Abstract

The application of blockchain technology in industrial product quality traceability is analyzed to construct a new model of product quality traceability that is mainly based on blockchain technology and supplemented by an identity system. The blockchain-enabled overall technical architecture of an industrial product quality traceability system is explored, and a blockchain-based industrial product full life cycle information traceability system is constructed. First, the weights of the information indicators of different links of the industrial equipment information traceability system were calculated using the EAHP hierarchical analysis method. The manufacturing link had the largest weight, with a value of 18.8%. Second, the system’s functional module design is based on the weights. We designed and developed the industrial product information traceability platform based on the hybrid blockchain chain structure of private chain + alliance chain. Finally, a manufacturing enterprise in the Xinjiang region is taken as the research object, query validation is carried out for the products produced by the enterprise, and the average query time of the system is measured to be 65.376 ms. It can meet the traceability needs of consumers and enterprise users. The research can provide theoretical support and reference for the whole life cycle information traceability of industrial products.

1. Introduction

The whole life cycle management of industrial products involves a long industrial chain [1] and a complex process [2]. Enterprises and related departments are relatively weak in product quality control, which leads to difficulties in tracing the quality of industrial products flowing to the market [3]. In addition, integrity issues with tampering and counterfeit products, faced by all industries, have seriously constrained the improvement of industrial product quality. Trillions of dollars of counterfeit products circulate on the global trade market today, and as early as 2015, the economic share of the counterfeit market accounted for 2% of the world’s GDP [4]. For example, industrial opacity in product safety leads to food safety problems. At present, reliability is difficult to ensure in electronic depository data, the original information is difficult to identify, and there are non-negligible security risks. For distributors, the ability to identify industrial products with quality issues can help curb their distribution and avoid unnecessary downtime due to product quality issues; for manufacturing enterprises, if they can identify products with hidden quality problems early and carry out culling and standardized management, it will help eliminate the flow of substandard products to the market from the root cause. Due to the hidden nature of the information in the whole process of industrial production, there is no effective means to control the information in the whole process. Therefore, there is an urgent need to realize the whole life cycle of the trusted traceability of industrial products to ensure product quality conformity.

Industrial internet identity resolution technology includes a kind of identity card for everything as its basis, with the interconnection interface as the link, similar to the domain name resolution system (DNS) in the field of the internet [5], realizing global addressing using these identities and then realizing the interconnection of human beings, machines, and things by binding the relevant information with the identity codes. At present, the research and application of product quality traceability at home and abroad mainly focus on the fields of agricultural products, food, and pharmaceuticals [6,7,8]; with the promotion and application of industrial internet identity resolution technology, the quality traceability of products has been successfully applied to many industries, including motorsports, building materials, automobiles, medical devices, hardware, etc. It has been comprehensively integrated into the research and development, purchasing, production, warehousing, logistics, sales, and other aspects of industrial enterprises. But whether it is industrial sectors or other industries facing the same problem of information silos, product quality traceability is difficult.

Blockchain [9] is a new application model for computer technology such as distributed data storage, peer-to-peer transmission, consensus mechanisms, encryption algorithms, etc. Its use of peer-to-peer networks, consensus algorithms, hash encryption, etc., makes it decentralized, information-transparent, tamper-proof, traceable, etc., and no institution can have absolute control over it. Numerous scholars have carried out detailed studies on the above issues with the help of blockchain technology. Cao et al. [10] developed an IoT quality traceability system for steel using the alliance chain model and the Hyperledger blockchain platform. Qing et al. [11] proposed a product tracking scheme based on permissioned blockchain in a two-tier framework. An et al. [12] proposed a semi-centralized traceability architecture based on IoT technology. Hader et al. [13] proposed an approach to a shared traceability system using blockchain technology and big data, which not only provides information on the status of textile products to all supply chain members but also greatly reduces the risks associated with centralized information systems. Gomasta et al. [14] proposed a system based on a Hyperledger structure which improves the effectiveness of traceability throughout the pharmaceutical supply chain by simultaneously storing transaction information both on and off the chain to achieve secure and fast transactions. Gebreab et al. [15] proposed a solution based on non-homogenized tokens (NFTs) for a reliable and efficient medical device traceability system through a decentralized storage system. Zhang et al. [16] proposed a blockchain-based reverse supply chain recycling strategy for power batteries to establish a blockchain power battery recycling platform, which improves the utilization rate of used power batteries and the transparency of the battery recycling industry chain. With the rapid increase in the variety of spare parts, the complexity of the supply chain of aircraft components leads to inefficiencies in traceability; for this reason, Ho et al. [17] proposed a blockchain-based system that improves the quality of traceability data and enables secure and adequate information sharing. Yang et al. [18] utilized blockchain technology to achieve steel transaction data transparency, and experimental comparisons show that the improved PBFT algorithm has some improvement in fault tolerance, throughput, and execution efficiency. Sreenu et al. [19] proposed a vaccine supply chain based on blockchain and the Internet of Things (IoT), and the proposed system enables resilience, tracking, and tracing of vaccine distribution. Visconti et al. [20] developed a traceability and on-farm management system based on IoT technology which effectively calibrates irrigation and fertilization operations. Vukatana et al. [21] developed an agile and automated traceability system based on the ISO food standard. Appelhanz et al. [22] proposed a traceability information system for obtaining, processing, and providing information about wood furniture products, which can increase consumer trust and willingness to purchase environmentally friendly products. Arvana et al. [23] proposed an agri-food traceability system based on a multi-chain architecture that ensures the invariance, reliability, and transparency of data along the value chain. Liu et al. [24] proposed a blockchain-based method for storing agricultural monitoring data, which can ensure the privacy and security of monitoring data. Tao et al. [25] proposed a blockchain-based food traceability system that can improve consumers’ willingness to purchase agricultural products. However, research on incorporating blockchain technology to securely protect the data in the interaction process for information and identity resolution for each link in the whole life cycle of industrial products and then realizing information management for the whole life cycle of industrial products has not been reported so far, which is a kind of research idea worth exploring for the credible traceability of the quality of the whole life cycle of industrial products.

To sum up, identity resolution plays a pivotal role in the quality management of the whole life cycle of industrial products, bridging the information barriers between different industries or enterprises and promoting the integration of information. It is also an indispensable step in realizing the intelligent manufacturing of industrial products. It is urgently needed to improve the safety and security capabilities of information storage and data resolution. With the help of blockchain technology, we can make up for the lack of an information storage and resolution process security capability in industrial product identity resolution systems so as to truly realize “horizontal to the edge, vertical to the end” in the whole life cycle information management of industrial products. Therefore, this paper attempts to reconstruct an industrial product quality traceability system with the help of blockchain technology, aiming to standardize the functions of secure storage, collaborative sharing, and the traceability of the data for critical information in the whole life cycle of product design, manufacturing, logistics, warehousing, use, and operation and maintenance, with a view to strengthening the application of the quality traceability system to the market circulation of industrial products and assisting the supervisory authorities in making intelligent decisions. The main contributions of this paper are summarized as follows: (1) Based on blockchain and industrial internet identity resolution technology, the overall technical architecture of a blockchain-enabled industrial product quality traceability system is designed, which eliminates the information barriers between different departments and enterprises for products at all stages of the whole life cycle through research on industrial product identity code design and data storage technology; (2) From the perspective of the full life cycle management of industrial products, industrial product information traceability is divided into pre-preparation monitoring, mid-term production practice, and post-life cycle management along the supply chain to track and store link information, which ensures the credibility and completeness of the link information; (3) Adopting the hybrid blockchain structure of “alliance chain + private chain” solves the shortcomings of the traditional alliance chain mode, such as heavy node storage, low throughput, high cost, etc., ensures the security and privacy of data, reduces the pressure of the overall data processing and storage, improves the efficiency and performance of the system, and provides a suitable opportunity for the dynamic supervision of industrial product supply chain information; (4) Using the Postman (version 8.0.6) system performance testing software, the whole life cycle information traceability system for industrial products proposed in this paper is verified, which can realize rapid tracing of problematic products and rapid positioning of responsible subjects.

The rest of the article is structured as follows. Section 2 describes the design of the system, including industrial product quality traceability process analysis, system architecture design, and application module weight design. Section 3 introduces key blockchain technologies. Section 4 describes the implementation of the blockchain-based full life cycle information traceability system for industrial products. Section 5 validates the system built in this paper by writing data and querying data through the testing tool Postman (Version 8.0.6).

2. System Design

The system is built using Spring Boot + Vue + HTML, which mainly includes system process analysis, system architecture design, and application module weighting design, as described below.

2.1. Industrial Product Quality Traceability Process Analysis

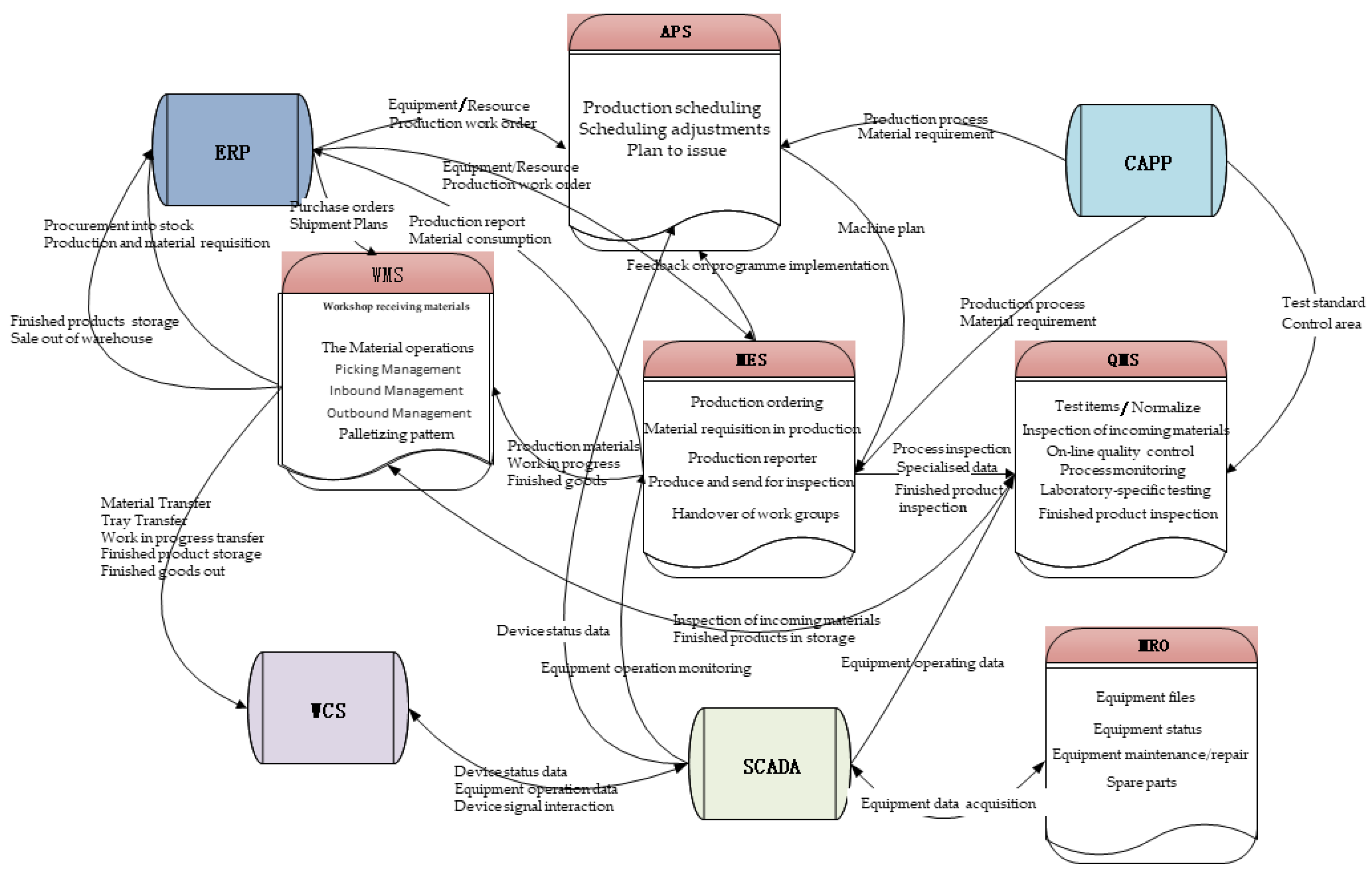

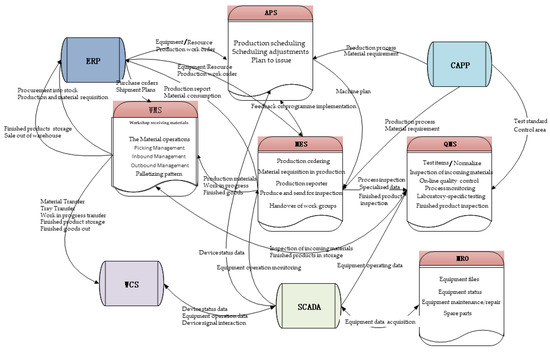

In industrial product market circulation, substandard products are becoming increasingly prominent, so it is imperative to build an accurate, fast, convenient, and safe industrial product quality traceability system. Based on the whole life cycle management process for industrial products and the participating subjects, quality traceability includes multiple links, such as warehousing, sales, the logistics of supplier enterprises, and the processes of planning, purchasing, stockpiling, installation, use, and maintenance on the part of demand enterprises, as well as resource recycling and the reuse of third-party platforms, which cover various stages of product design, development, production, delivery, use, maintenance, and decommissioning. Among them, the manufacturing stage, as the source of industrial product supply chain management, aims to ensure that the product matches market demand and meets the expected goals regarding quality and user experience, which is the focus of this quality traceability study. Figure 1 shows the interaction of the information flow in the manufacturing stage for industrial products. It mainly contains an ERP subsystem, a WMS subsystem, an APS subsystem, a WCS subsystem, a CAPP subsystem, an MES subsystem, a QMS subsystem, an MRO subsystem, and a SCADA subsystem. The subsystems are connected to interact with each other in a directed line segment using IoT and advanced sensing technologies.

Figure 1.

Schematic diagram of industrial product information flow system interaction at the manufacturing stage.

2.2. System Architecture Design

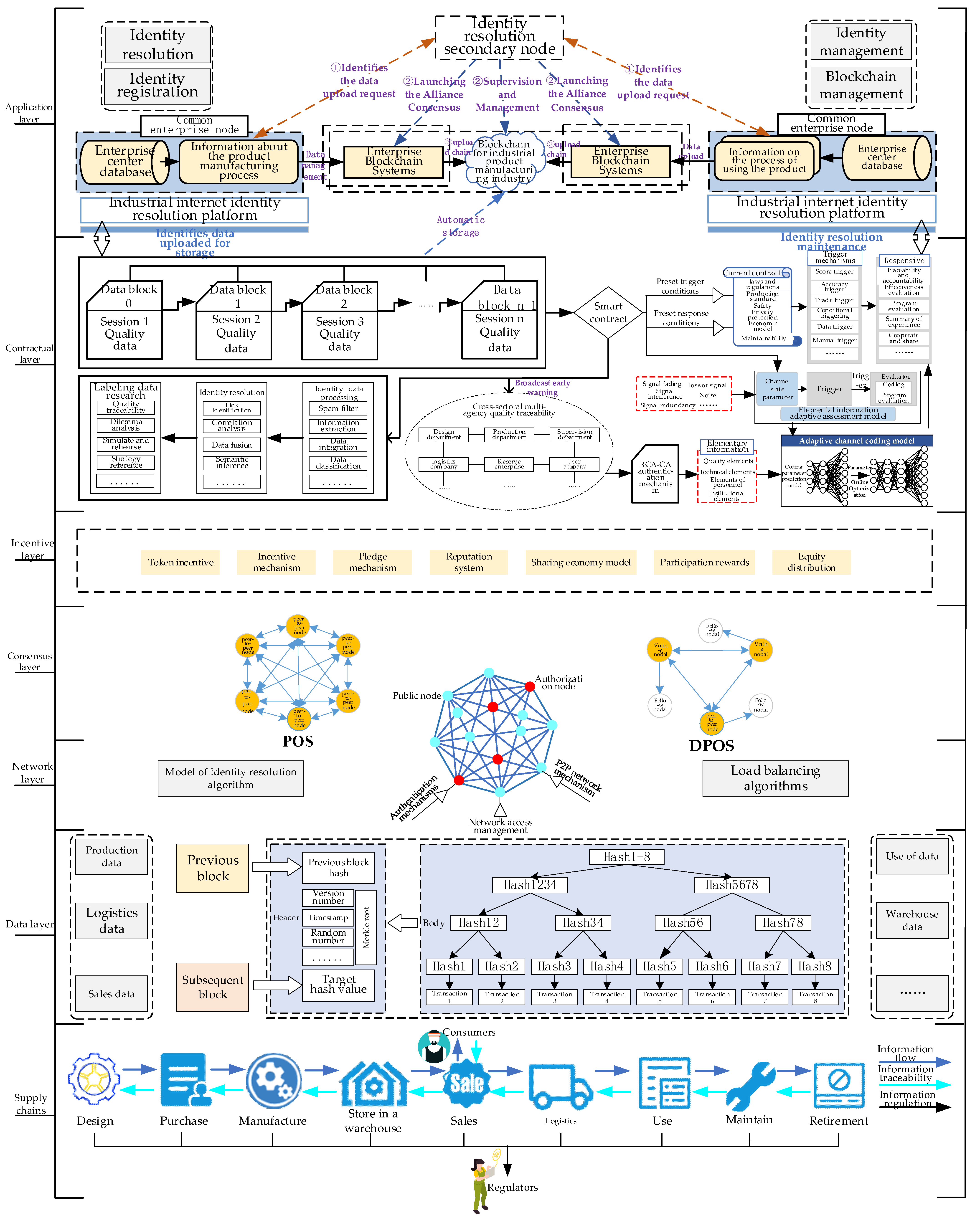

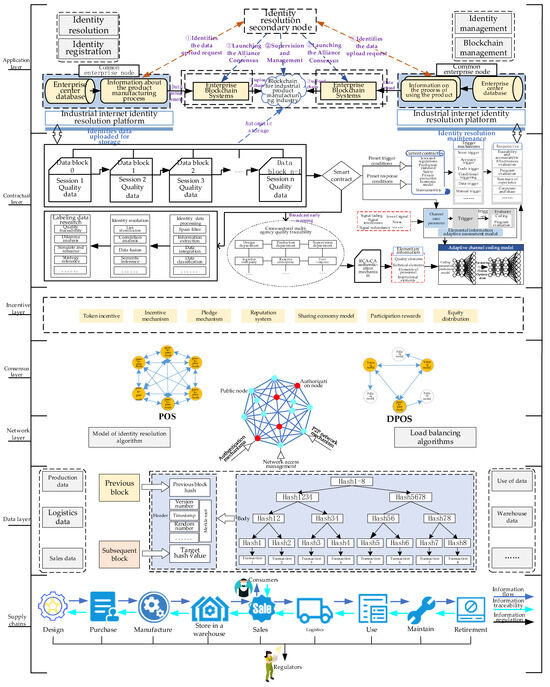

The overall technical architecture of the industrial product quality traceability system is mainly composed of the following parts: the supply chain, data layer, network layer, consensus layer, incentive layer, contract layer, and application layer, as shown in Figure 2. The supply chain layer includes the information system and related data for each link in the preparatory monitoring stage of design and procurement; manufacturing and warehousing in the production practice stage; and sales, logistics, use, maintenance, and decommissioning in the life cycle management stage. The data generated by it are the core data source in this traceability study, which contain important information about the products at different stages and are crucial for tracing the origin, production, flow, and quality of the products. They are crucial for tracing the source, production, flow, and quality of products. A hash encryption algorithm, timestamps, random numbers, and a transfer mechanism between blocks are used to store the above data in a block data structure in the data layer of the blockchain. The network layer provides the infrastructure for the system to communicate, supports information exchange and data transmission between nodes, and enables effective storage of blockchain data in the nodes through identity and privilege authentication, node management, and discovery, combined with the P2P network protocol. The consensus layer is the crucial part to ensure that all the nodes in the network reach a consensus on the consistency of the data; the practical Byzantine fault tolerance (PBFT) algorithm [26] is used for data resource management, which is not based on proof of interest but a consensus algorithm used in distributed systems that focuses on reaching consistency among nodes that ensures that the consistency of the system can be maintained even if there are node failures or malicious behavior. Its consensus process includes several stages: pre-prepare, prepare, commit, etc. The nodes reach a consensus through mutual communication and message passing. In this process, the concepts of entitlement and resources are not involved, but rather, the consistency and reliability of data are ensured through mutual authentication, message validation, and mutual communication between nodes. The incentive layer is a critical component of the blockchain system. It is used to incentivize participants in the network to perform specific behaviors or provide specific services in order to ensure that they actively participate and maintain the rules of the system. In blockchain, the incentive layer can be used to include token incentives, reward mechanisms, pledge mechanisms, reputation systems, participation rewards, etc. Effective incentives can encourage participants to faithfully and actively participate in the system and ensure its security, reliability, and continuous development.

Figure 2.

The overall technical architecture of blockchain-enabled industrial product quality traceability system.

The application layer is the top layer of the blockchain system, providing the interface and functionality for users to interact with the system. In order to realize the function of identification and resolution of industrial product quality traceability systems, as well as the collection and transmission of identification data, it is necessary to establish a metadata template for their identification data. In addition, the identification data can be stored in a distributed manner in the blockchain by adopting the above consensus algorithm, which guarantees their non-comparability and traceability, thus ensuring the trustworthiness and accuracy of the data. In the data storage stage, by associating the acquired data on industrial products at all stages of their full life cycle with corresponding identifiers, data addition and block generation operations within the blockchain are realized by recording the data in the blocks of the blockchain network. The process of storing the identification data begins with the user constructing them into transactions and sending them to the blockchain network. These transactions are verified and packaged into blocks. Before the data are subjected to blockchain storage, all participating nodes in the blockchain are confirmed by the nodes in the network using a consensus mechanism before deciding whether or not to commit the identifying data in the form of a transaction and publish it to the blockchain through the creation of an excellent smart contract to be broadcasted to each node in the network in a tamper-proof manner. At the same time, the identity resolution secondary node also returns the hash value of this transaction, which allows the system to quickly look up specific blocks and transactions without having to traverse the entire blockchain through the generated hash pointer, giving the blockchain the ability to locate and access the transaction quickly. It can also be used as a voucher for this transaction. In the identity data acquisition phase, the node first verifies whether the received request is legitimate and valid, verifies the signature of the request to confirm that the request comes from a legitimate user and the node, then locates the block where the identity data are located using the hash pointer generated in the storage phase, resolves the transaction data, reads the relevant information fields, and sends these data back to the requesting party to complete the identity resolution operation for the industrial product.

2.3. Application Module Weighting Design

2.3.1. Assessment of Weighting Indicators for Traceability Links

Legitimate users and nodes locate the block where the identity data are located using the hash pointer generated in the storage phase and then parse the transaction data, read the relevant information fields, and feed these data back to the requesting party, thus completing identity resolution for the industrial product. In the traditional analytic hierarchy process (AHP), there are defects in the evaluation of the above traceability links by the relevant personnel due to its subjectivity [27]. The extension analytic hierarchy process (EAHP) was applied to realize the analysis of each functional indicator of the quality traceability of industrial products throughout their life cycle [28]. This study takes a manufacturing enterprise in the Xinjiang region as the research object, selects 15 product quality management personnel, adopts a 1~9-point Satty scale method for rating, and obtains judgment matrix A: , , , and , , where matrix A is a extension interval number matrix, and we compute the maximum eigenvalue of matrix A as follows.

where . According to the weights of the first-level indicators, it can be seen that the importance levels of the quality traceability aspects for industrial products throughout their life cycle are T3 manufacturing, T1 design, T5 sales, T6 logistics, T7 use, T8 maintenance, T2 purchasing, T4 warehousing, and T9 decommissioning. From Table 1, it can be seen that quality managers prioritize the manufacturing and design aspects of the traceability system. The T1 design standard layer, the T2 procurement standard layer, the T3 manufacturing standard layer, the T4 warehousing standard layer, the T5 sales standard layer, the T6 logistics standard layer, the T7 use standard layer, the T8 maintenance standard layer, and the T9 decommissioning standard layer evaluation index weights are calculated sequentially, and the results of the calculation can be used as a reference for the system design and function development. In the EAHP, and are the metrics used to assess the consistency of the extension interval number judgment matrix. According to the consistency test index 0 ≤ k ≤ 1 ≤ m, this extension interval number judgment matrix satisfies the consistency test, and the resulting weights have consistency.

Table 1.

Expandable intervals of the importance of each attribute of the criterion layer to the target layer and comprehensive evaluation results.

2.3.2. Analysis of the Elements of the Industrial Product Quality Traceability System

Based on the different industrial product stage attributes and focused elemental data, in order to facilitate flexible mediation of the management and control focuses, objectives, and implementation strategies, combined with the results of the EAHP hierarchical analysis method in Section 2.3.1, the entire life cycle of the product is divided into the early stage, preparatory monitoring, the middle stage, production practice, and the late stage, life cycle management, starting from the viewpoint of its entire life cycle management. Life cycle management has three stages. Its quality traceability focuses on the whole process management for products, from design and manufacture to use, maintenance, and decommissioning, which mainly involves quality elements, technical elements, personnel elements, and institutional elements. The quality element encompasses the management of raw materials and the supply chain, ensuring raw material quality and supplier reliability, and the whole process of preparatory monitoring, production practice, and life cycle management, including production process control, quality inspection, and testing, information record system construction, risk management, and problem-solving mechanism. It involves equipment maintenance, staff training, decision-making traceability, supply traceability, production process and early warning traceability, reserve traceability, and packaging traceability. The information on these elements is interwoven to form a comprehensive system that helps ensure industrial product quality, efficiency, and customer satisfaction. By combining the supply process for the whole life cycle of industrial products and the characteristics of the participating subjects, the quality elements are categorized into industrial product decision-making traceability, supply traceability, production process and early warning traceability, stockpiling traceability, packaging traceability, transportation traceability, use traceability, operation and maintenance traceability, and end-of-life traceability (see Table 2).

Table 2.

Elements of industrial product quality traceability system.

3. Key Technologies

3.1. Supply Chain Traceability Block Structure

Each block in a blockchain consists of two main parts: the Block Header and the block body. The Block Header is the block’s metadata, which contain a summary of information about the block itself, mainly consisting of the previous block hash, timestamp, difficulty Target, and so on, which are used to link the previous block. The block body contains specific data information about the production, transportation, and certification of industrial products verified during the creation of the block, as well as all the traceability records that exist. Traceability records involve raw material sources and quality inspection information, production process monitoring and quality control records, product batches, certification and compliance information, and quality problem handling records. Traceability records are generated according to identity resolution of the unique code and the relevant traceability content information; the traceability content records product certification, inspection, compliance with regulations, and standards information. The use of a Merkle tree to store the above encoding into the root hash of the blockchain can effectively verify the integrity and authenticity of the data. If batch product quality problems can be quickly located in the entire life cycle data, we avoid enterprise nodes in the industrial product supply chain blaming each other due to the quality problems caused by product recall being unsolvable from the root cause and avoid reoccurrence.

Based on the chaining characteristics of the whole-life quality traceability process for industrial products, each block represents the traceability data over a given time, and the blocks are linked to each other by the address of the Block Header. The Block Header of each block contains the compressed information of the traceability record of the previous block, and each block is arranged in chronological order, forming an ever-extending traceability blockchain. Each subject is given a public and private key as part of the registration.

3.2. Traceability of Subject Identification

Combined with the functions, responsibilities, and authorities assumed by each traceability subject on the blockchain, the supply chain will be divided into the quality traceability management party, the node administrator; the quality traceability service party, the supplier; quality traceability owner parties, enterprise users; and the quality traceability demand side, consumers. A blockchain-based industrial product quality traceability system needs to authenticate the identity of each traceability subject, requiring each traceability subject in the industrial product supply chain to be registered in the blockchain, including two parts, the logo information and enterprise information, which involve the profile of the logo prefix, registration time, registration service organization, registration status, the Chinese name of the enterprise, its official website, the industry to which it belongs, its Chinese address, and other information. Upon successful registration, each participating subject will have a unique profile containing detailed information about the enterprise, such as its name, social unified credit code, address, and legal representative. The public key will be publicly stored on the blockchain and disclosed to all members of the blockchain so other participants can verify the enterprise’s identity, while the private key will be the key for performing transactions and authentication. The above asymmetric encryption algorithm protects the subject’s identity information and ensures that the data are not tampered with during transmission and storage. The system requires any data entry to be verified according to the consensus of the nodes across the network before it can be recorded in the blockchain. The key is to solve the distributed consistency problem to ensure the consistency of information across the nodes in the network.

3.3. Industrial Product Safety Consensus Mechanism

Production and operation units, as quality traceability service providers, can establish nodes and join the network to participate in the management of traceability information after obtaining the approval of the industrial product market supervision and management departments. Once joined, the node is involved in maintaining the ledger of the entire supply chain, and the system requires that any data entry needs to be verified according to the consensus of the nodes in the whole network before it can be recorded, and the key is to solve the distributed consistency problem to ensure the consistency of the information of the nodes in the network. Aiming at the upstream and downstream business relationships in the market circulation of industrial products, the practical Byzantine fault-tolerant consensus algorithm describe in Section 2.2 is chosen, which can effectively deal with abnormal situations that may occur in the distributed network and ensure the consistency and reliability of the data.

4. System Realization

Through research and field visits to Xinjiang Petroleum Machinery and Equipment Manufacturing Company, it was found that the enterprise had not established a sound mechanism for tracing information on the whole life cycle of its industrial products. The degree of application is at the electronic stage, with intelligent scheduling, quality process monitoring, and total life cycle management of equipment missing; difficulty in the manipulation and verification of the credibility of data; and a lack of harmonization of standards. The main focus is on industrial engineering improvement, and there is a lack of means to trace the whole process of information on industrial products. This often leads to a lack of assurance about the quality of the industrial products that reach the market. Downtime problems due to industrial product quality are commonplace. The damage they cause is also irreparable. The information traceability system is built using an industrial product quality traceability model of blockchain and identification analysis technology. It provides a reliable method for solving the above problems.

4.1. Traceability System Architecture Design

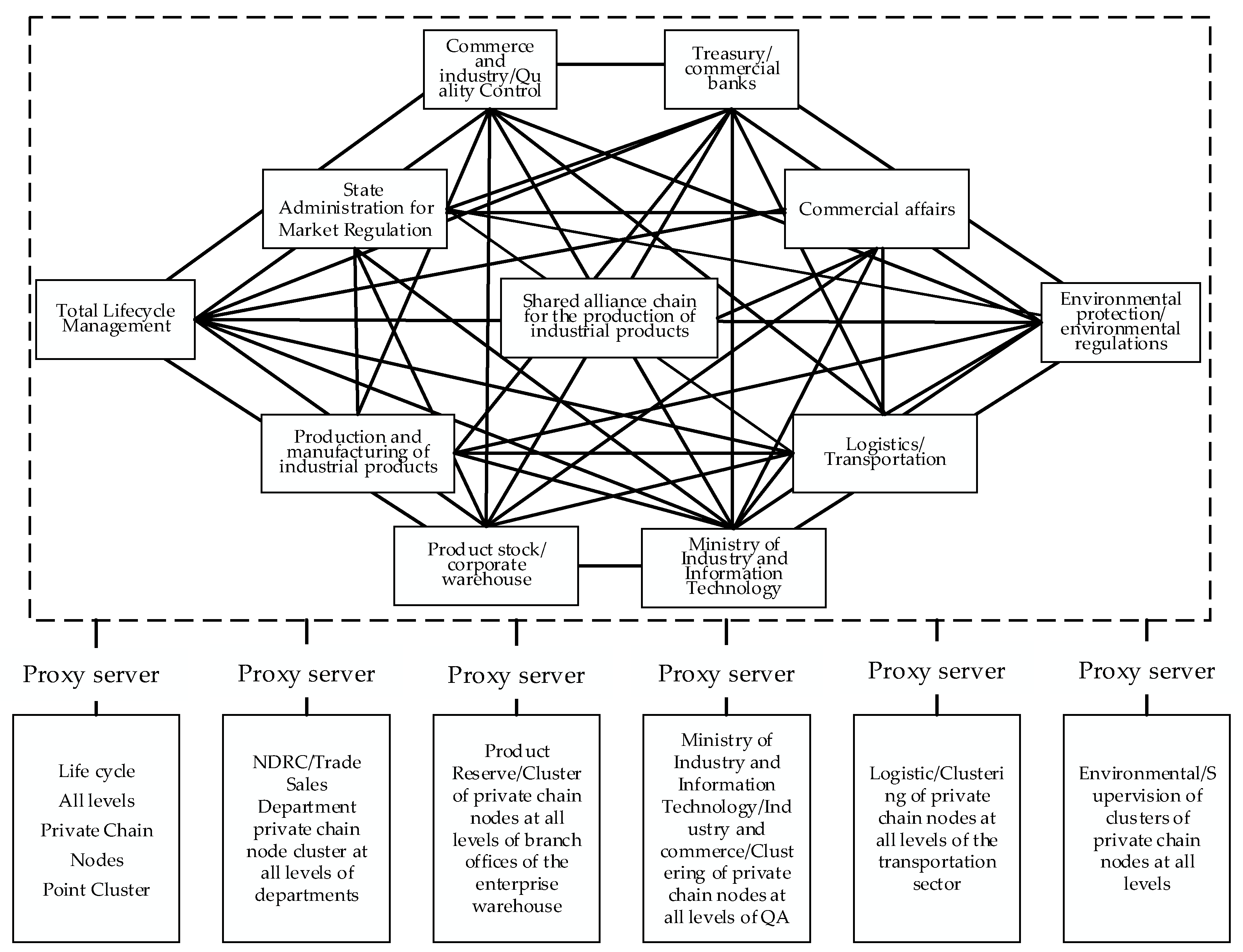

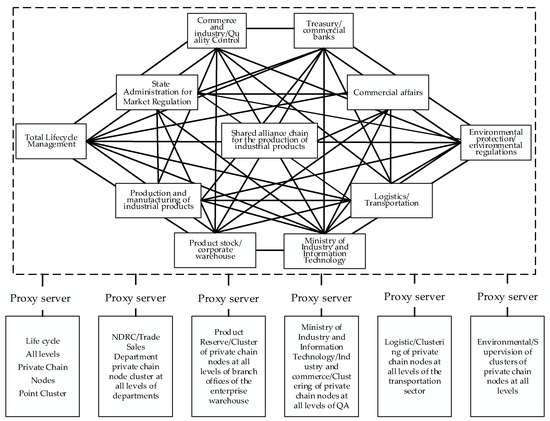

Considering the many suppliers in industrial product manufacturing; the variety of parts and components; the massive heterogeneity of the production management data; the demand for information sharing in industrial product manufacturing; the cost and scalability of handling and the inability to handle highly concurrent large-scale data; and the throughput constraints of blockchain technology, this study tries to adopt the “alliance chain + private chain” model based on the technical architecture in Section 2.2 to build a hybrid blockchain for a industrial product quality traceability system, as shown in Figure 3.

Figure 3.

Industrial product quality traceability blockchain platform architecture.

Hybrid blockchain is a blockchain technology architecture that combines the characteristics of an alliance chain [29] and a private chain [30], which is adapted from the alliance chain by replacing the participating nodes with a combination of “nodes + private chain”. Compared to the traditional alliance chain model, the hybrid blockchain stores the data by transmitting valuable information in the data that needs to be shared with the corresponding alliance chain node of the private chain. The hybrid blockchain architecture retains the advantages of alliance chains, such as permission control and high-performance consensus mechanisms. At the same time, introducing a private chain solves the defects of the traditional alliance chain mode, such as excessive node storage, low throughput, and high cost. Sharing data flexibly between alliance chain nodes and private chains ensures data security and privacy, reduces the pressure of overall data processing and storage, and improves system efficiency and performance.

The system architecture of this industrial product quality traceability system consists of an alliance chain and multiple private chains, in which the alliance chain consists of the whole life cycle supervision, the General Administration of Market Supervision, the production and manufacturing of industrial products, industry and commerce, quality inspection, product stockpiling, finance, the Ministry of Industry and Informatization, logistics, environmental protection, and other departments as nodes. According to the “Supervision and Management Provisions on the Implementation of Quality and Safety Responsibility of Industrial Product Manufacturing Units” and “Supervision and Management Provisions on the Implementation of Quality and Safety Responsibility of Industrial Product Sales Units” issued by the General Administration of Market Supervision and Regulation, and in combination with the market circulation norms for industrial products, we will arrange and deploy the nodes of the alliance chain mentioned above according to their functions and classify them into four subsystems, which are the production and manufacturing subsystem; the sales, circulation, transportation, and logistics subsystem, the product reserve subsystems; and the regulatory subsystems, respectively, to build a private chain of the four subsystems. Based on the data interactions and storage requirements for the quality information on the whole life cycle of industrial products, the hybrid blockchain adopts the Interplanetary file system (IPFS) network. Constructed based on BitTorrent protocol and Kademlia Distributed Hash Table (DHT) technology, it ensures that the peer nodes in the network structure can conveniently relocate objects and manage metadata, and each private chain interacts with alliance chains through a proxy server for data interaction and information sharing. Product design/decision-making, raw material procurement/supply, product manufacturing/production processes and early warnings, product warehousing/stockpiling, sales/packaging, logistics/transportation, use/condition monitoring, maintenance/inspection and repair, decommissioning/recycling and remanufacturing, and other quality information generated in the process of quality traceability for the whole life cycle of industrial products are uploaded to the private chains and their corresponding sub-systems for storing and sharing. Each private chain has at least one management node in the alliance chain, through which the private chain and the alliance chain realize information sharing and interaction. The industrial product quality traceability system is vertically coordinated at the national–provincial–municipal–county levels. It contains government departments such as the Ministry of Industry and Information Technology, the General Administration of Market Supervision, the Ministry of Commerce, the Industry and Commerce Bureau, the Ministry of Transportation, and other government departments and supply chain segments, such as manufacturing enterprises, stockpiling enterprises, transportation enterprises, etc. The blockchain-based industrial product quality traceability system compensates for the top-down pyramid storage model of the traditional quality traceability system and is combined with industrial internet identity resolution technology; it provides an opportunity to solve the problem of information islands during the whole life cycle management of industrial products and the circulation of elements and to realize data interoperability, credible identity resolution, and massive information mining.

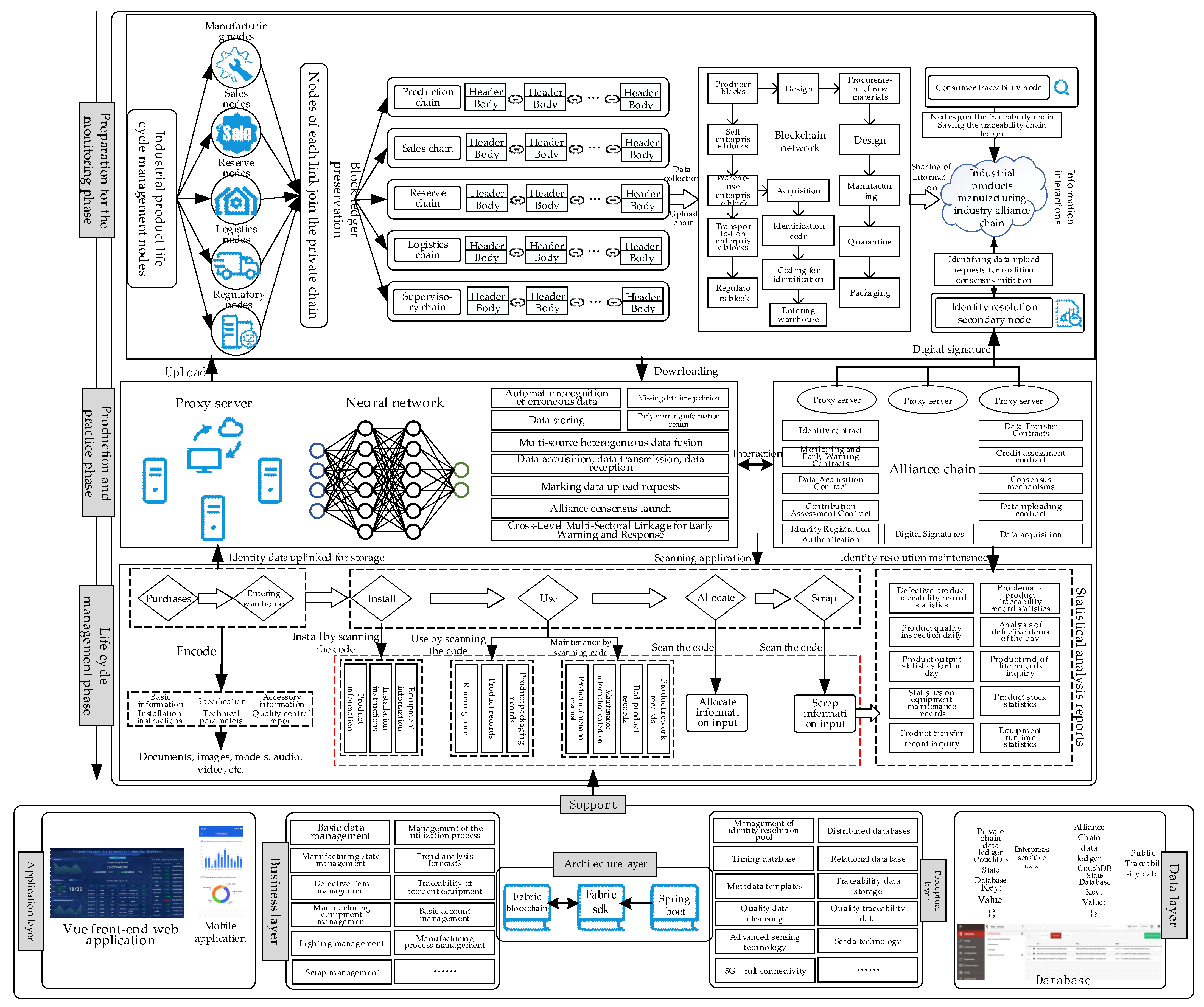

4.2. Functional Designs

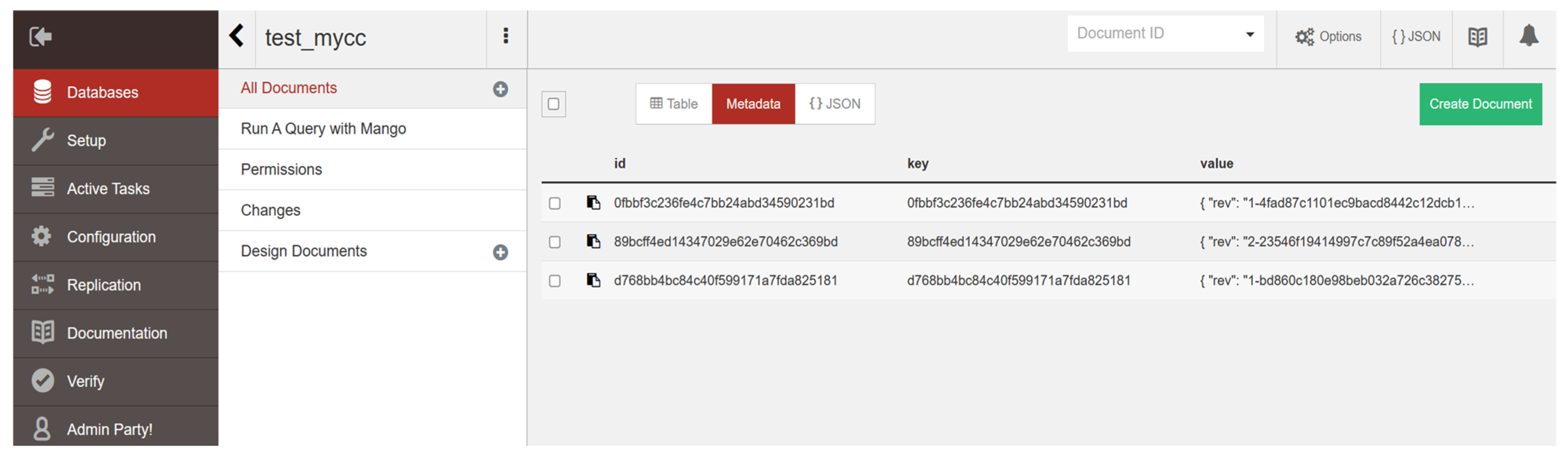

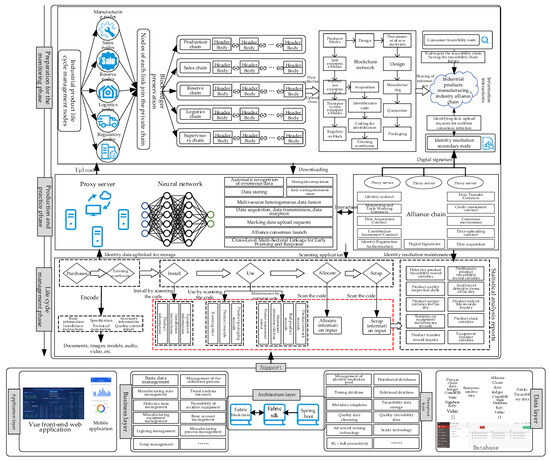

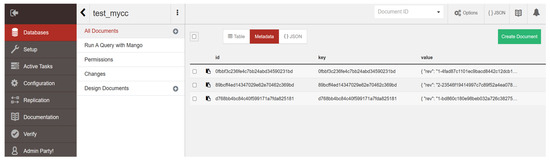

This part explains the blockchain-based industrial product quality traceability process according to three stages, preparatory monitoring, production practice, and life cycle management, as shown in Figure 4. test_mycc is the database for this system, as shown in Figure 5. The fabric uses CouchDB, a blockchain state-of-the-world database, and stores the state of the world and history in JSON format. Based on the alliance chain, to secure the storage of the traceability data, the generation of each new block needs to be voted for by the nodes of all the alliance chains, combined with the DDBFT consensus algorithm to guarantee the reliability and security of the traceability data.

Figure 4.

Operation process of industrial product quality traceability system based on blockchain.

Figure 5.

Example of test_mycc database.

4.3. User Interface Design and Development

The blockchain-based industrial product quality traceability system includes web services and front-end pages and is built based on the Hyperledger Fabric technology architecture. With the web front-end developed using Vue and Node.js technology, users can use permissions to fill out data in the front-end, including consumer feedback, anti-counterfeiting information, logistics information, etc., with the server processing them to return them to the JSON data format to store their history. The web page is written using Vue.js + HTML + CSS, combining the requirements of industrial product life cycle management with the design of functional classification names and the coding of the user interface and providing a user interaction interface with View and ViewModel elements and a modularized data application. Hyperledger Fabric, an open-source project under the Linux Foundation, provides enterprise users with a scalable, modular blockchain platform that allows users to configure consensus validation and smart contracts based on business attributes. Using the popular uni-app cross-end development framework, you can use code to generate small programs, such as Android and iOS terminals. The large screen for monitoring the industrial product quality information during the manufacturing phase is shown in Figure 6.

Figure 6.

Large screen for monitoring industrial product quality information at the manufacturing stage.

The blockchain is deployed on 5 Centos 7.6 VMs, and the Kafka mode is selected to realize the connection of multiple machines on the local LAN, containing one order node and four peer nodes. First, we configure and start the Kafka Broker to provide communication services. We configure blockchain peer nodes on four nodes and ensure they can connect to the order node. Using the Fabric blockchain platform, we configure the connection to the above nodes to ensure that they can communicate, interact, and share data and participate in and jointly maintain the blockchain network. This enables uplinked data to be broadcast and synchronized across five nodes for tamper-free, distributed storage; credible identification; and traceability of product full life cycle data.

4.4. Results of the Experiment

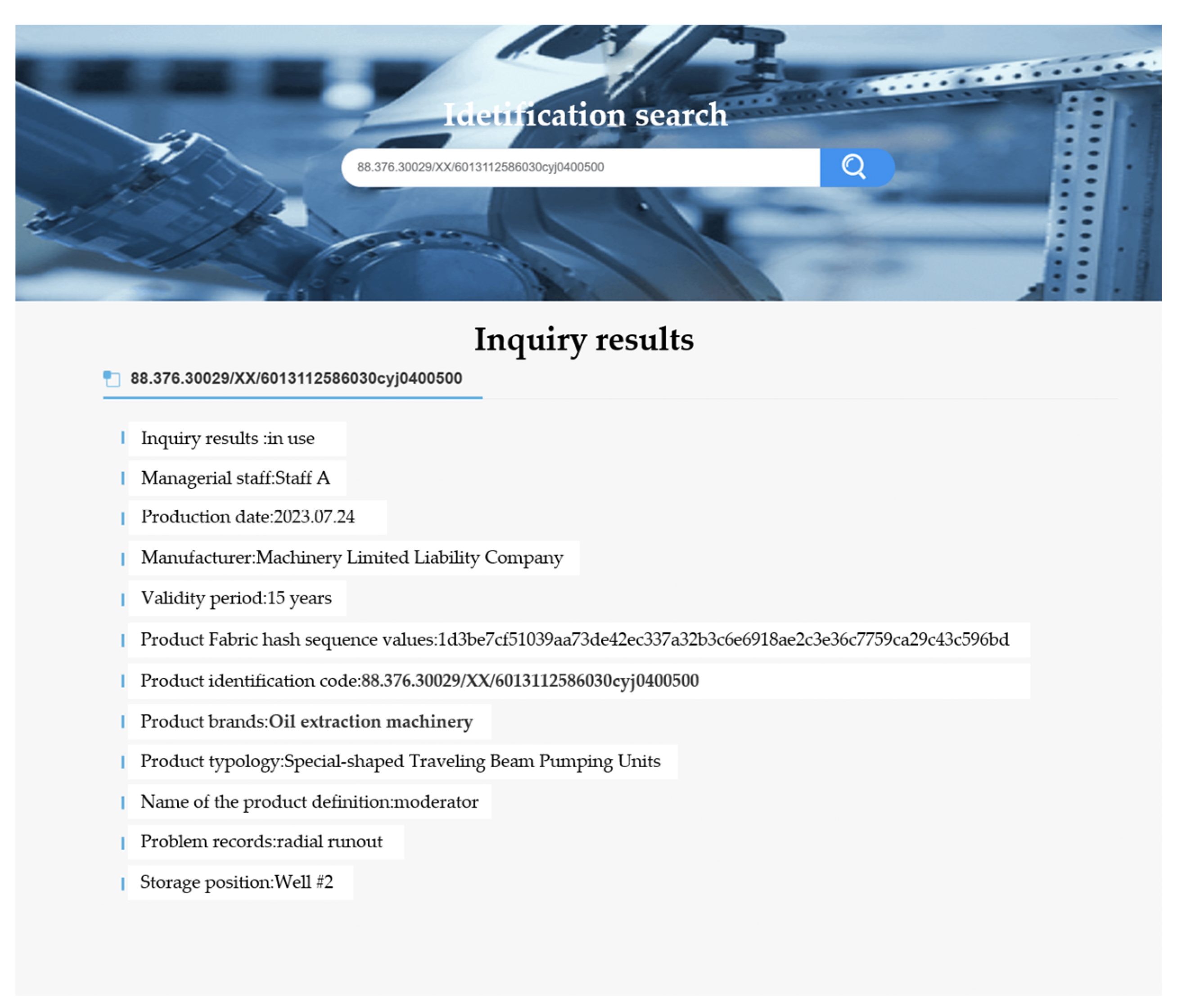

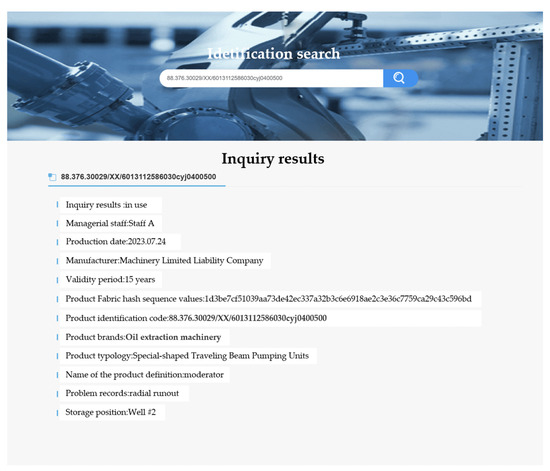

We develop and deploy the industrial product information traceability system under the environment built above, take the quality and safety information on the critical parts of a specially shaped beam pumping machine produced by a Xinjiang petroleum machinery manufacturing enterprise as a sample to test, carry out the uplink operation for the product’s information, execute the same endorsement strategy, and synchronize the storage among the nodes, and the product quality and safety information of the industrial product can be traced through the QR code of the associated identification information. Figure 7 shows the general consumer traceability query page; by entering the product’s unique identification code for a product traceability query, you can query information on the product from its production to its sale in the intermediate stage from various links in the information. In terms of the state of the product, the department/point inspector to which it belongs, and its production date, the product is associated with the code ID, Fabric hash sequence value, and other information, breaking the traditional information exchange barriers in the traceability process between enterprises to improve the efficiency of product traceability; when there are product quality problems, we can quickly locate the responsible body and pursue those responsible for remediation. An example of partial traceability data validation for industrial products is shown in Table 3.

Figure 7.

Example of a traceability query.

Table 3.

Example of partial traceability data validation for industrial products.

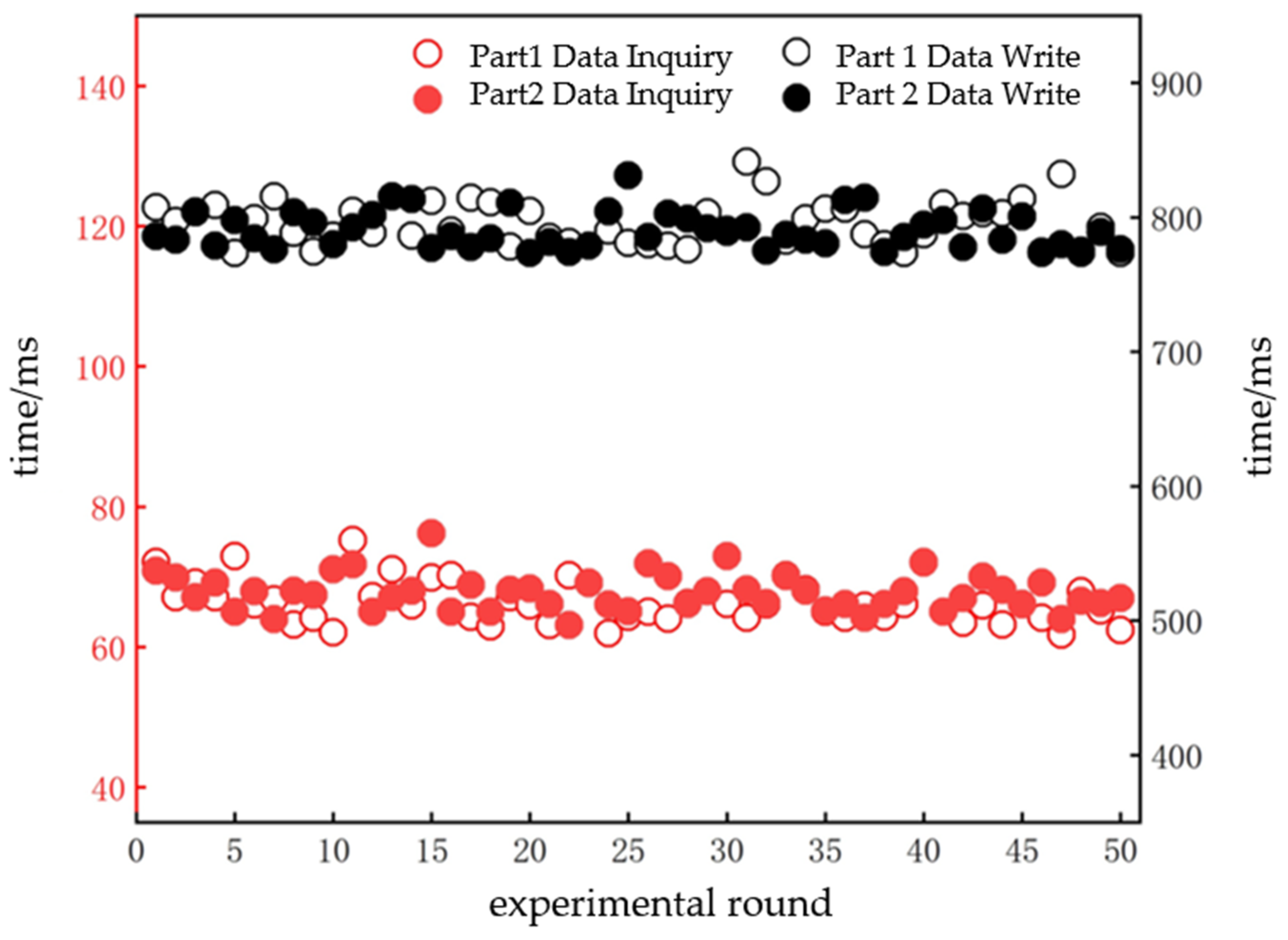

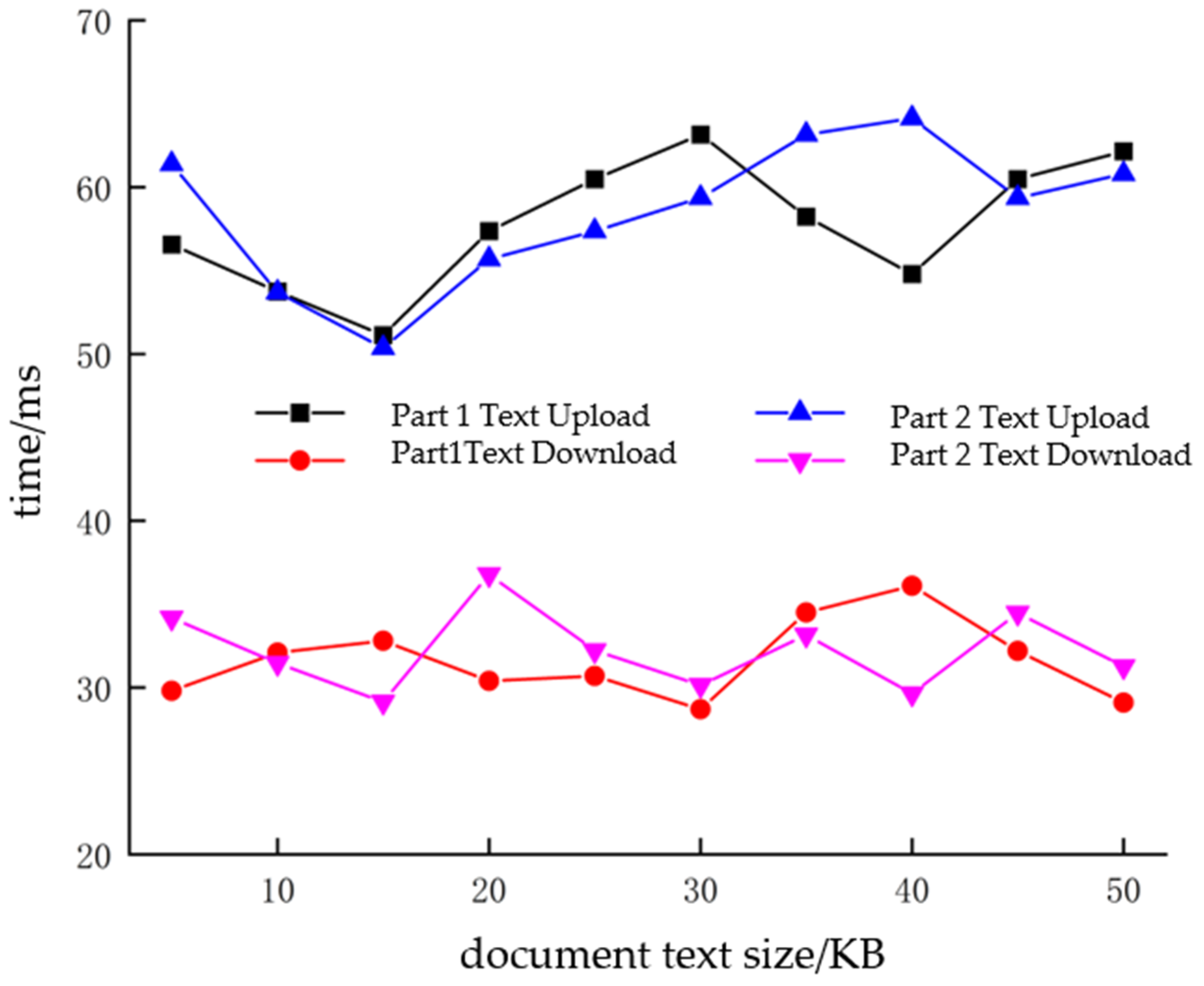

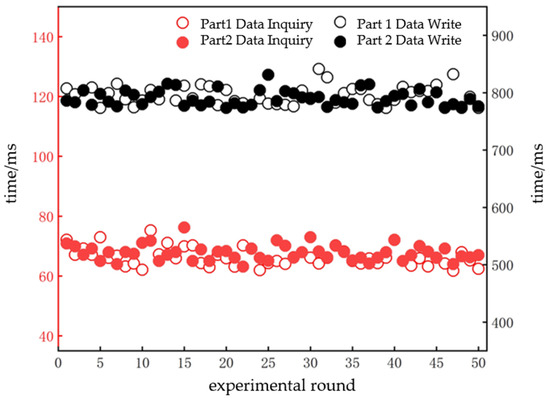

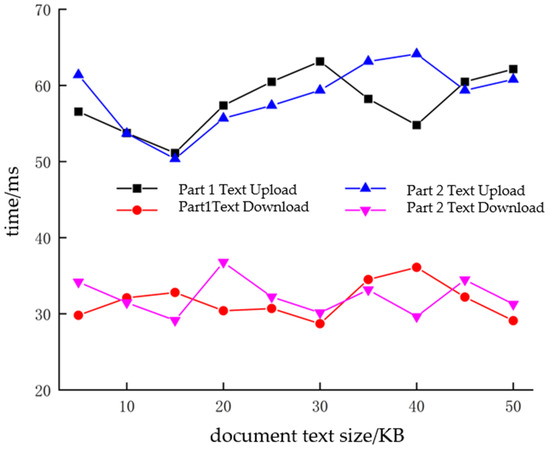

5. Performance Analytics

We perform data writing and querying using the test tool Postman (version 8.0.6), testing shared data from the alliance chain, including text and image information. All the tests are repeated 20 times, each time sending the same type and size of data, and we record the response time of each request, ultimately taking the average of all the test results in order to ensure that the average response time is relatively stable and reliable. The system was tested for 50 rounds through the interface. The performance test results are shown in Figure 8 and Figure 9. Among them, the average upload time for donkey pump and moving beam text data is 51.592 ms and 52.448 ms, respectively; the average download time is 31.64 ms and 32.25 ms, respectively; the average write time for the data is 786.571 ms and 785.896 ms; and the average query time is 65.376 ms and 67.700 ms, respectively, which can meet the needs of consumers and enterprises to obtain product information quickly. At the same time, data on donkey pumps and moving beams, key components of petroleum machinery and equipment, were used for comparisons during the testing process. The results show that the uploading, writing, querying, and downloading times for the two types of parts tend to be the same, and the system is more stable.

Figure 8.

Pumping machine part data writing and query time.

Figure 9.

Text data upload and download.

6. Conclusions

This paper focuses on the demand for full life cycle traceability for industrial products and, based on blockchain and industrial internet identity resolution technology, explores a blockchain-enabled overall technical architecture for a industrial product quality traceability system, which eliminates the information barriers between different departments and enterprises for products in the pre-, mid-, and post-phase stages through research on the design of industrial product identity coding and data storage technology. By analyzing the upstream and downstream business relationships in the market circulation of industrial products, information traceability throughout the entire life cycle of industrial products is divided into the preparatory monitoring stage, the production practice stage, and the life cycle management stage along the supply chain to track and store the link information, which ensures the credibility and completeness of the link information. Adopting an “alliance chain + private chain” hybrid blockchain chain structure, with Xinjiang Petroleum Machinery and Equipment Manufacturing Company as the research object, we constructed an industrial product whole life cycle information traceability system, which provides the opportunity to realize dynamic supervision of the whole chain of information in the industrial product supply chain. Using the Postman (version 8.0.6) system performance testing software to verify the whole life cycle information traceability system for industrial products proposed in this paper, the results show that the average query time for consumer traceability is 65.376 ms, which can realize rapid tracing of problematic products and fast positioning of the responsible subject and provide theoretical support for the realization of credible marking and information traceability for industrial products and references.

Research and development on the quality traceability of industrial products throughout their life cycle are still ongoing and lacking. Some shortcomings may be in the design, construction, and use of systems. There may be a failure to adequately consider the needs of the functions at the design stage. In actual use, certain missing features or insufficient performance may be encountered. At the same time, traceability management for information on the whole life cycle of industrial products is a large scope, and the entire life cycle process of the industrial products mentioned is the typical link. The next step of this paper will be, on the basis of the existing technology, to further introduce artificial intelligence, big data analysis, and other technologies to achieve more intelligent management of the traceability system. The blockchain-based industrial product full life cycle information traceability system will continue to be improved in the future, providing more credible and efficient information traceability services for industrial production and promoting the continuous improvement of industrial quality management and supply chain optimization.

Author Contributions

Conceptualization, L.X. and S.C.; methodology, L.X.; formal analysis, L.X.; funding acquisition, W.S.; investigation, L.X.; software, L.X. and C.L.; resources, L.X.; data curation, L.X.; validation, R.J.; writing—original draft preparation, L.X.; writing—review and editing, L.X.; visualization, L.X.; supervision, W.S.; project administration, W.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Industrial Internet of Things Identity Resolution All Elements Integrated Platform (a major project of the Ministry of Industry and Information Technology, Grant No.TC210A02E) and Research and Development of Key Technology for Integration of All Elements of Industrial Internet of Things Identity Resolution (Natural Science Foundation of Xinjiang Province, Grant No. 2022B01049).

Institutional Review Board Statement

The study did not involve humans or animals.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

References

- Jüttner, U.; Godsell, J.; Christopher, M.G. Demand chain alignment competence—Delivering value through product life cycle management. Ind. Mark. Manag. 2006, 35, 989–1001. [Google Scholar] [CrossRef]

- Gmelin, H.; Seuring, S. Achieving sustainable new product development by integrating product life-cycle management capabilities. Int. J. Prod. Econ. 2014, 154, 166–177. [Google Scholar] [CrossRef]

- Kuhn, M.; Funk, F.; Franke, J. Blockchain architecture for automotive traceability. Procedia Cirp 2021, 97, 390–395. [Google Scholar] [CrossRef]

- Kempen, A. Counterfeit goods & second-hand goods distinguishing the good from the bad and the ugly. Servamus Community-Based Saf. Secur. Mag. 2019, 112, 50–52. [Google Scholar]

- Van Der Toorn, O.; Müller, M.; Dickinson, S.; Hesselman, C.; Sperotto, A.; Rijswijk-Deij, R.V. Addressing the challenges of modern DNS a comprehensive tutorial. Comput. Sci. Rev. 2022, 45, 100469. [Google Scholar] [CrossRef]

- Prashar, D.; Jha, N.; Jha, S.; Lee, Y.; Joshi, G.P. Blockchain-based traceability and visibility for agricultural products: A decentralized way of ensuring food safety in india. Sustainability 2020, 12, 3497. [Google Scholar] [CrossRef]

- George, R.V.; Harsh, H.O.; Ray, P.; Babu, A. Food quality traceability prototype for restaurants using blockchain and food quality data index. J. Clean. Prod. 2019, 240, 118021. [Google Scholar] [CrossRef]

- Liu, X.; Barenji, A.V.; Li, Z.; Montreuil, B.; Huang, G.Q. Blockchain-based smart tracking and tracing platform for drug supply chain. Comput. Ind. Eng. 2021, 161, 107669. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, X.; Ni, Y.; Gu, L.; Zhu, H. Blockchain for the IoT and industrial IoT: A review. Internet Things 2020, 10, 100081. [Google Scholar] [CrossRef]

- Cao, Y.; Jia, F.; Manogaran, G. Efficient traceability systems of steel products using blockchain-based industrial Internet of Things. IEEE Trans. Ind. Inform. 2019, 16, 6004–6012. [Google Scholar] [CrossRef]

- Ding, Q.; Gao, S.; Zhu, J.M.; Yuan, C. Permissioned blockchain-based double-layer framework for product traceability system. IEEE Access 2019, 8, 6209–6225. [Google Scholar] [CrossRef]

- An, J.; Chen, G.; Zou, Z.; Sun, Y.J.; Liu, R.; Zheng, L. An IoT-based traceability platform for wind turbines. Energies 2021, 14, 2676. [Google Scholar] [CrossRef]

- Hader, M.; Tchoffa, D.; El Mhamedi, A.; Ghodous, P.; DolguI, A.; Abouabdellah, A. Applying integrated Blockchain and Big Data technologies to improve supply chain traceability and information sharing in the textile sector. J. Ind. Inf. Integr. 2022, 28, 100345. [Google Scholar] [CrossRef]

- Gomasta, S.S.; Dhali, A.; Tahlil, T.; Anwar, M.M.; Ali, A.B. PharmaChain: Blockchain-based drug supply chain provenance verification system. Heliyon 2023, 9, e17957. [Google Scholar] [CrossRef]

- Gebreab, S.A.; Hasan, H.R.; Salah, K.; Jayaraman, R. NFT-based traceability and ownership management of medical devices. IEEE Access 2022, 10, 126394–126411. [Google Scholar] [CrossRef]

- Zhang, X.; Feng, X.; Jiang, Z.; Gong, Q.; Wang, Y. A blockchain-enabled framework for reverse supply chain management of power batteries. J. Clean. Prod. 2023, 415, 137823. [Google Scholar] [CrossRef]

- Ho, G.T.S.; Tang, Y.M.; Tsang, K.Y.; Tang, V.; Chau, K.Y. A blockchain-based system to enhance aircraft parts traceability and trackability for inventory management. Expert Syst. Appl. 2021, 179, 115101. [Google Scholar] [CrossRef]

- Yang, A.; Li, Y.; Liu, C.; Li, J.; Zhang, Y.; Wang, J. Research on logistics supply chain of iron and steel enterprises based on block chain technology. Future Gener. Comput. Syst. 2019, 101, 635–645. [Google Scholar] [CrossRef]

- Sreenu, M.; Gupta, N.; Jatoth, C.; Saad, A.; Alharbi, A.; Nkenyereye, L. Blockchain based secure and reliable Cyber Physical ecosystem for vaccine supply chain. Comput. Commun. 2022, 191, 173–183. [Google Scholar] [CrossRef]

- Visconti, P.; de Fazio, R.; Velázquez, R.; Del-Valle-Soto, C.; Giannoccaro, N.N. Development of sensors-based agri-food traceability system remotely managed by a software platform for optimized farm management. Sensors 2020, 20, 3632. [Google Scholar] [CrossRef]

- Vukatana, K.; Sevrani, K.; Hoxha, E. Wine traceability: A data model and prototype in Albanian context. Foods 2016, 5, 11. [Google Scholar] [CrossRef]

- Appelhanz, S.; Osburg, V.S.; Toporowski, W.; Schumann, M. Traceability system for capturing, processing and providing consumer-relevant information about wood products: System solution and its economic feasibility. J. Clean. Prod. 2016, 110, 132–148. [Google Scholar] [CrossRef]

- Arvana, M.; Rocha, A.D.; Barata, J. Agri-Food Value Chain Traceability Using Blockchain Technology: Portuguese Hams’ Production Scenario. Foods 2023, 12, 4246. [Google Scholar] [CrossRef]

- Zhaoliang, L.; Huang, W.; Wang, D. Functional agricultural monitoring data storage based on sustainable block chain technology. J. Clean. Prod. 2021, 281, 124078. [Google Scholar] [CrossRef]

- Tao, Z.; Chao, J. The impact of a blockchain-based food traceability system on the online purchase intention of organic agricultural products. Innov. Food Sci. Emerg. Technol. 2024, 92, 103598. [Google Scholar] [CrossRef]

- Marcozzi, M.; Mostarda, L. Analytical model for performability evaluation of Practical Byzantine Fault-Tolerant systems. Expert Syst. Appl. 2024, 238, 121838. [Google Scholar] [CrossRef]

- Agarwal, A.; Ojha, R. Prioritizing implications of Industry-4.0 on the sustainable development goals: A perspective from the analytic hierarchy process in manufacturing operations. J. Clean. Prod. 2024, 444, 141189. [Google Scholar] [CrossRef]

- Weng, G.; Ruan, H.; Qian, C.; Fei, W.; Yu, G.; Wei, G. Assessment method for wind-resistance resilience of power grid based on extension analytic hierarchy process. Int. J. Ind. Syst. Eng. 2021, 38, 416–431. [Google Scholar]

- Li, J.; Han, D.; Wu, Z.; Wang, J.; Li, K.C.; Castiglione, A. A novel system for medical equipment supply chain traceability based on alliance chain and attribute and role access control. Future Gener. Comput. Syst. 2023, 142, 195–211. [Google Scholar] [CrossRef]

- Umran, S.M.; Lu, S.F.; Abduljabbar, Z.A.; Nyangaresi, V.O. Multi-chain blockchain based secure data-sharing framework for industrial IoTs smart devices in petroleum industry. Internet Things 2023, 24, 100969. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).