Optimizing the Performance of Window Frames: A Comprehensive Review of Materials in China

Abstract

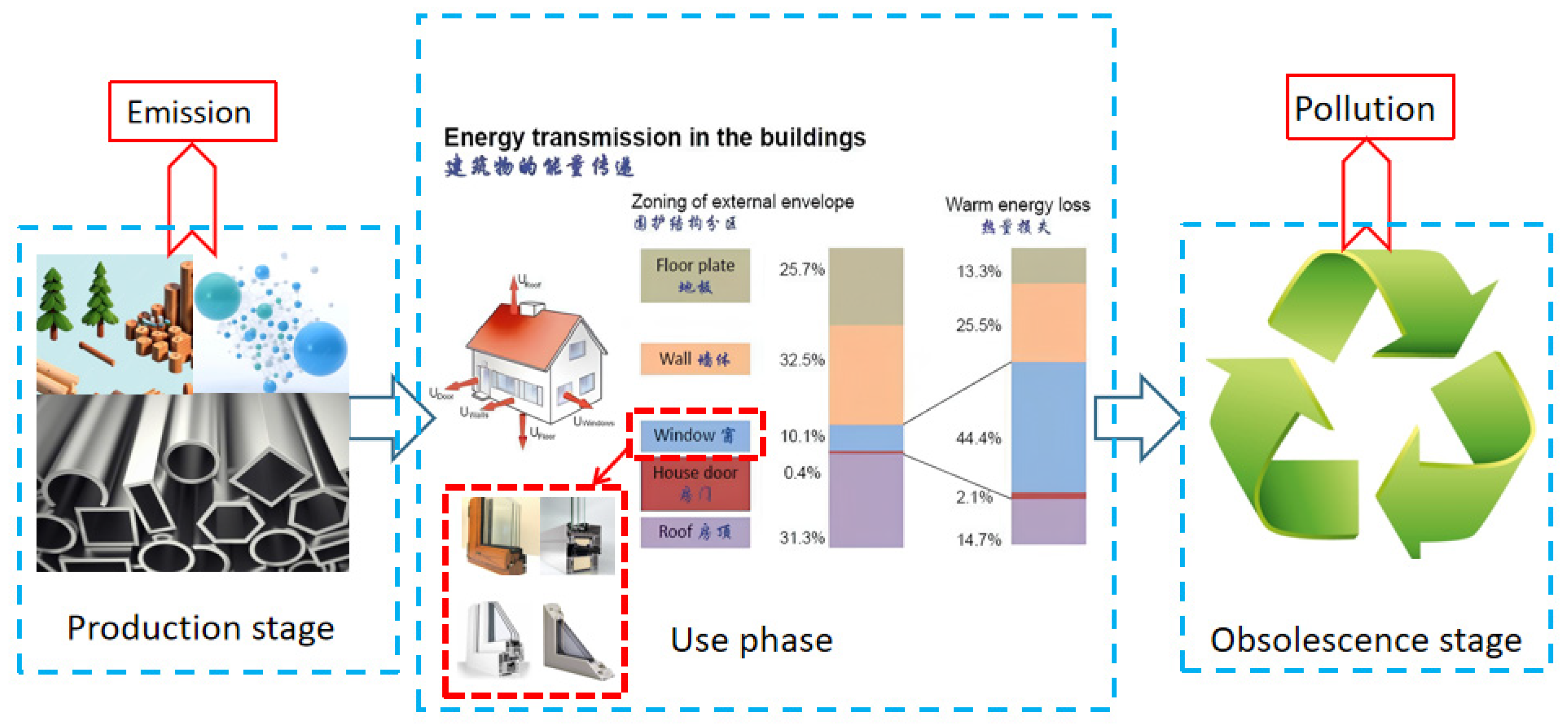

1. Introduction

2. Material Characteristics

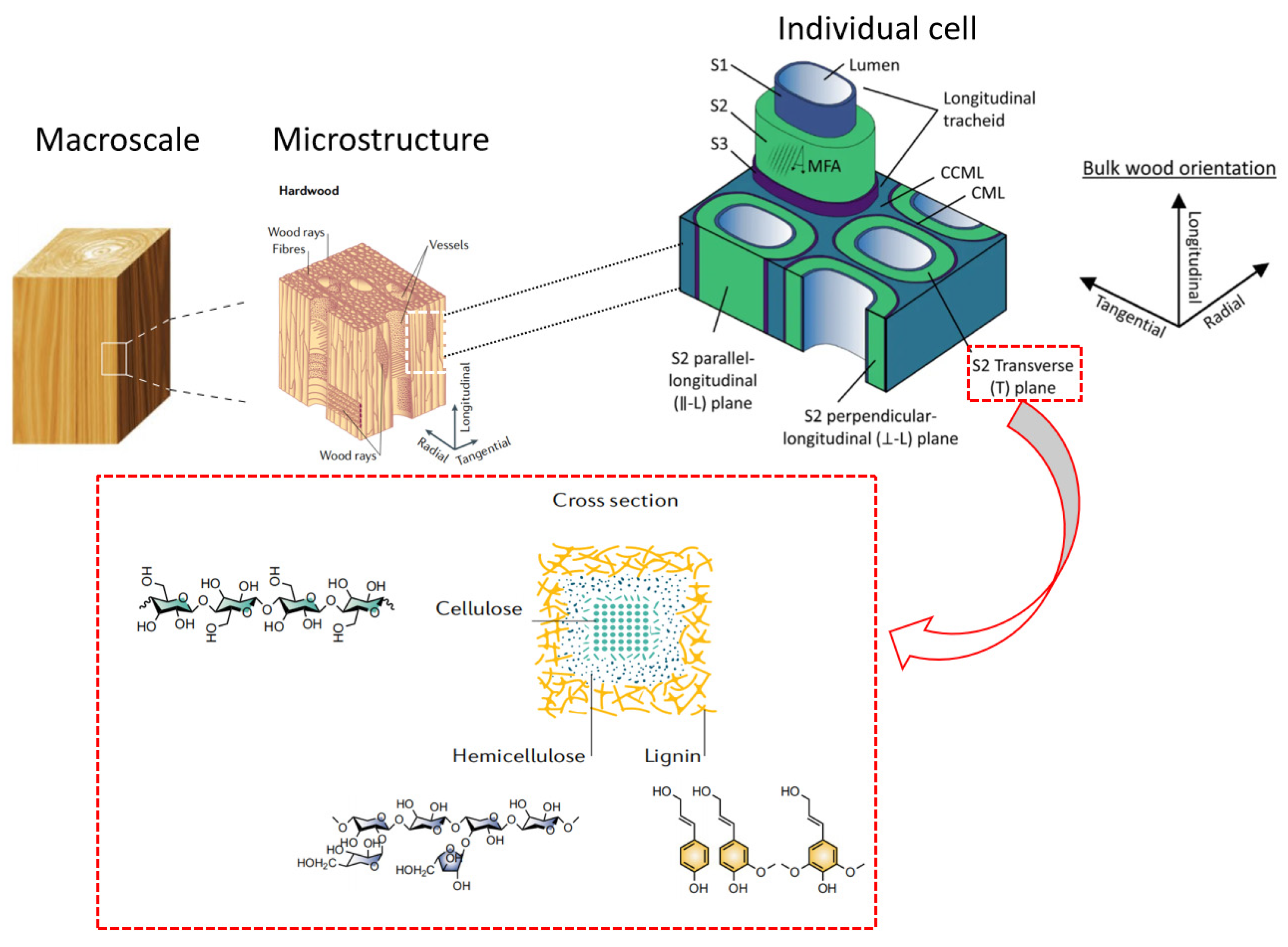

2.1. Wooden Window Frame

2.2. Polymer Window Frame

2.3. Metal Window Frame

3. Improvement Methods and Sustainability Assessment

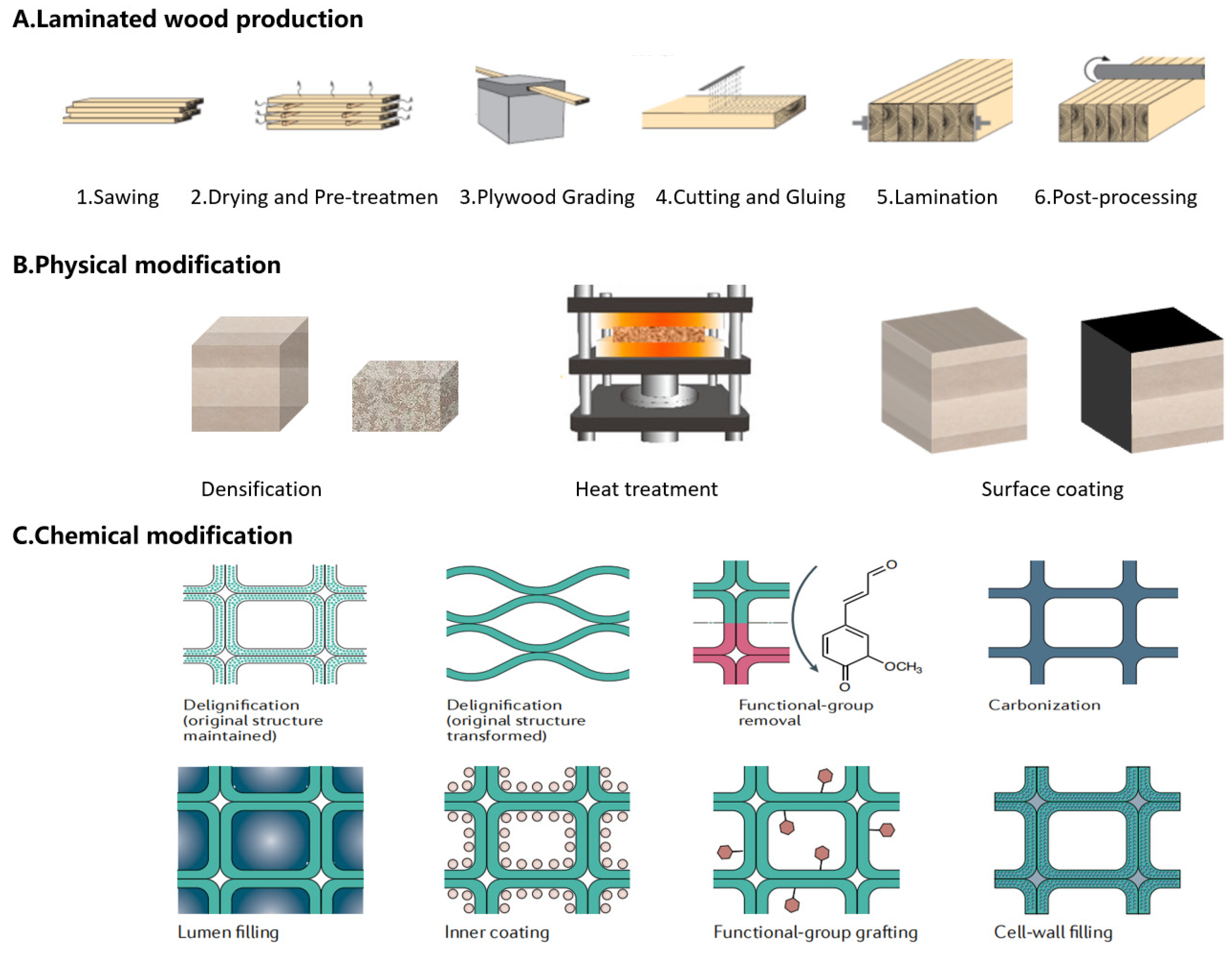

3.1. Wood

- Adhesive technologies

- Physical modifications

- Chemical modifications

- Discussion

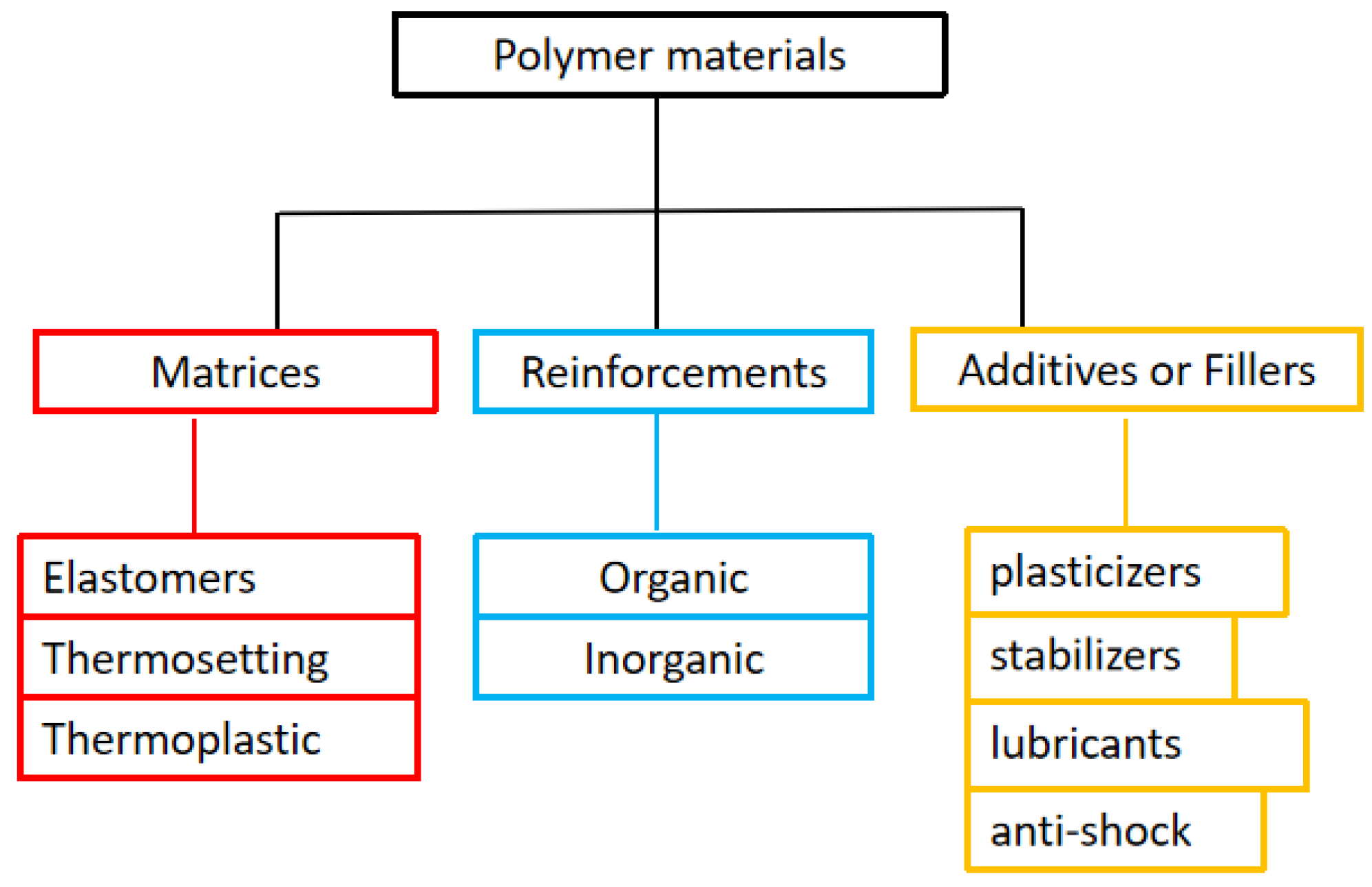

3.2. Polymer

- Matrix

- Reinforcement

- Additives

- (I)

- Compatibility with the basis resin: non-toxicity, absence of coloring, chemical inertness and neutrality, heat and light stability, low water absorption, no influence on the stability of the polymer or its color.

- (II)

- Wettability: good distribution of powders in the polymer matrix or adhesion of the fibers to the basis polymer, uniformity of quality and grain size, low abrasive action.

- Discussion

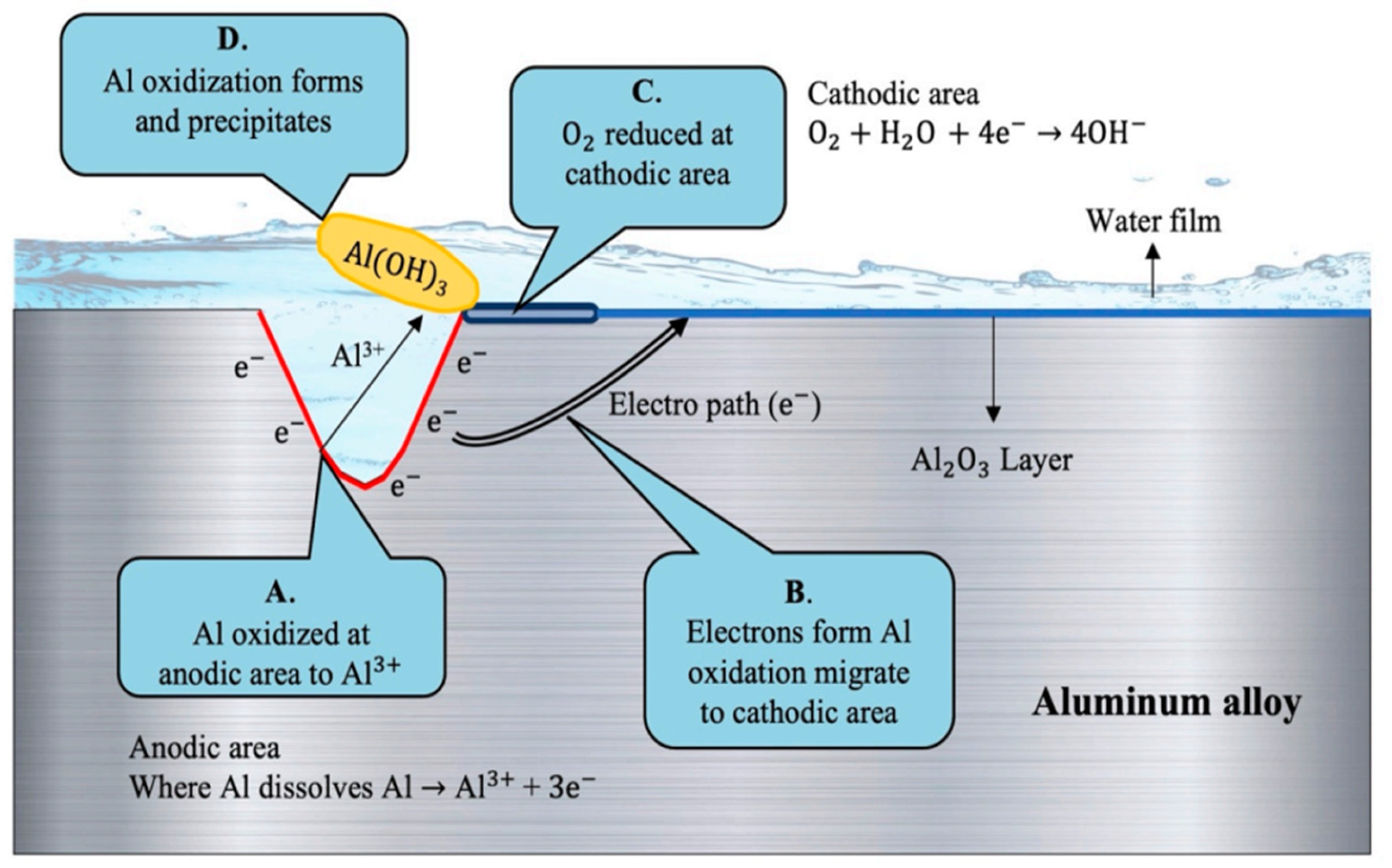

3.3. Metal

- Selection of categories

- Corrosion

- Thermal

- Laboratory tests

- Discussion

3.4. Combination Window Frames

3.5. Sustainability Assessment

- Life cycle assessment

- Thermal performance

- Life expectancy

4. Conclusions

- Wood, as an environmentally friendly material, has minimal environmental impact throughout its life cycle. The dimensional stability of wood when exposed to water, temperature, bacteria, or weather for extended periods is a crucial consideration, given the hydrophilic and biodegradable nature of wood cellulose. Heat treatment improves wood stability against water and bacteria, but it may compromise mechanical properties due to a significant reduction in hydrogen bonds. Coating wood’s outer or inner surfaces with stable polymers or inorganic materials as a stopgap measure can enhance stability without sacrificing mechanical performance. Moreover, current improvements mostly remain at the laboratory scale. Chemical enhancements to small-sized veneers (thin wood pieces, sometimes bark) and assembling them into large panels are promising directions to meet the dimensional requirements of the final product. At the current stage of using wood as a window frame material, it needs to be processed into engineered wood products. Whether focusing on the improvement of wood itself or the design of wood components, narrowing the gap between academic research and industrial practices is an essential area for future research. This will facilitate the practical application of more wood materials for the benefit of society.

- Polymer materials are systems composed of a relatively large number of components; hence, the actual number of composite materials that can be realized from this array of basic elements is virtually infinite. Thermosetting composite materials exhibit excellent mechanical properties and thermal resistance at high temperatures. Composite materials reinforced with glass fibers and carbon fibers demonstrate outstanding tensile and compressive strength. Advanced composite materials are currently under research and application in various industries, such as glass fiber-reinforced polyurethane window frames. However, polymers are energy-intensive during the synthesis process and are associated with the generation of toxic gases. This impact on the environment persists throughout the entire life cycle of polymers. The heterogeneity of polymers and their difficulty in degradation make recycling both technically and economically challenging.

- Aluminum alloy, known for its excellent mechanical properties and recyclability, has found increasing applications in structural engineering. This trend has prompted extensive research on the structural performance of aluminum alloys and the development of precise design methods. The production of aluminum alloys falls within the category of energy-intensive industries. The use of thermal break structures is common to enhance the thermal performance of aluminum alloy window frames. However, this often requires collaboration with insulation materials to achieve optimal thermal properties. Improving the thermal performance of window frames may increase their ecological footprint from cradle to gate, and there is currently no conclusive evidence on how much the reduction in heating, cooling, and power loads during the usage phase can offset this environmental impact.

- Combination window frames represent a compromise by mechanically combining the advantages of different materials. Compared to using a single type of window frame material, combination window frames, which involve the stacking of different materials, reduce the overall environmental impact. They demonstrate higher structural safety and energy efficiency performance, providing enhanced comfort experiences. This approach holds promising market prospects. The future selection of window frame materials is diverse, including wood, aluminum alloy, polymer, and more. Each material has its unique characteristics and advantages, so the choice of window frame material requires consideration of various factors such as durability, maintenance costs, insulation performance, and environmental friendliness. In the future, with technological advancements and increasing emphasis on environmental protection and energy efficiency, window frame materials are expected to prioritize ecological performance and energy efficiency, and there will also be a greater focus on the sustainability and recyclability of materials.

Funding

Conflicts of Interest

References

- Wang, F.; Harindintwali, J.D.; Yuan, Z.; Wang, M.; Wang, F.; Li, S.; Yin, Z.; Huang, L.; Fu, Y.; Li, L.; et al. Technologies and perspectives for achieving carbon neutrality. Innovation 2021, 2, 100180. [Google Scholar] [CrossRef]

- Al-Sakkaf, A.; Bagchi, A.; Zayed, T. Evaluating life-cycle energy costs of heritage buildings. Buildings 2022, 12, 1271. [Google Scholar] [CrossRef]

- Yang, F.; Yang, B.; Guo, X.Z.; Yang, T.G. Energy-saving doors and windows and current technology research status. New Build. Mater. 2012, 1056, 84–89. [Google Scholar]

- Gustavsen, A.; Grynning, S.; Arasteh, D.; Jelle, B.P.; Goudey, H. Key elements of material performance targets for highly insulating window frames. Energy Build. 2011, 43, 2583–2594. [Google Scholar] [CrossRef]

- Tao, X.; Liang, S.Q.; Fu, F. Heat transfer enhancement mechanism and preparation technology of wood-based thermal conductive composite. J. Funct. Mater. Gongneng Cailiao 2022, 53, 1–9. [Google Scholar] [CrossRef]

- Yano, H.; Hirose, A.; Inaba, S. High-strength wood-based materials. J. Mater. Sci. Lett. 1997, 16, 1906–1909. [Google Scholar] [CrossRef]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Fahlén, J.; Salmén, L. Cross-sectional structure of the secondary wall of wood fibers as affected by processing. J. Mater. Sci. 2003, 38, 119–126. [Google Scholar] [CrossRef]

- Berglund, L.A.; Burgert, I. Bioinspired wood nanotechnology for functional materials. Adv. Mater. 2018, 30, 1704285. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chen, P.-Y.; Lin, A.Y.-M.; Seki, Y. Biological materials: Structure and mechanical properties. Prog. Mater. Sci. 2008, 53, 1–206. [Google Scholar] [CrossRef]

- Fratzl, P.; Weinkamer, R. Nature’s hierarchical materials. Prog. Mater. Sci. 2007, 52, 1263–1334. [Google Scholar] [CrossRef]

- Barthelat, F.; Yin, Z.; Buehler, M.J. Structure and mechanics of interfaces in biological materials. Nat. Rev. Mater. 2016, 1, 16007. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, R.; Lu, D. Investigation of polymer aging mechanisms using molecular simulations: A review. Polymers 2023, 15, 1928. [Google Scholar] [CrossRef]

- Oliveira, M.S.; da Luz, F.S.; Monteiro, S.N. Research progress of aging effects on fiber-reinforced polymer composites: A brief review. In Characterization of Minerals, Metals, and Materials; Springer: Cham, Switzerland, 2021; pp. 505–515. [Google Scholar] [CrossRef]

- Liu, J.; Li, X. Progress in study of polymer degradation behaviors and mechanisms in various environment conditions. Polym. Bull. 2005, 3, 62. [Google Scholar]

- Zhu, Z.P.; Pi, H.; Guo, S.Y.; Li, G.X. Research on the aging behaviors of polymer materials under stress. Polyvinyl Chloride 2008, 36, 5. [Google Scholar]

- Wang, K.; Wang, Y.; Yue, X.; Cai, W. Multiphysics modeling and uncertainty quantification of tribocorrosion in aluminum alloys. Corros. Sci. 2021, 178, 109095. [Google Scholar] [CrossRef]

- Georgantzia, E.; Gkantou, M.; Kamaris, G.S. Aluminium alloys as structural material: A review of research. Eng. Struct. 2021, 227, 111372. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, S. Preparation of wear and corrosion resistant micro-arc oxidation coating on 7N01 aluminum alloy. Surf. Coat. Technol. 2020, 388, 125453. [Google Scholar] [CrossRef]

- Birbilis, N.; Hinton, B. Corrosion and corrosion protection of aluminium. In Fundamentals of Aluminium Metallurgy; Woodhead Publishing: Sawston, UK, 2011; pp. 574–604. [Google Scholar] [CrossRef]

- Reboul, M.C.; Baroux, B. Metallurgical aspects of corrosion resistance of aluminium alloys. Mater. Corros. 2011, 62, 215–233. [Google Scholar] [CrossRef]

- Chen, H.; Chow, C.L.; Lau, D. Deterioration mechanisms and advanced inspection technologies of aluminum windows. Materials 2022, 15, 354. [Google Scholar] [CrossRef]

- Cai, Z.; Zhu, M.; Shen, H.; Zhou, Z.; Jin, X. Torsional fretting wear behaviour of 7075 aluminium alloy in various relative humidity environments. Wear 2009, 267, 330–339. [Google Scholar] [CrossRef]

- Huo, Y.; Tan, M.Y.; Shu, L. Effects of high salt concentration and residue on copper and aluminum corrosion. Chem. Res. Chin. Univ. 2013, 29, 538–544. [Google Scholar] [CrossRef]

- Zhou, A.; Qin, R.; Chow, C.L.; Lau, D. Structural performance of FRP confined seawater concrete columns under chloride environment. Compos. Struct. 2019, 216, 12–19. [Google Scholar] [CrossRef]

- Gou, G.; Zhang, M.; Chen, H.; Chen, J.; Li, P.; Yang, Y.P. Effect of humidity on porosity, microstructure, and fatigue strength of A7N01S-T5 aluminum alloy welded joints in high-speed trains. Mater. Des. 2015, 85, 309–317. [Google Scholar] [CrossRef]

- Zaid, B.; Saidi, D.; Benzaid, A.; Hadji, S. Effects of pH and chloride concentration on pitting corrosion of AA6061 aluminum alloy. Corros. Sci. 2008, 50, 1841–1847. [Google Scholar] [CrossRef]

- Leclere TJ, R.; Davenport, A.J.; Newman, R.C. Enhancement of localized corrosion in aluminum alloys by weak acids. Corrosion 2007, 63, 338–345. [Google Scholar] [CrossRef]

- Musa, A.Y.; Mohamad, A.B.; Kadhum AA, H.; Chee, E.P. Galvanic corrosion of aluminum alloy (Al2024) and copper in 1.0 M nitric acid. Int. J. Electrochem. Sci. 2011, 6, 5052–5065. [Google Scholar] [CrossRef]

- Makinson, R.E.B. The thermal conductivity of metals. In Mathematical Proceedings of the Cambridge Philosophical Society; Cambridge University Press: Cambridge, UK, 1938; Volume 34, pp. 474–497. [Google Scholar] [CrossRef]

- Arzola-Villegas, X.; Lakes, R.; Plaza, N.Z.; Jakes, J.E. Wood moisture-induced swelling at the cellular scale—Ab intra. Forests 2019, 10, 996. [Google Scholar] [CrossRef]

- Bai, O.; Li, Z.; Jiang, J. Hygroscopicity and Swelling Behavior of Catalpa bungei Earlywood and Latewood. Sci. Silvae Sin. 2021, 57, 176–183. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Ren, H.; Jiang, Z. Wood density and wood shrinkage in relation to initial spacing and tree growth in black spruce (Picea mariana). J. Wood Sci. 2021, 67, 30. [Google Scholar] [CrossRef]

- Aicher, S.; Dill-Langer, G. Effect of lamination anisotropy and lay-up in glued-laminated timbers. J. Struct. Eng. 2005, 131, 1095–1103. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, S.; Fei, B.; Qin, D.; Yang, J.; Li, H.; Wang, X. Bending and shear performance of a cross-laminated composite consisting of flattened bamboo board and Chinese fir lumber. Constr. Build. Mater. 2023, 392, 131913. [Google Scholar] [CrossRef]

- Chief editor of Southwest Institute of China Construction. Wood Structure Design Manual, 4th ed.; China Architecture and Building Press: Beijing, China, 2017. [Google Scholar]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar] [CrossRef]

- Sandberg, D.; Haller, P.; Navi, P. Thermo-hydro and thermo-hydro-mechanical wood processing: An opportunity for future environmentally friendly wood products. Wood Mater. Sci. Eng. 2013, 8, 64–88. [Google Scholar] [CrossRef]

- Kitamori, A.; Jung, K.; Mori, T.; Komatsu, K. Mechanical properties of compressed wood in accordance with the compression ratio. J. Jpn. Wood Res. Soc. 2010, 56, 67–78. [Google Scholar] [CrossRef][Green Version]

- Huang, R.; Fujimoto, N.; Sakagami, H.; Feng, S. Sandwich compression of sugi (Cryptomeria japonica) and hinoki (Chamaecyparis obtusa) wood: Density distribution, surface hardness and their controllability. J. Wood Sci. 2021, 67, 43. [Google Scholar] [CrossRef]

- Huang, R.; Feng, S.; Gao, Z. Effect of water/moisture migration in wood preheated by hot press on sandwich compression formation. Holzforschung 2022, 76, 1003–1012. [Google Scholar] [CrossRef]

- Kutnar, A.; Kamke, F.A. Influence of temperature and steam environment on set recovery of compressive deformation of wood. Wood Sci. Technol. 2012, 46, 953–964. [Google Scholar] [CrossRef]

- Hoseinzadeh, F.; Zabihzadeh, S.M.; Dastoorian, F. Creep behavior of heat treated beech wood and the relation to its chemical structure. Constr. Build. Mater. 2019, 226, 220–226. [Google Scholar] [CrossRef]

- Kojima, E.; Yamasaki, M.; Imaeda, K.; Lee, C.G.; Sugimoto, T.; Sasaki, Y. Effects of thermal modification on the mechanical properties of the wood cell wall of soft wood: Behavior of S2 cellulose microfibrils under tensile loading. J. Mater. Sci. 2020, 55, 5038–5047. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Y.; Ren, R.; Li, L.; Chen, Y. Enhanced mechanical and humidity resistance properties of heat-treated wood by impregnation of low-molecular-weight lignin. Wood Sci. Technol. 2022, 56, 1551–1565. [Google Scholar] [CrossRef]

- Lahtela, V.; Kärki, T. Effects of impregnation and heat treatment on the physical and mechanical properties of Scots pine (Pinus sylvestris) wood. Wood Mater. Sci. Eng. 2016, 11, 217–227. [Google Scholar] [CrossRef]

- Awoyemi, L.; Westermark, U. Effects of borate impregnation on the response of wood strength to heat treatment. Wood Sci. Technol. 2005, 39, 484–491. [Google Scholar] [CrossRef]

- Homan, W.J.; Jorissen, A.J. Wood modification developments. Heron 2004, 49, 361–385. [Google Scholar]

- Popescu, C.M.; Pfriem, A. Treatments and modification to improve the reaction to fire of wood and wood based products—An overview. Fire Mater. 2020, 44, 100–111. [Google Scholar] [CrossRef]

- Dastpak, A.; Yliniemi, K.; de Oliveira Monteiro, M.C.; Höhn, S.; Virtanen, S.; Lundström, M.; Wilson, B.P. From waste to valuable resource: Lignin as a sustainable anti-corrosion coating. Coatings 2018, 8, 454. [Google Scholar] [CrossRef]

- Ma, B.; Xiong, F.; Wang, H.; Qing, Y.; Chu, F.; Wu, Y. Tailorable and scalable production of eco-friendly lignin micro-nanospheres and their application in functional superhydrophobic coating. Chem. Eng. J. 2023, 457, 141309. [Google Scholar] [CrossRef]

- Li, T.; Song, J.; Zhao, X.; Yang, Z.; Pastel, G.; Xu, S.; Jia, C.; Dai, J.; Chen, C.; Gong, A.; et al. Anisotropic, lightweight, strong, and super thermally insulating nanowood with naturally aligned nanocellulose. Sci. Adv. 2018, 4, eaar3724. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Li, S.X.; Kong, W.; Chen, C.; Hitz, E.; Jia, C.; Dai, J.; Zhang, X.; Briber, R.; Siwy, Z.; et al. A nanofluidic ion regulation membrane with aligned cellulose nanofibers. Sci. Adv. 2019, 5, eaau4238. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Chen, C.; Yang, Z.; Kuang, Y.; Li, T.; Li, Y.; Huang, H.; Kierzewski, I.; Liu, B.; He, S.; et al. Highly compressible, anisotropic aerogel with aligned cellulose nanofibers. ACS Nano 2018, 12, 140–147. [Google Scholar] [CrossRef]

- Kawamata, Y.; Yoshikawa, T.; Aoki, H.; Koyama, Y.; Nakasaka, Y.; Yoshida, M.; Masuda, T. Kinetic analysis of delignification of cedar wood during organosolv treatment with a two-phase solvent using the unreacted-core model. Chem. Eng. J. 2019, 368, 71–78. [Google Scholar] [CrossRef]

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure–property–function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Li, J.; Chen, C.; Zhu, J.Y.; Ragauskas, A.J.; Hu, L. In Situ Wood Delignification toward Sustainable Applications. Acc. Mater. Res. 2021, 2, 606–620. [Google Scholar] [CrossRef]

- Zhu, M.; Li, Y.; Chen, F.; Zhu, X.; Dai, J.; Li, Y.; Yang, Z.; Yan, X.; Song, J.; Wang, Y.; et al. Plasmonic wood for high-efficiency solar steam generation. Adv. Energy Mater. 2018, 8, 1701028. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Fan, H.; Wang, J. Wood carbonization as a protective treatment on resistance to wood destroying fungi. Int. Biodeterior. Biodegrad. 2018, 129, 42–49. [Google Scholar] [CrossRef]

- Donath, S.; Militz, H.; Mai, C. Wood modification with alkoxysilanes. Wood Sci. Technol. 2004, 38, 555–566. [Google Scholar] [CrossRef]

- Kong, L.; Guan, H.; Wang, X. In situ polymerization of furfuryl alcohol with ammonium dihydrogen phosphate in poplar wood for improved dimensional stability and flame retardancy. ACS Sustain. Chem. Eng. 2018, 6, 3349–3357. [Google Scholar] [CrossRef]

- Merk, V.; Chanana, M.; Gaan, S.; Burgert, I. Mineralization of wood by calcium carbonate insertion for improved flame retardancy. Holzforschung 2016, 70, 867–876. [Google Scholar] [CrossRef]

- Li, Y.F.; Liu, Y.X.; Wang, X.M.; Wu, Q.L.; Yu, H.P.; Li, J. Wood–polymer composites prepared by the in situ polymerization of monomers within wood. J. Appl. Polym. Sci. 2011, 119, 3207–3216. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef]

- Ahmadijokani, F.; Shojaei, A.; Dordanihaghighi, S.; Jafarpour, E.; Mohammadi, S.; Arjmand, M. Effects of hybrid carbon-aramid fiber on performance of non-asbestos organic brake friction composites. Wear 2020, 452, 203280. [Google Scholar] [CrossRef]

- Arabpour, A.; Shockravi, A.; Rezania, H.; Farahati, R. Investigation of anticorrosive properties of novel silane-functionalized polyamide/GO nanocomposite as steel coatings. Surf. Interfaces 2020, 18, 100453. [Google Scholar] [CrossRef]

- Dong, Z.J.; Zhou, T.; Luan, H.; Williams, R.C.; Wang, P.; Leng, Z. Composite modification mechanism of blended bio-asphalt combining styrene-butadiene-styrene with crumb rubber: A sustainable and environmental-friendly solution for wastes. J. Clean. Prod. 2019, 214, 593–605. [Google Scholar] [CrossRef]

- Khalil, H.A.; Tehrani, M.A.; Davoudpour, Y.; Bhat, A.H.; Jawaid, M.; Hassan, A. Natural fiber reinforced poly (vinyl chloride) composites: A review. J. Reinf. Plast. Compos. 2013, 32, 330–356. [Google Scholar] [CrossRef]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Baek, Y.M.; Shin, P.S.; Kim, J.H.; Park, H.S.; DeVries, K.L.; Park, J.M. Thermal transfer, interfacial, and mechanical properties of carbon fiber/polycarbonate-CNT composites using infrared thermography. Polym. Test. 2020, 81, 106247. [Google Scholar] [CrossRef]

- De, S.; Fulmali, A.O.; Shivangi, P.N.; Choudhury, S.; Prusty, R.K.; Ray, B.C. Interface modification of carbon fiber reinforced epoxy composite by hydroxyl/carboxyl functionalized carbon nanotube. Mater. Today Proc. 2020, 27, 1473–1478. [Google Scholar] [CrossRef]

- Mortensen, A.; Llorca, J. Metal matrix composites. Annu. Rev. Mater. Res. 2010, 40, 243–270. [Google Scholar] [CrossRef]

- Bhanuprakash, L.; Manikandan, N.; Varghese, L.; Joseph, J. Study on aluminium metal matrix composites reinforced with SiC and granite powder. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Chairi, M.; El Bahaoui, J.; Hanafi, I.; Cabrera, F.M.; Di Bella, G. Composite Materials: A Review of Polymer and Metal Matrix Composites, Their Mechanical Characterization, and Mechanical Properties. In Next Generation Fiber-Reinforced Composites-New Insights; IntechOpen: London, UK, 2023. [Google Scholar] [CrossRef]

- Xavier, J.R.; Ramesh, B. Experimental investigation of polymer matrix filled with silanized cerium carbide nanofillers and graphene oxide in automotive components. Appl. Nanosci. 2023, 13, 6133–6149. [Google Scholar] [CrossRef]

- Cui, K.; Lu, D.; Jiang, T.; Zhang, J.; Jiang, Z.; Zhang, G.; Chang, J.; Lau, D. Understanding the role of carbon nanotubes in low carbon sulfoaluminate cement-based composite. J. Clean. Prod. 2023, 416, 137843. [Google Scholar] [CrossRef]

- Gong, M.; Zhang, D.; Liu, Y.; Zhang, J.; Li, J.; Chen, X. Progresses of In-situ Polymerization Manufacturing Technology of Fiber Reinforced Thermoplastic Composites: A Review. Mater. Rep. 2020, 34, 21180–21187. [Google Scholar] [CrossRef]

- Lu, L.; Li, W.; Cheng, Y.; Liu, M. Chemical recycling technologies for PVC waste and PVC-containing plastic waste: A review. Waste Manag. 2023, 166, 245–258. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Lin, L.; Schlarb, A.K. Artificial neural network accomplished prediction on tribology—A promising procedure to facilitate the tribological characterization of polymer composites. Wear 2023, 532, 205106. [Google Scholar] [CrossRef]

- Liu, Q.X.; Zhang, Y.Y.; Sun, Z.; Li, Y.Q.; Guan, B.W.; Guan, T.; Fu, Y.T.; Mo, X.L.; Fu, S.Y. High mechanical performance short carbon fiber reinforced polyetherimide composites via solution mixing process. Compos. Sci. Technol. 2023, 244, 110296. [Google Scholar] [CrossRef]

- Javidparvar, A.A.; Naderi, R.; Ramezanzadeh, B. Epoxy-polyamide nanocomposite coating with graphene oxide as cerium nanocontainer generating effective dual active/barrier corrosion protection. Compos. B Eng. 2019, 172, 363–375. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M. A review on thermomechanical properties of polymers and fibers reinforced polymer composites. J. Ind. Eng. Chem. 2018, 67, 1–11. [Google Scholar] [CrossRef]

- Liu, H.; Zhan, S.; Bo, Y.; Ding, W.; Yuan, R.; Yu, Z.; Zhang, Y.; Sun, Y.; Yu, L.; Wang, S.; et al. Preparation and application of high sound insulation polyurethane composite film through glass fiber reinforcement. J. Appl. Polym. Sci. 2024, 141, e54960. [Google Scholar] [CrossRef]

- Li, J.; Zhu, Y.; Bian, R.; Wei, Y.; Jiang, S.; Li, K.; Li, X.; Tian, D.; Zhan, X.; Li, J. Construction of a boron nitride nanosheet hybrid for tough, strong, and flame-retardant phenolic resins. Chem. Eng. J. 2023, 471, 144463. [Google Scholar] [CrossRef]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Gurjar, D.; Sharma, S.; Sarkar, M. A Review on testing methods of recycled Acrylonitrile Butadiene-Styrene. Mater. Today Proc. 2018, 5, 28296–28304. [Google Scholar] [CrossRef]

- Qian, C.; Fan, W.; Yang, G.; Han, L.; Xing, B.; Lv, X. Influence of crumb rubber particle size and SBS structure on properties of CR/SBS composite modified asphalt. Constr. Build. Mater. 2020, 235, 117517. [Google Scholar] [CrossRef]

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fiber-Reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Yang, G.; Park, M.; Park, S.J. Recent progresses of fabrication and characterization of fibers-reinforced composites: A review. Compos. Commun. 2019, 14, 34–42. [Google Scholar] [CrossRef]

- Jensen, R.E.; McKnight, S.H. Inorganic–organic fiber sizings for enhanced energy absorption in glass fiber-reinforced composites intended for structural applications. Compos. Sci. Technol. 2006, 66, 509–521. [Google Scholar] [CrossRef]

- Oladele, I.O.; Agbeboh, N.I. Development of mathematical models and estimation for the mechanical properties of organic fiber reinforced polyester composites. Fibers Polym. 2017, 18, 1336–1345. [Google Scholar] [CrossRef]

- Ishikawa, T. Advances in Inorganic Fibers. In Polymeric and Inorganic Fibers. Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2015; Volume 178. [Google Scholar] [CrossRef]

- Stickel, J.M.; Nagarajan, M. Glass fiber-reinforced composites: From formulation to application. Int. J. Appl. Glass Sci. 2012, 3, 122–136. [Google Scholar] [CrossRef]

- Ekşi, S.; Genel, K. Comparison of mechanical properties of unidirectional and woven carbon, glass and aramid fiber reinforced epoxy composites. Acta Phys. Pol. A 2017, 132, 879–882. [Google Scholar] [CrossRef]

- Shi, Z.Y.; Cui, P.; Li, X. A review on research progress of machining technologies of carbon fiber-reinforced polymer and aramid fiber-reinforced polymer. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4508–4520. [Google Scholar] [CrossRef]

- Fischer, G.; Li, V.C. Effect of fiber reinforcement on the response of structural members. Eng. Fract. Mech. 2007, 74, 258–272. [Google Scholar] [CrossRef]

- Rahman, M.; Brazel, C.S. The plasticizer market: An assessment of traditional plasticizers and research trends to meet new challenges. Prog. Polym. Sci. 2004, 29, 1223–1248. [Google Scholar] [CrossRef]

- Folarin, O.M.; Sadiku, E.R. Thermal stabilizers for poly (vinyl chloride): A review. Int. J. Phys. Sci. 2011, 6, 4323–4330. [Google Scholar]

- Cui, W.; Chen, H.; Zhao, J.; Ma, Q.; Xu, Q.; Ma, T. Progresses on cryo-tribology: Lubrication mechanisms, detection methods and applications. Int. J. Extrem. Manuf. 2023, 5, 022004. [Google Scholar] [CrossRef]

- Marturano, V.; Cerruti, P.; Ambrogi, V. Polymer additives. Phys. Sci. Rev. 2017, 2, 20160130. [Google Scholar] [CrossRef]

- Bart, J.C. Additives in Polymers: Industrial Analysis and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar] [CrossRef]

- Vijayakumar, M.D.; Dhinakaran, V.; Sathish, T.; Muthu, G. Experimental study of chemical composition of aluminium alloys. Mater. Today Proc. 2021, 37, 1790–1793. [Google Scholar] [CrossRef]

- Cayless, R.B.C. Alloy and Temper Designation Systems for Aluminum and Aluminum Alloys; ASM International: Almere, The Netherlands, 1990. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminum and Aluminum Alloys; ASM International: Materials Park, OH, USA, 1993; pp. 351–416. [Google Scholar]

- Gitter, R. Aluminium Materials for Structural Engineering–Essential Properties and Selection of Materials. Struct. Eng. Int. 2006, 16, 294–300. [Google Scholar] [CrossRef]

- Baruah, M.; Borah, A. Processing and precipitation strengthening of 6xxx series aluminium alloys: A review. Int. J. Mater. Sci. 2020, 1, 40–48. [Google Scholar] [CrossRef]

- Sun, Y. The use of aluminum alloys in structures: Review and outlook. Structures 2023, 57, 105290. [Google Scholar] [CrossRef]

- Theohari, S.; Kontogeorgou, C. Effect of temperature on the anodizing process of aluminum alloy AA 5052. Appl. Surf. Sci. 2013, 284, 611–618. [Google Scholar] [CrossRef]

- Sinyavskii, V.S.; Kalinin, V.D. Marine Corrosion and Protection of Aluminum Alloys According to Their Composition and Structure. Prot. Met. 2005, 41, 317–328. [Google Scholar] [CrossRef]

- Wei, T.; Yan, F.; Tian, J. Characterization and wear-and corrosion-resistance of microarc oxidation ceramic coatings on aluminum alloy. J. Alloys Compd. 2005, 389, 169–176. [Google Scholar] [CrossRef]

- Bouchama, L.; Azzouz, N.; Boukmouche, N.; Chopart, J.P.; Daltin, A.L.; Bouznit, Y. Enhancing aluminum corrosion resistance by two-step anodizing process. Surf. Coat. Technol. 2013, 235, 676–684. [Google Scholar] [CrossRef]

- Rana, R.S.; Purohit, R.; Das, S. Reviews on the influences of alloying elements on the microstructure and mechanical properties of aluminum alloys and aluminum alloy composites. Int. J. Sci. Res. Publ. 2012, 2, 1–7. [Google Scholar]

- Liang, G.; Zhu, S.; Wang, W.; Wang, X.; Han, G.; Ren, Z. Research Status and Development Trend of Aluminum Alloy Anticorrosion Technology. Mater. Rep. 2020, 34, 429–436. [Google Scholar]

- Zheng, Y.; Si, P.; Zhang, Y.; Shi, L.; Huang, C.; Huang, D.; Jin, Z. Study on the effect of radiant insulation panel in cavity on the thermal performance of broken-bridge aluminum window frame. Buildings 2022, 13, 58. [Google Scholar] [CrossRef]

- Zajas, J.; Heiselberg, P. Parametric study and multi objective optimization of window frame geometry. Build. Simul. 2014, 7, 579–593. [Google Scholar] [CrossRef]

- Appelfeld, D.; Hansen, C.S.; Svendsen, S. Development of a slim window frame made of glass fibre reinforced polyester. Energy Build. 2010, 42, 1918–1925. [Google Scholar] [CrossRef]

- Paulos, J.; Berardi, U. Optimizing the thermal performance of window frames through aerogel-enhancements. Appl. Energy 2020, 266, 114776. [Google Scholar] [CrossRef]

- Goulouti, K.; De Castro, J.; Keller, T. Aramid/glass fiber-reinforced thermal break–thermal and structural performance. Compos. Struct. 2016, 136, 113–123. [Google Scholar] [CrossRef]

- Sun, Y.; Fu, Z.; Song, Y.; Xia, J. Cross-sectional behavior of aluminum alloy channel section stub columns after exposure to fire. J. Struct. Eng. 2023, 149, 04023085. [Google Scholar] [CrossRef]

- Lugaresi, F.; Kotsovinos, P.; Lenk, P.; Rein, G. Review of the mechanical failure of non-combustible facade systems in fire. Constr. Build. Mater. 2022, 361, 129506. [Google Scholar] [CrossRef]

- Su, M.N.; Young, B. Material properties of normal and high strength aluminium alloys at elevated temperatures. Thin-Walled Struct. 2019, 137, 463–471. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, C.; Li, M.; Han, Q.; Li, H.T.; Zhao, D. Mechanical properties of 7A04-T6 high strength structural aluminium alloy at elevated temperatures and after cooling down. Thin-Walled Struct. 2022, 180, 109930. [Google Scholar] [CrossRef]

- Das, S.C.; Nizam, M.E.H. Applications of Fiber Reinforced Polymer Composites (FRP) in Civil Engineering. Int. J. Adv. Struct. Geotech. Eng. 2014, 3, 299–309. [Google Scholar]

- Adamus, J.; Pomada, M. Selected issues of choosing composite materials for window supporting beams. J. Build. Eng. 2020, 32, 101542. [Google Scholar] [CrossRef]

- Yi, Y.K.; Anis, M.; Jang, K.; Kim, Y.-J. Application of machine learning (ML) and genetic algorithm (GA) to optimize window wing wall design for natural ventilation. J. Build. Eng. 2023, 68, 106218. [Google Scholar] [CrossRef]

- Pittie, T.; Ahmad, S.; Singh, H.; Rashid, M.M.; Adhikari, S.; Shetty, S.; Krishnan, N.A. A combined experimental and numerical analysis framework for the design of aluminum windows. J. Build. Eng. 2024, 82, 108259. [Google Scholar] [CrossRef]

- Carlisle, S.; Friedlander, E. The influence of durability and recycling on life cycle impacts of window frame assemblies. Int. J. Life Cycle Assess. 2016, 21, 1645–1657. [Google Scholar] [CrossRef]

- Zhu, G.; Cui, X.; Zhang, Y.; Chen, S.; Dong, M.; Liu, H.; Shao, Q.; Ding, T.; Wu, S.; Guo, Z. Poly (vinyl butyral)/graphene oxide/poly (methylhydrosiloxane) nanocomposite coating for improved aluminum alloy anticorrosion. Polymer 2019, 172, 415–422. [Google Scholar] [CrossRef]

- Barroso-Bujans, F.; Fierro, J.L.; Veith, M. Grafting of poly (methyl vinyl ketone) onto aluminum surface. J. Colloid Interface Sci. 2007, 314, 160–166. [Google Scholar] [CrossRef]

- Bank, L.C. Composites for Construction: Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006; ISBN 978-0-471-68126-7. [Google Scholar]

- Bedon, C. Review on the use of FRP composites for facades and building skins. Am. J. Eng. Appl. Sci. 2016, 9, 713–723. [Google Scholar] [CrossRef]

- Luan, Z.; Chen, Y.; Liu, Y.; Xia, X.; Ma, K.; Lin, J.; Geng, B.; Li, H. Fabrication and characterization of corrosion resistant vinyl sulfone reactive dye-encapsulated colored aluminum pigment composites. Dye. Pigment. 2023, 211, 111069. [Google Scholar] [CrossRef]

- Ruggerio, C.A. Sustainability and sustainable development: A review of principles and definitions. Sci. Total Environ. 2021, 786, 147481. [Google Scholar] [CrossRef]

- Souviron, J.; Van Moeseke, G.; Khan, A.Z. Analyzing the environmental impact of windows: A review. Build. Environ. 2019, 161, 106268. [Google Scholar] [CrossRef]

- Asif, M.; Muneer, T.; Kubie, J. Sustainability analysis of window frames. Build. Serv. Eng. Res. Technol. 2005, 26, 71–87. [Google Scholar] [CrossRef]

- Maia, M.; Morais, R.; Silva, A. Application of the factor method to the service life prediction of window frames. Eng. Fail. Anal. 2020, 109, 104245. [Google Scholar] [CrossRef]

- Banaś, J.; Utnik-Banaś, K. Using timber as a renewable resource for energy production in sustainable forest management. Energies 2022, 15, 2264. [Google Scholar] [CrossRef]

- Tarantini, M.; Loprieno, A.D.; Porta, P.L. A life cycle approach to Green Public Procurement of building materials and elements: A case study on windows. Energy 2011, 36, 2473–2482. [Google Scholar] [CrossRef]

- Abdul Hamid, Z.A.; Abdull Razis, A.F. Wood Waste as a Renewable Energy Source: Effect of Pretreatment Technology for Sustainable Bioethanol Production. In Wood Waste Management and Products. Sustainable Materials and Technology; Sarmin, S.N., Jawaid, M., Elias, R., Eds.; Springer: Singapore, 2023. [Google Scholar] [CrossRef]

- Kucharikova, L.; Tillova, E.; Bokůvka, O. Recycling and properties of recycled aluminium alloys used in the transportation industry. Transp. Probl. 2016, 11, 117–122. [Google Scholar] [CrossRef]

- Zhu, S.; Gao, C.; Song, K.; Chen, M.; Wu, F.; Li, X. An assessment of environmental impacts and economic benefits of multiple aluminum production methods. J. Clean. Prod. 2022, 370, 133523. [Google Scholar] [CrossRef]

- Raabe, D.; Tasan, C.C.; Olivetti, E.A. Strategies for improving the sustainability of structural metals. Nature 2019, 575, 64–74. [Google Scholar] [CrossRef]

- Raabe, D.; Ponge, D.; Uggowitzer, P.J.; Roscher, M.; Paolantonio, M.; Liu, C.; Antrekowitsch, H.; Kozeschnik, E.; Seidmann, D.; Gault, B.; et al. Making sustainable aluminum by recycling scrap: The science of “dirty” alloys. Prog. Mater. Sci. 2022, 128, 100947. [Google Scholar] [CrossRef]

- Thornton, J. Environmental Impacts of Polyvinyl Chloride (PVC) Building Materials; Healthy Building Network: Washington, DC, USA, 2002. [Google Scholar]

- Ignatyev, I.A.; Thielemans, W.; Vander Beke, B. Recycling of polymers: A review. ChemSusChem 2014, 7, 1579–1593. [Google Scholar] [CrossRef] [PubMed]

- Sinha, A.; Kutnar, A. Carbon footprint versus performance of aluminum, plastic, and wood window frames from cradle to gate. Buildings 2012, 2, 542–553. [Google Scholar] [CrossRef]

- Scharai-Rad, M.; Welling, J. Environmental and Energy Balances of Wood Products and Substitutes; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2002. [Google Scholar]

- Karlsson, J. Windows: Optical Performance and Energy Efficiency. Ph.D. Thesis, Acta Universitatis Upsaliensis, Uppsala, Sweden, 2001. [Google Scholar]

- Lawson, W.R. Life cycle analysis of windows. In Proceedings of the Conference: Window Innovations Conference, Toronto, Canada, 5–9 June 1995; ISBN 0-660-16085-4. [Google Scholar]

- Gustavsen, A. State-of-the-Art Highly Insulating Window Frames–Research and Market Review; Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2007. [Google Scholar] [CrossRef]

- GB/T 8624-2006; Classification of Burning Performance of Building Materials and Products. Ministry of Housing and Urban-Rural Development, People’s Republic of China: Beijing, China, 2006.

- Saadatian, S.; Simoes, N.; Freire, F. Integrated environmental, energy and cost life-cycle analysis of windows: Optimal selection of components. Build. Environ. 2021, 188, 107516. [Google Scholar] [CrossRef]

- Menzies, G.F. Whole Life Analysis of Timber, Modified Timber and Aluminium-Clad Timber Windows: Service Life Planning (SLP), Whole Life Costing (WLC) and Life Cycle Assessment (LCA); Heriot-Watt University: Edinburgh, UK, 2013. [Google Scholar]

- Tushar, Q.; Bhuiyan, M.A.; Zhang, G. Energy simulation and modeling for window system: A comparative study of life cycle assessment and life cycle costing. J. Clean. Prod. 2022, 330, 129936. [Google Scholar] [CrossRef]

- Lacasse, M.A.; Sjöström, C. Recent Advances in Methods for Service Life Prediction of Buildings Materials and Components-an Overview. In Proceedings of the CIB World Building Congress, Toronto, ON, Canada, 1–7 May 2004; p. 104245. [Google Scholar]

- Fernandes, D.; De Brito, J.; Silva, A. Methodology for service life prediction of window frames. Can. J. Civ. Eng. 2019, 46, 1010–1020. [Google Scholar] [CrossRef]

- ISO 15686-1; Buildings and Constructed Assets-Service Life Planning—Part 1: General Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2011.

- GB/T 7106-2019; Test Methods for Air tightness, Water tightness, and Wind Pressure Resistance of External Doors and Windows in Buildings. Ministry of Housing and Urban-Rural Development, People’s Republic of China: Beijing, China, 2019.

- GB/T 50176-1993; Code for Thermal Design of Civil Buildings. Ministry of Housing and Urban-Rural Development, People’s Republic of China: Beijing, China, 1993.

| Plywood Type | Properties | Natural Durability | Maintenance | Adhesives | |

|---|---|---|---|---|---|

| Solid wood | Picea spp. | Low density, light weight, moderate strength | Poor, need anticorrosive treatment | Check every year and recoat every 2–3 years | Phenol Formaldehyde Resin; Isocyanate Adhesive; Polyurethane Adhesive; Phenol-Urea-Formaldehyde Resin |

| Pinus sylvestris | Low density, light weight, easy to process | Medium, requires antiseptic treatment | Scheduled maintenance and recoat every 2–3 years | ||

| Larix | Medium density, high strength, good weather resistance | Good, but prone to cracking when dry | Check regularly, sand and recoat if necessary | ||

| Quercus rubra | High density, high hardness, good wear resistance | better, needs to be treated with preservative | Annual maintenance inspection, regular sanding and repainting | ||

| Tectona grandis | High density, High stability | excellent durability, resistance to insect erosion | Minimal maintenance, annual cleaning and application of protective oil or wax | ||

| Modified wood | Good dimensional stability and mechanical strength, not easy to crack, deformation | Strong weather resistance, good corrosion resistance, no need for conventional anti-corrosion treatment, Suitable for long-term outdoor exposure | Maintenance costs are low, but reasonable coating and regular maintenance can effectively extend the service life and beauty | demands special surface preparation or the use of special adhesives | |

| Summary of Cast Aluminum Alloy Series | |||

|---|---|---|---|

| Series | Main Alloying Element (s) | Main Characteristics | Example Applications |

| 1xxx | Pure aluminum | High electrical and thermal conductivity; excellent corrosion resistance. | Big electrical rotors. |

| 2xxx | Copper | High strength But low corrosion resistance. | Cylinder heads and pistons, housing and bearings |

| 3xxx | Silicon, copper and/or magnesium | High strength and wear resistance; good corrosion resistance. | Motor parts, structural parts, and marine and aircraft castings. |

| 4xxx | Silicon | Moderate strength; high ductility; good impact resistance | Bridge railing support castings, dental equipment, and cookware. |

| 5xxx | Magnesium | Moderate to high strength; high corrosion resistance; good machinability; attractive appearance. | Architectural and ornamental castings and welded assemblies. |

| 7xxx | Zinc | Good finish; good corrosion resistance; high strength through heat treatment. | Automotive parts and mining equipment. |

| 8xxx | Tin | Low friction. | Bearing and bushing applications. |

| 1xxx | Pure aluminum | High electrical and thermal conductivity; excellent corrosion resistance. | Electrical conductors and chemical processing equipment. |

| 2xxx | Copper | High strength-to-weight ratio; low corrosion resistance. | Truck wheels and suspensions, aircraft fuselage and wings. |

| 3xxx | Manganese | Moderate strength and good workability. | General sheet work, recreation vehicles, and electronics. |

| 4xxx | Silicon | Low melting point and thermal expansion; high wear resistance. | Welding wire and brazing alloy, architectural applications, and forged engine pistons. |

| 5xxx | Magnesium | Moderate to high strength; good weldability; good corrosion resistance. | Appliances, automotive parts, and marine components. |

| 6xxx | Silicon and magnesium | Medium strength with good formability; weldability, machinability; corrosion resistance. | Structural applications, architectural extrusions, and recreational equipment. |

| 7xxx | Zinc | Moderate to very high strength. | Airframe structures, mobile equipment, and high-stress parts. |

| Technologies | Principle | Characteristics |

|---|---|---|

| anodization | In the electrolyte, aluminum alloy is used as the anode, and a current is applied to generate an oxide film on its surface. | Forms thin (5~20 μm) to thick (60~200 μm) oxide films, dense with high hardness, strong adhesion, and remarkable corrosion resistance. |

| chemical oxidation | Placing an aluminum alloy in an oxidation solution at a certain temperature allows aluminum atoms to undergo oxidation reactions in the solution, forming a dense oxide film on the surface | Simple operation, low cost, film thickness ranging from 0.5 to 4 μm. |

| spraying | The spray material is heated by a heat source to a molten or semi-molten state, then accelerated to impact and deposit on the substrate surface, where it cools and forms a coating | Preparation is versatile, widely applicable for spray materials such as metals, alloys, or non-metallic materials, with coatings exhibiting high bond strength and low porosity. |

| laser cladding technology | Using a high-energy laser beam to melt powder coatings onto the substrate surface, forming a dense cladding layer | Obtaining coatings with special protective properties, tightly bonded to the substrate, with controllable thickness of the cladding layer and minimal defects. |

| Nano-coating | Involves creating nanoscale films on the surface of aluminum alloys | The nano-coating is dense, uniform, and smooth, enhancing both corrosion resistance and wear resistance. It also meets the dimensional requirements of high-precision components. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Yao, L.; Shi, Y.; Zhao, D.; Chen, T. Optimizing the Performance of Window Frames: A Comprehensive Review of Materials in China. Appl. Sci. 2024, 14, 6091. https://doi.org/10.3390/app14146091

Wang Z, Yao L, Shi Y, Zhao D, Chen T. Optimizing the Performance of Window Frames: A Comprehensive Review of Materials in China. Applied Sciences. 2024; 14(14):6091. https://doi.org/10.3390/app14146091

Chicago/Turabian StyleWang, Zhen, Lihong Yao, Yongguang Shi, Dongxia Zhao, and Tianyu Chen. 2024. "Optimizing the Performance of Window Frames: A Comprehensive Review of Materials in China" Applied Sciences 14, no. 14: 6091. https://doi.org/10.3390/app14146091

APA StyleWang, Z., Yao, L., Shi, Y., Zhao, D., & Chen, T. (2024). Optimizing the Performance of Window Frames: A Comprehensive Review of Materials in China. Applied Sciences, 14(14), 6091. https://doi.org/10.3390/app14146091