Identification Model of Fault-Influencing Factors for Dam Concrete Production System Based on Grey Correlation Analysis

Abstract

1. Introduction

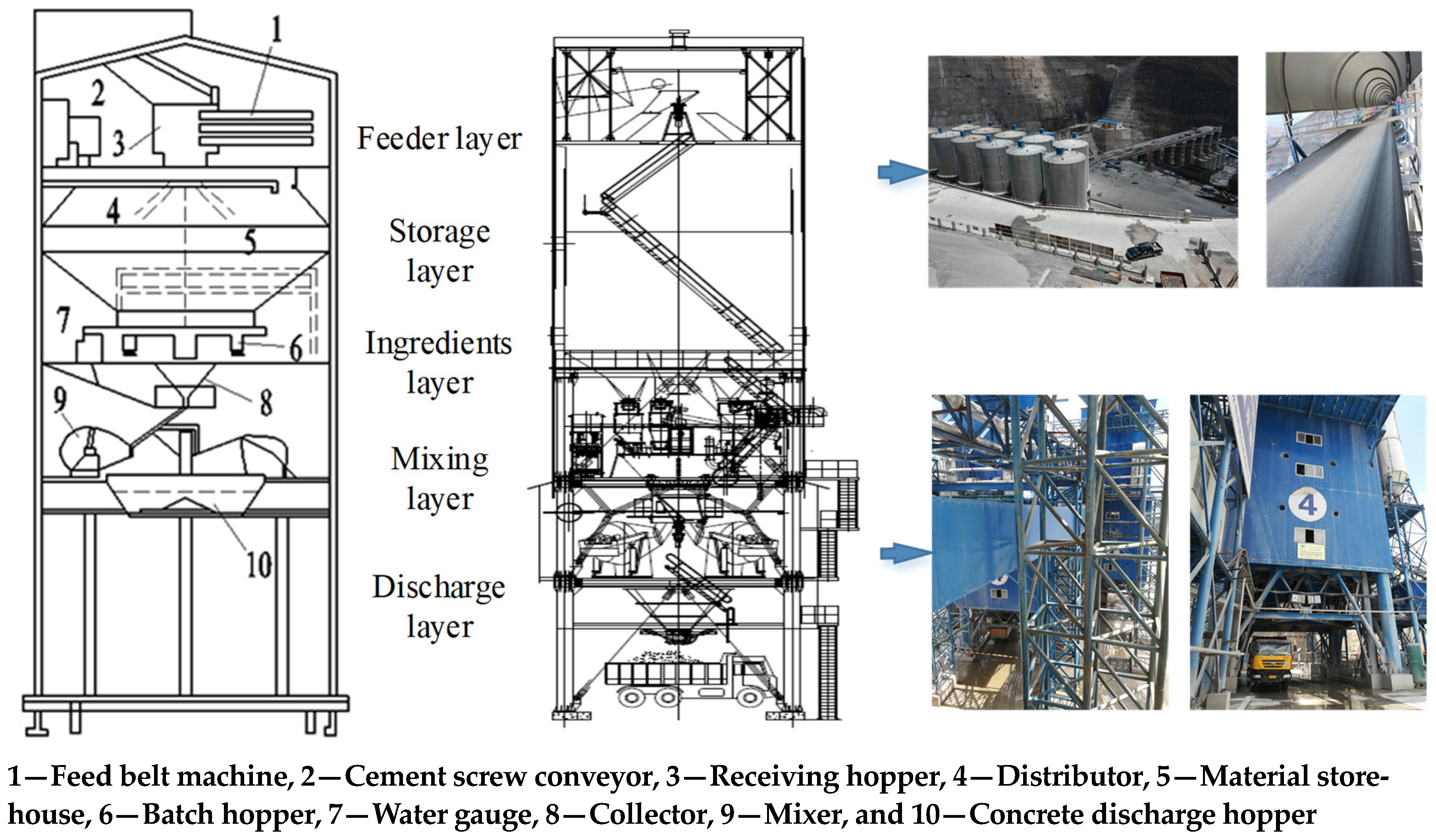

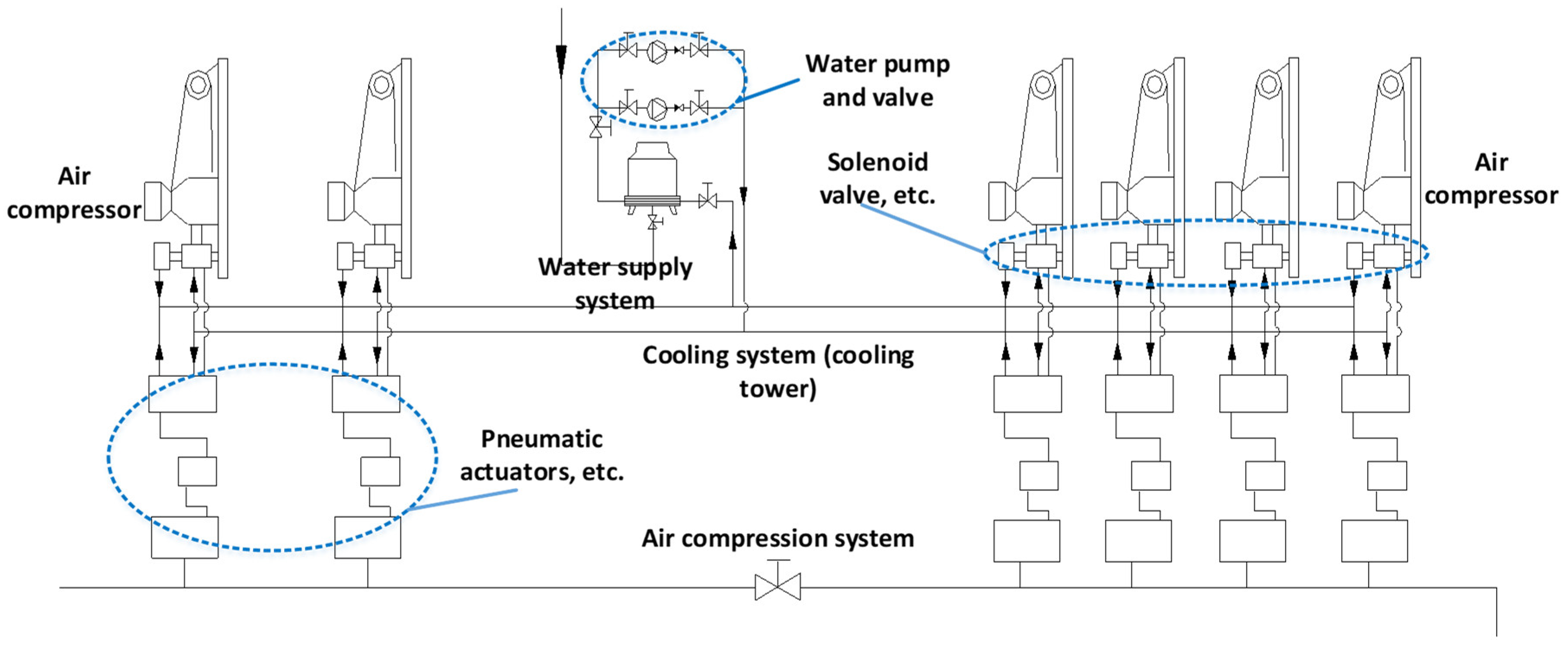

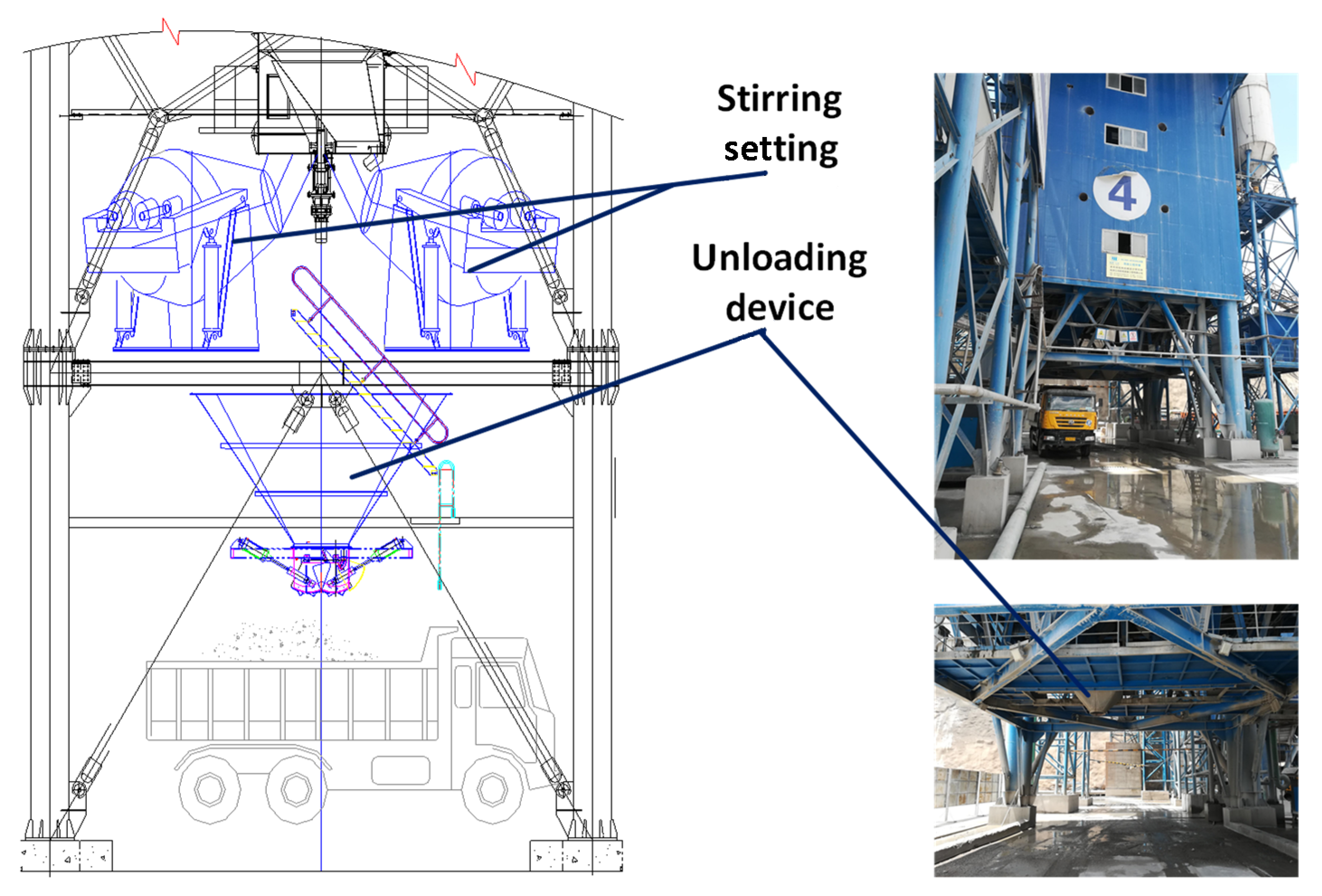

2. Component of a CPS

3. Fault Classification for CPSs

- Class A: Material handling system faults

- Class B: Batch metering system faults

- Class C: Pneumatic system fault

- Class D: Mixer fault

- (1)

- Human factors.

- (2)

- Environmental factors.

- (3)

- Service life factors of mechanical parts.

- (4)

- Other factors.

4. A Fault Identification Model for a CPS Based on Grey Relational Analysis

4.1. Basic Theory of Grey Relational Analysis

4.2. Establishment of an Identification Model for Fault-Influencing Factors

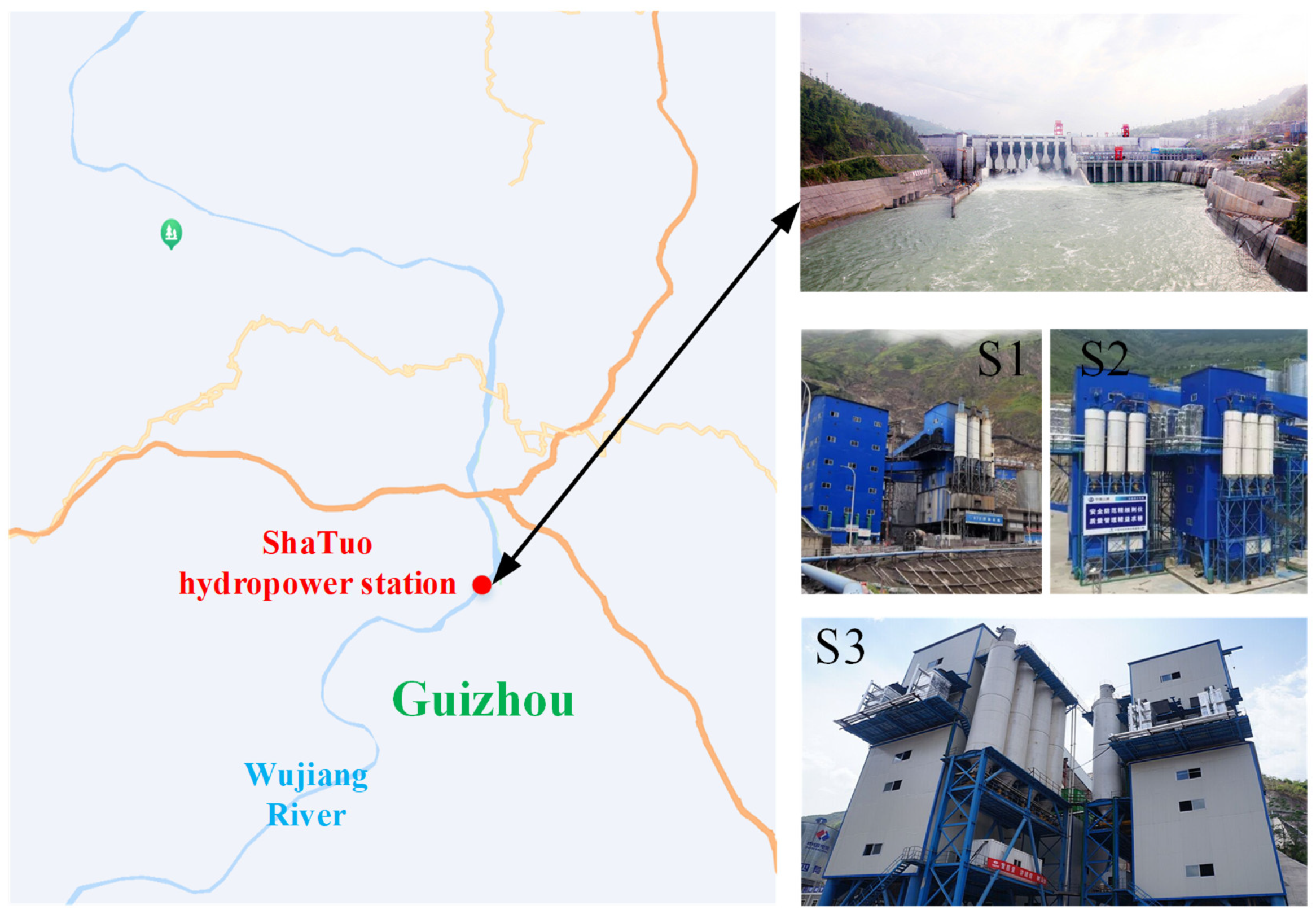

5. Case Study

5.1. Fault Classification Statistics

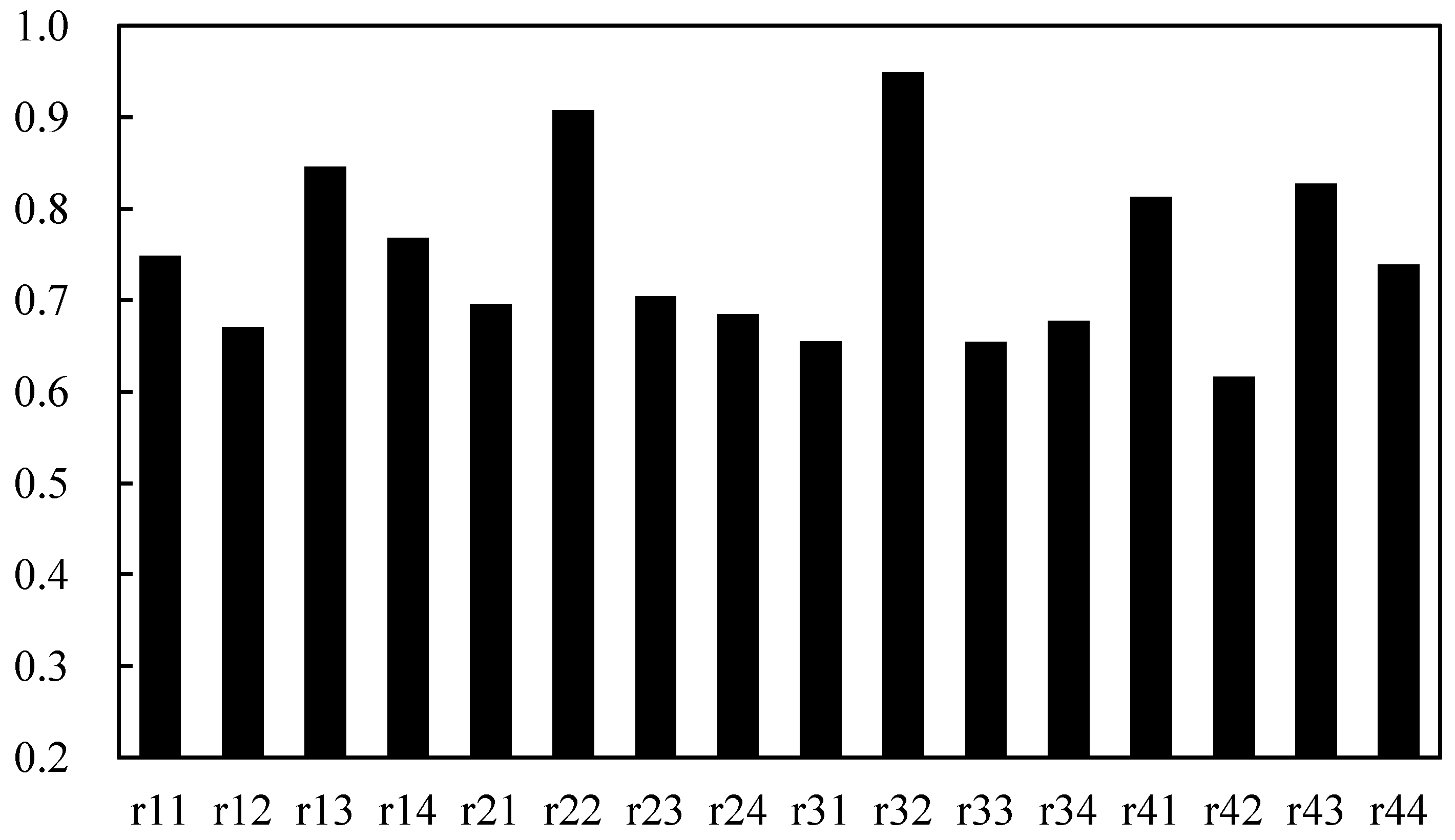

5.2. Identification and Calculation of Various Fault Factors

6. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Giovanni, B.; Fan, Q.X.; Peng, L. Introduction to the Special Issue “Super High Arch Dams and Underground Caverns in China”. Rock Mech. Rock Eng. 2018, 51, 2447–2450. [Google Scholar] [CrossRef]

- Jiang, H.C.; Peng, L.; Fan, Q.X.; Qiang, M.S. Real-Time Safety Risk Assessment Based on a Real-Time Location System for Hydropower Construction Sites. Sci. World J. 2014, 2014, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Fan, Q.X.; Zhang, C.R.; Chen, W.B.; Zhang, G.X.; Zhou, S.W.; Wang, Z.L.; Yang, Z.L.; Li, W.W.; Peng, H.; Chen, W.F.; et al. Key technologies of intelligent construction of Wudongde and Baihetan super high arch dams. J. Hydroelectr. Eng. 2019, 38, 22–35. [Google Scholar]

- Matallah, M.; Taibi, A.; Chimoto, T.T.; Maradzika, F.K. Mesoscale investigation of mass concrete temperature control systems and their consequences on concrete mechanical behaviour. Frat. Integrità Strutt. 2022, 16, 416–437. [Google Scholar] [CrossRef]

- Deligiannis, V.; Manesis, S. Concrete batching and mixing plants: A new modeling and control approach based on global automata. Autom. Constr. 2008, 17, 368–376. [Google Scholar] [CrossRef]

- Fan, Q.X.; Peng, L.; Wei, P.C.; Ning, Z.Y.; Li, G. Closed-loop control theory of intelligent construction. J. Tsinghua Univ. Sci. Tech. 2021, 61, 660–670. [Google Scholar] [CrossRef]

- Ghasri, M.; Maghrebi, M.; Rashidi, T.H.; Waller, S.T. Hazard-based model for concrete pouring duration using construction site and supply chain parameters. Autom. Constr. 2016, 71, 283–293. [Google Scholar] [CrossRef]

- Li, B.; Delpha, C.; Diallo, D.; Migan-Dubois, A. Application of Artificial Neural Networks to photovoltaic fault detection and diagnosis: A review. Renew. Sustain. Energy Rev. 2021, 138, 110512. [Google Scholar] [CrossRef]

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S.M.A. A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Livera, A.; Theristis, M.; Makrides, G.; Georghiou, G.E. Recent advances in failure diagnosis techniques based on performance data analysis for grid-connected photovoltaic systems. Renew. Energy 2019, 133, 126–143. [Google Scholar] [CrossRef]

- Harrou, F.; Dairi, A.; Taghezouit, B.; Sun, Y. An unsupervised monitoring procedure for detecting anomalies in photovoltaic systems using a one-class Support Vector Machine. Sol. Energy 2019, 179, 48–58. [Google Scholar] [CrossRef]

- Kumawat, A.; Panda, S. A robust edge detection algorithm based on feature-based image registration (FBIR) using improved canny with fuzzy logic (ICWFL). Vis. Comput. 2022, 38, 3681–3702. [Google Scholar] [CrossRef]

- Idrissi, A.E.; Derouich, A.; Mahfoud, S.; Ouanjli, N.E.; Chantoufi, A.; Al-Sumaiti, A.S.; Mossa, M.A. Bearing Fault Diagnosis for an Induction Motor Controlled by an Artificial Neural Network—Direct Torque Control Using the Hilbert Transform. Mathematics 2022, 10, 4258. [Google Scholar] [CrossRef]

- Demetgul, M. Fault diagnosis on production systems with support vector machine and decision trees algorithms. Int. J. Adv. Manuf. Technol. 2013, 67, 2183–2194. [Google Scholar] [CrossRef]

- Jamil, M.; Sharma, S.K.; Singh, R. Fault detectionn and classification in electrical power transmission system using artificial neural network. SpringerPlus 2015, 4, 334. [Google Scholar] [CrossRef] [PubMed]

- Heo, S.; Lee, J.H. Fault detection and classification using artificial neural networks. IFAC-PapersOnLine 2018, 51, 470–475. [Google Scholar] [CrossRef]

- Okwuosa, C.N.; Hur, J. A Filter-Based Feature-Engineering-Assisted SVC Fault Classification for SCIM at Minor-Load Conditions. Energies 2022, 15, 7597. [Google Scholar] [CrossRef]

- Gupta, M.; Wadhvani, R.; Rasool, A. A real-time adaptive model for bearing fault classification and remaining useful life estimation using deep neural network. Knowl. Based Syst. 2023, 259, 110070. [Google Scholar] [CrossRef]

- Casoli, P.; Pastori, M.; Scolari, F.; Rundo, M. A Vibration Signal-Based Method for Fault Identification and Classification in Hydraulic Axial Piston Pumps. Energies 2019, 12, 953. [Google Scholar] [CrossRef]

- Calabrese, F.; Regattieri, A.; Bortolini, M.; Galicia, F.G.; Visentini, L. Feature-Based Multi-Class Classification and Novelty Detection for Fault Diagnosis of Industrial Machinery. Appl. Sci. 2021, 11, 9580. [Google Scholar] [CrossRef]

- Youssef, A.; El-Telbany, M.; Zekry, A. The role of artificial intelligence in photo-voltaic systems design and control: A review. Renew. Sustain. Energy Rev. 2017, 78, 72–79. [Google Scholar] [CrossRef]

- Heinrich, M.; Meunier, S.; Samé, A.; Quéval, L.; Darga, A.; Oukhellou, L.; Multon, B. Detection of cleaning interventions on photovoltaic modules with machine learning. Appl. Energy 2020, 263, 114642. [Google Scholar] [CrossRef]

- Choi, J.; Edwards, P.; Ko, K.; Kim, Y. Definition and classification of fault damage zones: A review and a new methodological approach. Earth-Sci. Rev. 2016, 152, 70–87. [Google Scholar] [CrossRef]

- Chen, K.; Huang, C.; He, J. Fault detection, classification and location for transmission lines and distribution systems: A review on the methods. High Volt. 2016, 1, 25–33. [Google Scholar] [CrossRef]

- Bellanco, I.; Fuentes, E.; Vallès, M.; Salom, J. A review of the fault behavior of heat pumps and measurements, detection and diagnosis methods including virtual sensors. J. Build. Eng. 2021, 39, 102254. [Google Scholar] [CrossRef]

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Zhang, H.; Bai, Y. A smart diagnosis system based on automatic recognition of multiple rotor faults. Adv. Mech. Eng. 2017, 9, 755–764. [Google Scholar] [CrossRef]

- Cheng, J.T.; Li, A.; Duan, Z.M.; Yan, X. Fault Classification of Hydroelectric Generating Unit Based on Improved Evidence Theory. Open Fuels Energy Sci. J. 2014, 7, 78–83. [Google Scholar] [CrossRef]

- Cheng, J.T.; Lei, W.; Yan, X. An improved cuckoo search algorithm and its application in vibration fault diagnosis for a hydroelectric generating unit. Eng. Optim. 2018, 50, 1593–1608. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, L.; Xiong, Y. Cuckoo search algorithm with memory and the vibrant fault diagnosis for hydroelectric generating unit. Eng. Comput. 2019, 35, 687–702. [Google Scholar] [CrossRef]

- Zhou, H.W.; Zhou, Y.H.; Zhao, C.J. Fault-Response Mechanism of Production System in Concrete-Dam-Construction Simulation. J. Constr. Eng. Manag. 2016, 142, 04016065. [Google Scholar] [CrossRef]

- Liew, K.M.; Sojobi, A.O.; Zhang, L.W. Green concrete: Prospects and challenges. Constr. Build. Mater. 2017, 156, 1063–1095. [Google Scholar] [CrossRef]

- Majid, E.S.; Mohammad, H.; Jamie, E.P.; Gencturk, B. Probabilistic analysis of vertical concrete dry casks subjected to tip-over and aging effects. Nucl. Eng. Des. 2019, 343, 232–247. [Google Scholar] [CrossRef]

- Cazacliu, B.; Lê, N.D.; de Larrard, F. New methods for accurate water dosage in concrete central mix plants. Mater. Struct. 2008, 41, 1681–1696. [Google Scholar] [CrossRef]

- Sivilevičius, H.; Skrickij, V.; Skačkauskas, P. The Correlation between the Number of Asphalt Mixing Plants and the Production of Asphalt Mixtures in European Countries and the Baltic States. Appl. Sci. 2021, 11, 9375. [Google Scholar] [CrossRef]

- Sinenko, S.; Zhadanovskiy, B.; Pakhomova, L. Assessment of Complex Technological Processes of Concrete Mixes Preparation With on-Site Automated Concrete Mixing Plants, IOP conference series. Mater. Sci. Eng. 2018, 463, 32032. [Google Scholar] [CrossRef]

- Deng, J.L. The grey control system. J. Huanzhong Univ. Sci. Tech. 1982, 10, 9–18. [Google Scholar] [CrossRef]

- Deng, J.L. Control problems of grey systems. Syst. Control Lett. 1982, 1, 288–294. [Google Scholar] [CrossRef]

- Deng, J.L.; Zhou, C.S. Sufficient conditions for the stability of a class of interconnected dynamic systems. Syst. Control Lett. 1986, 7, 105–108. [Google Scholar] [CrossRef]

- Darong, H.; Jianping, T.; Ling, Z. A Fault Diagnosis Method of Power Systems Based on Grey System Theory. Math. Probl. Eng. 2015, 2015, 971257. [Google Scholar] [CrossRef]

- Ma, T.; Hu, Z.; Xu, Y.; Dong, H. Fault Location Based on Comprehensive Grey Correlation Degree Analysis for Flexible DC Distribution Network. Energies 2022, 15, 7820. [Google Scholar] [CrossRef]

- Shen, X.; Ren, Y.; Chai, L.; Wang, L.; Zhang, D.; Gao, F. Method of Evaluation for the Construction Geology of Transmission Line Based on Grey System Theory. IOP Conf. Ser. Earth Environ. Sci. 2019, 358, 42046. [Google Scholar] [CrossRef]

| Fault Category | Category Number | Fault Manifestation | Corresponding Number |

|---|---|---|---|

| Material handling system fault | A | Belt conveyor bearing damage | A1 |

| Pipe pump fault | A2 | ||

| Belt break | A3 | ||

| Roller wear through | A4 | ||

| Belt deviation | A5 | ||

| Belt conveyor crushed | A6 | ||

| Batch metering system fault | B | Load cell fault | B1 |

| Line fault | B2 | ||

| Power supply voltage fluctuation or poor grounding | B3 | ||

| Digital weighing instrument fault | B4 | ||

| Measuring bin door is stuck | B5 | ||

| Door solenoid valve fault | B6 | ||

| Pneumatic system fault | C | Gas source fault | C1 |

| Pneumatic execution of the original (cylinder) fault | C2 | ||

| Reversing valve fault | C3 | ||

| Pneumatic auxiliary original fault | C4 | ||

| Mechanical fault | C5 | ||

| Stirring system fault | D | The discharge door is stuck | D1 |

| Mixer inlet blocked | D2 | ||

| Gearbox mechanical fault | D3 | ||

| Mixer slag agglomeration | D4 | ||

| Mixer boring machine trip | D5 |

| Fault Category | Fault Manifestation | Statistical Sample Number S1 | Statistical Sample Number S2 | Statistical Sample Number S3 | |||

|---|---|---|---|---|---|---|---|

| Number of Faults | Proportion | Number of Cases | Proportion | Number of Cases | Proportion | ||

| A | A1 | 37 | 51.68% | 8 | 14.29% | 29 | 39.76% |

| A2 | 22 | 14 | 14 | ||||

| A3 | 6 | 11 | 11 | ||||

| A4 | 59 | 14 | 32 | ||||

| A5 | 18 | 9 | 8 | ||||

| A6 | 12 | 10 | 7 | ||||

| B | B1 | 9 | 8.05% | 19 | 26.13% | 11 | 18.11% |

| B2 | 5 | 16 | 8 | ||||

| B3 | 3 | 11 | 7 | ||||

| B4 | 1 | 3 | 6 | ||||

| B5 | 6 | 19 | 5 | ||||

| B6 | 4 | 7 | 9 | ||||

| C | C1 | 16 | 16.78% | 14 | 38.68% | 5 | 31.50% |

| C2 | 8 | 40 | 31 | ||||

| C3 | 14 | 31 | 23 | ||||

| C4 | 9 | 25 | 19 | ||||

| C5 | 3 | 6 | 2 | ||||

| D | D1 | 15 | 22.15% | 7 | 20.91% | 5 | 10.63% |

| D2 | 11 | 5 | 1 | ||||

| D3 | 17 | 4 | 3 | ||||

| D4 | 14 | 11 | 13 | ||||

| D5 | 9 | 3 | 5 | ||||

| Sum | 298 | - | 287 | - | 254 | - | |

| Faults | Number of Faults of Corresponding Types of Faults | Number of Faults Caused by Various Influencing Factors | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity | A | B | C | D | P | E | M | O | |

| S1 | 154 | 28 | 50 | 66 | 104 | 30 | 98 | 66 | |

| S2 | 66 | 75 | 116 | 30 | 97 | 57 | 75 | 58 | |

| S3 | 101 | 46 | 80 | 27 | 67 | 45 | 69 | 73 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Mi, T.; Zhao, C.; Liang, Z.; Fang, T.; Wang, F.; Zhou, Y. Identification Model of Fault-Influencing Factors for Dam Concrete Production System Based on Grey Correlation Analysis. Appl. Sci. 2024, 14, 4745. https://doi.org/10.3390/app14114745

Zhou H, Mi T, Zhao C, Liang Z, Fang T, Wang F, Zhou Y. Identification Model of Fault-Influencing Factors for Dam Concrete Production System Based on Grey Correlation Analysis. Applied Sciences. 2024; 14(11):4745. https://doi.org/10.3390/app14114745

Chicago/Turabian StyleZhou, Huawei, Tonghao Mi, Chunju Zhao, Zhipeng Liang, Tao Fang, Fang Wang, and Yihong Zhou. 2024. "Identification Model of Fault-Influencing Factors for Dam Concrete Production System Based on Grey Correlation Analysis" Applied Sciences 14, no. 11: 4745. https://doi.org/10.3390/app14114745

APA StyleZhou, H., Mi, T., Zhao, C., Liang, Z., Fang, T., Wang, F., & Zhou, Y. (2024). Identification Model of Fault-Influencing Factors for Dam Concrete Production System Based on Grey Correlation Analysis. Applied Sciences, 14(11), 4745. https://doi.org/10.3390/app14114745