Prediction of Grazing Incidence Focusing Mirror Imaging Quality Based on Accurate Modelling of the Surface Shape Accuracy for the Whole Assembly Process

Abstract

:1. Introduction

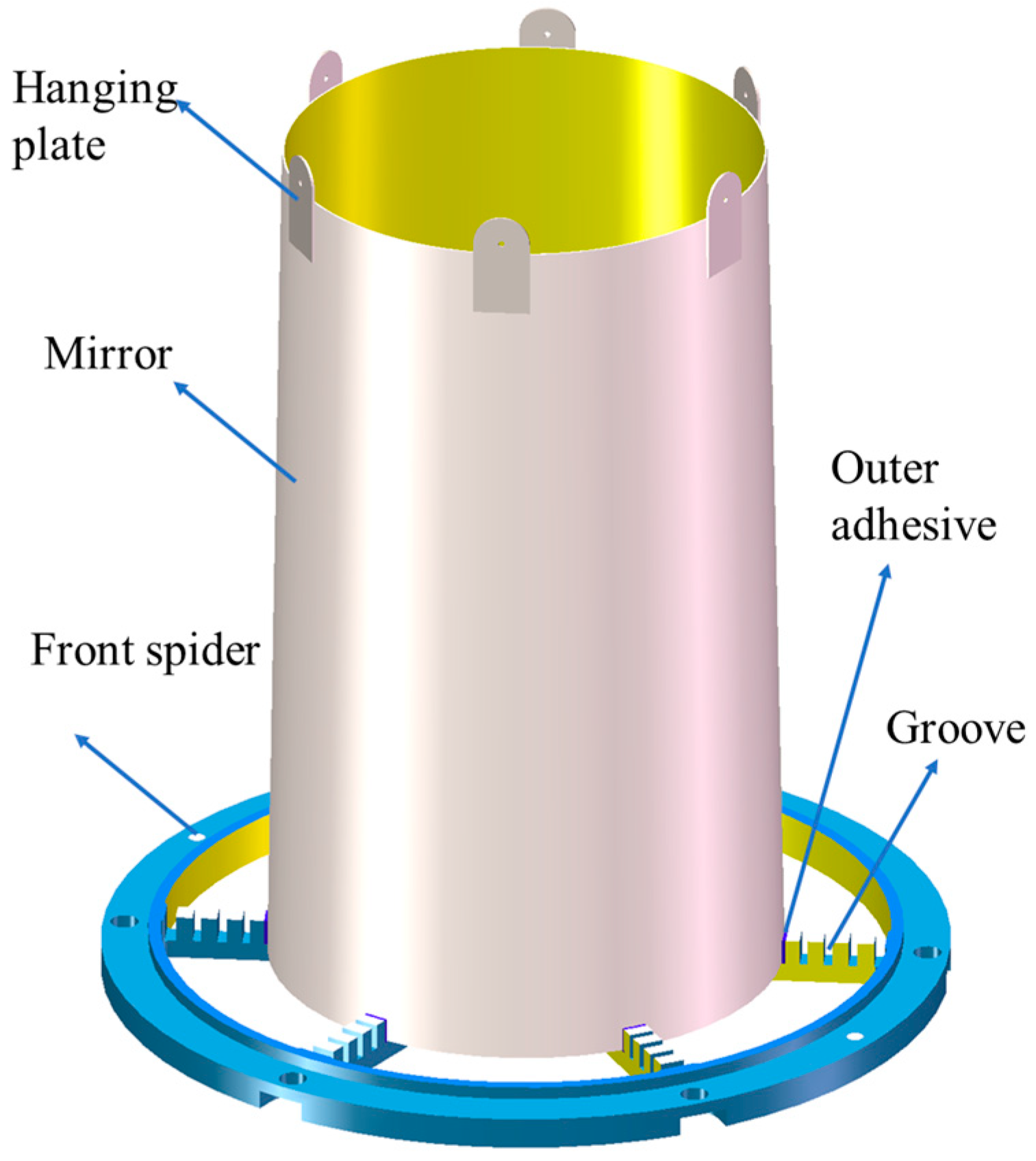

2. Assembly Process Modelling

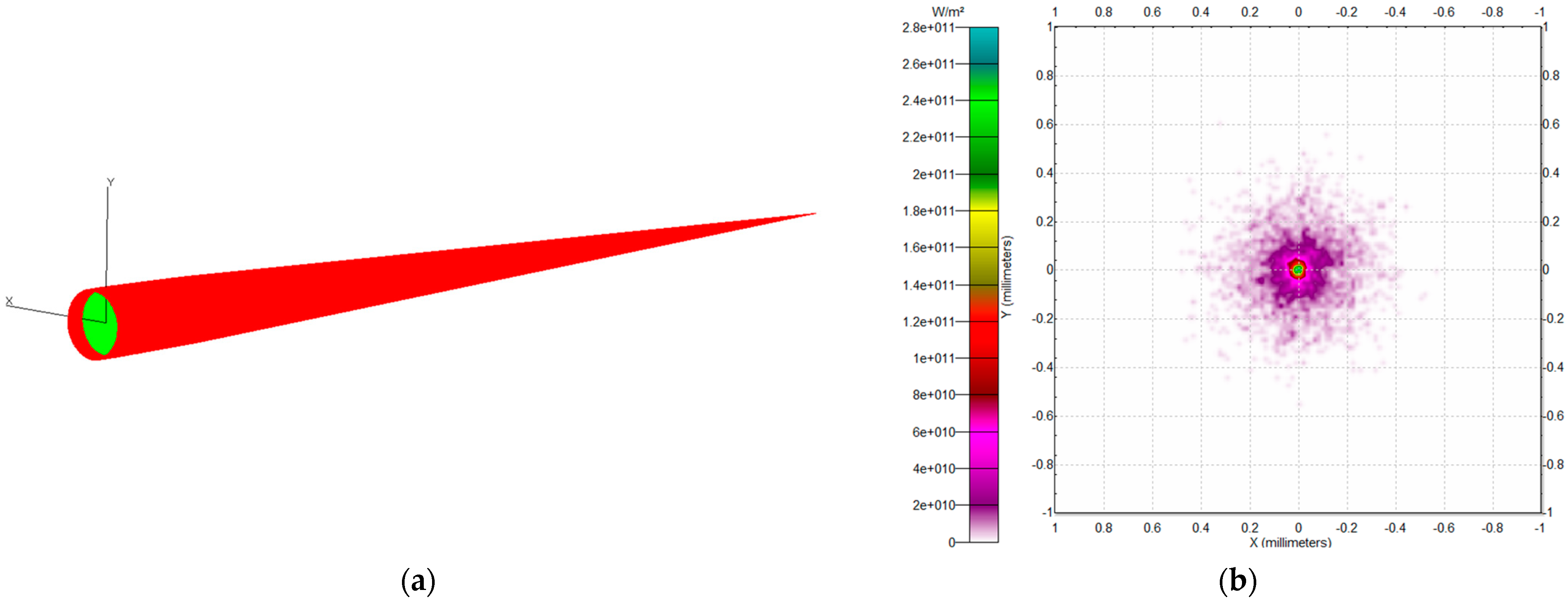

2.1. Pre-Assembly

2.2. During Assembly

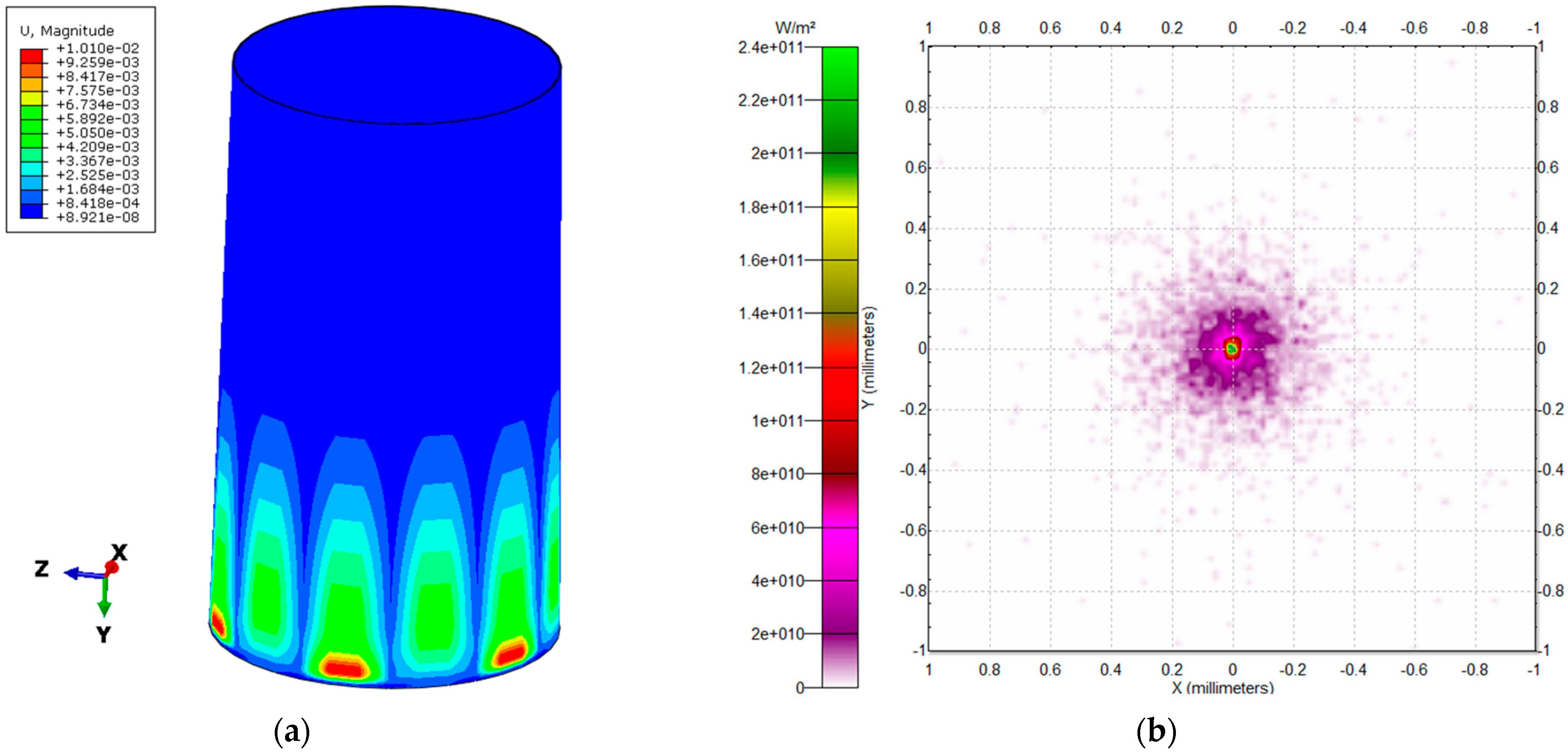

2.3. Post-Assembly

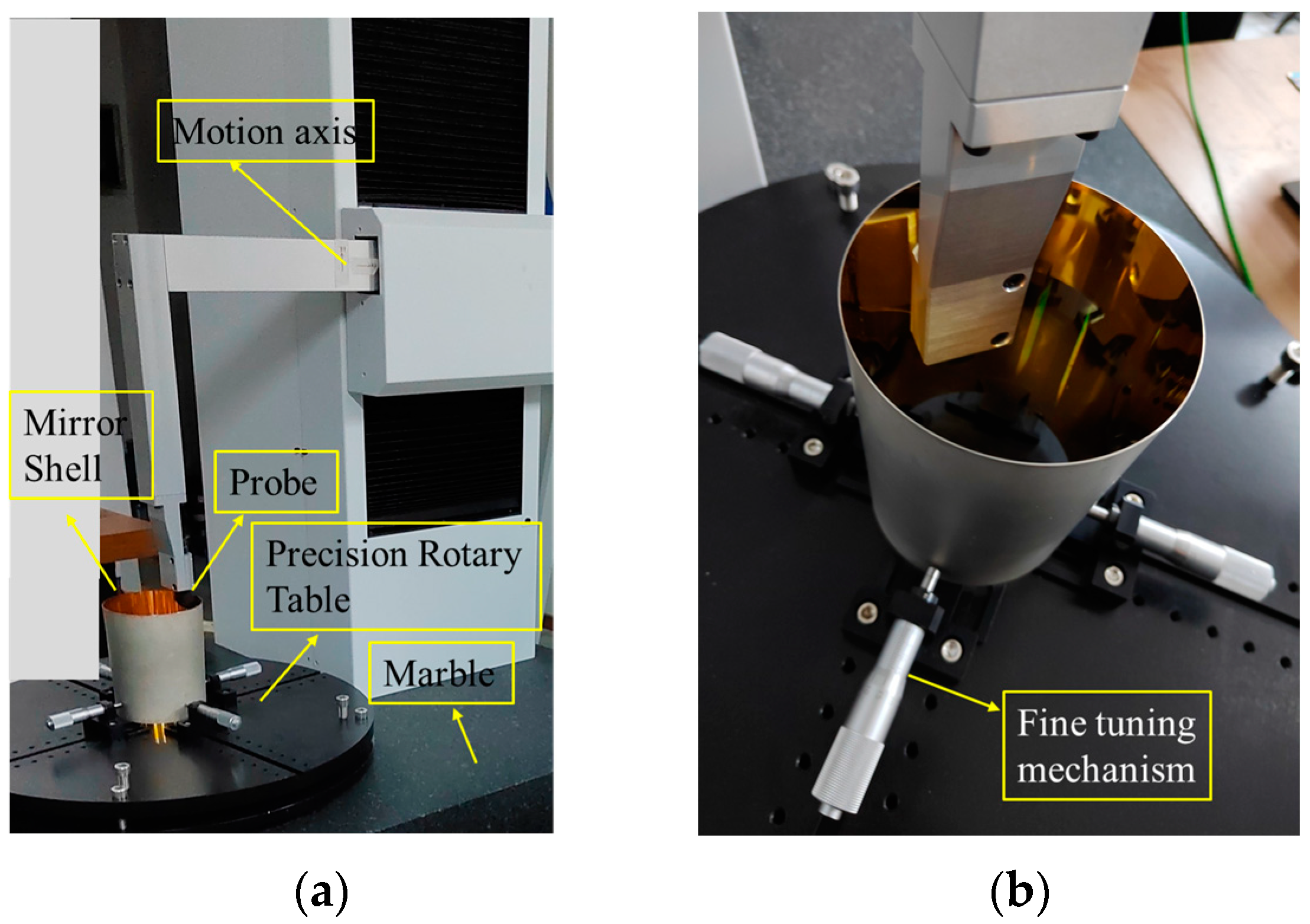

3. Experimental Verification

4. Discussion

4.1. Results of the Effect of Gravity

4.2. Results of the Effects of Post-Assembly Adhesive Curing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dong, L.Q.; Yang, L.X.; Su, Y.; Shan, R.Y. Development Trend of the Space X-Ray Detection Technology. Spacecr. Recover. Remote Sens. 2022, 43, 67–77. [Google Scholar]

- Civitani, M.M.; Parodi, G.; Vecchi, G.; Ghigo, M.; Basso, S.; Davis, J.M.; Elsner, R.F.; Kiranmayee, K.; Pareschi, G.; Swartz, D.; et al. Lynx x-ray optics based on thin monolithic shells: Design and development. J. Astron. Telesc. Instrum. Syst. 2019, 5, 021014. [Google Scholar] [CrossRef]

- Romaine, S.; Basso, S.; Bruni, R.J.; Burkert, W.; Citterio, O.; Conti, G.; Engelhaupt, D.; Freyberg, M.J.; Ghigo, M.; Gorenstein, P.; et al. Development of a Prototype Nickel Optic for the Constellation-X Hard x-Ray Telescope: IV. In Proceedings of the Space Telescopes and Instrumentation II: Ultraviolet to Gamma Ray, Orlando, FL, USA, 24–31 May 2006. [Google Scholar]

- Gubarev, M.; Ramsey, B.; O’Dell, S.L.; Elsner, R.; Kilaru, K.; McCracken, J.; Pavlinsky, M.; Tkachenko, A.; Lapshov, I.; Atkins, C.; et al. Development of Mirror Modules for the ART-XC Instrument Aboard the Spectrum-Roentgen-Gamma Mission. In Proceedings of the Optics for EUV, X-Ray, and Gamma-Ray Astronomy VI, San Diego, CA, USA, 26–29 August 2013. [Google Scholar]

- Friedrich, P.; Bräuninger, H.; Budau, B.; Burkert, W.; Eder, J.; Freyberg, M.J.; Hartner, G.; Mühlegger, M.; Predehl, P.; Erhard, M.; et al. Design and Development of the EROSITA X-Ray Mirrors. In Proceedings of the Space Telescopes and Instrumentation 2008: Ultraviolet to Gamma Ray, Marseille, France, 23–28 June 2008. [Google Scholar]

- Zuo, F.-C.; Mei, Z.-W.; Deng, L.-L.; Shi, Y.-Q.; He, Y.-B.; Li, L.-S.; Zhou, H.; Xie, J.; Zhang, H.-L.; Sun, Y. Development and in-orbit performance evaluation of multi-layered nested grazing incidence optics. Acta Phys. Sin. 2020, 69, 63–71. [Google Scholar] [CrossRef]

- Wang, B.; Yang, Y.-J.; Wang, D.-L.; Wang, L.-P.; Li, D.; Qiao, Z.; Ding, F.; Xue, J.-D.; Liao, Q.-Y. Ultra-precision manufacture of X-ray focusing mirror. Opt. Precis. Eng. 2021, 29, 1839–1846. [Google Scholar] [CrossRef]

- Sironi, G. Mandrels Manufacturing Processes for Ni Electroformed X-Ray Optics: Profile Errors Contribution to Imaging Degradation. In Proceedings of the Space Telescopes and Instrumentation 2008: Ultraviolet to Gamma Ray, Marseille, France, 23–28 June 2008. [Google Scholar]

- Wu, K.J.; Ding, F.; Wang, B.; Yang, Y.J.; Wang, Y.S.; Qiao, Z.; Li, D.; Jin, Y.; Qiang, P.F.; Zhao, Z.J.; et al. Simulation and an Experimental Study on the Optical Performance of a Wolter-I Focusing Mirror Based on a 3D Ray Tracing Algorithm. Opt. Express 2023, 31, 31533–31555. [Google Scholar] [CrossRef]

- Li, Y.M.; Deng, L.L.; Yang, J.; Tian, X.Y.; Zuo, F.C.; Shen, K.; Xie, J. Manufacturing Technology and Application Development of Electroformed Nickel Wolter-I Optical System. Aerosp. Control Appl. 2020, 46, 8–15. [Google Scholar]

- Zhang, J.W. CCD Data Processing for Dark Matter Experiments and Mounting of Domestically Produced X-Ray Focusing Mirrors. Master’s Thesis, Heilongjiang University, Harbin, China, 2020. [Google Scholar]

- Gubarev, M.V.; Ramsey, B.D.; Kester, T.; Speegle, C.O.; Engelhaupt, D.; Martin, G. Figure Measurements of High-Energy x-Ray Replicated Optics. In Proceedings of the Optics for EUV, X-Ray, and Gamma-Ray Astronomy, San Diego, CA, USA, 4–7 August 2004. [Google Scholar]

- Gubarev, M.; Ramsey, B.; Arnold, W. Alignment System for Full-Shell Replicated x-Ray Mirrors. In Proceedings of the EUV and X-Ray Optics: Synergy between Laboratory and Space, Prague, Czech Republic, 20–22 April 2009. [Google Scholar]

- Gubarev, M.; Arnold, W.; Benson, C.; Kester, T.; Lehner, D.; Ramsey, B.; Upton, R. Mounting and Alignment of Full-Shell Replicated x-Ray Optics. In Proceedings of the Optics for EUV, X-Ray, and Gamma-Ray Astronomy III, San Diego, CA, USA, 26–27 August 2007. [Google Scholar]

- Li, L.S.; Mei, Z.W.; Deng, L.L.; Lü, Z.X.; Liu, J.H.; Sun, J.B.; Sun, Y.; Zhou, H.; Zuo, F.C. Assembly Error Analysis and In-Orbit Verification of Grazing Incidence Focusing X-Ray Pulsar Telescope. J. Mech. Eng. 2018, 54, 49–60. [Google Scholar] [CrossRef]

- Ramsey, B.D.; Bongiorno, S.D.; Kolodziejczak, J.J.; Kilaru, K.; Alexander, C.; Baumgartner, W.H.; Breeding, S.; Elsner, R.F.; Le Roy, S.; McCracken, J.; et al. Optics for the imaging x-ray polarimetry explorer. J. Astron. Telesc. Instrum. Syst. 2022, 8, 024003. [Google Scholar] [CrossRef]

- Bongiorno, S.D.; Kolodziejczak, J.J.; Kilaru, K.; Eng, R.; Stahl, M.T.; Baumgartner, W.H.; Thomas, N.E.; Ranganathan, J.; Ramsey, B.D.; Tucker, J.M. Assembly of the IXPE Mirror Modules. In Proceedings of the Optics for EUV, X-Ray, and Gamma-Ray Astronomy X, San Diego, CA, USA, 1–5 August 2021. [Google Scholar]

- Roche, J.M.; Gubarev, M.V.; Smith, W.S.; O’Dell, S.L.; Kolodziejczak, J.J.; Weisskopf, M.C.; Ramsey, B.D.; Elsner, R.F. Mounting for Fabrication, Metrology, and Assembly of Full-Shell Grazing-Incidence Optics. In Proceedings of the Space Telescopes and Instrumentation 2014: Ultraviolet to Gamma Ray, Montréal, QC, Canada, 22–26 June 2014. [Google Scholar]

- Roche, J.M.; Kolodziejczak, J.J.; O’Dell, S.L.; Elsner, R.F.; Weisskopf, M.C.; Ramsey, B.; Gubarev, M.V. Opto-Mechanical Analyses for Performance Optimization of Lightweight Grazing-Incidence Mirrors. In Proceedings of the Optics for EUV, X-Ray, and Gamma-Ray Astronomy VI, San Diego, CA, USA, 26–29 August 2013. [Google Scholar]

- Li, L.S.; Qiang, P.F.; Sheng, L.Z.; Liu, Z.; Zhou, X.H.; Zhao, B.S.; Zhang, C.M. Development and Testing of Glass Substrate Wolter-1 X-Ray Focusing Mirror. Acta Phys. Sin. 2018, 67, 1–6. [Google Scholar]

- Civitani, M.M.; Basso, S.; Citterio, O.; Conconi, P.; Ghigo, M.; Pareschi, G.; Proserpio, L.; Salmaso, B.; Sironi, G.; Spiga, D.; et al. Accurate integration of segmented x-ray optics using interfacing ribs. Opt. Eng. 2013, 52, 091809. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Zhang, Y.; Yang, Y.J.; Chen, Y.; Wen, J. Numerical Study on Thermal Deformation of Wolter-I Focusing. Acta Photonica Sin. 2020, 49, 0512002. [Google Scholar] [CrossRef]

- Liu, J.; Yang, H.B.; Gong, Y.; Yuan, W.Q. Analysis of Surface Figure Error at Different Curing Time on Bonding Structure of Optical-Mechanical System. Opto-Electron. Eng. 2011, 38, 140–145. [Google Scholar]

- Li, W.J.; Wang, S.X.; Mu, Q.Q.; Yang, C.L.; Xuan, L. Using the Equivalent Stress to Analyze the Effect of Temperature Change on Surface Accuracy of the Bonded Mirror. Acta Photonica Sin. 2015, 44, 1212001. [Google Scholar]

- Dong, D.Y.; Li, Z.L.; Li, R.G.; Fan, Y.C.; Zhang, X.J. Simulation and Experiment of Influence of Adhesive Curing on Reflective Mirror Surface. Opt. Precis. Eng. 2014, 22, 2698–2707. [Google Scholar] [CrossRef]

- Hao, C.Y.; Qiu, S.H.; Pan, W.T.; Li, F.; Yan, Y.; Guan, X.F. Integrated Modeling and Simulation of X-Ray Focusing Telescope in Mounting Process. J. TONGJI Univ. 2020, 48, 602–609. [Google Scholar]

- Wang, S.; Yi, S.Z.; Wang, X.; Mu, B.Z. Analysis of X-Ray Focusing Telescope Structure Based on Finite Element Method. Opt. Instrum. 2015, 37, 441–446. [Google Scholar]

- Zhao, Z.J.; Wang, Y.; Zhang, L.Y.; Chen, C.; Ma, J. Experiments and Simulation of X-Ray Optical Wolter-I Focusing Mirror. Opt. Precis. Eng. 2019, 27, 2330–2336. [Google Scholar] [CrossRef]

- Liu, P.; Chen, B.; Zhang, Y.C.; He, L.P.; Wang, X.D. Imaging Quality Evaluation of Soft X-Ray Grazing Incidence Telescope. Opt. Precis. Eng. 2019, 27, 2136–2143. [Google Scholar]

- Mu, B.Z.; Liu, H.Y.; Jin, H.J.; Yang, X.J.; Wang, F.F.; Li, W.B.; Chen, H.; Wang, Z.S. Optimization of geometrical design of nested conical Wolter-I X-ray telescope. Chin. Opt. Lett. 2012, 10, 103401–103404. [Google Scholar] [CrossRef]

- Suszyński, M.; Peta, K.; Černohlávek, V.; Svoboda, M. Mechanical Assembly Sequence Determination Using Artificial Neural Networks Based on Selected DFA Rating Factors. Symmetry 2022, 14, 1013. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Z.; Jin, X.; Zhang, Q. A Novel Modelling Method of Geometric Errors for Precision Assembly. Int. J. Adv. Manuf. Technol. 2018, 94, 1139–1160. [Google Scholar] [CrossRef]

| Parameter | Rmax | Rmin | R0 | Mass | Thickness | Length |

|---|---|---|---|---|---|---|

| Value | 40.6683 mm | 38.1126 mm | 0.71909 mm | 0.12335 kg | 0.4 mm | 140 mm |

| Material | Young’s Modulus (Mpa) | Poisson’s Ratio | Density (t/mm3) | Equivalent Linear Expansion Coefficient (α/°C−1) |

|---|---|---|---|---|

| Hanging plate— Stainless Steel | 210,000 | 0.3 | 7.85 × 10−9 | 0 |

| Mirror—Ni | 207,000 | 0.31 | 8.9 × 10−9 | 0 |

| Adhesive—GHJ-01(Z) | 158.62 | 0.495 | 1.22 × 10−9 | 0.0066 |

| Front spider— Stainless Steel | 210,000 | 0.3 | 7.85 × 10−9 | 0 |

| Assembly Process | Angular Resolution |

|---|---|

| Standard surface (error-free) | 1.23″ |

| Standard surface with NURBS surface interpolation (error-free) | 1.51″ |

| Pre-assembly (with surface shape error) | 48.64″ |

| During assembly (three-hanging-point) | 51.37″ |

| During assembly (six-hanging-point) | 49.50″ |

| Post-assembly (after adhesive curing) | 52.23″ |

| Assembly Process | Simulation Results | Experimental Results |

|---|---|---|

| During assembly (three-hanging-point) | 51.37″ | 56.76″ |

| During assembly (six-hanging-point) | 49.50″ | 54.65″ |

| Post-assembly | 52.23″ | 58.86″ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, E.; Zhang, Z.; Li, C.; Zuo, F.; Mei, Z.; Su, T. Prediction of Grazing Incidence Focusing Mirror Imaging Quality Based on Accurate Modelling of the Surface Shape Accuracy for the Whole Assembly Process. Appl. Sci. 2024, 14, 6242. https://doi.org/10.3390/app14146242

Li E, Zhang Z, Li C, Zuo F, Mei Z, Su T. Prediction of Grazing Incidence Focusing Mirror Imaging Quality Based on Accurate Modelling of the Surface Shape Accuracy for the Whole Assembly Process. Applied Sciences. 2024; 14(14):6242. https://doi.org/10.3390/app14146242

Chicago/Turabian StyleLi, Erbo, Zhijing Zhang, Chaojiang Li, Fuchang Zuo, Zhiwu Mei, and Taiyu Su. 2024. "Prediction of Grazing Incidence Focusing Mirror Imaging Quality Based on Accurate Modelling of the Surface Shape Accuracy for the Whole Assembly Process" Applied Sciences 14, no. 14: 6242. https://doi.org/10.3390/app14146242

APA StyleLi, E., Zhang, Z., Li, C., Zuo, F., Mei, Z., & Su, T. (2024). Prediction of Grazing Incidence Focusing Mirror Imaging Quality Based on Accurate Modelling of the Surface Shape Accuracy for the Whole Assembly Process. Applied Sciences, 14(14), 6242. https://doi.org/10.3390/app14146242