Abstract

This paper presents the development and implementation of Integrated Multilevel Planning Solution (IMPS) a solution adhering to Industry 4.0 and 5.0 standards. Today, companies face challenges in understanding how new orders would impact existing production plans when there is limited traceability and information flow in their manufacturing process. The digital transformation of the production planning system enables a company to overcome the current challenges; however, to overcome the usual barriers of digital transformation a specialized solution for each company should be developed. IMPS was developed by first understanding the problems in the existing production planning process through a gemba (jap. for “actual place”) walk and interviews with stakeholders. The solution was designed with a human-centric approach and consists of seven components (Design System App (DSA), SAP (Systems Applications and Products in Data Processing), Microsoft Project, Microsoft Project Server, The Project Group (TPG) PSLink software, TPG ProjectLink, Tableau, and Smart Digital Assistance), which are well connected and integrated into the existing design. The system is accessible to the end user to find information, as the principles of Industry 5.0 require. A multivariant and multiuser planning capability was achieved with an interconnected Gantt chart of the master project with the ability to drill down into individual projects and custom views for various types of internal users. Most of the production planning solutions found in the literature were optimization-oriented, related to the improvements of the calculation methods within the planning activities in order to achieve a better efficiency of the planning system. Here, the goal was to achieve a system architecture that enabled a unique solution for design-to-order manufacturing without complex interventions into the existing system, which overcomes the most common barriers in Industry 4.0 implementations which are the human resistance to change, high investments, a lack of needed skills and knowledge for its implementation and use, and challenges of the adaptability to the new system. IMPS (ver 1.0) is a hybrid solution for SMEs, which aims to advance their planning system from the most commonly used Excel sheets towards a more advanced system but has financial and knowledge limitations from its implementation of highly complex software (ver. 1.0).

1. Introduction

The term Industry 4.0. was publicly introduced for the first time in 2011 at the Hannover Fair [1]. The implementation of Industry 4.0 in manufacturing companies is carried out by creating smart factories that contain all the components of Industry 4.0 together with the technologies and services that enable the operation of these components [2]. The National Institute of Standards and Technology of USA defines smart manufacturing as a fully integrated collaborative manufacturing system that reacts in real time to achieve changing demands and conditions in the factory, the supply network, and customer needs [3]. As a result, Industry 4.0 is frequently also recognized as smart manufacturing, defined as manufacturing that improves its performance aspects with intelligent and integrated use of processes and resources in the cyber, physical, and human spheres to create and deliver products and services, which also collaborates with other domains within the value chains of enterprises [4]. Smart manufacturing combines sensors, computer platforms, simulation, and predictive engineering with today’s and tomorrow’s manufacturing equipment. Cyberphysical systems, the Internet of things, cloud computing, service-orientated computing, artificial intelligence, and data science are all used in smart manufacturing [5]. Today, the only way for companies to remain competitive in an increasingly dynamic environment is to deploy Industry 4.0 digital technology. Many companies at the global level today lag far behind in implementing the elements of Industry 4.0 [2]. However, like all new initiatives, the implementation of Industry 4.0 creates resistance because people are wary of the unfamiliar and unproven and because they do not have enough information [6,7]. Furthermore, Industry 4.0 was criticized for placing more emphasis on improving production efficiency and flexibility than on the basic objectives of social justice and sustainability [8,9,10,11]. Therefore [8,9,10,11], ten years after the introduction of Industry 4.0, the European Commission unveiled the Industry 5.0 framework that reconciled human and machine activities to work in symbiosis [12].

Industry 5.0 recognizes the potential of the industry to not only create jobs and promote economic growth but also become a sustainable and resilient provider of prosperity by aligning production with environmental limits and placing the well-being of industrial workers at the forefront. It builds on the Industry 4.0 framework by utilizing research and innovation to transition to a sustainable, human-centered, and resilient industry [13]. This concept is a result of the European Commission’s consensus on the need to integrate social and environmental priorities into technological innovation and adopt a comprehensive approach rather than focusing solely on individual technologies. Some studies, such as that of Xun Xu et al. [14], discuss the coexistence of two industrial revolutions and define enabling technologies in Industry 5.0. Furthermore, in a paper by Jaewu Leng [15], three main characteristics of Industry 5.0. are defined. These are (1) human centricity, (2) sustainability, and (3) resilience. The study continues by examining important facilitators, the future implementation path, prospective uses, and difficulties of realistic Industry 5.0 situations. At the same time as Industry 5.0. was gaining recognition, a similar framework named Society 5.0 has come into existence to solve the problems in the current environment. Society 5.0 has been defined as a futuristic supersmart society where everyone can enjoy a high-quality and comfortable life through the fusion of cyberspace and physical space using the full power of information and communication technology [16]. The absence of labor skills is regularly cited in the literature as one of the main obstacles to the adoption of innovative business models and new technology [17]. This phenomenon can be minimized by building systems that can be used by existing staff and engineers, reducing the potential learning curve [18,19].

Since there is minimal evidence of Industry 4.0 implementation in practice of both manufacturing systems as a whole or partially [20], the idea of Industry 5.0 should enable it to speed up its implementation in every manufacturing sector, as well as in production planning. Production planning and scheduling is today one of the essential parts of manufacturing, demanding a flexible, resilient, and sustainable planning system, with respect to current unpredictable events in society [21]. In general, a relatively small amount of the overall manufacturing cost belongs to production planning, but any mistakes in these steps generate further major disruptions in cost calculation in future manufacturing stages and therefore can potentially generate a large amount of waste [22]. Therefore, the purpose of this paper is to define a novel approach to the human-centric Industry 5.0. production planning system. Therefore, the goal of this research is to answer the following research questions.

RQ1: What is the optimal approach for designing a human-centric production planning system in high-variability single-product manufacturing?

RQ2: Can a novel production planning system minimize the learning curve for the workforce?

RQ3: Can legacy databases be compatible and incorporated into a novel production planning system by Industry 5.0 standards?

RQ4: What is the optimal balance between functionality and simplicity in a real-time digital production planning system, and how can it be achieved?

This paper presents a comprehensive analysis of the current state-of-the-art findings in the field of production planning in Industry 4.0 and 5.0 based on which a novel production planning system is defined and implemented in a case study of a power transformer company. The introduction provides an overview of the research objectives and the significance of the study. The literature review critically evaluates the existing literature on the topic, highlighting key research questions and gaps in knowledge. The case study section presents a detailed examination of the methods and criteria used to develop a human-centric process-planning system, drawing on real-world examples to illustrate the key concepts. The conclusion summarizes the main findings of the study and highlights the potential for future research and development in this important area.

2. Related Works—Literature Review

The main goal of the literature review was to find evidence of the implementation of state-of-the-art production planning systems built according to the principles of Industry 4.0 or 5.0. Therefore, the most relevant research papers were searched on the Web of Knowledge platform. The keywords used were “production planning” AND “industry 4.0” or “industry 5.0” or “smart production planning” or “digital production planning”. Papers published from 2011 to 2022 were explored, as this is the time span of the presence of the concept of Industry 4.0 and later 5.0. The research was limited to articles published in the field of “engineering manufacturing” and “industrial engineering” to achieve a better relationship with the research. Overall, 587 records were found, and among many results, only 26 were examined in detail because of their relevance and similarity to the specific research topic of production planning system implementation and its elements from the Industry 4.0/5.0 concept in manufacturing companies.

2.1. Production Planning in Industry 4.0

Industry 4.0 is characterized by the integration of digital technologies into various aspects of manufacturing and industry. The main elements of Industry 4.0 include: the Internet of things (IoT) (the interconnection of devices and machines through the Internet which enables communication in real time); big data analytics (the collection and analysis of large volumes of data generated by interconnected devices providing valuable insights), artificial intelligence and machine learning (enabling machines to learn from data and make decisions without explicit programming), additive manufacturing (for the production of customized and complex components with reduced waste), cyberphysical systems (the integration of physical processes with digital technologies for real-time monitoring, control, and optimization of processes), cloud computing (cloud services provide scalable and flexible storage and processing capabilities), autonomous systems (the use of autonomous robots and vehicles in manufacturing processes), augmented and virtual reality (enhance training, maintenance, and operation processes), horizontal and vertical integration and security and privacy [23].

These elements collectively contribute to the transformation of traditional industries into more efficient, flexible, and adaptive systems in the context of Industry 4.0.

In an architecture for production planning and control by Industry 4.0 standards, different levels of management are identified by both their physical identity and their functional scope: knowledge-based enterprise resource planning (the business level, also responsible for cloud interaction); the high-level controller (the general performance level); and low-level controller (the operative level) [24]. Those are multilayer concepts that would allow a decentralized decision-making (a very important segment of the Industry 4.0 concept [25]) and a control of system performance. An increase in demands for data and technological quality can improve planning activities [26].

An integrated system enables the use of real-time data from various monitoring gadgets and sensors, which enables the upgrading of the traditional production planning and scheduling process and its optimization according to the principles of big data analytics [27]. As for the entire manufacturing system, production planning should be both flexible and efficient in a digital environment, which can be provided by an efficient screening procedure, to lessen the need for rescheduling [28]. Bueno et al. (2020) recognized key production planning performance indicators in Industry 4.0 such as manufacturing flexibility, agility, and reliability for the proposal of a list of smart capabilities such as real-time capabilities, adaptability and dynamicity, visibility and traceability, autonomy, smart scheduling, and PPC-as-a-service [29]. In addition, the innovative performance of the new smart production system and the benefits for enterprises can lead to smart economic growth [30].

The close connection of physical objects with the information network enables enterprises to connect and communicate through advanced Internet of things technologies, big data, and cloud computing. Large instances of production planning problems can be solved by joint optimization methods, such as the large neighborhood search (LNS) algorithm, which combines classical mathematical programming and metaheuristic techniques [10]. Multilevel planning heuristic outperforms basic scheduling rules such as earliest due date (EDD), shortest processing time (SPT) and longest processing time (LPT) [31].

Cloud computing and the Internet of things is one of the essential characteristics of Industry 4.0 and its use in production planning [32], while at the same time, there is an absence of practical applications of Industry 4.0 technologies in the field of production planning. A solution that uses cloud manufacturing principles as cloud-based process planning is a system that uses cloud technology and services to define process plans, as well as expert heuristic knowledge to optimize process plans and select the best solutions [33].

A machine learning approach as a solution for production planning was also proposed while noticing that 75% of the possible research domains in machine learning production planning and control had barely been explored or not addressed at all. Two key pitfalls were identified in the implementation of machine learning production planning and control models: the complexity of using Internet of things technologies to collect data and the difficulty of updating the machine learning model to adapt it to changes in the manufacturing system [34]. Shorter product life cycles require complex production requirements [35], which has an impact on the complexity of production planning and control. The use of artificial intelligence and a maturity model for the digital technologies of production planning was proposed.

Organizing and controlling production operations can be enabled through the industrial Internet of things (IIoT) and digital-twin-enabled graduation intelligent manufacturing system (GiMS) with real-time task allocation and execution mechanisms to achieve real-time information sharing and production planning, scheduling, execution, and control with reduced complexity and uncertainty. A digital twin can also be observed as a core component for smart production planning. This kind of integration leads to more flexible, efficient, and goal-orientated manufacturing execution processes but is only tested in laboratory systems, and Industry 4.0 is highly optimized [36]. Also, the resulting smart companies can have the benefits of increased flexibility and short lead times along with a better monitoring for maintenance, product quality, resource utilization, and efficiency [37].

Therefore, for production planning, the implementation of a Cyber Industry Network (CIN), an online platform for exchanging the production capacity of small and medium enterprises, for the efficient combination of free resources to realize joint production projects was proposed [10].

Such cyberphysical systems have a significant impact on production planning and scheduling [38]. There is a potential for real-time-capable production planning and control in engineering-led production companies to minimize time-dependent combinatorial complexity in the value chain [39].

Lean automation is often discussed by the objectives of cost, reusability, reliability, simplicity, compactness, fit, engagement, and culture that can lead to the development of a system for production planning by these variables [40]. With lean objectives, an Industry 4.0 model aims to schedule a production system as efficiently as possible with maximum flexibility and minimum schedule perturbation [41]. Called EPEC 4.0, it would improve production control by addressing the shortcomings of MRP.

On the other hand, current production planning approaches do not exploit all the 4.0 tools and technologies, and researchers usually employ CPS and simulation (Tobon Valencia et al., 2021 [11]). All approaches follow some form of agility, although not all its dimensions have been pursued equally. The results indicate that production planning approaches are mainly focused on balancing resource utilization at the operational planning level. Furthermore, the literature review show that there are yet to be fully implemented complex real-case validations.

2.2. Industry 5.0 Elements in Production Planning

Industry 5.0 is designed to overcome the most common barriers of Industry 4.0 [14]. As the previous concept was based around technology, the human aspect was neglected. The flexibility and modularity of the Industry 4.0 system are structured to deal with dynamic market changes; however, without the humans with the needed skills and knowledge to implement and work in such systems, it is not possible to achieve its high potential [42]. Industry 5.0 therefore is a human-centered, resilient, and sustainable system in which the focus is put on the collaboration of human and machines and adapting the system to the human needs in order to retain the needed productivity and efficiency in production [43]. The creation of strategic production planning can be based on the systematic use of the creativity and experience of a wide-ranging network of employees with the goal of establishing a practical and enduring integrated manufacturing-driven innovation road-mapping process [44].

With only a few solutions presented, there is a lack of a production planning framework in the literature related to Industry 5.0 [45], which is why the functions of smart production, planning, and control in Industry 4.0 were mostly identified.

The framework of one example of a production planning and control model focusing on internal production planning and control while using real-time information from the shop floor was introduced [5]. The question remained of how to solve capacity planning challenges with real-time data and suggest the development of intelligent or data-driven release criteria and the dynamic provision of resources at release time. Therefore, new solutions to support the decision-making of human operators in production were proposed as a future research direction.

Although digital, the importance of human influence within process planning at the conceptual level remains crucial. A cloud-based system enables decentralized development teams and process planning experts to collaborate and exchange knowledge. Experts in a collaborative process evaluate existing process plans, perform their modifications, and suggest entirely new process plans. The importance of a cloud-based production planning system within the cyberphysical system was enhanced with a framework and a case study of Taiwanese SMEs [46]. It was based on an intelligent dynamic planning and scheduling (IDPS) system, which could dynamically and effectively generate production and operations schedules and provide timely visual analysis data for production planners in SMEs.

Finding the best trade-off between product design and process/production plan efficiency is becoming more challenging than ever in multiproduct assemblies [10,47].

With the increase in demand and complexity of manufacturing systems, it is difficult to manage timely production and the proper implementation of an effective plan without incorporating all information from the industry [31,48].

Enhancing production planning and control functions can lead to a global improvement of manufacturing systems [49].

The combination of management methodologies such as just-in-time (JIT), optimized production technology (OPT), and/or quality risk management (QRM) with Industry 4.0 technologies enable the design of resilient and sustainable production planning systems [28,32,33,34]. The importance of behavior synchronization between physical and digital spaces has been mentioned to create an integrated production planning system. The support of the system should be advanced and new algorithms and AI, simulation, and optimization models employed [50].

However, the main challenges of state-of-the-art technologies in production planning remain, such as the integration of data, software, and decisions; massive data to develop an effective production plan using cutting-edge technologies; and dynamic and automatic management support for production planning [51]. The challenge is to develop tools that can react in real time and interact properly with the shop floor managers and the workers. In the production planning framework proposed in [21], the importance of reducing system complexity and implementing collaborative decision-making was paramount.

Synchronization-oriented manufacturing planning and control system (MPC) was developed due to the gap in the evolution of the logic and design of MPC systems [52]. It enables real-time data visibility and information sharing, the coordination of decision-making, and the synchronization of production activities by implementing technologies such as the Internet of things, cyberphysical systems, cloud computing, digital twin, human–robot collaboration, AI, and optimization technologies. All are provided through Internet apps, web server systems, and VR.

2.3. Challenges for the Production Planning in Industry 5.0

Based on the available literature, a few conclusions regarding state-of-the-art production planning systems in Industry 4.0 and 5.0 can be considered. Production planning faces similar challenges to the overall implementation of Industry 4.0 [9]. Although the concept has existed since 2011, there is very little evidence of implementation to a high degree, especially for process planning and scheduling. Integrated production planning systems that should be implemented have a theoretical framework available, but with respect to their complexity, they were not implemented at full capacity.

One of the main characteristics of smart production planning is the collection and analysis of real-time data [53,54,55]. It can be used to optimize the production plans and therefore plays a very important role. The data should be of high quality and lead to data-driven decisions while retaining the importance of humans in this kind of process [56,57,58]. The importance of decision support systems within Industry 4.0 is very high, as well as that of decentralized decision-making. It would improve the time-consuming, non-value-added traditional centralized decision-making activities and enable accurate and efficient production planning [59]. The use of certain optimization algorithms has proven to be efficient in production planning operations, but the complex use of artificial intelligence has not been described and there is no clear evidence of its implementation at a higher level [47,60,61]. Internet technologies are one of the most common and most important parts of Industry 4.0 and 5.0. Also, they are some of the technologies with the highest availability and therefore have an easier implementation at various levels. The use of cloud technologies in production planning and scheduling is also one of the most common segments of the new system both in theory (on a more complex level, related to the Internet of things) and in practice (at a simpler level) [21,37,38].

Therefore, the combination of traditional production planning and scheduling methods, which include certain optimization algorithms, can improve the process, but the further use of the AI concept has not yet been proven [35].

In design-to-order (or engineer-to-order) production, due to its high degree of complexity in the planning and coordination, the goal is to achieve complexity reduction through near real-time feedback, which can be provided by digitally automated continuous (re-)planning to avoid the system range shifting outside the design range. The scheduling phase is based on the idea that a schedule should entail the following functionalities: (a) short-term based replanning; (b) capacity planning; and (c) real-time planning, which means considering the actual progress of the different tasks on site [39].

The requirements of such systems are the following: (1) plan capacity at the customer inquiry stage to establish the due date of the project; (2) deal with uncertainty in the process and product specification by establishing confirmation points for delivering products and information; (3) deal with customer-oriented, nonrepetitive production and variable routings; (4) adopt different levels of planning and control, distinguishing project flow control from production unit control; and (5) manage the interface between production and sales [62].

The main tactical planning activities that should be covered by production planning systems are: (1) defining preliminary product specifications; (2) determining detailed engineering activities and resources; (3) estimating lead times and costs and setting due dates; and (4) identifying needs for external capabilities and additional capacity [63].

Even with relatively high levels of digitalization, the role of humans within the production planning system remains high [42,64]. The control and development functions must remain under human supervision, and teamwork is required for the production planning process optimization. This is why the EU has presented the Industry 5.0 concept, a human-centered digital manufacturing system that would enable it to overcome the obstacles and challenges set by the implementation of Industry 4.0 [65]. The human-related challenge that remains is the time-consuming learning and adaptation to newly implemented systems. The learning curve must be reduced so that not only current but also new workers can start to use the new system in as short a time as possible [18,19,66].

Finally, three very important characteristics of Industry 5.0 must be considered when creating a new production planning system, namely, sustainability and resilience [14,43]. Each manufacturer has its own specific demands; therefore, each implemented segment of Industry 5.0 should be highly customized but developed according to the general principles of the digital manufacturing concept. The production planning and scheduling system should be sustainable to avoid major changes in the near (or distant) future, with a possibility of modification in terms of flexibility and upgrades. The system should also be resilient to unpredicted and dynamic events within and outside of the system. As for the implementations of Industry 5.0 principles, many sources have showcased in case studies that there is no universal solution in providing a human-centric, sustainable, and resilient solution for multiple segments of manufacturing companies, therefore it has been suggested that an individual approach is most suitable. This means that the inclusion of multiple levels of the organization leads to a beneficial solution for any new technology implementation or its modification [43], while hybrid approaches can be developed for estimating the lead times of engineering activities considering both the capacity constraints for engineering resources and the characteristics of new engineering projects [63].

Therefore, the explicit guideline of a production planning system in an Industry 5.0 environment is not clearly defined in the literature, especially for the design-to-order systems, but certain segments are clear and were used for the design of the novel integrated production planning system in this research:

- -

- Real-time data availability and analytics. The data should be properly structured to avoid the appearance of data-related waste but should also be understandable to the specific user. Every modification should be visible in real time to each user to avoid misinterpretations and wrong decisions.

- -

- Decentralized decision-making. With available data adjusted to a specific user, the data-driven decisions can be made decentralized and more accurate.

- -

- Internet technologies and cloud computing. The data should be stored on the cloud and available from different platforms.

- -

- Complexity reduction. The system should be simple, user-friendly, and easy to use and to learn.

- -

- Sustainability and resilience. The production planning system should remain open to future modifications and upgrades which do not demand very complex tasks and high investments, such as a simple modification which enables the accurate and effective functioning in the future without disruptions.

These findings from the literature were a guideline for the development of a new integrated production planning system according to Industry 5.0 principles that was implemented and proven in practice for a leading power transformer manufacturer in Croatia.

3. Integrated Production Planning System According to Industry 5.0 Principles

Based on the state-of-the-art findings and evidence from the literature presented in Section 2 a digital production planning system was developed according to the Industry 5.0 standards for the unique needs of a local power transformer company in Croatia, taken as a case study. The manual manufacturing of special make-to-order products has a very high complexity of digitization, yet it must follow market trends to remain competitive. The company produces highly complex make-to-order transformers. This discipline requires best-in-class quality engineering and production processes. In a constant search for better performance and maturity, it is necessary to also constantly improve supporting processes such as product development, logistics, and production planning.

Based in Zagreb, Croatia, it specializes in the design, development, production, sale, testing, and servicing of power transformers. The company has been producing transformers since 1945. Today, its products span step-up transformers up to 550 kV/1000 MVA; network and autotransformers up to 550 kV/1000 MVA; HVDC transformers up to 550 kV DC; and shunt reactors up to 550 kV/250 MVAr.

As a specialist in transformer production for decades, the company makes its products in very small series—sometimes just one unit per customer and seldom more than three. Although the basic construction of a transformer follows the same pattern, there are often many customization options. At the same time, the current situation in Croatian manufacturing was considered as a guide towards the development of a novel production planning system for complex make-to-order products. In previous research, 60% of Croatian manufacturers were not familiar with the term Industry 4.0 or 5.0, while the greatest challenge in its implementation was recognized as the lack of time to develop and implement new technologies, as well as the unavailability of the technologies on the market. Companies that are open to digitalization and familiar with the concept have a higher tendency to accept innovative solutions, increasing the chances of successful implementation of the new system and the maximization of its future benefits [67].

3.1. Materials and Methods

The primary objective of our research was to enhance the efficiency of the company’s production planning process in line with Industry 5.0 standards. The company, a major player in the manufacturing industry, was facing challenges in its production planning and scheduling process. The lack of real-time data, unconnected plans across multiple departments, and inefficiencies in transitions between manufacturing stages were some of the key issues identified. The research was carried out as part of the EU-funded R&D project “Smart Factory”, with the aim of developing a modular expert system to manage discrete operations in the manufacturing industry.

3.2. Data Collection

A detailed account of the gemba walk that took place over a span of two weeks is provided. During that time, approximately 40 h were dedicated to observing the manufacturing hall. A gemba walk is a workplace walkthrough which aims to observe employees, ask about their tasks, and identify productivity gains. A key component of a gemba walk is to get the input of employees about what is going well and what is going wrong in a specific operation [66,68,69]. To gain a complete understanding of the production planning process, a structured approach was followed. The initial step involved reviewing the layout of the manufacturing hall and identifying key areas of interest. These areas specifically included the sections where transformers were assembled, tested, and prepared for shipment. Subsequently, several days were allocated to closely observing these areas. Notable observations included tracking the time it took a transformer to progress from one stage of the process to the next, monitoring the number of workers involved at each stage, and documenting any delays or bottlenecks that were encountered. During the gemba walk, an active engagement with workers on the manufacturing floor was carried out. Enquiries were made about their specific tasks, the obstacles they encountered, and any suggestions they had for improving the process. A diligent documentation of the observations was carried out, including the exact time, location, and nature of each observation, as well as the responses received from interactions with the workers. Furthermore, a value stream mapping tool was utilized to map the as-is condition of the manufacturing. However, it is important to note that while the value stream mapping tool was extensively utilized to delineate the as-is condition of the manufacturing process, specific details of the mapping cannot be disclosed in this article due to confidentiality constraints. Value stream mapping is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from its beginning through to the customer [69]. It is particularly beneficial in identifying inefficiencies and opportunities for improvement. In our study, this tool was instrumental in visualizing the entire transformer production process, from raw material intake to final product delivery.

The confidentiality agreement with our industry partner necessitates that certain operational details, especially those that reveal specific methodologies, timings, and internal strategies, remain undisclosed. This limitation, while posing a challenge in providing a full picture of our findings, underscores the importance of balancing academic inquiry with the practical realities of industrial confidentiality. Therefore, our discussion in this article focuses on generalized observations and conclusions drawn from the data collected, without revealing the intricate details of the value stream map. Business Process Model and Notation (BPMN) is a standard for business process modeling that provides a graphical notation for specifying business processes in a business process diagram [70]. However, in the context of our study, the primary focus was on the physical manufacturing process rather than the underlying IT infrastructure or business processes. The complexity and proprietary nature of the IT infrastructure in the manufacturing facility posed significant challenges. Due to confidentiality agreements and the sensitive nature of the IT systems involved, a detailed BPMN analysis was not feasible.

The process was continued with a stakeholder interview. The interviews were semistructured in nature, providing a balance between standardized inquiry and the flexibility to explore topics in depth. This approach allowed us to systematically address five key questions, ensuring a comprehensive coverage of relevant aspects while also accommodating the unique perspectives of each respondent. The questions were designed to elicit detailed information on the challenges faced in current processes, the impact on departmental operations, goals for future systems, envisioned interactions with new systems, and desired features and capabilities. The questions themselves were developed through a collaborative process involving experts in lean management and business process optimization, ensuring that they were both incisive and relevant to the varied domains of our respondents. Detailed responses were obtained through in-depth interviews [54,55] conducted with key personnel from various departments, such as production, logistics, operations management, and IT. These interviews were semistructured, allowing flexibility in the discussion while ensuring that all key topics were covered. The five questions discussed during the interviews were as follows:

- (1)

- What are the most significant challenges you face in the current production planning and scheduling process? Please provide specific details and examples.

- (2)

- How does the current process impact your department’s operations and overall efficiency? Explain the specific ways in which the existing system affects your team’s ability to perform their tasks effectively and efficiently.

- (3)

- What specific goals do you hope to achieve with a future system based on Industry 5.0 principles? Describe the desired outcomes or improvements you anticipate from implementing such a system.

- (4)

- How do you envision the interaction between your department and the new system? Describe the ideal working relationship between your team and the proposed system, considering factors such as data input, decision-making processes, and overall collaboration.

- (5)

- What features or capabilities would you like to see in the new system to support your department’s operations and goals? Provide a comprehensive list of functionalities and attributes that you believe would be beneficial for your team to have in the new system to improve their operations and help them achieve their goals more effectively.

To enhance the validity and reliability of the data collected, a pilot test of the interview protocol was conducted with a small group of participants similar to our target respondents. This pilot phase allowed us to refine the questions, adjust the flow of the conversation, and address any potential ambiguities. Feedback from the pilot participants was instrumental in fine-tuning the interview guide to better elicit detailed and meaningful responses. During the interview execution phase, each session was conducted in a controlled environment to minimize distractions and ensure a focus on the discussion. Interviews were audio-recorded, with the consent of participants, and later transcribed verbatim to preserve the accuracy of the data. Analytically, the responses were subjected to a thematic analysis, where data were coded and categorized to identify recurring patterns, discrepancies, and unique insights. This coding was performed independently by multiple members of the research team to ensure intercoder reliability, and discrepancies were resolved through discussion and consensus. Through this comprehensive and multifaceted interview methodology, we were able to glean profound insights into the operational intricacies of the manufacturing process and the expectations for a future Industry 5.0-compliant system.

3.3. Tools

The tools used in this research included direct observation (gemba walk), one-on-one interviews, and various software components for data analysis and visualization. During the gemba walk, standard observation techniques were used to document the production process. This included note-taking tools for recording observations and interactions, and a stopwatch for timing the duration of different stages of the manufacturing process. Semistructured interviews [56,57] were conducted using a prepared interview guide. This guide included open-ended questions designed to elicit detailed responses from interviewees. The interviews were recorded with the consent of the participants and the recordings were later transcribed for analysis. The data collected from the gemba walk and interviews were analyzed using qualitative data analysis software (https://www.ibm.com/products/spss-statistics, accessed on 10 January 2023). This software allowed the coding and categorization of the data, facilitating the identification of patterns and themes. In the development of Integrated Multilevel Planning Solution (IMPS), several software components were utilized. These included DSA, SAP, Microsoft Project, Microsoft Project Server, TPG PSLink, TPG ProjectLink, Tableau, and Smart Digital Assistance. Each of these components was chosen for its specific capabilities and the role it could play in creating an integrated, efficient, and user-friendly production planning system. Tools such as Tableau were used to create at-a-glance dashboards that could provide a wide range of internal users with easy access to key information about the production planning process. Each tool employed in our study, from qualitative data analysis software to gemba walk tools, played an important role in gathering and interpreting data through an Industry 5.0 lens, focusing on aspects such as system integration, data-driven decision-making, and human–technology interaction.

3.4. Data Analysis

The first step in the analysis process was to prepare the data for the analysis. This involved transcribing the recorded interviews and converting the observational notes from the gemba walk into a format suitable for analysis. The data were then imported into qualitative data analysis software. The transcribed interviews and observational notes were coded to identify key themes. Coding involved assigning labels to segments of the data that represented specific themes or concepts. For example, comments related to “inefficiencies in the production process” or the “lack of real-time data” were grouped under these respective codes. After coding, the data were reviewed to identify overarching themes. These themes represented the main issues and opportunities identified in the production planning process. For instance, one theme was “challenges in coordinating between different stages of manufacturing”. The final step in the analysis process was to interpret the findings. This involved examining the themes in the context of the research objectives and drawing conclusions about the current state of the production planning process and the potential improvements that could be made.

In terms of what was actually analyzed, the focus was on understanding the current production planning process, identifying its flaws, and determining the goals for the future system. This included analyzing the time it took for a transformer to move from one stage of the process to the next, the number of workers involved at each stage, any delays or bottlenecks that occurred, and the impact of new orders on existing production plans and staff resources. The analysis also considered the feedback of employees and management on what was going well and what was going wrong in the production planning process. The insights gained from this analysis were instrumental in the development of Integrated Multilevel Planning Solution (IMPS), guiding the choice of components and the design of the system to address the identified challenges and meet the company’s goals.

3.5. Solution Development

The design of IMPS was developed that incorporated seven components: DSA, SAP, Microsoft Project, Microsoft Project Server, TPG PSLink, TPG ProjectLink, Tableau, and Smart Digital Assistance. Each component was chosen for its specific capabilities and the role it could play in achieving the goals set. The design, guided by Industry 5.0. principles, also ensured that these components were well connected and integrated into the existing design [63,66,67].

3.6. Identified Challenges [66,68,69]

The lack of visibility of where each transformer was in the manufacturing process was seen as one of the biggest challenges of the current period. There was also a need to optimize the transitions between each manufacturing stage. For example, it sometimes happened that due to replanning during production, there was no possibility to coordinate efficiently the plan to have congestions, especially in the testing lab.

The laboratory could only test one transformer at a time due to its size and complexity. On the contrary, there was sometimes a long interval between one transformer leaving the testing lab and the next one arriving.

This inefficiency was mainly because the production plan of each transformer was contained in its own independent file, which was not connected to other business systems. Thus, if someone were to change the schedule for one transformer, the business information system would not adapt to it.

The company also had limited visibility into the effect that new orders would have on existing production plans or on the staff resources available for future orders. Furthermore, company management wanted to make this information available with at-a-glance dashboards to a wide range of internal users (potentially up to 1000) (Figure 1).

Through the provided interviews and gemba walk, several characteristics of the production planning sector were made clear, and those led to a lot of time and energy waste.

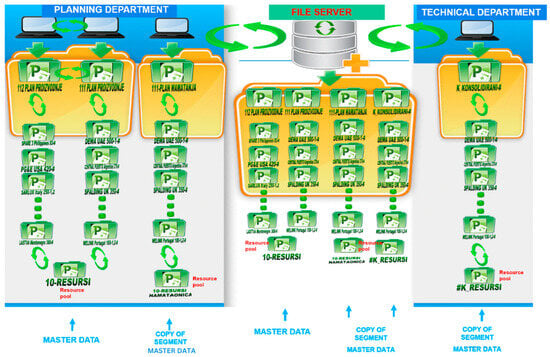

- There were multiple (not connected) plans in multiple departments (Figure 2).

- Rewriting plans between different program planning systems.

- There was no interface with ERP and other systems (feedback).

- The publication of plans took a long time and was demanding and complex.

- Changing plans and keeping them aligned in all concerned areas required extra effort (feedback).

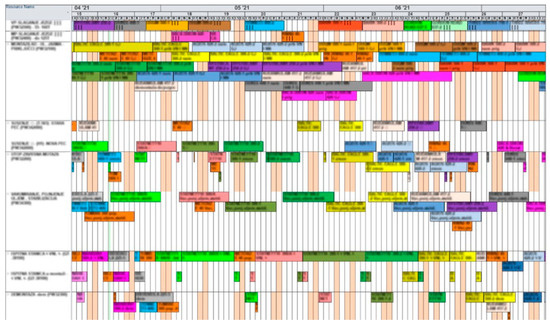

- Multiuser operation was not possible (Figure 3).

- Plans and files were shared by file server paths (slow, fault-intolerant, old-fashioned)

Figure 1.

Communication scheme between the planning and technical departments.

Figure 2.

Footage of the old planning system. The system is not connected.

Figure 3.

A display which is not suitable for presentation to the end user. It is used exclusively for work in MS Project.

The specific goals of the company were to increase efficiency in its core processes by the digitalization of production planning as follows:

Centralized and easily accessible data for all users and roles preventing double work and data inconsistency.

Data are structured and harmonized equally for each individual project. This would prevent comparing “apples and pears”.

Connection to other systems via defined rules and connections using standard software for interface jobs.

Adding a time component to material structures in the ERP system.

If publishing plans is easy, production disruptions become easier to handle because replanning cycles are faster and more transparent.

User-friendly, previously used, and familiar software interface, flexible to customize without coding.

The ability to easily create different filtered views, landscapes, and operational Gantt charts.

The possibility of simple data outputs and exports for processing and analysis (fast and graphically appealing reports).

The foundations of the new system should be on accumulated knowledge and their own solutions based on previously known system philosophy.

To decrease the learning curve and reduce implementation time and investment, research was conducted to develop a simple system with already available (or similar) tools that would have all the characteristics of an Industry 5.0 production planning system.

3.7. Validation Metrics

To validate the efficacy of the IMPS system within an Industry 5.0 framework, we propose a set of metrics focused on measuring human-centricity, resilience, and sustainability in the production planning process. These metrics include:

Human-centricity index (HCI): a composite metric assessing the degree of worker involvement and satisfaction in the production process postimplementation of IMPS.

Resilience score (RS): quantifies the system’s adaptability to changes and disruptions, measured by the frequency and efficiency of adjustments made in response to operational variances.

Sustainability index (SI): evaluates improvements in resource utilization and waste reduction achieved through IMPS.

4. Results—IMPS (Integrated Multilevel Planning Solution)

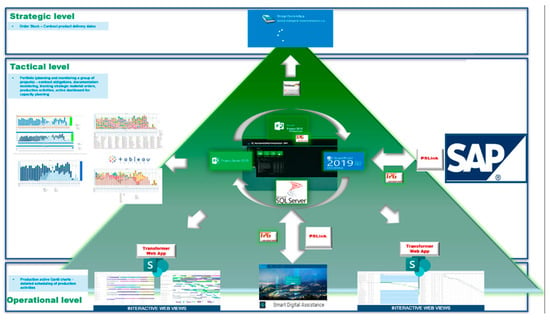

The central part of the previous production planning system was the Microsoft Project server. It is a structured SQL database with a familiar client interface based on the MS Project tool, a project management tool to plan, manage, and deliver work effortlessly, from one-time projects to large initiatives. It simplifies planning and reduces training time with the help of familiar scheduling features for project managers. In this case, the most used feature was view (Gantt chart). The MS Project needed to be connected to a new centralized SQL database. It also had to be connected to the current ERP system (SAP), as a business process management tool and a direct communication path with other parts of the supply and value chain. We divided the architecture of the new smart integrated production planning system into three levels: strategic planning, tactical planning, and operational planning/workplace activity.

Therefore, the name of the new system was integrated multilevel planning solution (IMPS). To assess the impact of IMPS, we applied the aforementioned metrics postimplementation. The HCI was derived from surveys measuring employee satisfaction and engagement, the RS from the analysis of production data pre- and postimplementation, and the SI from metrics on resource usage and waste generation. These metrics collectively demonstrated a significant enhancement in line with Industry 5.0 objectives, with a notable increase in HCI and RS, and a substantial improvement in SI.

The multilevel model followed the definition of the automation pyramid [71]; it consisted of five different hierarchy levels: (1) the value-creating production or manufacturing process; (2) physical subprocesses executed and controlled by devices and sensors; (3) monitoring, supervision and control; (4) all activities of manufacturing operations and control; (5) business planning and logistics (BPL), which consists of planning the material demand, logistics and inventory stock with an addition, the definition of production program, based on the given production capacity and resource availability.

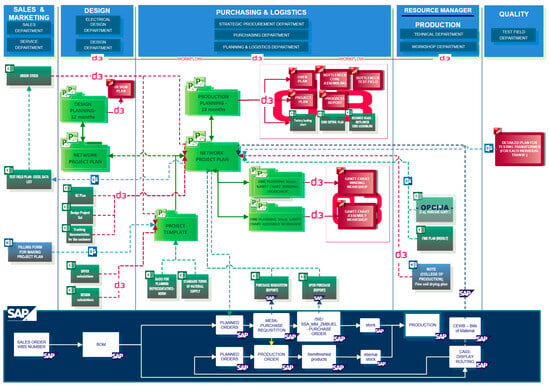

Figure 4 shows the three layers of IMPS software (ver 1.0), divided into three levels of plans, strategic, tactical, and operational levels, which are described in detail in the following sections. All levels are interconnected.

Figure 4.

IMPS system architecture.

4.1. Strategic Planning

Strategic planning is the highest level of planning, followed by tactical and operational planning. In our case, there was a large company with many managers who needed to have a real-time overview of projects. Regarding strategic planning, the first difficulty was monitoring the status of projects in real time. Project managers must be able to find out the project phase information of an individual transformer at any moment.

The very high inefficiency of this method of monitoring projects was multiplied by a large number of employees. By applying IMPS, every employee, in accordance with their authorizations, could monitor the state and phase of projects in real time and carry out what-if analyses.

Another key thing at the strategic level was monitoring the amount of inventory available for projects that were voided through tables input. The strategic plan (order stock) that previously was in excel format was successfully replaced by the new Design System App (DSA). The data in the Design System App were automatically updated with the IMPS plan database via TPG PSLink. Production plans were structured as Design System App “Order stock”, filtered by fiscal year, which facilitated the control of strategic material orders by preparation and procurement officials and provided up-to-date and timely information in SAP. Through the digital integration of business with suppliers, the shortening of the delivery terms and the increased reliability of the delivery of the materials were achieved successfully. The ordering of components was conducted through a 3D model with all the necessary information for production, the exchange of commercial and logistic data through a digital platform, and the tracking of deliveries using barcodes. Finally, an analysis of transactional data on suppliers was performed through a quality assessment and risk analysis.

The strategic level of management also included customer relationship management. It was achieved through an integrated digital platform (CRM) that communicated with other databases through a custom interface, using TPG PSLink. The goal, of course, was to increase profit and customer satisfaction and loyalty. When sales, marketing, and customer service activities were consolidated into one system, a competitive advantage in the market was gained.

4.2. Tactical Planning

IMPS was compared with the most commonly used solutions for production planning and scheduling [72,73]. According to developers, this software “enables increased resource utilization and on-time delivery, while also helping to reduce inventory levels and waste”. It also enables “manufacturers to easily generate plans and schedules and then react quickly and intelligently to changes”. The customized solution better suited the needs of the company than finished software solutions because of the characteristics of the business, the main focus of the company, existing planning structures within the company, software standardization level, no need for a niche software, the availability of the standard interface, and the availability of the know-how.

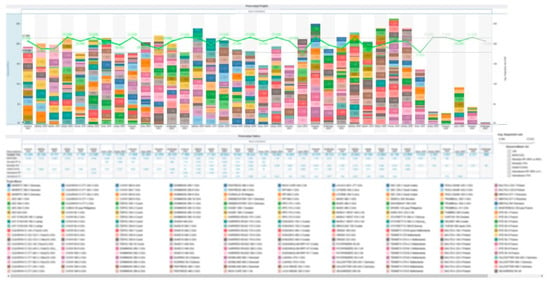

The next step was to achieve the connectivity between the three layers of production planning. This was adapted to the needs of the MS Project Server and developed by the company TPG as a special add-in, TPG ProjectLink. It was used for sharing information on deadlines, work, costs, and other information across projects. This provided crucial transparency by creating and showing links between tasks in different projects, as well as multiproject overviews of status information for steering committees. As a result, IMPS provided an overarching master plan covering every phase of transformer production from design to production. It included a plan for the design phase, one for core stacking, one for the coil-winding phase, and so on through to testing. Each sub-project was automatically uploaded to the overarching plan. As each part was interrelated, every individual plan was adapted when someone altered one aspect of one project. The result was a consolidated master plan that delivered exceptional transparency. An additional feature was the Tableau dashboard, which had an automatic connection to the SQL database, as shown in Figure 5. The system thus enabled capacity planning in real time. It was possible to easily manage available and required working hours, or in customized views, to identify working hours for a specific project on a time scale.

Figure 5.

Factory load chart. The Tableau system was connected to the MS Project database and was used for reporting and production capacity planning.

4.3. Operational Planning Activity/Workplace Level

Operational planning is the lowest level among all levels and consists of a detailed scheduling of production activities to follow the schedule defined earlier. For the scheduling of production activities to work, it is necessary to receive information from production in real time. This information should include parameters such as the percentage of scrap, the percentage of the completed norm, the number of parts completed, the productivity per workplace, etc. The company used a tool called Smart Digital Assistance (SDA) to bring information and services into production. SDA (Figure 6) is a very simple setup for real-time communication with production. For the implementation of the SDA integral system, it is necessary to ensure the necessary prerequisites in production as well. It is necessary to install computers in workplaces and connect them appropriately to the network. These prerequisites can have significant costs. In the future, with a 5G network, the connection itself could potentially be much simpler, but currently it relies on a LAN or Wi-Fi signal.

Figure 6.

Smart Digital Assistance (SDA).

The first step is to check the availability of the signal in production to determine the exact positions for the workstations. Next, it is necessary to clearly define the requirements for computers. It is necessary to consider the conditions at the workplace itself, starting with how much space there is, whether there is a possibility of damage to the computer/screen (if there are moving objects in the environment), and what kinds of data are displayed on the screen. In our case, it was concluded that it was necessary to ensure that the screens were protected by an armor because in all places there was a possibility of falling objects or damage from the transfer of materials and the like. It was necessary to analyze the place where the screens and computers (portals) would be located—fixed places (tables), brackets attached to the wall, carts, lickers at workplaces, and so on. The company tested fixed and trolley portals. Carts were found to be challenging because it was necessary to define how and when it would be possible to provide time to charge the battery. It is important to consider whether the workers need to visualize the drawings and, if so, what kind of drawings they are. Drawings showing elongated components where it is necessary to see smaller details in several places at the same time require the use of 55” screens. Workers who worked with simpler drawings where it is enough to show one detail, which can be achieved by zooming in on the region, can use smaller 27” or 42” screens. During the test period, the workers were satisfied with the sizes initially selected.

It was initially estimated that it would be ideal to use touch screens. When working with 2D drawings and documentation, this solution turned out to be very good. However, for workplaces where it is necessary to use 3D models and make additional measurements (elevations) on them, a mouse is needed. When it was not necessary to make additional elevations, the workers were satisfied with using only the touch screen and the hybrid keyboard on the screen. The basic functionality was to replace paper plans with plans on portals. Saving on paper is not the main motivation but rather the availability of the latest approved version of the documentation (from the PLM or DMS system) and the availability of additional drafts or information in all shifts (even when the archive or office workers are not available). From experience with other similar locations, the approaches were very different. Considering the goals, it is logical that the system on such screens must be adapted in such a way that workers automatically receive the necessary and adapted information for their workplace and that they can easily access other data. This means that it is necessary to make maximum use of the known data of the workplace by connecting them to other databases.

4.4. Components and Their Roles in IMPS

The IMPS novel production planning system consists of seven components that are well connected and integrated into an existing system. The overview of the components and its functions leads us to a framework of an IMPS system which is based on interconnecting the existing components. The connectivity enables the system digitalization, central database system, data availability in real time, data decentralization as well as decision-making decentralization, as shown in Table 1.

Table 1.

IMPS components.

5. Discussion

The implementation of IMPS was a challenging task, but the final results remained highly positive. The implementation procedure had not only a technical but also a human component which demanded adaptation at several organizational levels. The implementation of IMPS was a big risk, from the company’s point of view, in both financial and business forms. Therefore, the support of management was key to making a final decision about its implementation. This correlates to many previously published research studies in which the human factor is often one of the greatest barriers in Industry 4.0/5.0 implementation [6,7,10]. Another challenge was the inability of the many contacts during the implementation; therefore, many meetings were conducted via online meeting platforms because IMPS was implemented when certain COVID restrictions were active. MS Project had been used at this company since 2003; therefore, the reactions to its upgrade were positive within the organization, while the IMPS system enabled a centralized, database-based fast system for all users and roles, which prevented double work and data inconsistency and increased efficiencies in their core processes. The validation metrics provided tangible evidence of IMPS aligning with Industry 5.0 principles. The human–computer interaction (HCI) revealed a marked improvement in employee involvement and satisfaction, indicating a successful human-centric approach. The RS underscored the system’s enhanced adaptability, a key aspect of resilience in Industry 5.0. Finally, the SI illustrated progress in sustainable production practices, aligning with the ecological goals of Industry 5.0.

The idea of the system is to be accessible to the end user to find information, as the principles of Industry 5.0 require. A multivariant and multiuser planning capability was aimed to be achieved along with an interconnected Gantt chart of the master project with the ability to drill down into individual projects and custom views for various types of internal users. Most of the production planning solutions found in the literature [39,62,63,74] were optimization-oriented, related to the improvements of the calculation methods within the planning activities in order to achieve a better efficiency of the planning system. Here, the goal was to achieve the system architecture that enabled a unique solution for design-to-order manufacturing without complex interventions into the existing system, overcoming the most common barriers in Industry 4.0 implementation [6,7], which are the human resistance to change, high investments, a lack of needed skills and knowledge for its implementation and use, and challenges of the adaptability to the new system. IMPS is a hybrid solution for SMEs, which aims to advance their planning system from commonly used Excel sheets to a more advanced system, although there are financial and knowledge limitations for the implementation of highly complex software.

The implementation took place over six months and currently, fifteen people use it, four of the planners actively. The users quickly adapted to the new system and the terms it uses. No major technical issues were recorded, only human logical errors. The next step which the company now aims to achieve is that more people are included in the planning system.

IMPS provides an overarching master plan that covers every phase of KPT’s transformer production from design through production. It includes a plan for the design phase, one for core stacking, one for the coil-winding phase, and so on through to testing. Each subproject is automatically uploaded to the overarching plan. As each part is interrelated, every individual plan is adapted when someone alters one aspect of one project. The result is a consolidated master plan that delivers exceptional transparency.

Previously, they had to open each project individually, review it, and send multiple emails to each other to check the status of this or that project. They also produced a PDF overview at the end of each week, but it clearly was not always up to date. Now, they have a complete overview of the consolidated master plan and can drill down into the details of each project. A what-if analysis is also possible. If something in one project is changed, how the modification will affect each of the other projects and the master plan can be recognized.

Simply, the team can now see how long transformer X has been in production, what stage transformer Y is at, when transformer Z is due to move from the design phase into production, and more. Staff can also conduct tailored searches, such as finding out which production plans are due to complete in the next X weeks.

An add-in product called Transformer Selection System (TSS), which is available both as a web app and as a client, enables an enormous amount of insight they did not have before. It can be seen exactly at what stage they are at with the core stacking operation and if there is a threat of bottlenecks anywhere in the process. It enables the production planning team to standardize the planning process and provides information such as deadlines, manufacturing schedules for months or even years ahead, and which resources will be available or unavailable during those times.

The management has noticed that they now have confidence that their plans are always accurate. If one due date is changed, all the others also are, and the stock inventory is also connected to the plan. The bottleneck situation has improved. They now no longer have to send out weekly PDFs with this information, which was already out of date after a couple of days.

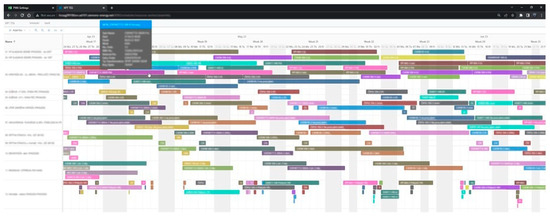

People from different departments can also easily collaborate with the production planning department, which was too complicated before, not only at that company but also mentioned as one of the challenges in the digitalization of production planning from sources in the literature [30,31,37,48]. The reporting solution is web-based, enabling users with the relevant permissions to drill down into individual plans without losing sight of the overall consolidated plan. Figure 7 illustrates the information linked to the MS Project SQL database, which is automatically updated if some information changes and is published in the database.

Figure 7.

TSS Web App—interactive web display of short-term plans.

All this supports the resilient principle characteristic of Industry 5.0, as before, the single production plans were fixed, and every change required many disruptions in the system with manual rescheduling. Now, every change made in the system automatically are reflected to others in real time, so the system response is immediate, and the possibility of error in planning is minimized. The system responsiveness enables an easier and accurate response to every change and disruption, which is one of the main features in resilience. The sustainability aspect of Industry 5.0 is closely related to the resilience of the system, while the capacity and resource planning is easier while the company can take higher risks and address them in a proper way.

Regarding the third characteristic of the Industry 5.0, which is human-centricity, IMPS is an employee-centric solution. The human needs played a central role in the development and implementation of this system, so the workers operate in the new, but to them very common, behavior with novel, automatized processes in the system background. This is also how the learning curve is minimized, while the system enables a unique view on the data, based on the specific needs of each worker. This is how the interpretation of the data remains as accurate as possible with a display of specific data from the single production plan to each user.

The system was developed in a manner which, due to its architecture, future upgrades and modifications are possible and simple, while the connection of the database can be adapted for the needs of both inside and outside systems.

6. Conclusions

This paper presented the development and implementation of a digital production planning system according to Industry 5.0 standards for the unique needs of a local power transformer company in Croatia, based on a comprehensive analysis of current state-of-the-art findings in the field of production planning in Industry 4.0 and 5.0 and current company needs. Three significant characteristics of Industry 5.0 [14,16,42], human-centricity, sustainability, and resilience, were considered when creating the new production planning system. Demonstrated software (ver 1.0) with its components was chosen as the most adequate solution for this type of discrete production.

First, a lack of traceability was observed in the manufacturing process and a lack of information about how new orders would affect the existing production plan. The company needed a way to ensure that all project schedules would be adapted if an alteration was made to one project. It was emphasized that the production planning program must also be easy to use to shorten the existing employees’ learning curve. By dividing the architecture of the new integrated production planning system into three levels—strategic planning, tactical planning, and operational planning/workplace activity, the new Integrated Multilevel Planning Solution (IMPS) system was developed. The IMPS novel production planning system consists of seven components (DSA, SAP, Microsoft Project, Microsoft Project Server, TPG PSLink, TPG ProjectLink, Tableau, and Smart Digital Assistance) that are well connected and integrated into an existing design.

It has been shown that the appropriate approach to designing a human-centric production planning system is first to familiarize oneself with the problems of the existing method of production planning in detail. After the gemba walk, it turned out to be worthwhile to conduct interviews with various stakeholders in the production planning process. During the interview, it was possible to identify the minimum required functionality of the system and the design of a front-end interface that would be simple enough for most employees to work with, which answered RQ1.

By using a user-friendly interface, flexible to customization without coding, and the ability to easily create different filtered views and landscapes, including operational Gantt charts, the learning curve was minimized, which provided an answer to RQ2.

By linking to other systems via defined rules and connections using standard software for interface jobs, IMPS was able to communicate with different legacy databases. This was how the legacy databases were incorporated into a new production planning system, which answered RQ3.

The optimal balance between functionality and simplicity in a real-time digital production planning system can be achieved by conducting expert interviews to define a minimum level of functionality and building customized solutions based on a familiar philosophy (or similar to the know-how available) and an easy-to-use Microsoft interface, which answered RQ4.

The impact of this research is the useability and functionality of a novel production planning solution, which has a limitation because it is a customized solution developed for that particular company. But a similar development approach can be used in many other companies that aim towards the digitalization of production planning. The human-centered solution should be customized to the need of each company and at the same time developed according to the principles of the smart factory. Therefore, this is not a universal solution, but the implemented elements and the intention behind its structure provide a solution for the future design of other custom solutions which do not require radical interventions but the adaptation of the current system and addition of relatively simple and common tools which can be, from a human perspective, even better and more useful than complex systems.

For future research directions, a similar approach of digitalization should be provided for the other phases of the manufacturing process which would be based on a current solution available in the company, its upgrade with digital technologies providing a resilient, sustainable, and human-centered system with a minimal learning curve, following of Industry 5.0 principles.

Author Contributions

Conceptualization, P.G. and Ž.J.; methodology D.S. and M.T.; software, Ž.J. and D.S.; validation, M.T. and P.G.; formal analysis, P.G.; investigation, M.T.; resources, Ž.J. and D.S.; data curation, Ž.J. and D.S.; writing—original draft preparation, M.T. and P.G.; writing—review and editing, M.T. and P.G.; visualization, Ž.J.; supervision, Ž.J.; project administration, P.G.; funding acquisition, P.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by European Regional Development Fund KK.01.1.1.07.0052.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Additional data available on request: petar.greguric@fsb.hr. The data are not publicly available due to privacy.

Conflicts of Interest

Authors Žarko Janić and Domagoj Salaj were employed by the company Končar—Power Transformers. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Vogel-Heuser, B.; Hess, D. Guest Editorial Industry 4.0-Prerequisites and Visions. IEEE Trans. Autom. Sci. Eng. 2016, 13, 411–413. [Google Scholar] [CrossRef]

- Hegedić, M.; Gregurić, P.; Gudlin, M.; Golec, M.; Denadija, A.; Tošanović, N.; Štefanić, N. Design and Establishment of a Learning Factory at the FMENA Zagreb. Teh. Glas. 2022, 16, 426–431. [Google Scholar] [CrossRef]

- Kusiak, A. Smart Manufacturing. Int. J. Prod. Res. 2017, 56, 508–517. [Google Scholar] [CrossRef]

- Industry 4.0 and Smart Manufacturing. Available online: https://www.isa.org/intech-home/2022/august-2022/features/introduction-the-birth-of-industry-4-0-and-smart-m (accessed on 25 June 2023).

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the Annual Hawaii International Conference on System Sciences, Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar] [CrossRef]

- Jones, M.D.; Hutcheson, S.; Camba, J.D. Past, Present, and Future Barriers to Digital Transformation in Manufacturing: A Review. J. Manuf. Syst. 2021, 60, 936–948. [Google Scholar] [CrossRef]

- Stentoft, J.; Adsbøll Wickstrøm, K.; Philipsen, K.; Haug, A. Drivers and Barriers for Industry 4.0 Readiness and Practice: Empirical Evidence from Small and Medium-Sized Manufacturers. Prod. Plan. Control 2021, 32, 811–828. [Google Scholar] [CrossRef]

- Matsuda, K.; Uesugi, S.; Naruse, K.; Morita, M. Technologies of Production with Society 5.0. In Proceedings of the BESC 2019—6th International Conference on Behavioral, Economic and Socio-Cultural Computing, Beijing, China, 28–30 October 2019. [Google Scholar] [CrossRef]

- Rahmani, M.; Romsdal, A.; Sgarbossa, F.; Strandhagen, J.O.; Holm, M. Towards Smart Production Planning and Control; a Conceptual Framework Linking Planning Environment Characteristics with the Need for Smart Production Planning and Control. Annu. Rev. Control 2022, 53, 370–381. [Google Scholar] [CrossRef]

- Saniuk, S.; Saniuk, A. Challenges of Industry 4.0 for Production Enterprises Functioning Within Cyber Industry Networks. Manag. Syst. Prod. Eng. 2018, 26, 212–216. [Google Scholar] [CrossRef]

- Tobon Valencia, E.; Lamouri, S.; Pellerin, R.; Moeuf, A. A Novel Analysis Framework of 4.0 Production Planning Approaches—Part II. Stud. Comput. Intell. 2021, 987, 133–150. [Google Scholar] [CrossRef]

- Hegedić, M.; Gregurić, P.; Gudlin, M.; Golec, M.; Đenadija, A.; Tošanović, N.; Štefanić, N. Designing Modular Learning Factory Concept at the FMENA Zagreb—A Case Study. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022; pp. 1–3. [Google Scholar] [CrossRef]

- Industry 5.0—Publications Office of the EU. Available online: https://op.europa.eu/en/publication-detail/-/publication/468a892a-5097-11eb-b59f-01aa75ed71a1/ (accessed on 21 April 2023).

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, Conception and Perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and Retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Huang, S.; Wang, B.; Li, X.; Zheng, P.; Mourtzis, D.; Wang, L. Industry 5.0 and Society 5.0—Comparison, Complementation and Co-Evolution. J. Manuf. Syst. 2022, 64, 424–428. [Google Scholar] [CrossRef]

- Trstenjak, M.; Opetuk, T.; Cajner, H.; Hegedić, M. Industry 4.0 Readiness Calculation—Transitional Strategy Definition by Decision Support Systems. Sensors 2022, 22, 1185. [Google Scholar] [CrossRef]

- Lapré, M.A. Inside the Learning Curve: Opening the Black Box of the Learning Curve. In Learning Curves: Theory, Models, and Applications; CRC Press: Boca Raton, FL, USA, 2009; pp. 23–35. [Google Scholar] [CrossRef]

- Argote, L.; Epple, D. Learning Curves in Manufacturing. Science 1990, 247, 920–924. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Trstenjak, M.; Cosic, P. Process Planning in Industry 4.0 Environment. Procedia Manuf. 2017, 11, 1744–1750. [Google Scholar] [CrossRef]

- Trstenjak, M.; Opetuk, T.; Cajner, H.; Tosanovic, N. Process Planning in Industry 4.0—Current State, Potential and Management of Transformation. Sustainability 2020, 12, 5878. [Google Scholar] [CrossRef]