Lifting Activities Assessment Using Lumbosacral Compression and Shear Forces

Abstract

:1. Introduction

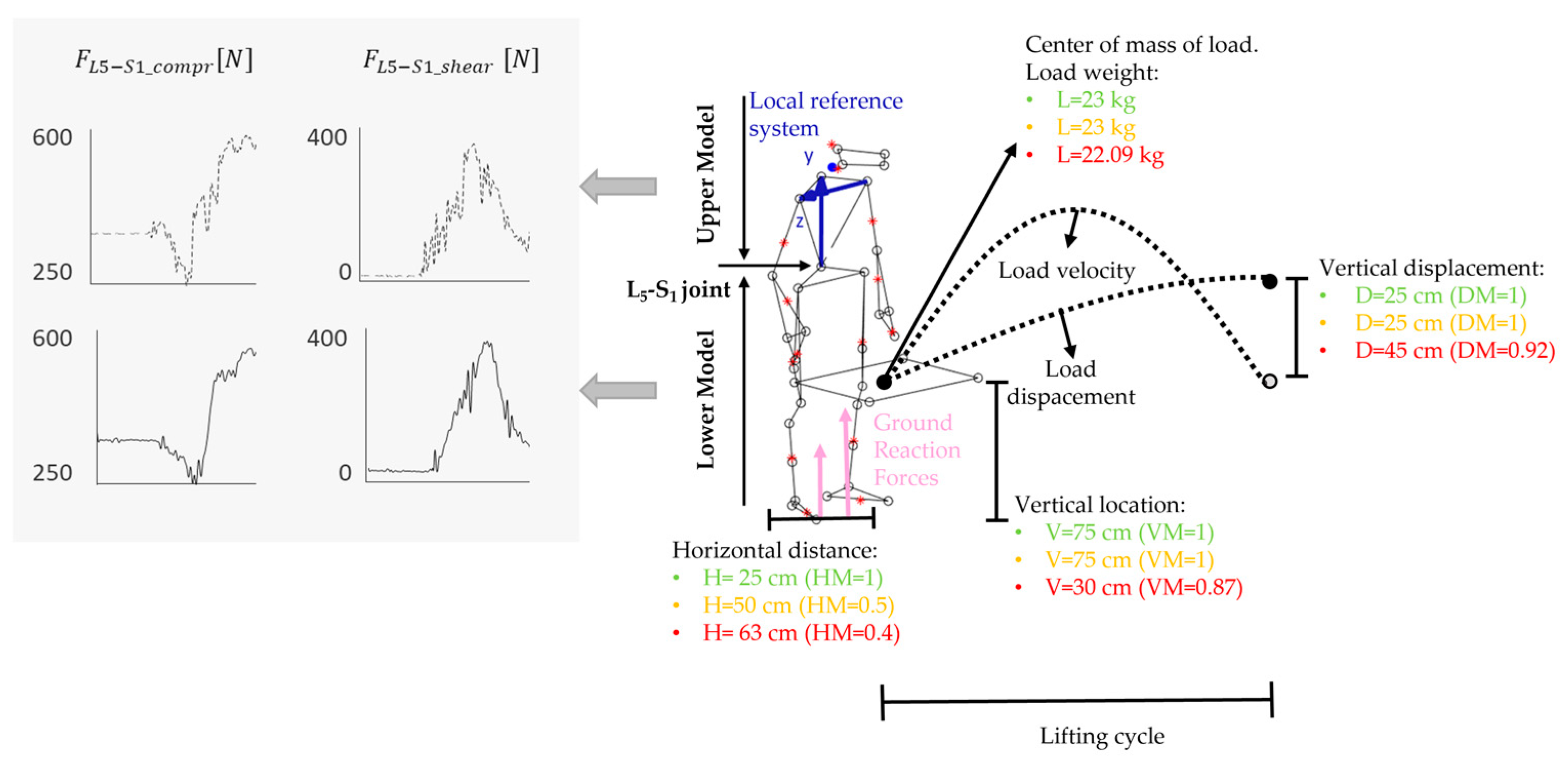

2. Materials and Methods

2.1. Subjects

2.2. Kinematic and Kinetic Recordings

2.3. Experimental Procedures

2.4. Data Analysis

2.4.1. Lifting Cycle Detection

2.4.2. Force Calculation

- is the rth external force;

- is the number of external forces;

- is the number of body segments considered;

- is the acceleration of gravity;

2.5. Statistical Analysis

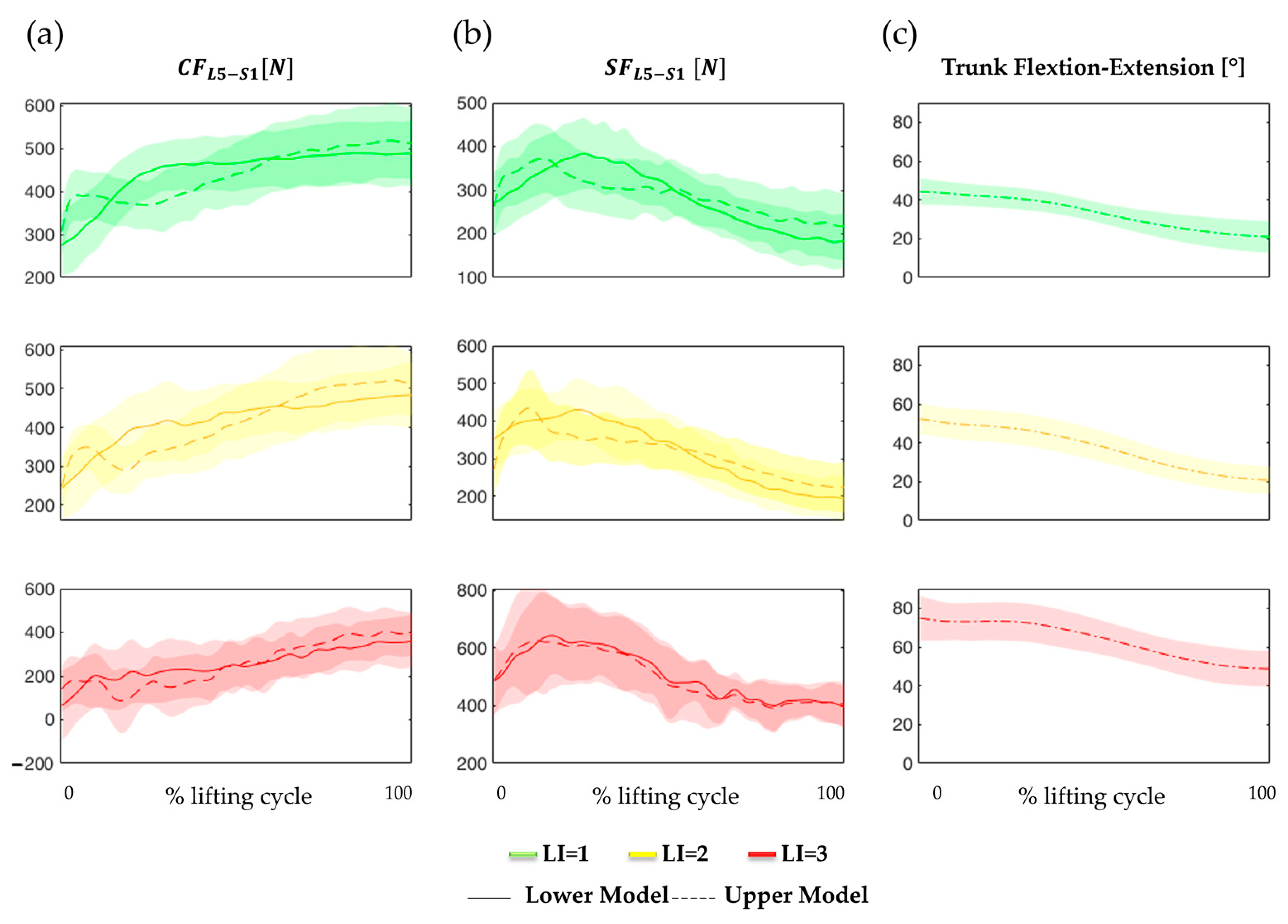

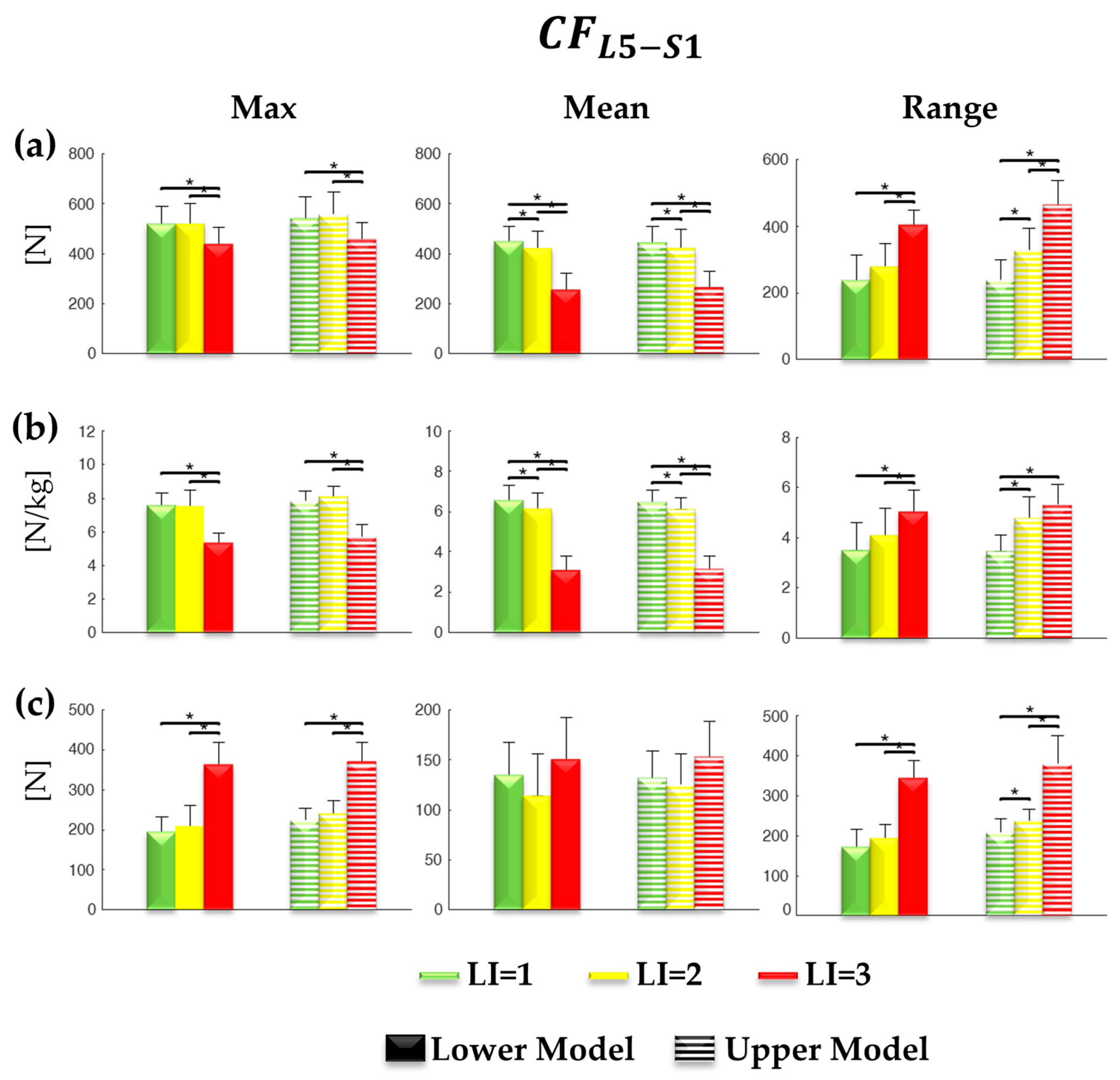

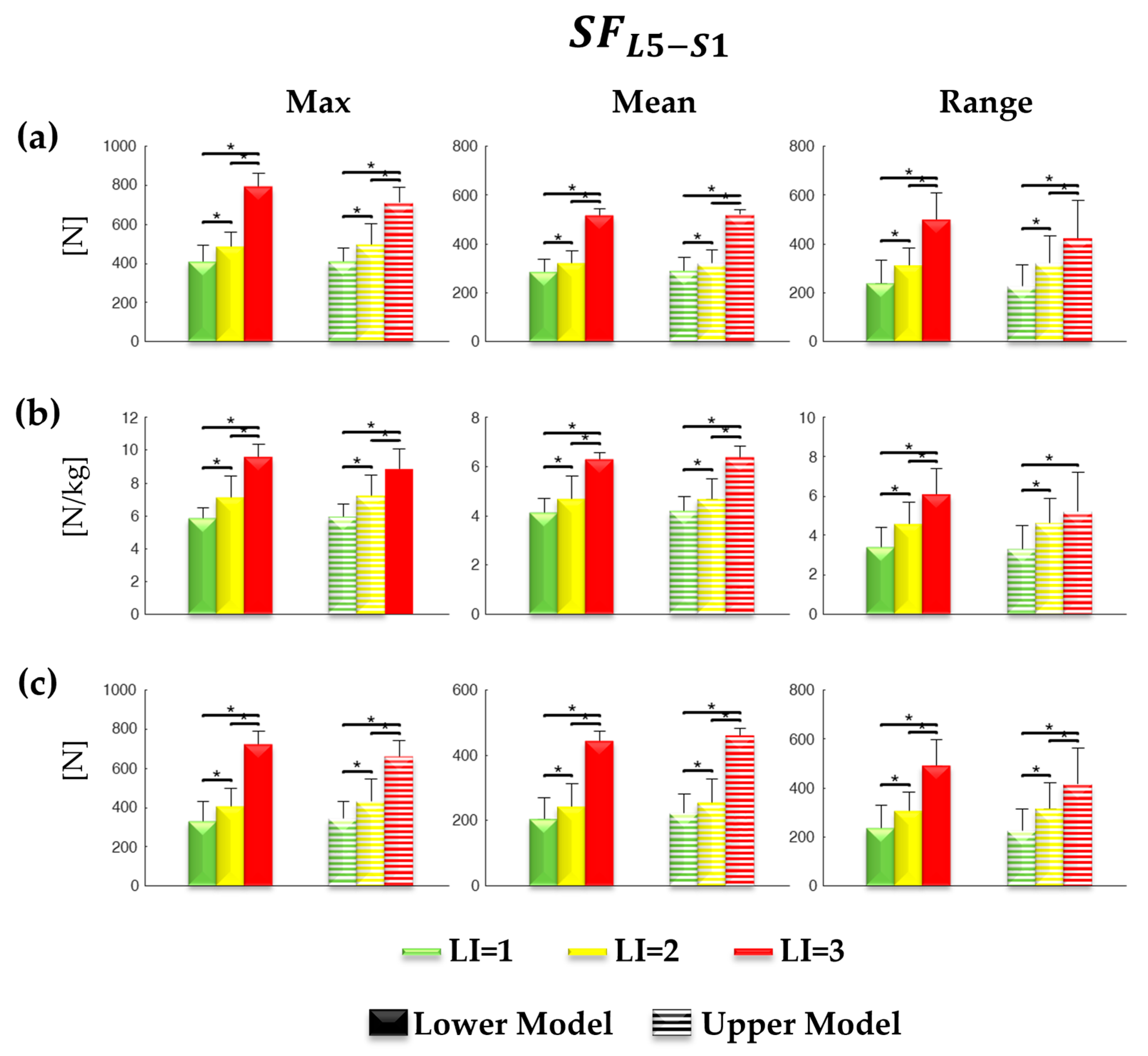

3. Results

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bosch, T.; van Eck, J.; Knitel, K.; de Looze, M. The effects of a passive exoskeleton on muscle activity, discomfort and endurance time in forward bending work. Appl. Ergon. 2016, 54, 212–217. [Google Scholar] [CrossRef] [PubMed]

- Alemi, M.M.; Geissinger, J.; Simon, A.A.; Chang, S.E.; Asbeck, A.T. A passive exoskeleton reduces peak and mean EMG during symmetric and asymmetric lifting. J. Electromyogr. Kinesiol. 2019, 47, 25–34. [Google Scholar] [CrossRef] [PubMed]

- Flor-Unda, O.; Casa, B.; Fuentes, M.; Solorzano, S.; Narvaez-Espinoza, F.; Acosta-Vargas, P. Exoskeletons: Contribution to Occupational Health and Safety. Bioengineering 2023, 10, 1039. [Google Scholar] [CrossRef] [PubMed]

- Waters, T.; Putz-Anderson, V.; Garg, A. Applications Manual for the Revised NIOSH Lifting Equation; DHHS Publication: Cincinnati, OH, USA, 1994. Available online: https://stacks.cdc.gov/view/cdc/5434 (accessed on 2 February 2024).

- Waters, T.R.; Putz-Anderson, V.; Garg, A.; Fine, L.J. Revised NIOSH equation for the design and evaluation of manual lifting tasks. Ergonomics 1993, 36, 749–776. [Google Scholar] [CrossRef] [PubMed]

- ISO/DIS 11228-1; Ergonomics—Manual Handling—Part 1: Lifting and Carrying. ISO: Geneva, Switzerland, 2003.

- ISO 11228-2; Ergonomics—Manual Handling—Part 2: Pushing and Pulling. ISO: Geneva, Switzerland, 2007.

- ISO/DIS 11228-3; Ergonomics—Manual Handling—Part 3: Handling of Low Loads at High Frequency. ISO: Geneva, Switzerland, 2007.

- Ranavolo, A.; Ajoudani, A.; Cherubini, A.; Bianchi, M.; Fritzsche, L.; Iavicoli, S.; Sartori, M.; Silvetti, A.; Vanderborght, B.; Varrecchia, T.; et al. The Sensor-Based Biomechanical Risk Assessment at the Base of the Need for Revising of Standards for Human Ergonomics. Sensors 2020, 20, 5750. [Google Scholar] [CrossRef] [PubMed]

- CWA 17938:2023; Guideline for Introducing and Implementing Real-Time Instrumental-Based Tools for Biomechanical Risk Assessment. CEN-CENELEC Management Centre: Belgium, 2023. Available online: https://www.cencenelec.eu/media/CEN-CENELEC/CWAs/RI/2023/cwa17938_2023.pdf (accessed on 10 July 2024).

- Armstrong, T.J.; Burdorf, A.; Descatha, A.; Farioli, A.; Graf, M.; Horie, S.; Marras, W.S.; Potvin, J.R.; Rempel, D.; Spatari, G.; et al. Scientific basis of ISO standards on biomechanical risk factors. Scand. J. Work. Environ. Health 2018, 44, 323–329. [Google Scholar] [CrossRef] [PubMed]

- Ranavolo, A.; Draicchio, F.; Varrecchia, T.; Silvetti, A.; Iavicoli, S. Wearable Monitoring Devices for Biomechanical Risk Assessment at Work: Current Status and Future Challenges—A Systematic Review. Int. J. Environ. Res. Public Health 2018, 15, 2001, Erratum in Int. J. Environ. Res. Public Health 2018, 15, 2569. [Google Scholar] [CrossRef] [PubMed]

- Ranavolo, A.; Varrecchia, T.; Iavicoli, S.; Marchesi, A.; Rinaldi, M.; Serrao, M.; Conforto, S.; Cesarelli, M.; Draicchio, F. Surface electromyography for risk assessment in work activities designed using the “revised NIOSH lifting equation”. Int. J. Ind. Ergon. 2018, 68, 34–45. [Google Scholar] [CrossRef]

- Ranavolo, A.; Varrecchia, T.; Rinaldi, M.; Silvetti, A.; Serrao, M.; Conforto, S.; Draicchio, F. Mechanical lifting energy consumption in work activities designed by means of the “revised NIOSH lifting equation”. Ind. Health 2017, 55, 444–454. [Google Scholar] [CrossRef]

- Varrecchia, T.; De Marchis, C.; Rinaldi, M.; Draicchio, F.; Serrao, M.; Schmid, M.; Conforto, S.; Alberto, R. Lifting activity assessment using surface electromyographic features and neural networks. Int. J. Ind. Ergon. 2018, 66, 1–9. [Google Scholar] [CrossRef]

- Varrecchia, T.; De Marchis, C.; Draicchio, F.; Schmid, M.; Conforto, S.; Alberto, R. Lifting activity assessment using kinematic features and neural networks. Appl. Sci. 2020, 10, 1989. [Google Scholar] [CrossRef]

- Chini, G.; Varrecchia, T.; Conforto, S.; De Nunzio, A.M.; Draicchio, F.; Falla, D.; Ranavolo, A. Trunk stability in fatiguing frequency-dependent lifting activities. Gait Posture 2023, 102, 72–79. [Google Scholar] [CrossRef] [PubMed]

- Ranavolo, A.; Ajoudani, A.; Chini, G.; Lorenzini, M.; Varrecchia, T. Adaptive Lifting Index (aLI) for Real-Time Instrumental Biomechanical Risk Assessment: Concepts, Mathematics, and First Experimental Results. Sensors 2024, 24, 1474. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Siegler, S.; Allard, P.; Kirtley, C.; Leardini, A.; Rosenbaum, D.; Whittle, M.; D’Lima, D.D.; Cristofolini, L.; Witte, H.; et al. Standardization and Terminology Committee of the International Society of Biomechanics ISB recommendation on definitions of joint coordinate system of various joints for the reporting of human joint motion—Part I: Ankle, hip, and spine. J. Biomech. 2002, 35, 543–548. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; van der Helm, F.C.; Veeger, H.E.; Makhsous, M.; Van Roy, P.; Anglin, C.; Nagels, J.; Karduna, A.R.; McQuade, K.; Wang, X.; et al. International Society of Biomechanics. ISB Recommendation on Definitions of Joint Coordinate Systems of Various Joints for the Reporting of Human Joint Motion. Part II.; Shoulder, Elbow, Wrist and Hand. J. Biomech. 2005, 38, 981–992. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez-Farewik, E.M.; Bartonek, A.; Saraste, H. Comparison and evaluation of two common methods to measure center of mass displacement in three dimensions during gait. Hum. Mov. Sci. 2006, 25, 238–256. [Google Scholar] [CrossRef] [PubMed]

- Rab, G.; Petuskey, K.; Bagley, A. A method for determination of upper extremity kinematics. Gait Posture 2002, 15, 113–119. [Google Scholar] [CrossRef]

- Davis, R.B., 3rd; Õunpuu, S.; Tyburski, D.; Gage, J.R. A gait analysis data collection and reduction technique. Hum. Mov. Sci. 1991, 10, 575–587. [Google Scholar] [CrossRef]

- Plamondon, A.; Gagnon, M.; Desjardins, P. Validation of two 3-D segment models to calculate the net reaction forces and moments at the L5/S1 joint in lifting. Clin. Biomech. 1996, 11, 101–110. [Google Scholar] [CrossRef]

- Zatsiorsky, V.M.; Seluyanov, V.N.; Chugunova, L.G. Methods of Determining Mass-Inertial Characteristics of Human Body Segments; Chernyi, G.G., Regirer, S.A., Eds.; Contemporary Problems of Biomechanics: Boca Raton, FL, USA, 1990; pp. 272–291. [Google Scholar]

- de Leva, P. Adjustments to Zatsiorsky-Seluyanov’s segment inertia parameters. J. Biomech. 1996, 29, 1223–1230. [Google Scholar] [CrossRef]

- Armstrong, D.P.; Fischer, S.L. Understanding individual differences in lifting mechanics: Do some people adopt motor control strategies that minimize biomechanical exposure. Hum. Mov. Sci. 2020, 74, 102689. [Google Scholar] [CrossRef] [PubMed]

- Ranavolo, A.; Mari, S.; Conte, C.; Serrao, M.; Silvetti, A.; Iavicoli, S.; Draicchio, F. A new muscle co-activation index for biomechanical load evaluation in work activities. Ergonomics 2015, 58, 966–979. [Google Scholar] [CrossRef] [PubMed]

- Arjmand, N.; Plamondon, A.; Shirazi-Adl, A.; Lariviere, C.; Parnianpour, M. Predictive equations to estimate spinal loads in symmetric lifting tasks. J. Biomech. 2011, 44, 84–91. [Google Scholar] [CrossRef] [PubMed]

- Naing, L.; Winn, T.; Rusli, B.N. Practical issues in calculating the sample size for prevalence studies. Arch. Orofac. Sci. 2006, 1, 9–14. [Google Scholar]

- Fillingim, R.B.; King, C.D.; Ribeiro-Dasilva, M.C.; Rahim-Williams, B.; Riley, J.L. Sex, gender, and pain: A review of recent clinical and experimental findings. J. Pain 2009, 10, 447–485. [Google Scholar] [CrossRef] [PubMed]

- Hunter, S.K. Sex differences in human fatigability: Mechanisms and insight to physiological responses. Acta Physiol. 2014, 210, 768–789. [Google Scholar] [CrossRef] [PubMed]

- Sullivan, B.E.; Carroll, C.C.; Jemiolo, B.; Trappe, S.W.; Magnusson, S.P.; Dossing, S.; Kjaer, M.; Trappe, T.A. Effect of acute resistance exercise and sex on human patellar tendon structural and regulatory mRNA expression. J. Appl. Physiol. 2009, 106, 468–475. [Google Scholar] [CrossRef] [PubMed]

- Johansen, T.; Samani, A.; Antle, D.; Côté, J.N.; Madeleine, P. Gender effects on the coordination of subdivisions of the trapezius muscle during a repetitive box-folding task. Eur. J. Appl. Physiol. 2013, 113, 175–182. [Google Scholar] [CrossRef]

- Sartori, M.; Reggiani, M.; Farina, D.; Lloyd, D.G. EMG-Driven Forward-Dynamic Estimation of Muscle Force and Joint Moment about Multiple Degrees of Freedom in the Human Lower Extremity. PLoS ONE 2012, 7, e52618. [Google Scholar] [CrossRef]

- Moya-Esteban, A.; van der Kooij, H.; Sartori, M. Robust estimation of lumbar joint forces in symmetric and asymmetric lifting tasks via large-scale electromyography-driven musculoskeletal models. J. Biomech. 2022, 144, 111307. [Google Scholar] [CrossRef]

- Lloyd, D.G.; Besier, T.F. An EMG-driven musculoskeletal model to estimate muscle forces and knee joint moments in vivo. J. Biomech. 2003, 36, 765–776. [Google Scholar] [CrossRef]

| Segment | Markers | Mass (%Mass) | CM (%Length) | ||

|---|---|---|---|---|---|

| Female | Male | Female | Male | ||

| Head | Temple and posterior-superior parietal bone | 6.68 | 6.94 | 58.94 | 59.76 |

| Trunk | seventh vertebrae, acromions, sacrum and anterior superior iliac spines | 42.57 | 43.46 | 41.51 | 44.86 |

| Pelvis | sacrum, rasis and l asis | 12.47 | 11.17 | 49.2 | 61.15 |

| Upper Arm | Acromion and olecranon | 2.55 | 2.71 | 57.54 | 57.72 |

| Forearm | olecranon and radial processes | 1.38 | 1.62 | 45.59 | 45.74 |

| Hand | radial processes and head of the third metacarpal bone | 0.56 | 0.61 | 74.74 | 79 |

| Thigh | great trochanter and lateral femoral condyle | 14.78 | 14.16 | 36.12 | 40.95 |

| Shank | lateral femoral condyle and fibula head | 4.81 | 4.33 | 44.16 | 44.59 |

| Foot | metatarsal head and heel | 1.29 | 1.37 | 40.14 | 44.15 |

| Maximum | Mean | Range | ||

|---|---|---|---|---|

| Lower Model | [N] | F = 17.515, df = 2, p < 0.001 | F = 103.466, df = 2, p < 0.001 | F = 40.791, df = 2, p < 0.001 |

| [N/kg] | F = 79.112, df = 2, p < 0.001 | F = 165.761, df = 2, p < 0.001 | F = 13.255, df = 2, p < 0.001 | |

| | [N] | F = 83.555, df = 2, p < 0.001 | F = 5.457, df = 2, p = 0.058 | F = 89.527, df = 2, p < 0.001 | |

| Upper Model | [N] | F = 17.343, df = 2, p < 0.001 | F = 72.977, df = 2, p < 0.001 | F = 63.171, df = 2, p < 0.001 |

| [N/kg] | F = 79.155, df = 2, p < 0.001 | F = 201.366, df = 2, p < 0.001 | F = 44.220, df = 2, p < 0.001 | |

| | [N] | F = 107.897, df = 2, p < 0.001 | F = 4.899, df = 2, p = 0.013 | F = 58.671, df = 2, p < 0.001 | |

| Lower Model | [N] | F = 214.901, df = 2, p < 0.001 | F = 217.721, df = 2, p < 0.001 | F = 66.483, df = 2, p < 0.001 |

| [N/kg] | F = 89.655, df = 2, p < 0.001 | F = 77.830, df = 2, p < 0.001 | F = 34.145, df = 2, p < 0.001 | |

| | [N] | F = 182.187, df = 2, p < 0.001 | F = 165.385, df = 2, p < 0.001 | F = 63.568, df = 2, p < 0.001 | |

| Upper Model | [N] | F = 78.062, df = 2, p < 0.001 | F = 205.992, df = 2, p < 0.001 | F = 13.265, df = 2, p < 0.001 |

| [N/kg] | F = 98.477, df = 2, p < 0.001 | F = 39.379, df = 2, p < 0.001 | F = 7.883, df = 2, p = 0.001 | |

| | [N] | F = 75.125, df = 2, p < 0.001 | F = 179.363, df = 2, p < 0.001 | F = 13.497, df = 2, p < 0.001 |

| LI | Maximum | Mean | Range | |||||

|---|---|---|---|---|---|---|---|---|

| p Value | Cohen’s d | p Value | Cohen’s d | p Value | Cohen’s d | |||

| Lower Model | [N] | 1 vs. 2 | 1.000 | 0.007 | 0.005 | 0.41 | 0.053 | 0.55 |

| 1 vs. 3 | 0.001 | 1.16 | <0.001 | 2.99 | <0.001 | 2.63 | ||

| 2 vs. 3 | 0.001 | 1.05 | <0.001 | 2.37 | <0.001 | 2.10 | ||

| [N/kg] | 1 vs. 2 | 1.000 | 0.02 | 0.008 | 0.52 | 0.066 | 0.53 | |

| 1 vs. 3 | <0.001 | 3.16 | <0.001 | 4.74 | 0.002 | 1.52 | ||

| 2 vs. 3 | <0.001 | 2.74 | <0.001 | 3.95 | 0.010 | 0.95 | ||

| | [N] | 1 vs. 2 | 0.487 | 0.32 | 0.051 | 0.54 | 0.178 | 0.55 | |

| 1 vs. 3 | <0.001 | 3.57 | 0.595 | 0.42 | <0.001 | 3.78 | ||

| 2 vs. 3 | <0.001 | 2.86 | 0.053 | 0.87 | <0.001 | 3.72 | ||

| Upper Model | [N] | 1 vs. 2 | 0.107 | 0.17 | 0.018 | 0.29 | <0.001 | 1.37 |

| 1 vs. 3 | 0.003 | 1.08 | <0.001 | 2.71 | <0.001 | 3.28 | ||

| 2 vs. 3 | 0.001 | 1.22 | <0.001 | 2.19 | <0.001 | 1.95 | ||

| [N/kg] | 1 vs. 2 | 0.054 | 0.42 | 0.016 | 0.59 | <0.001 | 1.72 | |

| 1 vs. 3 | <0.001 | 3.05 | <0.001 | 5.28 | <0.001 | 2.46 | ||

| 2 vs. 3 | <0.001 | 3.40 | <0.001 | 4.83 | 0.098 | 0.64 | ||

| | [N] | 1 vs. 2 | 0.062 | 0.52 | 0.850 | 0.23 | 0.003 | 0.86 | |

| 1 vs. 3 | <0.001 | 3.65 | 0.105 | 0.64 | <0.001 | 3.09 | ||

| 2 vs. 3 | <0.001 | 3.13 | 0.078 | 0.81 | <0.001 | 2.62 | ||

| Lower Model | [N] | 1 vs. 2 | 0.001 | 0.94 | 0.013 | 0.64 | 0.001 | 0.85 |

| 1 vs. 3 | <0.001 | 4.82 | <0.001 | 5.22 | <0.001 | 2.51 | ||

| 2 vs. 3 | <0.001 | 4.06 | <0.001 | 4.39 | <0.001 | 1.98 | ||

| [N/kg] | 1 vs. 2 | 0.001 | 1.18 | 0.014 | 0.68 | 0.002 | 1.08 | |

| 1 vs. 3 | <0.001 | 5.06 | <0.001 | 4.59 | 0.002 | 2.25 | ||

| 2 vs. 3 | <0.001 | 2.25 | <0.001 | 2.29 | 0.001 | 1.21 | ||

| | [N] | 1 vs. 2 | 0.001 | 0.75 | 0.006 | 0.54 | 0.001 | 0.77 | |

| 1 vs. 3 | <0.001 | 4.44 | <0.001 | 4.52 | <0.001 | 2.45 | ||

| 2 vs. 3 | <0.001 | 3.72 | <0.001 | 3.59 | <0.001 | 1.93 | ||

| Upper Model | [N] | 1 vs. 2 | 0.002 | 0.93 | 0.011 | 0.55 | 0.034 | 0.91 |

| 1 vs. 3 | <0.001 | 3.92 | <0.001 | 5.40 | 0.002 | 1.52 | ||

| 2 vs. 3 | <0.001 | 2.23 | <0.001 | 4.52 | 0.006 | 0.73 | ||

| [N/kg] | 1 vs. 2 | 0.001 | 1.15 | 0.014 | 0.66 | 0.019 | 1.04 | |

| 1 vs. 3 | <0.001 | 2.67 | <0.001 | 4.06 | 0.022 | 1.14 | ||

| 2 vs. 3 | <0.001 | 1.23 | <0.001 | 2.52 | 0.388 | 0.35 | ||

| | [N] | 1 vs. 2 | 0.002 | 0.83 | 0.007 | 0.48 | 0.032 | 0.90 | |

| 1 vs. 3 | <0.001 | 3.59 | <0.001 | 5.19 | 0.002 | 1.53 | ||

| 2 vs. 3 | <0.001 | 2.24 | <0.001 | 3.72 | 0.006 | 0.77 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varrecchia, T.; Chini, G.; Serrao, M.; Ranavolo, A. Lifting Activities Assessment Using Lumbosacral Compression and Shear Forces. Appl. Sci. 2024, 14, 6044. https://doi.org/10.3390/app14146044

Varrecchia T, Chini G, Serrao M, Ranavolo A. Lifting Activities Assessment Using Lumbosacral Compression and Shear Forces. Applied Sciences. 2024; 14(14):6044. https://doi.org/10.3390/app14146044

Chicago/Turabian StyleVarrecchia, Tiwana, Giorgia Chini, Mariano Serrao, and Alberto Ranavolo. 2024. "Lifting Activities Assessment Using Lumbosacral Compression and Shear Forces" Applied Sciences 14, no. 14: 6044. https://doi.org/10.3390/app14146044

APA StyleVarrecchia, T., Chini, G., Serrao, M., & Ranavolo, A. (2024). Lifting Activities Assessment Using Lumbosacral Compression and Shear Forces. Applied Sciences, 14(14), 6044. https://doi.org/10.3390/app14146044