Load-Bearing Characteristics of PHC Piles Constructed by the Inner Digging Method Based on Ultimate Load Testing and Numerical Simulation

Abstract

1. Introduction

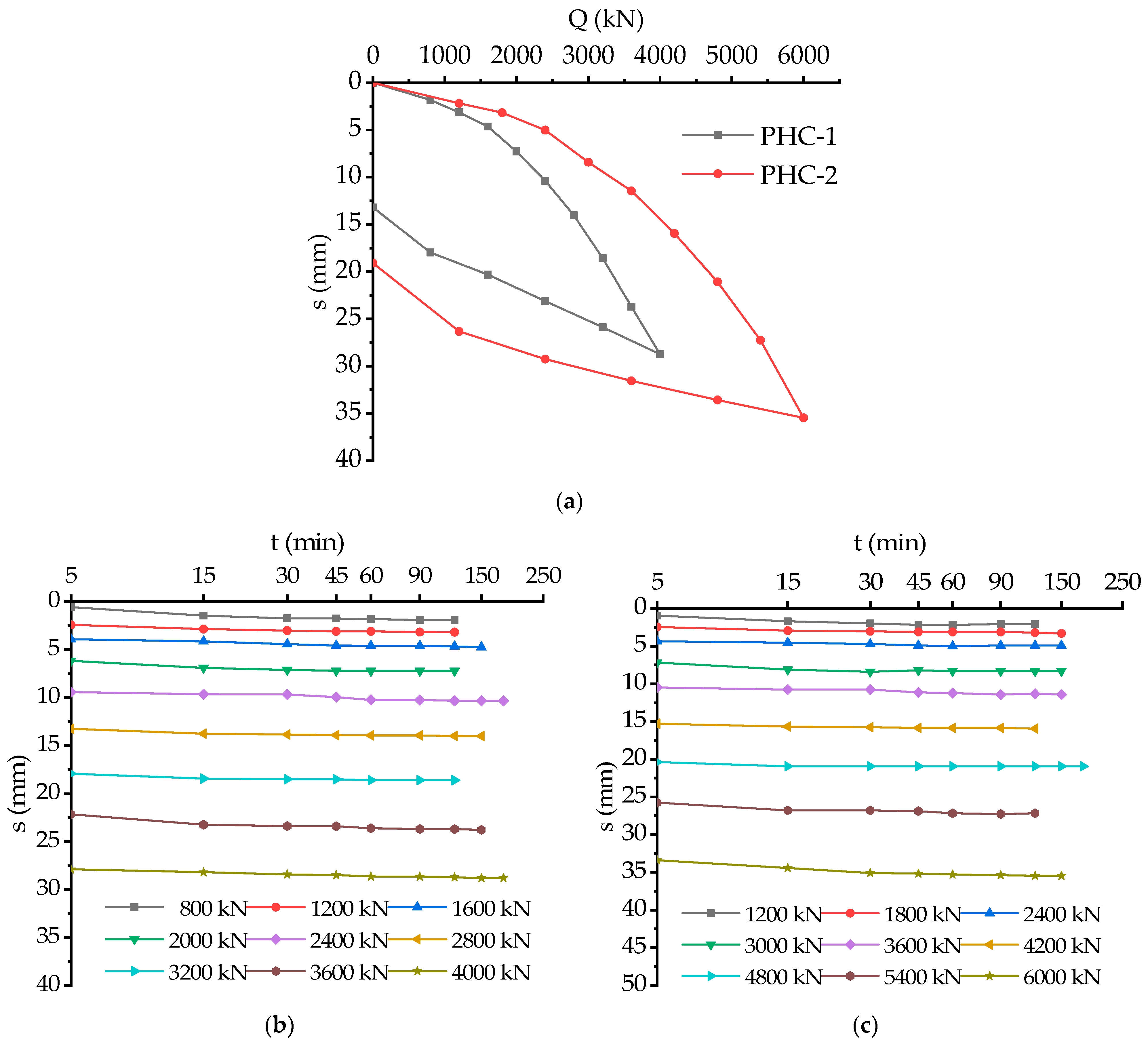

2. Test Overview

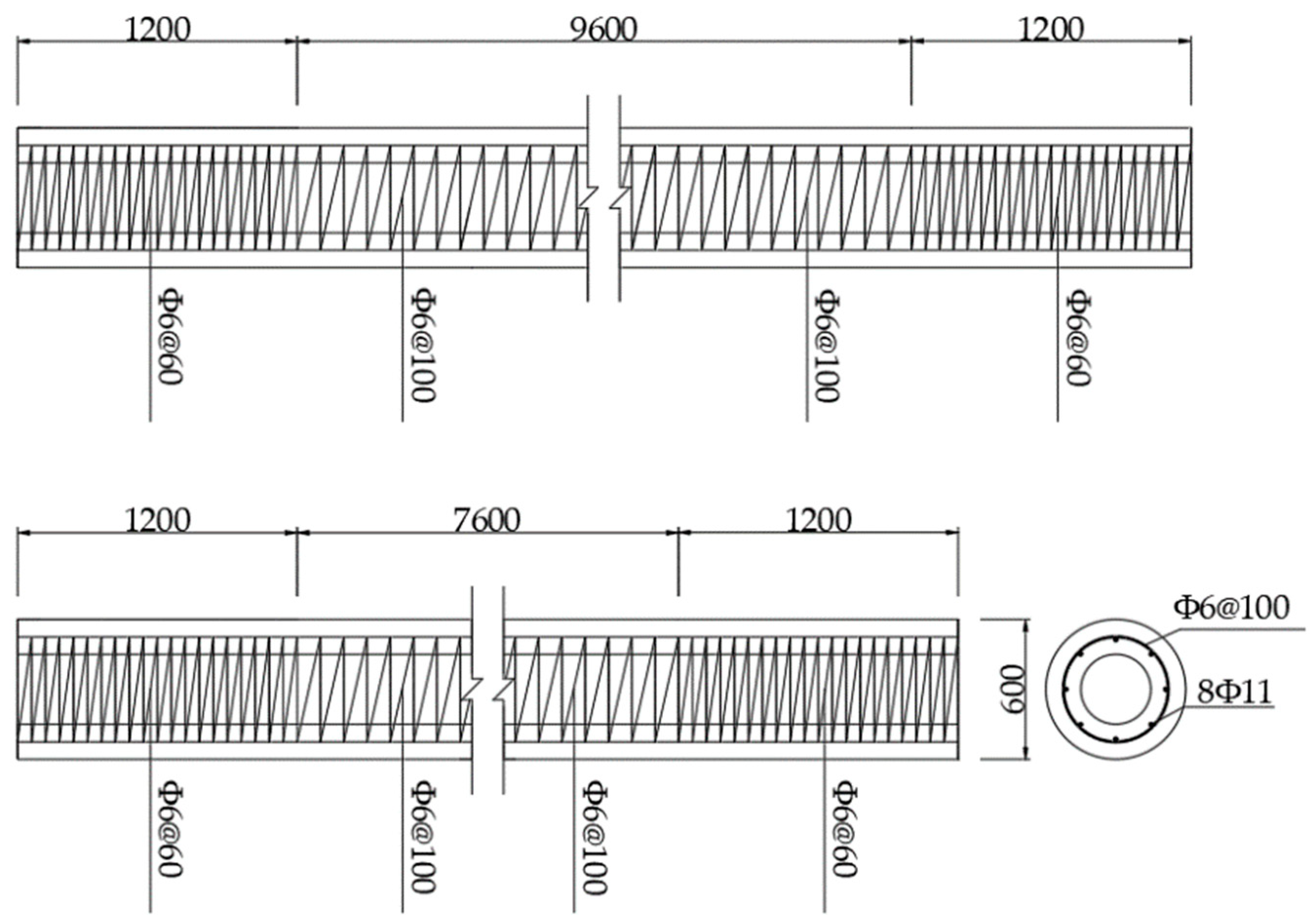

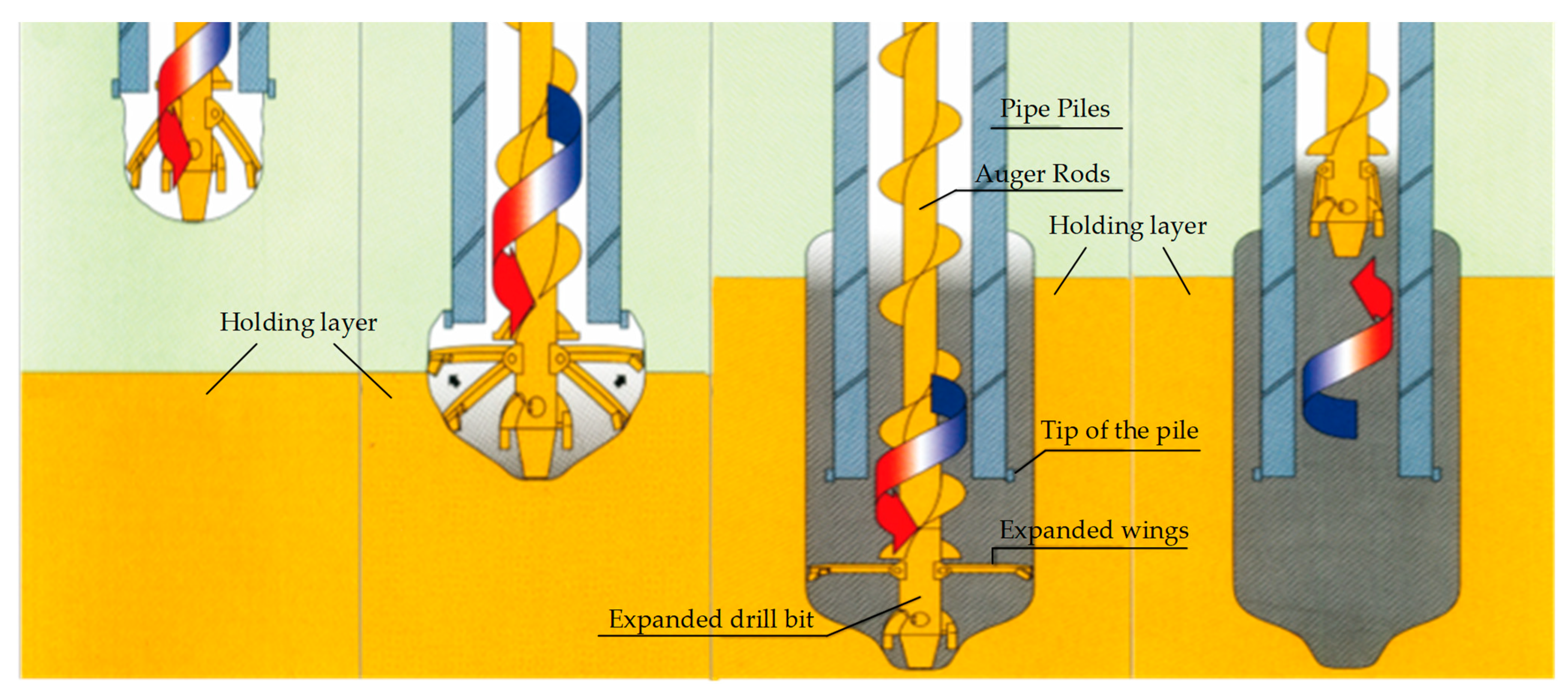

2.1. Test Pile and Project Overview

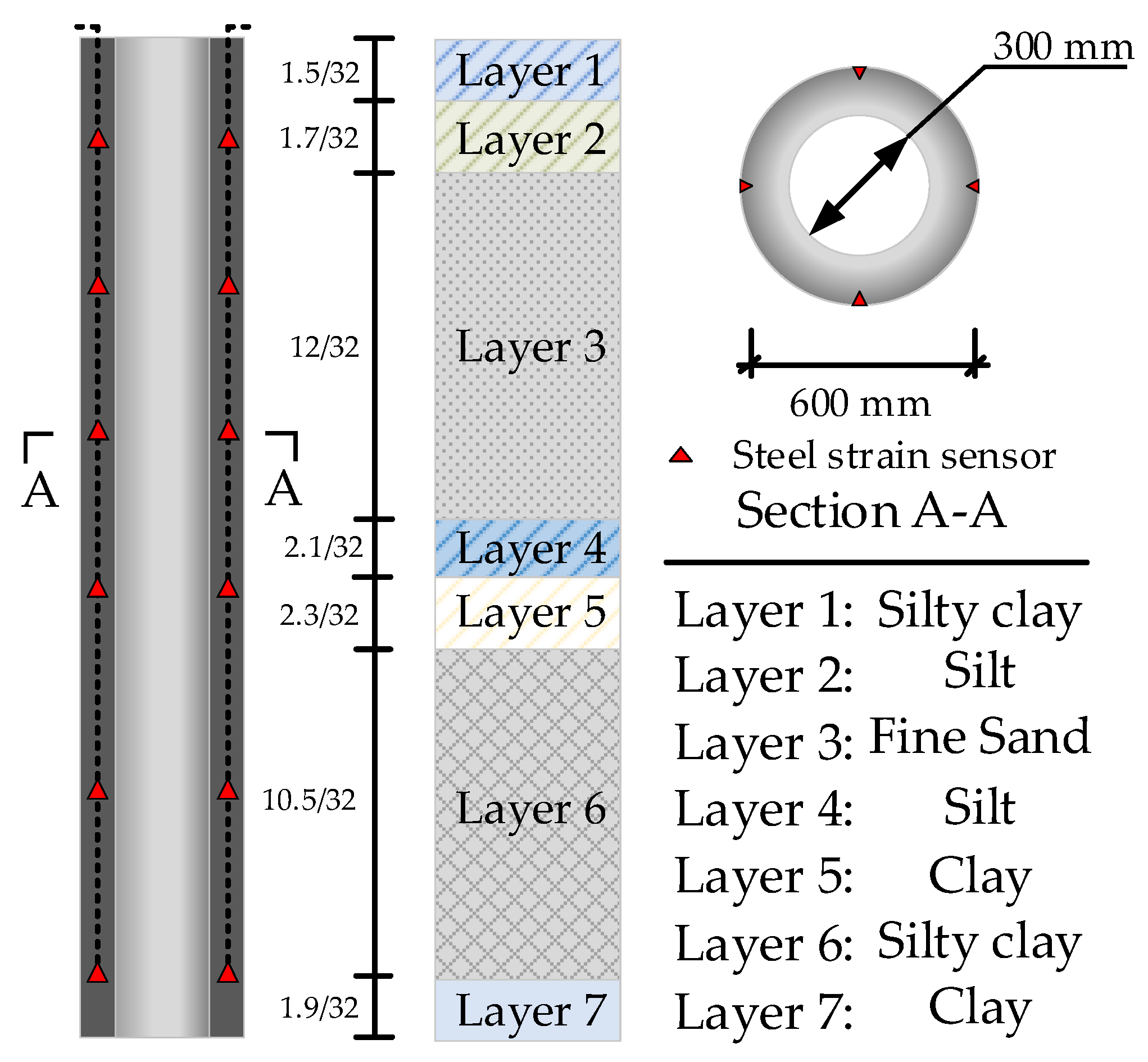

2.2. Geological Survey of Site

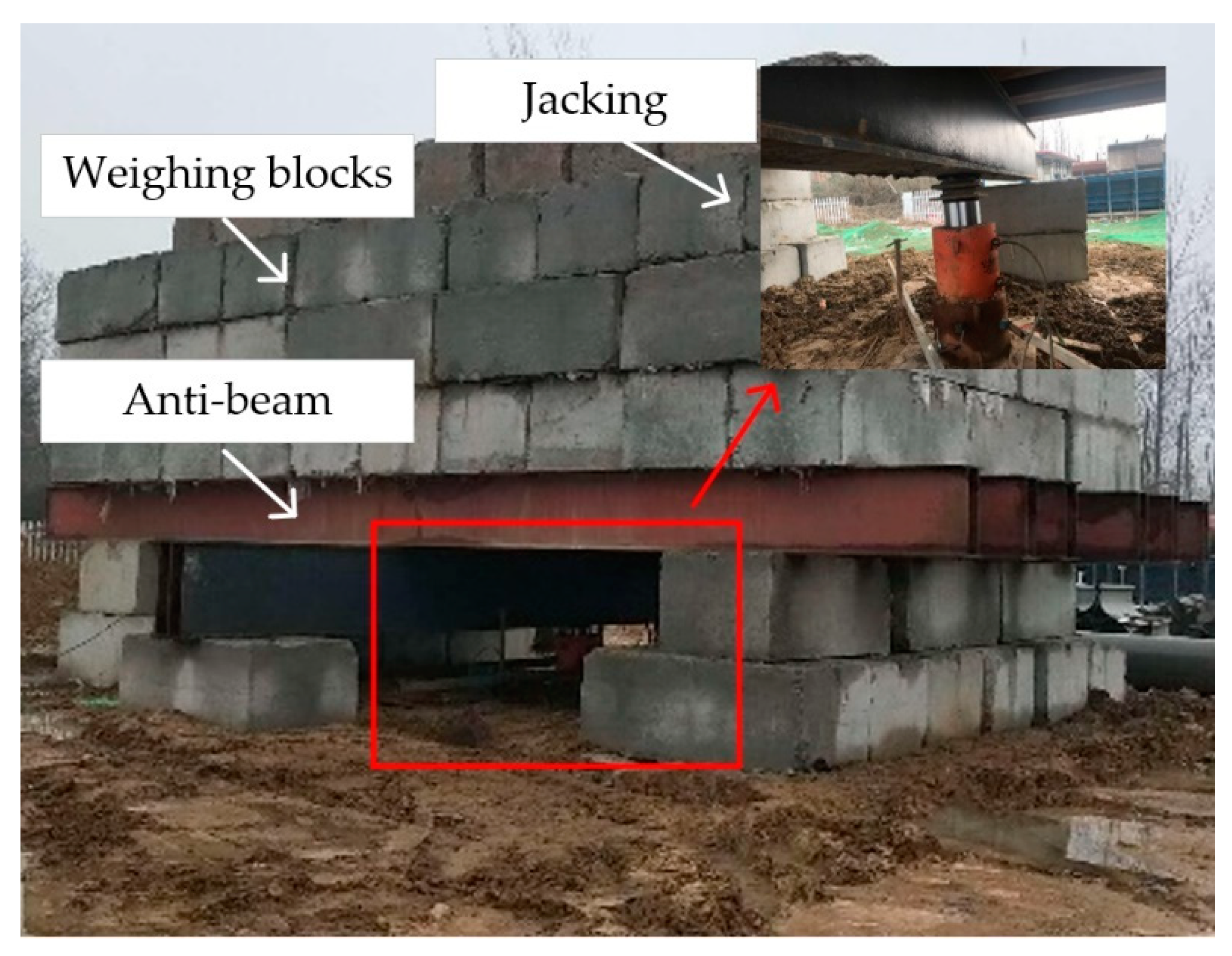

2.3. Test Scheme

3. Analysis of Test Results

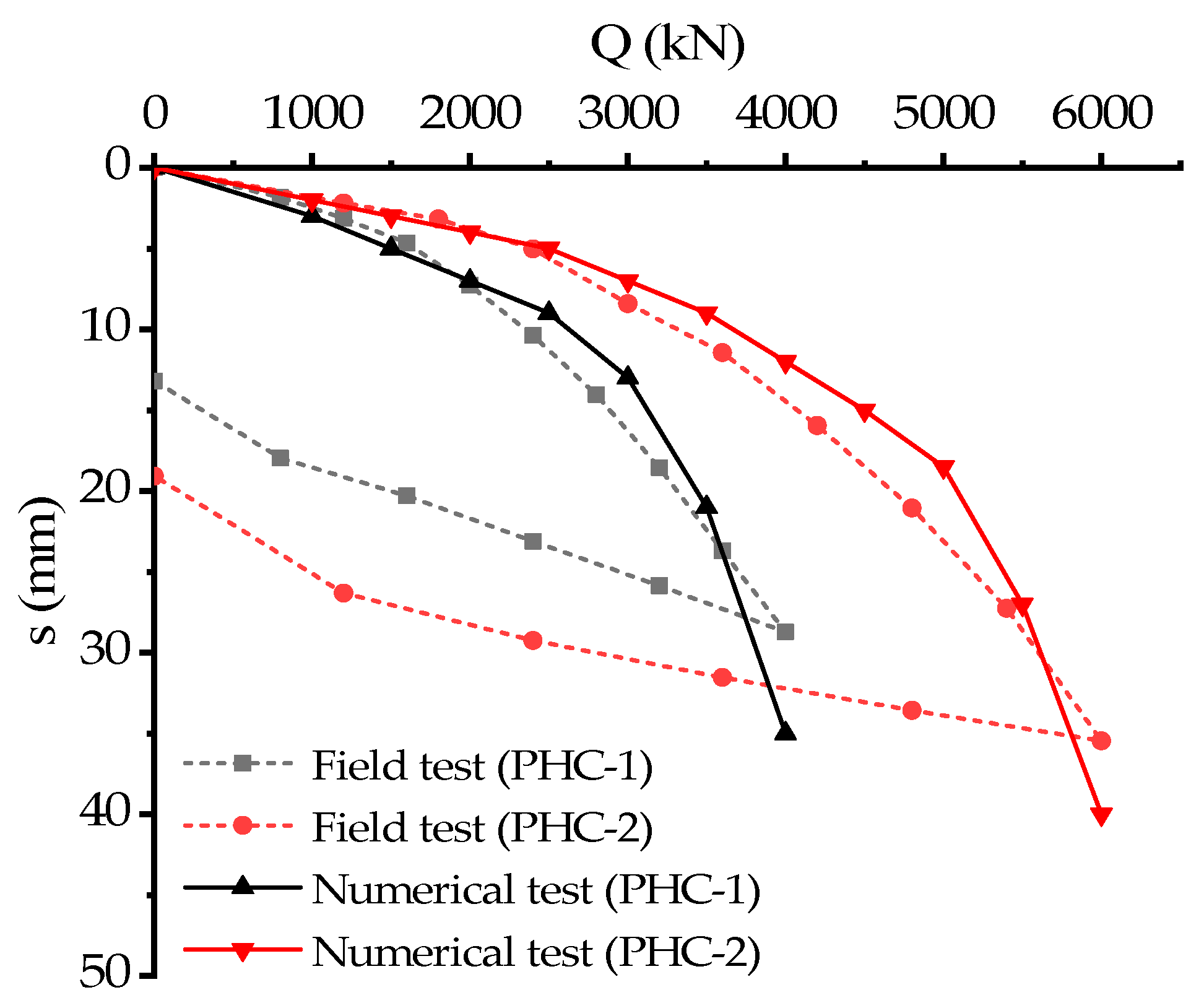

3.1. Analysis of Load–Settlement and Settlement-Lg Curves

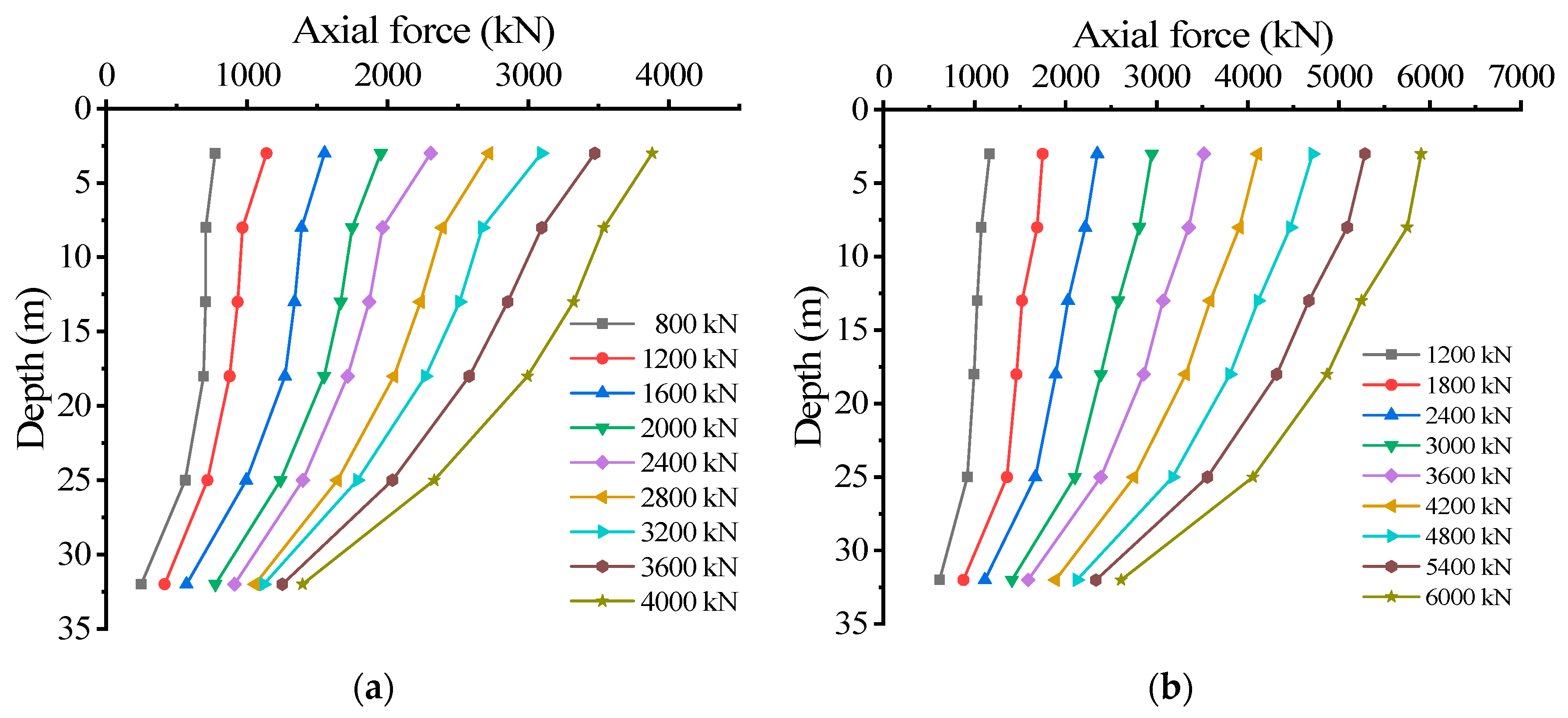

3.2. Analysis of the Distribution of Pile Axial Force on Pile Body

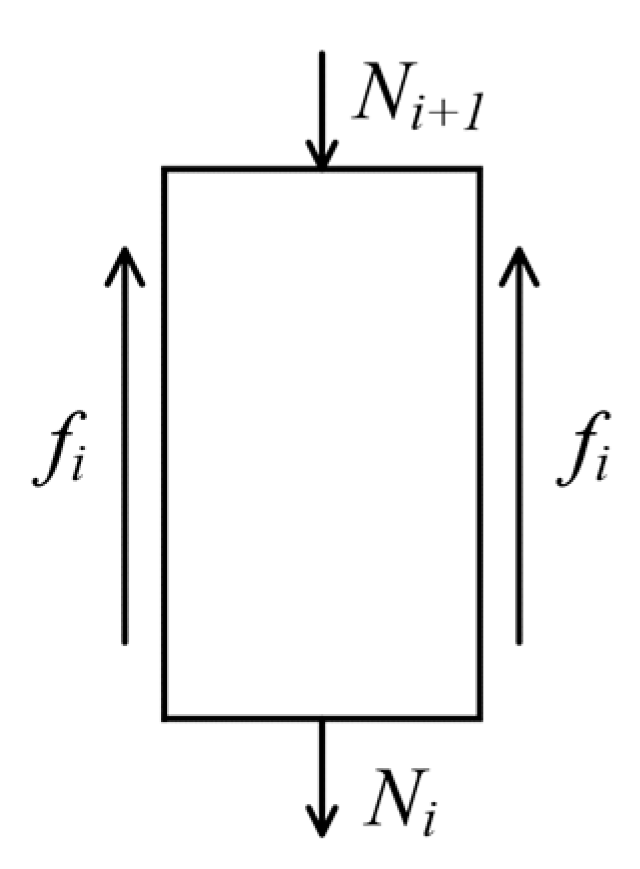

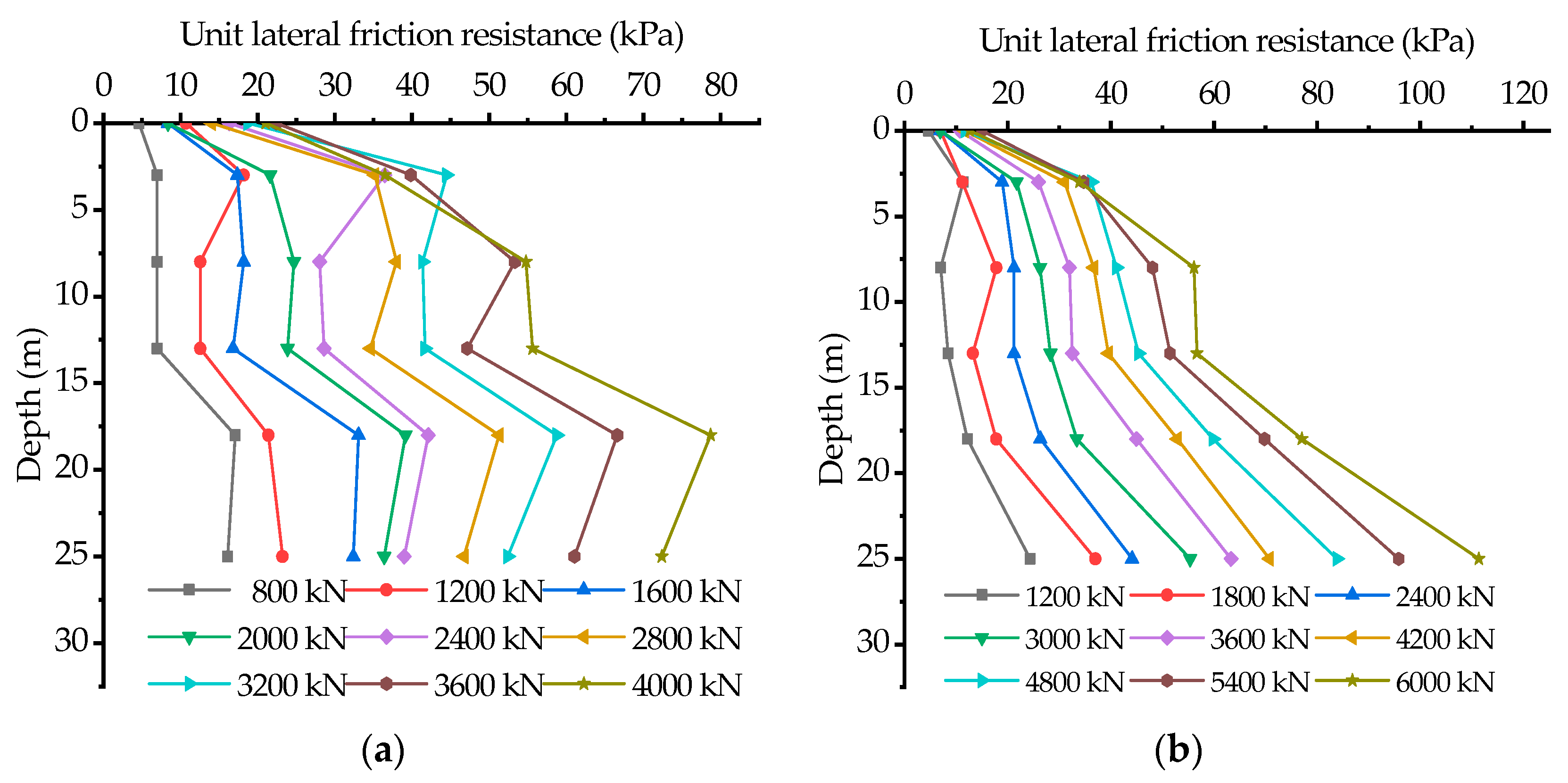

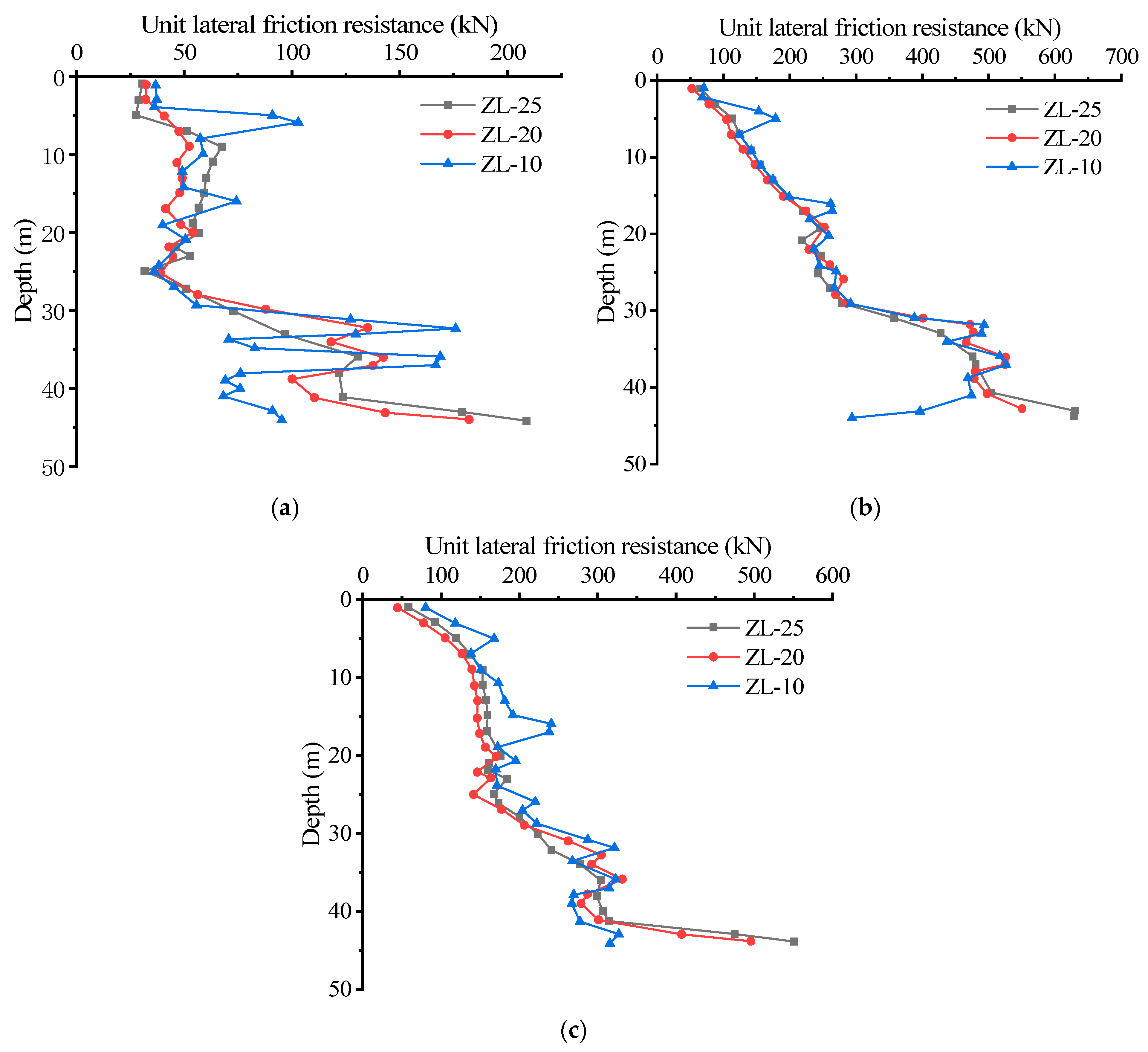

3.3. Study on Traits of Lateral Frictional Resistance of the Test Piles

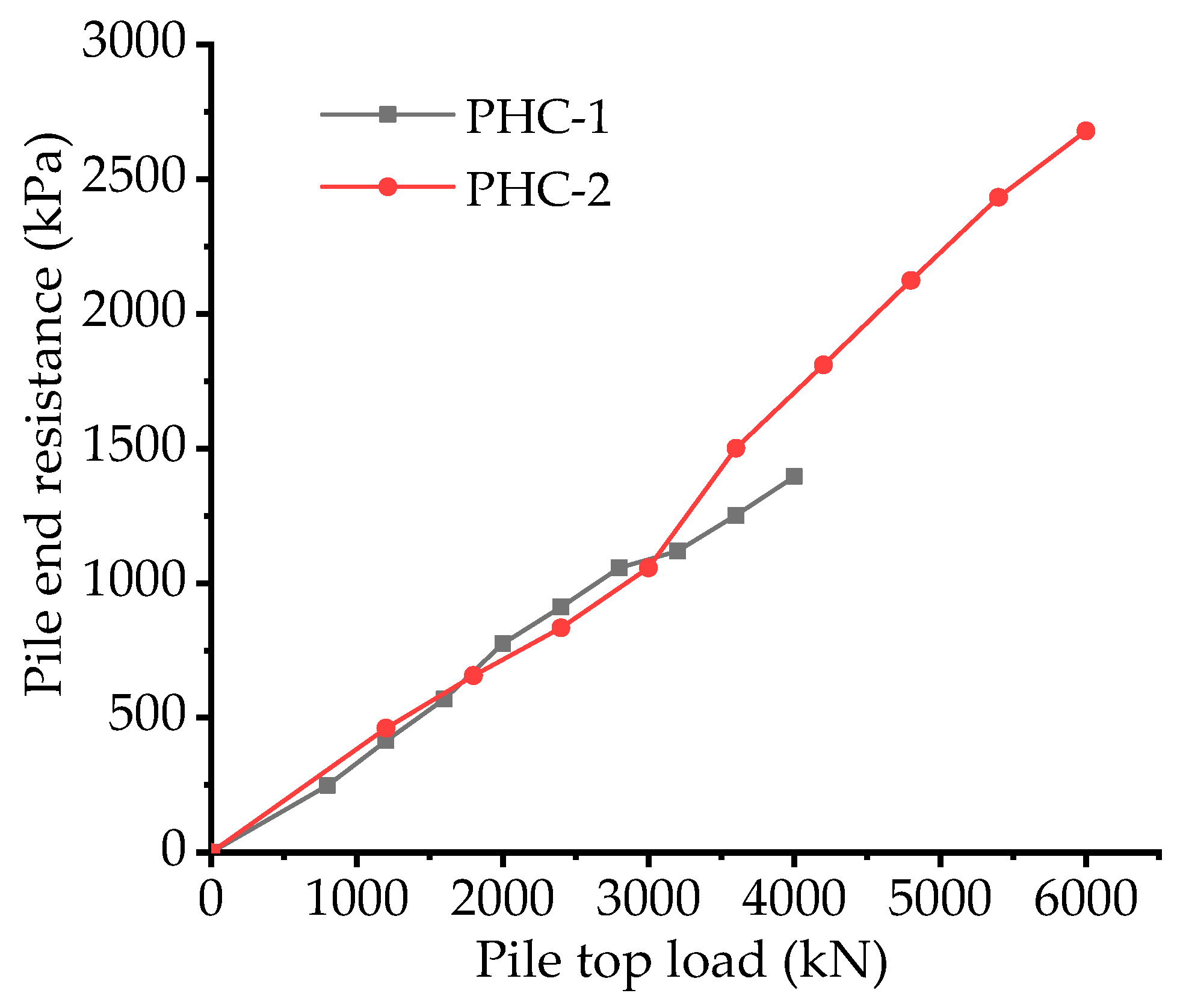

3.4. Relationship between Pile End Resistance and Pile Top Load

4. Finite Difference Method Simulation

4.1. FD Modeling

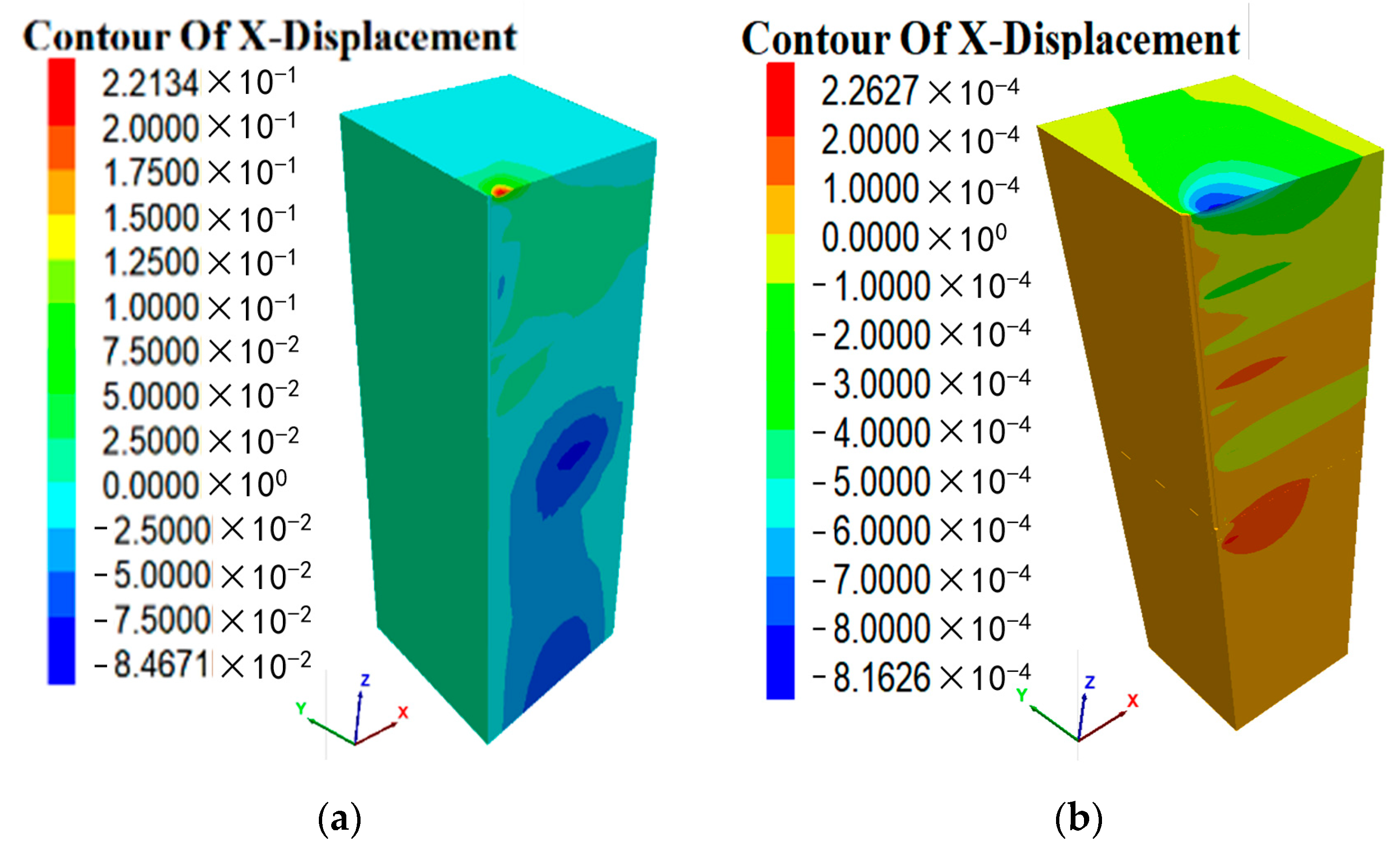

4.2. Loading and Analysis of the Effect of Bottom Expansion

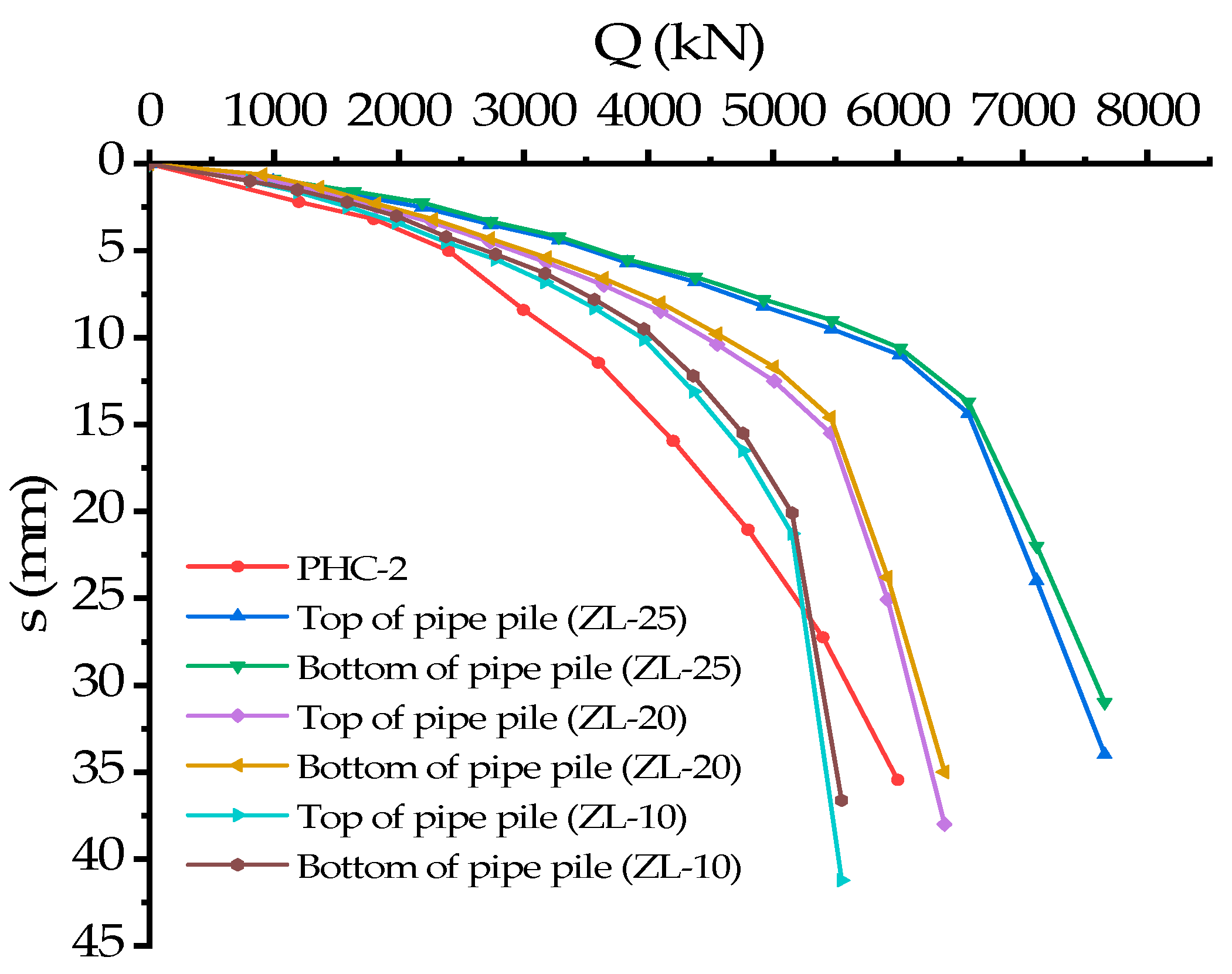

4.3. Loading and Analysis of the Effect of Pile Diameter

- (a)

- The inflection points of the load–settlement curves of the three pile types are obvious, and the linear section curves of the three pile types in the middle period before loading are very close. This is because all three pile types are large diameter deep and long piles, and according to the model soil parameters, it is known that all three pile types are friction piles, and the load applied at the top is mainly borne by the frictional resistance of the soil on the side of the pile. Since the outer diameter of the three pile types is the same, the surface area on the pile side of the three types is also the same, and the contact area with the soil on the pile side is also the same. This causes the vertical bearing performance of the three pile types to not change greatly when the frictional resistance on the pile side is not fully exerted. This is consistent with the results obtained by Ma, JX et al. [38]. However, the straight line section of the precompression interim curve of the 10 cm wall pile is steeper than the first two, indicating that this pile type is weaker than the others in terms of settlement at the top of the pile when subjected to the same load and the ability to withstand vertical loads than the other two pile types. This is due to the smaller volume of the wall 0.1 m pipe pile, its pile can withstand less elastic compression, and the pile displacement is mainly the rigid displacement of the pile body.

- (b)

- From the comparative graph of load–settlement of the three pile types, it can be seen that as the inner diameter of the pile increases, the position of the inflection point of the three curves gradually moves to the left side of the curve and does not completely coincide. This is because although the lateral frictional resistance of the pile takes up most of the top load before the load–settlement curve enters the steeply descending section, a small portion of the load is still provided by the soil layer at the pile end. As the internal diameter of the pile gradually increases, the contact area between the pile end position and the pile end soil layer becomes smaller, resulting in a smaller load-carrying capacity provided by the pile end soil layer.

- (c)

- From the comparison graph of load–settlement of the three pile types it can be seen that after the load–settlement curve enters the steep fall section, the steep fall section curve of the three curves gradually becomes steeper with an increase in the inner diameter of the pile body. This is because at the late stage of loading, the lateral frictional resistance of the pile has exerted its ultimate value, and the increased load at the top of the pile is all borne by the soil layer at the end of the pile thereafter. As the internal diameter of the pile becomes larger, the contact area between the pile end position and the pile end soil layer becomes smaller, resulting in a reduction in the bearing capacity that the pile end soil layer can provide. The value of the load borne by the soil layer at the pile end increases at this stage, resulting in relatively large differences in the curves of the steeply descending section of the three curves. The calculation of the pile lateral frictional resistance was carried out by monitoring and recording the pile axial force distribution. The calculation method is the same as Equation (1). The pile lateral friction resistance diagrams for the three pile types under all levels of loading are shown in Figure 16.

5. Conclusions

- Under the same pile diameter and pile length, the single pile bearing capacity of the pipe pile by the inner digging method was 50% higher than that of the ordinary hammering method, and the enlarged part of the pile end had a significant effect on the improvement of the bearing capacity. Therefore, the bearing capacity of the structural foundation can be improved by using the inner digging method when the construction conditions allow.

- The axial force of the middle-digging and bottom-expanding method pipe pile plays from top to bottom; when the top load is small, the axial force of the pile is distributed more evenly as the top load keeps increasing, and the axial force of the part of the pile near the surface increases obviously and decreases rapidly along the direction away from the surface, at this time the pile end force also keeps increasing, the pile side resistance and pile end resistance is an asynchronous process of play. The lateral resistance of the pile is more evenly distributed along the pile body.

- When the top load of the medium-drilled pipe pile reaches the ultimate bearing capacity, the pile end-bearing capacity is strong, and the pile end resistance accounts for 40% to 50% of the pile top load. The pile will appear as an end-bearing friction pile or even as a friction end-bearing pile. In contrast, the higher pile end-bearing capacity helps to improve the pile side-bearing capacity, especially the lateral frictional resistance of the soil near the pile end. The piles have a high vertical load-carrying capacity.

- The simulation results show that increasing the diameter of the enlarged head or enlarging the range of the enlarged head has a certain improvement effect on the bearing capacity and settlement of the pipe pile. The enlarged head can be increased from 1.2 times the pile diameter to 1.4 times or more by mechanical modification of the pile driver. The large diameter enlarged head is preferable for the actual construction of the pipe pile as far as the mechanical conditions allow.

- When the pile is subjected to vertical load, it can be concluded that in different stages of the loading process, PHC pile inner diameter changes have different effects on the pile bearing capacity. When the pile side friction resistance is large in the early stage, the vertical bearing capacity of PHC pile with different wall thicknesses is not very different from other types of piles, and when the top pile load is large, the PHC inner diameter is too small to have a large effect on the pile bearing capacity, therefore, reducing the inner diameter of PHC pile within a certain range can improve the economy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, J.P. Comparison for the behavior of expanded-base pile and normal pile driving in soil. Disaster Adv. 2013, 6, 99–106. [Google Scholar]

- Choi, Y.; Kim, D.C. Implementation of Noise-Free and vibration-Free PHC Screw Piles on the Basis of Full-Scale Tests. J. Constr. Eng. Manag. 2013, 139, 960–967. [Google Scholar] [CrossRef]

- Yang, S.H. Design of temporary pier pile foundation construction plan for bridge in soft soil area. Railw. Constr. Technol. 2008, S1, 407–408. [Google Scholar]

- Rooz, A.F.H.; Hamidi, A. Numerical Analysis of Factors Affecting Ground Vibrations due to Continuous Impact Pile Driving. Int. J. Geomech. 2017, 17, 04017107. [Google Scholar] [CrossRef]

- Nguyen, T.N.; Pham, T.Q. Predicting Tensile Strength for Prestressed Reinforced Concrete-Driven Piles. Appl. Sci. 2022, 12, 7112. [Google Scholar] [CrossRef]

- Ya, H.D. Quality control of PHC pipe pile construction by hammering method. J. Cent. South Univ. 2010, 2, 196–199. [Google Scholar]

- Cao, S.S. Construction technology and problem solving of PHC pipe piles by static compression. Fujian Build. Mater. 2019, 12, 59–61. [Google Scholar]

- Daryaei, R.; Bakroom, M.; Aubram, D. Numerical evaluation of the soil behanior during pipe-pile installation using impact and vibratory driing in sand. Soil. Dyn. Earthq. Eng. 2020, 134, 106177. [Google Scholar] [CrossRef]

- Sofiste, V.T.; Godinho, L. Numerical modelling for prediction of ground-borne vibrations induced by pile driving. Eng. Struct. 2021, 242, 112533. [Google Scholar] [CrossRef]

- Zhou, P.; Li, J.P.; Li, L.; Xie, F. Analysis of the existing pile response induced by adjacent pile driving in undrained clay. Comput. Geotech. 2021, 138, 104319. [Google Scholar] [CrossRef]

- Zhang, K.P. Analysis of the effect of soil extrusion on the piling effect of pre-stressed pipe piles constructed by the hydrostatic method. West. Resour. 2022, 1, 55–57. [Google Scholar]

- Zhou, J.J.; Gong, X.N.; Wang, K.H.; Zhang, R.H. A field study on the behavior of static drill rooted nodular piles with caps under compression. J. Zhejiang Univ. Sci. A 2015, 12, 951–963. [Google Scholar] [CrossRef]

- Cao, Z.H.; Liu, H.L.; Kong, G.Q.; Zhou, H. Physical modelling of pipe piles under oblique pullout loads using transparent soil and particle image velocimetry. J. Cent. South Univ. 2015, 22, 4329–4336. [Google Scholar] [CrossRef]

- Kong, G.Q.; Zhou, H.; Ding, X.M.; Cao, Z.H. Measuring effects of X-section pile installation in soft clay. Proc. Inst. Civ. Eng.-Geotech. Eng. 2015, 168, 296–305. [Google Scholar] [CrossRef]

- Liu, J.; Wang, F.; He, S.; Wang, E.; Zhou, H. Enlarging a large-diameter shield tunnel using the Pile-Beam-Arch method to create a metro station. Tunn. Undergr. Space Technol. 2015, 49, 130–143. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, D.; Fang, J. Finite element analysis of deepwater conductor bearing capacity to analyze the subsea wellhead stability with consideration of contact interface models between pile and soil. J. Petrol. Sci. Eng. 2015, 126, 48–54. [Google Scholar] [CrossRef]

- Lei, K.H.; Zhou, D.W.; Liu, T. Field Performance of Open-Ended Prestressed High-Strength Concrete Pipe Piles Jacked into Clay. Sensors 2018, 18, 4216. [Google Scholar]

- Kou, H.L.; Yu, F.; Liu, T. Strain Monitoring on PHC pipe piles Based on Fiber Bragg Grating Sensors. J. Perform. Constr. Fac. 2019, 33, 04019003. [Google Scholar] [CrossRef]

- Ozturk, B.; Kodsy, A.; Iskander, M. Forecasting the Capacity of Open-Ended Pipe Piles Using Machine Learning. Infrastructures 2023, 8, 12. [Google Scholar] [CrossRef]

- Baca, M.; Ivannikov, A.L.; Rybak, J. Numerical Modelling of Various Aspects of Pipe Pile Static Load Test. Energies 2021, 14, 8598. [Google Scholar] [CrossRef]

- Baca, M.; Rybak, J. Pile Base and Shaft Capacity under Various Types of Loading. Appl. Sci. 2021, 11, 3396. [Google Scholar] [CrossRef]

- Zhou, X.L.; Kou, H.L.; Li, C.H. Shaft Resistances of Jacked Open-ended PHC Pipe Piles. Geotech. Eng. 2017, 48, 111–114. [Google Scholar]

- Zhang, Z.J.; Li, G.C.; Wang, W.J. Experimental lnvestigation and Nonlinear Finite Element Analysis on Seismic Performance of PHC Piles. Struct. Eng. Int. 2018, 28, 475–488. [Google Scholar]

- GTao, L.; Chen, X.J.; Chen, J.; Pan, Y.P. Study on seismic damage model of PHC pipe pile embedded in clay soil. IOP Conf. Ser. Earth. Environ. Sci. 2019, 304, 042033. [Google Scholar]

- Huang, F.Y.; Wu, S.W.; Luo, X.Y.; Lin, Y.W. Pseudo-static low cycle test on the mechanical behavior of PHC pipe piles with consideration of soil-pile interaction. Eng. Struct. 2018, 171, 992–1006. [Google Scholar] [CrossRef]

- Ren, J.W.; Xu, Q.B.; Chen, G.; Lu, Y. Flexural performance of pretensioned centrifugal spun concrete piles with combined steel strands and reinforcing bars. Structures 2021, 34, 4467–4485. [Google Scholar] [CrossRef]

- Wang, J.W.; Hyun, J.H.; Lee, B.Y.; Kim, Y.Y. Cyclic behavior of connection between footing and concrete-infilled composite PHC pile. Struct. Eng. Mech. 2014, 50, 741–754. [Google Scholar]

- Liu, J.W.; Zhang, Z.M.; Zhang, R.H.; Wang, S.F. Comparative Experimental Study on Flexural Property of Reinforced and Conventional PHC Pile. Adv. Mater. Res. 2010, 165, 2376–2380. [Google Scholar]

- Li, L.; Yang, C.Y.; Li, J.P. Corrosion initiation life of laterally loaded PHC pipe piles served in marine environment: Theoretical prediction and analysis. Constr. Build. Mater. 2021, 293, 123457. [Google Scholar] [CrossRef]

- Cao, X.L.; Dai, G.L.; Gong, W.M.; Tang, J.N. Experimental study on the seismic behavior of new PHC piles. Arab. J. Geosci. 2020, 13, 259–270. [Google Scholar] [CrossRef]

- Yao, Y.; Tian, T.; Wang, B. Impact of Marine Chloride ion Erosion Environment on the Durability of Deep Sea Pile Foundation. J. Coastal. Res. 2019, 98, 6–9. [Google Scholar]

- Zhou, J.J.; Yu, J.L.; Gong, X.N. Field study on the behavior of pre-bored grouted planted pile with enlarged grout base. Acta Geotech. 2021, 16, 3327–3338. [Google Scholar] [CrossRef]

- Ruan, B.Y. Rational construction analysis of follow-on drilling method pipe piles in sandy soils for railway bridges. Railw. Stand. Des. 2018, 10, 79–82. [Google Scholar]

- Li, Z.G.; Li, Y.; Zhao, C.F. Bearing performance of large-diameter medium-drilled expanded bottom method pipe piles in soft soil areas Field test analysis of performance. Chin. Civ. Eng. J. 2016, 49, 78–86. [Google Scholar]

- Zhao, C.; Du, X.H.; Zhao, C.F. Vertical bearing capacity of inner-digging prestressed piles. Chin. J. Geotech. Eng. 2013, 35 (Suppl. 1), 393–398. [Google Scholar]

- DB34/5005-2014; Technical Specifications for Pretensioned Pre-Stressed Spun Concrete Pile Foundation, 1st ed. Anhui Province Engineering Construction Standard Design Office: Hefei, China, 2014.

- JGJ 106-2014; Technical Code for Testing of Building Foundation Piles. China Architecture Publishing & Media Co., Ltd.: Beijing, China, 2014.

- Ma, J.X.; Wang, Y.H.; Zhang, M.Y. Penetration Characteristics of Jacked Piles with Different Pile Diameters Based on Fiber Bragg Grating Sensing Technology. Chin. J. Lasers 2020, 47, 0504003. [Google Scholar]

| Layer Number | Soil Type | Soil Thickness (m) | Cohesion (kPa) | Internal Friction Angle (°) | Compression Modulus (MPa) | Shear Modulus (MPa) | Stiffness (N/m) | Density (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| 1 | Silty clay | 1.5 | 14.7 | 21.7 | 5.349 | 3.101 | 2.35 × 1013 | 1900 |

| 2 | Silt | 1.7 | 12.0 | 24.5 | 7.472 | 5.984 | 3.86 × 1013 | 2040 |

| 3 | Fine Sand | 12 | 0 | 18.0 | 19.556 | 6.175 | 8.05 × 1013 | 2030 |

| 4 | Silt | 2.1 | 25.0 | 25.0 | 24.510 | 9.398 | 6.95 × 1013 | 2030 |

| 5 | Clay | 2.3 | 14.7 | 21.7 | 5.3 | 3.1 | 7.2 × 1013 | 2000 |

| 6 | Silty Clay | 10.5 | 12.5 | 25.0 | 5.8 | 3.5 | 2.65 × 1013 | 2010 |

| 7 | Clay | 1.9 | 0 | 18 | 20.6 | 6.2 | 1.95 × 1013 | 2000 |

| 8 | Fully Weathered Sandstone | 15 | 18.4 | 22.8 | 22.837 | 8.273 | -- | 2310 |

| Test Pile | Maximum Load | Loading Series | Load per Level (kN) | Initial Load (kN) |

|---|---|---|---|---|

| PHC−1 | 4800 | 10 | 400 | 800 |

| PHC−2 | 7200 | 10 | 600 | 1200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, Y.; Zhang, Y.; Wang, Z.; Yang, D.; Shi, J. Load-Bearing Characteristics of PHC Piles Constructed by the Inner Digging Method Based on Ultimate Load Testing and Numerical Simulation. Appl. Sci. 2023, 13, 5641. https://doi.org/10.3390/app13095641

Qu Y, Zhang Y, Wang Z, Yang D, Shi J. Load-Bearing Characteristics of PHC Piles Constructed by the Inner Digging Method Based on Ultimate Load Testing and Numerical Simulation. Applied Sciences. 2023; 13(9):5641. https://doi.org/10.3390/app13095641

Chicago/Turabian StyleQu, Yiwen, Yi Zhang, Zhitian Wang, Dahai Yang, and Jun Shi. 2023. "Load-Bearing Characteristics of PHC Piles Constructed by the Inner Digging Method Based on Ultimate Load Testing and Numerical Simulation" Applied Sciences 13, no. 9: 5641. https://doi.org/10.3390/app13095641

APA StyleQu, Y., Zhang, Y., Wang, Z., Yang, D., & Shi, J. (2023). Load-Bearing Characteristics of PHC Piles Constructed by the Inner Digging Method Based on Ultimate Load Testing and Numerical Simulation. Applied Sciences, 13(9), 5641. https://doi.org/10.3390/app13095641