Abstract

In the post-epidemic economic recovery background, under the influence of the international situation brought by the Russia-Ukraine conflict, the world is facing a significant rebound in total energy consumption. In order to seek a smooth transition for national energy low-carbon transformation, it is urgent that research be conducted on the trap dynamic sealing capacity evaluation and site optimization for underground storage in depleted gas reserves. Based on the geological data of Block S in Northeast China, combined with a dynamic acoustic test and a static triaxial test, a rock mechanical property model for wells is established, and the stress model of the underground storage in depleted gas reserves before construction is inverted. The sealing of the cap rock and faults in the underground gas storage is evaluated from both static and dynamic perspectives. The results show that the maximum horizontal principal stress of the cap rock and reservoir before construction is distributed between 48–76 MPa and 50–85 MPa, respectively. The reservoir of the Yingcheng Formation has strong stratigraphic mechanical strength and can be used as the main space for underground gas storage. The global cap rock shear safety factor is between 0.7–0.9, and the fault slip factor is only 0.1, indicating that this reservoir has strong dynamic closure sealing and is suitable for construction, thereby realizing the dynamic evaluation of sealing and site optimization for underground gas storage in a depleted gas reserve, providing a guarantee for the safe and stable operation of its subsequent expansion, multi-cycle injection, and production.

1. Introduction

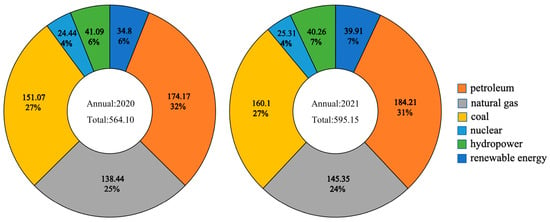

With the development and progress of industrial technology, global energy utilization continues to rise. In the context of the post-epidemic era, governments worldwide have implemented economic recovery policies in response to the COVID-19 epidemic. Additionally, due to the international situation resulting from the Russia-Ukraine conflict, global energy consumption has been further increased. According to the “BP Statistical Review of World Energy (2022)” statistics, see Figure 1 [1], the global primary energy consumption in 2021 reached 595.15 EJ, compared to 564.10 EJ in 2020 during the epidemic containment period. For the first time, the annual average growth rate of primary energy consumption reached a record high of 5.8%. In 2021, the total consumption of fossil fuels such as oil, coal, and natural gas reached 489.66 EJ, accounting for 82.3%, with a year-on-year growth of 5.6%, maintaining its dominant position. However, the combustion of fossil fuels and oxygen produces excessive CO2, leading to severe carbon emissions exceeding the limit in the atmosphere. Consequently, global temperatures are rapidly rising, Antarctic glaciers are melting, and sea levels are rising, seriously disrupting the ecological balance of oceans and land [2,3,4]. To address the worsening ecological and environmental problems caused by excessive carbon emissions, seeking active and effective measures to control carbon emissions and efficient technologies has become a global consensus [5,6].

Figure 1.

The proportion of global primary energy consumption in 2020 and 2021.

In the current global context of the low-carbon transition, renewable energy generates virtually no pollutants throughout the entire energy utilization cycle and has low marginal carbon emissions. However, renewable energy sources such as wind and solar power are subject to significant fluctuations due to environmental and seasonal impacts, necessitating complementary energy storage facilities for sustainable energy supply. Presently, energy storage technology is not yet mature, resulting in high utilization costs for renewable energy and hindering large-scale deployment [7,8,9]. At this time, natural gas, as a low-carbon energy source, can meet the low-carbon clean energy supply requirements while reducing the transformation span of the supply-side energy consumption structure. Thus, achieving large-scale, safe, and concealed natural gas reserves is crucial for the smooth transition from high-energy-consuming sources such as coal to clean energy sources like renewable energy. This also provides assurance for national energy supply security and stable industrial energy efficiency.

Currently, underground natural gas storage is characterized by high efficiency, safety, and stable operation. It has become the primary way of storing natural gas globally with nearly 13% of the world’s natural gas being stored in underground storage for future peak processing. At the same time, with the continuous exploitation of natural gas resources, the pressure in the original gas reservoirs is declining, and some reservoirs are reaching depletion. Nevertheless, due to the completeness of the gas-exploited facilities, these depleted reservoirs are perfect carriers for the economical and efficient construction of underground natural gas storage [10,11,12]. Therefore, in the current international scenario where there is a significant rebound in global primary energy consumption, urgent research is needed on the dynamic closure sealing evaluation and site optimization of underground natural gas storage, especially those with depleted gas reservoirs. This is a critical aspect in the construction of underground storage in depleted gas reserves, and it directly impacts the safe and smooth operation of subsequent capacity expansion, production, and cyclic injection and exploitation [13,14,15,16].

According to a large number of statistics, mudstone, carbonate rock, and gypsum-salt rock are the main lithological characteristics of the cap rock in large and medium-sized oil and gas fields, with mudstone being the most common one [16]. Some people [17] believe that there is a significant difference in the maximum hydrocarbon column height for cap rock sealing of oil and gas reservoirs with different lithological characteristics, with the closure hydrocarbon column height from high to low being gypsum-salt rock, mudstone, and carbonate rock. In continental basins, the displacement pressure of cap rock varies according to different lithological features, leading to differentiated cap rock sealing capabilities: gypsum-salt rock is the best, followed by mudstone, and carbonate rock having poor sealing performance. Heath et al. [18] further analyzed the micro-morphology of continental and marine mudstones through scanning electron microscopy and detected the relevant characteristic parameters of mudstones using X-ray diffraction behavior. They pointed out that the sealing efficiency of cap rock in underground storage in depleted gas reserves is mainly determined by pore diameter and lining. In the same period, Pang Jing et al. quantitatively evaluated the sealing performance of faults using the mudstone smearing factor algorithm based on the fault throw and juxtaposition relationship between the two rock strata on either side of the fault, combined with dynamic production data of gas reservoirs. This was used to discuss the feasibility of reconstructing underground storage in depleted gas reserves in Xinjiang. In the following year, Armitage et al. [19] conducted experiments to investigate the effect of saturated CO2 solution on the trap dynamic sealing capacity of the underground storage in depleted gas reserves. The results showed that the permeability of the sealing system of underground gas storage composed of siltstone cap rock would be affected by the saturated CO2 solution. When the fluid flows through the siltstone cap rock, it would directly increase the permeability by one order of magnitude, thereby sharply reducing the sealing performance of the underground gas storage sealing system.

In addition to its own lithological characteristics, the mechanical characteristics of the cap rock in depleted gas reservoirs also affect the trap dynamic sealing capacity of underground gas storage. The main brittle-ductile evaluation indexes reflecting the mechanical characteristics of the cap rock are the Rock Brittleness Index (BRI), Overburden Confining Ratio (OCR), rock internal friction angle, and rock density. Ingram et al. [20] proposed the Brittleness Index in 1999 to quantitatively describe the rock’s ability to undergo brittle fracturing:

where is the uniaxial compressive strength of normally consolidated rock, is the uniaxial compressive strength of over consolidated rock.

Research has shown that the oil and gas reservoir cap rock are more prone to brittle fracture when the exceeds 2. Additionally, Nygrad et al. [21] evaluated mudstones in the North Sea basin and found that similar to the contribution of cap rock fractures, when the OCR exceeds 2.5, the rock will fracture, leading to natural gas leakage. The internal friction angle of rock and the intrinsic properties reflected by the specific surface area of the rock are both composite indicators of rock porosity, grain size, degree of compaction, and cementation. If the specific surface area is less than 300 m2/g, it indicates strong cementation and poor sealing of the cap rock in oil and gas reservoirs, making it prone to brittle fracture [16]. Similarly, rock density, greater than 2.1 g/m3, also exhibits brittle rock characteristics, compromising the original sealing performance of the cap rock [17]. Building on this, Lin Jianpin et al. [22] approached from a rock mechanics perspective, using cap-breaking pressure tests to reveal the physical sealing mechanism of the cap rock, and considering the full stress-strain characteristics to construct a brittle evaluation model for cap rock, providing a quantitative assessment method for the trap dynamic sealing capacity at the site option of the underground storage in depleted gas reserve.

Overall, the existing methods for evaluating the sealing performance of cap rock and faults in oil and gas reservoirs are relatively perfect, with most of the focus on the knowledge acquired during the development phase of oil and gas reservoirs. Various experiments, simulations, and theoretical derivations have been used to quantitatively characterize the sealing performance of a specific reservoir’s cap rock and faults. However, the underground storage in depleted gas reserves is built based on long-exploited depleted gas reservoirs. In the process of developing natural gas resources, the reservoir porosity is damaged, which affects the geological characteristics of the reservoir, and the performance of the cap rock may differ from its initial sealing performance. Considering that the geological parameters of the depleted gas reservoir were known during the development phase, there has been no research on the dynamic evolution process of the sealing and gas storage performance of the cap rock in oil and gas reservoirs. This will result in the existing analysis of the sealing storage gas performance of depleted gas reservoir cap layers and original gas reservoir cap layers being separated from each other and unable to describe the true sealing storage gas performance of cap rock in depleted gas reservoirs. Therefore, it is necessary to invert the 3D stress model of the depleted gas reservoir before construction based on dynamic development data of oil and gas reservoirs and geological data of depleted gas reservoirs, in order to describe the dynamic evolution process of the sealing and gas storage performance of the cap rock in oil and gas reservoirs. This will ultimately achieve a dynamic evaluation of sealing and site optimization for underground gas storage in depleted gas reserves.

2. Study Area and Geological Features

2.1. Geologic and Tectonic Characteristics of Depleted Gas Reservoirs

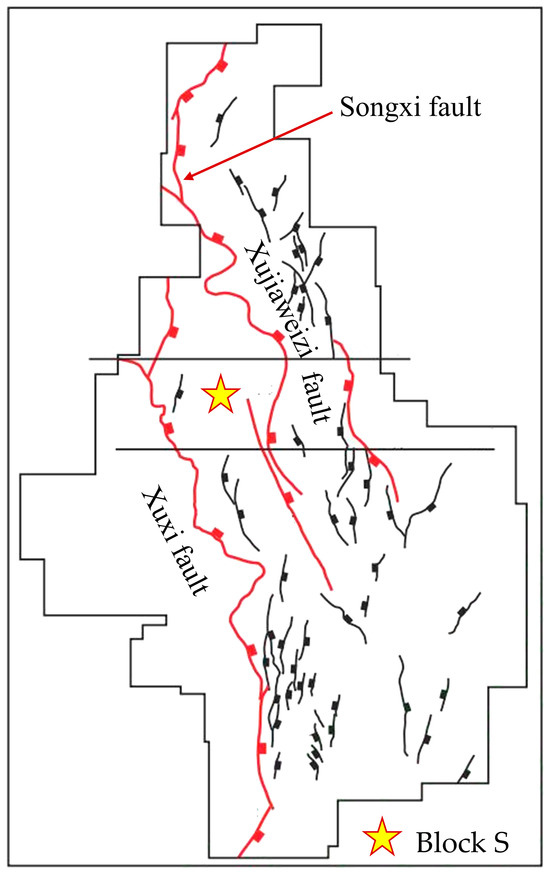

The structural location of Block S is on the northern segment of the Xingshan fault depression in the middle of the Xujiaweizi fault depression zone in the deep Songliao basin and its geological map, see Figure 2 [23,24]. The Xujiaweizi fault depression is one of the seven fault depression structural units in the northern Songliao basin, and it is composed of a graben basin controlled by two main fault zones, Xuxi and Songxi [25]. It can be further divided into three second-level structural units and sixteen third-level structural belts [26].

Figure 2.

The geological maps of Block S.

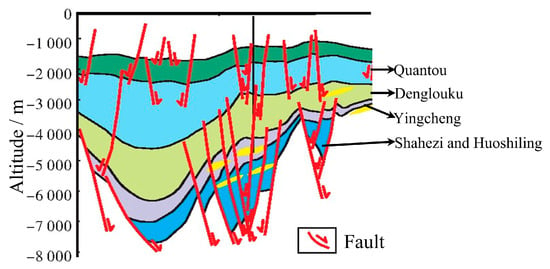

According to drilling data, the deep strata in the northern part of the Songliao basin where Block S is located developed from bottom to top as follows: basement (C-P series) metamorphic rocks, Hercynian intrusive rocks, the Huoshiling formation of Upper Jurassic system, the Shahezi formation, the Yingcheng formation, the Denglouku formation, and the Quantou formation of the lower Cretaceous and the above strata [27]. The specific sequence of deep strata can be seen in Table 1. Among them, the Yingcheng formation is divided into two members of Yc3 and Yc4 based on the typical lithology differences, and the Yc3 can be further divided into three gas layer formations: Yc3I1, Yc3I2, and Yc3I3, with the gas bearing layer mainly located in the upper Yc3I1. Analysis reveals that the main reservoir layer for underground storage in depleted gas reserves is the Yingcheng formation, with the gas-bearing layer mainly distributed in the Yc3 [24]. The specific profile of Block S can be seen in Figure 3.

Table 1.

Deep stratigraphic sequence of the block S.

Figure 3.

The drill profile of Block S [28].

Regarding the development of faults, a total of four major faults have developed in the underground storage in the depleted gas reserve, starting from the deposition period of the Huoshiling formation and continuing until the end of the deposition of the Yingcheng formation [29]. These four faults control the formation and evolution of the strata deposition and the development of uplifts in this area. During the Yingcheng formation period, the activity of the fault weakened, and the faults have the characteristics of being fewer in number and shorter in extension. Three sets of faults developed in the directions of north-northwest, nearly north-south, and north-northeast during the Yingcheng formation period, with the north-northwest direction being the main one. Particularly in the fourth layer of the Yingcheng formation, 332 faults were identified, with 63 of them having an extension length greater than 1.5 km, and 269 being less than 1.5 km. Moreover, in the area serving as a depleted gas reservoir-type underground gas storage, there are a total of 12 faults in the Yingcheng formation, mainly in the north-northwest direction. Among them, 3 faults penetrate through the reservoir and cap rock, 6 are internal faults within the reservoir and cap rock, and 3 are source-reservoir faults.

The Denglouku formation has a total of 28 faults that developed from the deposition period and continued until the deposition period of the Quantou formation and Qingshankou formation ended [30,31]. A total of nine faults developed in the Denglouku formation within the area of the depleted gas reservoir. Among them, there are three faults from the Yingcheng formation to the top of the D2 formation, mainly trending in a north-northwest direction. F2, F5, and F11 are faults from the Yingcheng formation to the top of the D2 formation, with relatively short lengths and gentle displacements. Considering the influence of late tectonic movements, the number of faults in the upper T3 layer is higher than in the lower T4 and T5 layers, and they have more diverse trends, all of which are normal faults.

The central-fracture-type volcanic channels of the Yingcheng formation are depicted through planar and cross-sectional methods. The volcanic vents are distributed in a north-northwest direction, generally consistent with the major faults. The seismic reflection characteristics on the profiles are mound-shaped and irregularly cylindrical, often cutting through reflection layers, with medium to high frequency, medium amplitude, and poor continuity. In addition, the boundary of the trap is the actual boundary of the trap for the underground storage in the depleted gas reserve. The overall geological body of Block S in the area extends to 200 km2. The overall structural shape of the depleted gas reservoir is a dustpan-shaped fault depression, faulting to the west and overlapping to the east, with the main development of the reservoir structure in the downthrown block of the Xuxi fault. Therefore, the Yc3I1 gas reservoir in the Yingcheng formation is interpreted to have eight sealing layers controlled by the fault trend, with a total area of 31.67 km2. The trap type of underground storage in depleted gas reserves is mainly dominated by anticlines, faults, and compound traps. The structural formation of the depleted gas reservoir is controlled by multiple volcanic structures distributed along the faults, which overall form a single compound anticline. The high point of the main trap structure is at a burial depth of 2650 m, with a trap line depth of 2820 m, a trap amplitude of 170 m, and a total trap area of 22.62 km2.

2.2. Reservoir Characterization of Depleted Gas Reservoirs

Due to the differences in reservoir spatial morphology formed by different volcanic rock lithological conditions, a statistical analysis of the reservoir spatial morphology in different lithological areas of the depleted gas reservoir was conducted. The results show that for the rhyolite, primary pores are the main type, accounting for 69.25%, followed by devitrified pores at 22.89%, and a small amount of microfracture pores. For the rhyolitic tuff and rhyolitic welded tuff, volcanic ash dissolution pores are the main type, accounting for 72.22% and 88.89%, respectively, followed by primary pores. Andesitic breccia has intra-boulder and inter-boulder pores and volcanic ash dissolution pores as the main types, followed by primary pores, feldspar dissolution pores, and a small amount of microfracture pores [32]. Considering that the main reservoir spatial distribution in the underground storage in the depleted gas reserve is in the Yingcheng formation, based on the geological characteristics data, the majority of the lithology is rhyolite, accounting for 73.40%. It can be assumed that the reservoir spatial morphology of the underground gas storage facility for depleted gas reservoirs is primarily dominated by primary pores [33].

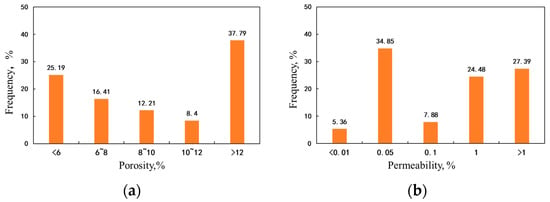

The spatial morphology of the reservoir determines various physical parameters of the reservoir. The porosity and permeability parameters of the depleted gas reservoir are crucial for gas reservoir exploitation and processes such as cyclic injection and production in underground gas storage [34]. Therefore, physical property analysis was also conducted on 262 core samples from 9 core wells encountered in the Yingcheng formation within the underground gas storage for depleted gas reservoirs. The statistical results of the core physical property analysis are shown in Figure 4. The porosity of the reservoir ranges from 4.0% to 27.5%, with an average of 8.4%. Samples with porosity greater than 12% account for 37.79%, while those with porosity less than 6% account for 25.19%. The permeability of the reservoir ranges from 0.006 mD to 319 mD, with an average of 1.19 mD, mainly distributed between 0.01 mD and 1 mD. Samples with permeability greater than 1.0 mD account for 27.39%, and those with permeability between 0.1 mD and 1 mD account for 40%.

Figure 4.

Statistical results of core physical property data analysis should be listed as: (a) Core porosity frequency distribution; (b) Frequency distribution of core permeability.

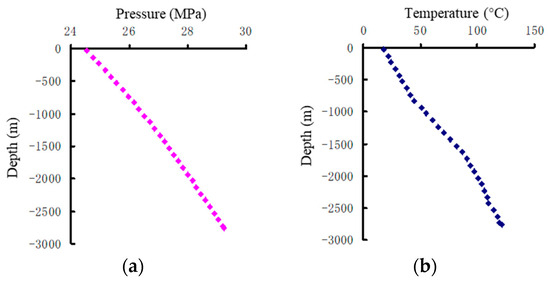

In addition, as geological environmental conditions, the temperature and pressure system of the formation also affect the storage and sealing of gas in the reservoir and therefore require analysis [35,36]. As shown in Figure 5, the formation temperature of the depleted gas reservoir is around 120 °C, with a temperature gradient of 3.29 °C/100 m. The original formation pressure of the depleted gas reservoir is 31.78 MPa, and the pressure gradient ranges from 0.15 to 0.2 MPa/100 m, all within the normal range for the temperature-pressure system.

Figure 5.

Temperature and pressure system of formation should be listed as: (a) Typical well temperature depth relationship curve; (b) Typical well pressure depth relation curve.

The overall gas-water distribution characteristics of the depleted gas reservoir are complex, and controlled by both structural and volcanic factors. In the vertical direction, it follows the law of gravity differentiation, showing a general distribution pattern of gas above and water below. The depleted gas reservoir has a roughly unified gas-water interface, with the depth of the gas-water interface for most wells located around 3000 m. In the northern region, some gas-water interfaces are deeper, exceeding 3150 m. In most areas, the gas layers are mainly distributed in the Yc3I1 gas reservoir group, which is also the basis for the selection of the Yc3I1 segment of the Yingcheng formation as the main sealing and storage space for the depleted gas reservoir.

3. Materials and Methods

3.1. Static Triaxial Rock Mechanical Parameter Test

The rock mechanical parameter is the basis for studying the characteristics of formation rocks and is one of the key data for evaluating the dynamic sealing of underground gas storage in depleted gas reservoirs. This mainly reflects the rock mechanics strength parameter (yield strength) and elastic parameter (elastic modulus, Poisson’s ratio). Currently, rock mechanical tests are mainly divided into two methods: static and dynamic. In the static method, rock deformation is measured through static loading and confining pressure. The specific experimental steps are as follows:

- (1)

- Preparation of rock core: For the Yingcheng formation and Denglouku formation, full-diameter rock core samples are extracted from 12 core wells according to different formations. Based on the rock core preparation device, each rock core sample is processed into three small cores with dimensions of 2.5 × 5.0 cm. The two ends of the small rock core are ground flat using a grinding machine.

- (2)

- Installation of rock core: The processed small rock core samples are placed into the cavity of the triaxial mechanical testing instrument. Rubber rings are used to seal the boundary of the hydraulic module to prevent the fluid used for applying stress from permeating into the small rock core, thus affecting the accuracy of the triaxial rock mechanics test data. During the installation of the pressure plate and related components of the press, it is considered that although the ground flat surfaces of the small rock core have high-precision smoothness, there are still some micro-scale unevenness on the pressure plate surface in contact with the small rock core. Therefore, rubber pads are added to the contact surface between the pressure plate and the small rock core to balance the test error caused by the unevenness due to the inclined contact surface of the small rock core.

- (3)

- Confining pressure loading: After the installation of the rock core, three small rock core samples are subjected to three-directional confining pressures of 20 MPa, 30 MPa, and 40 MPa, respectively. The initial confining pressure is set to a low value with a pre-set loading rate of 0.05 MPa/s. Then, the pore pressure in the rock is increased by 10 MPa at a rate of 0.2 MPa/s and kept constant. Subsequently, the confining pressure is further increased until the effective confining pressure reaches the set value. The triaxial mechanical testing instrument automatically records the shear stress, normal stress, and strain of the rock on the loaded surface area in the tangential and normal directions. The stress state that leads the rock to reach the shear limit is also recorded. Finally, the static shear strength, static elastic modulus, and static Poisson’s ratio are calculated using formulas.

3.2. Dynamic Acoustic Rock Mechanical Parameter Test

The elastic parameters in rock mechanics (elastic modulus, Poisson’s ratio) are essential for the study of reservoir stress, inversion simulation calculations, and dynamic sealing evaluation in underground storage in depleted gas reserves. In order to accurately describe the evolution of reservoir stress, it is necessary to use acoustic and density logging data to measure the propagation velocity of ultrasonic waves in rock core samples to obtain dynamic mechanical parameters of rocks. The specific experimental steps are as follows:

- (1)

- The preparation method of the rock core is consistent with static triaxial rock mechanical experiments.

- (2)

- Installation of rock core: Place the small rock core samples, which have been processed to the qualified size, into the rock ultrasonic parameter tester. When measuring the longitudinal wave velocity, vaseline is used as the coupling agent between the small rock core and the transducer, while when measuring the transverse wave velocity, the coupling agent between the small rock core and the transducer should be replaced with aluminum foil solid material to avoid errors caused by the rapid release of strain energy and the formation of stress waves. Apply a pressure of 0.05 MPa to fix the small rock core sample between the transducer and receiver.

- (3)

- Sonic wave testing: After the installation of the small rock core is completed, the sonic wave generator and oscilloscope are turned on. Considering the comparability of the results between static triaxial rock mechanics tests and dynamic sonic wave rock mechanics tests, the testing conditions for the small rock core sample are set to be consistent with the static triaxial rock mechanical test. The emission frequency of the transducer can be determined as:

After setting the testing conditions, the sonic wave generator is used to emit longitudinal and transverse waves through the transducer to the fixed small rock core sample. After the sonic waves penetrate the small rock core, the transducer collects the sonic wave information, and the time difference between the transverse and longitudinal waves of the three small rock core samples in each well is recorded at the terminal. Additionally, after the testing is completed, the emission transducer and receiving transducer need to be connected to each other to measure the delay time between the transverse and longitudinal wave transducers and the instrument testing module. Then, the dynamic elastic modulus and dynamic Poisson’s ratio are calculated separately using Equation (4).

where is the dynamic elastic modulus of the rock, Pa; is the dynamic Poisson’s ratio of the rock; is the density of the rock at the point of sound wave movement, kg/m3; is the longitudinal wave velocity, m/s; is the transverse wave velocity, m/s; is the length of the core sample of the reservoir rock to be tested in the direction of acoustic wave penetration, m.

3.3. Numerical Simulation Calculations

Based on the above dynamic and static rock mechanical test results, well data, and relevant geological data in the Study Area and Geological Features Section, the regional-scale 3D model of the underground storage in depleted gas reserves was created. The transversal range and thickness of its reservoir are 20 km × 10 km × 1.2 km, respectively, and the average porosity and permeability are taken to be 8.4% and 1.19 mD, respectively, with all boundaries considered to be no-water-flow boundaries. The top of the aquifer is located at 3000 m from the ground surface and is simulated with the Carter-Tracy Model. When creating a 3D geological model, the overall model is discretized. The plane grid size of the geological model is 50 × 50 m, and the vertical grid size is determined based on the research needs for different layers. The vertical grid size for specific layers is 1 m for the D2, Yc3, and Yc4, 10 m for the D3 and D4. The total number of grids is 93.8 million. This is used to build the geomechanical modeling of the gas reservoir based on the Petrel 2013 and the Visage 9.1.

4. Results and Discussion

4.1. Analysis of Rock Mechanical Properties at Well Points

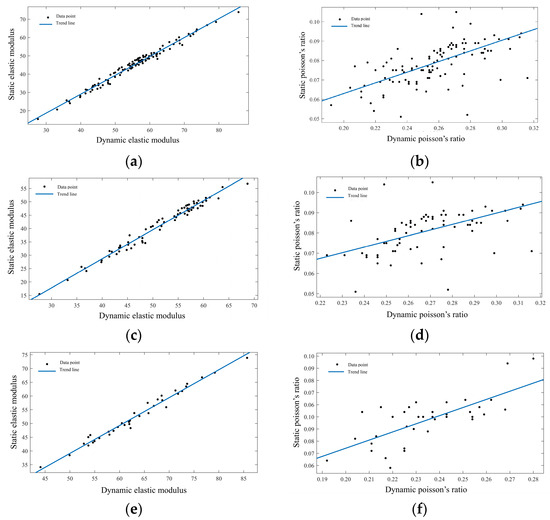

Based on the static triaxial rock mechanical tests and dynamic acoustic rock mechanical tests, static and dynamic elastic modulus, as well as static and dynamic Poisson’s ratio, are obtained for different wells and formations. This is aimed at exploring the dynamic-static transformation relationship between the static rock mechanics parameters and the dynamic rock mechanics parameters.

Using static elastic modulus or static Poisson’s ratio as the dependent variable, and dynamic elastic modulus or dynamic Poisson’s ratio as the independent variable, a linear regression analysis is performed to establish the dynamic-static transformation relationship for rock elastic modulus and Poisson’s ratio, as shown in Table 2.

Table 2.

The dynamic-static transformation relationship for rock elastic modulus and Poisson’s ratio.

The regression curves between dynamic and static elastic modulus and dynamic and static Poisson’s ratio are shown in Figure 6, where the correlation coefficients for each formation are all above 0.97, indicating a strong linear correlation for the dynamic and static elastic modulus of the reservoir rock formations (Figure 6a,c,e); while the dynamic and static Poisson’s ratio for each formation is around 0.77, showing a lower linear correlation compared to the elastic modulus, but still exhibiting a certain degree of a linear relationship (Figure 6b,d,f). Additionally, under the same conditions, the dynamic elastic modulus (Poisson’s ratio) of the reservoir rock is generally greater than its static elastic modulus (Poisson’s ratio). Furthermore, compared to the dynamic and static Young’s modulus, the reduction in static Poisson’s ratio compared to the dynamic Poisson’s ratio is more significant, indicating pronounced differences in the lateral expansion characteristics of the rock under different conditions.

Figure 6.

Regression curves of dynamic and static modulus of elasticity and dynamic and static Poisson’s ratios in different formations should be listed as: (a) Regression curves of static and dynamic modulus of elasticity for all formations; (b) Regression curves of static and dynamic Poisson’s ratio; (c) Regression curves of static and dynamic modulus of elasticity for the Denglouku formation; (d) Regression curves of static and dynamic Poisson’s ratio for the Denglouku formation; (e) Regression curves of static and dynamic modulus of elasticity for the Yingcheng formation; (f) Regression curves of static and dynamic Poisson’s ratio for the Yingcheng formation.

In different lithological formations, the regression equations for dynamic and static elastic modulus and Poisson’s ratio exhibit distinct characteristics. The sandstone, siltstone, and mudstone of the Denglouku formation show regression equations for dynamic and static elastic modulus with high slope and low intercept characteristics, indicating that within a lower range of dynamic elastic modulus, the volcanic rocks of the Yingcheng formation will exhibit higher static elastic modulus, while within a higher range of dynamic elastic modulus, the sandstone, siltstone, and mudstone of the Denglouku formation exhibit higher static elastic modulus (Figure 6c,e). The regression equations for dynamic and static Poisson’s ratios for the two lithological formations show the opposite behavior. Within a lower range of dynamic Poisson’s ratio, the sandstone, siltstone, and mudstone of the Denglouku formation will exhibit higher static Poisson’s ratio, while within a higher range of dynamic Poisson’s ratio, the volcanic rocks of the Yingcheng formation will exhibit a higher static Poisson’s ratio (Figure 6d,f). When the dynamic elastic modulus is 43.91 MPa or the Poisson’s ratio is 0.1978, the two lithologies have the same static elastic modulus. Additionally, although the transformation relationship of the Poisson’s ratio for the volcanic rocks of the Yingcheng formation has a higher change slope, it is limited by the fact that its overall dynamic Poisson’s ratio is lower than that of the sandstone, siltstone, and mudstone of the Denglouku formation. As a result, the ranges of static Poisson’s ratio for the two lithological formations are relatively consistent.

Although laboratory dynamic acoustic wave rock mechanical experiments can obtain the time difference between longitudinal and transverse waves of core samples, they are limited by the discreteness of the core sample depth and cannot directly generate a continuous profile of rock mechanical parameters for the reservoir rock. Therefore, based on the dynamic-static conversion relationship of rock elastic modulus and Poisson’s ratio in Table 2, combined with XMAC multipole array acoustic logging data, a continuous profile of static rock mechanical parameters for the reservoir rock of depleted gas reservoirs can be formed, with specific statistical parameters seen in Table 3. Among these parameters, although the sandstone, siltstone, and mudstone of the Denglouku formation exhibit characteristics of high slope and low intercept, their dynamic elastic modulus is lower than that of the Yincheng formation volcanic rocks, so the static elastic modulus of the Yincheng formation volcanic rocks is significantly greater than that of the sandstone, siltstone, and mudstone of the Denglouku formation. While the dynamic-static conversion relationship of Poisson’s ratio of the Yincheng formation volcanic rocks has a higher change slope, it is similarly limited by its dynamic Poisson’s ratio, which is slightly lower than that of the sandstone, siltstone, and mudstone of the Denglouku formation. Ultimately, the static Poisson’s ratio ranges of the two lithological strata are quite consistent, which also coincides with the ranges of dynamic and static elastic modulus (Poisson’s ratio) on the horizontal and vertical axes in Figure 4.

Table 3.

Statistical parameters of continuous profiles of static mechanical parameters of reservoir rocks in the underground storage in depleted gas reserves.

4.2. Description of 3D Stress Inversion before Reservoir Construction

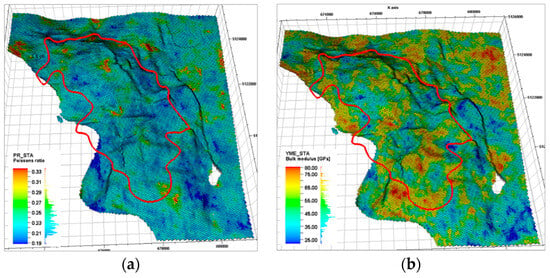

Based on the rock mechanical model of well points, the stress state of the measurement points can be determined, and combined with porosity, permeability data, water saturation, and other reservoir properties as constraints, a 3D stress model of the depleted gas reservoir is constructed. The stress state is inverted before reservoir construction. The 3D models of the Poisson’s ratio and Young’s modulus of the reservoir can be seen in Figure 7. The results show that the distribution of Young’s modulus in 3D space is affected by “phase control” and porosity. In regions with higher porosity, Young’s modulus is relatively smaller, which is consistent with the law of sedimentary sandstone. The correlation between the Poisson’s ratio of the reservoir and conventional physical properties such as porosity is relatively poor, and its discreteness is relatively strong. In regions with a larger Young’s modulus (greater rock strength), the Poisson’s ratio is relatively smaller, indicating a weaker lateral expansion effect in harder rocks, consistent with the conclusions of the rock mechanical model at the well points.

Figure 7.

A 3D model of Poisson’s ratio and Young’s modulus should be listed as: (a) Poisson’s ratio; (b) Young’s modulus.

In addition, the cap rock and the reservoir of the underground storage in depleted gas reserves exhibit different geological characteristics. The 3D models of the Poisson’s ratio and Young’s modulus for the cap rock are shown in Figure 8. Compared to the reservoir, the spatial distribution of Young’s modulus and Poisson’s ratio in the cap rock is relatively less dispersed in 3D space. However, the corresponding relationship between the Poisson’s ratio and Young’s modulus in the cap rock is similar to the reservoir, in this area with greater rock mechanical strength, the Poisson’s ratio is relatively smaller.

Figure 8.

A 3D model of Poisson’s ratio and Young’s modulus of caprock should be listed as: (a) Poisson’s ratio; (b) Young’s modulus.

Based on the 3D stress inversion before the reservoir construction, the distribution pattern of the pre-construction stress field is obtained. The stress field has three principal stresses, with the vertical principal stress being the overburden pressure, and the other two horizontal principal stresses being the maximum and minimum horizontal principal stresses.

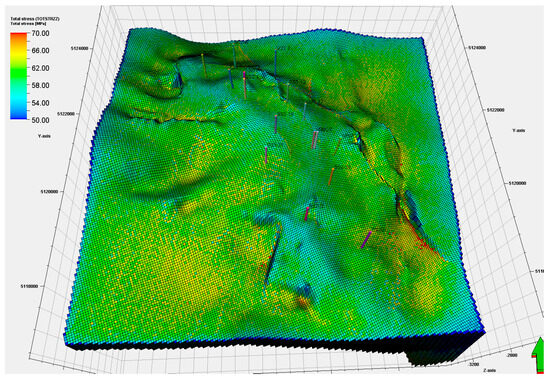

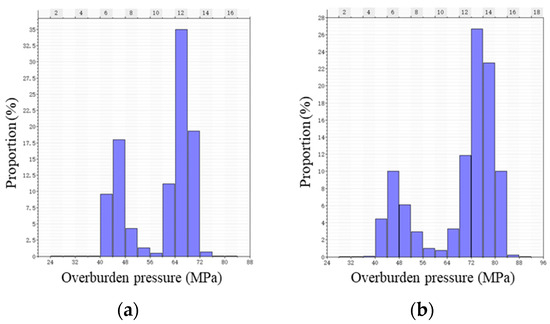

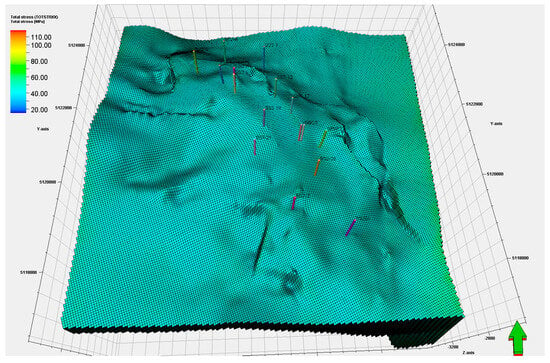

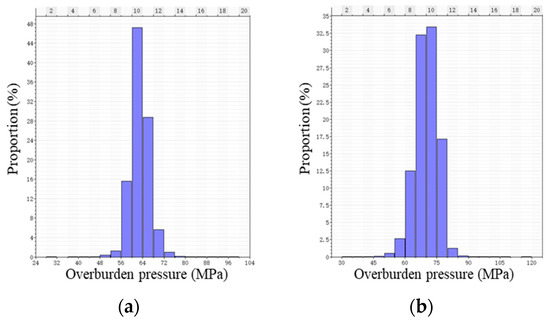

From the analysis of the overall stress field, the overburden pressure is mainly determined by the rock density of the overburden strata and can be obtained through stress balance calculations. It will undergo systematic changes with depth. The distribution of overburden pressure before construction is shown in Figure 9, with the pressure distribution of the overburden in the cap rock ranging from 40 MPa to 76 MPa (Figure 10a), and in the reservoir layer ranging from 40 MPa to 88 MPa (Figure 10b). The distribution of maximum horizontal principal stress before construction is shown in Figure 11, with the distribution of maximum horizontal principal stress in the cap rock ranging from 48 MPa to 76 MPa (Figure 12a), and in the reservoir layer ranging from 50 MPa to 85 MPa (Figure 12b).

Figure 9.

Distribution of the original vertical principal stress.

Figure 10.

The original vertical principal stress distribution in cap rock and reservoir should be listed as: (a) Cap rock; (b) Reservoir.

Figure 11.

The original maximum horizontal principal stress distribution.

Figure 12.

The original maximum horizontal principal stress distribution of profile 1 in cap rock and reservoir should be listed as: (a) Cap rock; (b). Reservoir.

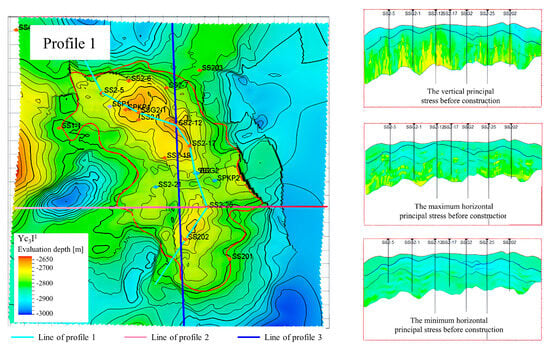

Dividing three typical profiles, as shown in Figure 13, according to the characteristics of the distribution of the stress field, Profile 1 passes through seven wells: SS2−5, SS2−1, SS2−12, SS2−17, SS2, SS2−25, and SS202. Before the construction of Profile 1, the overburden pressure was between 55 MPa and 75 MPa, the maximum horizontal principal stress was between 40 MPa and 55 MPa, and the minimum horizontal principal stress was between 25 MPa and 40 MPa.

Figure 13.

The principal stress distribution of profile 1.

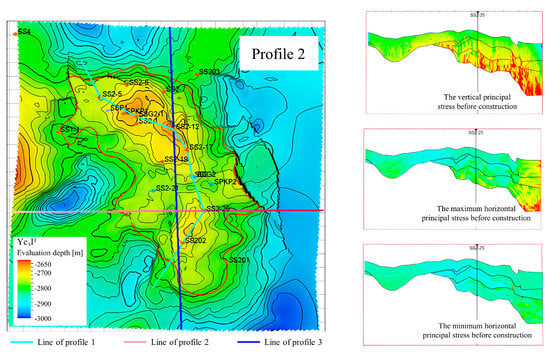

As shown in Figure 14, Profile 2 passes through well SS2−25. Before the construction of Profile 2, the overburden pressure is between 55 MPa and 75 MPa, the maximum horizontal principal stress is between 40 MPa and 70 MPa, and the minimum horizontal principal stress is between 25 MPa and 55 MPa.

Figure 14.

The principal stress distribution of profile 2.

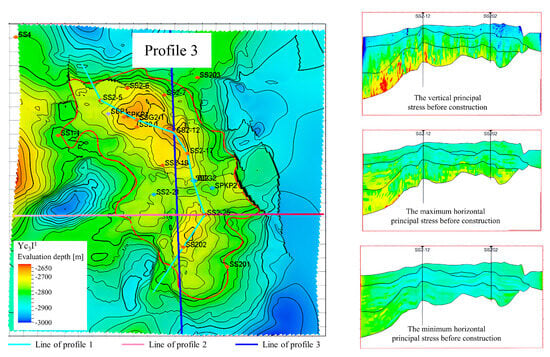

As shown in Figure 15, Profile 3 passes through well SS2−12 and SS201. Before the construction of Profile 3, the overburden pressure was between 55 MPa and 80 MPa, the maximum horizontal principal stress was between 40 MPa and 60 MPa, and the minimum horizontal principal stress was between 25 MPa and 45 MPa.

Figure 15.

The principal stress distribution of profile 3.

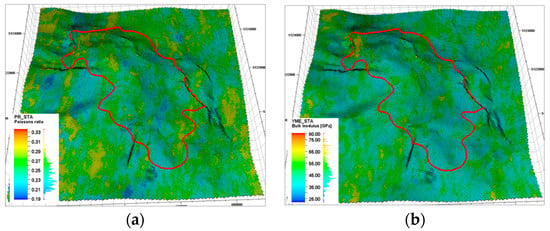

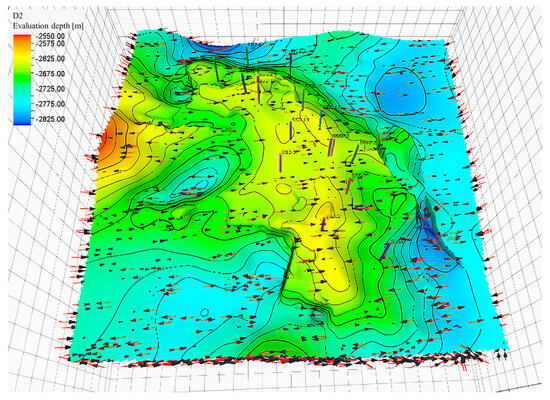

In the pre-construction stress field, the horizontal principal stress increases with depth, but there are significant differences between different geological layers. Due to the spatial distribution of Young’s modulus in the Yc3 volcanic reservoir, the local stress at the same depth is relatively large, while the adjacent grid’s stress decreases, showing a significant “stress arch” effect. The distribution of the maximum horizontal principal stress direction in the cap rock and reservoir of the depleted gas reservoir is shown in Figure 16 and Figure 17, and the direction is basically consistent, mostly in the east-west direction, which is generally consistent with the analysis results of the single−well stress study in the geological data of the reservoir layer.

Figure 16.

Distribution of the maximum horizontal principal stress direction in the stress field of the cap rock before construction.

Figure 17.

Distribution of the maximum horizontal principal stress direction in the stress field of the reservoir before construction.

4.3. Evaluation of the Trap Static Sealing Capacity

4.3.1. Evaluation of the Static Sealing Capacity of Cap Rock

According to the stratigraphic sequence and the main reservoir area of the underground storage in the depleted gas reserve, the cap rock of the gas storage reservoir is the second section of the Denglouku formation, mainly composed of dark purple mudstone and siltstone, with a thickness of 300−400 m. The porosity of the cap rock core of the two pilot test wells ranges from 1.25% to 3.54%, with an average of 2.08%; the permeability ranges from 0.001 mD to 0.018 mD, with an average of 0.004 mD. This indicates that the distribution of the cap rock in the region is stable, thick, and has good sealing properties.

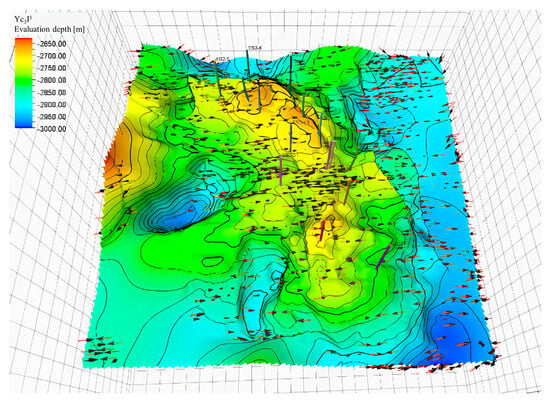

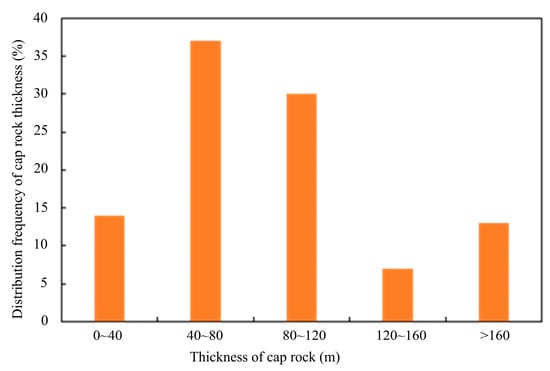

From the perspective of the planar distribution characteristics of the cap rock, the thickness of the cap rock is inverted. The characteristics of the cap rock thickness show the characteristics being thick around the perimeter and thin in the middle. As shown in Figure 18, the cap rock is thick, with the thickness mainly distributed between 40 m and 120 m above the reservoir range of the depleted gas reservoir, with an average of 83 m.

Figure 18.

Characterization of the cap rock of the underground storage in depleted gas reserve.

The results of the mud content inversion of the cap rock indicate a high content, with the majority of the area having a mud content ranging from 50% to 90%.

Meanwhile, the relationship between the measured displacement pressure and the acoustic travel time of the cap rock mudstone. It can be seen that the displacement pressure of the cap rock mudstone mainly ranges from 4 MPa to 7 MPa, indicating a medium-to-good level of quality. Within the gas storage range, the displacement pressure of the D2 formation mainly exceeds 6 MPa, indicating a good sealing property.

In addition, the analysis of the breakthrough pressure test in the pilot test wells also indicates that the breakthrough pressure distribution of the cap rock in well SPKP1 ranges from 6.0 MPa to 20.5 MPa for five samples, while in well SPKP2, the breakthrough pressure distribution ranges from 4.7 MPa to 17.5 MPa for five samples. The cap rock has relatively high breakthrough pressure, indicating good sealing properties.

4.3.2. Evaluation of Static Sealing of Faults

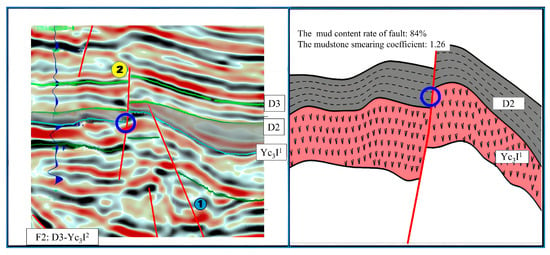

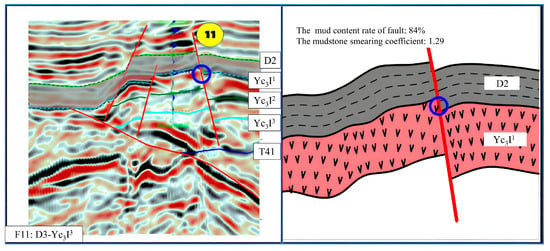

For the lateral sealing of the underground storage in the depleted gas reserve, there are a total of nine faults within the trap structure. The main faults affecting the sealing of the gas storage reservoir are 3 faults: F2, F5, and F11, all of which pass through the reservoir of the Yingcheng formation and the upper cap rock of the D2 formation.

The sealing of fault F2 is shown in Figure 19, where, on the left side of the top reservoir, there is a mudstone juxtaposition with good lateral sealing. The thickness of mudstone in the fault area is 26.1 m, with a vertical displacement of 31.11 m. The calculated mud content rate is 84%, and the mudstone smearing coefficient is 1.26, resulting in good lateral fault sealing.

Figure 19.

Seismic profile of the F2 fault and on both sides juxtaposition relationship.

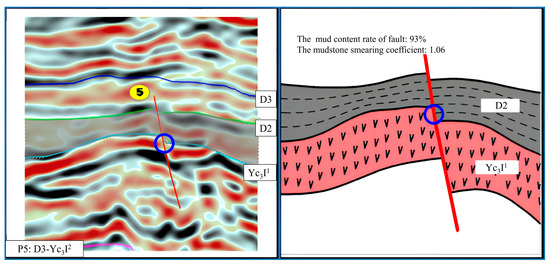

The sealing of fault F5 is shown in Figure 20, where, on the right side of the top reservoir, there is a mudstone juxtaposition with good lateral sealing. The thickness of mudstone in the fault area is 29.58 m, with a vertical displacement of 31.66 m. The calculated mud content rate is 93%, and the mudstone smearing coefficient is 1.09, resulting in good lateral fault sealing.

Figure 20.

Seismic profile of the F5 fault and on both sides juxtaposition relationship.

The sealing of fault F11 is shown in Figure 21, which on the right side of the top reservoir, there is a mudstone juxtaposition with good lateral sealing. The thickness of mudstone in the fault area is 21.67 m, with a vertical displacement of 25.86 m. The calculated mud content rate is 84%, and the mudstone smearing coefficient is 1.29, resulting in good lateral fault sealing.

Figure 21.

Seismic profile of the F11 fault and on both sides juxtaposition relationship.

For the fault F2, F5, and F11, the smearing coefficient of mudstone is less than four, and the mud content rate is greater than 80%, indicating that the underground storage in the depleted gas reserve has good lateral fault sealing.

The vertical sealing performance of the underground storage in depleted gas reserve is mainly evaluated from the aspects of the normal stress on the fault surface, mud content, and displacement pressure. According to the pilot test results, the evaluation indicators for the vertical sealing performance of faults F2, F5, and F11 are shown in Table 4. The results indicate that the normal stress on the fault zone is around 33 MPa to 45 MPa, the mud content in the fault zone is maintained at 80% or above, and the displacement pressure of the fault rock is around 5 MPa, demonstrating the strong vertical sealing performance of the fault zone in the underground gas storage of the depleted gas reservoir.

Table 4.

The evaluation indicators for the vertical sealing performance of faults.

4.4. Evaluation of the Trap Dynamic Sealing Capacity

4.4.1. Evaluation of Dynamic Sealing of the Cap Rock

Based on the 3D stress model, combined with the scheme and results of the pilot test, the dynamic sealing performance of the cap rock is usually described using the shearing safety index during the process of dynamic stress field changes.

where is the shearing safety index of the cap rock; is the cohesion of the cap rock; is the internal friction angle of the cap rock; is the current shearing stress of the cap rock, Pa; is the maximum shearing stress of the cap rock, Pa.

The shearing safety index represents the degree to which the cap rock deviates from the critical shearing failure state of the underground storage in a depleted gas reserve at any given moment. When the index is between 0 and 1, it indicates that the cap rock has not yet experienced shear failure, and the larger the value of the shearing safety index of the cap rock, the smaller the risk of shear failure. When the index is equal to 0, it means that the cap rock of the gas storage has reached the critical shear failure state and is no longer able to continue dynamically storing natural gas in the reservoir layer.

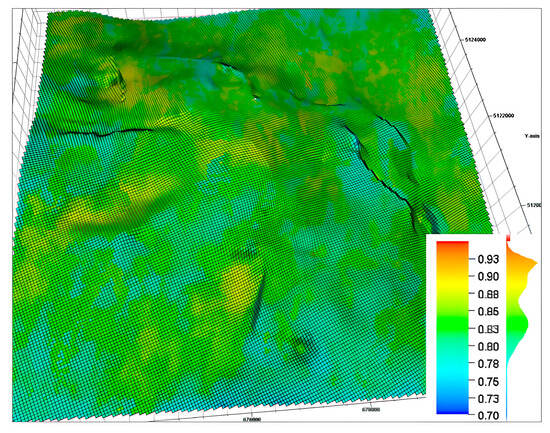

During the dynamic process of changes in the stress field of the underground gas storage in the depleted gas reserve due to natural gas injection and extraction, the stress state with the minimum shearing safety index of the cap rock was selected for analysis. At this time, the distribution of the shearing safety index of the cap rock is shown in Figure 22, with the global shearing safety index ranging from 0.7 to 0.9, far exceeding the critical value required for integrity (considering safety factors, generally around 0.2). From a planar distribution perspective, in the vicinity of faults and locally complex structural areas, due to the concentration or sudden changes in stress, the changes in the shearing safety index are more noticeable, but the cap rock can still maintain a relatively high shearing safety index. This indicates that the underground gas storage in the depleted gas reservoir can still maintain a strong dynamic sealing of the cap rock.

Figure 22.

Shear safety index distribution of direct caprock before reservoir construction.

4.4.2. Evaluation of the Static Sealing Capacity of Cap Rock

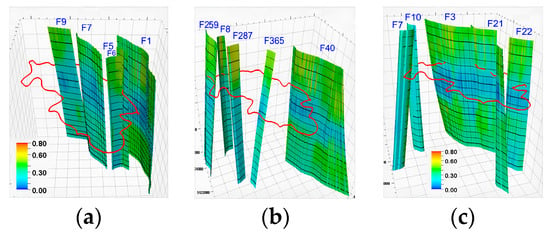

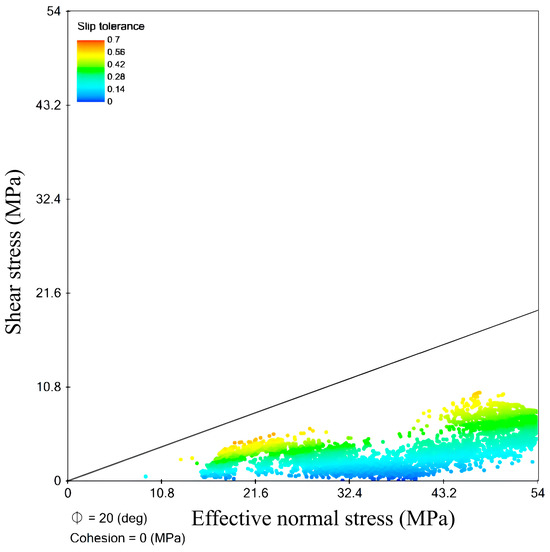

Due to the disturbance of the stress field caused by the cyclic injection and production stage of the underground storage in the depleted gas reserve, when the shear stress applied to the fault exceeds the product of the effective normal stress and the friction coefficient, the fault will undergo unstable slip, ultimately leading to longitudinal seal failure. Therefore, the dynamic sealing performance of the fault is usually described using the fault slip index.

where is the fault slip index; is the tangential stress of fault, Pa; is the effective normal stress of fault, Pa.

The fault slip index represents the degree to which the fault deviates from the critical slip state at any given time in the underground storage in a depleted gas reserve. In geological mechanics research, it is generally considered that the friction coefficient of the fault is 0.6. Therefore, when the fault slip index is less than 0.6, it indicates strong fault stability, and no-slip will occur. However, when the fault slip index exceeds 0.6, the tangential frictional resistance caused by the normal stress cannot balance the tangential stress on the fault, leading to a certain degree of fault slip.

When the designed upper-pressure limit conditions are reached, the distribution of the slip index of various faults is shown in Figure 23a–c. The results indicate that under the current design pressure range, the risk of activation of internal and peripheral fault slips in the underground storage in depleted gas reserves is very low, with an average slip index of only around 0.1. According to the statistical data of the fault grid slip index in Figure 24, it can also be seen that the faults have strong dynamic sealing characteristics.

Figure 23.

The distribution map of the current design upper limit pressure slip index should be listed as: (a) Penetrate through cap rock, reservoir, and layers below the cap rock; (b) Penetrate through cap rock and reservoir; (c) Penetrate through layers below the reservoir.

Figure 24.

The grid slip index statistics of faults.

Considering that the injection phase in the underground storage in depleted gas reserve will continuously increase the formation pressure, analysis the fault activation limit pressure when the fault is in the critical slip state, the activation limit pressure of faults in reservoir segments F1, F3, F4, F5, F6, F10, and F11 are all distributed between 37.9 MPa and 50.6 MPa, with fault F5 having the smallest activation limit pressure. Based on fault activation theory, the analysis of fault-related parameters is shown in Table 5, and the results indicate that the dynamic sealing of faults within the gas-bearing zone and around it, as well as the covering faults, is strong. Thus, the combined static and dynamic evaluation shows that the overall sealing integrity of the fault in the gas reservoir is good, and it meets the conditions for construction.

Table 5.

Statistical table of fault analysis results.

Specifically, based on the dynamic development data of oil and gas reservoirs and geological data of depleted gas reservoirs, we have performed an inversion of a three-dimensional stress model of the underground gas storage before construction. We describe the stress state of the cap rock and reservoir in the underground gas storage before construction. Based on this, we assessed the sealing of the cap rock and faults of the underground storage in depleted gas reserves from both static and dynamic perspectives to further determine the feasibility and sealing of the depleted gas reservoir as an optimal site for underground gas storage. This article did not address the determination of the corresponding operating upper pressure and lower pressure after this inversion of the pre-construction stress state. These operating pressure limits are crucial factors in determining the capacity of natural gas in the underground gas storage during the construction process. In particular, some scholars believe that the upper operating pressure of underground gas storage can exceed the original fluid pore pressure, even up to 140% of the original pore pressure, potentially increasing the gas storage capacity to 400% of the original capacity [37]. Therefore, it is necessary to conduct further research on the maximum limit pressure that exceeds the original reservoir pore pressure under the influence of cyclic loading during subsequent injection and extraction stages, based on rock fatigue damage theory. Furthermore, under these extreme pressure operating conditions, the design of compatible injection and extraction schemes and innovative research and development of surface equipment will also be a future research focus. This will effectively increase the actual operating pressure of underground gas storage and significantly expand the underground gas storage volume.

5. Conclusions

Considering that the underground storage in depleted gas reserves is based on the development of long-exploited depleted gas reservoirs, the original formation parameters from the gas reservoir development phase have become obsolete and cannot accurately describe the actual sealing and gas storage performance of cap rock. Therefore, based on dynamic development data of oil and gas reservoirs and the Study Area and Geological Features, combined with the results of static and dynamic rock mechanical parameter experiments, the rock mechanical attribute model for well points was constructed. Among these, there is a linear correlation between the dynamic and static data of the elastic modulus and Poisson’s ratio, with the dynamic elastic modulus of the reservoir rock generally being greater than its static elastic modulus, and with significant differences in rock lateral expansion characteristics. For different lithological formations, the static elastic modulus of the volcanic rock in the Yingcheng formation is relatively consistent with that of the sandstone, siltstone, and mudstone of the Denglouku formation when the dynamic elastic modulus is 43.91 MPa or the Poisson’s ratio is 0.1978. However, due to the differences in dynamic elastic modulus and dynamic Poisson ratio between the two lithologic strata, the static elastic modulus of the volcanic rock in the Yingcheng formation is significantly larger than that of the sandstone, siltstone, and mudstone of the Denglouku formation, the Yingcheng formation has better lithostatic mechanical strength and can serve as the primary gas storage space for the underground gas reservoir. Additionally, the 3D stress model of the current formation stress state was inverted to the stress state of the depleted gas reservoir before construction, describing the dynamic evolution process of the sealing and gas storage performance of the depleted cap rock and reservoir. The results show that the maximum horizontal principal stress in the cap and reservoir of the underground storage in depleted gas reserve before construction is distributed between 48–76 MPa and 50–85 MPa, respectively. Furthermore, the local stress of the volcanic rock reservoir in the Yingcheng formation is relatively high, while the stress of the adjacent grid decreases at the same depth, there is a significant “stress arch” effect, and the direction of the maximum horizontal principal stress in the cap rock and reservoir is nearly east-west.

Furthermore, the sealing of the cap rock and faults of the underground storage in depleted gas reserves was assessed from both static and dynamic perspectives. The results indicate that the cap layer has a higher breakthrough pressure, and the faults of F2, F5, and F11 exhibit strong lateral and vertical sealing performance, demonstrating excellent static sealing performance. According to the dynamic stress field change process, the global cap rock shearing safety index is between 0.7 and 0.9, and the average fault slip index is only about 0.1, which indicates strong dynamic sealing performance and is suitable for construction as a gas storage, thereby realizing the dynamic evaluation of sealing and site optimization for underground gas storage in depleted gas reserve, providing guarantee for the safe and stable operation of its subsequent expansion, multi-cycle injection and production.

Author Contributions

X.Z.: investigation, resources, writing—original draft; J.H.: methodology, validation, writing—editing; C.W.: investigation, resources, writing—review; J.W.: methodology, investigation; H.X.: conceptualization, funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This work presented in this paper was financially supported by the National Natural Science Foundation of China (Grant No. 52074090) and the Key Research & Development Program of Heilongjiang Province (Grant No. JD22A004).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available from the corresponding author by request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- BP Statistical Review of World Energy. Available online: https://www.bp.com/en/global/corporate.html (accessed on 26 June 2022).

- Mountourakis, F.; Papazi, A.; Kotzabasis, K. The Microalga Chlorella vulgaris as a Natural Bioenergetic System for Effective CO2 Mitigation-New Perspectives against Global Warming. Symmetry 2021, 13, 997. [Google Scholar] [CrossRef]

- Liu, Y.; Xue, Y.K.; MacDonald, G.; Cox, P.; Zhang, Z.Q. Global vegetation variability and its response to elevated CO2, global warming, and climate variability—A study using the offline SSiB4/TRIFFID model and satellite data. Earth Syst. Dyn. 2019, 10, 9–29. [Google Scholar] [CrossRef]

- Kawahata, H.; Fujita, K.; Iguchi, A.; Inoue, M.; Iwasaki, S.; Kuroyanagi, A.; Maeda, A.; Manaka, T.; Moriya, K.; Takagi, H.; et al. Perspective on the response of marine calcifiers to global warming and ocean acidification-Behavior of corals and foraminifera in a high CO2 world “hot house”. Prog. Earth Planet. Sci. 2019, 6, 1–37. [Google Scholar] [CrossRef]

- Bastami, M.S.B.; Jones, D.L.; Chadwick, D.R. Reduction of Methane Emission during Slurry Storage by the Addition of Effective Microorganisms and Excessive Carbon Source from Brewing Sugar. J. Environ. Qual. 2016, 45, 2016–2022. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.Z.; Liu, S.X. How Do FDI and Technological Innovation Affect Carbon Emission Efficiency in China? Energies 2022, 15, 9209. [Google Scholar] [CrossRef]

- Ostergaard, P.A.; Duic, N.; Noorollahi, Y.; Kalogirou, S. Renewable energy for sustainable development. Renew. Energy 2022, 199, 1145–1152. [Google Scholar] [CrossRef]

- Shrestha, A.; Mustafa, A.A.; Htike, M.M.; You, V.; Kakinaka, M. Evolution of energy mix in emerging countries: Modern renewable energy, traditional renewable energy, and non-renewable energy. Renew. Energy 2022, 199, 419–432. [Google Scholar] [CrossRef]

- Ostergaard, P.A.; Duic, N.; Noorollahi, Y.; Kalogirou, S.A. Recent advances in renewable energy technology for the energy transition. Renew. Energy 2021, 179, 877–884. [Google Scholar] [CrossRef]

- Molíková, A.; Vítezová, M.; Vítez, T.; Buriánková, I.; Huber, H.; Dengler, L.; Hanisáková, N.; Onderka, V.; Urbanová, I. Underground gas storage as a promising natural methane bioreactor and reservoir? J. Energy Storage 2021, 47, 1036310. [Google Scholar] [CrossRef]

- Fu, Y. Reconstructing depleted fractured oil reservoirs into underground natural gas storages with the consideration of the effect of molecular diffusion and medium deformation on the dynamic performances. Arab. J. Geosci. 2020, 13, 122. [Google Scholar] [CrossRef]

- Liao, W.; Liu, G.L.; Chen, R.H.; Sun, J.C.; Zhang, S.J.; Wang, Y.S.; Liu, X.S. Evaluation on the dynamic sealing capacity of underground gas storages rebuilt from gas reservoirs: A case study of Xinjiang H underground gas storage. Nat. Gas Ind. B 2021, 8, 334–343. [Google Scholar] [CrossRef]

- Jin, Z.J.; Yuan, Y.S.; Sun, D.S.; Liu, Q.Y.; Li, S.J. Models for dynamic evaluation of mudstone/shale cap rocks and their applications in the Lower Paleozoic sequences, Sichuan Basin, SW China. Mar. Petrol. Geol. 2014, 49, 121–128. [Google Scholar] [CrossRef]

- Lamarche, J.; Lavenu, A.P.C.; Gauthier, B.D.M.; Guglielmi, Y.; Jayet, O. Relationships between fracture patterns, geodynamics and mechanical stratigraphy in Carbonates (South-East Basin, France). Tectonophysics 2012, 581, 231–245. [Google Scholar] [CrossRef]

- Ingram, G.M.; Urai, J.L.; Naylor, M.A. Sealing processes and top seal assessment. Nor. Pet. Soc. Spec. Publ. 1997, 7, 165–174. [Google Scholar] [CrossRef]

- Fu, X.F.; Wu, T.; Lv, Y.F.; Liu, S.B.; Tian, H.; Lu, M.X. Research status and development trend of the reservoir caprock sealing properties. Oil Gas Geol. 2018, 3, 454–471. [Google Scholar] [CrossRef]

- Bailey, W.R.; Underschultz, J.; Dewhurst, D.N.; Kovack, G.; Mildren, S.; Raven, M. Multi-disciplinary approach to fault and top seal appraisal; Pyrenees-Macedon oil and gas fields, Exmouth Sub-basin, Australian Northwest Shelf. Mar. Petrol. Geol. 2006, 23, 241–259. [Google Scholar] [CrossRef]

- Heath, J.E.; Dewers, T.A.; McPherson, B.J.O.L.; Nemer, M.B.; Kotula, P.G. Pore-lining phases and capillary breakthrough pressure of mudstone caprocks: Sealing efficiency of geologic CO2 storage sites. Int. J. Greenh. Gas Control 2012, 11, 204–220. [Google Scholar] [CrossRef]

- Armitage, P.J.; Faulkner, D.R.; Worden, R.H. Caprock corrosion. Nat. Geosci. 2013, 6, 79–80. [Google Scholar] [CrossRef]

- Ingram, G.M.; Urai, J.L. Top-seal leakage through faults and fractures: The role of mudrock properties. Geol. Soc. 1999, 158, 125–135. [Google Scholar] [CrossRef]

- Fu, X.F.; Jia, R.; Wang, H.X.; Wu, T.; Meng, L.D.; Sun, Y.H. Quantitative evaluation of fault-caprock sealing capacity: A case from Dabei-Kelasu structural belt in Kuqa Depression, Tarim Basin, NW China. Petrol. Explor. Dev. 2015, 3, 300–309. [Google Scholar] [CrossRef]

- Lin, J.P.; Jia, S.P.; Liu, T.H.; Yan, A.H.; Xi, Z.Q. Comprehensive Evaluation of Sealing Ability of Mudstone Cap Rock for Xing 9 Depleted Gas Reservoir in Reconstructing Underground Gas Storage. J. Rock Mech. Eng. 2015, 34, 4099–4107. [Google Scholar]

- Gong, L.; Gao, S.; Fu, X.F.; Chen, S.M.; Lyu, B.Y.; Yao, J.Q. Fracture characteristics and their effects on hydrocarbon migration and accumulation in tight volcanic reservoirs: A case study of the Xujiaweizi fault depression, Songliao Basin, China. Interpretation 2017, 4, SP57–SP70. [Google Scholar] [CrossRef]

- Feng, Z.H.; Yin, C.H.; Lu, J.M.; Zhu, Y.K. Formation and accumulation of tight sandy conglomerate gas: A case from the Lower Cretaceous Yingcheng Formation of Xujiaweizi fault depression, Songliao Basin. Petrol. Explor. Dev. 2013, 40, 696–703. [Google Scholar] [CrossRef]

- Lu, J.M.; Yang, L.; Zhu, Y.K.; Sun, L.D.; Lu, S.F.; Zhang, P.F.; Zou, N.W.; Lin, Z.Z. Pore Structure and Multifractal Characteristics of Overmature Continental Shale: A Case Study from the Xujiaweizi Fault Depression, Songliao Basin, China. Geofluids 2022, 2022, 3539482. [Google Scholar] [CrossRef]

- Zhang, E.H.; Jiang, C.J.; Zhang, Y.G.; Li, Z.A.; Feng, X.Y.; Wu, J. Study on the formation and evolution of deep structure of Xujiaweizi fault depression. Acta Petrol. Sin. 2010, 26, 149–157. [Google Scholar]

- Feng, Z.Q.; Jia, C.Z.; Xie, X.N.; Zhang, S.; Feng, Z.H.; Cross, T.A. Tectonostratigraphic units and stratigraphic sequences of the nonmarine Songliao basin, northeast China. Basin Res. 2010, 22, 79–95. [Google Scholar] [CrossRef]

- Meng, Q.A.; Li, C.B.; Bai, X.F.; Zhang, W.J.; Xue, T.; Peng, J.L.; Tang, Z.G. Petroleum exploration history and enlightenment in the northern Songliao basin. Xinjiang Pet. Geol. 2021, 42, 264–271. [Google Scholar]

- Cai, Z.R.; Huang, Q.T.; Xia, B.; Lu, B.F.; Liu, W.L.; Wan, Z.F. Development features of volcanic rocks of the Yingcheng Formation and their relationship with fault structure in the Xujiaweizi Fault Depression, Songliao Basin, China. Petrol. Sci. 2012, 9, 436–443. [Google Scholar] [CrossRef]

- He, C.Y.; Lin, Y.N.; Zhang, T.Z.; Ma, J.S.; Li, Y.F.; Cheng, J.J.; Zhang, Y.D. Study on the structural characteristics of the Yangdachengzi oil layer in the Quantou Formation, ZY block, central depression, Songliao Basin. Front. Earth Sci. 2023, 11, 251–296. [Google Scholar] [CrossRef]

- Zhang, S.C.; Zhang, B.; Wang, X.M.; Feng, Z.H.; He, H.; Wang, H.J.; Fu, X.L.; Liu, Y.K.; Yang, C.L. Gulong shale oil enrichment mechanism and orderly distribution of conventional-unconventional oils in the Cretaceous Qingshankou Formation, Songliao Basin, NE China. Petrol. Explor. Dev. 2023, 50, 1045–1059. [Google Scholar] [CrossRef]

- He, D.; Li, J.H.; Liu, S.J. Volcanic edifice types and eruption model of Yingcheng Formation, Lower Cretaceous, in Xujiaweizi fault depression, northern Songliao Basin. Acta Petrol. Sin. 2009, 25, 659–666. [Google Scholar]

- Liu, G.P.; Zeng, L.B.; Sun, G.Q.; Zu, K.W.; Qin, L.B.; Mao, Z.; Mehdi, O. Natural fractures in tight gas volcanic reservoirs and their influences on production in the Xujiaweizi depression, Songliao Basin, China. AAPG Bull. 2020, 104, 2099–2123. [Google Scholar] [CrossRef]

- Lyu, X.Y.; Yun, L.; Xu, J.G.; Liu, H.; Yu, X.N.; Peng, P.; Ouyang, M.K.; Luo, Y. Sealing capacity evolution of gypsum salt caprocks under multi-cycle alternating stress during operations of underground gas storage. J. Petrol. Sci. Eng. 2023, 220, 147–192. [Google Scholar] [CrossRef]

- Xue, T.; Liu, Y.X.; Yang, X.F.; Liu, J.Y. A study on the features of fractures in the volcanic reservoirs of Shengping gas field. Nat. Gas Ind. B 2009, 29, 12966. [Google Scholar] [CrossRef]

- Ma, X.; Zheng, D.; Shen, R.; Wang, C.; Luo, J.; Sun, J. Key technologies and practice for gas field storage facility construction of complex geological conditions in China. Petrol. Explor. Dev. 2018, 45, 489–499. [Google Scholar] [CrossRef]

- Castelletto, N.; Ferronato, M.; Gambolati, G.; Janna, C.; Marzorati, D.; Teatini, P. Can natural fluid pore pressure be safely exceeded in storing gas underground? Eng. Geol. 2013, 153, 35–44. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).