Abstract

The valve, armature, and armature pin are critical factors influencing the hydraulic pressure differences in diesel injectors, and are essential for injection and backflow quantity control. These components play crucial roles in enhancing energy efficiency and reducing engine emissions. This experimental study investigated the effects of clearance between the valve, armature, and armature pin guidance. Forty-nine 2000 bar common-rail injectors (Bosch) were tested in calibrated stations. Injection quantities were assessed at both minimum and maximum operational pressures. Backflow rates were specifically examined at maximum pressure. A correlation matrix was created using Python to analyze the relationship between inputs and outputs, identifying dominant characteristics that define injector behavior. Increased injector precision correlated with reduced fuel consumption and enhanced energy efficiency. The study found that the effect of clearance between the armature and armature pins was more significant than that between the valve and armature. Injection quantities were observed to increase with pressure, and no critical difference in injection quantities was noted among different diameter groups at the minimum pressure point. Backflow quantities were consistent within groups when the armature–armature pin and valve–armature clearances were minimized.

1. Introduction

1.1. Literature Review

The development of internal combustion engines (ICEs) spans several centuries and has significantly influenced modern society by broadening transportation and mechanization horizons. Despite their benefits, ICEs are associated with substantial gas and particle emissions, prompting ongoing research into innovative technologies and strategies to mitigate these effects. Fuel injectors are critical in this context, impacting engine efficiency and emissions [1,2].

In diesel engines, particularly within the common-rail (CR) fuel injection system, critical parameters such as injection timing, injection, and duration are controlled to enhance efficiency and minimize emissions [3]. Extensive research indicates that delayed injection timing is effective in reducing NOx emissions by lowering peak combustion temperatures and pressures within the cylinder [4,5,6,7]. Increasing injection pressure improves fuel atomization, which facilitates a more uniform fuel–air mix, decreasing ignition delays and promoting complete combustion [8,9]. However, higher injection pressures may also lead to increased NOx emissions [10,11,12].

Adopting multiple injection strategies offers another approach to optimize injection timing and reduce emissions from compression-ignition engines [13]. Zhuang et al. investigated the effects of various injection timings and quantities—main, pilot, and post-injection—in a four-cylinder diesel engine [14]. Their findings suggest that an early pilot injection coupled with a delayed main injection can decrease both NOx emissions and combustion noise. Additionally, they observed that incorporating post-injection with delayed main injection further contributes to reductions in NOx and soot emissions. Precise control over injection parameters is critical for achieving optimal combustion efficiency and maximum energy output. This study examines factors that influence injector precision, such as armature closing time, needle opening time, and flow rate.

Fuel injection is a crucial factor in controlling combustion within diesel engines. The CR fuel injection system enables precise control of fuel injection speed, which is essential for enhancing engine performance and reducing exhaust emissions. Chau et al. examined the effects of high injection pressures (ranging from 400 to 1600 bar) on injection rate characteristics using a six-hole solenoid CR injector with a fixed injector energization time of 1.5 ms [15]. Their findings indicated that higher injection pressures significantly shortened the hydraulic injection delay from 0.5 to 0.25 ms.

The profile of fuel injection speed serves as a direct indicator of the fuel injection process and significantly influences the atomization and combustion within the engine. Gao et al. utilized an empirical calculation method to analyze the fuel injection speed profiles of high-pressure injectors [16]. By adjusting the injection pressure and energization time, they determined the fuel injection duration, the maximum speed of fuel injection, and the dynamics of the rise and fall curves in the fuel injection profile. Notably, they observed that under conditions with shorter energization times, injection duration increased with higher injection pressures. Conversely, marginally extending the energization time led to a decrease in injection duration as the pressure increased. Moreover, the injection duration exhibited varied growth trends under different rail pressures and energization durations.

Zhao et al. highlighted an often-overlooked aspect in literature: the impact of hydrodynamic forces on injector dynamic characteristics [17]. They noted that during the armature’s opening phase, the exiting fuel acts as a cushion between the armature’s upper surface and the electromagnet, which mitigates the impact force on the armature and considerably inhibits cavitation. To explore this phenomenon further, they simulated the interaction between hydrodynamic forces and the movement of the injector armature and electromagnet. Their study also investigated the influence of the number of damping holes in the armature on hydrodynamic forces. The faster the armature ascends, the earlier cavitation occurs on its lower surface, thereby increasing the intensity of the cavitation. They found that an increase in the number of damping holes from three to six did not alter the hydrodynamic effects during the initial armature rise. However, as the armature continued to rise, the hydrodynamic forces on the upper surface of a six-hole armature increased more gradually. They also observed that fuel backflow through the electromagnet’s middle chamber significantly affected hydrodynamic forces and enhanced cavitation intensity.

Chung et al. developed a numerical model to simulate the dynamic flow characteristics of hydraulic components in an indirect-acting piezo injector, validated by comparing it with experimental results [18]. Their analysis indicated that the piezo injector achieved increased gross liquid penetration than a solenoid injector, demonstrating steeper closing behavior and a quicker injection opening ramp. Consequently, the indirect piezo injector was found to have superior spray formation capabilities, which enhanced engine performance owing to the more effective mixing of fuel with air in the combustion chamber.

Huang et al. employed X-ray phase-contrast imaging to examine needle movement within the nozzle and liquid-jet dynamics in the near-nozzle region for a variety of injection-pulse durations [19]. Their research extensively analyzed the dependence of liquid jet dynamics and axial velocities on needle lift. They identified that needle lift speed primarily depended on the injection pressure, while needle closing speed exhibited limited sensitivity to pressure changes. Injection-pulse time, when maintained at a constant pressure, did not significantly affect needle dynamics. Regardless of the needle’s position, whether open or closed, the needle’s lifting motion and the injection pressure were the predominant factors influencing liquid jet dynamics in the nozzle area. The results revealed that insufficient needle lift during short injection-pulse durations could adversely affect jet momentum and flow rate. Therefore, the study suggested that for optimal performance, the maximum needle lift height in the examined injector should exceed 80 µm to achieve a steady jet speed.

The movement of the needle within the nozzle significantly affects fuel spray characteristics, with precise, centered, and vibration-free movement along the vertical axis being ideal. Eccentric needle movement is identified as a crucial factor that contributes to inaccuracies within the nozzle and variability between spray holes [2]. Factors such as needle geometry, manufacturing deviations, spray pressure, and the number of nozzle holes can influence this eccentric movement. While the oscillation frequency of the needle depends on its mechanical properties, the oscillation amplitude is influenced by the internal nozzle flow. Studies on piezo-actuated diesel injectors have demonstrated that the initiation of injection relies more on the needle’s lifting movement than on the fuel pressure within the injector [20]. Moreover, the profile of needle lift can significantly influence fuel penetration into the injector.

Further research has examined the relationship between needle movement and fuel pressure, finding that increased fuel pressure correlates with both a higher needle lift speed and an increased lift amplitude [21]. The study noted that the needle lift speed consistently surpassed the closing speed. The velocity of fuel injected into the cylinder primarily depends on the needle lift motion, suggesting that fuel speed has a more substantial impact than both fuel pressure and injection duration. Additional studies confirm that needle lift speed is predominantly influenced by fuel pressure rather than by closing speed [19]. Additionally, extending the duration of injection under constant pressure did not affect needle dynamics.

Backflow in injectors, a critical aspect of injection dynamics, was divided into two categories in the studies: dynamic backflow occurring during movement and static backflow. Ferrari et al. explored both states, noting a significant increase in static backflow, especially at higher pressure levels [22]. Their findings reveal the significance of forced backflow, which occurs because of the clearance between the armature and armature pin, with backflow intensifying under increased pressures and leading to rapid shifts in pressure balance during injector activation.

Ren et al. investigated the interplay between pressure chamber structure and armature pin design, specifically a pin designed with a ball valve [23]. Their analysis indicated that a reduced flow area around the ball-valve-designed armature pin and an increased gas phase ratio in the fuel impede fuel movement within the pressure chamber, thereby delaying discharge. This reduction in flow area also increased friction, lowered pressure, and reduced cavitation.

Vrublevskyi et al. introduced a novel approach to measuring part movements within injectors, particularly focusing on the needle and nozzle movement in the control room [24]. They developed a mathematical model to describe these dynamics. The model reveals that high pressure within the injector not only increases stress tension but also significantly influences needle lift height and overall injector functionality. Their research highlights the necessity of analyzing needle movement and electrical signals concurrently to accurately determine injector functional parameters.

Dimensional variability within the pressure chamber, especially around the valve, armature, and armature pin, is a primary contributor to erratic needle movement [25]. These variations arise from geometric discrepancies among the components, leading to unequal pressure forces exerted on different points of the needle. Consequently, injector performance is notably impacted by backflow in these regions.

Krivtsov et al. explored the relationship between backflow and injection quantity, revealing that a threefold increase in backflow corresponded to a 13–40% increase in injection quantity [26]. This finding reveals the significance of managing backflow to enhance combustion efficiency and achieve more energy-efficient engines. D’Ambrosio et al. found that injection amounts increase with pressure when the energization time is maintained constant. They also indicated that static leakages due to backflow can decrease rail pressure and, consequently, the injection flow rate [27]. These observations emphasize the critical impact of backflow on injector functionality.

Ferrari et al. demonstrated that reducing injector clearance and leakage can lead to a reduction of approximately 1% in fuel consumption for both passenger cars and heavy-duty applications across the entire operation map [28]. Besides the benefits to fuel economy, minimizing injector clearance leakages also enhances idle start and stop functionality. Moreover, increased injector clearance leakages can escalate the risk of fuel deterioration, a consequence of high local temperatures in the fuel return lines.

1.2. Novelty

Existing literature on injector performance improvement primarily focuses on variables such as fuel pressure, energization timing and duration, needle opening profile, and total backflow during the injector’s static and dynamic behavior. However, injection processes are fundamentally driven by the hydraulic pressure differences created by backflow through the valve, armature, and armature pin. Research exploring the causes of these pressure differences, particularly the guidance effects of the valve, armature, and armature pin, is notably scarce. This scarcity is partly attributable to the limited accessibility of these components within the injector. Additionally, conducting functional tests on assembled injector sub-parts demands highly specialized test stations, further complicating research efforts.

Our study aims to address this gap by investigating the impact of geometric variability between the valve, armature, and armature pin on armature guidance. A controlled experimental design was utilized to manufacture injectors, which were then analyzed using computational fluid dynamics through the Ansys Fluent 2022 R1 software to evaluate the effects of dimensional variations on backflow. The results of these tests and simulations were subsequently used to develop a correlation matrix. This matrix quantifies the influence of alterations in injector geometry tolerances on injector performance. Ultimately, this research seeks to identify optimal guidance parameters that could significantly enhance injector function and efficiency.

2. Materials and Methods

2.1. System and Problem Definition

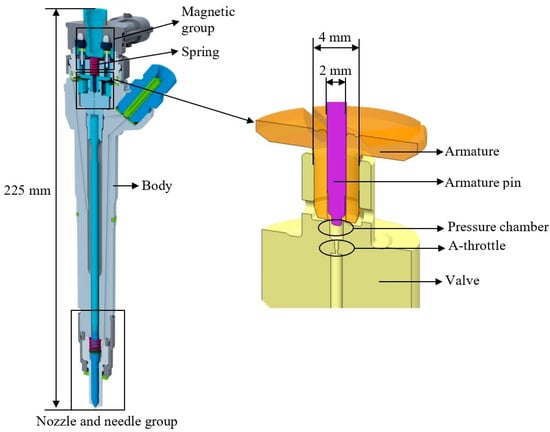

In this study, a magnetically triggered solenoid CR diesel injector (Bosch), designed to operate at a pressure of 2000 bar, was utilized. This injector is currently in mass production and is distributed globally to various well-known vehicle brands. For further investigation and replication of the study, it can be obtained from the aftermarket with the type definition BX-CRI2-20 (0 986 435). Figure 1 provides a cross-sectional view of the injector, highlighting its key components, including the complete injector, armature, armature pin, and valve.

Figure 1.

Cross-sectional view of complete injector, armature, armature pin, and valve.

The working principle of the CR injector is based on generating a hydraulic pressure difference. As illustrated in Figure 1, when the magnetic group is triggered, the armature moves upward, causing fuel in the valve area to be discharged back through the A-throttle [25,29]. This action forms a low-pressure zone in the pressure chamber. The high-pressure force acting on the tip of the injector needle then overcomes the opposing spring force in this low-pressure region, allowing the needle to open. When the magnetic triggering ceases, the armature moves downward under the influence of the spring, creating a seal on the A-throttle and preventing low-pressure formation. Consequently, the vertical spring force returns the needle to the closed position.

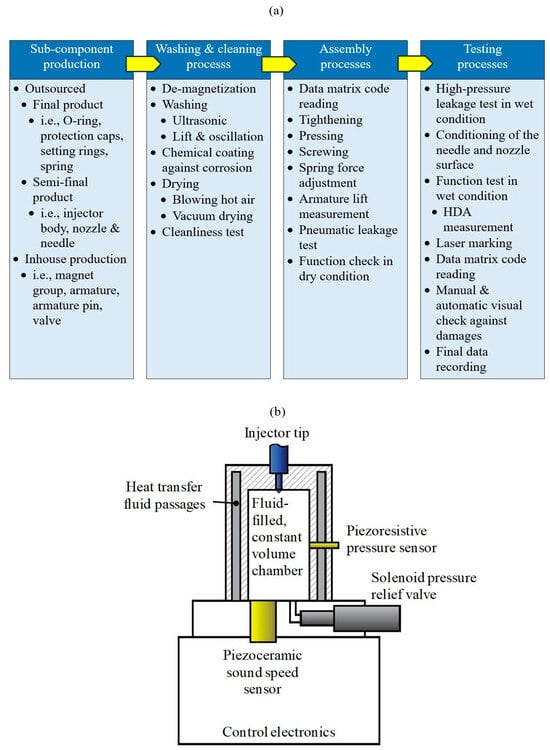

The injector assembly and testing process is depicted in Figure 2a. Sub-components are delivered to assembly lines through three different paths. As shown in Figure 2a, the armature, armature pin, and valve parts are produced in-house to their final form using various machining processes, including turning, washing, hardening, milling, drilling, and brushing. Parts are measured using a coordinate measurement machine (Zeiss, Oberkochen, Germany) and tactile measurement devices (Heidenhain, Traunreut, Germany) to define the desired inner/outer diameter and length. A schematic of the injector-function measurement device, which serves as the core measurement tool for this study, is shown in Figure 2b.

Figure 2.

(a) Injector assembly and testing process flow and (b) HDA measurement schematic.

The HDA device (Moehwald, Homburg, Germany), where HDA stands for “Hydraulischer Druckanstieg” (a German abbreviation for hydraulic pressure increase), is employed to measure the injection rate and mass. This device operates by detecting changes in hydraulic pressure as the liquid is injected into a sealed chamber filled with liquid. The primary measurement principle is based on monitoring pressure and the speed of sound within a constant volume chamber. The injection mass flow rate, assuming reversible, adiabatic (isentropic) injection into the chamber, can be expressed as follows:

where m is fuel mass in the chamber, V is chamber volume, t is time, ρ is fuel density, c is the speed of sound in the fuel, and P is chamber pressure.

Integrating this equation between two points in time (and two different pressures) yields the cumulative mass:

Mass flow rate and cumulative mass can be calculated for a specific chamber volume, provided that the time-dependent pressure and pressure-dependent speed of sound are known. The HDA measures the speed of sound directly, which mitigates the influence of other variables, such as density and mass, on the results. The schematic of the HDA, shown in Figure 2b, illustrates its key components.

The test chamber has a volume of 128 mL and is temperature-regulated by an external heat pump. A piezoresistive pressure sensor located in the cylinder wall measures the pressure signal. This signal is filtered through an anti-aliasing filter with a cutoff frequency of 25 kHz, then digitized at a 16-bit resolution and a sampling rate of 100 kHz. Finite impulse response filters are used to digitally filter the signal.

The critical element within the HDA setup is the piezoceramic sensor, which generates a pressure wave in the test liquid in the chamber. The same sensor at the top of the chamber detects the reflecting waves. The average chamber pressure is recorded as the initial pressure (P1) before the measurement begins. The speed of sound is also measured and recorded as the initial sound speed (c1). Subsequent measurements of the mean pressure in the chamber (P2) and speed of sound (c2) are taken during the injection process. These measurements are integral to calculating the total mass, as outlined in Equation (2). [30]. This study’s reference pressure (P1) is set to 50 bar. Commercially available Divinol CAF test oil (Item Nr.: 2928V3), a product of Zeller+Gmelin GmbH & Co. KG (Eislingen/Fils, Germany), was used for HDA measurements. Regular calibration of the HDA machine by the manufacturer ensures the stability of measurements, and repeatability is verified by multiple measurements of previously produced injectors to avoid any deviations.

A gravimetric procedure is employed for calibration. If the first set of stability injectors fails, a second set is measured under identical conditions to ascertain whether deviations arise from the injectors or the calibration equipment. A standard calibration procedure is implemented prior to measurements; results are verified, and no abnormalities are detected with the machine.

Stable injector behavior is critical for achieving accurate results in HDA measurements. Proper vertical movement of the armature is essential for establishing a hydraulic pressure balance and ensuring injector stability. This stability necessitates precise guidance of the armature pin and valve interior. Excessive clearance in the guidance mechanism leads to off-axis armature movement and vibration, which can cause premature pressure differences and needle activation. Conversely, inadequate clearance may result in surface abrasions, particle formation, delayed pressure difference formation, and delayed needle opening.

While the existing literature predominantly focuses on needle movement and fuel injection, research addressing the connections between the valve, armature, and armature pin—crucial determinants of needle movement—remains insufficient. Operational vibrations can lead to eccentric armature movement, which fails to achieve complete sealing and the desired hydraulic pressure balance. Consequently, rapid pressure drops in the control chamber may prematurely open the needle, leading to excessive fuel injection. Thus, the critical role of precise guidance in injector operation becomes evident.

The findings of this study have significant potential to positively impact millions of injectors currently in production.

2.2. Experimental Method

Experimental groups were established based on injector production expertise. The experiment focused on two variables:

- (a)

- clearance between the valve and armature;

- (b)

- clearance between the armature and armature pin.

Each variable was evaluated at three levels:

- high clearance;

- low clearance;

- lowest clearance.

While one variable was investigated, the other was maintained at medium clearance, allowing each factor to be examined independently. This approach resulted in a total of six experiments. Additionally, one experiment (group 4) was independently added as a reference group with both clearances set to medium. Other sub-components were manufactured to medium tolerance levels and were not considered variables; thus, they were not included as separate experimental groups.

In total, seven different groups were formed. The details of these groups are presented in Table 1. The “Research package” column clarifies the purpose of each experiment, while the “Group number” column specifies the identifiers for the experimental groups. Each group consists of seven injectors, culminating in the production of 49 injectors. In groups 1, 2, and 3, the clearance between the armature pin and armature was set at a medium value, focusing solely on the effect of the clearance between the valve and armature. Conversely, in groups 5, 6, and 7, the clearance between the valve and armature was maintained at a medium value, exclusively examining the impact of the clearance between the armature and armature pin. Group 4 served as the reference group, with both clearances set to medium.

Table 1.

Experimental groups.

Apart from the valve, armature, and armature pin, the spring, nozzle, and magnet group are other sub-components that directly impact injector function and spray characteristics. The critical parameters and dimensions of these parts were standardized at medium values for all injectors. The spring influences the armature’s opening–closing behavior based on armature movement, while the magnet group electrically triggers this movement.

Once the experimental groups were established, injector production commenced. All relevant sub-parts likely to affect performance were measured using calibrated precision measuring devices to ensure they were free of dents and scratches during assembly. Transition parameters were recorded during injector assembly, and final function and sealing tests were conducted.

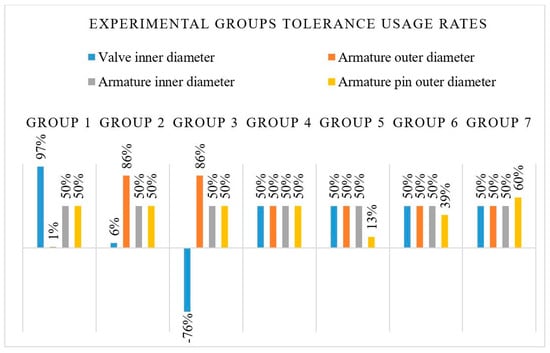

The diameter tolerance usage rates of the sub-parts are depicted in Figure 3. Given the variability in size and tolerance values of each part, these rates were used as a reference to analyze relationships between the experimental results.

Figure 3.

Diameter tolerance usage rates of experimental groups.

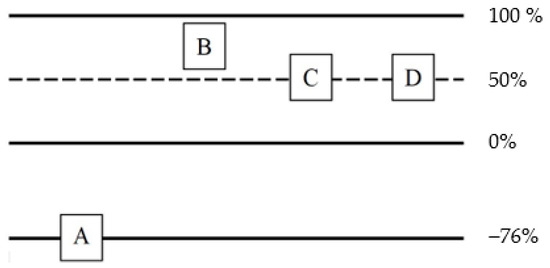

The percentage values in Figure 3 represent each part’s position within its total tolerance range, starting from the lower limit. For instance, the inner diameter of the valve in the first group is at 97% of its tolerance range from the lower limit. The outer diameter of the armature is marginally above the lower limit, at approximately 1% of the total tolerance. Both the armature’s inner diameter and the armature pin’s outer diameter are positioned at the intermediate value of 50%. In the case of the third group, the valve inner diameter value of −76% indicates that the valve’s inner diameter is 76% below its lower tolerance limit, placing it out of tolerance and aligning it with the armature’s outer diameter. Further elucidation of the positioning of parts within the total tolerance scale is provided in Figure 4.

Figure 4.

Level of diameters in group 3 considering total tolerance (A: valve inner diameter, B: armature outer diameter, C: armature inner diameter, D: armature pin outer diameter).

2.3. Geometry and Case Setup

Backflow amounts between the valve, armature, and armature pin were compared through simulations of the inlet–outlet boundary conditions. The design was according to the seven different experimental groups outlined in Table 1, and flow rates, pressures, and velocities were computed for each group. This study employed the finite-volume method to solve the conservation of mass and momentum equations using Ansys Fluent. The mass conservation and momentum equations are provided in Equations (3) and (4), respectively. Additionally, the pressure drop can be determined using Equation (5), while the Reynolds number (Re) can be calculated using Equation (6).

where ρ is the fluid density, is the fluid velocity vector, P is fluid pressure, and is the gravity acceleration vector.

Simulation studies corresponding to the groups listed in Table 1 were conducted using Ansys Fluent. Given that Re ≤ 2300, the flow was determined to be laminar. The analyses were performed under steady-state conditions. The inner and intermediate pipe inlet pressure were determined as 500 kPa. The outlet pressure of both was 100 kPa. The SIMPLE (semi-implicit method for pressure-linked equations) algorithm was utilized as the solution method. Because of its ease of converge, first-order upwind spatial discretization was preferred for momentum and pressure. After convergence was achieved, the analysis solution was continued with second-order upwind spatial discretization. The test fluid properties in Section 2.1 were used as the fluid.

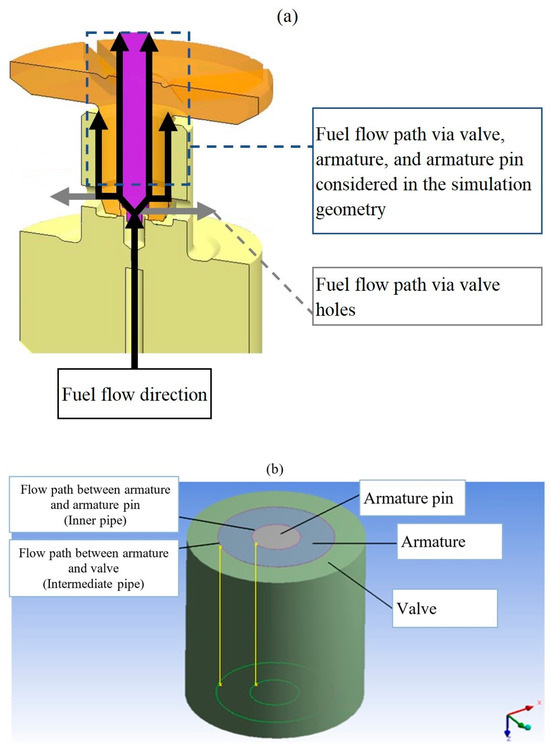

Figure 5 illustrates the fuel flow path between the armature, armature pin, and valve (a) and the model geometry used for the simulation study (b).

Figure 5.

(a) Fuel flow path between valve, armature, and armature pin; (b) definition of inner pipe and intermediate pipe.

Backflow occurs through three pathways: between the valve and armature, between the armature and armature pin, and through the valve holes. A continuous flow between the armature and armature pin is independent of the energizing time. However, flow through the valve holes only begins after the armature is lifted, also continuing through the valve holes. Because liquid typically follows the path of least resistance, the primary backflow of fuel occurs through the valve holes when the injector remains energized for an extended duration. However, if the energization time is brief, the backflow from the valve holes may be less than the flow between the valve and armature, as well as between the armature and armature pin. In the absence of energization, which represents a significant portion of the injector’s lifespan, backflow occurs solely between the armature and armature pin. The importance of continuous leakage (backflow) over the injection rate has also been mentioned in the study by d’Ambrosio et al. They noted that static condition leakages (backflow) are higher than those in dynamic conditions in solenoid injectors [27].

To maintain consistency across all experimental groups, the energization time was set to a minimum, and as the valve holes were uniformly produced in the same size across all groups, backflow from these holes was disregarded. This approach ensures that the influence of the valve holes remains neutral. Consequently, only the fuel flow paths between the valve, armature, and armature pin were considered in the simulation geometry. Within this simulation, the flow between the armature and armature pin was defined as the “inner pipe”, and the flow between the armature and valve was defined as the “intermediate pipe”.

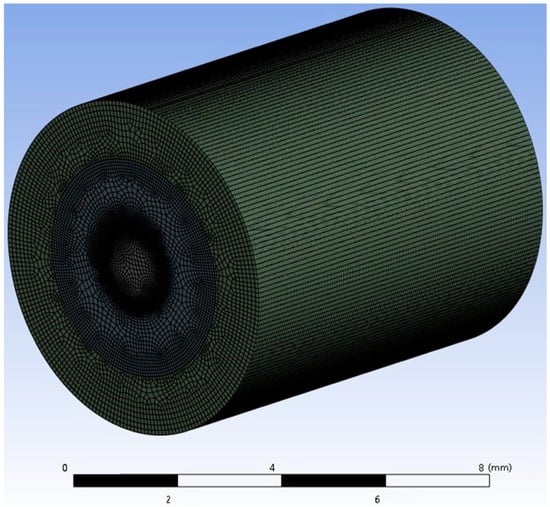

Figure 6 depicts the mesh structure of the model. A 12-layer inflation layer (boundary layer) was generated on the upper and lower walls of the flow channels. During the mesh independence study, meshes with element counts of 1,517,192, 3,577,536, and 8,326,656 were created. Owing to the limitations of the available computer hardware, a further increase in the number of elements was not feasible.

Figure 6.

View of the geometry mesh structure.

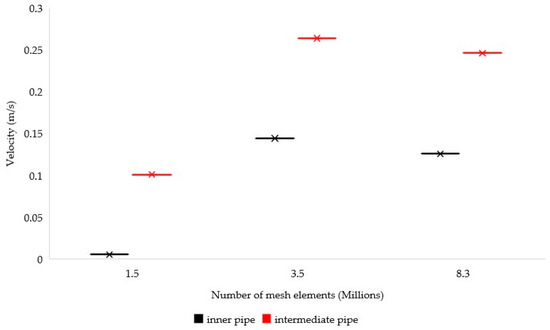

Calculations were performed using the element numbers mentioned above to simplify calculation time and provide mesh-independent results. A comparative analysis was necessary to determine the adequate mesh size for accurate simulations. A straight line was delineated along the inner pipe and intermediate pipe, as illustrated in Figure 5. The velocity variation along this line was assessed based on the number of meshes.

Mesh independence analysis was conducted by defining 100 points along the specified line in the z-component of the flow. Consistency was maintained across all mesh studies by utilizing the same reference line.

Figure 7 shows the outcomes of the mesh study. Since the speed did not change along the line, the average of the speed values taken from 100 points was used. The results indicate that the differences between the 3.5M and 8.3M meshes in both channels are less than 5% for the intermediate pipe and less than 10% for the inner pipe. Based on these findings, the most suitable number of mesh elements for the study was determined to be 3.5M.

Figure 7.

Velocity variations in flow channels according to mesh size.

3. Results and Discussion

3.1. Simulation Results

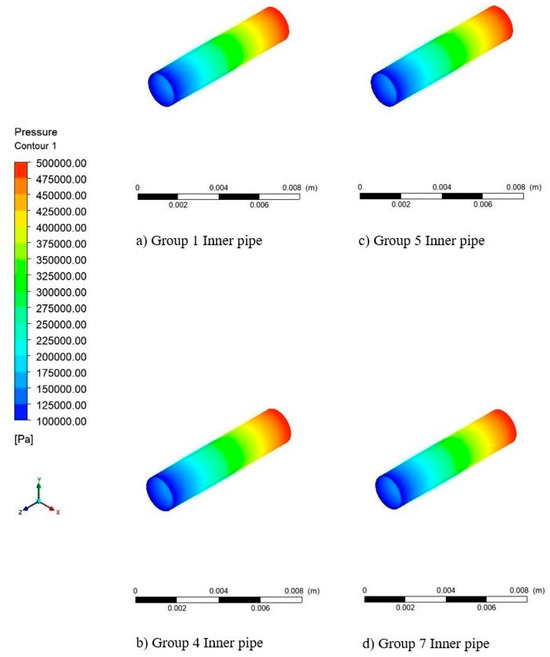

Flow simulations were conducted for each group following magnetic triggering when the armature was in the upper position and the opening was at its maximum. Dynamic armature movement was not considered in these simulations. System pressure was used as the inlet pressure, while the outlet pressure was set to match the pressure within the fuel tank.

Figure 8 illustrates the pressure variation along the fuel path within the inner pipe (between the armature and armature pin). The inlet pressure corresponds to the pressure within the pressure chamber region, as depicted in Figure 1, while the outlet pressure represents the backflow pressure. Detailed pressure distributions along the inner pipe for each group are shown in Figure 8. The fluid exhibited high pressure at the inlet, which gradually decreased towards the backflow region owing to internal channel friction. Notably, there were no significant deviations in pressure distribution among the groups.

Figure 8.

Pressure distribution of the fuel path through the inner pipe.

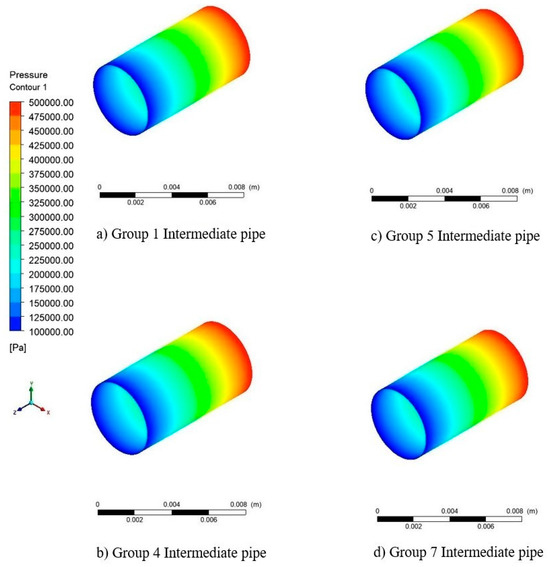

Figure 9 illustrates the pressure fluctuations along the fuel path within the intermediate pipe (between the armature and valve). Similar to observations in the inner pipe, the pressure values and distributions across all groups within the intermediate pipe showed similarities.

Figure 9.

Pressure distribution of the fuel path through the intermediate pipe.

Table 2 shows the pressure drops for the inner and intermediate pipes according to the model results of different groups. It can be seen that the changes in inlet–outlet pressures are compatible with the design changes specified in Figure 3. However, due to the minimal design dimensions, the pressure drop difference between the seven group designs is very low.

Table 2.

Pressure difference between inlet and outlet for inner pipe and intermediate pipe.

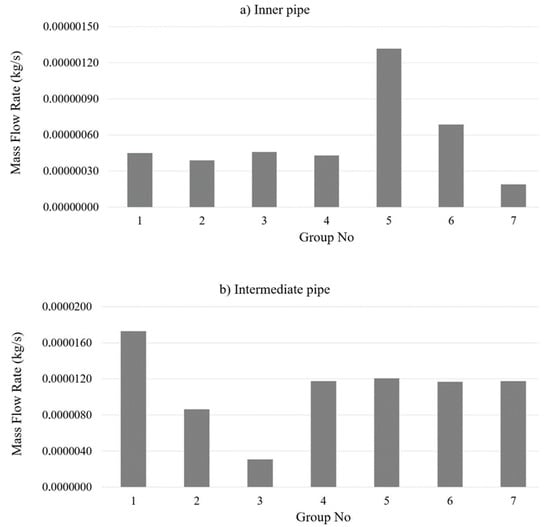

Figure 10 depicts the changes in the fuel flow rate within the inner pipe. In groups 1, 2, 3, and 4, where the clearance between the armature and armature pin falls within the middle of the tolerance range, and the flow rates are relatively consistent and close to medium values. Conversely, the flow rate is notably elevated in group 5, where the clearance is significantly higher. In group 6, although the clearance is lower than in group 5, it still exceeds the nominal tolerance, resulting in a higher flow rate. Conversely, the flow rate falls below the average value in group 7, where the clearance is at its lowest level.

Figure 10.

Fuel flow rates through (a) inner pipe and (b) intermediate pipe.

Furthermore, Figure 10 illustrates variations in the fuel flow rate between the armature and valve within the intermediate pipe across different groups. The flow rate values are relatively consistent in groups 4, 5, 6, and 7, where the clearance between the armature and valve falls within the middle of the tolerance range. However, in group 1, where the clearance between the valve and armature is at its highest level, the fuel flow rate is notably higher. Conversely, in group 2, where the clearance is below the middle value, the flow rate decreases accordingly. Finally, in group 3, where the clearance is at its lowest level, the fuel flow rate reaches its minimum.

3.2. Injector Function Results

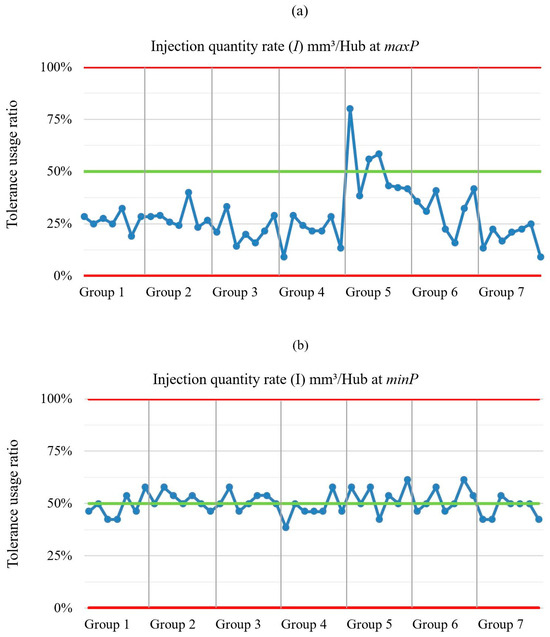

The measurements of sub-parts and the functional tests of injectors were finalized. The results of these injector function measurements, which correspond to the measurements of the sub-parts, are presented in Figure 11. Additionally, to align with the lower part tolerance analysis, tolerance values were also assessed at the pressure (P), spray (I), and backflow (G) measurement points.

Figure 11.

Injection quantity rate (I) at (a) maxP and (b) minP.

Analysis of the graphs in Figure 11 shows that the injection quantities in groups 1, 2, 3, 4, 6, and 7 are closely clustered at each pressure point. As outlined in Table 1, in the first four groups, the clearance between the valve and armature varies, while the clearance between the armature and armature pin remains constant. Conversely, in the remaining three groups, the clearance between the valve and armature is constant, whereas the clearance between the armature and armature pin varies. The results depicted in Figure 11a suggest that the impact of the clearance between the armature and armature pin is more significant than that of the clearance between the valve and armature. Notably, the clearance in the fifth group is considerably high, causing the injector’s injection quantity to fall out of tolerance. However, no significant difference is observed at minP, as seen in Figure 11b. When minP and maxP are evaluated together, it is observed that the increase in pressure highlights the effect of the gap between the armature and armature pin. However, the increase in pressure does not significantly alter the effect of the clearance between the valve and armature. To gain further insight into this discrepancy, the backflow rates of injectors in the same groups are compared in Figure 12.

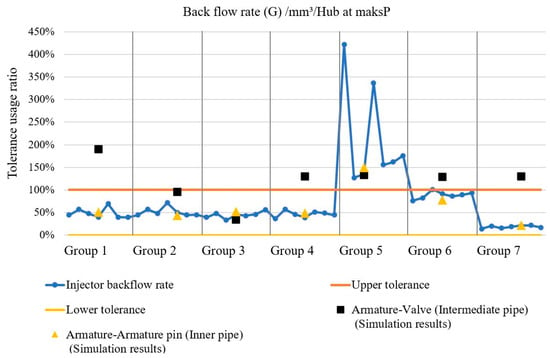

Figure 12.

Backflow rate results comparison of injector experiment vs. simulation at maxP.

Figure 12 reveals that the backflow rates in groups 1, 2, 3, and 4 are closely aligned. However, in the fifth group, characterized by a significantly high clearance between the armature and armature pin, the backflow rate surpasses the tolerance threshold, resulting in unintended injection quantities and inefficient combustion within the cylinder. Consequently, the engine’s energy efficiency decreases while pollutant emissions increase. Similarly, in the sixth group, where the clearance is relatively high, the backflow rates approach the upper tolerance level. Conversely, the backflow rates remain within the tolerance limits in the seventh group, which has minimal clearance. In summary, the contrasting effects of clearance on backflow values are observed predominantly in the armature and armature pin, specifically within groups 5, 6, and 7.

The flow rate between the armature and armature pin, as obtained from simulation results, closely mirrors the injector’s backflow amount determined through physical measurements. However, the flow rate between the armature and valve varies depending on the injector’s backflow amount, indicating that design changes between these components minimally impact backflow.

Two primary factors contribute to the fuel movement that generates the low-pressure region: the clearance between the valve and armature and the clearance between the armature and armature pin. The backflow behavior illustrated in Figure 12 aligns with the spray flow behavior observed in Figure 11. A comprehensive examination of these figures reveals that the clearance between the valve and armature is significantly less impactful than that between the armature and armature pin. An important aspect supporting this observation is the continuous backflow between the armature and armature pin, regardless of the energizing time or armature lift.

In contrast, the flow between the valve and armature only begins after the armature is lifted, which occurs during only one of the four engine strokes. Because backflow occurs in the injector even when there is no energizing, the majority of it depends on the flow between the armature and armature pin. This finding aligns with the study by Ferrari et al. [22] regarding backflow during the static state. The increase in injector spray amount as the clearance between the armature and armature pin increases is attributed to higher backflow rates, resulting in earlier needle rise and prolonged needle opening during the defined time interval. Consequently, increased clearance between the valve, armature, and armature pin leads to increased injection amounts. This phenomenon primarily occurs because of the accelerated deterioration of hydraulic pressure balance and the extended needle opening time within the triggering period arising from the earlier rise of the injector needle. The injection amount is influenced by three key factors:

- armature opening closing time;

- injector needle opening and closing time;

- nozzle hole flow amount.

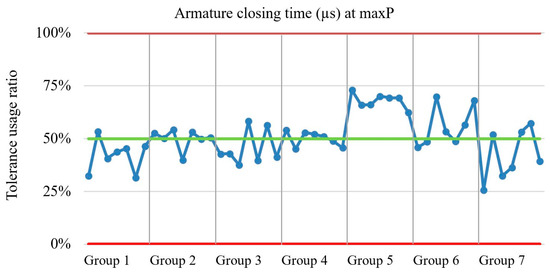

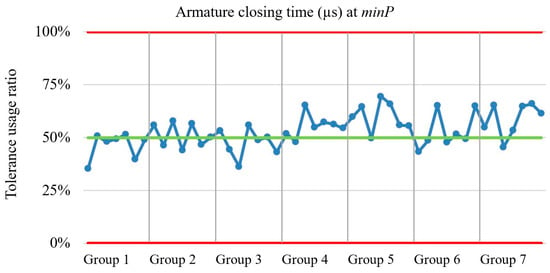

The opening and closing times of the armature are influenced by factors such as the clearance between the armature and armature pin, magnetic trigger timing, armature geometry, and the spring force acting on the armature. Except for the armature and armature pin, all factors and sub-parts remain constant. The impact of the clearance between the armature and armature pin on the injector spray and backflow rate has been previously analyzed. The closing time of the armature is evaluated in Figure 13 and Figure 14.

Figure 13.

Armature closing time at maxP.

Figure 14.

Armature closing time at minP.

The opening and closing times of the injector needle depend on the valve, armature, armature pin, backflow amount, needle geometry, and spring force acting on the needle. Similarly, all variables except the valve, armature, and armature pin are considered constant.

Figure 13 reveals negligible variance in armature closing times among groups 1, 2, 3, and 4 at maxP. However, in the fifth group, characterized by the highest clearance between the armature and armature pin, the armature closing time also reaches its peak. This occurrence is attributed to the armature elevating earlier owing to the same magnetic trigger initiation. Subsequently, upon completion of magnetic triggering, the armatures across all groups revert to their original positions simultaneously, driven by the spring force. Notably, an armature that opens earlier remains open for a longer overall duration. In the sixth group, the closing time of the armature was prolonged in two injectors, deviating from the norm. This deviation could be attributed to variations in the physical properties of the magnetic coil or a partially premature trigger initiation. Further investigation is needed to elucidate this result, potentially forming a basis for subsequent studies.

Figure 14 reveals that the armature closing time in the fifth group at the minP value is shorter compared to the maxP value. This discrepancy arises because of the reduced back pressure force exerted by the fuel on the armature at minP compared to maxP. During the initiation of triggering, the fuel pressure force propels the armature upwards, and upon triggering cessation, the armature swiftly returns to its closing position. Consequently, the total duration of openness is abbreviated.

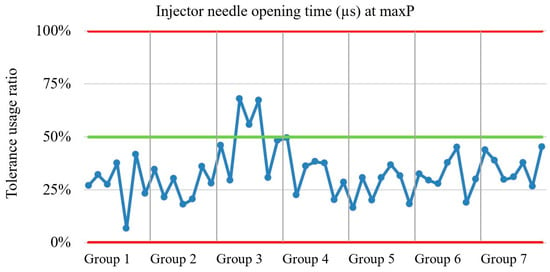

The data presented in Figure 15 illustrate the duration required for the injector needle to overcome the spring force and reach its fully open position. This metric is crucial for assessing the influence of components beyond the valve, armature, and armature pin, such as nozzle geometry and needle spring force, during the period following the disruption of hydraulic balance. The durations depicted in the figure exhibit proximity across all groups. As previously mentioned, the specialized production, measurement, and control of sub-parts, excluding the valve, armature, and armature pin, contribute to this outcome. Once the pressure balance is disrupted, resulting in low pressure in the upper region of the needle, other components cease to impact the needle opening. Although the values for three injectors in the third group appear marginally elevated, they do not significantly affect the overall average.

Figure 15.

Injector needle opening time at maxP.

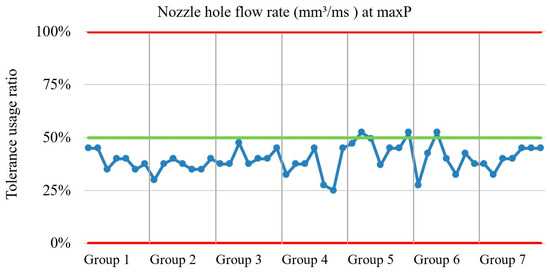

Figure 16 shows the nozzle hole flow amount, measured with the injector needle in the fully open position. The flow rate through the nozzle orifice can be considered independent as it pertains to the flow after the needle opening. Consequently, the effect of all variables influencing the needle opening is eliminated. If the nozzle holes are manufactured with values closely matched to each other, it is anticipated that they will be minimally affected by the aforementioned variables or not affected at all. This effect is explored in Figure 16. Values are close across all groups, differing marginally owing to variations in hole diameters, numbers, or forms. However, the reason for the different spray amounts observed in various groups is not attributable to differences in the nozzle holes but rather to differences in the total open time of the injector needle. Nozzle hole flow rate measurement is conducted independently from injectors, ensuring that no side effects come from nozzles. As seen in Figure 16, no apparent effects are observed in any groups, confirming that nozzles remain neutral within this study.

Figure 16.

Nozzle hole flow rate at maxP.

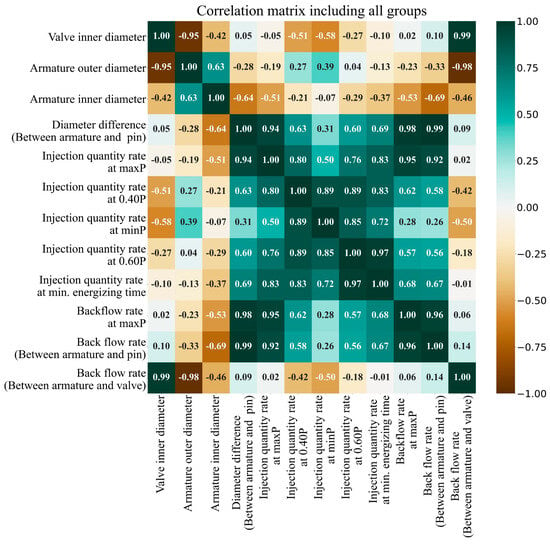

3.3. Correlation Matrix

To understand the interactions among the pertinent parameters of the injector, the actual behavior of the injector was analyzed using a Python program. Subsequently, a correlation matrix was generated based on the obtained results. In Python, correlation matrices are calculated using libraries such as “pandas,” which computes the correlation coefficient between pairs of variables in a dataset. The correlation coefficient, often denoted by ρ (rho) or r, measures the strength and direction of the linear relationship between two variables.

There are different methods to compute the correlation coefficient; this study utilized the Pearson correlation coefficient, which measures linear correlation between two variables. It is calculated as the covariance of the two variables divided by the product of their standard deviations. Mathematically, for two variables X and Y, the Pearson correlation coefficient r is calculated as follows:

where and are the individual data points, and are the means of X and Y, respectively, and n is the number of data points.

The output of this calculation is a correlation matrix for the variables X and Y, where each entry represents the correlation coefficient between corresponding variables. The correlation coefficient ranges from −1 to 1:

- r = 1 indicates a perfect positive linear relationship;

- r = −1 indicates a perfect positive linear relationship;

- r = 0 indicates no linear relationship.

This study revealed significant interactions between the functions of the injector and other sub-component parameters. These findings enable providing feedback to independent processes for optimal production without physical prototyping. The interpretation of the correlation matrix is as follows:

- The terms such as “valve inner diameter”, “armature inner diameter”, “armature outer diameter”, and “clearance between the armature and armature pin” in the correlation matrix represent inputs, while the other terms represent results.

- A value approaching +1 indicates a strong positive interaction between two variables, suggesting that as one variable increases, the other also increases.

- A value approaching −1 indicates a strong negative interaction between two variables, where one variable’s increase corresponds with the other’s decrease.

- A value approaching 0 suggests a weak or no interaction between two variables, indicating they are not significantly affected by each other.

The correlation matrix, encompassing all groups, was generated using the Python program, incorporating flow rates obtained from the simulation. This matrix allowed us to identify characteristics that interacted significantly across all groups.

Figure 17 reveals a robust positive correlation between the backflow rate from the armature to the armature pin, the total backflow rate, and the spray amount at maximum pressure. Conversely, there is minimal correlation between the backflow rate from the armature to the valve and the total backflow rate. This suggests that the primary determinant of backflow is the interaction between the armature and armature pin. This is attributed to the mechanism by which fuel, upon contact with the valve when the armature is open, is directly expelled out of the valve and into the main tank rather than moving between the armature and valve.

Figure 17.

Correlation matrix including all groups.

Backflow rates increase with injection pressure. The highest correlation is observed at maxP, indicating that backflow amounts are also greatest at this pressure level.

In summary, the backflow rate positively correlates with the injector spray value. The clearance between the armature and armature pin is the main factor influencing backflow. As this clearance increases, backflow intensifies, leading to faster pressure changes, earlier needle opening, and an increased spray amount.

4. Conclusions

In CR solenoid diesel injectors, needle movement for spraying is driven by hydraulic pressure differences within the injector, primarily influenced by the valve and armature components. This study revealed several key insights:

- The spray amount at maxP is notably influenced by the clearance between the armature pin and armature. Conversely, variations in the clearance between the armature and valve have minimal impact on the spray amount.

- The clearance between the armature pin and armature exerts the most significant effect at maxP. When this clearance is minimized, spray amounts at minP are comparable.

- High pressure accelerates changes in hydraulic pressure balance, resulting in earlier needle lift and longer open times during the standard magnetic trigger period, leading to increased fuel injection.

- Backflow is minimized when the clearance between the armature and armature pin is at its lowest. High pressure exacerbates forced backflow between these components and increases backflow due to needle movement.

- The amount of backflow at maxP is directly impacted by the clearance between the armature pin and armature. However, changes in the clearance between the armature and valve have minimal impact on backflow. Hence, optimizing backflow and injection quantity necessitates focusing on the armature and armature pin clearance. The continuous flow between the armature and armature pin, independent of energizing duration, further supports this phenomenon. In scenarios where there is no energizing, which corresponds to a larger portion of the injector’s lifespan, there is no flow between the valve and armature.

- The armature, armature pin, and valve are critical sub-components for creating hydraulic pressure differences and triggering needle movement in the injector. Despite being considered a black box owing to production and testing constraints, focusing on these components can yield significant improvements in injector performance and manufacturing efficiency, such as reducing scrap rates and saving cost, which lead competitive advantages

- More accurate and reliable injectors can enhance engine efficiency, reducing harmful combustion emissions and positively impacting environmental safety.

- Similar methodologies can be employed to separately evaluate the effects of all injector sub-parts on injector function, identifying critical areas for improvement studies.

In conclusion, understanding and optimizing the interaction between injector sub-parts can lead to more efficient combustion processes, improved fuel efficiency, and reduced environmental impact, ultimately benefiting both manufacturers and consumers.

Author Contributions

Conceptualization, G.Ş. and F.I.; methodology, G.Ş. and A.S.; software, F.I. and A.S.; validation, G.Ş., F.I. and A.S.; formal analysis, G.Ş. and F.I.; investigation, G.Ş.; resources, G.Ş. and F.I.; data curation, G.Ş. and A.S.; writing—original draft preparation, G.Ş. and F.I.; writing—review and editing, G.Ş., F.I. and A.S.; visualization, G.Ş. and F.I.; supervision, A.S.; project administration, G.Ş. and F.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to the production company’s core technology privacy policy.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Payri, R.; Salvador, F.J.; Gimeno, J.; Morena, D. Influence of injector technology on injection and combustion development-Part1: Hydraulic characterization. Appl. Energy 2011, 88, 1068–1074. [Google Scholar] [CrossRef]

- Huang, W.; Moon, S.; Gao, Y.; Li, Z.; Wang, J. Eccentric needle motion effect on near-nozzle dynamics of diesel spray. Fuel 2017, 206, 409–419. [Google Scholar] [CrossRef]

- Teoh, Y.H.; How, H.G.; Peh, C.G.; Le, T.D.; Nguyen, H.T. Implementation of Common Rail Direct Injection System and Optimization of Fuel Injector Parameters in an Experimental Single-Cylinder Diesel Engine. Processes 2020, 8, 1122. [Google Scholar] [CrossRef]

- Lim, G.; Lee, S.; Park, C.; Choi, Y. Effect of ignition timing retard strategy on NOx reduction in hydrogen-compressed natural gas blend engine with increased compression ratio. Int. J. Hydrogen Energy 2013, 39, 2399–2408. [Google Scholar] [CrossRef]

- Natarajan, S.; Trasy, K.A.; Srihari, N.; Raja, S. Effects of injection timing on CI engine fuelled with algae oil blend with Taguchi technique. Energy Procedia 2017, 105, 1043–1050. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Raj, R.T.K.; Bhasker, J.P.; Vignesh, D.S. Influence of injection timing and exhaust gas recirculation of a Calophyllum inophyllum methyl ester fuelled CI engine. Fuel Process. Technol. 2017, 167, 18–30. [Google Scholar] [CrossRef]

- How, H.G.; Masjuki, H.H.; Kalam, M.A.; Teoh, Y.H. Influence of injection timing and split injection strategies on performance, emissions, and combustion characteristics of diesel engine fueled with biodiesel blended fuels. Fuel 2018, 213, 106–114. [Google Scholar] [CrossRef]

- Khalid, A.; Manshoor, B. Effect of high injection pressure on mixture formation, burning process and combustion characteristics in diesel combustion. World Acad. Sci. Eng. Technol. 2012, 71, 73–77. [Google Scholar]

- Chen, P.-C.; Wang, W.-C.; Roberts, W.I.; Fang, T. Spray and atomization of diesel fuel and its alternatives from a single-hole injector using a common rail fuel injection system. Fuel 2013, 103, 850–861. [Google Scholar] [CrossRef]

- Xu-Gang, T.; Hai-Lang, S.; Tao, Q.; Zhi-Qiang, F.; Wen-Hui, Y. The impact of common rail system’s control parameters on the performance of high-power diesel. Energy Procedia 2012, 16, 2067–2072. [Google Scholar] [CrossRef]

- Gumus, M.; Sayin, C.; Canakci, M. The impact of fuel injection pressure on the exhaust emission of a direct injection diesel engine fueled with biodiesel-diesel fuel blends. Fuel 2012, 95, 486–494. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Raj, R.T.K. Influence of fuel injection pressures on Calophyllum inophyllum methyl ester fuelled direct injection diesel engine. Energy Convers. Manag. 2016, 116, 165–173. [Google Scholar] [CrossRef]

- Wang, Z.; Wyszynski, M.L.; Xu, H.; Abdullah, N.R.; Piaszyk, J. Fuel injection and combustion study by the combination of mass flow rate and heat release rate with single and multiple injection strategies. Fuel Process. Technol. 2015, 132, 118–132. [Google Scholar] [CrossRef]

- Zhuang, J.; Qiao, X.; Bai, J.; Hu, Z. Effect of injection-strategy on combustion, performance and emission characteristics in a DI-diesel engine fueled with diesel from direct coal liquefaction. Fuel 2014, 121, 141–148. [Google Scholar] [CrossRef]

- Chau, V.T.; Long, T.D.; Vang, H.B.; Hoang, N.M.; Phuc, N.H.; Sy, N.Q. A study on the injection rate characteristics of the solenoid common-rail injector under using a high-pressure fuel system. Jurnal Teknologi 2023, 85, 25–33. [Google Scholar] [CrossRef]

- Gao, Z.; Li, G.; Xu, C.; Li, H.; Wang, M. A calculation method and experiment study of high-pressure common rail injection rate with solenoid injectors. Sci. Prog. 2021, 104, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Zhao, S.; Grekhov, L. Study on transient fuel hydrodynamic force characteristics of high-speed solenoid valve for common rail injector. Int. J. Automot. Technol. 2020, 21, 1257–1269. [Google Scholar] [CrossRef]

- Chung, M.; Kim, J.; Kim, S.; Sung, G.; Lee, J. Effects of hydraulic flow and spray characteristics on diesel combustion in CR direct-injection engine with indirect-acting Piezo injector. J. Mech. Sci. Technol. 2015, 29, 2517–2528. [Google Scholar] [CrossRef]

- Huang, W.; Moon, S.; Ohsawa, K. Near-nozzle dynamics of diesel spray under varied needle lifts and its prediction using analytical model. Fuel 2016, 180, 292–300. [Google Scholar] [CrossRef]

- Payri, R.; Gimeno, J.; Vierai, J.P.; Plazas, A.H. Needle lift profile influence on the vapor phase penetration for a prototype diesel direct acting piezoelectric injector. Fuel 2013, 113, 257–265. [Google Scholar] [CrossRef]

- Pratama, R.H.; Huang, W.; Moon, S. Unveiling needle lift dependence on near-nozzle spray Dynamics of diesel injector. Fuel 2021, 285, 119088. [Google Scholar] [CrossRef]

- Ferrari, A.; Mittica, A.; Paocelli, F.; Pizzo, P. Hydraulic characterization of solenoid-actuated injectors for diesel engine common rail systems. Energy Procedia 2016, 101, 878–885. [Google Scholar] [CrossRef]

- Ren, R.; Su, T.; Ma, F.; Zhao, X.; Xu, C.; Wu, X. Influence of the flow area around the ball valve on the flow characteristics of the injector control valve. Flow Meas. Instrum. 2023, 90, 102333. [Google Scholar] [CrossRef]

- Vrublevskyi, O.; Wierzbicki, S. Measurement and theoretical analysis of the displacement characteristics of moving components in a solenoid injector in view of wave phenomena. Measurement 2021, 187, 110323. [Google Scholar] [CrossRef]

- Leonhard, R.; Warga, J.; Pauer, T.; Rückle, M.; Schnell, M. Solenoid common-rail injector for 1800 bar. MTZ Worldw. 2010, 71, 10–15. [Google Scholar] [CrossRef]

- Krivtsov, S.N.; Yakimov, I.V.; Ozornin, S.P. Numerical analysis and experimental studies on solenoid common rail diesel injector with worn control valve. IOP Conf. Ser. Mater. Sci. Eng. 2017, 327, 042057. [Google Scholar] [CrossRef]

- D’Ambrosio, S.; Ferrari, A. Diesel engines equipped with piezoelectric and solenoid injectors: Hydraulic performance of the injectors and comparison of the emissions, noise and fuel consumption. Appl. Energy 2017, 211, 1324–1342. [Google Scholar] [CrossRef]

- Ferrari, A.; Paocelli, F.; Pizzo, P. The new-generation of solenoid injectors equipped with pressure-balanced pilot valves for energy saving and dynamic response improvement. Appl. Energy 2015, 151, 367–376. [Google Scholar] [CrossRef]

- Common-Rail Injector CRI2-20/-22. Available online: https://boschdiesel.co.za/wp-content/uploads/2021/08/Poster_CRI_2_20_22_en_87688.pdf (accessed on 27 February 2024).

- Busch, S.; Miles, C.P. Parametric study of injection rates with solenoid injectors in an injection quantity and rate measuring device. J. Eng. Gas Turbines Power 2015, 137, 101503. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).