Design and Verification of a Large-Scaled Flapping-Wing Aircraft Named “Cloud Owl”

Abstract

1. Introduction

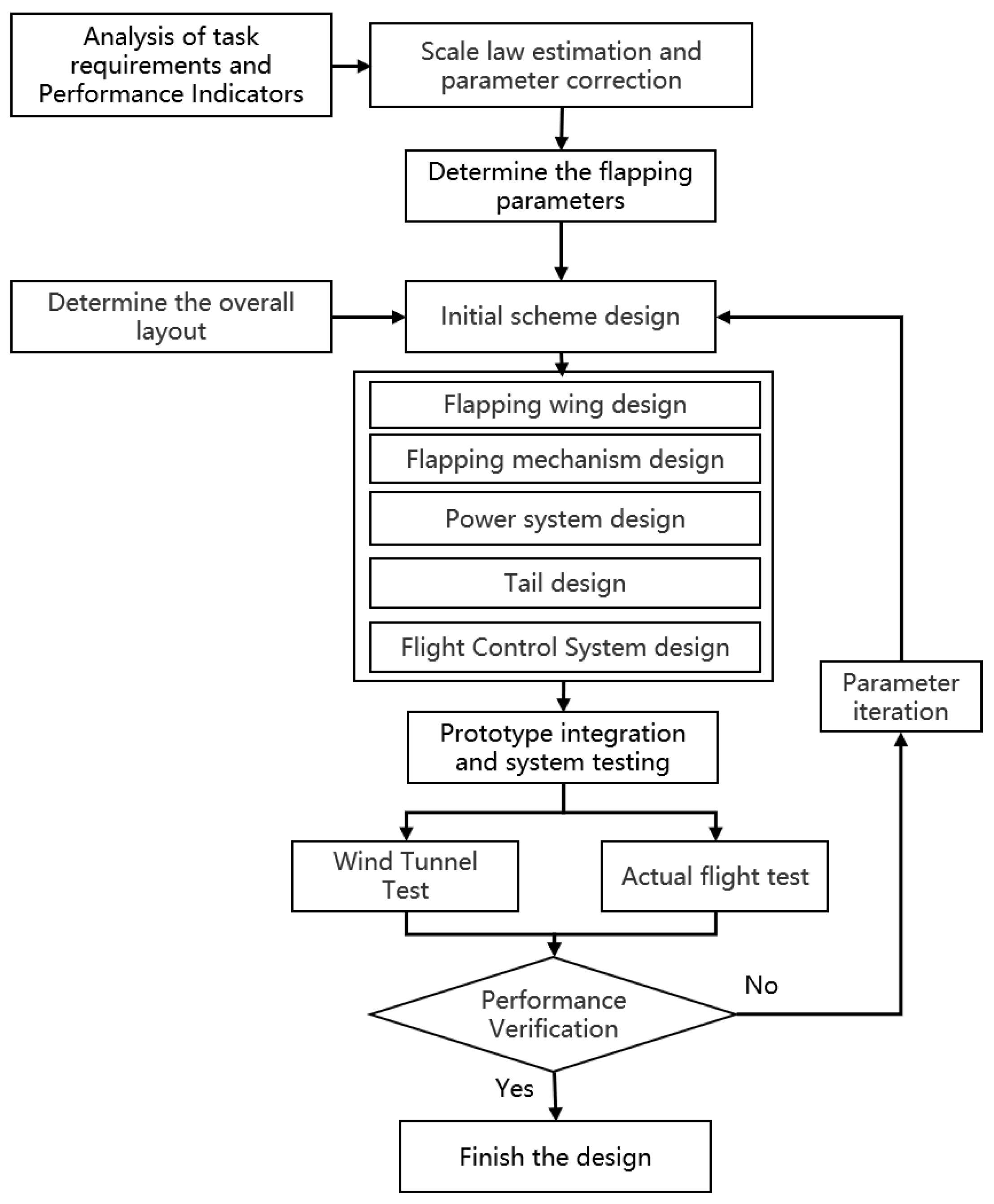

2. Materials and Methods

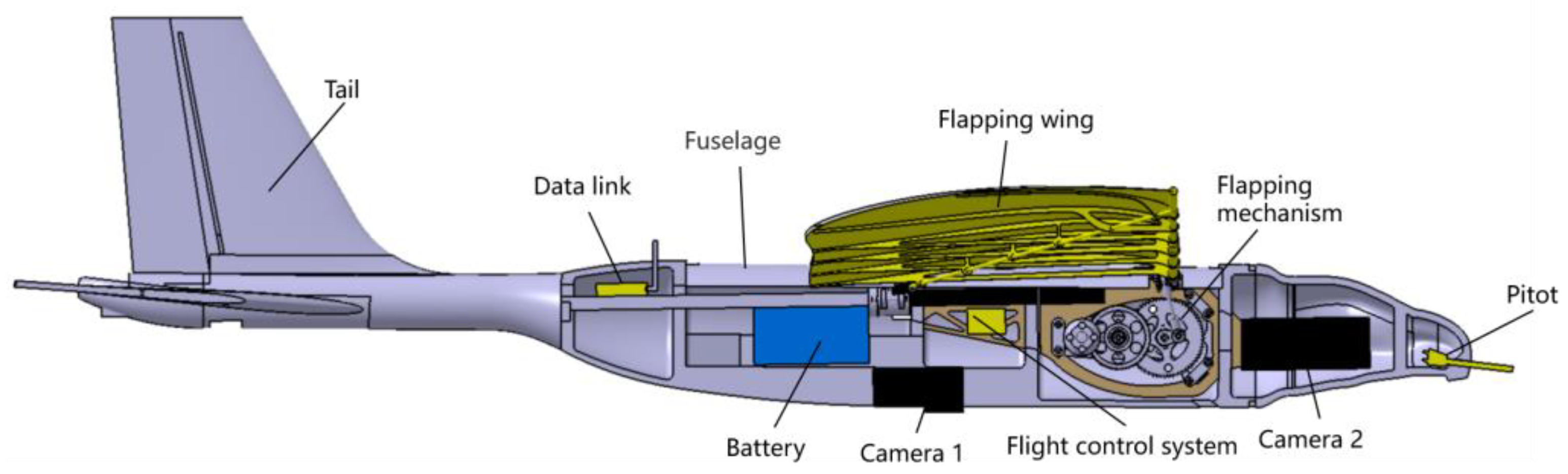

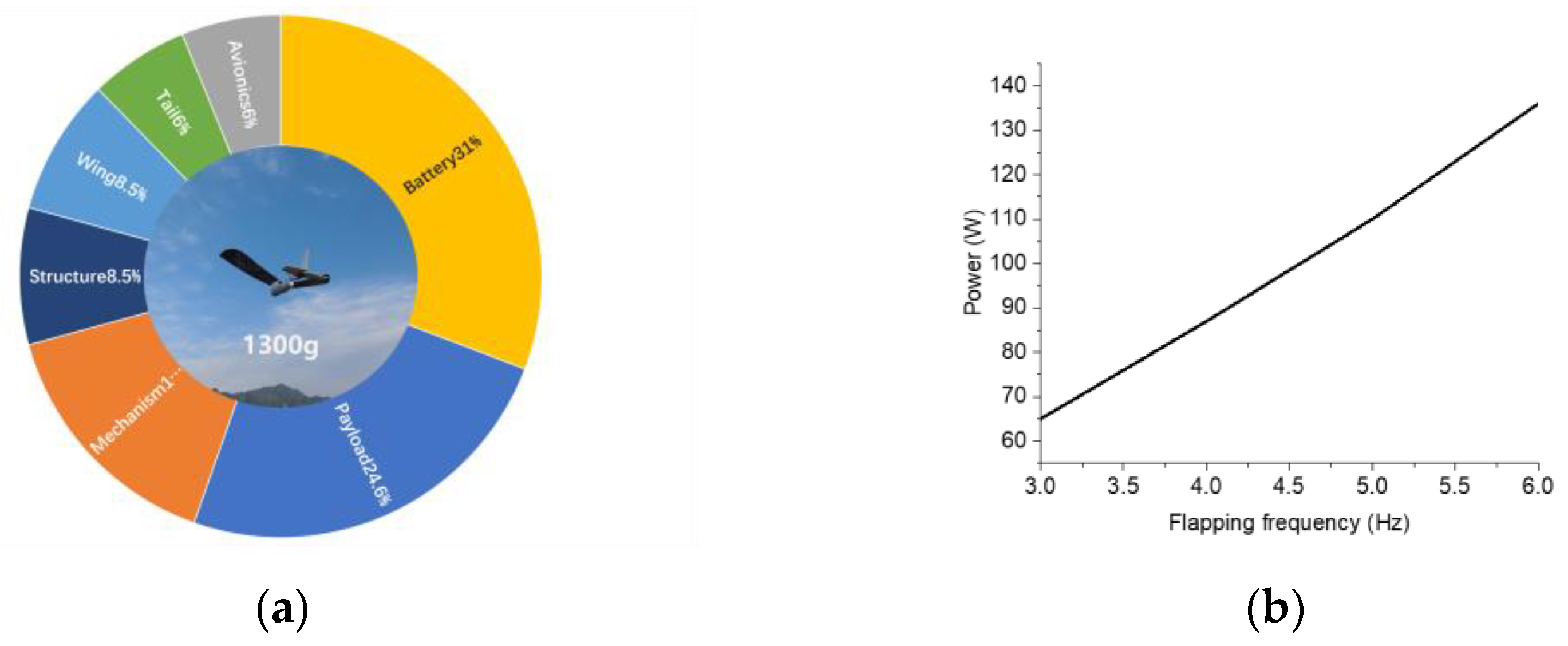

2.1. Overall Layout and Weight Estimation

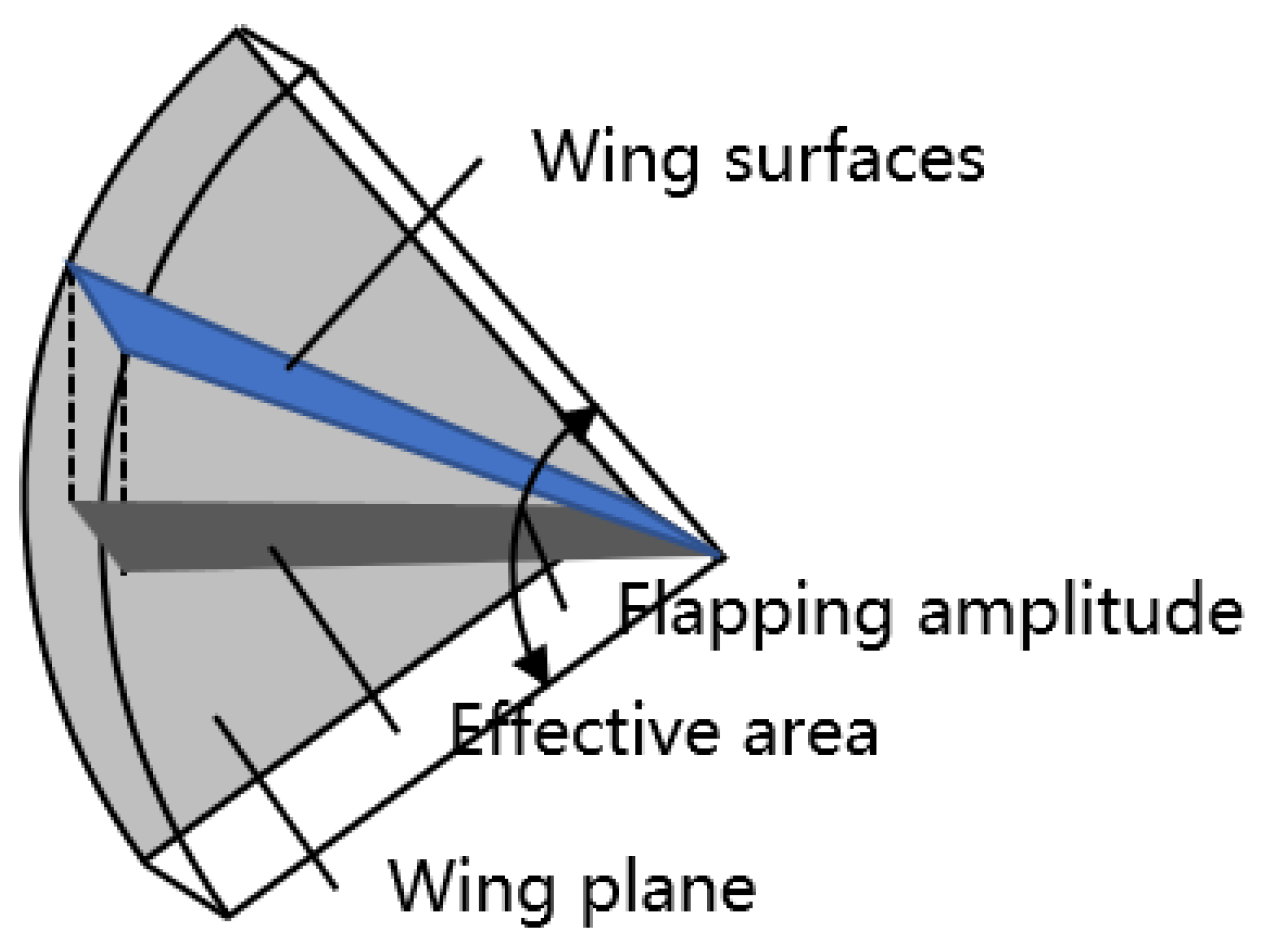

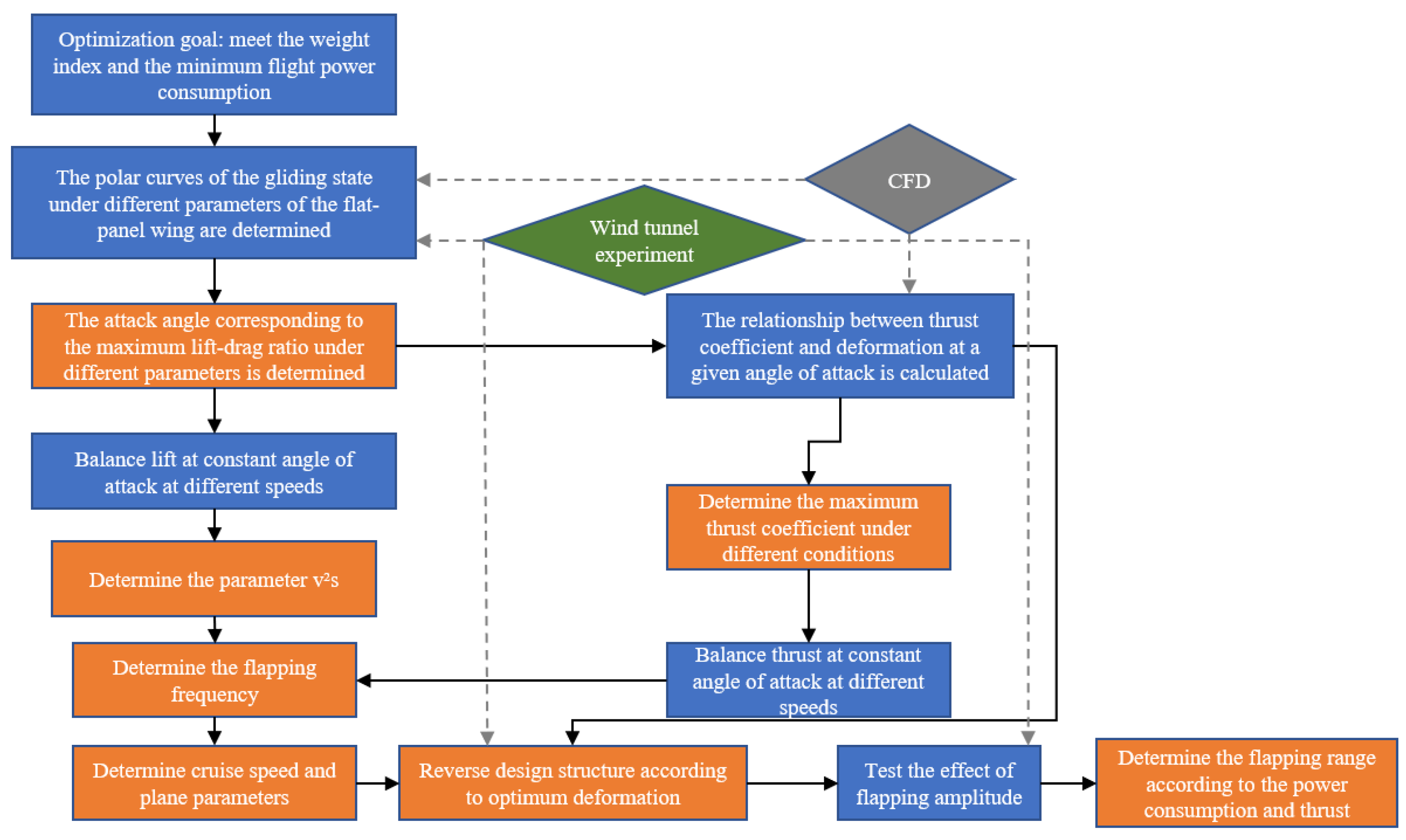

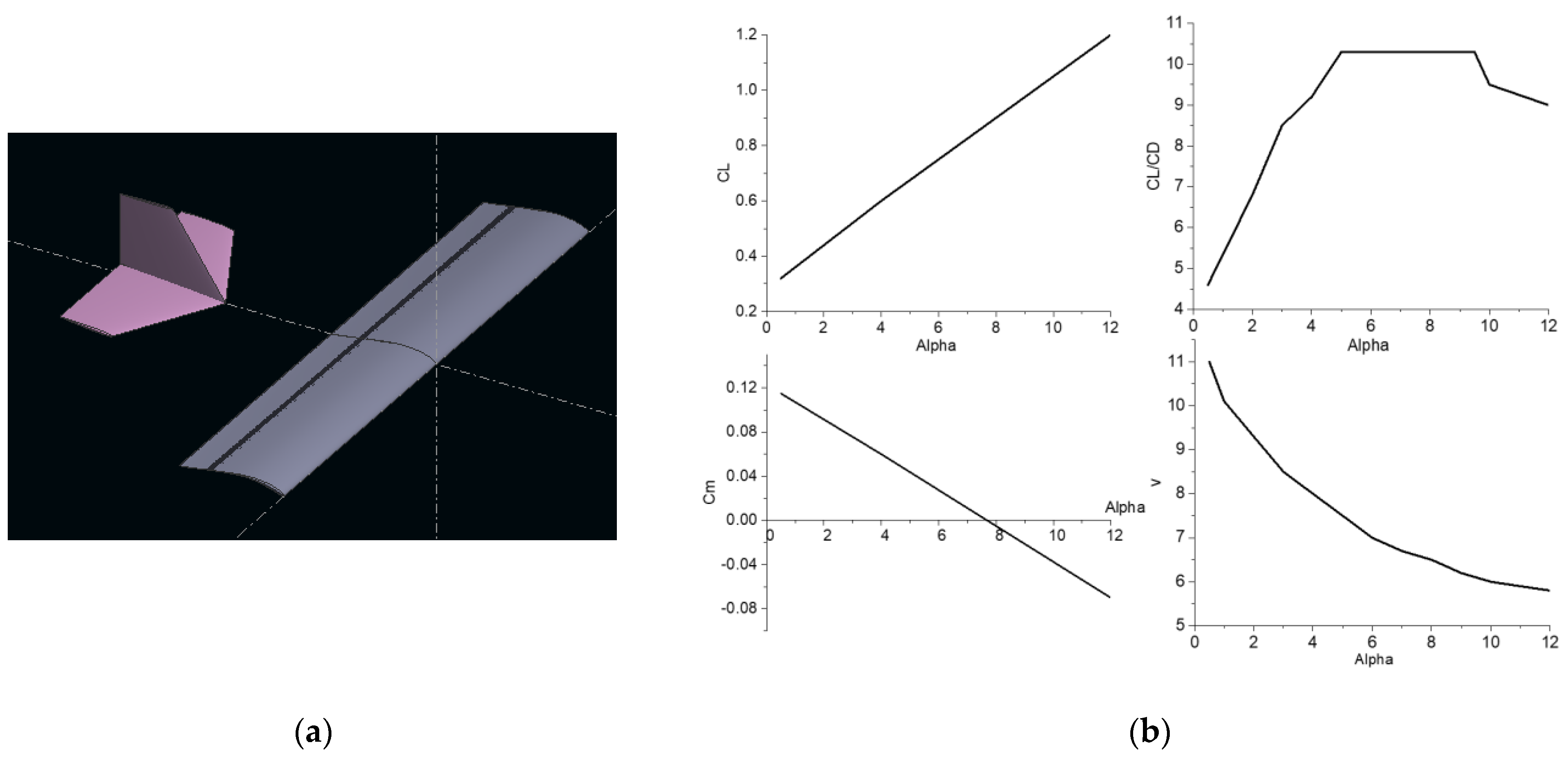

2.2. Wing Design

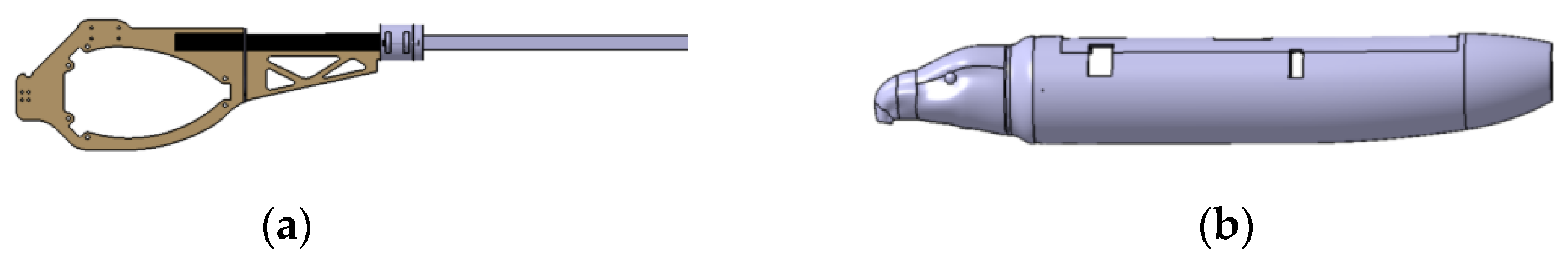

2.3. Tail Design

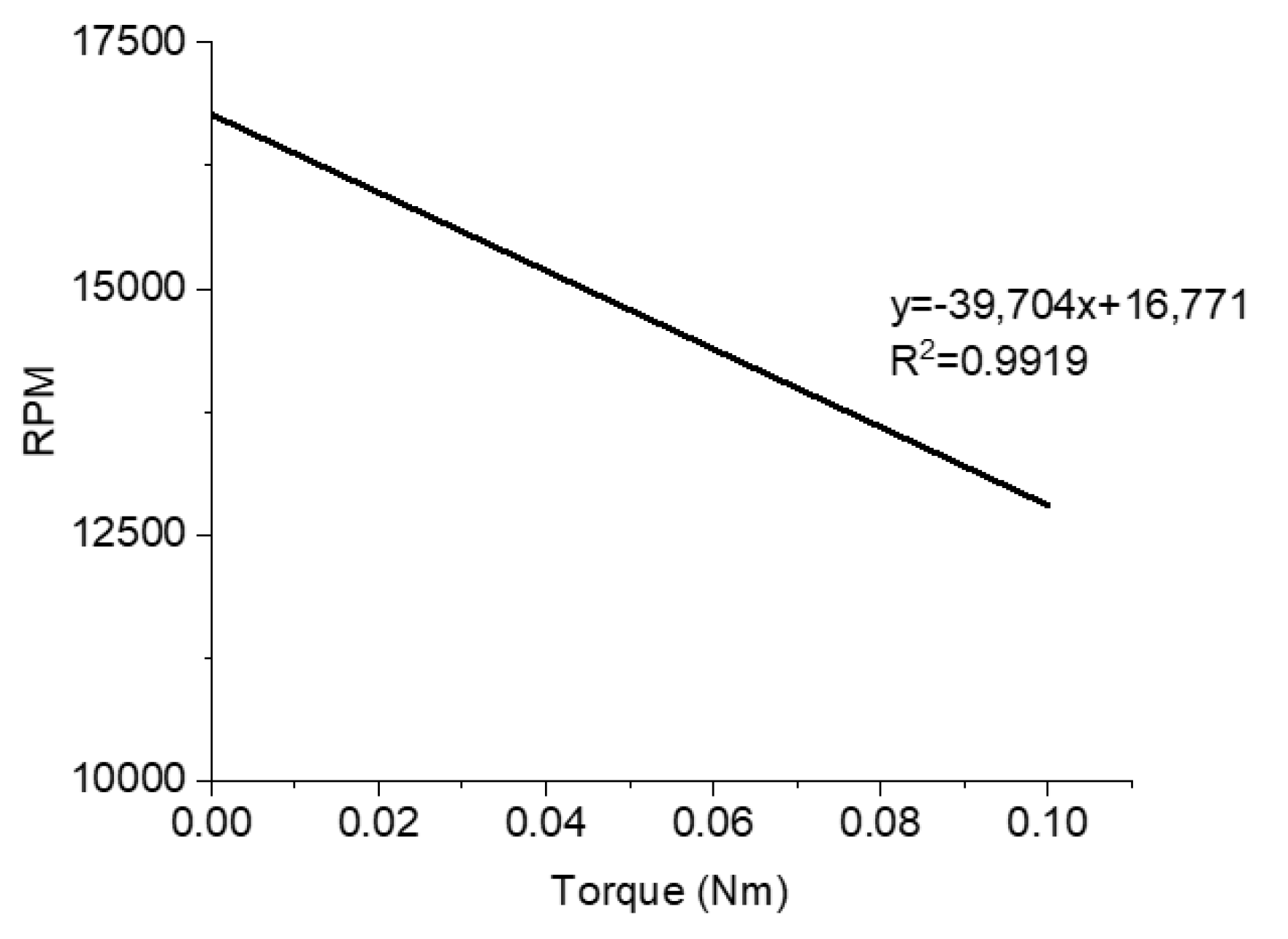

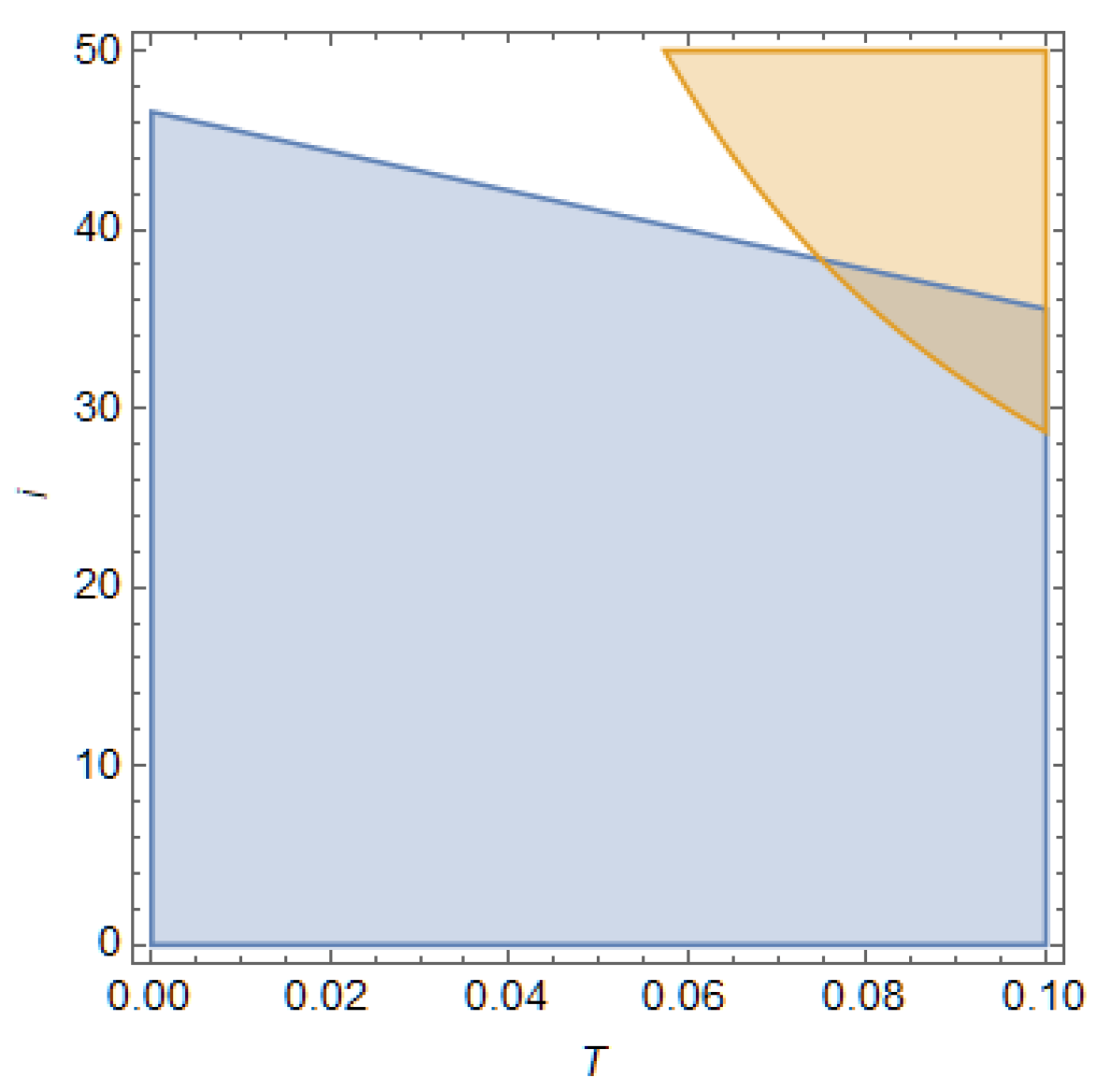

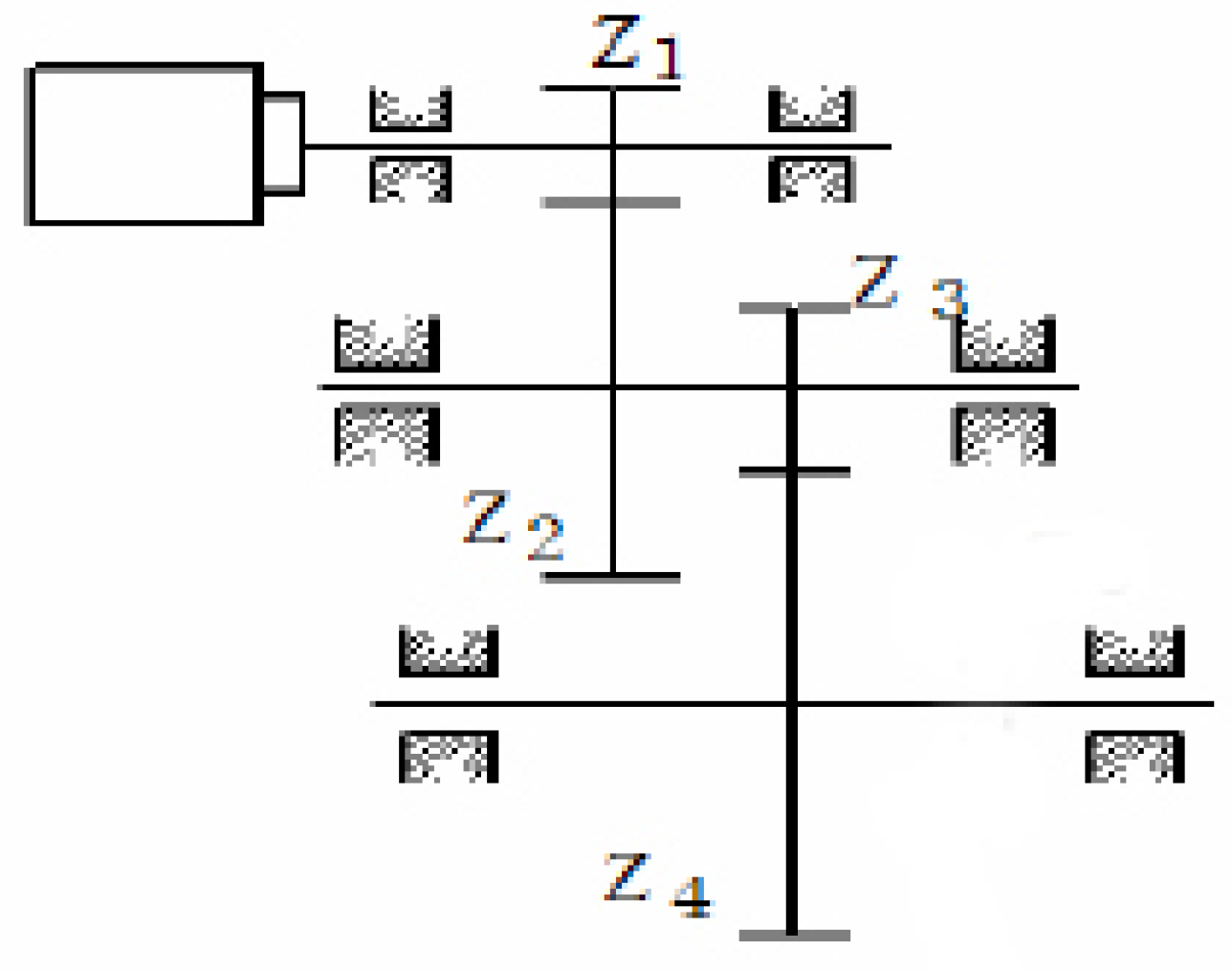

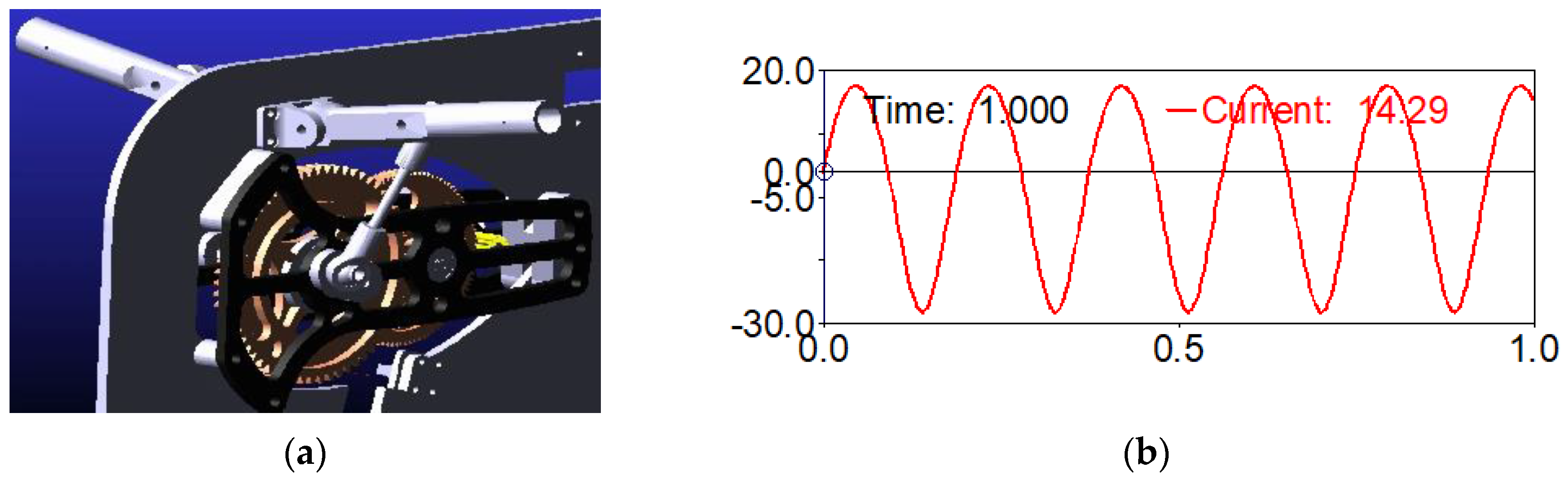

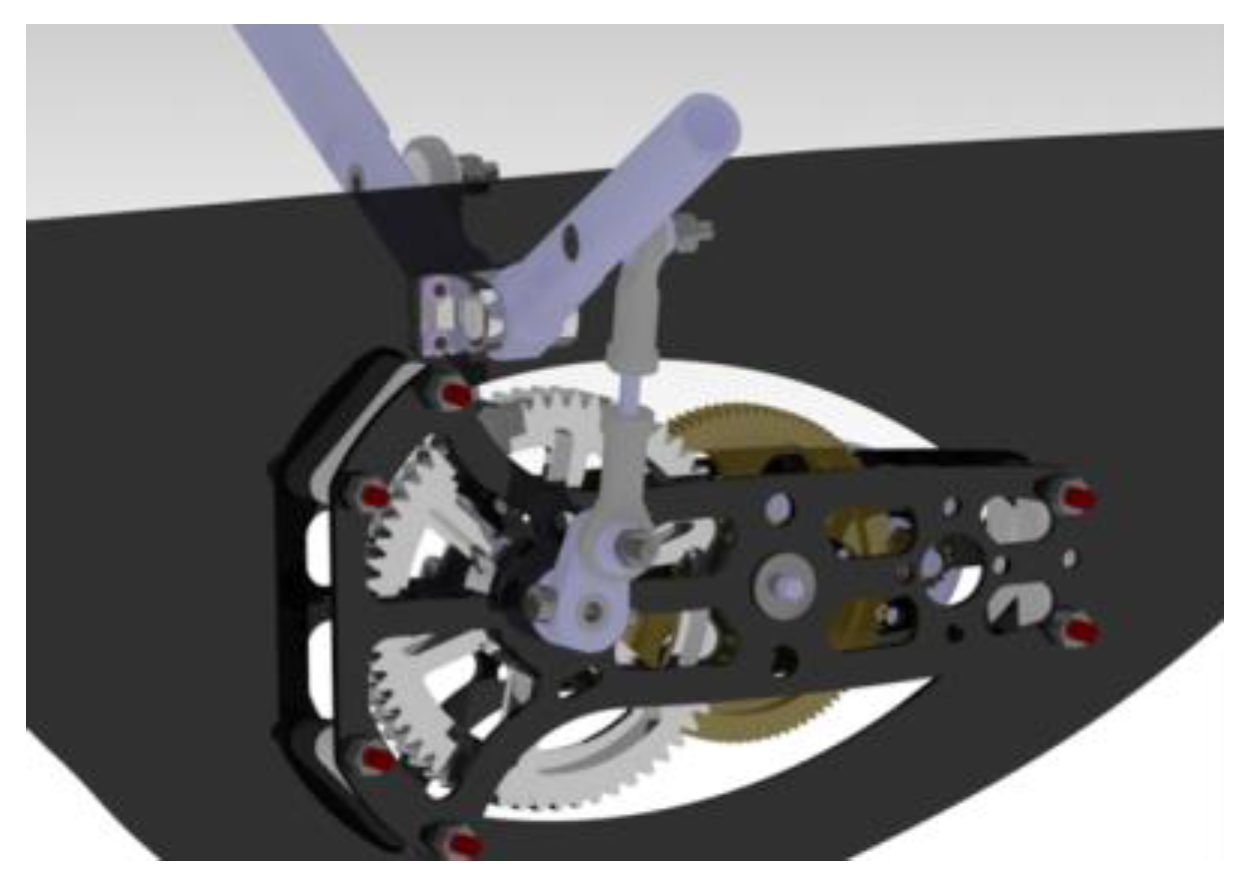

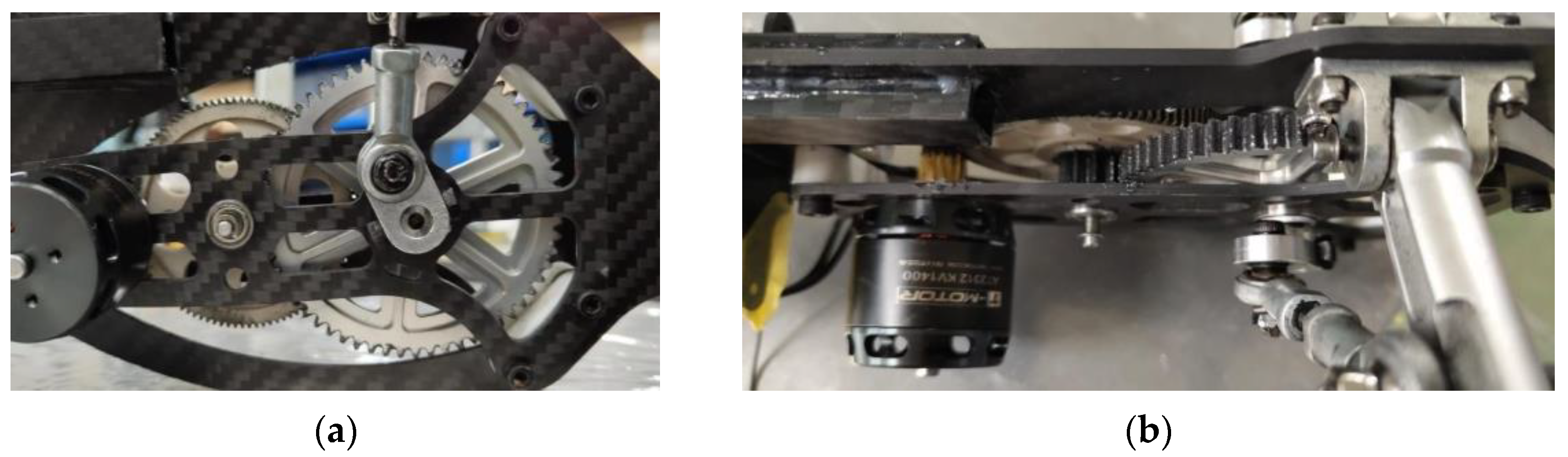

2.4. Power System Design

2.5. Avionics of the Cloud Owl

2.6. The Fuselage of the Cloud Owl

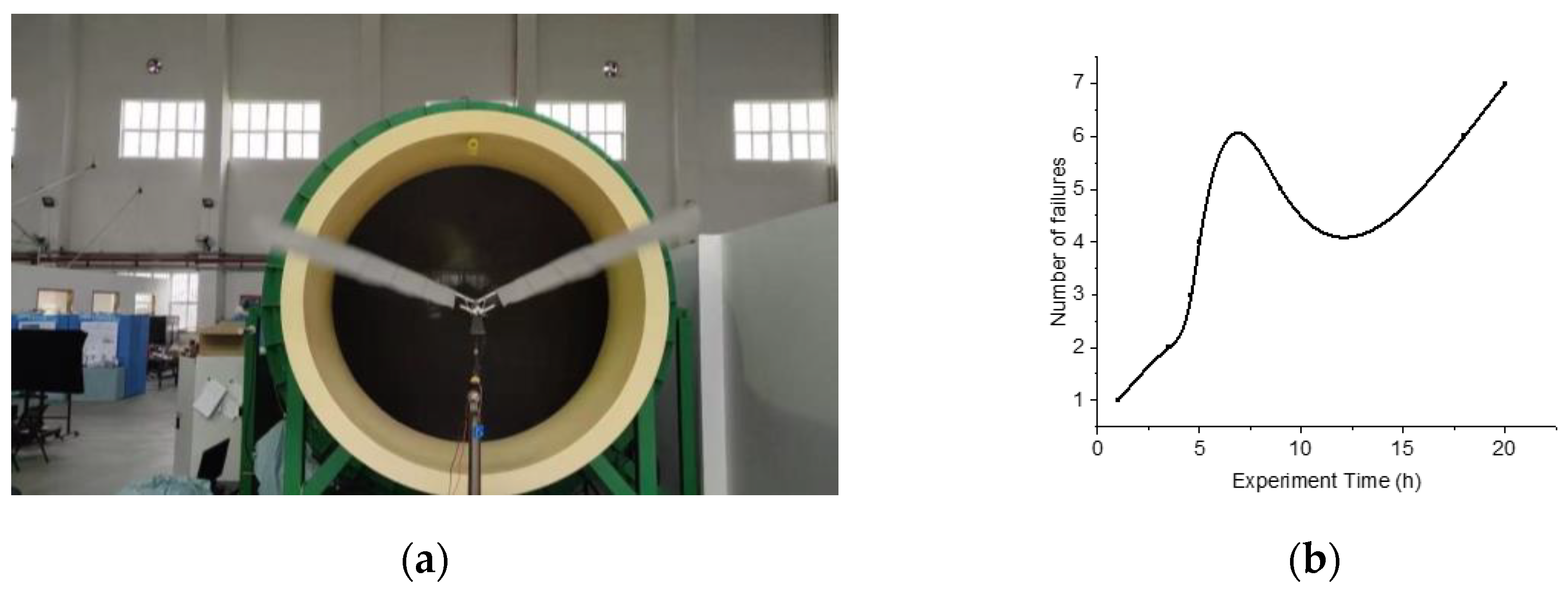

3. Results and Discussion

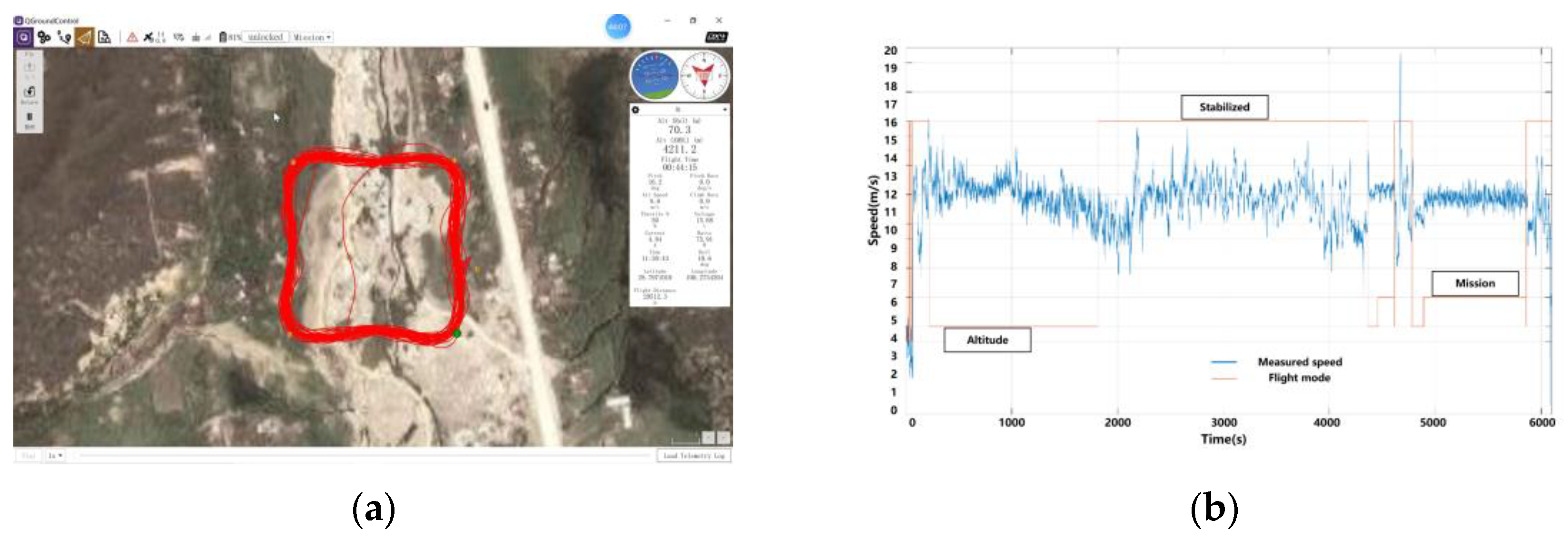

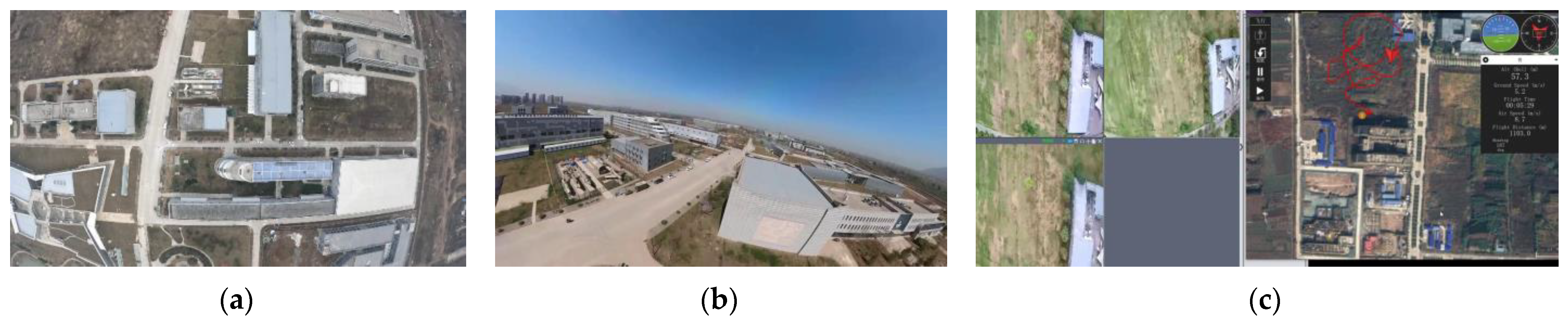

3.1. Prototype Integration and Flight Test

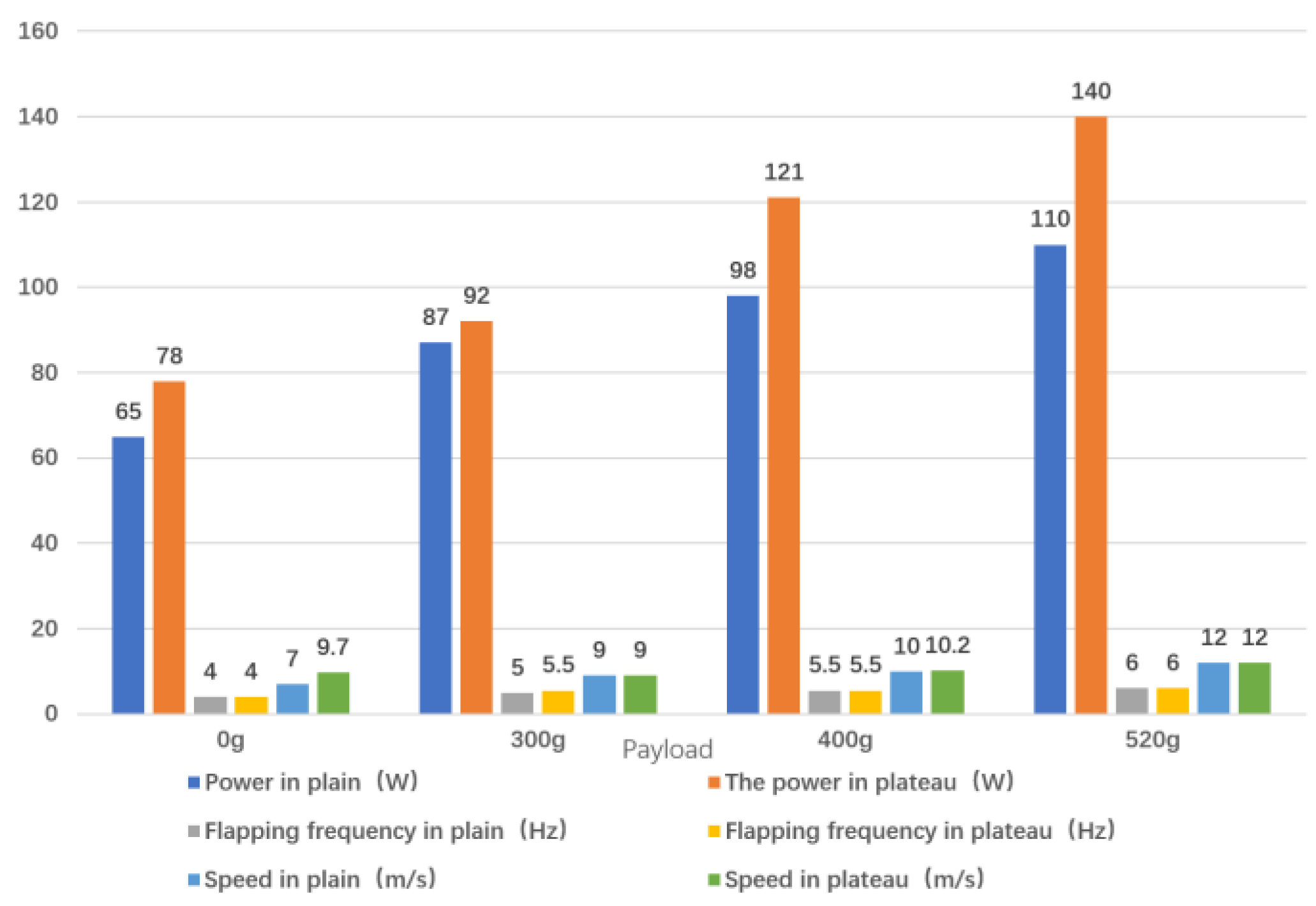

3.2. Payload Capacity Test

3.3. Flight Tests with Payload

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, H.; Kumar, A.G.; Abate, G.; Albertani, R.A. An experimental investigation on the aerodynamic performances of flexible membrane wings in flapping flight. Aerosp. Sci. Technol. 2010, 8, 575–586. [Google Scholar] [CrossRef]

- Paranjape, A.A.; Chung, S.J.; Hilton, H.H.; Chakravarthy, A.D. Dynamics and Performance of Tailless Micro Aerial Vehicle with Flexible Articulated Wings. AIAA J. 2012, 50, 1177–1188. [Google Scholar] [CrossRef]

- Send, W.; Fischer, M.; Jebens, K.; Mugrauer, R.; Nagarathinam, A.; Scharstein, F. Artificial hinged-wing bird with active torsion and partially linear kinematics. In Proceedings of the 28th Congress of the International Council of the Aeronautical Sciences, Brisbane, Australia, 23–28 September 2012; Volume 2, pp. 1148–1157. [Google Scholar]

- Sangyol, Y.; Lae, H.K.; Sungho, J. Development of Air Vehicle with Active Flapping and Twisting of Wing. J. Bionic Eng. 2011, 8, 1–9. [Google Scholar]

- Gerdes, J.; Holness, A.; Perez-Rosado, A.; Roberts, L.; Greisinger, A.; Barnett, E. Robo Raven: A flapping-wing air vehicle with highly compliant and independently controlled wings. Soft Robot. 2014, 1, 275–288. [Google Scholar] [CrossRef]

- Holness, A.E.; Bruck, H.; Gupta, S.K. Design of propeller-assisted flapping wing air vehicles for enhanced aerodynamic performance. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 57137. [Google Scholar]

- Chen, A.; Song, B.; Wang, Z.; Xue, D.; Liu, K. A Novel Actuation Strategy for an Agile Bioinspired FWAV Performing a Morphing-Coupled Wingbeat Pattern. IEEE Trans. Robot. 2023, 39, 452–469. [Google Scholar] [CrossRef]

- Pan, E.; Xu, H.; Yuan, H.; Peng, J.Q.; Xu, W.F. HIT-Hawk and HIT-Phoenix: Two kinds of flapping-wing flight robotic birds with wingspans beyond 2 meters. Biomim. Intell. Robot. 2021, 1, 100002. [Google Scholar] [CrossRef]

- Pan, E.; Chen, L.; Zhang, B.; Xu, W.F. A Kind of Large-Sized Flapping Wing Robotic Bird: Design and Experiments. Intell. Robot. Appl. 2017, 10464, 538–550. [Google Scholar]

- Pan, E.; Chen, L.; Xu, W.F. Development of Vision Stabilizing System for a Large-Scale Flapping-Wing Robotic Bird. IEEE Sens. J. 2020, 20, 8017–8028. [Google Scholar] [CrossRef]

- Deng, S.; Wang, J.; Liu, H. Experimental study of a bio-inspired flapping wing mav by means of force and piv measurements. Aerosp. Sci. Technol. 2019, 94, 105382. [Google Scholar] [CrossRef]

- Wen, L.; Wang, T.; Wu, G.; Liang, J.; Wang, C. Novel method for the modeling and control investigation of efficient swimming for robotic fish. IEEE Trans. Ind. Electron. 2011, 59, 3176–3188. [Google Scholar] [CrossRef]

- Zufferey, R.; Tormo, B.J.; Guzm, M.M.; Maldonado, F.J.; Sanchez, L.E. Design of the high-payload flapping wing robot e-flap. IEEE Robot. Autom. Lett. 2021, 6, 3097–3104. [Google Scholar] [CrossRef]

- Yang, W.Q.; Wang, L.G.; Song, B.F. Dove: A biomimetic flapping-wing micro air vehicle. Int. J. Micro Air Veh. 2018, 10, 70–84. [Google Scholar] [CrossRef]

- Shyy, W.; Berg, M.; Ljungqvist, D. Flapping and flexible wings for biological and micro air vehicle. Prog. Aerosp. Sci. 1999, 35, 455–505. [Google Scholar] [CrossRef]

- Hassanalian, M.; Abdelkefi, A.; Wei, M.; Ziaei, R.S. A novel methodology for wing sizing of bio-inspired flapping wing micro air vehicles: Theory and prototype. Acta Mech. 2017, 228, 1097–1113. [Google Scholar] [CrossRef]

- Nian, P.; Song, B.F. Study on flexible flapping wings with three-dimensional asymmetric passive deformation in a flapping cycle. Aerosp. Sci. Technol. 2020, 104, 105944. [Google Scholar] [CrossRef]

- Bao, H.; Song, B.; Yang, W.; Xue, D. The function of the alula with different geometric parameters on the flapping wing. Phys. Fluids 2021, 33, 101907. [Google Scholar] [CrossRef]

- He, W.; Zhao, M.; Zou, Y.; Fu, Q. Effects of airfoil on aerodynamic performance of flapping wing. Biomim. Intell. Robot. 2021, 1, 100004. [Google Scholar]

- Yang, W.Q.; Song, W.P.; Song, B.F. The effects of span-wise and chord-wise flexibility on the aerodynamic performance of micro flapping-wing. Chin. Sci. Bull. 2012, 57, 2887–2897. [Google Scholar] [CrossRef]

- Yang, W.Q.; Wang, L.G.; Song, B.F. Dynamic fluid-structure coupling method of flexible flapping wing for MAV. J. Aerosp. Eng. 2015, 28, 04015006. [Google Scholar] [CrossRef]

- Zhu, Z.C.; Xue, D.; Song, B.F. Design and Verification of Large-Scaled Flapping Wings for High Altitude Environment. Appl. Sci. 2022, 12, 5140. [Google Scholar] [CrossRef]

- Nian, P.; Xuan, J.L.; Song, B.F.; Wang, S.Q. Modeling method for propulsion system of flapping wing vehicles. Acta Aeronaut. Astronaut. Sin. 2020, 42, 224646. [Google Scholar]

- Zhao, J.S.; Yan, Z.F.; Ye, L. Design of planar four-bar linkage with n specified positions for a flapping wing robot. Mech. Mach. Theory 2014, 82, 33–55. [Google Scholar] [CrossRef]

- Sun, C.; Xu, W.; Bronlund, J.E.; Morgenstern, M. Dynamics and compliance control of a linkage robot for food chewing. IEEE Trans. Ind. Electron. 2013, 61, 377–386. [Google Scholar] [CrossRef]

| Parameter | Value | Description |

|---|---|---|

| B | 1.82 m | Wing span |

| M | 0.98 kg | Mass |

| S | 0.46 m2 | Wing area |

| St | 0.225 m2 | Tail area |

| Φ | 45° | Flapping amplitude |

| F | 4–6 Hz | Flapping frequency |

| V | 6–13 m/s | Speed |

| T | 154 min | Endurance |

| V | 16.8 V | Battery voltage |

| C | 10.5 Ah | Battery capacity |

| Part | Materials | Density (kg/m3) | Weight Estimation(g) | Proportion of Cloud Owl’s Weight (%) | Proportion of Dove’s Weight (%) |

|---|---|---|---|---|---|

| Fuselage | EPP | 30 | 40 | 3 | 7.1 |

| Structure | 3K carbon fiber composite | 1500 | 80 | 6.1 | 14.3 |

| Flapping wing | 3K carbon fiber composite | 1500 | 100 | 7..6 | 5 |

| Tail | Laminates, KT board | 500,140 | 80 | 6.1 | 2.5 |

| Flapping mechanism | 3K carbon fiber composite, 7075 aluminum alloy, nylon | 1500,2810,150 | 200 | 15.3 | 17.9 |

| Avionics | / | / | 110 | 8.4 | 15.7 |

| Payload | / | / | 300 | 23 | 14.3 |

| Battery | / | / | 400 | 30.5 | 23.2 |

| Total weight | / | / | 1310 | 100 | 100 |

| Parameter | K | p | Estimated Results |

|---|---|---|---|

| Wing span | 1.237 | 0.368 | 1.3624 m |

| Wing area | 0.164 | 0.667 | 0.1954 m2 |

| Flapping frequency | 3.991 | −0.202 | 3.785 Hz |

| Minimum Power Speed | 8.704 | 0.158 | 9.0724 m/s |

| Maximum Range Speed | 11.591 | 0.158 | 12.0816 m/s |

| Flight Power | 45.21 | 0.728 | 54.7249 W |

| Maximum power | 84.388 | 0.734 | 102.14 W |

| Motor Type | KV of Motor | Maximum Continuous Input Power | Weight |

|---|---|---|---|

| 2308 | 1450 | 250 W, 11.1 V | 47 g |

| 2600 | 300 W, 11.1 V | ||

| 2312 | 1400 | 320 W, 11.1 V | 60 g |

| 1150 | 350 W, 14.8 V | ||

| 2317 | 880 | 340 W, 14.8 V | 80 g |

| 1250 | 520 W, 14.8 V |

| Flapping Amplitude | Anhedral | b | l |

|---|---|---|---|

| 45° | 15° | 11 mm | 49.25 mm |

| Wind Speed | Angle of Attack | Output Power | Flapping Frequency | Temperature | Equipment |

|---|---|---|---|---|---|

| 8 m/s | 10° | 90 W–100 W | 4–5 Hz | 25 °C | The wind tunnel, regulated power supply, fixture |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, R.; Song, B.; Xuan, J.; Yang, X. Design and Verification of a Large-Scaled Flapping-Wing Aircraft Named “Cloud Owl”. Appl. Sci. 2023, 13, 5667. https://doi.org/10.3390/app13095667

Meng R, Song B, Xuan J, Yang X. Design and Verification of a Large-Scaled Flapping-Wing Aircraft Named “Cloud Owl”. Applied Sciences. 2023; 13(9):5667. https://doi.org/10.3390/app13095667

Chicago/Turabian StyleMeng, Rui, Bifeng Song, Jianlin Xuan, and Xiaojun Yang. 2023. "Design and Verification of a Large-Scaled Flapping-Wing Aircraft Named “Cloud Owl”" Applied Sciences 13, no. 9: 5667. https://doi.org/10.3390/app13095667

APA StyleMeng, R., Song, B., Xuan, J., & Yang, X. (2023). Design and Verification of a Large-Scaled Flapping-Wing Aircraft Named “Cloud Owl”. Applied Sciences, 13(9), 5667. https://doi.org/10.3390/app13095667