1. Introduction

Earthworks, a fundamental component of construction endeavors, encompass the handling of soil through processes such as cutting, filling, and the removal of excess material [

1]. Spanning projects of varying scales, from modest residential constructions to expansive undertakings like apartment complexes, roads, airports, and bridges, earthworks lay the groundwork for all subsequent construction activities [

2]. This intricate process relies heavily on construction equipment, notably excavators and dump trucks, which are utilized to execute these essential operations [

3,

4]. Given the excavator’s remarkable attributes of flexibility, durability, and efficiency, it has emerged as indispensable on construction sites [

5,

6]. Excavators facilitate efficient soil movement, trench excavation, foundational work, and slope adjustments, significantly enhancing construction site productivity [

7]. Additionally, their versatility is augmented by various attachments, enabling tasks such as demolition, grading, and the movement of heavy objects. Such adaptability shows the excavator’s crucial assets in earthmoving projects, playing a pivotal role in optimizing project efficiency, time, and cost [

8,

9].

Dump trucks, alongside excavators, hold a significant role in earthworks by transporting materials like silt, gravel, and crushed stone, that were moved by heavy equipment such as excavators and loaders [

10,

11]. Their capacity, adaptability to varying terrains, and mobility streamline workflows at earthworks sites, reducing time and costs. Dump trucks are essential for both large-scale civil engineering projects and smaller ventures in confined spaces. Their diverse sizes and configurations make them adaptable to different work environments and project requirements [

12]. Consequently, the collaboration between excavators and dump trucks is pivotal in enhancing project efficiency and productivity in earthmoving [

13]. Moreover, this partnership plays a crucial role in logistical planning at job sites, optimizing work sequences and schedules systematically. By applying principles of construction engineering and project management, this approach maximizes productivity and economizes effectively [

14].

Traditionally, task planning revolved around minimizing the transportation of earth materials. However, the advent of new earthwork planning methods leveraging construction automation technology has alleviated constraints on improving efficiency and productivity that were previously reliant on construction workers’ experience and intuition [

3,

15]. In earthwork sites employing various types of construction equipment, strategic planning becomes imperative to enhance the efficiency and productivity of earthwork through the integration of automation equipment or technology. Of paramount importance is the coordinated operation of the two primary earthwork equipment: excavators and dump trucks.

To address the issue, this study introduces a novel task component design for excavator–truck operation planning that operates autonomously within earthwork project sites. In contrast to traditional task planning systems that primarily aim to minimize total travel distance, this research adopts a more hierarchical programming approach that considers the operational capabilities of both excavators and dump trucks. By integrating scenarios that reflect the key functions of the excavator and its interaction with dump trucks, the proposed algorithm significantly enhances practical applicability in real construction settings. Furthermore, this study incorporates a JavaScript Object Notation (JSON)-type protocol designed to facilitate efficient integration with other subsystems, ensuring seamless communication and coordination within the broader earthwork automation system. The necessity of field tests for validating this integration is paramount, as they provide empirical evidence of the system’s effectiveness. These tests confirm that the task component design not only meets theoretical expectations but also performs robustly in dynamic, real-world construction environments.

The paper is structured as follows:

Section 2 offers an overview of the techniques relevant to the recognition of earthwork task planning and identifies the research gap. In

Section 3, the proposed methodology, prerequisites for automated excavator task planning, setting excavator specifications and truck access positioning, JSON task plan protocol, and task component design are elaborated. Additionally,

Section 4 outlines the results and discussion. Finally, in

Section 5, the conclusion, limitations, research contributions, and future directions are provided.

2. Literature Review

In recent years, there has been an increasing interest in the task planning of construction equipment. The work plan related to earthmoving equipment can be classified into two parts. The first part is an object-level task plan. It considers the pieces or parts of the earthwork site as objects, and the sequence of work on these objects is determined by the plan. The level of detail encompassed in this type of task plan varies depending on the specific requirements of the construction management process, with a predominant focus on large-scale work areas or sections. The detailed work plan here refers to the movement of soil and equipment within the site, specifically referring to the process of cutting and filling. The second part is the manipulator-level work plan for the movement of the excavator bucket when the excavator platform is positioned in a fixed position [

16,

17]. Earthmoving equipment work plans are predominantly centered around excavators. Additionally, prior research on work planning has predominantly focused on excavators and dump trucks. There has also been a focus on separately analyzing task plans for excavators and dump trucks [

18,

19,

20,

21].

While prior study has delved into automation for automatic excavation and loading operations with stationary excavators, there remains a gap in the exploration of task planning for automated excavators capable of responding to changes in the external environment. Although discussions have centered around task planning for automated excavators within structured environments, there is a notable absence in addressing planning strategies that accommodate changes in initial work conditions, such as geometric variations, site boundaries, and entry points. Consequently, this study embarks on the development of an autonomously operating excavator task planning algorithm that incorporates collaboration with dump trucks at designated civil engineering sites [

22,

23,

24]. This study focuses on developing a task planning strategy for an autonomously operated excavator for a given civil engineering site. It verifies the similarity by comparing the results of this study with those determined manually. This paper deals with automatically calculating the excavator’s task plan considering the dump truck.

Kim et al. [

16] proposed the problem that the various technologies have not been integrated for an automated excavator to be utilized at construction sites. Limited terrain modeling and updating capabilities have existed, and there are an insufficient number of studies on the object-level task planning necessary for the control of an automated excavator at an actual construction site. So, the authors developed a task planning algorithm to partition the work area and generate the excavator path. This research presents the excavation task planner devised to incorporate the intelligence of a construction planner and a skillful operator into the robotic control mechanism of the automated excavation system; however, this paper is about the development of an algorithm for a module of an excavation task planner, developed by analyzing the terrain and geometrical structure of the excavator and the operating characteristics of excavators as well as the heurism and rules used at the construction site. This study does not reflect constraints such as obstacles, dump trucks, and temporary roads, because it is about the excavator task plan path at the basic stage. In the field of civil engineering, earthworks are increasingly performed by automated construction equipment, as skilled operators for construction equipment are becoming scarce. This trend amplifies the need for integrating advanced automation to maintain operational efficacy and mitigate workforce limitations [

24]. Thus, construction automation and information technology are considered the best technical approaches to solving these challenges, and among the various earthwork equipment used for civil engineering work, the intelligentization of excavators used for general use has been required first [

25,

26].

Koo et al. [

27] identified the decision factors and importance of excavator movement through literature surveys, expert surveys, and interviews. The authors presented a model for the cell division of earthworks sites for generating excavator paths and suggested a method for determining cell size considering the specifications and safety distance of excavators. Also, they proposed work methods according to the location of the excavator platform, determining the final path and presenting the platform location through the cell network extraction method and network discovery method (considering Traveling Salesman Problem: TPS [

28]). This study presents a methodology for automatically generating an excavator path based on given design and site information. However, this study focuses on the path creation of an excavator and has the limitation that it only deals with the minimum cost distance, natural drainage direction, and continuity of the excavation direction by considering the operators’ work behavior and does not address dump trucks and the site.

Previous studies predominantly focused on analyzing the excavation routes of excavators within earthworks and the haul routes of external dump trucks [

29,

30]. However, the collaboration between excavators and dump trucks is paramount for efficient loading and transport operations. Despite this significance, there has been relatively limited study dedicated to task planning for the cooperative interaction between excavators and dump trucks compared to studies focusing solely on individual task plans for each machine [

31,

32,

33,

34,

35]. Recent studies on task plans for automated excavators and dump trucks have revealed certain shortcomings concerning system integration [

23]. These plans often lacked compatibility with web-based systems, and the dump truck’s location or approach did not always align with the site’s unique circumstances. Consequently, the complexity of on-site operations compromised maneuverability for entry and exit, thereby presenting significant challenges in adapting to such scenarios.

While previous studies have delved into study on automatically generating excavation work, there is a notable scarcity of studies on task updates to accommodate the dynamic nature of construction sites. Moreover, the desired task updates by managers or administrators typically entail partial daily updates, yet previous studies predominantly offered automatic updates for the entire task, proving to be inefficient. Additionally, there is a lack of earthwork topography modeling considering the level of automation or task planning systems that factor in collaboration between excavators and trucks. Establishing an autonomous excavation task planning system that considers the automated excavator’s characteristics, environmental factors, and design conditions can support the automatic task planning of excavators and trucks, even for individuals lacking expertise in earthwork. This study aims to propose optimal task planning and operation strategies for collaborative automated excavators and trucks in earthwork projects. The following sections will explicate the step-by-step procedures, utilizing a construction site grading project as a testbed to substantiate the effectiveness and feasibility of the proposed methodology.

The primary distinction between this paper and previous studies lies in its departure from proposing a simplistic JSON-type protocol for connecting and integrating with a comprehensive automation system, and its comprehensive treatment of various work types. In contrast to prior studies, which predominantly focused on enhancing the automation functions of individual equipment [

36,

37], this study developed an integrated system facilitating collaboration between automated excavators and dump trucks for each earthwork type typically involving these machines. This approach significantly broadens the scope of what the automation system can achieve in terms of managing and executing construction projects and it enhances the productivity and operational efficiency of the construction site.

3. Methodology

While prior research extensively explored autonomous excavation task planning systems, practical implementations have remained elusive [

23,

24]. This study addresses these gaps by integrating the excavator’s specifications, work environment, and design constraints into an algorithm that autonomously generates excavation plans for various construction types. It introduces a web-operable system and protocol designed to automate earthwork processes, seamlessly integrating with other subsystems using JSON within the overarching operational framework. This integration empowers even non-experts in earthworks to autonomously establish operational and work plans for excavators and dump trucks.

The proposed system employs a hierarchical planning approach that incorporates both high-level operation planning and task planning, alongside specialized sub-task planners utilizing task components for precise operational execution. This dual-layered planning structure has been demonstrated to effectively manage tasks in both simulated and real-world settings, proving particularly adept in trenching and large-scale material handling scenarios.

3.1. Prerequisites for Automated Excavator Task Planning

Before implementing automated excavator task planning for collaborative earthworks with dump trucks, it is crucial to establish a comprehensive operational framework [

38]. This study underscores the significance of laying down fundamental environmental settings as a prerequisite. Such preparatory steps are essential for effectively integrating and operationalizing automation technologies within the complexities of earthwork tasks.

3.1.1. Creating Basic Drawings

In this study, the automated excavator–truck operation planning was initially established on a site-wide basis, as illustrated in

Figure 1 [

23,

39]. However, practical on-site conditions, including the previous day’s construction progress, daily site conditions, and equipment status, often require adjustments to specific site area work plans. Therefore, it is essential to meticulously refine these plans based on real-time on-site conditions. Despite the automation of equipment work plans, operator intervention remains crucial. Detailed editing of work conditions enables the creation of realistic and practical automated equipment work plans. To meet this need, Computer-Aided Design (CAD)-based basic drawings (

Table 1) must be generated initially for the specific area where the excavator will operate on a given day. Subsequently, these drawings are uploaded to a web-based system facilitating automated excavator–dump truck collaboration. The system utilizes these drawings to inform its work plan generation algorithm, thereby ensuring the adaptation of the automated plan to real-time on-site conditions.

3.1.2. Uploading Drawings to the System and Entering Excavator Specifications

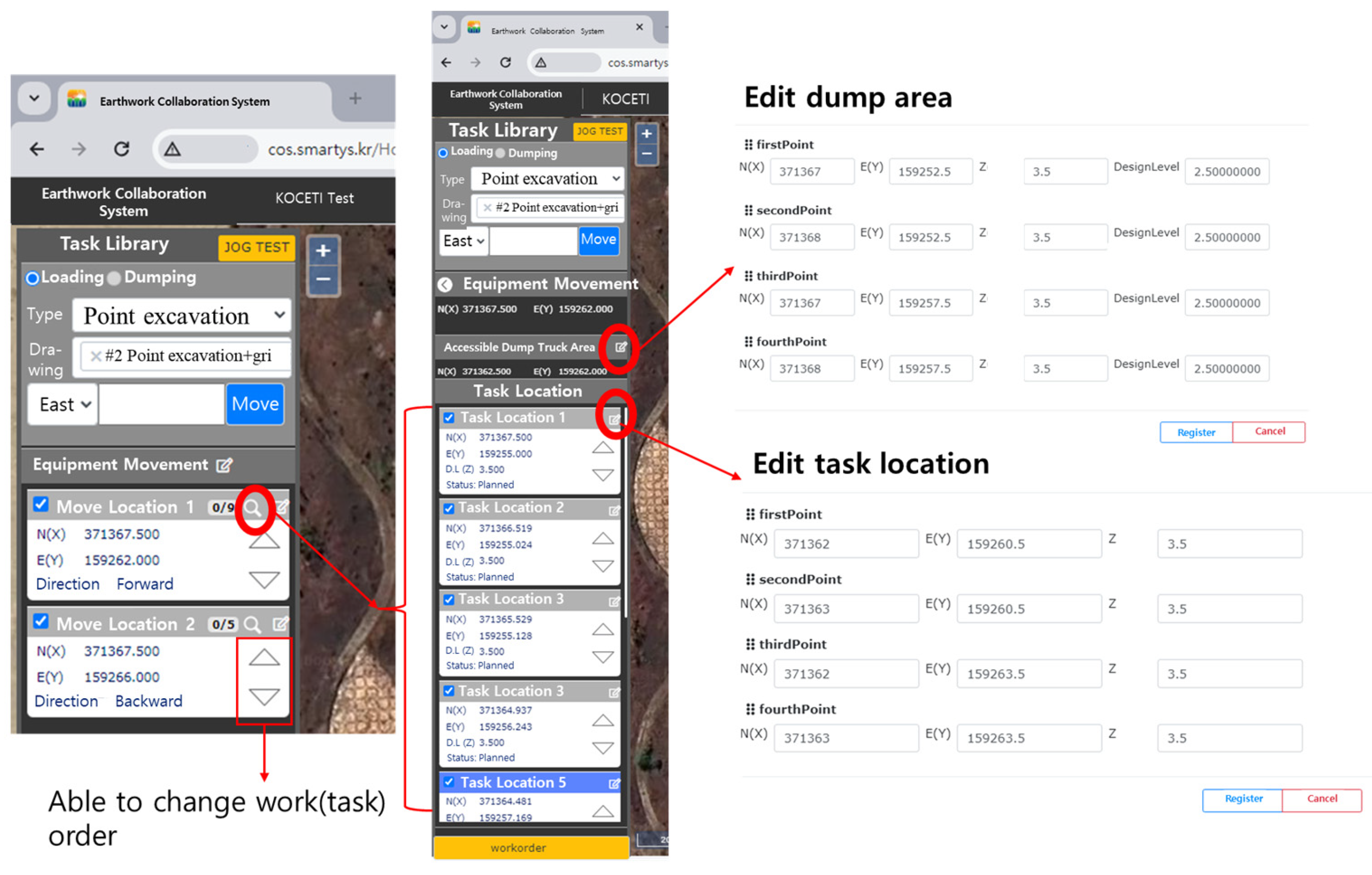

Once the basic drawings are developed, they are extracted in Drawing Exchange Format (DXF) format and uploaded to the automated excavator–dump truck collaboration system, as depicted in

Figure 2. Upon uploading a task, the system algorithmically generates a task plan based on the selected work type, as depicted in

Figure 3. The available work types encompass point digging, trench excavation, independent foundation excavation, and wall foundation excavation.

3.2. Setting Excavator Specifications and Truck Access Positioning

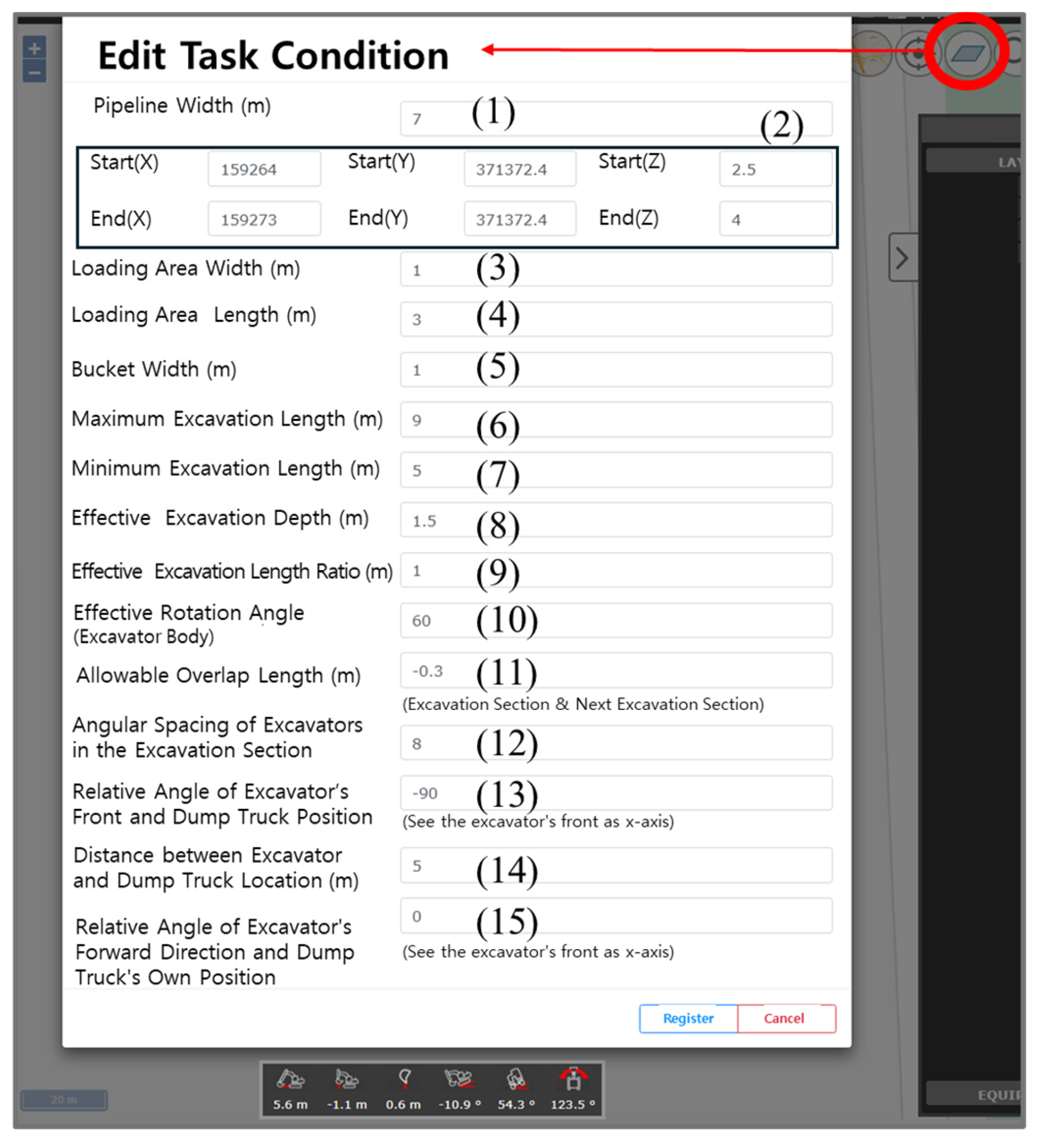

Once the drawing is uploaded based on the designated work type, detailed specifications of the automated excavator and corresponding working conditions must be provided to ensure seamless coordination with the dump truck. This step allows operators to adjust equipment specifications and working conditions in detail according to on-site requirements.

This study primarily focuses on automating the collaborative work between excavators and trucks, necessitating an understanding of their interaction. In environments where multiple excavators and dump trucks collaborate, establishing route planning poses a challenge, particularly ensuring easy access between the excavator and the dump truck. Existing studies and algorithms often prioritize truck accessibility to address this challenge [

23]. At construction sites, the precise loading position of the truck is typically determined based on signals from the excavator, such as horn or guidance signals. As a common interaction, when the excavator lifts soil in the bucket, the truck adjusts its position relative to the excavator and the boom. However, complexities arise in complex earthwork sites due to various variables such as soil type and weather conditions, making it challenging to determine the optimal loading position. To simplify this aspect, this study assumes a large-scale earthwork site without obstacles. Users are then prompted to input the truck’s approach location based on entrance information, considering the size of the excavator being used. Since the truck is not automated, users can select the most suitable location for it to access and park next to the automated excavator, providing flexibility to adapt to field conditions. The system allows users to modify parameters such as the length of the boom arm bucket and dump truck specifications within a specified angle range (−90° to 90°) through the editing function. This customizable feature enhances user control and adaptability to varying work conditions. Detailed descriptions of each task condition editing function are provided in

Figure 4 and

Table 2.

3.3. JSON-Task Plan Protocol

The results of the task planning for excavators and dump trucks comprise an excavation plan that specifies the locations and depths of the excavation sites, and a plan for the dump sites for loading or unloading (

Figure 5). These are integrated into a cohesive task planning unit utilizing JSON format, transmitted via WebSocket, and organized by indexing. The task sequence involves multiple excavation and dump site plans laid out in a continuous cycle (move → excavate → move → excavate), with each component registered in the worklist as a distinct JSON-formatted task. In this schema, movements are classified under ‘move’, consisting of coordinates, while operational tasks are grouped under ‘working’, detailed with dump locations and a coordinate array. Each location is delineated by the task sequence index ‘idx’ and consists of four points (

Table 3). A JSON file is delivered to the automated excavator and works according to the contents contained in the file. Additionally, the task plan is designed to enable on-site personnel to adapt it according to varying construction site conditions.

3.4. Task Component Design

This study focuses on several specific tasks performed by excavators, such as point excavation and trench excavation, which constitute a significant portion of excavator operations and entail direct collaboration (loading) with trucks, as well as preparatory work linked with subsequent tasks. When designing task components for different work types, integrating common functions within algorithms has proven highly effective. These functions facilitate code reuse, conserving development, and maintenance time, enhancing code modularity, improving readability, and reducing dependencies between different code segments. Utilizing verified, reusable functions diminishes the chances of errors and bolsters the system’s reliability. Moreover, optimizing specific functions can enhance the performance of all algorithms that incorporate them. In cases where function modification is necessary, updating only the specific function simplifies maintenance and avoids extensive code revisions.

Therefore, the judicious utilization of shared functions is indispensable for optimizing code efficiency and orchestrating algorithms adeptly. This strategy finds resonance in crafting algorithms for tasks such as point and trench excavation, where exactitude and effectiveness reign supreme [

40,

41]. Among the arsenal of functions commonly employed in constructing task plan generation algorithms, discerning choices play a pivotal role, as delineated in

Table 4.

3.4.1. Point Excavation

Point excavation represents the fundamental form of excavation, where the excavator is stationed at a fixed point to excavate a designated area. The algorithm commences by initializing an empty list named ‘diggingInfo’ to store the outcomes of excavation activities. Initially, the excavator is positioned at the predetermined starting location, facilitating the initiation of the digging process. Utilizing the ‘dumpingAreaHint’, the algorithm computes the optimal area for depositing excavated material, ensuring disposal sites are chosen based on accessibility and efficiency. The process then iterates through potential swing angles available to the excavator, identified via the ‘excavator.SwingAngles()’ function. This step is pivotal for evaluating the effective range of the excavation operation. For each angle, the area impacted by the excavator’s bucket, termed ‘bucketSquare’, is calculated. The algorithm determines the intersection of ‘bucketSquare’ with the ‘targetArea’ to pinpoint precise locations for excavation, ensuring that digging activity remains confined within designated boundaries. The excavator executes digging at these intersections, accounting for specific soil properties. Each result of the digging operation, along with dumping area information, is appended to the ‘diggingInfo’ list. Upon processing all swing angles and documenting corresponding digging information, the algorithm concludes by returning ‘diggingInfo’. This dataset furnishes a comprehensive record of excavation activities, encompassing locations and volumes of displaced soil, crucial for subsequent operational analysis and planning. The algorithm pseudo-code encapsulating these steps is provided below (

Figure 6).

3.4.2. Trench Excavation

To initialize data collection on excavation activities, an empty list named ‘diggingInfo’ is prepared. The algorithm (

Figure 7) commences by iterating over each line in the provided lines, delineating the paths necessitating trench excavation. For every line, the area earmarked for excavation, designated as ‘lineArea’, is computed based on the line and its specified width. Subsequently, the algorithm generates a sequence of movement points for the excavator along the line, termed ‘stepPoints’, which outline the sequential positions the excavator will traverse during the trench digging process.

As the excavator maneuvers through these points, it precisely navigates to each designated position. With precision, it calculates the ideal dumping area for excavated material based on the provided ‘dumpingAreaHint’, ensuring efficient soil disposal. Next, the algorithm meticulously analyzes the excavator’s swing angles using ‘excavator.SwingAngles()’ to determine the optimal excavation range for every movement point. For each swing angle, the algorithm meticulously computes the area impacted by the excavator’s bucket, referred to as ‘bucketSquare’. This calculation precisely determines the specific segments of the trench requiring soil removal within the ‘lineArea’. With keen precision, the excavator then executes digging at these identified intersections, considering the nuanced properties of the soil. Subsequently, the results of these strategic operations, along with comprehensive dumping area specifications, are seamlessly integrated into the ‘diggingInfo’ dataset.

After processing all lines, movement points, and swing angles, the algorithm gracefully concludes its execution by delivering the invaluable ‘diggingInfo’ dataset. This repository encapsulates a wealth of intricate details regarding every trench excavation activity, meticulously documenting the precise locations and volumes of displaced soil. Such granular data serve as a cornerstone for subsequent project management and planning endeavors, empowering informed decision-making and strategic execution.

3.5. Challenges of Developed Method

Firstly, the system presented in this study is dependent on CAD design. The system requires a certain amount of manual input for the initial design phase. While automation assists execution, significant human intervention is still required during the early design stages. Secondly, there is the issue of boundary setting. Site boundaries must be manually specified, highlighting the system’s limitations in autonomously adapting to new environments without preset parameters. Thirdly, manual input is needed in task operations. Specific task sequences involving dump trucks still require manual adjustments. Designating loading zones and ensuring proper alignment between excavators and trucks fall under this category. Fourthly, operational inefficiency is another limitation. The case study revealed that occasional manual intervention is necessary, which can lead to potential delays. Additionally, the system lacks the capability for dynamic adjustment based on real-time feedback, making it challenging to maintain a continuous workflow. Construction planning personnel must assess the usability and areas for improvement of this system. This will help establish empirical validation standards for what to measure and verify through the task planning system and provide a clear direction for future research and development efforts. So, in future work, practical validation will be conducted with results and more data support. These limitations indicate areas for system improvement and provide clear directions for future research and development efforts. They contribute to the achievement of a fully autonomous excavation process. Addressing these issues can significantly enhance the system’s efficiency, adaptability, and applicability across various construction scenarios.

4. Results and Discussion

In the study, task components of excavators and algorithms were specifically designed for different types of excavator and dump truck earthwork operations. They were implemented within a web-based evaluation program. This program was integrated with an automated control system to validate its applicability in real-world scenarios. An earthwork site was selected as the testing environment for evaluating the developed system. The experiments were conducted across three separate sessions: in August, September, and November of 2023 (

Figure 8).

Utilizing CAD software, a task plan was devised for each testing phase, with a particular focus on tasks like point and trench excavation, typical in large-scale earthwork endeavors. These designs were then exported in JSON format, serving as the standardized data interchange format to seamlessly convey information to the integrated control system and subsequently to the excavator’s control system. The results vividly illustrate the precise execution of excavation tasks in accordance with predefined parameters of location and depth, meticulously outlined in the work plans. This study’s findings underscore the efficacy of developed algorithms and the seamless integration capabilities of the system in faithfully replicating planned tasks within a controlled test environment.

In the study, representations of point and trench excavation tasks are provided in accompanying figures (

Table 5 (a1), (a2)), where excavation sectors are represented by an array of yellow boxes, and the designated loading positions for the dump truck are indicated by a blue box. These graphical representations assist in providing a clear visual distinction between the different types of excavation tasks. Additionally, the empirical outcomes, as demonstrated in

Table 5 (b1), (b2), show that the actual outputs for each task are consistent in both shape and size, confirming the precision and reliability of the excavation process as executed per the task plan (

Table 5 (c1), (c2)). This unwavering consistency underscores the efficacy of the methodologies deployed in achieving precise excavation specifications.

The experimental outcomes of this study should be considered within the context of its specific limitations, particularly the selection of a simplified earthwork site for testing. This environment lacked common real-world complexities such as obstructions or varied topography, which are typical in standard construction sites. This simplification might restrict the applicability of the findings, as the actual performance of these excavation techniques in conventional settings has not been examined. While using a simplified site can help in systematically assessing system capabilities and making initial evaluations, it does not fully replicate the diverse challenges present in normal earthwork operations, which could lead to a gap between anticipated and actual performance in varied operational contexts.

Moreover, the system’s dependence on manually inputted designs for site boundaries and specific excavation areas introduces a significant element of human intervention. This requirement for manual data input of CAD designs could hinder the system’s flexibility and scalability, as each change in project scope or site layout necessitates new inputs and assessments. Although the demonstrated precision of task execution is impressive, the overall effectiveness of these operations heavily relies on the accuracy of the initial design inputs. Mistakes or inaccuracies during this stage can cause errors in the final excavation, leading to cost overruns in earthwork. The integration of dump truck operations within this system also shows a limitation in automation scope, particularly in the manual specification of loading areas. This aspect suggests partial automation where critical elements like the dynamic positioning of dump trucks still require manual intervention, which could lead to operational inefficiencies in practice. Optimizing the coordination between excavators and dump trucks without human input remains an essential development goal. Enhancing this aspect of the system could significantly improve operational continuity and efficiency, particularly in fluid and changing construction environments.

Despite efficiently replicating planned tasks in controlled environments, the system’s true worth in actual earthwork projects hinges on its performance under unpredictable real-world conditions. Future research should encompass a spectrum of environmental settings to comprehensively assess the system’s prowess and operational constraints. Moreover, advancing automation in task planning and dynamic adjustment capabilities is crucial for reducing manual dependencies and enhancing responsiveness to real-time environmental shifts. These advancements are pivotal for transitioning from controlled experimental validations to practical, deployable systems equipped to tackle the intricacies of large-scale earthwork operations. Its adaptive nature, dynamically responding to shifting site dynamics and real-time data inputs, signifies a departure from static methodologies, ushering in a new era of agile problem-solving in construction operations. Moreover, the implementation of such automated systems heralds a paradigm shift, reducing the reliance on manual oversight and ushering in a future where labor and resources are optimized to their fullest potential. Beyond the realms of excavation and hauling, this technology holds the promise of reshaping various facets of the construction industry, offering novel solutions and unprecedented efficiencies through real-time, automated task planning.

5. Conclusions

This study has successfully demonstrated the application of task component design in excavator–truck operation planning using web-based systems. The developed algorithm improves the earthwork construction equipment operation ability considering the dynamic nature of the construction sites. It improves coordination between excavators and dump trucks, improving the productivity and operation of earthwork in construction projects.

The study develops a task planning algorithm that uses a web-operable system and protocol that autonomously generates excavation plans for various construction types. By integrating excavator specifications, work environment details, and design constraints into an algorithm, the system can efficiently manage and execute construction projects. The developed system utilizes a JSON-based protocol that integrates with sub-systems and it allows construction managers and stakeholders to establish operational and work plans for excavators and dump trucks even if they do not have any knowledge of excavation planning. It employs a hierarchical planning approach that includes high-level operation planning and task planning, alongside specialized sub-task planners. The system demonstrates effectiveness in managing tasks in both simulated and real-world settings. This research enhances the productivity and operational efficiency of earthwork construction projects by improving the coordination between excavators and dump trucks.

Further research could explore integrating additional types of construction machinery into this automated system to provide a comprehensive solution for site management. Studies could also assess the long-term impacts of such automation on project timelines and overall construction costs and its adaptability to different types of construction environments. Challenges such as varying site conditions and machine malfunctions need to be addressed to ensure reliability and effectiveness. To ensure reliability and effectiveness, the algorithm needs to be further refined to handle unexpected environmental variables and machine malfunctions. By pushing the boundaries of construction technology, this research contributes to the evolving field of construction automation. It promises a future where such technologies are commonplace, thereby enhancing operational efficiency and sustainability in construction projects.

Author Contributions

Conceptualization, S.P. and J.K.; methodology, S.P. and J.K.; software, S.P.; validation, S.P.; investigation, S.P.; writing—original draft preparation, S.P.; writing—review and editing, J.K.; visualization, S.P.; supervision, J.S.; project administration, J.S. and K.C.; funding acquisition, J.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Technology Innovation Program or Industrial Strategic Technology Development Program-Development of Collaborated Self Control System and Unmanned Excavator Technology for an Automated Earthworks (20010776) and Development of data management system for fleet management and data linkage of construction equipment in smart construction sites (20023755) funded By the Ministry of Trade, Industry & Energy (MOTIE, Korea). This work was also supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (Grant No. RS-2024-00356995).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Restrictions apply to the datasets: The datasets presented in this article are not readily available because the data are part of an ongoing study. Requests to access the datasets should be directed to 1st author or corresponding authors.

Conflicts of Interest

S-Tech E&C is a company established within Hanyang University, author Soohyun Park was employed by the company S-Tech E&C. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Lee, S.; Sharafat, A.; Kim, I.S.; Seo, J. Development and Assessment of an Intelligent Compaction System for Compaction Quality Monitoring, Assurance, and Management. Appl. Sci. 2022, 12, 6855. [Google Scholar] [CrossRef]

- Naji, K.K.; Gunduz, M.; Alhenzab, F.; Al-Hababi, H.; Al-Qahtani, A. Assessing the Digital Transformation Readiness of the Construction Industry Utilizing the Delphi Method. Buildings 2024, 14, 601. [Google Scholar] [CrossRef]

- Kim, S.-K.; Kim, G.-Y.; Park, J.-H. An Approach for Solid Modeling and Equipment Fleet Management towards Low-Carbon Earthwork. J. Korean Soc. Civ. Eng. 2015, 35, 501–514. [Google Scholar] [CrossRef]

- Park, S.; Kim, S. 3D Point Cloud Dataset of Heavy Construction Equipment. Appl. Sci. 2024, 14, 3599. [Google Scholar] [CrossRef]

- Tanoli, W.A.; Sharafat, A.; Park, J.; Seo, J.W. Damage Prevention for Underground Utilities Using Machine Guidance. Autom. Constr. 2019, 107, 102893. [Google Scholar] [CrossRef]

- Sharafat, A.; Khan, M.S.; Latif, K.; Tanoli, W.A.; Park, W.; Seo, J. BIM-GIS-Based Integrated Framework for Underground Utility Management System for Earthwork Operations. Appl. Sci. 2021, 11, 5721. [Google Scholar] [CrossRef]

- Seo, J.; Haas, C.T.; Saidi, K.; Sreenivasan, S.V. Graphical Control Interface for Construction and Maintenance Equipment. J. Constr. Eng. Manag. 2000, 126, 210–218. [Google Scholar] [CrossRef]

- Herc Rentals Inc. How the Right Excavator Improves Project Efficiency and Productivity. Available online: https://blog.hercrentals.com/earthmoving/how-the-right-excavator-improves-project-efficiency-and-productivity/ (accessed on 30 April 2024).

- BuildWitt What Is an Excavator and What’s It Used for? Available online: https://www.buildwitt.com/learning-hub/dirt-101/what-is-an-excavator-used-for (accessed on 30 April 2024).

- Saunier, L.; Hoffmann, N.; Preda, M.; Fetita, C. Virtual Reality Interface Evaluation for Earthwork Teleoperation. Electronics 2023, 12, 4151. [Google Scholar] [CrossRef]

- Tanoli, W.A.; Seo, J.W.; Sharafat, A.; Lee, S.S. 3D Design Modeling Application in Machine Guidance System for Earthwork Operations. KSCE J. Civ. Eng. 2018, 22, 4779–4790. [Google Scholar] [CrossRef]

- P-Fleet Different Types of Construction Trucks and Equipment Explained. Available online: https://www.pfleet.com/blog/types-of-construction-trucks-and-equipment-explained (accessed on 30 April 2024).

- Kim, J.; Lee, S.; Seo, J.; Lee, D.-E.; Choi, H.S. The Integration of Earthwork Design Review and Planning Using UAV-Based Point Cloud and BIM. Appl. Sci. 2021, 11, 3435. [Google Scholar] [CrossRef]

- Yoon, J.; Kim, J.; Seo, J.; Suh, S. Spatial Factors Affecting the Loading Efficiency of Excavators. Autom. Constr. 2014, 48, 97–106. [Google Scholar] [CrossRef]

- Kim, J.; Lee, S.S.; Seo, J.; Kamat, V.R. Modular Data Communication Methods for a Robotic Excavator. Autom. Constr. 2018, 90, 166–177. [Google Scholar] [CrossRef]

- Seo, J.; Lee, S.; Kim, J.; Kim, S.-K. Task Planner Design for an Automated Excavation System. Autom. Constr. 2011, 20, 954–966. [Google Scholar] [CrossRef]

- Folgado, F.; Calderón, D.; González, I.; Calderón, A. Review of Industry 4.0 from the Perspective of Automation and Supervision Systems: Definitions, Architectures and Recent Trends. Electronics 2024, 13, 782. [Google Scholar] [CrossRef]

- Stentz, A.; Bares, J.; Singh, S.; Rowe, P. A Robotic Excavator for Autonomous Truck Loading. Auton. Robot. 1999, 7, 175–186. [Google Scholar] [CrossRef]

- Demirel, N.; Taghizadeh, A.; Khouri, S.; Tyuleneva, E. Optimization of the Excavator-and-Dump Truck Complex at Open Pit Mines–the Case Study. E3S Web Conf. 2018, 41, 01006. [Google Scholar] [CrossRef]

- Kim, J.; Chi, S.; Seo, J. Interaction Analysis for Vision-Based Activity Identification of Earthmoving Excavators and Dump Trucks. Autom. Constr. 2018, 87, 297–308. [Google Scholar] [CrossRef]

- Gwak, H.-S.; Seo, J.; Lee, D.-E. Optimal Cut-Fill Pairing and Sequencing Method in Earthwork Operation. Autom. Constr. 2018, 87, 60–73. [Google Scholar] [CrossRef]

- Kim, J.; Seo, J. Task Planner for Autonomous Excavator Considering Work Environment. In Proceedings of the 28th ISARC, Seoul, Korea, 29 June 2011; pp. 770–771. [Google Scholar]

- Kim, J.; Lee, D.; Seo, J. Task Planning Strategy and Path Similarity Analysis for an Autonomous Excavator. Autom. Constr. 2020, 112, 103108. [Google Scholar] [CrossRef]

- Chui, M.; Mischke, J. Global Infrastructure Initiative the Impact and Opportunities of Automation in Construction Courtesy of Autodesk: Royal BAM Group’s BAM Infra and Saint-Gobain Weber Beamix Demonstrate the Use of a 3-D Printing Robot for Offsite Manufacturing for Construction. 2019. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/the-impact-and-opportunities-of-automation-in-construction/ (accessed on 30 April 2024).

- Kim, M.J.; Chi, H.-L.; Wang, X.; Ding, L. Automation and Robotics in Construction and Civil Engineering. J. Intell. Robot. Syst. 2015, 79, 347–350. [Google Scholar] [CrossRef]

- Yousif, O.S.; Zakaria, R.B.; Aminudin, E.; Yahya, K.; Mohd Sam, A.R.; Singaram, L.; Munikanan, V.; Yahya, M.A.; Wahi, N.; Shamsuddin, S.M. Review of Big Data Integration in Construction Industry Digitalization. Front. Built Environ. 2021, 7, 770496. [Google Scholar] [CrossRef]

- Kim, S.-K.; Koo, B. A Path Generation Method Considering the Work Behavior of Operators for an Intelligent Excavator. J. Korean Soc. Civ. Eng. 2010, 30, 433–442. [Google Scholar]

- Vazquez-Santiago, K.; Goh, C.F.; Basdeo, R.; Shimada, K. Optimization Framework for Global Path Planning and Local Motion Planning for Robotic Welding of Multiple Large Industrial Parts. In Proceedings of the 2023 IEEE 19th International Conference on Automation Science and Engineering (CASE), Auckland, New Zealand, 26–30 August 2023; pp. 1–8. [Google Scholar]

- Zhang, L.; Zhao, J.; Long, P.; Wang, L.; Qian, L.; Lu, F.; Song, X.; Manocha, D. An Autonomous Excavator System for Material Loading Tasks. Sci. Robot. 2021, 6, eabc3164. [Google Scholar] [CrossRef] [PubMed]

- Alhasan, A.; White, D.J. Earthwork Haul-Truck Cycle-Time Monitoring: A Case Study; Iowa State University: Ames, IA, USA, 2016. [Google Scholar]

- Ha, Q.P.; Yen, L.; Balaguer, C. Robotic Autonomous Systems for Earthmoving in Military Applications. Autom. Constr. 2019, 107, 102934. [Google Scholar] [CrossRef]

- Eraliev, O.M.U.; Lee, K.-H.; Shin, D.-Y.; Lee, C.-H. Sensing, Perception, Decision, Planning and Action of Autonomous Excavators. Autom. Constr. 2022, 141, 104428. [Google Scholar] [CrossRef]

- Frimpong, S.; Changirwa, R.; Szymanski, J. Simulation of Automated Dump Trucks for Large Scale Surface Mining Operations. Int. J. Surf. Min. Reclam. Environ. 2003, 17, 183–195. [Google Scholar] [CrossRef]

- Vagenas, N. Dispatch Control of a Fleet of Remote-Controlled/Automatic Load-Haul-Dump Vehicles in Underground Mines. Int. J. Prod. Res. 1991, 29, 2347–2363. [Google Scholar] [CrossRef]

- Ferrein, A.; Reke, M.; Scholl, I.; Decker, B.; Limpert, N.; Nikolovski, G.; Schiffer, S. Towards a Fleet of Autonomous Haul-Dump Vehicles in Hybrid Mines. In Proceedings of the 15th International Conference on Agents and Artificial Intelligence—(Volume 1), Lisbon, Portugal, 22–24 February 2023; pp. 278–288. [Google Scholar]

- Kim, I.-S.; Latif, K.; Kim, J.; Sharafat, A.; Lee, D.-E.; Seo, J. Vision-Based Activity Classification of Excavators by Bidirectional LSTM. Appl. Sci. 2022, 13, 272. [Google Scholar] [CrossRef]

- Rafi, Y.F.; Witjaksana, B. Productivity Analysis of Excavator and Dump Truck Heavy Equipment on Digging and Loading Works Flood Control Afvoer Watudakon Mojokerto. J. Tek. Sipil 2023, 23, 205–210. [Google Scholar] [CrossRef]

- Zhao, Z.; Bi, L. A New Challenge: Path Planning for Autonomous Truck of Open-Pit Mines in The Last Transport Section. Appl. Sci. 2020, 10, 6622. [Google Scholar] [CrossRef]

- Pradhananga, N.; Teizer, J. Cell-Based Construction Site Simulation Model for Earthmoving Operations Using Real-Time Equipment Location Data. Vis. Eng. 2015, 3, 12. [Google Scholar] [CrossRef]

- ALEX 2.6—Why Functions Are Useful, and How to Use Them Effectively. Available online: https://www.learncpp.com/cpp-tutorial/why-functions-are-useful-and-how-to-use-them-effectively/ (accessed on 18 December 2023).

- Private: Learning Math: Patterns, Functions, and Algebra. Available online: https://www.learner.org/series/learning-math-patterns-functions-and-algebra/functions-and-algorithms/ (accessed on 18 December 2023).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).