1. Introduction

Wildfires and resultant forest disturbances have become common globally, and their scale and severity have increased since the beginning of the 2000s [

1,

2,

3,

4]. This has mostly been attributed to climate change and sudden regional weather phenomena, such as droughts and heat loads during summer seasons, but partly due to human behavior and machine work activities in nature and the built environment [

5,

6,

7,

8,

9,

10]. Most wildfires, with respect to the overwhelmingly largest areas, have been in the Russian Federation, Canada, the U.S. West, Australia, and Mediterranean countries [

2].

In Finland, the forest fire incidence level is very low [

3]. For example, 470 hectares of land damaged by forest fires was reported in 2017, and the benchmark of over 1000 hectares was destroyed only in 2006 [

11]. There is a short span of seasons when forests are vulnerable to fire, ranging from May to September, with June and July remaining as the peak periods; relatively cool and rainy summers, high forest and second-home road densities, and efficient aerial fire control and prevention have contributed to the low incidence rate [

12]. However, with climate change causing drought periods during summer, more trees suffering and drying from bark beetle damage, and the practice of leaving standing and wind-fallen trees for biodiversity management after final harvesting, vulnerability to fires is predicted to increase in the coming decades [

13].

The forest stand structure and site, tree species, and fire intensity largely determine the consequences for trees and their probability of surviving a forest fire [

7,

14,

15]. A dense stand, dry site, small diameter, thin bark, and large crown have been observed to lead to a high mortality of trees [

5,

6,

7,

8,

9,

10]. Owing to fire, drying that results in checking may occur in sapwood if the bark deteriorates first; additionally, notable charring and grayish discoloration occur because of char and soot, but the heartwood should remain essentially unchanged [

6,

8,

12,

15,

16]. In wood material, drying starts slowly due to direct heating at a temperature as low as 20–100 °C; thereafter, the rate increases, and the intensity multiplies [

17]. Chemical transformation affecting the physico-mechanical properties starts at 50–100 °C with the decomposition of certain extractives, and the major changes begin at 160–180 °C with the decomposition of hemicelluloses and above 250 °C with lignin [

18]. Physical changes start above 150 °C with a decrease in the equilibrium moisture content and a reduction in hygroscopicity, absorbability, and surface activity; these changes continue and later cause an increase in dimensional stability, color changes, and a decrease in some mechanical properties [

17,

18,

19].

Few studies have considered the effects of forest fires on the physico-mechanical properties of wood or wood products. No effects on density or shrinkage properties have been found in the wood of loblolly pine in Brazil [

20] or maritime pine in Portugal [

21]. However, significant reductions in the bending properties (the modulus of rupture, MOR, and the modulus of elasticity, MOE), compression strength, and toughness values have been observed for loblolly pine when flames consume the total crown, and the compression strength has been shown to be reduced when the crown is partially consumed [

20]. Maritime pine wood showed a similar response in a severe forest fire, but the reduction in the properties was traced more to biological degradation due to prolonged wood harvesting than the fire [

21]. Fire effects on physico-mechanical properties and chemical composition do not cause sufficient chemical degradation or strength reduction, which would cause the rejection of these woods for commodity uses of mechanical wood processing; however, in structural uses, caution should be taken for wood from trees that have been fully or partially consumed by fire. In Uganda, Caribbean pine wood from 10-year-old burned trees has a significantly lower density, MOE, and MOR than wood from unburned trees, and it should not be used for high-strength structural purposes but rather in low-strength construction works, such as shuttering and ceilings [

22].

Both the direct and indirect effects of forest fire are present in wood salvaged from fire areas, and their nature and severity depend on the time between the fire and harvesting [

5,

14,

16]. Trees with lowered vitality are susceptible to insect and microbial attacks and wind falls; the resultant wood defects lower the basic quality of sawn timber and veneer-based products but do not ruin their potential use. The susceptibility varies a lot between individual forest stands, but the following generalizations have been presented [

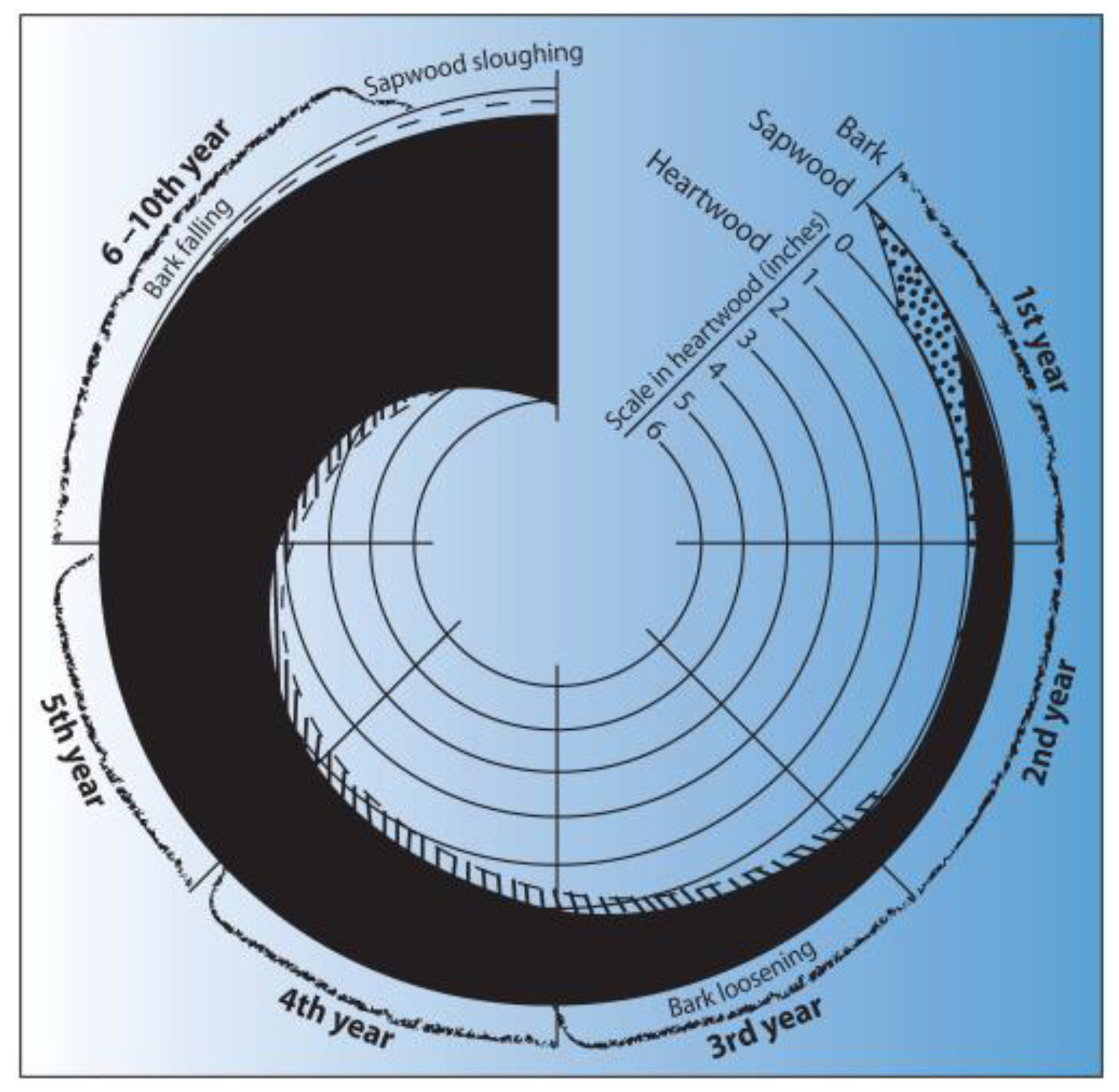

16,

23]: (1) blue stain occurs in the first year after the fire, lowering the visual quality; (2) heartwood starts to decay, and the deterioration of sapwood accelerates in the second year, reducing the quality for high-strength products; and (3) the sapwood of most coniferous species is unworthy for any construction purpose three years after the fire. The types and rates of deterioration of burned wood after forest fires in North America are illustrated in

Figure 1.

In practice, wood salvaged from forest fire areas has been allocated to either bioenergy or low-grade sawn timber; in North America, some wood has also been allocated to laminated veneer lumber (LVL) [

16,

24,

25,

26]. The suitability of burned wood has also been studied for oriented strand board (OSB) and medium-density fiberboard (MDF) [

27,

28]. Burned wood is not accepted for pulp, paper, or paperboard processes or products due to char and soot [

28]. In North America, burned timber has been posited to still be usable for sawn timber if the logs are harvested within two years after the fire [

29], but other sources claim that harvesting should be done at the latest one year after the fire to recover the full economic benefits of such logging [

30,

31]. In Finland, the Forest Damage Prevention Act suggests that forest-damaged trees should be harvested from the forest if their volume exceeds 10 or 20 m

3/ha for Norway spruce or Scots pine, respectively, counting trees with a stump diameter of more than 10 cm [

32].

The objective of this study was to investigate the raw material potential of sawn wood and to select further processed products of Norway spruce and Scots pine sawn log trees from salvage harvesting in forest fire areas with northern European climatic conditions by comparing selected physical and mechanical properties of fire-affected trees and virgin reference trees. The effects of fire on the MOE, MOR, Brinell hardness (HB), moisture gradient, and wood color (CIE L*a*b*) were studied on clear wood specimens of outer sapwood and inner heartwood, and linear mixed models were constructed to analyze the sources of variation. Recommendations are provided for sawmill managers, further processors, and forest owners on wood allocation and potential products from forest fire areas in Finland.

2. Materials and Methods

Wood samples of forest fire trees were collected from burned stands of Norway spruce and Scots pine in an area of 227 hectares in Kalajoki, Western Finland (64°00′15.0″ N 24°08′09.0″ E), in November 2021, four months after the fire in July 2021. In Kalajoki, flammability was high before the fire. The local temperature was 27 °C, and the air humidity was 44% on the first day of the fire, 26 July 2021. The wind speed was 3.5 m/s, and in gusts, it was 9–10 m/s. In the beginning, the fire spread 2–3 m/min, and at its highest, the rate of spread was 15–20 m/min. The fire reached the entire area in two and a half days (until 28 July 2021), and in its most intense phases, it spread into forests as a crown fire [

33].

The studied stands are presented in

Figure 2 and

Figure 3. The samples of the reference trees were collected simultaneously from stands located near the fire area in Kalajoki and supplemented with trees in February 2022 from Raahe (64°23′36.8″ N 25°03′01.8″ E) to obtain comparable reference data in terms of tree age and diameter.

The stems of the burned trees and reference trees were cut in the forest into 4 m logs up to a top diameter of about 10 cm, which is close to the commercial minimum diameter of small-diameter logs. Four normal-sized log burned trees (diameter at breast height, DBH, about 25–30 cm) and four small-log burned trees (DBH, about 14–18 cm) of both Norway spruce and Scots pine were selected, and the total number of logs with references was 24 (

Table 1). Before the cut, the length of the area damaged by the fire was measured on the burned trees based on the signs visible on the bark in two ways: (1) by considering the entire circumference of the stem, i.e., the shell surface burned, and (2) by considering all clear signs of the effects of the fire on the bark of the stem. From each 4 m log, a block of approximately 60 cm was further cut as the material to be used in physical and mechanical tests. The blocks (total number of 72) represented the butt, middle, and top logs.

In the case of spruce, the diameters and lengths of the burned and reference trees were comparable, but the normal-sized log burned trees were younger than the reference trees (

Table 2). For pine, the lengths and diameters of the burned and reference trees were comparable, but the burned trees were slightly older than the reference trees.

Sixty-centimeter blocks were through and through sawn with a band saw in Joensuu in February 2022. A 60 mm thick pith-centered balk from each block was sawn towards the surface, totaling 72 balks for further tests. If there were visually noticeable differences in the intensity of the burning on different sides of the block, the direction of sawing was set in such a way that the most heavily burned area (the more damaged side) of the stem was placed on one edge of the pith-centered balk. The slightly burned area (the less damaged side) was placed on the opposite edge of the balk. The sawing direction was set for the reference blocks and the blocks that were burned entirely around the circumference to minimize knots and other defects in the final balks.

The balks were stored at room temperature (around 20 °C) for one week. The top end was trimmed with a blade saw from each balk (length of 60 cm); one cross-sectional slice was sawn to determine bark thickness, basic density, and moisture content; and two slices (thickness of 10 mm) were sawn for annual ring and chemical analyses.

The ring width was, on average, larger in the burned trees than in the reference trees, excluding the top and middle logs of Scots pine, indicating the somewhat younger age of the burned trees. The bark was generally thin in all materials, partly because of the multiple handling of logs and balk during sampling. As expected, the bark was thinner in the burned trees than in the reference trees for both species. Among the butt logs, the bark was thicker for Scots pine than for Norway spruce but thinner in the middle and top logs. A large ring width may indicate tree vitality and recovery ability after a fire. Thick bark before the fire may indicate a high protective capacity against the fire, while thin bark after the fire may indicate its large reductive and devastating effects. The variations in ring width and bark thickness in the data are described in

Table 3. Before the preparation of the mechanical test specimens, the bark and outer branches were removed with a precision circular table saw from the outer faces of the remaining part of each balk (approximate length of 55 cm). Subsequently, the balks were planed on flat sides to a 60 mm thickness, and bars of 60 × 30 mm (tangential × radial) were sawn in the longitudinal direction from the outer faces (sapwood section) and the core of 10–15 annual rings from the pith (heartwood section). It was hypothesized that the effect of the fire was at its highest in the sapwood pieces, which were located immediately close to the bark. The nominal number of bars was 288.

The bars, coded with marks on the outer faces, were conditioned for 7–8 days in a weather chamber (60 °C, RH 45%). Subsequently, the bars were slightly planed on both sides. A piece of 340 mm was cut and planed from the pith side to a thickness of 20 mm. The samples were finished with a dual-blade circular saw to standard test specimens (20 × 20 × 340 mm) for determining the bending properties of clear wood (

Table 4). The specimens were conditioned under standard conditions (20 °C, RH 65%) to reach a moisture content of 12% (dry weight basis). From the remaining parts of the bars, specimens for the HB test (60 × 28.5 × 90 mm) and CIE L*a*b* color analysis (30 × 20 × 60 mm) were prepared.

For the mechanical tests, the air-dry density was determined for each specimen according to ISO standard 13061-2 [

34]. The MOE (

, GPa) and the static bending strength, the MOR (

, MPa), were determined using a three-point bending test in the tangential direction according to standards ISO 13061-4 and ISO 13061-3, respectively [

35,

36]. Flexural stress (

, MPa) and strain (

, %) were calculated according to standard ISO 178 [

37]:

where

P is the difference between the higher load and the lower load (N);

l is the span (mm);

b is the specimen width (mm);

h is the specimen height (mm);

f is the deflection (mm);

Pmax is the maximum load (N); and

Pappl is the applied load (N).

Stored energy (

, MJ/m

3) at maximum stress was calculated using the following formula:

where

is the strain at maximum stress.

The moisture content of the samples was determined after each mechanical test and oven drying, and it was calculated on a dry weight basis, according to ISO standard 13061-1 [

38]. The samples were weighed, dried at 103 °C for 24 h, and weighed dry. On average, the moisture content was 9.9% in pine samples and 10.7% in spruce samples. An approximate adjustment of the MOE and MOR to 12% moisture content was performed according to the given ISO standard.

HB was determined under air-dry conditions following standard EN 1534 [

39]. A force of 1 kN was applied to a steel ball with a contact radius of 10 mm. In the test, defect-free spots from the outer edge of the sample were chosen.

where

HB is the Brinell hardness (N/mm²);

F is the maximum load force (N);

D is the diameter of the ball (mm);

d is the diameter of the residual indentation (mm); and

h is the depth of the residual indentation (mm). The MOE, MOR, and HB were determined using the universal material testing machine Zwick Z050 (ZwickRoell GmbH, Ulm, Germany; maximum load of 50 kN).

Variations in basic density and moisture content variation, called the moisture gradient, were determined starting from the 72 battens, which were sawn in the radial direction from the cross-sectional slices (see before). The samples were stored in airproof plastic bags. From each batten, 2–4 cubes (dimensions of 20 × 20 × 20 mm) were sawn between the pith and bark, with the number of cubes depending on the diameter of the original log. The first cube was always taken immediately under the bark, and the following cubes were taken towards the pith at a distance of 20 mm each. If the log diameter did not allow for a 20 mm distance between the third and fourth cubes, the fourth cube was taken with a smaller distance from the third cube. The basic density and moisture gradient were determined from the same samples. The basic density of wood (kg/m

3) was determined using the oven-dry method, according to standard ISO 13061-2 [

34].

A color analysis was performed on HB specimens according to standard ISO/CIE 11664-4 [

40] with a portable spectrophotometer (Konica Minolta 2600d, Osaka, Japan). In the CIELAB color space, L* indicates lightness from black to white, a* represents the red/green coordinate, and b* represents the yellow/blue coordinate. Two measurements were taken from each specimen on its outer edge. The specimens were conditioned in a weather chamber approximately 1 week before the measurements. The color difference between the reference trees and burned trees was calculated using the CIE76 color difference formula:

where

is the color difference, and

,

, and

are the differences in the corresponding CIELAB coordinates.

Descriptive statistics of the density and mechanical properties and the Pearson correlation between them are reported. Linear mixed-effect models (LMMs) were used to determine the variability in the mechanical properties, moisture gradient, color, and effects of selected factors on them:

where

is the modulus of elasticity (GPa), modulus of rupture (MPa), or Brinell hardness (N/mm²);

is the moisture content (%);

is the CIELAB color coordinate

,

, or

;

is the intercept;

is the fire damage class;

is the height class;

is the dummy term of the radial position (sapwood);

is the air-dry density (kg/m

3);

is the basic density (kg/m

3);

is the interaction term of the radial position and air-dry density;

is the interaction term of the fire damage class and radial position;

is the interaction term of the radial position and basic density;

is the random stand effect;

is the random tree effect; and

is the random error term.

The LMM allows for the inclusion of dependent fixed effects (such as fire damage and radial position) and more than one source of random variation (such as tree and stand-level effect) in the model [

41]. The fire damage class was included as a fixed factor in all models. The linear mixed-effects model (MIXED) procedure in IBM SPSS Statistics fits the model to the data. Normal probability distributions were tested and therefore assumed in the models. The accuracy of the predictions of the linear model was determined by calculating the proportion of explained variance (R²), bias, and root mean square error (RMSE) using only the fixed effects. The relative bias (bias, %) and relative error (RMSE, %) were calculated by dividing the bias and RMSE by the mean of the measured values.

4. Discussion

Due to the global increase in forest fires during the 2000s, the direct and indirect damage that deteriorates raw wood materials has become more frequent in tree stock, resulting in challenges in the allocation of salvaged wood to the roundwood market and profitable utilization in forest industries [

3,

16,

24]. The risk increase is not only commonly traced to climate change, regional droughts, and heat loads but also to human behavior and working with machines in nature and the built environment [

5,

6,

7,

8,

9,

10].

The data from this study represent a typical forest fire in Finland in terms of vastness, intensity, and season. According to our visual observations in the studied stands, the mortality of trees and fire patterns were consistent with previous findings in practical forestry. Based on the crown’s status, most spruces were judged as dead or dying, whereas almost all pines remained living. The vertical length of the fire effect, starting from the base of the tree, was relatively short, with values of 9% for spruce and 12% for pine when the bark was required to have burned for the entire circumference, but the values were as high as 39% for spruce and 20% for pine when any signs of the fire effect were considered on bark. In a study on two forest stands in northern Europe, 20% of Scots pine trees survived in a heavy forest fire, with the proportion reaching 50% for trees with a DBH of 20 cm or more if the fire remained at a low height and below the living crown, whereas 99% of Norway spruce trees and 98% of broadleaved trees died [

42].

Our results show that fire damage had only minor or no significant effects on the wood properties studied, evident only in sapwood. The changes in wood properties were more substantial in spruce than in pine, presumably because of the thinner bark, especially in the lower parts of the trees, that protects wood less from deterioration, and the longer crown that accelerates the spread of fire in the middle and top parts of trees [

12,

15,

23,

42].

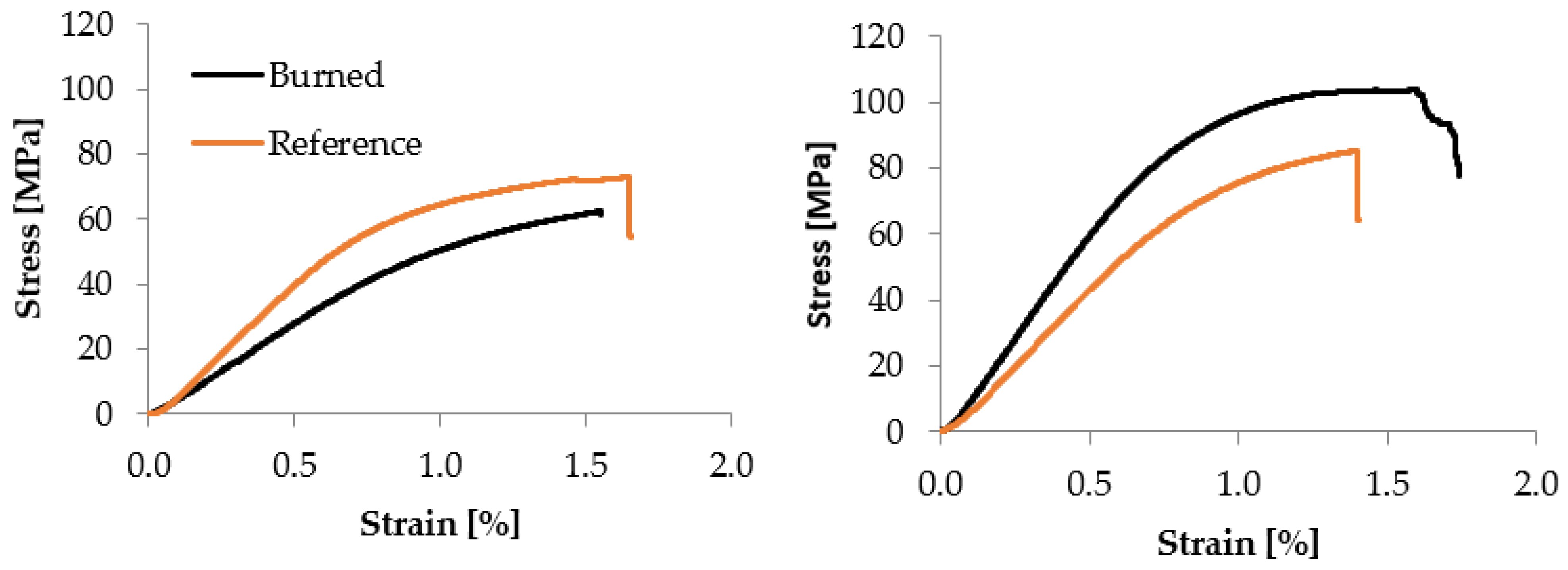

In the mechanical tests, the physical properties and position of a tree explained most of the variation in wood properties. As expected, wood density proved to be the strongest predictor by far, followed by height location and the radial position. The fire damage class of trees at respective heights was identified as a significant factor only for the MOR in Scots pine (decrease) and for HB in Norway spruce (increase). In general, the models obtained were more accurate in predicting the mechanical properties of Scots pine. In Norway spruce, the bias and variation by random effects were relatively high, and the R2 values were relatively low. This indicates that only some of the essential factors in modeling the bending properties of spruce are recognized. In flexural strain at maximum force, no clear differences were detected between the burned and the reference trees. In spruce logs, flexural strain decreased towards the top, but in pine, the lowest values were observed in the middle logs.

In studies on Brazilian loblolly pine and Portuguese maritime pine, where the forest fire intensities were heavier than in our study, more substantial effects on wood properties were observed. The consumption of the full crown of loblolly pine by fire led to a decrease in the MOE and MOR in static bending by 17% and 12%, respectively, in addition to decreases in ultimate stress and stress at the proportional limit in parallel compression by 19% and 34% and the resilience coefficient for toughness by 17% [

20]. Similar reductions in these properties have been observed for maritime pine, albeit associated with reductions in biological degradation because of harvest 5–7 months after the fire [

21]. The effect of the biological and chemical degradation of wood translates into changes in viscoelastic behavior [

43].

Clear positive correlations between density and mechanical properties were noted in our study, as in numerous previous studies [

44,

45]. In sapwood (mature wood), the mechanical properties were also higher than in heartwood (juvenile wood), particularly in pine. Structural differences between the mature wood and juvenile wood of softwoods have been reported in several compilation works [

45,

46,

47].

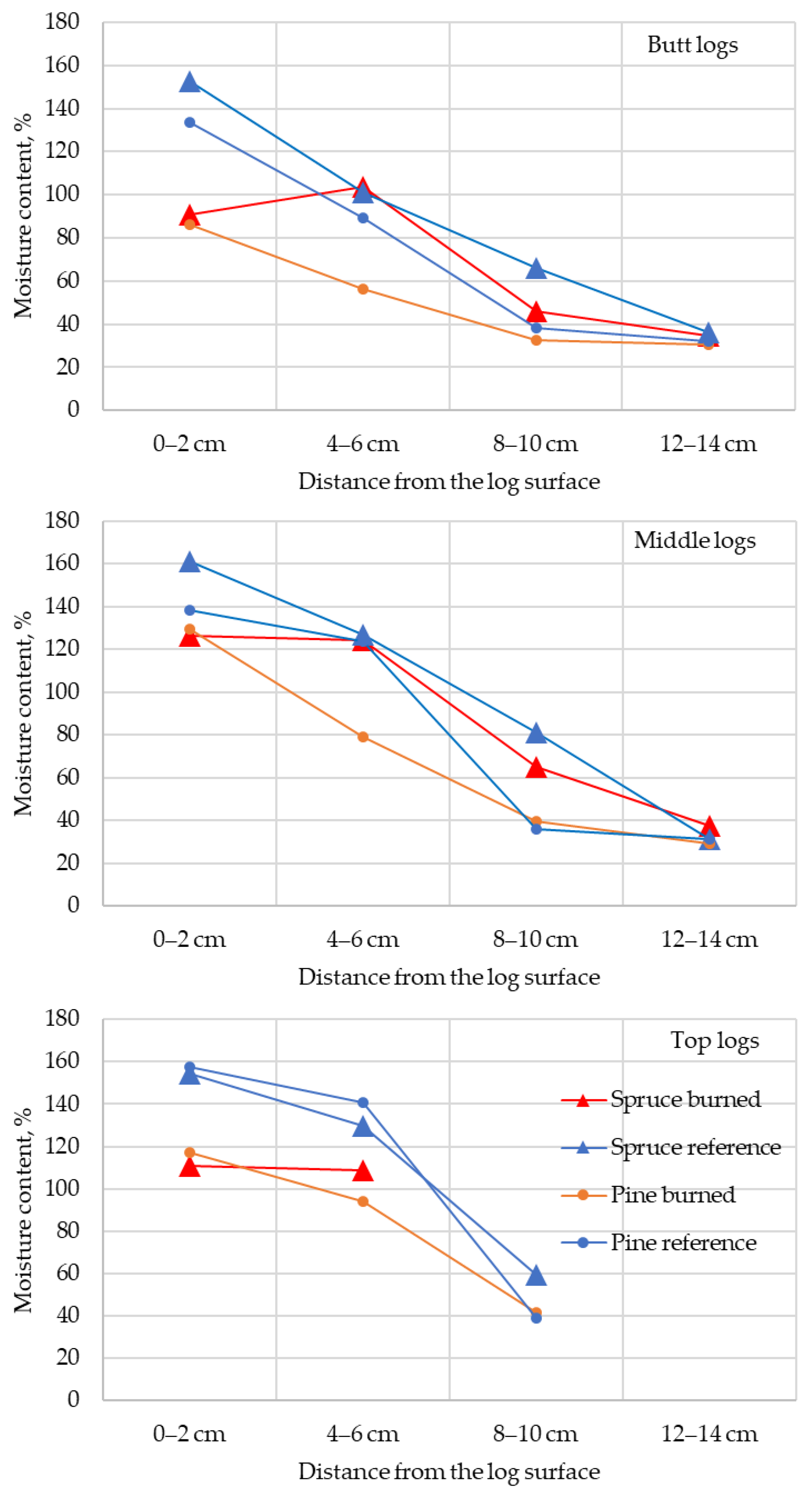

Forest fire caused a decrease in the moisture content in spruce sapwood due to its thin bark and partly dead wood (high mortality of trees). The moisture gradient between sapwood and heartwood after the fire was larger in pine wood than in spruce. The radial position and basic density had significant effects on the moisture content. Density and the moisture content were partially negatively correlated for pine but not for spruce. In both species, the moisture content decreased from the butt to the top. When modeling the moisture content, the RMSE values were relatively high in both species, and the model’s explanatory power was higher in Scots pine. The slight difference in harvesting time may have influenced the moisture content difference between the burned trees and reference trees, with the former being harvested in November and the latter in February (except for small-log spruce trees). In Northern Europe, the moisture content of spruce and pine is the highest in the middle of winter and usually 2–4% lower in November than in February [

48,

49].

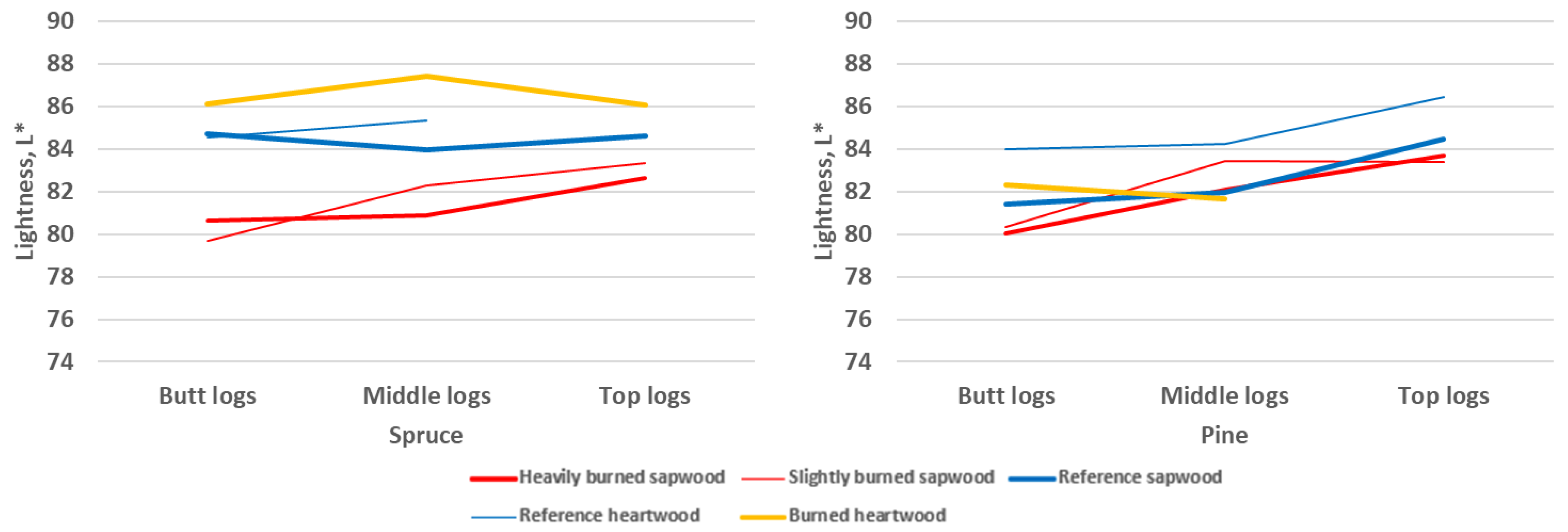

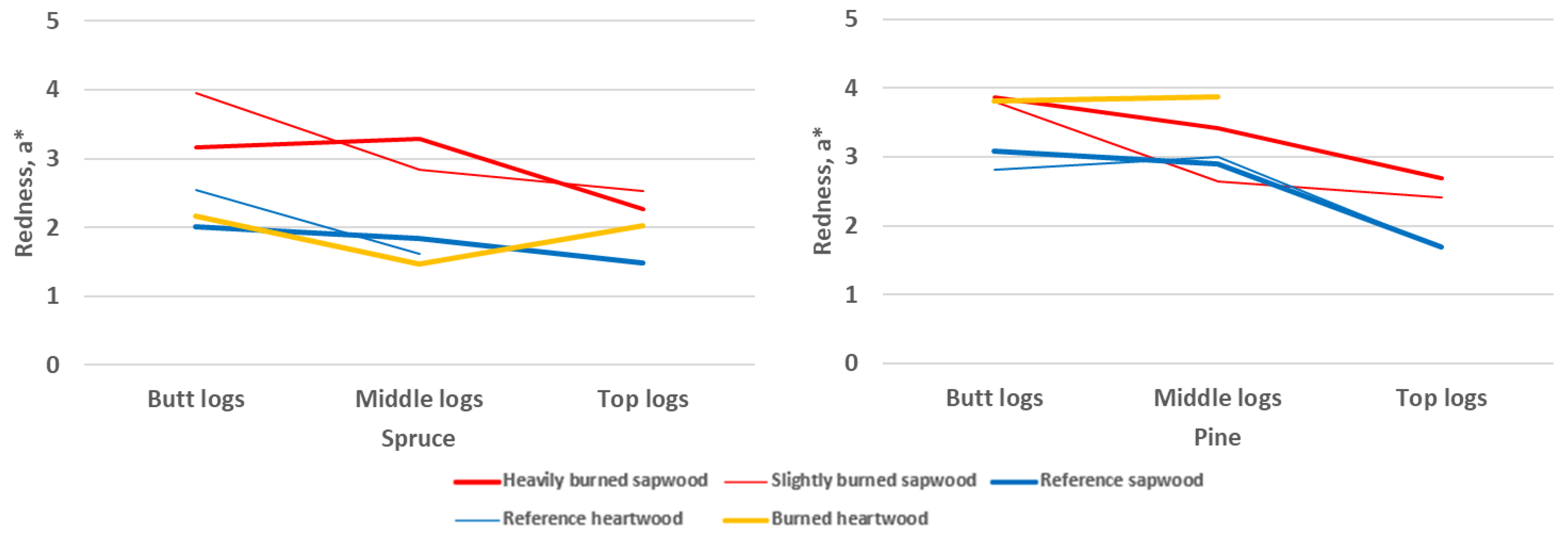

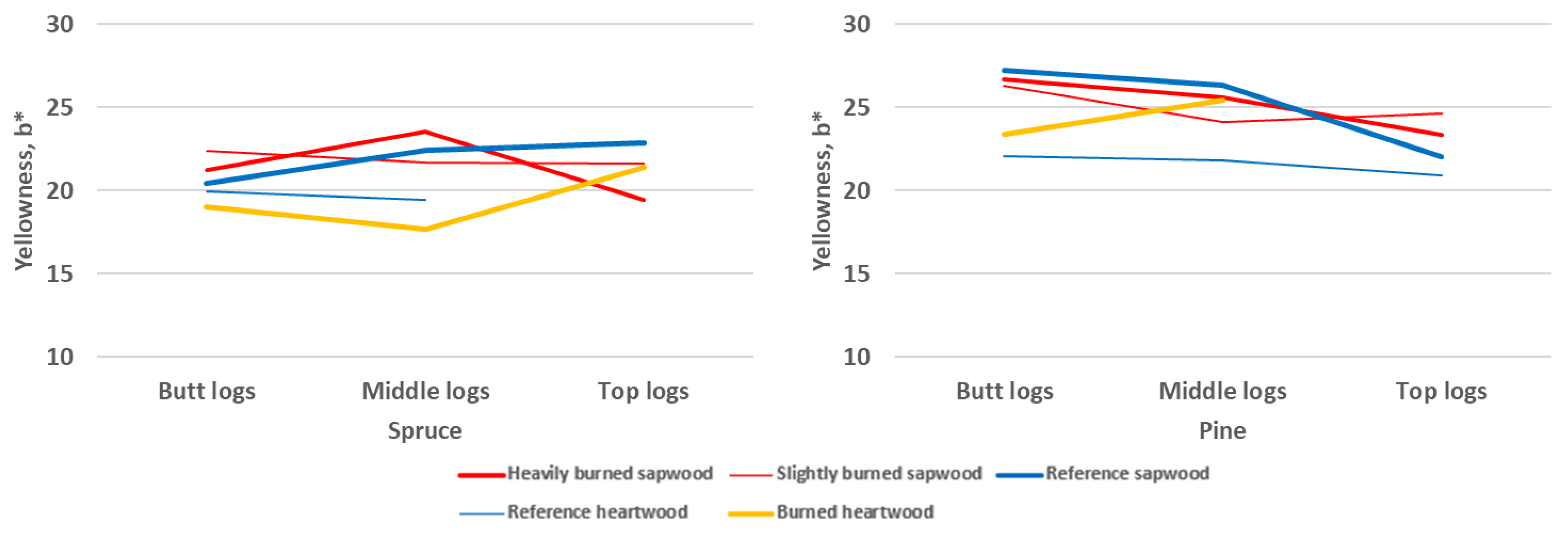

In Norway spruce and Scots pine sapwood, a perceptible color difference due to the fire was observed. In heartwood, the Δ

E values indicated slight changes in color but were mostly below the perceptibility level of Δ

E*ab = 2 for wooden surfaces [

50]. The wood color was the darkest in the burned Norway spruce wood of all studied wood materials.

Changes in wood color might indicate some chemical changes in the wood at high temperatures during the forest fire or some staining due to soot and char. The increase in the relative proportion of darker latewood with an increased cambial age explains the difference between heartwood and sapwood. In Scots pine, the color difference due to heartwood formation is naturally visible between sapwood and heartwood. A sharp boundary between heartwood and sapwood occurs naturally in Scots pine, while in Norway spruce, yellowish heartwood is not clearly distinguished from sapwood [

51,

52]. The differences in color parameters between heartwood and sapwood can mainly be explained by their different chemical compositions. The color of Scots pine heartwood is usually brown with a hue of red. The color of sapwood, especially earlywood, is typically very light, with a hue of yellow in both species. In addition, the proportion of darker latewood is higher in heartwood than in earlywood.

It is well known that the temperature level and burning time of the exposed area during a fire are critical factors for changes in the physico-mechanical and chemical properties of wood [

12,

23]. We had no information available on the thermal circumstances during the forest fire, but we assumed that the temperature elevation stayed lower than in the prescribed burning. The following temperatures were measured in experiments in the forest: 400–500 °C at ground level, 220 °C at the 3 m level, 150 °C at the 6 m level, and 45 °C at the 9 m level [

15].

In a forest fire, bark provides protective support for wood, slowing or inhibiting the rise in temperature and the chemical and physical alteration of wood. Accordingly, in the loblolly pine study in Brazil, only the most severe burning level, where the flames consumed the total crown, had any effect on the chemical composition of the wood, decreasing the content of cold water-soluble extracts (tannins, gums, sugars, pigments, or colorants) due to the movement of water within the wood tissue [

20]. Similarly, no chemical effects of fire on wood were observed in an Aleppo pine study conducted in Turkey [

53].

The mortality rate of the burned trees and the high deterioration rate of fire-affected wood were evident for Norway spruce but less severe for Scots pine. Similar to North American softwoods [

16], rapid wood procurement after a fire is essential to prevent excessive drying and further biological–physical degradation of the material. In Finland, the Forest Damage Prevention Act effectively prevents the advancement of secondary defects to a harmful degree in salvaged wood [

32].

The partial suitability of burned wood has also been found for wood panel applications. Jack pine wood in Wisconsin, USA, had a similar engineering performance for oriented strand board (OSB) at four fire damage levels and met the standard mechanical properties when all char was removed from the flakes [

27]. In a parallel study on red pine wood from fire-killed, fire-affected, and virgin trees, the addition of 20% charred bark among flakes reduced bending strength, still providing OSB mechanical properties meeting the standard requirements for all fire levels, but bark addition of up to 20% improved the stability of the boards. Scots pine fiber material from burned wood was tested as a mixture of virgin beech and oak to manufacture a medium-density fiberboard (MDF) in Turkey. All test panels met the mechanical properties of general-purpose MDF panels, but surface roughness remained higher and dimensional stability remained weaker than control panels from unburned beech and oak [

28].

5. Conclusions

This study, based on wood materials from a forest fire area and a neighboring forest area in Western Finland, showed fire-induced changes in the physical and mechanical properties of the sapwood of Norway spruce and Scots pine in Northern Europe. The changes in the properties were more substantial in spruce than in pine, presumably because the thinner bark, especially in the lower parts of trees, protects wood less from deterioration, and the longer crown accelerates the spread of fire in the middle and top parts of trees.

In spruce, the moisture content decreased, and the color darkened compared to the reference trees. In pine, color changes were observed. Spruce wood underwent greater changes, probably due to the thinner bark and the longer crown being more susceptible to fire. The changes in mechanical properties were mostly unessential. In spruce, a slight increase in HB was observed, and in pine, a slight decrease in bending strength was observed.

Due to the minor deterioration, and from a mechanical point of view, fresh wood salvaged from forest fire areas, especially Scots pine but also Norway spruce, is a potential raw material for middle-quality and low-quality sawn timber and selected end-uses where the requirements for quality are moderate and aesthetic or hygienic criteria are not critical, including the following: varieties of construction, non-food packaging and pallets, and other less sensitive uses of wood. However, most physico-mechanical properties of virgin wood change only a little in a forest fire, especially in spruce char and soot, making use difficult in many product applications and manufacturing processes. Sapwood is prone to excessive drying, which may initiate checking in wood after being sawn, sliced, or rotary cut but reduces the need for drying wood products. We recommend further studies on the following to create and develop the use of wood from forest fire areas: (1) chemical composition and surface activity of burned wood, (2) performance and usability in different types of production and products (mechanical, chemical, and hybrid), (3) potential for diversified biorefining processes and chemical treatments, and (4) technical procedures to remove or reduce char and soot in wood material before processing.