Study of Pavement Macro- and Micro-Texture Evolution Law during Compaction Using 3D Laser Scanning Technology

Abstract

1. Introduction

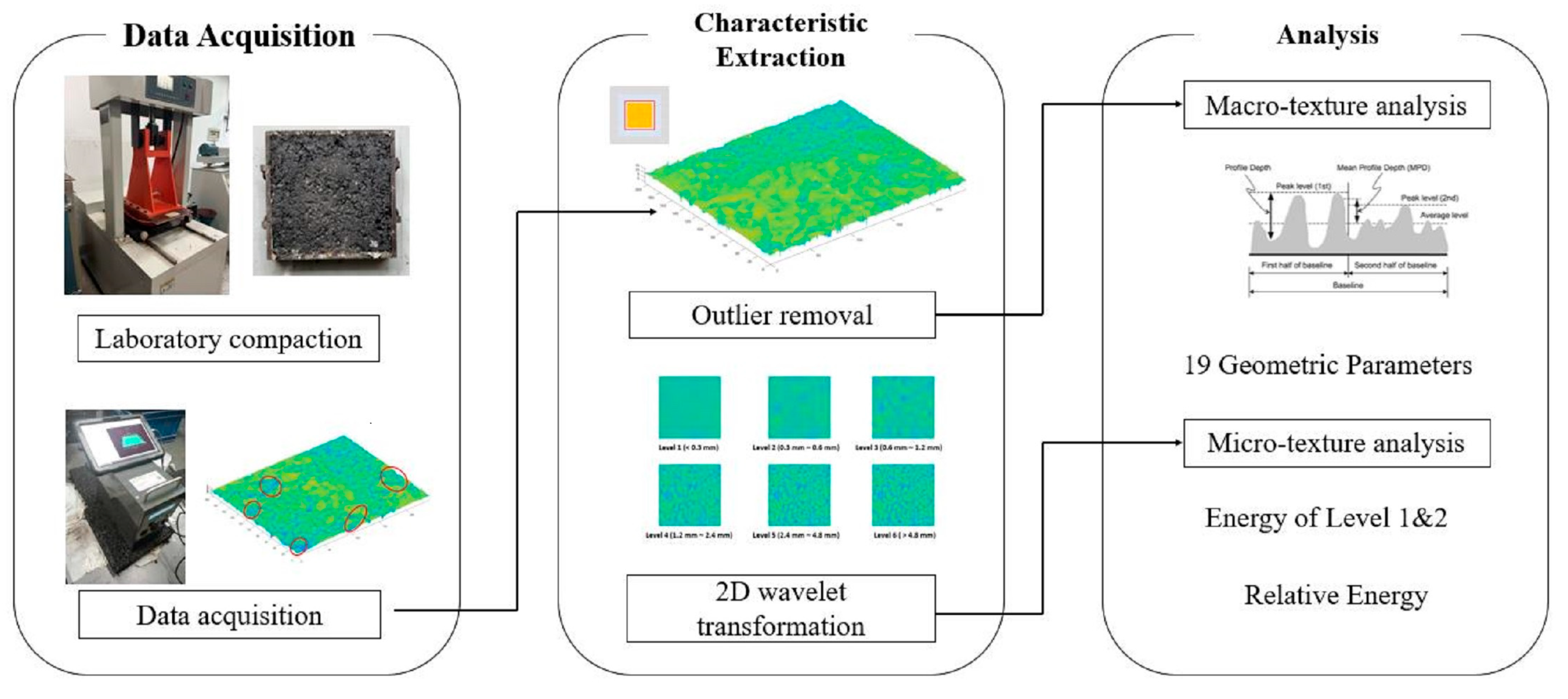

2. Materials and Test Method

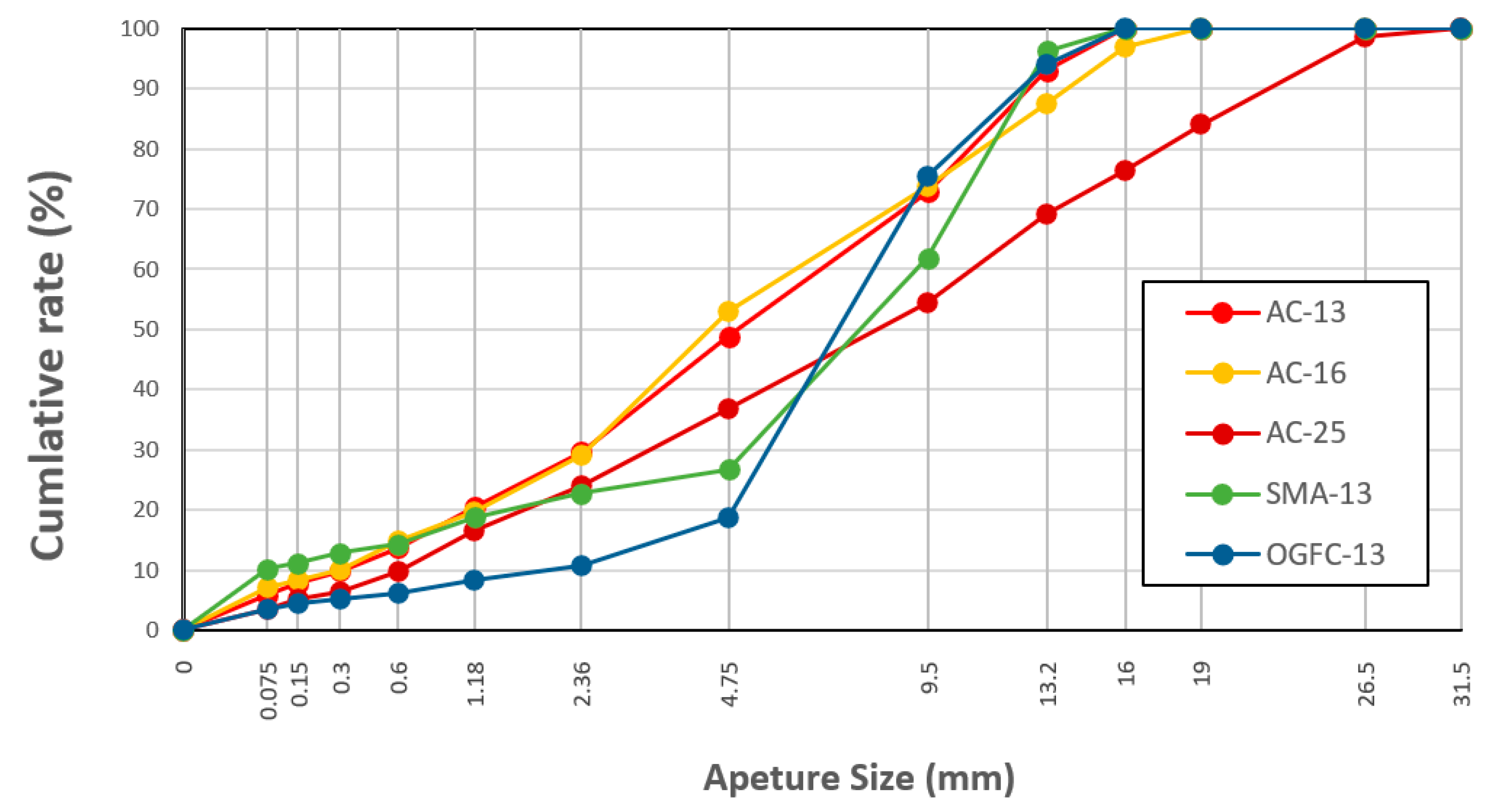

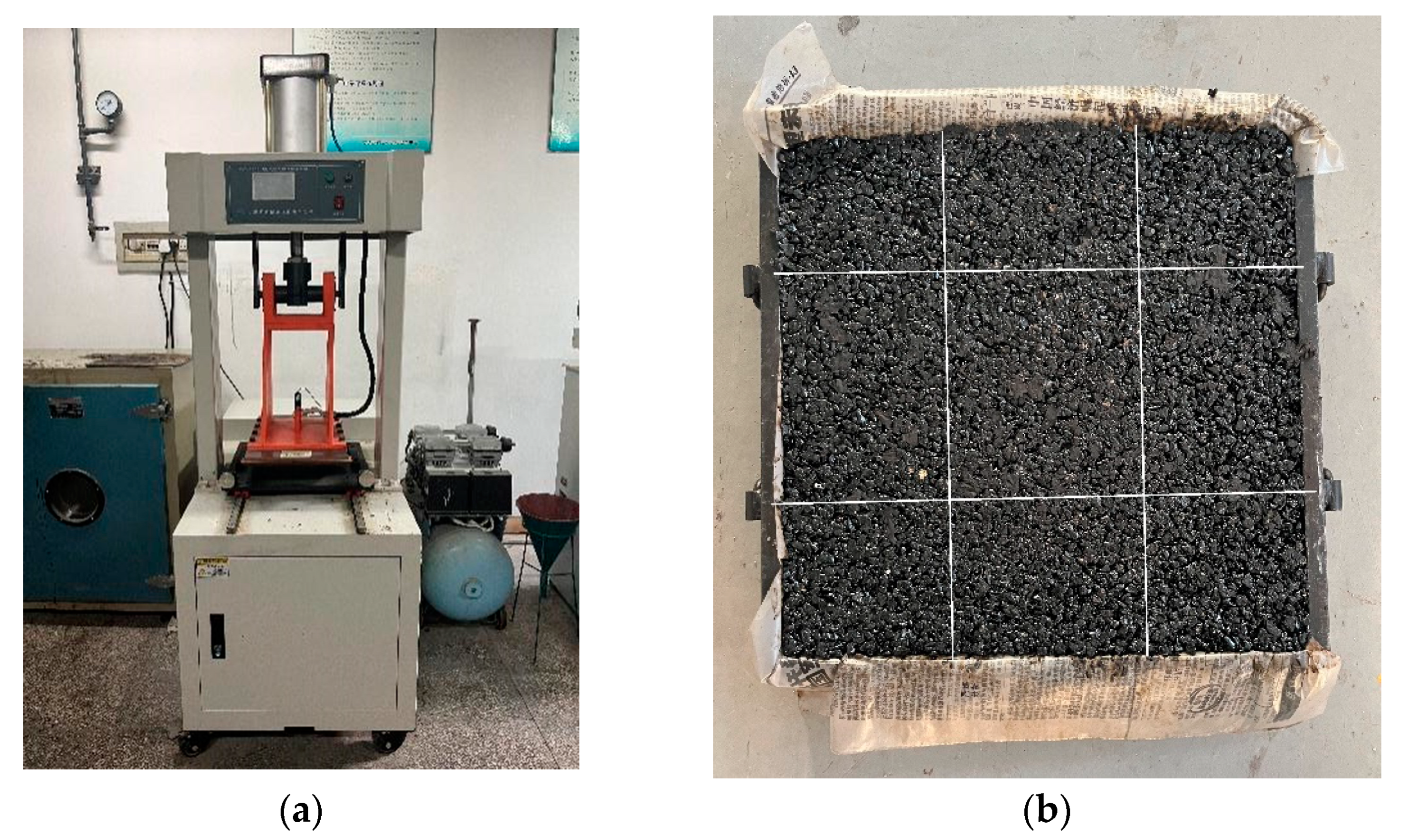

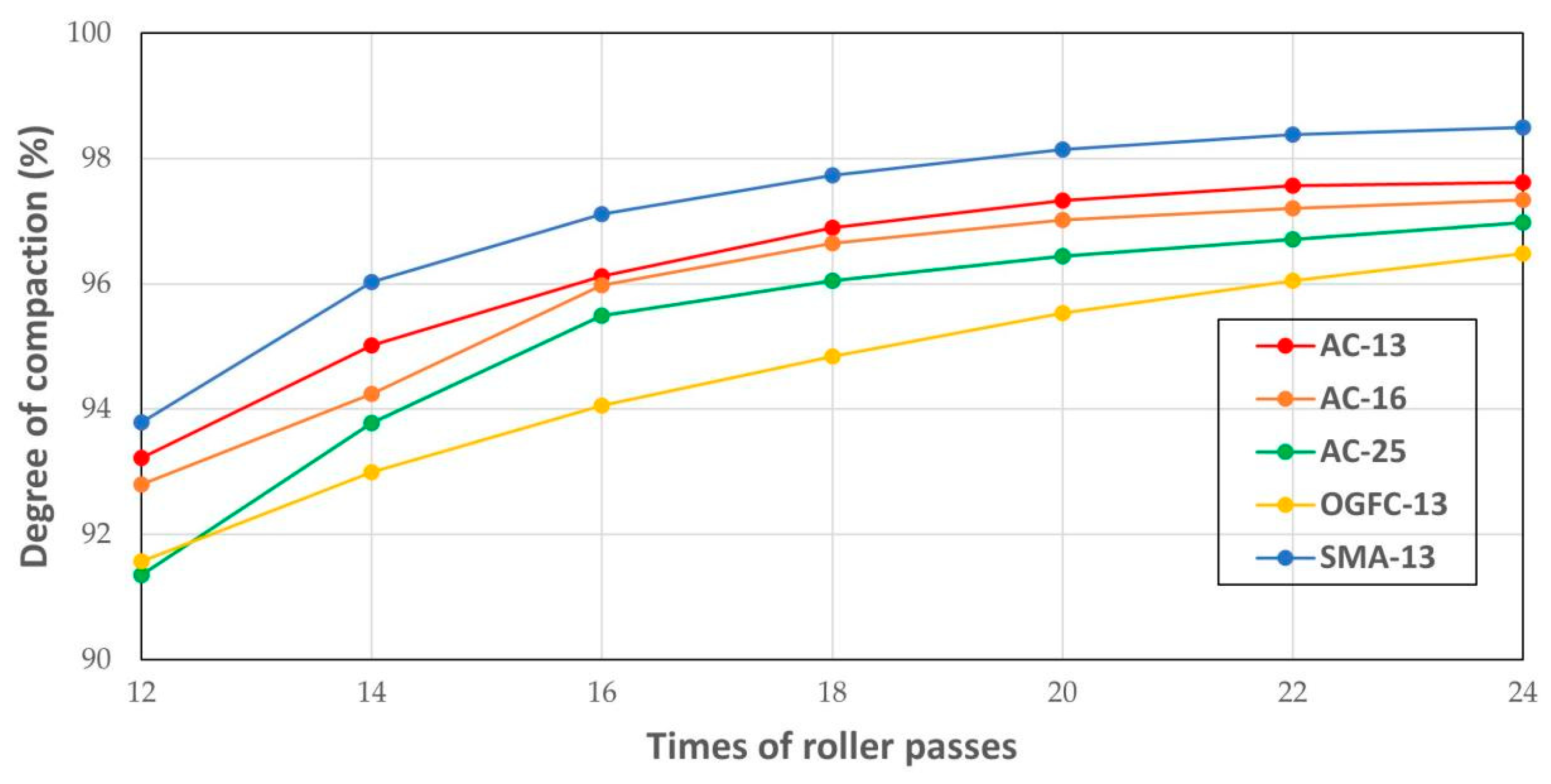

2.1. Preparation of Asphalt Mixture

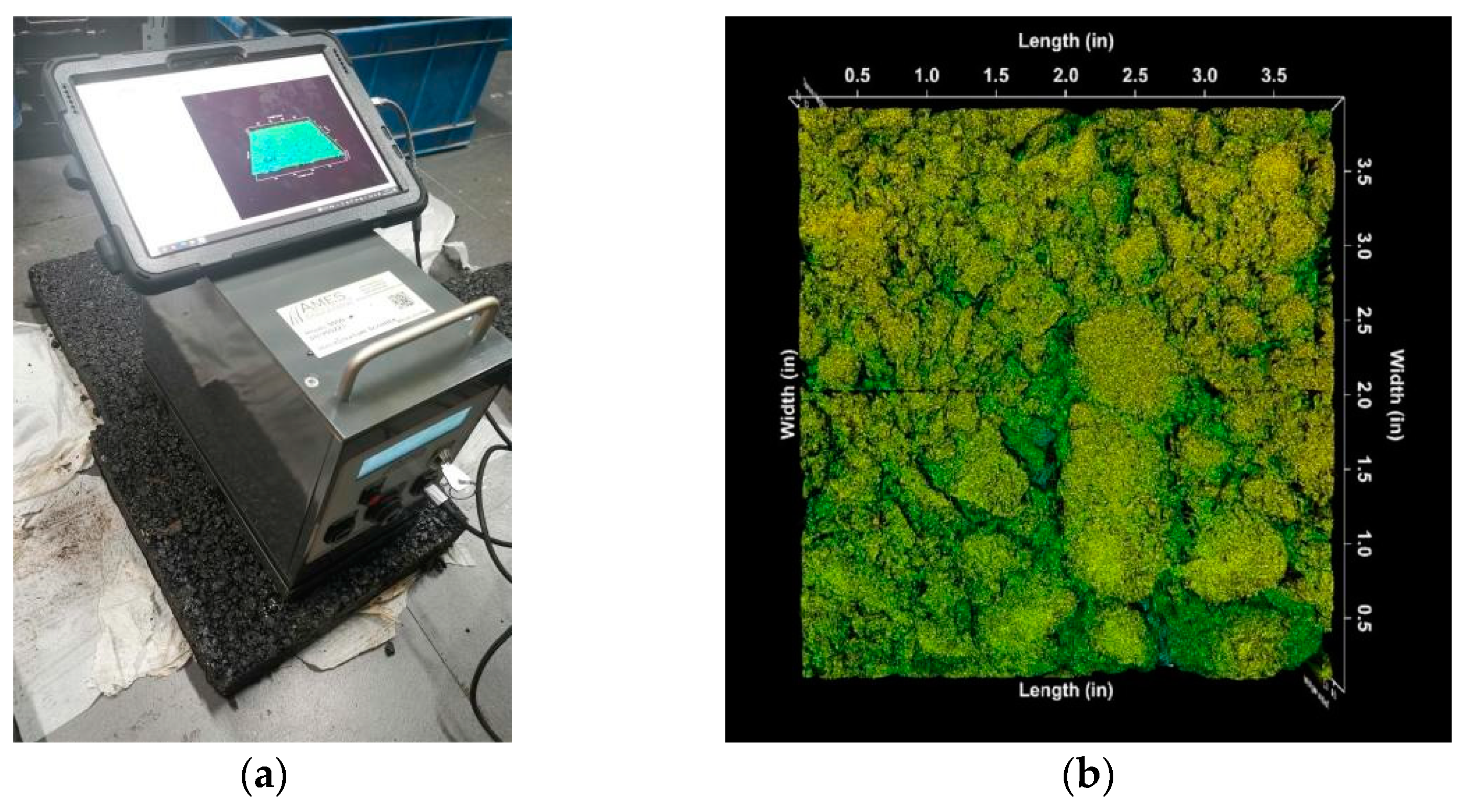

2.2. Data Collection

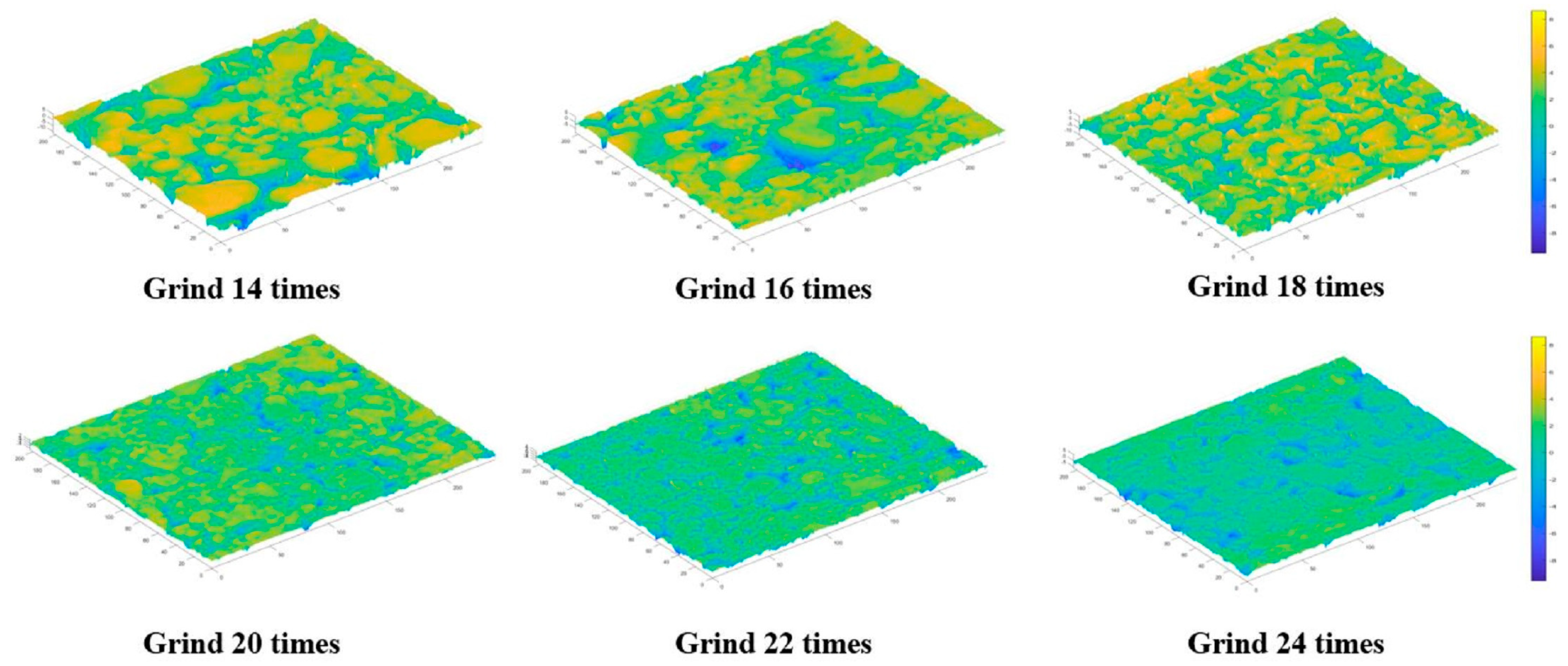

2.3. Scanning Results

3. Methodology

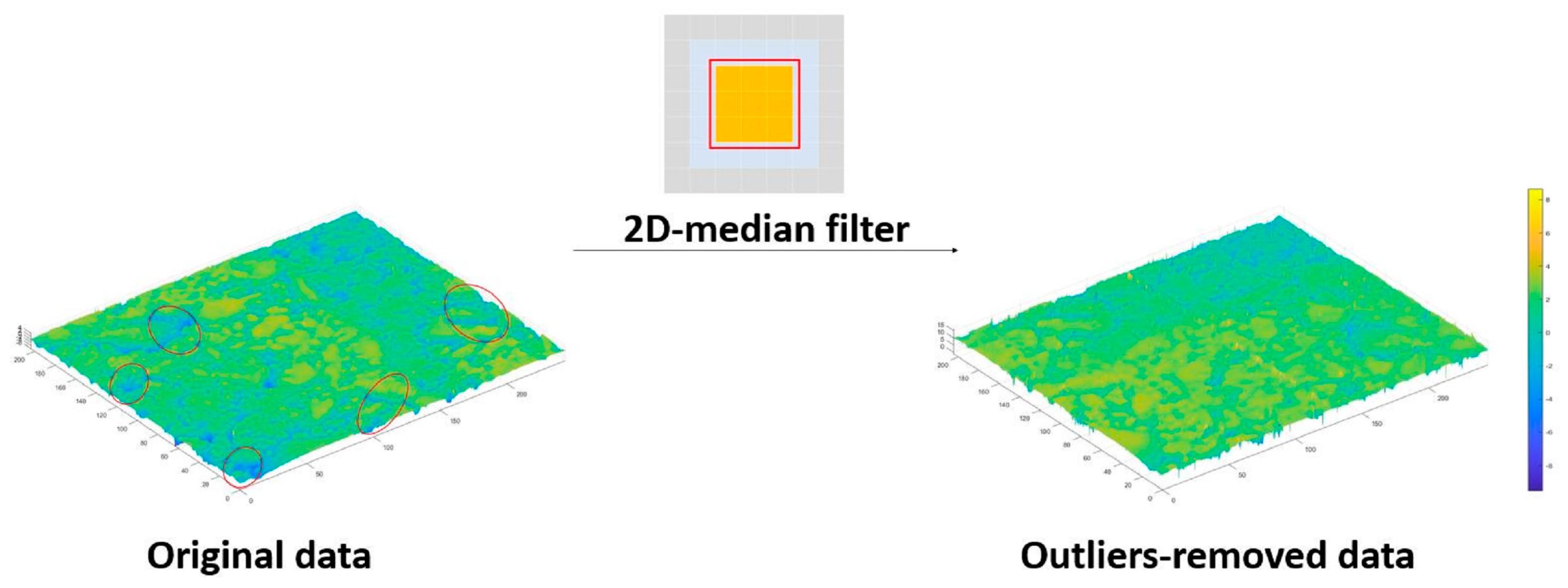

3.1. Data Pre-Process

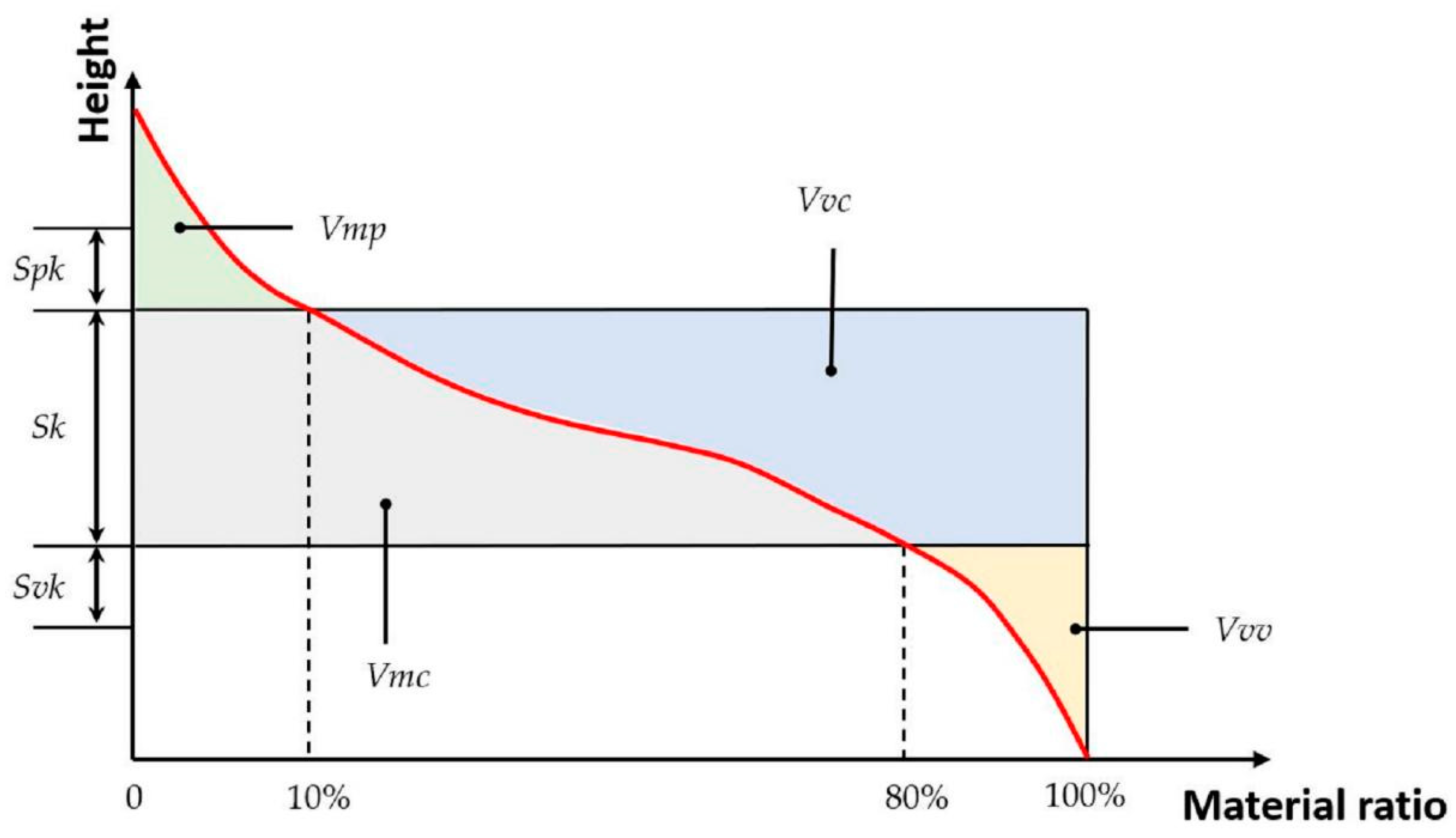

3.2. Calculation of Geometric Parameters

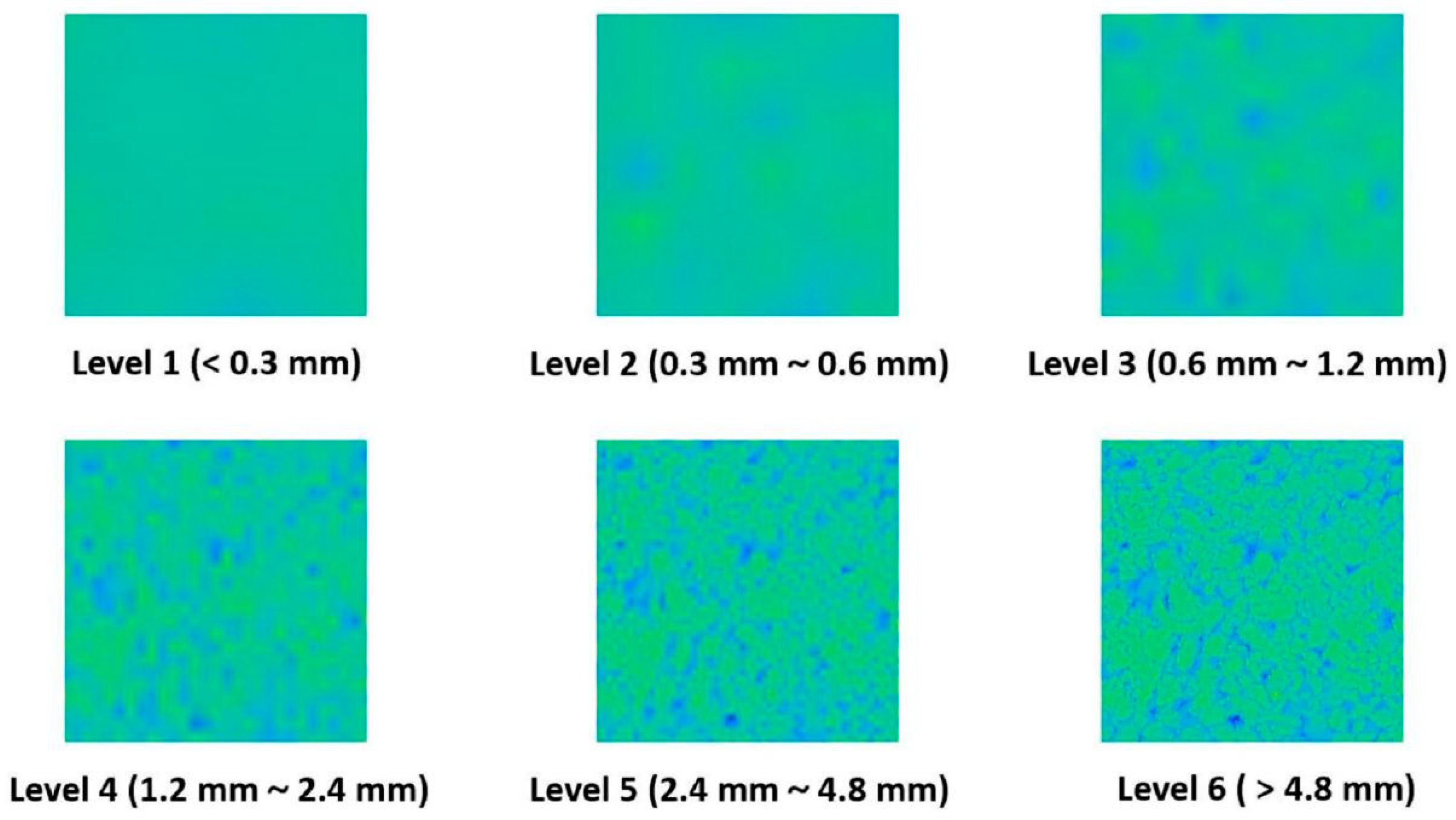

3.3. 2D Wavelet Decomposition

4. Results and Discussion

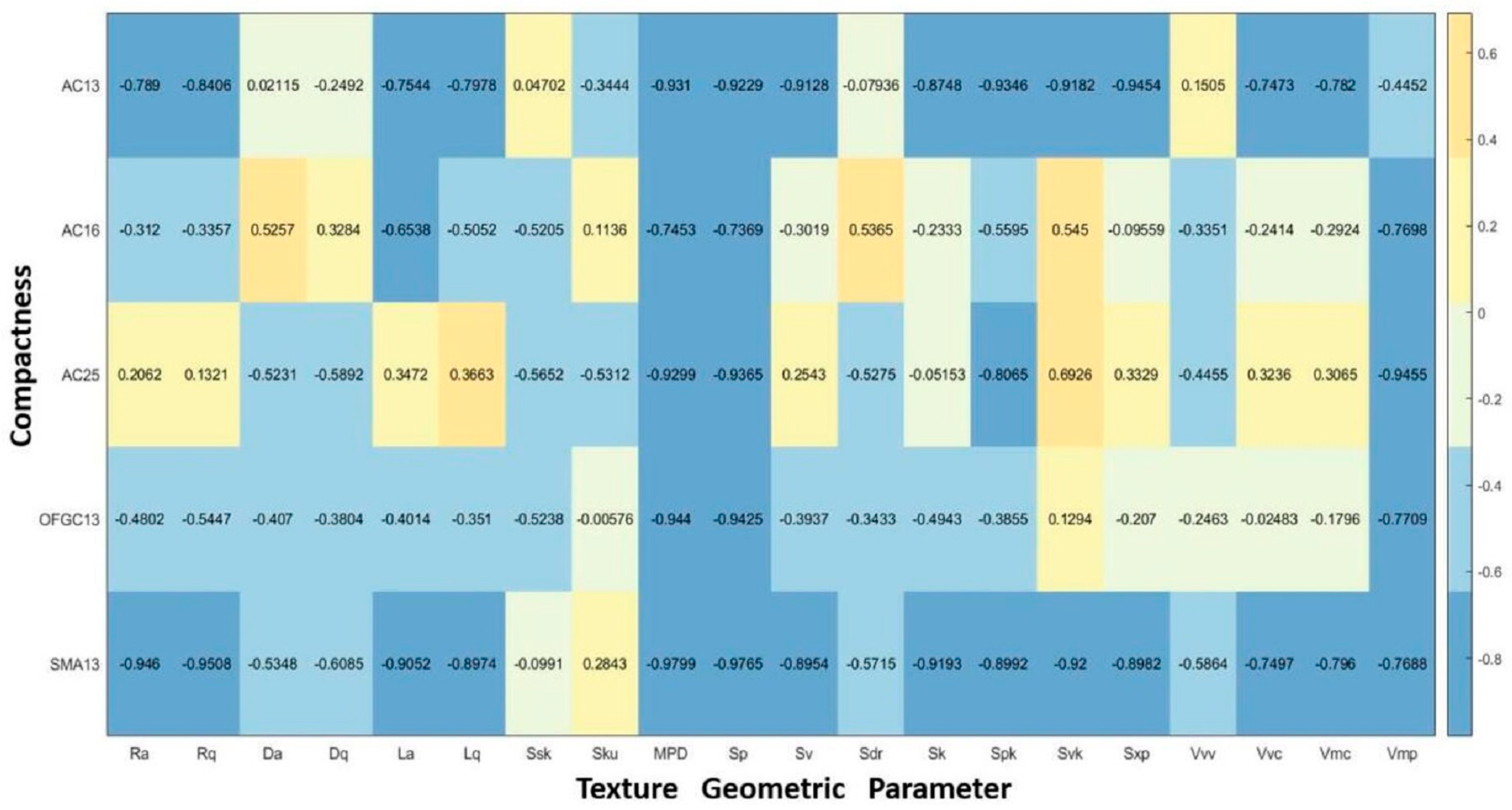

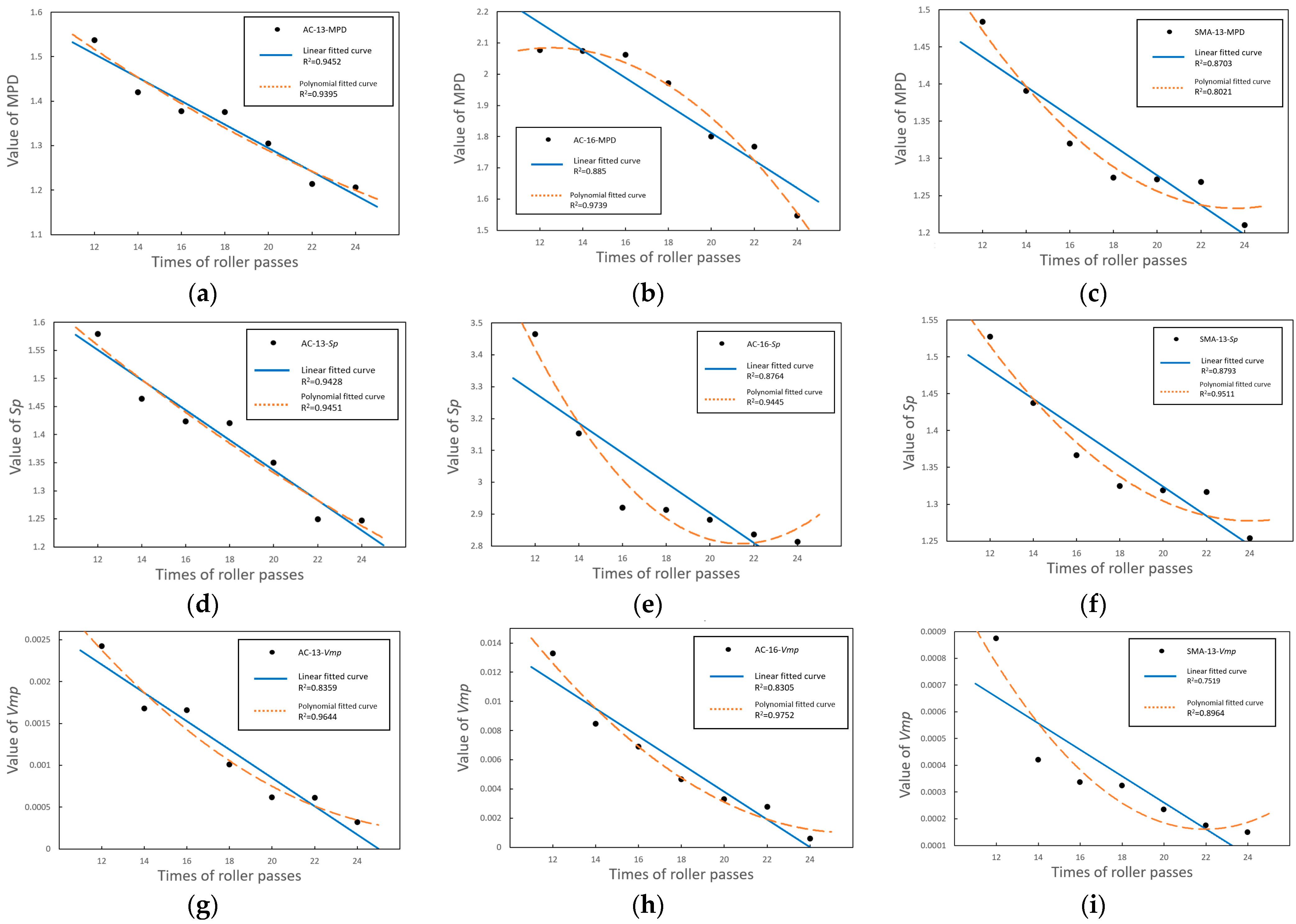

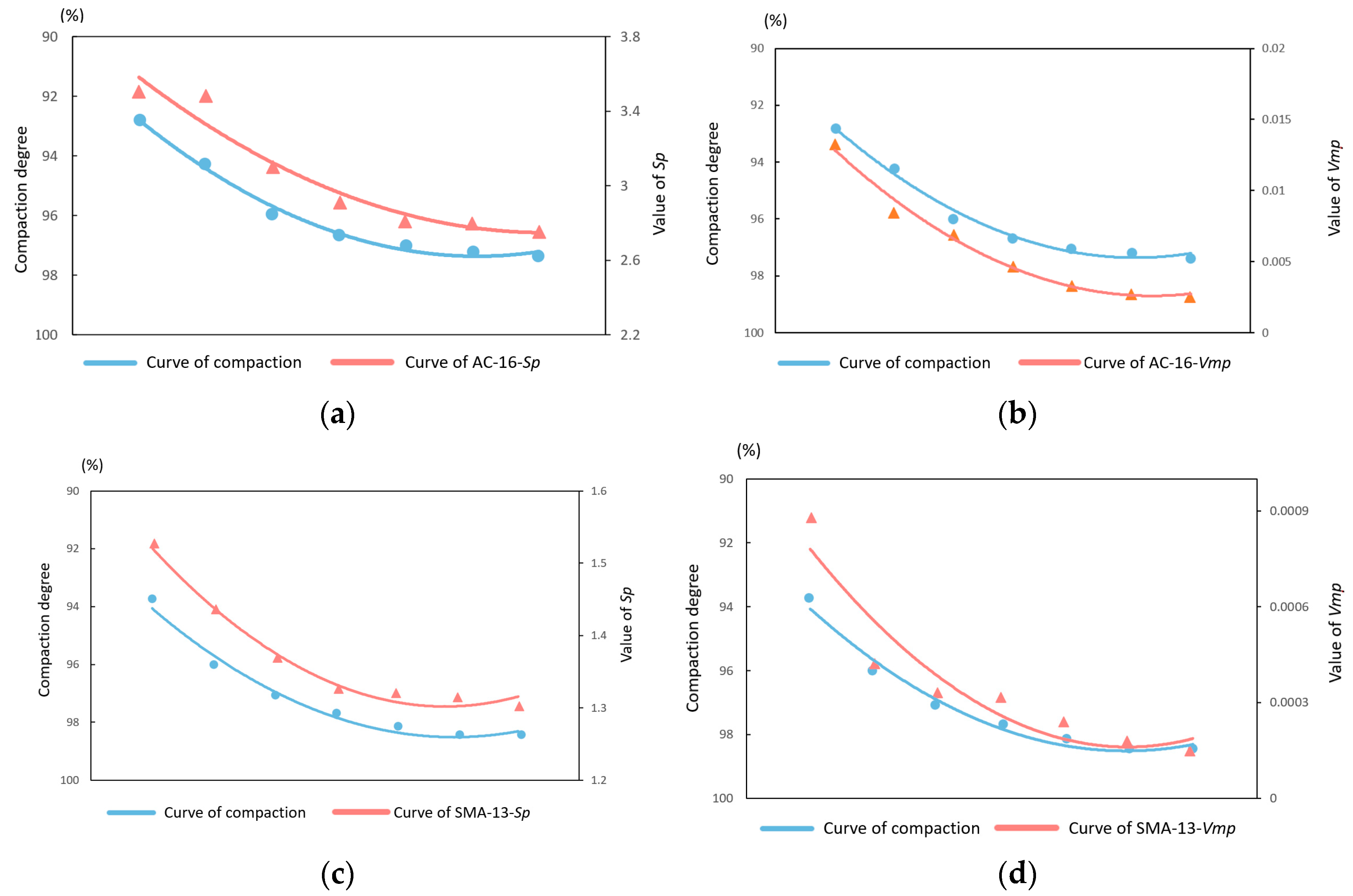

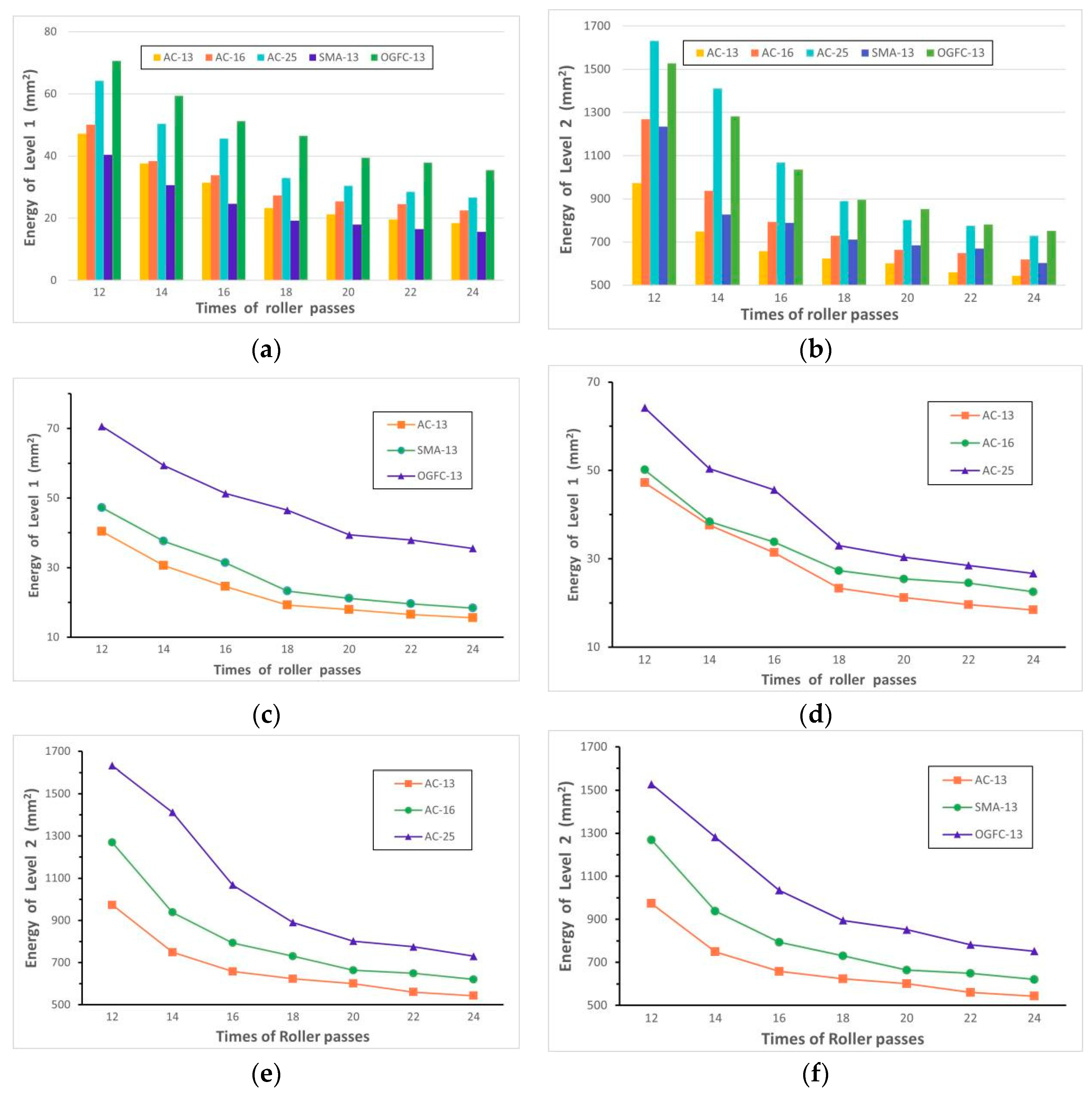

4.1. Evolution Law of Macro-Texture Characteristics

4.2. Evolution Law of Micro-Texture Characteristics

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jia, X. Evaluation of Compaction Uniformity of Asphalt Pavement Based on Construction Depth Variation. J. Appl. Math. 2022, 2022, 5732050. [Google Scholar] [CrossRef]

- Lai, F.; Huang, Z.; Guo, F. Noise Reduction Characteristics of Macroporous Asphalt Pavement Based on a Weighted Sound Pressure Level Sensor. Materials 2021, 14, 4356. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Xu, N.; Weng, Z.; Li, Y.; Du, Y.; Cao, J. Effective pavement skid resistance measurement using multi-scale textures and deep fusion network. Comput.-Aided Civ. Infrastruct. Eng. 2022, 38, 1041–1058. [Google Scholar] [CrossRef]

- Zhao, C.; Song, A.; Zhu, Y.; Jiang, S.; Liao, F.; Du, Y. Data-driven indoor positioning correction for infrastructure-enabled autonomous driving systems: A lifelong framework. IEEE Trans. Intell. Transp. Syst. 2023, 24, 3908–3921. [Google Scholar] [CrossRef]

- Ji, Y.; Ni, L.; Zhao, C.; Lei, C.; Du, Y.; Wang, W. TriPField: A 3D potential field model and its applications to local path planning of autonomous vehicles. IEEE Trans. Intell. Transp. Syst. 2023, 24, 3541–3554. [Google Scholar] [CrossRef]

- Du, Y.; Chen, J.; Zhao, C.; Liao, F.; Zhu, M. A hierarchical framework for improving ride comfort of autonomous vehicles via deep reinforcement learning with external knowledge. Comput.-Aided Civ. Infrastruct. Eng. 2022, 38, 1059–1078. [Google Scholar] [CrossRef]

- Bitelli, G.; Simone, A.; Girardi, F.; Lantieri, C. Laser Scanning on Road Pavements: A New Approach for Characterizing Surface Texture. Sensors 2012, 12, 9110–9128. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, D.; Zhang, P.; Niu, Y.; Xia, H.; Liu, P. Macro-meso multiscale analysis of asphalt concrete in different laboratory compaction methods and field compaction. Constr. Build. Mater. 2022, 361, 129607. [Google Scholar] [CrossRef]

- Cao, M.; Yong, L.; Ming, F. To Discuss the Asphalt Pavement’s Early Damages. In Proceedings of the International Conference on Civil Engineering & Urban Planning, Yantai, China, 18–20 August 2012. [Google Scholar]

- PIARC World Road Association. PIARC “Report of the Committee on Surface Characteristics”. In Proceedings of the XVIII World Road Congress, Brussels, Belgium, 13–19 September 1987. [Google Scholar]

- Plati, C.; Pomoni, M.; Stergiou, T. From mean texture depth to mean profile depth: Exploring possibilities. In Bituminous Mixtures and Pavements VII; CRC Press: Boca Raton, FL, USA, 2019; pp. 660–665. [Google Scholar]

- Liu, C.L.; Nie, T.; Du, Y.C.; Cao, J.; Wu, D.F.; Li, F. A Response-Type Road Anomaly Detection and Evaluation Method for Steady Driving of Automated Vehicles. IEEE Trans. Intell. Transp. Syst. 2022, 23, 21984–21995. [Google Scholar] [CrossRef]

- Du, Y.; Li, Y.; Jiang, S.; Shen, Y. Mobile Light Detection and Ranging for Automated Pavement Friction Estimation. Transp. Res. Rec. 2019, 2673, 663–672. [Google Scholar] [CrossRef]

- Abbas, A.; Kutay, M.E.; Azari, H.; Rasmussen, R. Three-dimensional surface texture characterization of Portland cement concrete pavements. Comput. Aided Civ. Infrastruct. Eng. 2007, 22, 197–209. [Google Scholar] [CrossRef]

- Hao, X.; Sha, A.; Sun, Z.; Li, W.; Zhao, H. Evaluation and Comparison of Real-Time Laser and Electric Sand-Patch Pavement Texture-Depth Measurement Methods. J. Transp. Eng. 2016, 142, 04016022. [Google Scholar] [CrossRef]

- Yu, M.; Xu, X.; Wu, C.; Li, S.; Li, M.; Chen, H. Research on the Prediction Model of the Friction Coefficient of Asphalt Pavement Based on Tire-Pavement Coupling. Adv. Mater. Sci. Eng. 2021, 2021, 6650525. [Google Scholar] [CrossRef]

- Weng, Z.; Ablat, G.; Wu, D.; Liu, C.; Li, F.; Du, Y.; Cao, J. Rapid pavement aggregate gradation estimation based on 3D data using a multi-feature fusion network. Autom. Constr. 2022, 134, 104050. [Google Scholar] [CrossRef]

- Du, Y.; Qin, B.; Weng, Z.; Wu, D.; Liu, C. Promoting the pavement skid resistance estimation by extracting tire-contacted texture based on 3D surface data. Constr. Build. Mater. 2021, 307, 124729. [Google Scholar] [CrossRef]

- Kanafi, M.M.; Tuononen, A.J. Top topography surface roughness power spectrum for pavement friction evaluation. Tribol. Int. 2017, 107, 240–249. [Google Scholar] [CrossRef]

- Kane, M.; Rado, Z.; Timmons, A. Exploring the texture-friction relationship: From texture empirical decomposition to pavement friction. Int. J. Pavement Eng. 2015, 16, 919–928. [Google Scholar] [CrossRef]

- Miao, Y.H.; Wu, J.Q.; Hou, Y.; Wang, L.B.; Yu, W.X.; Wang, S.D. Study on Asphalt Pavement Surface Texture Degradation Using 3-D Image Processing Techniques and Entropy Theory. Entropy 2019, 21, 208. [Google Scholar] [CrossRef]

- Hartikainen, L.; Petry, F.; Westermann, S. Frequency-wise correlation of the power spectral density of asphalt surface roughness and tire wet friction. Wear 2014, 317, 111–119. [Google Scholar] [CrossRef]

- Du, Y.C.; Weng, Z.H.; Li, F.; Ablat, G.; Wu, D.F.; Liu, C.L. A novel approach for pavement texture characterisation using 2D-wavelet decomposition. Int. J. Pavement Eng. 2022, 23, 1851–1866. [Google Scholar] [CrossRef]

- Li, Y.S.; Liu, C.L.; Yue, G.H.; Gao, Q.; Du, Y.C. Deep learning-based pavement subsurface distress detection via ground penetrating radar data. Autom. Constr. 2022, 142, 104516. [Google Scholar] [CrossRef]

- Du, Y.C.; Liu, C.L.; Song, Y.; Li, Y.S.; Shen, Y. Rapid Estimation of Road Friction for Anti-Skid Autonomous Driving. IEEE Trans. Intell. Transp. Syst. 2020, 21, 2461–2470. [Google Scholar] [CrossRef]

- Li, Y.S.; Liu, C.L.; Gao, Q.; Wu, D.F.; Li, F.; Du, Y.C.A. ConTrack Distress Dataset: A Continuous Observation for Pavement Deterioration Spatio-Temporal Analysis. IEEE Trans. Intell. Transp. Syst. 2022, 23, 25004–25017. [Google Scholar] [CrossRef]

- Nivitha, M.R.; Krishnan, J.M. Rheological characterisation of unmodified and modified bitumen in the 90-200 degrees C temperature regime. Road Mater. Pavement Des. 2020, 21, 1341–1358. [Google Scholar] [CrossRef]

- Ingrassia, L.P.; Lu, X.H.; Ferrotti, G.; Canestrari, F. Chemical, morphological and rheological characterization of bitumen partially replaced with wood bio-oil: Towards more sustainable materials in road pavements. J. Traffic Transp. Eng. Engl. Ed. 2020, 7, 192–204. [Google Scholar] [CrossRef]

- Hu, C.C.; Feng, J.Q.; Zhou, N.; Zhu, J.; Zhang, S.C. Hydrochar from corn stalk used as bio-asphalt modifier: High-temperature performance improvement. Environ. Res. 2021, 193, 110157. [Google Scholar] [CrossRef]

- Gallivan, V.L.; Chang, G.K.; Horan, D.R. Intelligent compaction for improving roadway construction. In Emerging Technologies for Material, Design, Rehabilitation, and Inspection of Roadway Pavements; American Society of Civil Engineers: Reston, VI, USA, 2011; pp. 117–124. [Google Scholar]

- Wang, S.Q.; Sui, X.; Leng, Z.; Jiang, J.W.; Lu, G.Y. Asphalt pavement density measurement using non-destructive testing methods: Current practices, challenges, and future vision. Constr. Build. Mater. 2022, 344, 128154. [Google Scholar] [CrossRef]

- Yaacob, H.; Hassan, N.A.; Hainin, M.R.; Rosli, M.F. Comparison of sand patch test and multi laser profiler in pavement surface measurement. J. Teknol. 2014, 70, 103–106. [Google Scholar] [CrossRef]

- Pietruszewski, P.; Poswiata, A.; Wesolowski, M. Evaluation of airfield pavement evenness. In Proceedings of the Conference on Resilient and Safe Road Infrastructure (KIELCE), Kielce, Poland, 8–9 May 2018. [Google Scholar]

- Konrad, J.M.; Lachance, D. Use of in situ penetration tests in pavement evaluation. Can. Geotech. J. 2001, 38, 924–935. [Google Scholar] [CrossRef]

- Quantifying Laboratory Compaction Effects on the Internal Structure of Asphalt Concrete. Transp. Res. Rec. 1999, 1681, 179–185. [CrossRef]

- Boscaino, G.; Celauro, B.; Celauro, C.; Amadore, A. Evaluation of the laboratory prediction of surface properties of bituminous mixtures. Constr. Build. Mater. 2009, 23, 943–952. [Google Scholar] [CrossRef]

- Georgiou, P.; Loizos, A. Quality assurance of HMA pavement surface macrotexture: Empirical models vs experimental approach. Int. J. Pavement Res. Technol. 2019, 12, 356–363. [Google Scholar] [CrossRef]

- Walsh, S.B.; Borello, D.J.; Guldur, B.; Hajjar, J.F. Data Processing of Point Clouds for Object Detection for Structural Engineering Applications. Comput. Aided Civ. Infrastruct. Eng. 2013, 28, 495–508. [Google Scholar] [CrossRef]

- Ergun, M.; Iyinam, S.; Iyinam, A.F. Prediction of road surface friction coefficient using only macro- and microtexture measurements. J. Transp. Eng. Asce 2005, 131, 311–319. [Google Scholar] [CrossRef]

- Hu, L.Q.; Yun, D.; Liu, Z.Z.; Du, S.W.; Zhang, Z.; Bao, Y.B. Effect of three-dimensional macrotexture characteristics on dynamic frictional coefficient of asphalt pavement surface. Constr. Build. Mater. 2016, 126, 720–729. [Google Scholar] [CrossRef]

- Li, Q.; Yang, G.W.; Wang, K.C.P.; Zhan, Y.; Wang, C.H. Novel Macro- and Microtexture Indicators for Pavement Friction by Using High-Resolution Three-Dimensional Surface Data. Transp. Res. Rec. 2017, 2641, 164–176. [Google Scholar] [CrossRef]

- Zelelew, H.M.; Papagiannakis, A.T.; Izeppi, E.D.D. Pavement macro-texture analysis using wavelets. Int. J. Pavement Eng. 2013, 14, 725–735. [Google Scholar] [CrossRef]

- Zelelew, H.; Khasawneh, M.; Abbas, A. Wavelet-based characterisation of asphalt pavement surface macro-texture. Road Mater. Pavement Des. 2014, 15, 622–641. [Google Scholar] [CrossRef]

- Yang, G.W.; Li, Q.J.; Zhan, Y.J.; Wang, K.C.P.; Wang, C.H. Wavelet based macrotexture analysis for pavement friction prediction. Ksce J. Civ. Eng. 2018, 22, 117–124. [Google Scholar] [CrossRef]

| Parameters | Meaning | Equation |

|---|---|---|

| Profile parameters | ||

| MPD (mm) | Mean profile depth | |

| Ra (mm) | Roughness average | |

| Rq (mm) | RMS roughness | |

| Da | Arithmetic mean slope | |

| Dq | RMS slope | |

| La (mm) | Average wavelength | |

| Lq (mm) | RMS wavelength | |

| Height parameters | ||

| Ssk | Skewness of height distribution | |

| Sku | Kurtosis of height distribution | |

| Sp (mm) | Maximum peak height | |

| Sv (mm) | Maximum valley height | |

| Functional parameters | ||

| Sk (mm) | Core height | |

| Spk (mm) | Reduced peak height | |

| Svk (mm) | Reduse valley height | |

| Volume parameters | ||

| Vvv (mm3/mm2) | Dale void volume | |

| Vvc (mm3/mm2) | Core void volume | |

| Vmp (mm3/mm2) | Peak material volume | |

| Vmc (mm3/mm2) | Core material volume | |

| Hybrid parameters | ||

| Sdr | Developed interfacial area ratio |

| RE of Mixtures after Roller Passes 12 Times | AC-13 | AC-16 | AC-25 | SMA-13 | OGFC-13 | |

| Decomposition Level | Level 1 | 0.2 | 0.2 | 0.3 | 0.1 | 0.3 |

| Level 2 | 4.1 | 5.1 | 7.6 | 3.1 | 6.5 | |

| Level 3 | 6.6 | 7.2 | 9.3 | 14.2 | 7.5 | |

| Level 4 | 24.4 | 14.3 | 9.5 | 24.9 | 10.2 | |

| Level 5 | 12.5 | 26.5 | 12.4 | 16.5 | 16.3 | |

| Level 6 | 52.1 | 46.7 | 60.9 | 41.2 | 59.1 | |

| RE of Mixtures after Roller Passes 24 times | AC-13 | AC-16 | AC-25 | SMA-13 | OGFC-13 | |

| Decomposition Level | Level 1 | 0.1 | 0.2 | 0.3 | 0.1 | 0.4 |

| Level 2 | 3.0 | 5.5 | 8.2 | 3.9 | 8.5 | |

| Level 3 | 5.2 | 12.4 | 9.0 | 16.2 | 8.5 | |

| Level 4 | 26.5 | 13.8 | 9.7 | t.3 | 13.0 | |

| Level 5 | 14.2 | 23.9 | 12.4 | 17.3 | 13.2 | |

| Level 6 | 50.9 | 44.2 | 60.3 | 42.2 | 56.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.; Dong, C.; Wu, D.; Jiang, S.; Xiang, H.; Weng, Z. Study of Pavement Macro- and Micro-Texture Evolution Law during Compaction Using 3D Laser Scanning Technology. Appl. Sci. 2023, 13, 5736. https://doi.org/10.3390/app13095736

Lin Y, Dong C, Wu D, Jiang S, Xiang H, Weng Z. Study of Pavement Macro- and Micro-Texture Evolution Law during Compaction Using 3D Laser Scanning Technology. Applied Sciences. 2023; 13(9):5736. https://doi.org/10.3390/app13095736

Chicago/Turabian StyleLin, Yuchao, Chenyang Dong, Difei Wu, Shengchuan Jiang, Hui Xiang, and Zihang Weng. 2023. "Study of Pavement Macro- and Micro-Texture Evolution Law during Compaction Using 3D Laser Scanning Technology" Applied Sciences 13, no. 9: 5736. https://doi.org/10.3390/app13095736

APA StyleLin, Y., Dong, C., Wu, D., Jiang, S., Xiang, H., & Weng, Z. (2023). Study of Pavement Macro- and Micro-Texture Evolution Law during Compaction Using 3D Laser Scanning Technology. Applied Sciences, 13(9), 5736. https://doi.org/10.3390/app13095736