Rolling Bearing Fault Diagnosis Based on CEEMDAN and CNN-SVM

Abstract

1. Introduction

2. Basic Principles

2.1. CEEMDAN Decomposition Algorithm

- Add i (i = 1, 2, …, m) times of Gaussian white noise ni(t), obeying the standard normal distribution of the original signal y(t), and obtain the new signal yi(t).

- The EMD decomposition of yi(t) is performed, the first modal component is retained and a mean-taking calculation is performed to obtain the IIMF1:

- 3.

- Adding i (i = m) times Gaussian white noise ni(t), obeying standard normal distribution, to the residual component R1(t) yields :

- 4.

- Repeat the above steps j (j = n) times until the residual component cannot be decomposed. IIMF1, IIMF2, …, IIMFn and residual components are obtained sequentially. The original signal can be expressed as:

2.2. Convolutional Neural Network

2.2.1. Convolutional Layer

2.2.2. Pooling Layer

2.2.3. Fully Connected Layers

2.3. Support Vector Machines

2.4. Grey Wolf Optimiser

3. CEEMDAN and CNN-SVM Fault Diagnosis Models

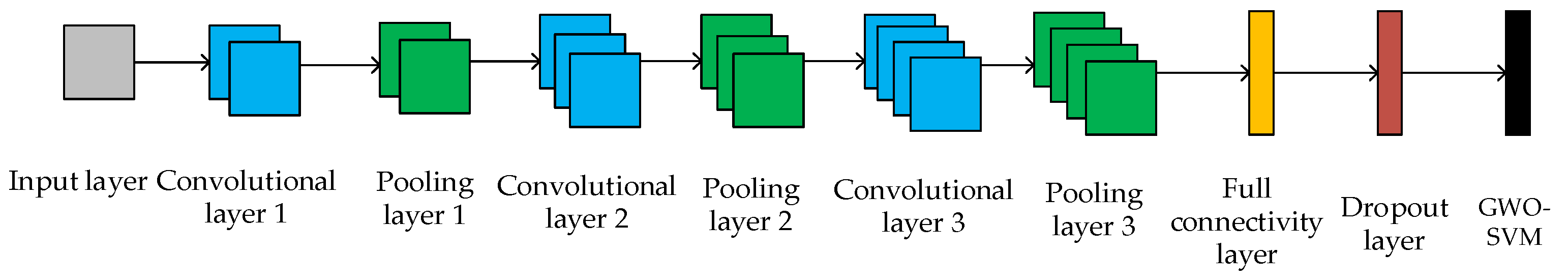

3.1. CNN Network Structure Design

3.2. GWO-SVM Classifier

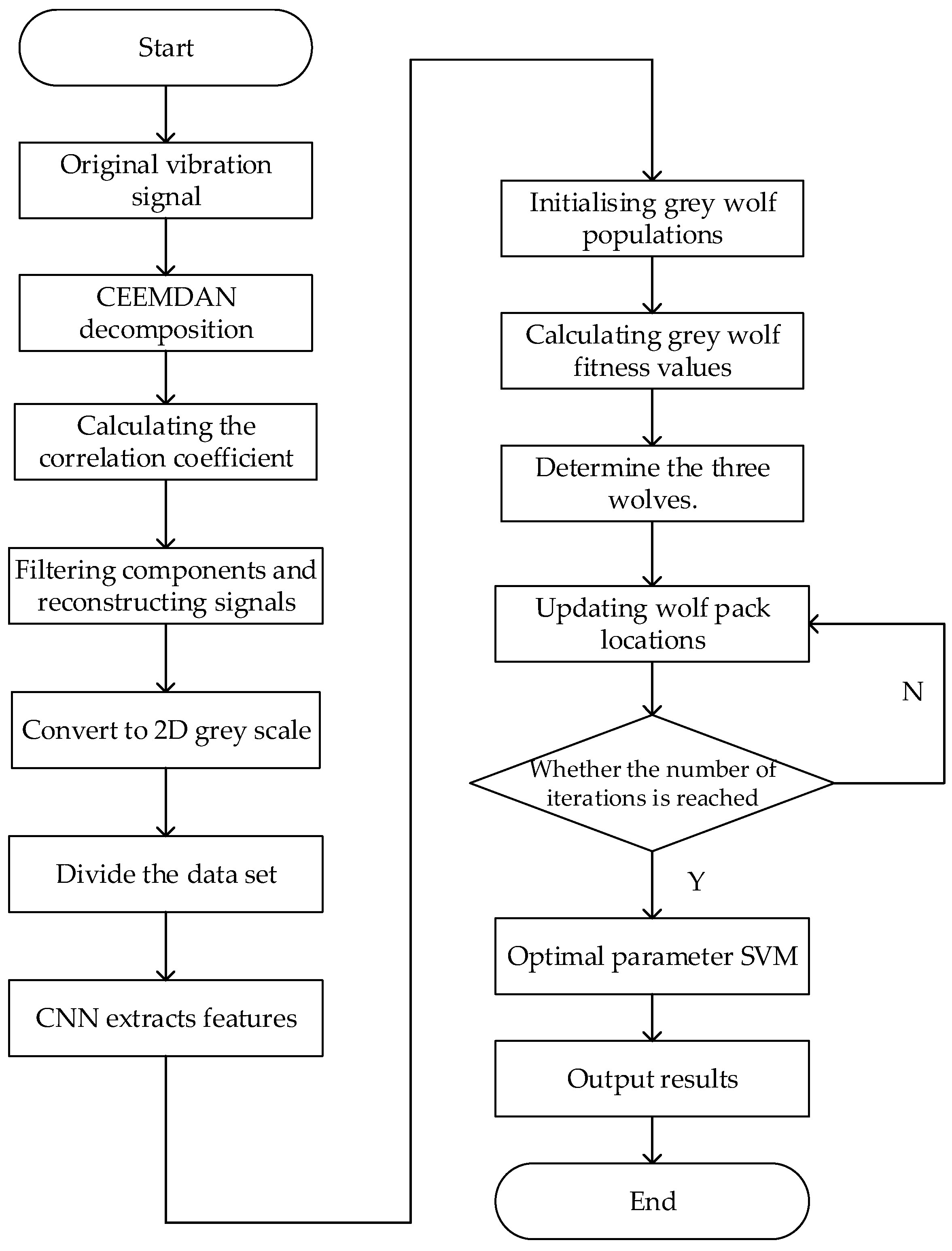

- Initialise the number of wolves M and the number of iterations N, set the penalty factor C and the range of values of the kernel function parameter σ, initialise the location of the wolves and calculate the value of the individual initial fitness.

- Using the error rate as the objective function, the parameter penalty factor C and the kernel function parameter σ are used as the prey for the optimisation search.

- When the objective function value is smaller than the individual fitness value of the grey wolf, update the individual fitness value to the current optimal objective function value.

- When the maximum number of iterations is reached, the optimal penalty factor C and kernel function parameter σ are obtained, and the optimal parametric SVM classifier is built.

3.3. Fault Diagnosis Process

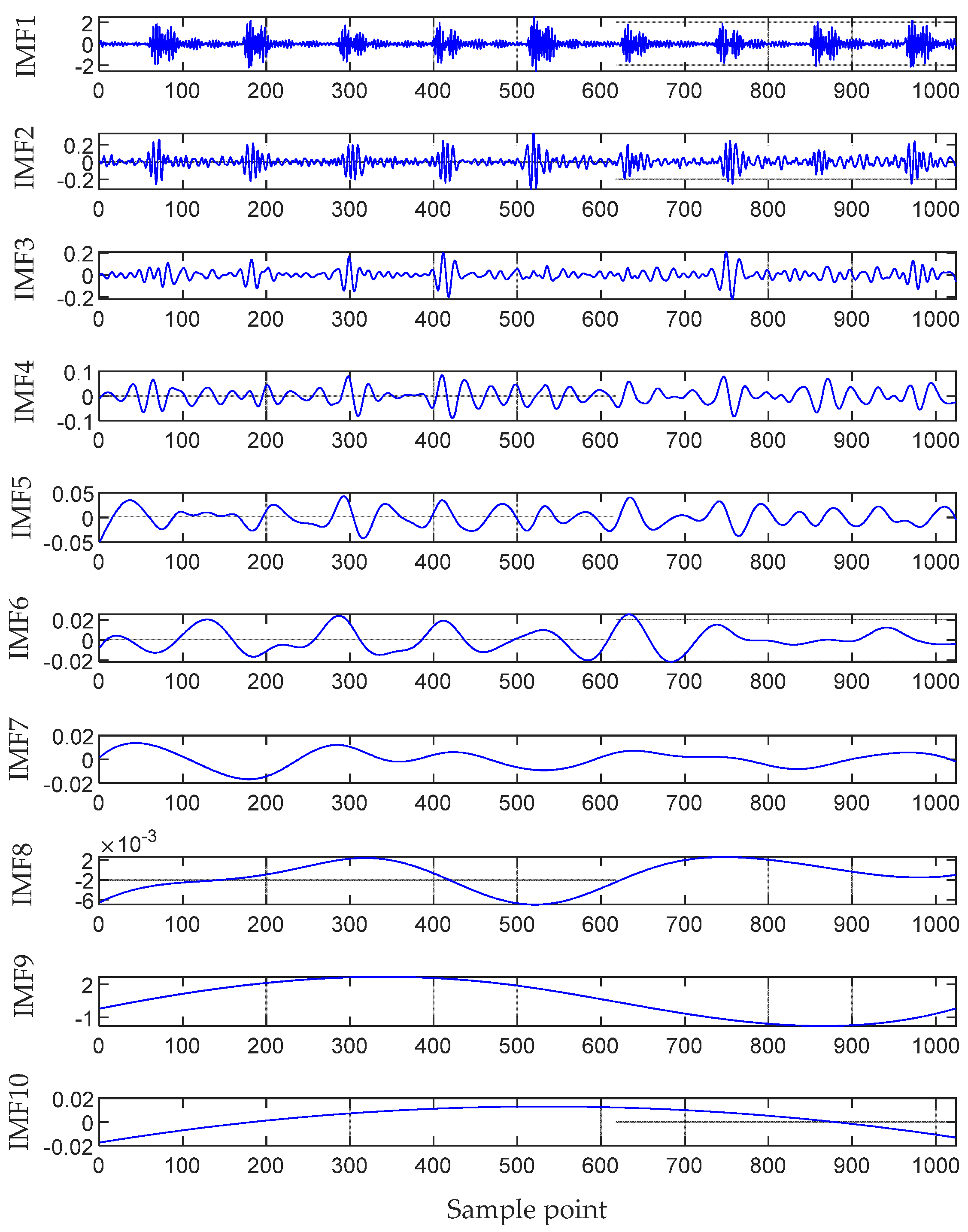

- Signal decomposition using CEEMDAN algorithm. The original vibration signal is decomposed into multiple IMF components using the CEEMDAN algorithm, each with different frequency characteristics.

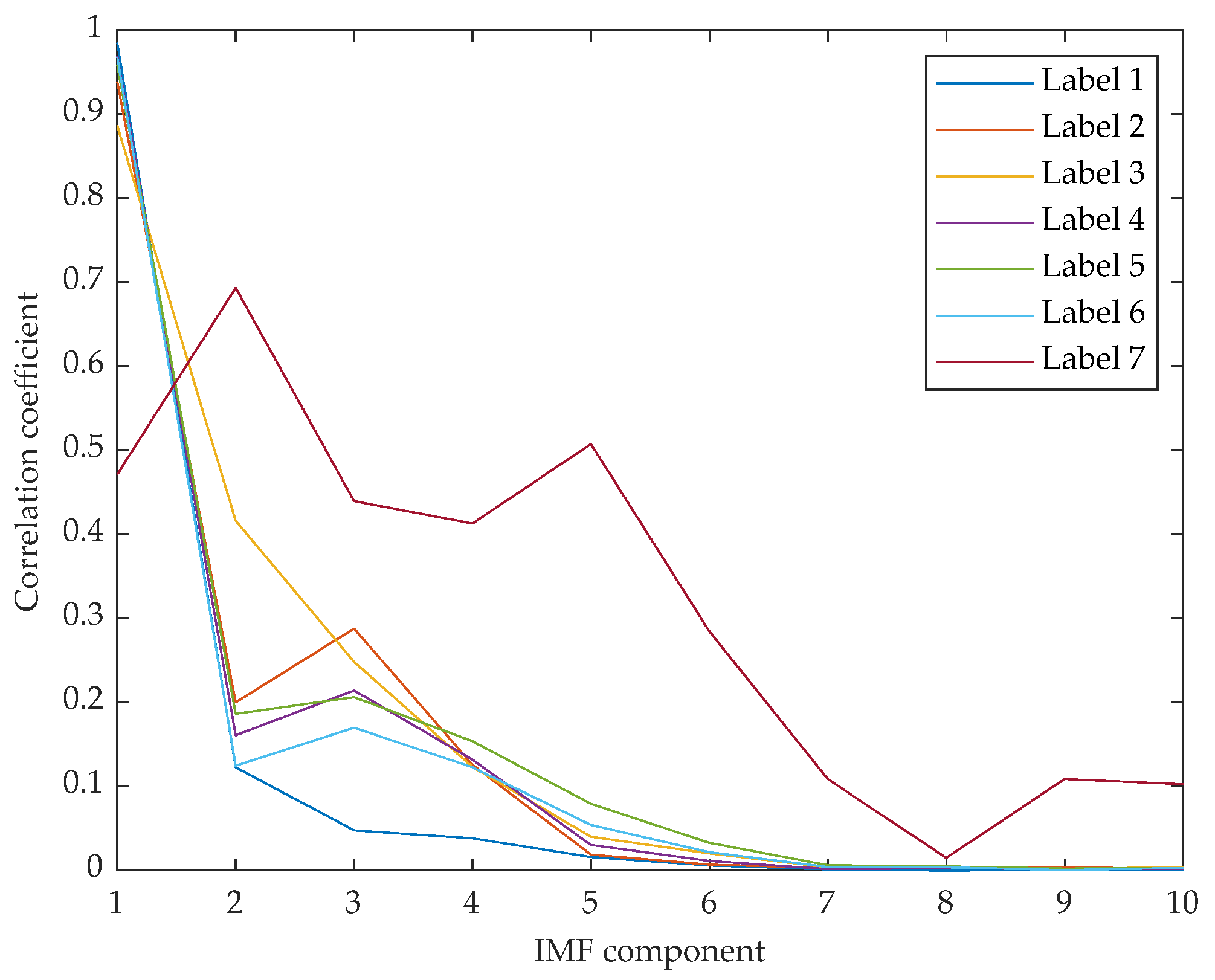

- Filter and reconstruct the signal. By calculating the correlation coefficient of each IMF component, screen the IMF components and reconstruct the signal to remove noise interference.

- Signal transformation and division of the data set. The reconstructed one-dimensional vibration signal is converted into a two-dimensional grey-scale map, and the training set, validation set and test set are divided according to the ratio of 3:1:1.

- Feature extraction using CNN. CNN extracts feature vectors from the 2D grey-scale map which will be used for subsequent fault classification.

- Training of GWO-SVM classifier. Optimise the parameters of SVM using GWO to retrieve the SVM classifier with optimal parameters.

- Perform fault classification and output results. Input the feature vectors of the test set into the SVM classifier with optimal parameters, perform classification and output the fault classification results.

4. Experimental Validation

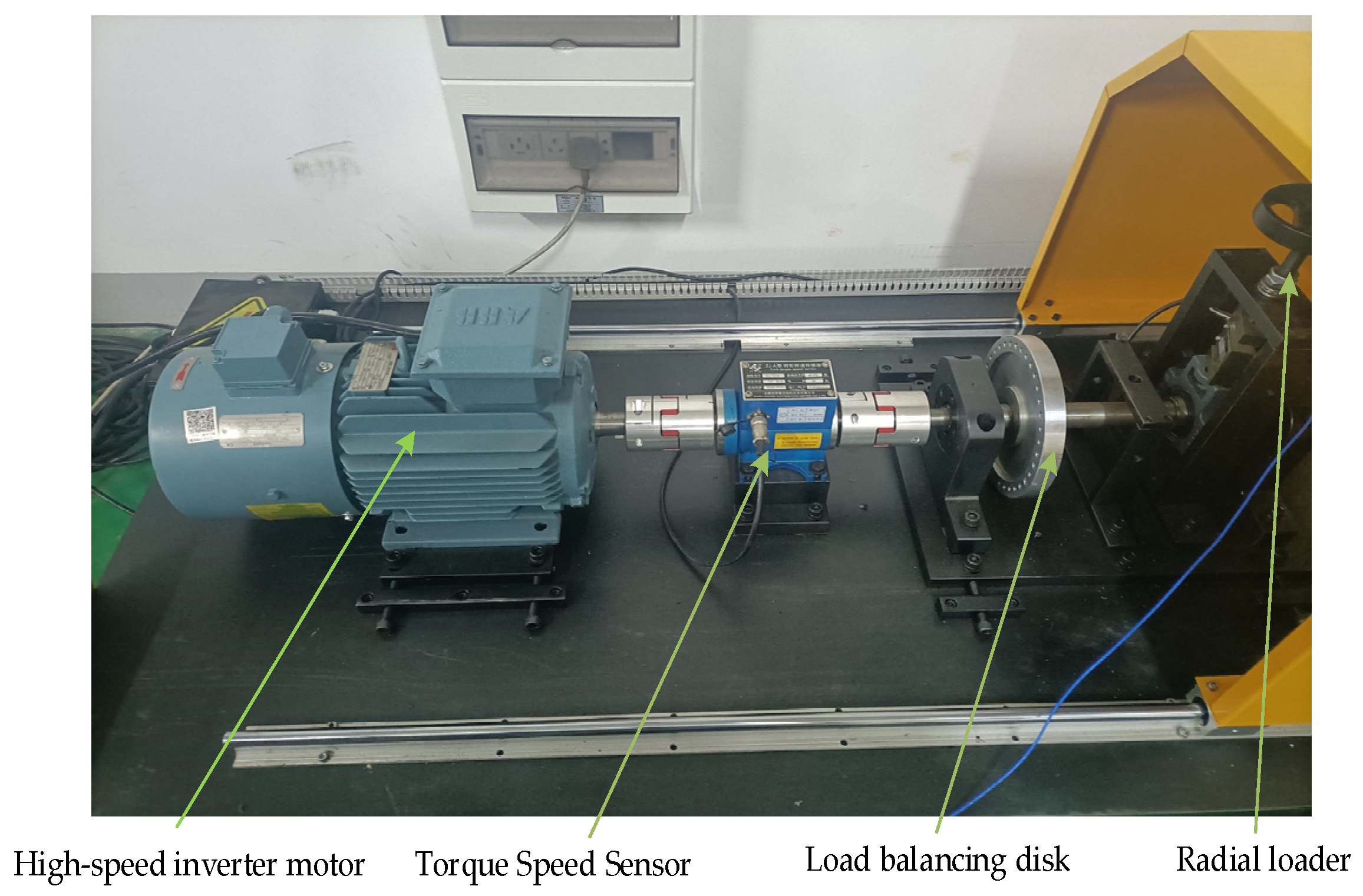

4.1. Experimental Data Sources

4.2. Data Processing

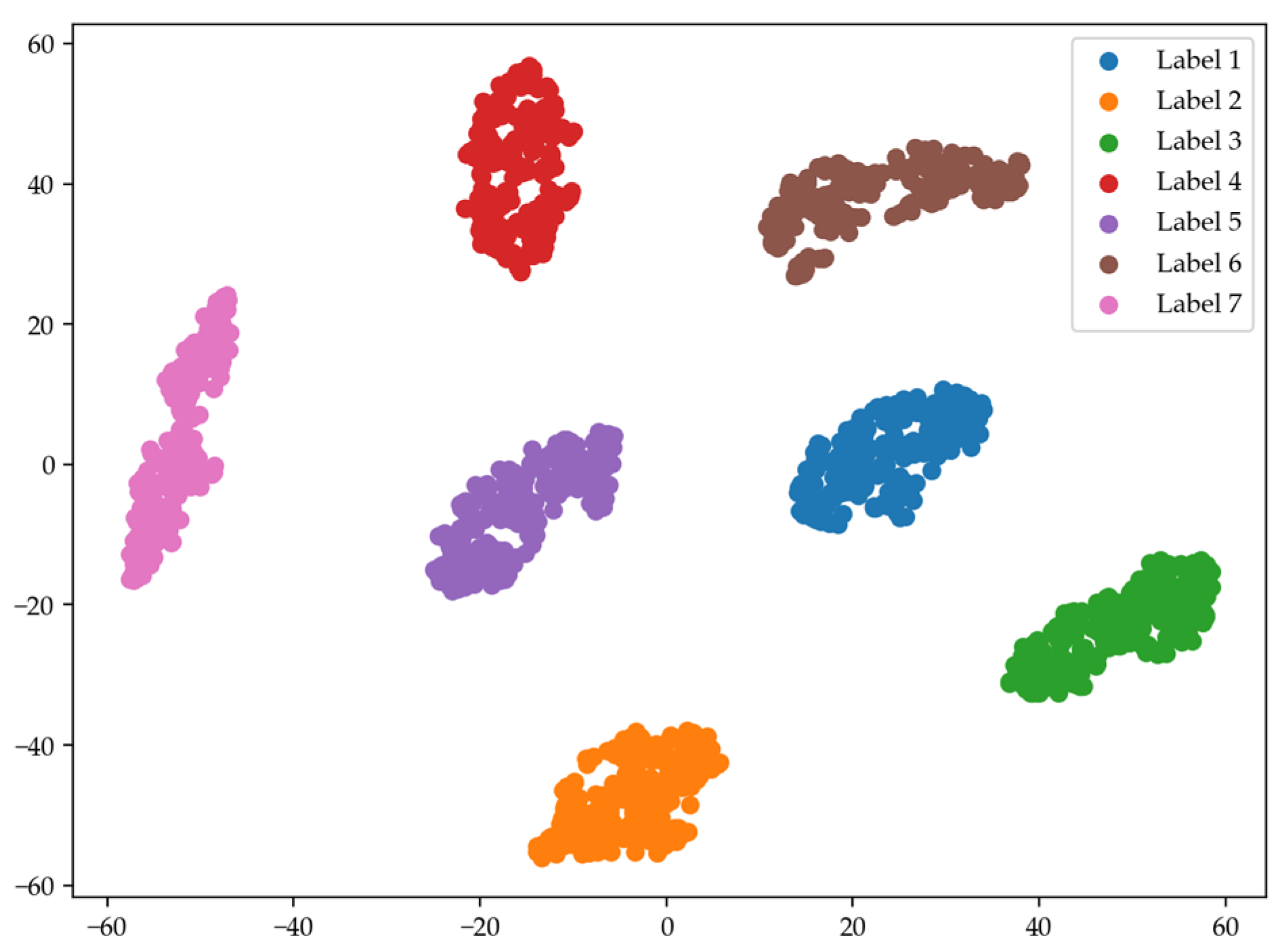

4.3. Visualisation of Feature Extraction

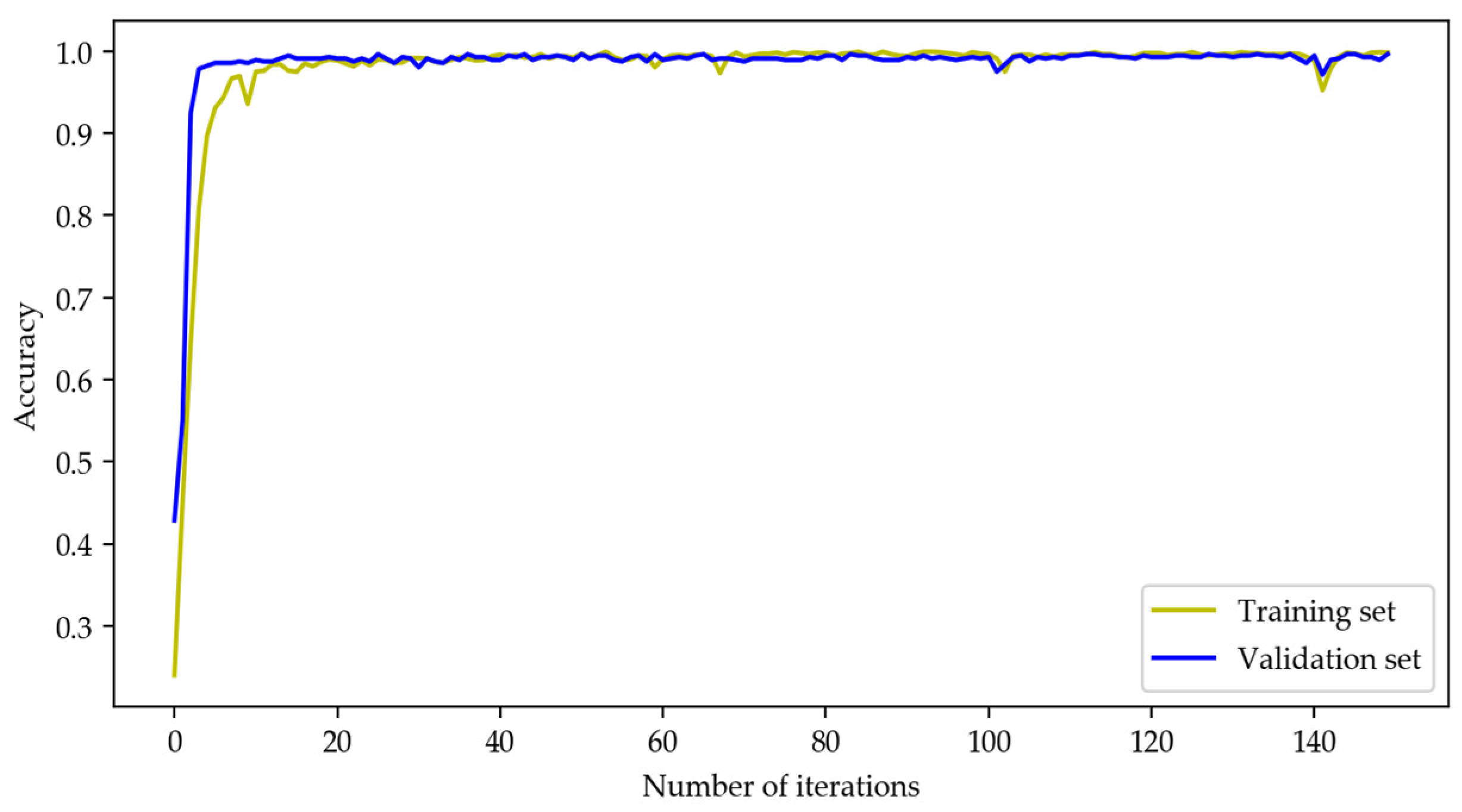

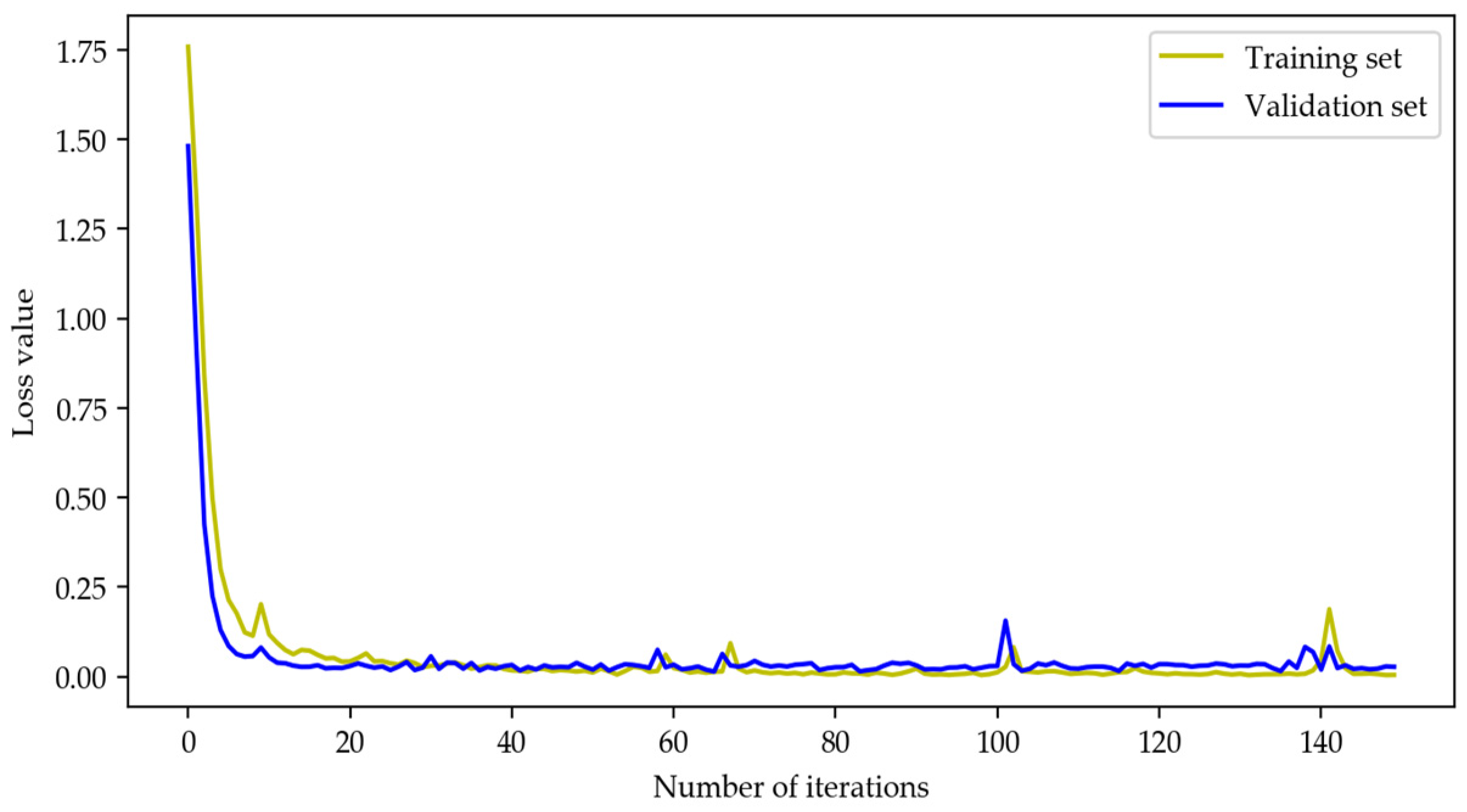

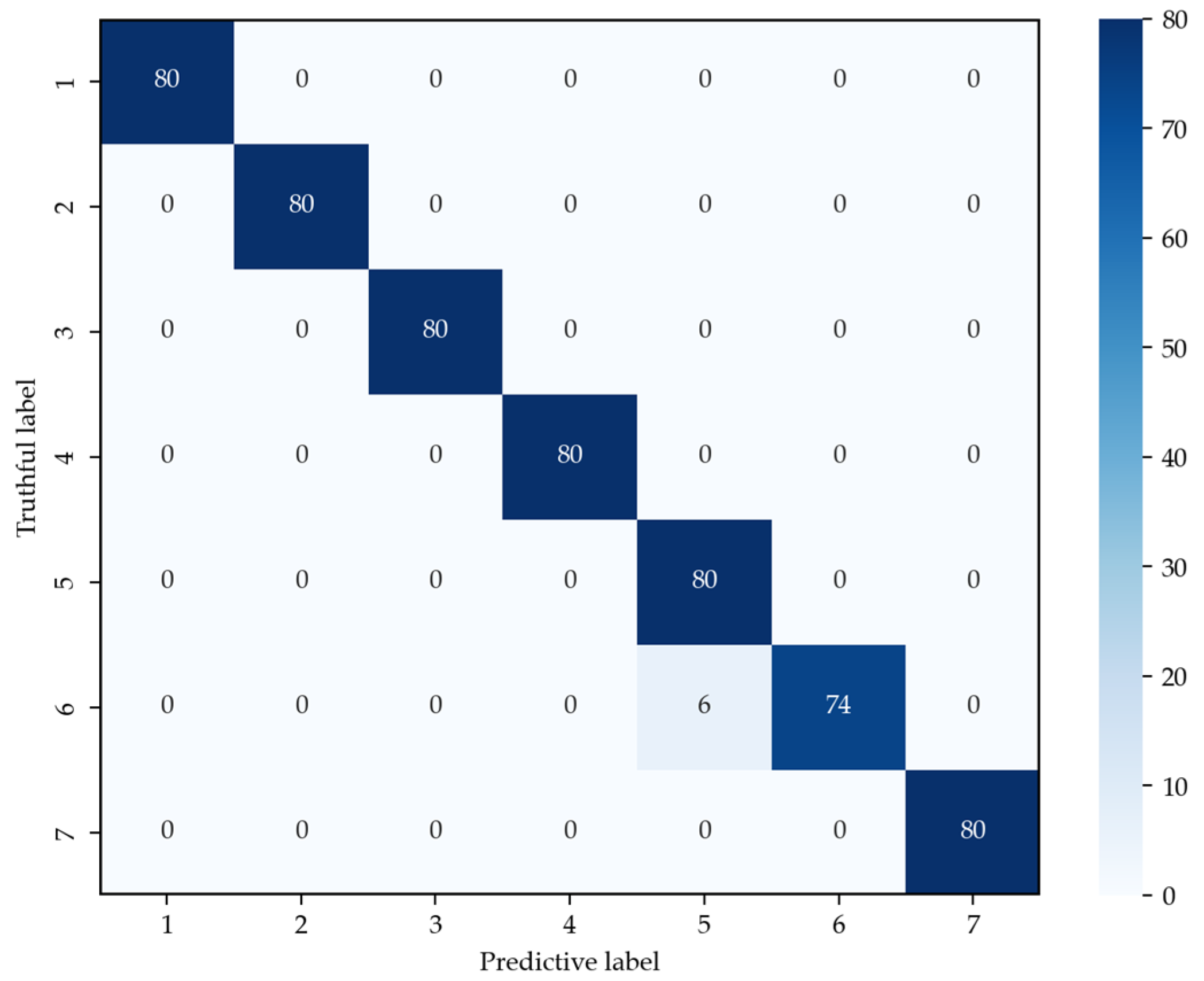

4.4. Experimental Results and Analyses

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, G.; Yan, T.; Yang, G.; Chai, H.; Cao, C. A Review on Rolling Bearing Fault Signal Detection Methods Based on Different Sensors. Sensors 2022, 22, 8330. [Google Scholar] [CrossRef] [PubMed]

- Ding, P.; Xu, Y.; Qin, P.; Sun, X. A novel deep learning approach for intelligent bearing fault diagnosis under extremely small samples. Appl. Intell. 2024, 54, 5306–5316. [Google Scholar] [CrossRef]

- Hakim, M.; Omran, A.A.B.; Ahmed, A.N.; Al-Waily, M.; Abdellatif, A. A systematic review of rolling bearing fault diagnoses based on deep learning and transfer learning: Taxonomy, overview, application, open challenges, weaknesses and recommendations. Ain Shams Eng. J. 2023, 14, 101945. [Google Scholar] [CrossRef]

- Zhai, L.; Wang, X.; Si, Z.; Wang, Z. A Deep Learning Method for Bearing Cross-Domain Fault Diagnostics Based on the Standard Envelope Spectrum. Sensors 2024, 24, 3500. [Google Scholar] [CrossRef] [PubMed]

- Peng, B.; Bi, Y.; Xue, B.; Zhang, M.; Wan, S. A Survey on Fault Diagnosis of Rolling Bearings. Algorithms 2022, 15, 347. [Google Scholar] [CrossRef]

- Skowron, M.; Frankiewicz, O.; Jarosz, J.J.; Wolkiewicz, M.; Dybkowski, M.; Weisse, S.; Valire, J.; Wyłomańska, A.; Zimroz, R.; Szabat, K. Detection and Classification of Rolling Bearing Defects Using Direct Signal Processing with Deep Convolutional Neural Network. Electronics 2024, 13, 1722. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Zhao, L.; Chi, X.; Li, P.; Ding, J. Incipient Fault Feature Enhancement of Rolling Bearings Based on CEEMDAN and MCKD. Appl. Sci. 2023, 13, 5688. [Google Scholar] [CrossRef]

- Colominas, M.A.; Schlotthauer, G.; Torres, M.E. Improved complete ensemble EMD: A suitable tool for biomedical signal processing. Biomed. Signal Process. Control 2014, 14, 19–29. [Google Scholar] [CrossRef]

- Lv, K.; Ma, Z.; Bao, C.; Liu, G. Indirect Prediction of Lithium-Ion Battery RUL Based on CEEMDAN and CNN-BiGRU. Energies 2024, 17, 1704. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, Y.; Jiang, Y.; Zhao, T.; Xu, H.; Qian, P.; Li, C. A Novel Wind Turbine Rolling Element Bearing Fault Diagnosis Method Based on CEEMDAN and Improved TFR Demodulation Analysis. Energies 2024, 17, 819. [Google Scholar] [CrossRef]

- Wang, L.; Li, H.; Xi, T.; Wei, S. Fault Feature Extraction Method for Rolling Bearings Based on Complete Ensemble Empirical Mode Decomposition with Adaptive Noise and Variational Mode Decomposition. Sensors 2023, 23, 9441. [Google Scholar] [CrossRef]

- Liu, Z.; Li, T.; Zhu, Z.; Li, M.; Nie, C.; Tang, Z. Noise Reduction Method for the Vibration Signal of Reactor CRDM Based on CEEMDAACN-SK. Electronics 2023, 12, 4681. [Google Scholar] [CrossRef]

- Qiu, S.; Cui, X.; Ping, Z.; Shan, N.; Li, Z.; Bao, X.; Xu, X. Deep Learning Techniques in Intelligent Fault Diagnosis and Prognosis for Industrial Systems: A Review. Sensors 2023, 23, 1305. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Qiu, W.; Hu, X.; Wang, W. A rolling bearing fault diagnosis technique based on recurrence quantification analysis and Bayesian optimization SVM. Appl. Soft Comput. 2024, 156, 111506. [Google Scholar] [CrossRef]

- Huang, X.; Xie, T.; Wu, J.; Zhou, Q.; Hu, J. Deep continuous convolutional networks for fault diagnosis. Knowl. Based Syst. 2024, 292, 111623. [Google Scholar] [CrossRef]

- Zhang, D.; Tao, H. Bearing Fault Diagnosis Based on Parameter-Optimized Variational Mode Extraction and an Improved One-Dimensional Convolutional Neural Network. Appl. Sci. 2024, 14, 3289. [Google Scholar] [CrossRef]

- Guo, B.; Qiao, Z.; Zhang, N.; Wang, Y.; Wu, F.; Peng, Q. Attention-based ConvNeXt with a parallel multiscale dilated convolution residual module for fault diagnosis of rotating machinery. Expert Syst. Appl. 2024, 249, 123764. [Google Scholar] [CrossRef]

- Guan, Y.; Meng, Z.; Li, J.; Cao, W.; Sun, D.; Liu, J.; Fan, F. A novel diagnostic framework based on vibration image encoding and multi-scale neural network. Expert Syst. Appl. 2024, 251, 124054. [Google Scholar] [CrossRef]

- Jiang, C.; Zhou, Q.; Lei, J.; Wang, X. A Two-Stage Structural Damage Detection Method Based on 1D-CNN and SVM. Appl. Sci. 2022, 12, 10394. [Google Scholar] [CrossRef]

- Hu, B.; Liu, J.; Zhao, R.; Xu, Y.; Huo, T. A New Fault Diagnosis Method for Unbalanced Data Based on 1DCNN and L2-SVM. Appl. Sci. 2022, 12, 9880. [Google Scholar] [CrossRef]

- Li, Y.; Tang, B.; Huang, B.; Xue, X. A Dual-Optimization Fault Diagnosis Method for Rolling Bearings Based on Hierarchical Slope Entropy and SVM Synergized with Shark Optimization Algorithm. Sensors 2023, 23, 5630. [Google Scholar] [CrossRef] [PubMed]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Xu, Z.; Yan, J.; Sui, G.; Wu, Y.; Qi, M.; Zhang, Z.; Geng, Y.; Wang, J. Intelligent Mechanical Fault Diagnosis Method for High-Voltage Circuit Breakers Based on Grey Wolf Optimization and Multi-Grained Cascade Forest Algorithms. Appl. Sci. 2024, 14, 3183. [Google Scholar] [CrossRef]

- Wongkhuenkaew, R.; Auephanwiriyakul, S.; Chaiworawitkul, M.; Theera-Umpon, N.; Yeesarapat, U. Grey Wolf Optimizer with Behavior Considerations and Dimensional Learning in Three-Dimensional Tooth Model Reconstruction. Bioengineering 2024, 11, 254. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhu, J.; Li, W. An Improved Back Propagation Neural Network Based on Differential Evolution and Grey Wolf Optimizer and Its Application in the Height Prediction of Water-Conducting Fracture Zone. Appl. Sci. 2024, 14, 4509. [Google Scholar] [CrossRef]

- Ahdeema, J.; Sefat, M.H.; Muradov, K.; Moradi, A.; Moldestad, B.M.E. Completion Performance Evaluation in Multilateral Wells Incorporating Single and Multiple Types of Flow Control Devices Using Grey Wolf Optimizer. Processes 2024, 12, 785. [Google Scholar] [CrossRef]

- Shen, W.; Xiao, M.; Wang, Z.; Song, X. Rolling Bearing Fault Diagnosis Based on Support Vector Machine Optimized by Improved Grey Wolf Algorithm. Sensors 2023, 23, 6645. [Google Scholar] [CrossRef]

| Network Layer | Parameter Setting | Pacemaker | Network Layer Output |

|---|---|---|---|

| Convolutional layer 1 | 8@3 × 3 | 1 | 8@32 × 32 |

| Pooling layer 1 | 2 × 2 | 2 | 8@16 × 16 |

| Convolutional layer 2 | 16@3 × 3 | 1 | 16@16 × 16 |

| Pooling layer 2 | 2 × 2 | 2 | 16@8 × 8 |

| Convolutional layer 3 | 32@3 × 3 | 1 | 32@8 × 8 |

| Pooling layer 3 | 2 × 2 | 2 | 32@4 × 4 |

| Bearing Condition | Fault Diameter (mm) | Sample Length | Sample Size | Label |

|---|---|---|---|---|

| Normal state | 0 | 1024 | 400 | 1 |

| Rolling body failure | 0.2 | 1024 | 400 | 2 |

| 0.5 | 1024 | 400 | 3 | |

| Inner ring failure | 0.2 | 1024 | 400 | 4 |

| 0.5 | 1024 | 400 | 5 | |

| Outer ring failure | 0.2 | 1024 | 400 | 6 |

| 0.5 | 1024 | 400 | 7 |

| Model | Accuracy (%) | ||

|---|---|---|---|

| Maximum Value | Minimum Value | Average Value | |

| SVM | 86.25 | 81.61 | 82.71 |

| CNN | 90.54 | 88.93 | 89.73 |

| EMD+CNN | 96.25 | 94.64 | 95.11 |

| EEMD+CNN | 98.04 | 96.43 | 96.87 |

| CEEMDAN+CNN-Softmax | 98.59 | 97.86 | 98.52 |

| CEEMDAN+CNN-SVM | 100 | 98.39 | 99.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, L.; Liu, W.; You, D.; Yang, S. Rolling Bearing Fault Diagnosis Based on CEEMDAN and CNN-SVM. Appl. Sci. 2024, 14, 5847. https://doi.org/10.3390/app14135847

Shi L, Liu W, You D, Yang S. Rolling Bearing Fault Diagnosis Based on CEEMDAN and CNN-SVM. Applied Sciences. 2024; 14(13):5847. https://doi.org/10.3390/app14135847

Chicago/Turabian StyleShi, Lei, Wenchao Liu, Dazhang You, and Sheng Yang. 2024. "Rolling Bearing Fault Diagnosis Based on CEEMDAN and CNN-SVM" Applied Sciences 14, no. 13: 5847. https://doi.org/10.3390/app14135847

APA StyleShi, L., Liu, W., You, D., & Yang, S. (2024). Rolling Bearing Fault Diagnosis Based on CEEMDAN and CNN-SVM. Applied Sciences, 14(13), 5847. https://doi.org/10.3390/app14135847