrossRef]

- Concrete, A. Guide for Structural Lightweight; ACI: Indonesia, India, 1987. [Google Scholar]

- Ke, Y.; Beaucour, A.; Ortola, S.; Dumontet, H.; Cabrillac, R. Influence of volume fraction and characteristics of lightweight aggregates on the mechanical properties of concrete. Constr. Build. Mater. 2009, 23, 2821–2828. [Google Scholar] [CrossRef]

- Dinelli, G.; Belz, G.; Majorana, C.; Schrefler, B. Experimental investigation on the use of fly ash for lightweight precast structural elements. Mater. Struct. 1996, 29, 632–638. [Google Scholar] [CrossRef]

- Roberz, F.; Loonen, R.; Hoes, P.; Hensen, J. Ultra-lightweight concrete: Energy and comfort performance evaluation in relation to buildings with low and high thermal mass. Energy Build. 2017, 138, 432–442. [Google Scholar] [CrossRef]

- Real, S.; Gomes, M.G.; Rodrigues, A.M.; Bogas, J.A. Contribution of structural lightweight aggregate concrete to the reduction of thermal bridging effect in buildings. Constr. Build. Mater. 2016, 121, 460–470. [Google Scholar] [CrossRef]

- Jones, M.; McCarthy, A. Utilising unprocessed low-lime coal fly ash in foamed concrete. Fuel 2005, 84, 1398–1409. [Google Scholar] [CrossRef]

- Alnahhal, A.M.; Alengaram, U.J.; Yusoff, S.; Singh, R.; Radwan, M.K.; Deboucha, W. Synthesis of sustainable lightweight foamed concrete using palm oil fuel ash as a cement replacement material. J. Build. Eng. 2021, 35, 102047. [Google Scholar] [CrossRef]

- Alghamdi, H.; Neithalath, N. Synthesis and characterization of 3D-printable geopolymeric foams for thermally efficient building envelope materials. Cem. Concr. Compos. 2019, 104, 103377. [Google Scholar] [CrossRef]

- Dhasindrakrishna, K.; Ramakrishnan, S.; Pasupathy, K.; Sanjayan, J. Collapse of fresh foam concrete: Mechanisms and influencing parameters. Cem. Concr. Compos. 2021, 122, 104151. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. 3D-printable lightweight foamed concrete and comparison with classical foamed concrete in terms of fresh state properties and mechanical strength. Constr. Build. Mater. 2020, 254, 119271. [Google Scholar] [CrossRef]

- Markin, V.; Nerella, V.N.; Schröfl, C.; Guseynova, G.; Mechtcherine, V. Material design and performance evaluation of foam concrete for digital fabrication. Materials 2019, 12, 2433. [Google Scholar] [CrossRef] [PubMed]

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Enhancing the properties of foam concrete 3D printing using porous aggregates. Cem. Concr. Compos. 2022, 133, 104687. [Google Scholar] [CrossRef]

- Cho, S.; Kruger, J.; van Rooyen, A.; van Zijl, G. Rheology and application of buoyant foam concrete for digital fabrication. Compos. Part B Eng. 2021, 215, 108800. [Google Scholar] [CrossRef]

- Liu, C.; Wang, X.; Chen, Y.; Zhang, C.; Ma, L.; Deng, Z.; Chen, C.; Zhang, Y.; Pan, J.; Banthia, N. Influence of hydroxypropyl methylcellulose and silica fume on stability, rheological properties, and printability of 3D printing foam concrete. Cem. Concr. Compos. 2021, 122, 104158. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Feng, T.; Zhou, M.; Zhao, L.; Zhou, A.; Li, Z. Immobilizing bacteria in expanded perlite for the crack self-healing in concrete. Constr. Build. Mater. 2017, 148, 610–617. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, H.; Li, Z.; Ma, G. Mechanical behaviors of 3D printed lightweight concrete structure with hollow section. Arch. Civ. Mech. Eng. 2020, 20, 1–17. [Google Scholar]

- Gencel, O.; Bayraktar, O.Y.; Kaplan, G.; Arslan, O.; Nodehi, M.; Benli, A.; Gholampour, A.; Ozbakkaloglu, T. Lightweight foam concrete containing expanded perlite and glass sand: Physico-mechanical, durability, and insulation properties. Constr. Build. Mater. 2022, 320, 126187. [Google Scholar] [CrossRef]

- Jiang, L.; Lu, W.; Wang, W.; Zhang, Y.; Han, Q.; Li, Z. Mechanical properties and frost resistance of self-healing concrete based on expended perlite immobilized bacteria. Constr. Build. Mater. 2022, 348, 128652. [Google Scholar] [CrossRef]

- Schlaich, M.; Hückler, A. Infraleichtbeton: Reif für die Praxis. Beton-Und Stahlbetonbau 2017, 112, 772–783. [Google Scholar] [CrossRef]

- Cho, S.; Van Rooyen, A.; Kearsley, E.; Van Zijl, G. Foam stability of 3D printable foamed concrete. J. Build. Eng. 2022, 47, 103884. [Google Scholar] [CrossRef]

- Türkmen, İ.; Kantarci, A. Effects of Expanded Perlite Aggregate and Different Curing Conditions on the Drying Shrinkage of Self-Compacting Concrete; CSIR: New Delhi, India, 2006. [Google Scholar]

- Türkmen, İ.; Kantarcı, A. Effects of expanded perlite aggregate and different curing conditions on the physical and mechanical properties of self-compacting concrete. Build. Environ. 2007, 42, 2378–2383. [Google Scholar] [CrossRef]

- Karakoç, M.B.; Demirboga, R. HSC with expanded perlite aggregate at wet and dry curing conditions. J. Mater. Civ. Eng. 2010, 22, 1252–1259. [Google Scholar] [CrossRef]

- Oktay, H.; Yumrutaş, R.; Akpolat, A. Mechanical and thermophysical properties of lightweight aggregate concretes. Constr. Build. Mater. 2015, 96, 217–225. [Google Scholar] [CrossRef]

- Różycka, A.; Pichór, W. Effect of perlite waste addition on the properties of autoclaved aerated concrete. Constr. Build. Mater. 2016, 120, 65–71. [Google Scholar] [CrossRef]

- Rashad, A.M. A synopsis about perlite as building material–A best practice guide for Civil Engineer. Constr. Build. Mater. 2016, 121, 338–353. [Google Scholar] [CrossRef]

- Schumacher, K.; Saßmannshausen, N.; Pritzel, C.; Trettin, R. Lightweight aggregate concrete with an open structure and a porous matrix with an improved ratio of compressive strength to dry density. Constr. Build. Mater. 2020, 264, 120167. [Google Scholar] [CrossRef]

- Othman, R.; Jaya, R.P.; Muthusamy, K.; Sulaiman, M.; Duraisamy, Y.; Abdullah, M.M.A.B.; Przybył, A.; Sochacki, W.; Skrzypczak, T.; Vizureanu, P. Relation between density and compressive strength of foamed concrete. Materials 2021, 14, 2967. [Google Scholar] [CrossRef]

- Matalkah, F.; Ababneh, A.; Aqel, R. Synthesis of calcined kaolin-based geopolymer foam: Assessment of mechanical properties, thermal insulation, and elevated temperature stability. Ceram. Int. 2023, 49, 9967–9977. [Google Scholar] [CrossRef]

- Peng, X.; Shuai, Q.; Li, H.; Ding, Q.; Gu, Y.; Cheng, C.; Xu, Z. Fabrication and fireproofing performance of the coal fly ash-metakaolin-based geopolymer foams. Materials 2020, 13, 1750. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Q.; Zhou, D.; Khayat, K.H.; Feys, D.; Shi, C. On the measurement of evolution of structural build-up of cement paste with time by static yield stress test vs. small amplitude oscillatory shear test. Cem. Concr. Res. 2017, 99, 183–189. [Google Scholar] [CrossRef]

- Qian, Y.; Kawashima, S. Distinguishing dynamic and static yield stress of fresh cement mortars through thixotropy. Cem. Concr. Compos. 2018, 86, 288–296. [Google Scholar] [CrossRef]

| Component | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Na2O | K2O | TiO2 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 48.98 | 27.61 | 10.34 | 3.39 | 2.32 | 1.85 | 0.21 | 0.65 | 0.47 | 3.66 |

| Expanded perlite | 2.62 | 72.13 | 12.91 | 0.916 | 0.65 | 0.0388 | 5.99 | 2.88 | 0.164 | 1.42 |

| Name | Appearance | Particle Size | Bulk Density | Thermal Conductivity | Water Absorption Rate |

|---|---|---|---|---|---|

| Expanded perlite | White solid particles | 30–50 mesh | 240–300 kg/m3 | 0.070 W/(m·K) | 30% |

| Sample | Cement/g | Expanded Perlite/g | Sand/g | Surfactant/g | Slushing Agent/g | Thickener/g | W/C |

|---|---|---|---|---|---|---|---|

| EP40S1 | 100 | 8.75 | 72 | 1 | 0.2 | 0.1 | 0.43 |

| EP40S2 | 100 | 8.75 | 72 | 2 | 0.2 | 0.1 | 0.43 |

| EP80S1 | 100 | 17.5 | 24 | 1 | 0.2 | 0.1 | 0.45 |

| EP80S2 | 100 | 17.5 | 24 | 2 | 0.2 | 0.1 | 0.45 |

| EP100S1 | 100 | 21.875 | 0 | 1 | 0.2 | 0.1 | 0.46 |

| EP100S2 | 100 | 21.875 | 0 | 2 | 0.2 | 0.1 | 0.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, S.; Wang, Y.; Hua, S.; Yue, H.; Zhang, Y. Preparation and Performance Characterization of Low-Density 3D-Printed Expanded Perlite–Foam Concrete. Appl. Sci. 2024, 14, 6796. https://doi.org/10.3390/app14156796

Jiang S, Wang Y, Hua S, Yue H, Zhang Y. Preparation and Performance Characterization of Low-Density 3D-Printed Expanded Perlite–Foam Concrete. Applied Sciences. 2024; 14(15):6796. https://doi.org/10.3390/app14156796

Chicago/Turabian StyleJiang, Shangjin, Yuntao Wang, Sudong Hua, Hongfei Yue, and Yanan Zhang. 2024. "Preparation and Performance Characterization of Low-Density 3D-Printed Expanded Perlite–Foam Concrete" Applied Sciences 14, no. 15: 6796. https://doi.org/10.3390/app14156796

APA StyleJiang, S., Wang, Y., Hua, S., Yue, H., & Zhang, Y. (2024). Preparation and Performance Characterization of Low-Density 3D-Printed Expanded Perlite–Foam Concrete. Applied Sciences, 14(15), 6796. https://doi.org/10.3390/app14156796