Sand Sedimentation Mechanism in and around the Railway Culvert and Its Structural Optimization of Sediment Reduction

Abstract

:1. Introduction

2. Numerical Model

2.1. Theoretical Equations

2.2. Railway Culvert Model

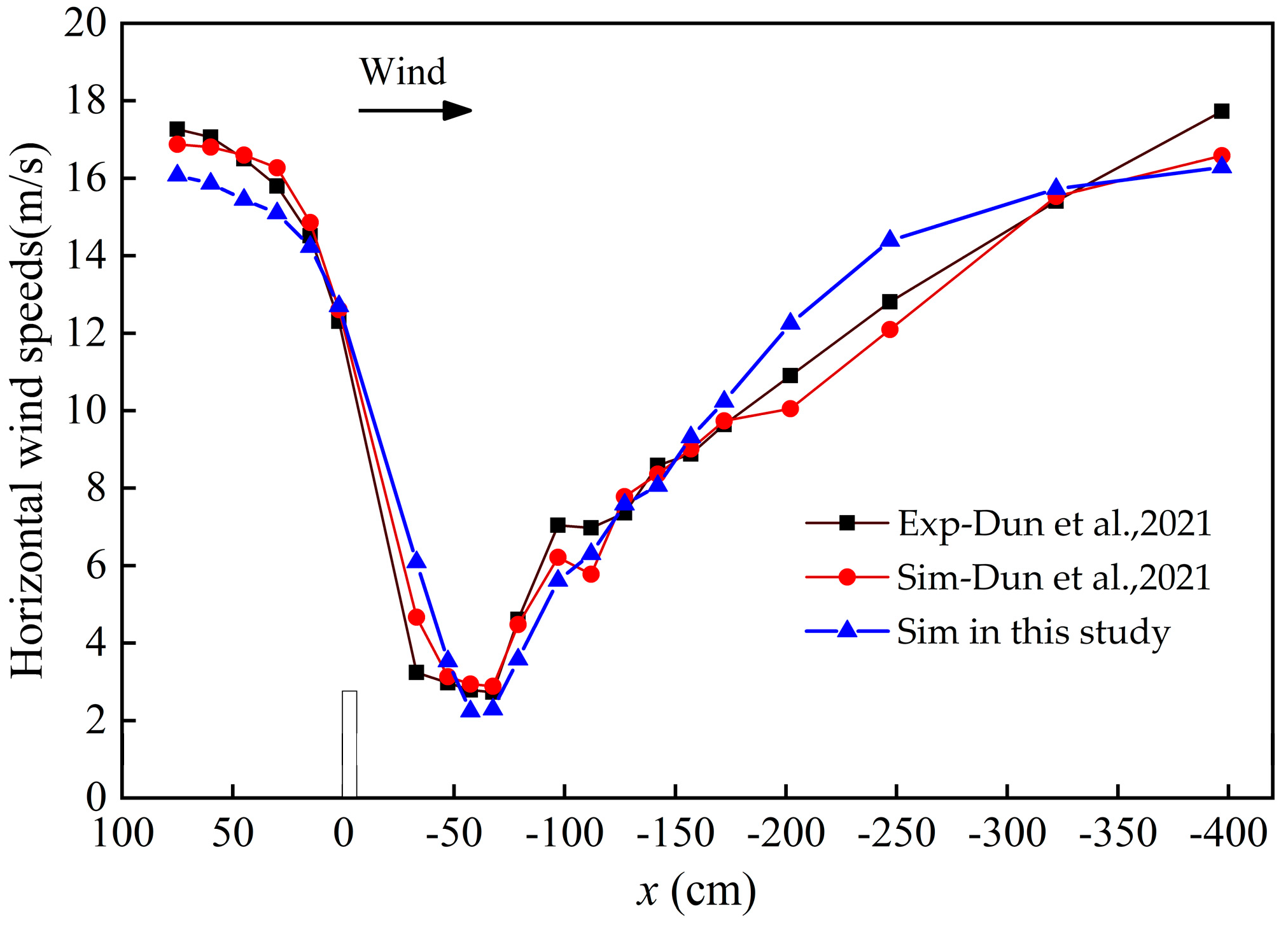

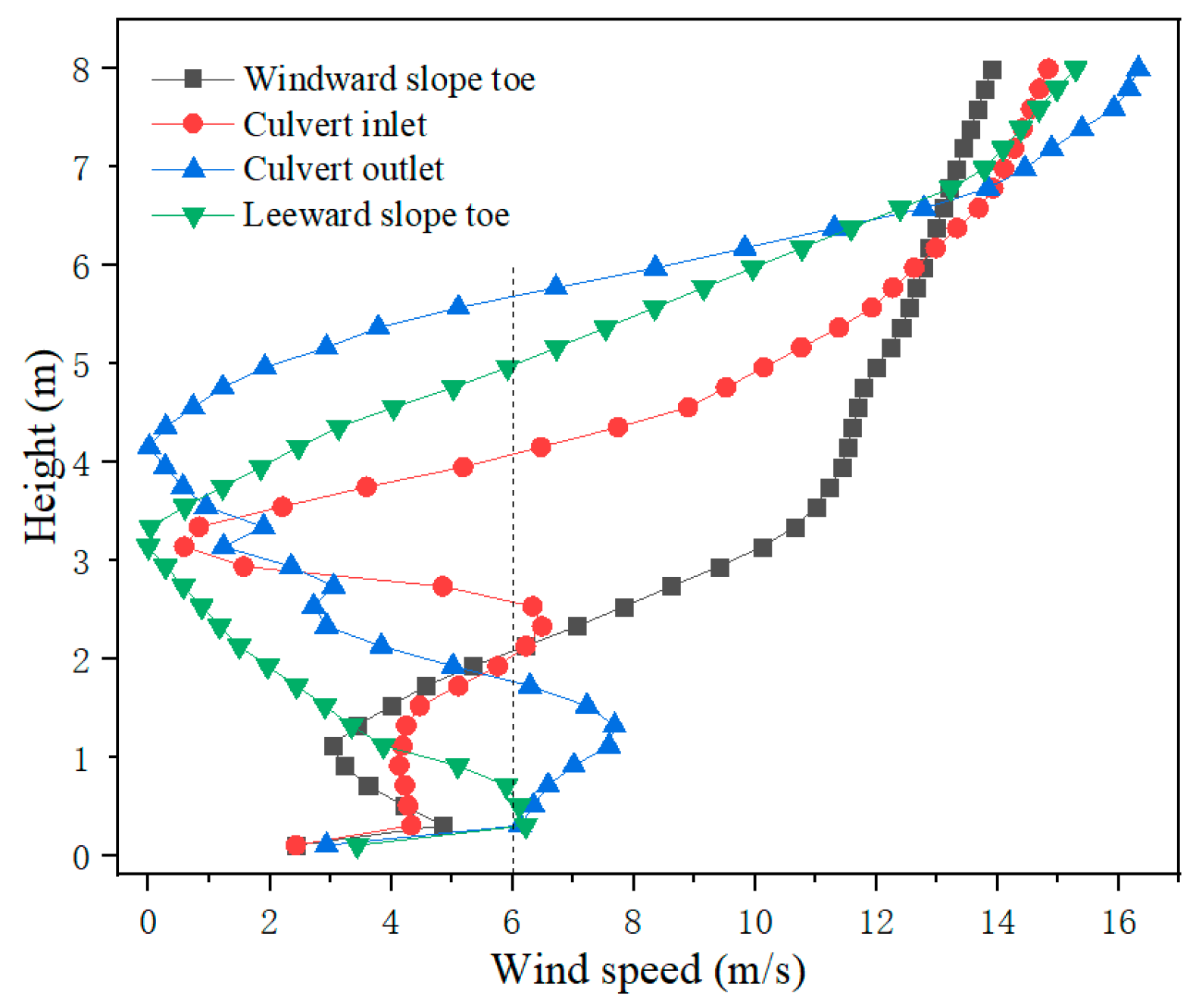

2.3. Model Verification

3. Results

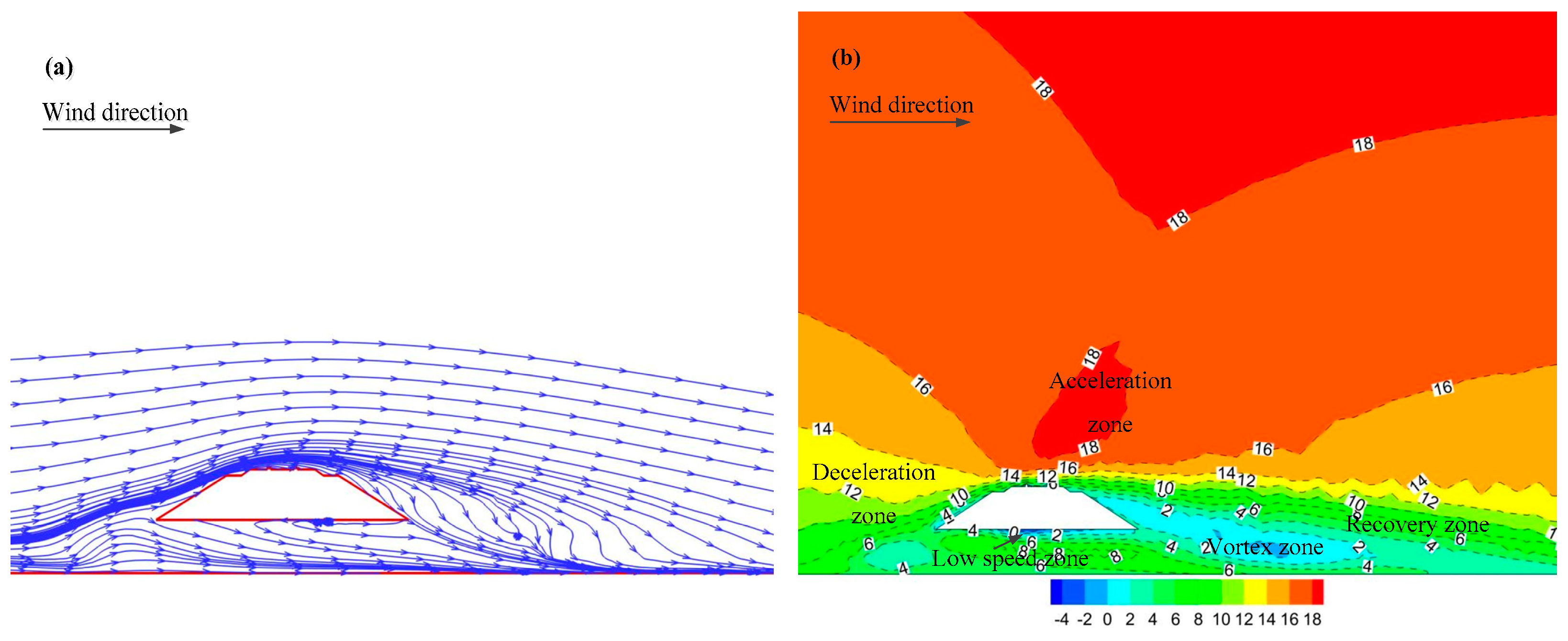

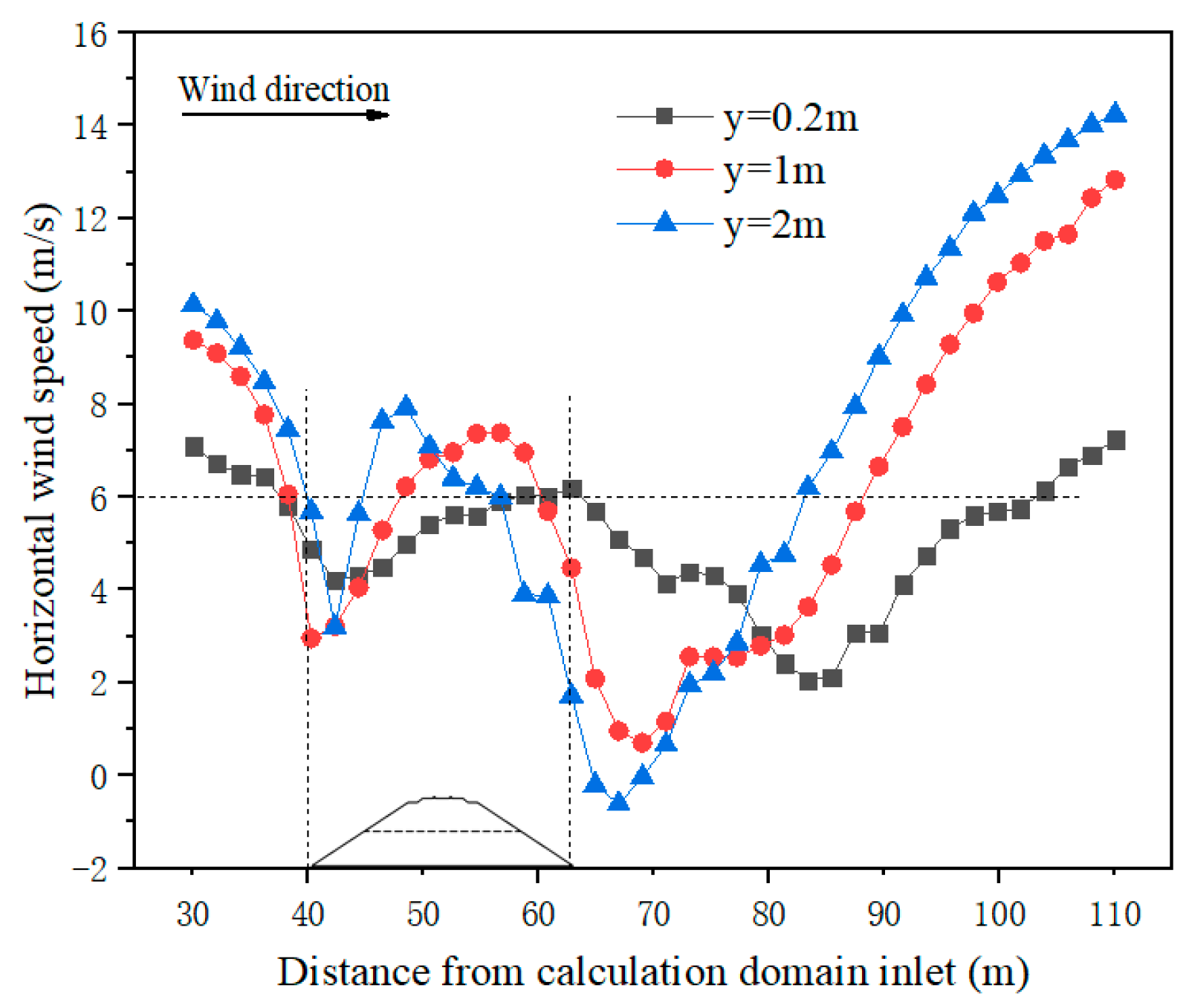

3.1. Flow Field Characteristics of Railway Culvert

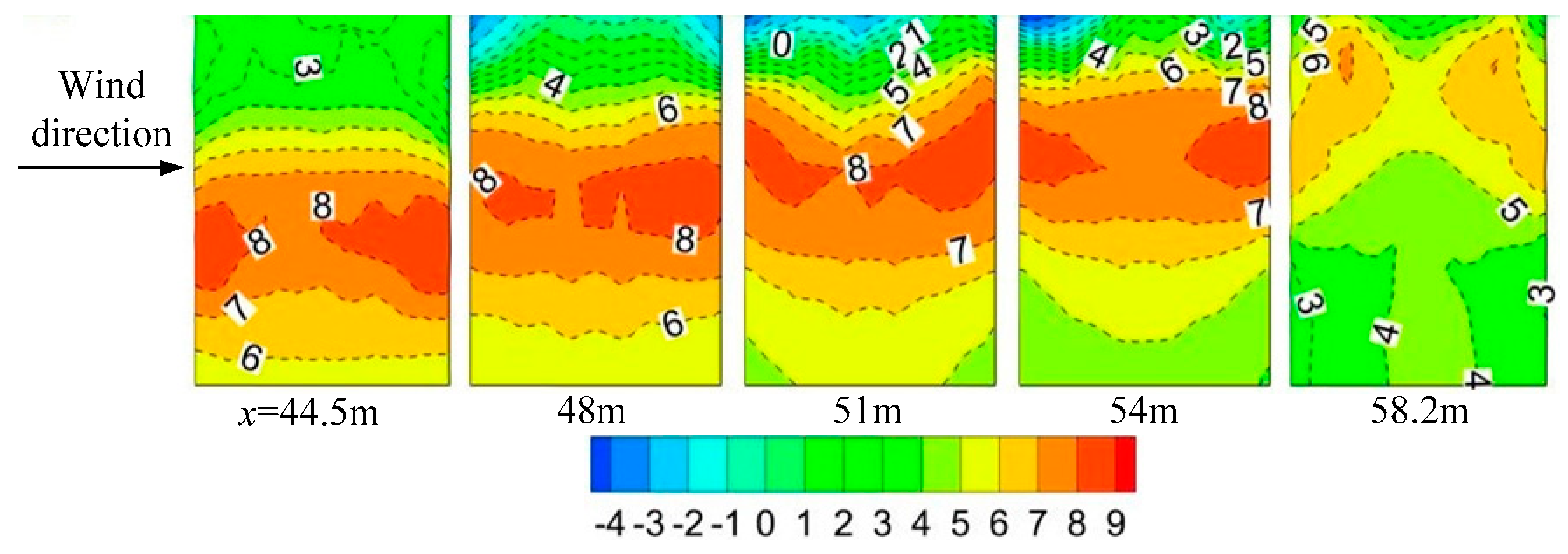

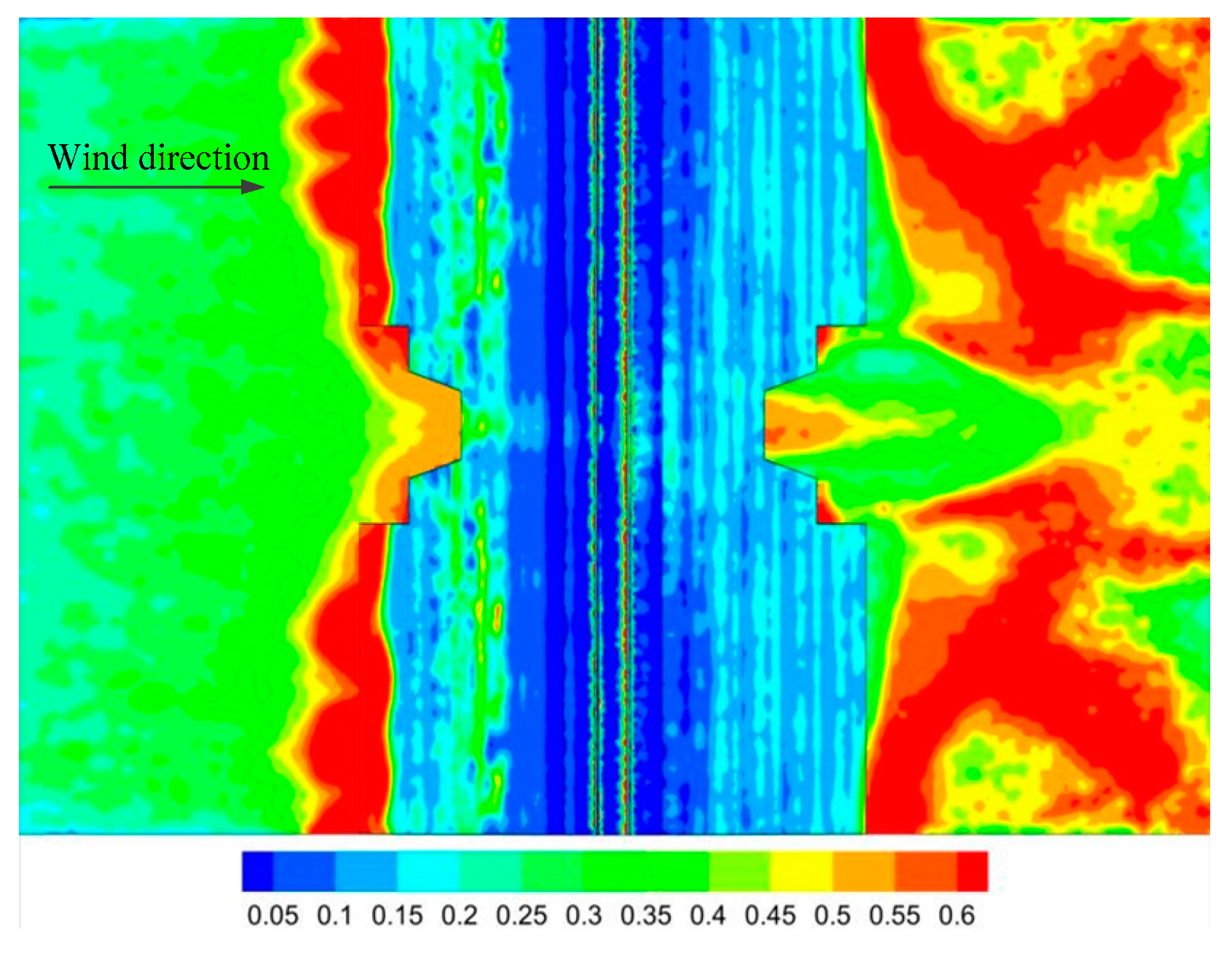

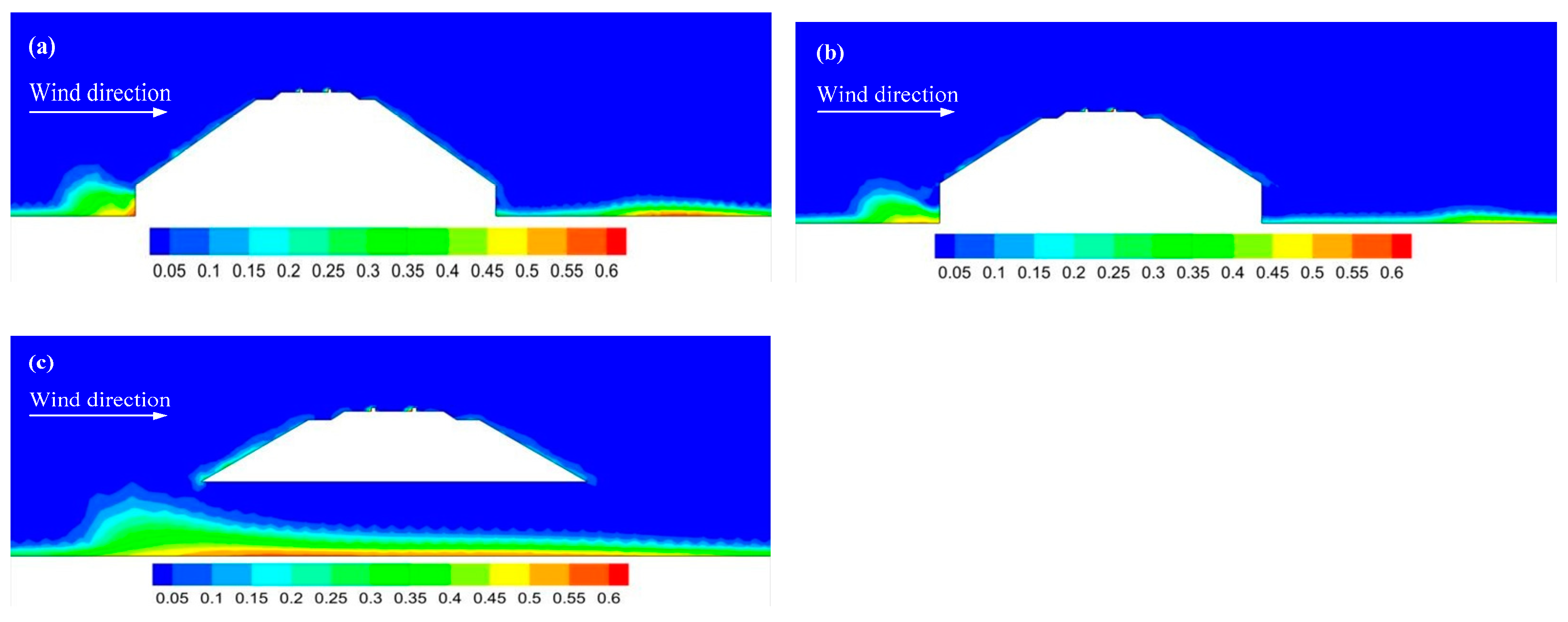

3.2. Sediment Transport Characteristics of Railway Culvert

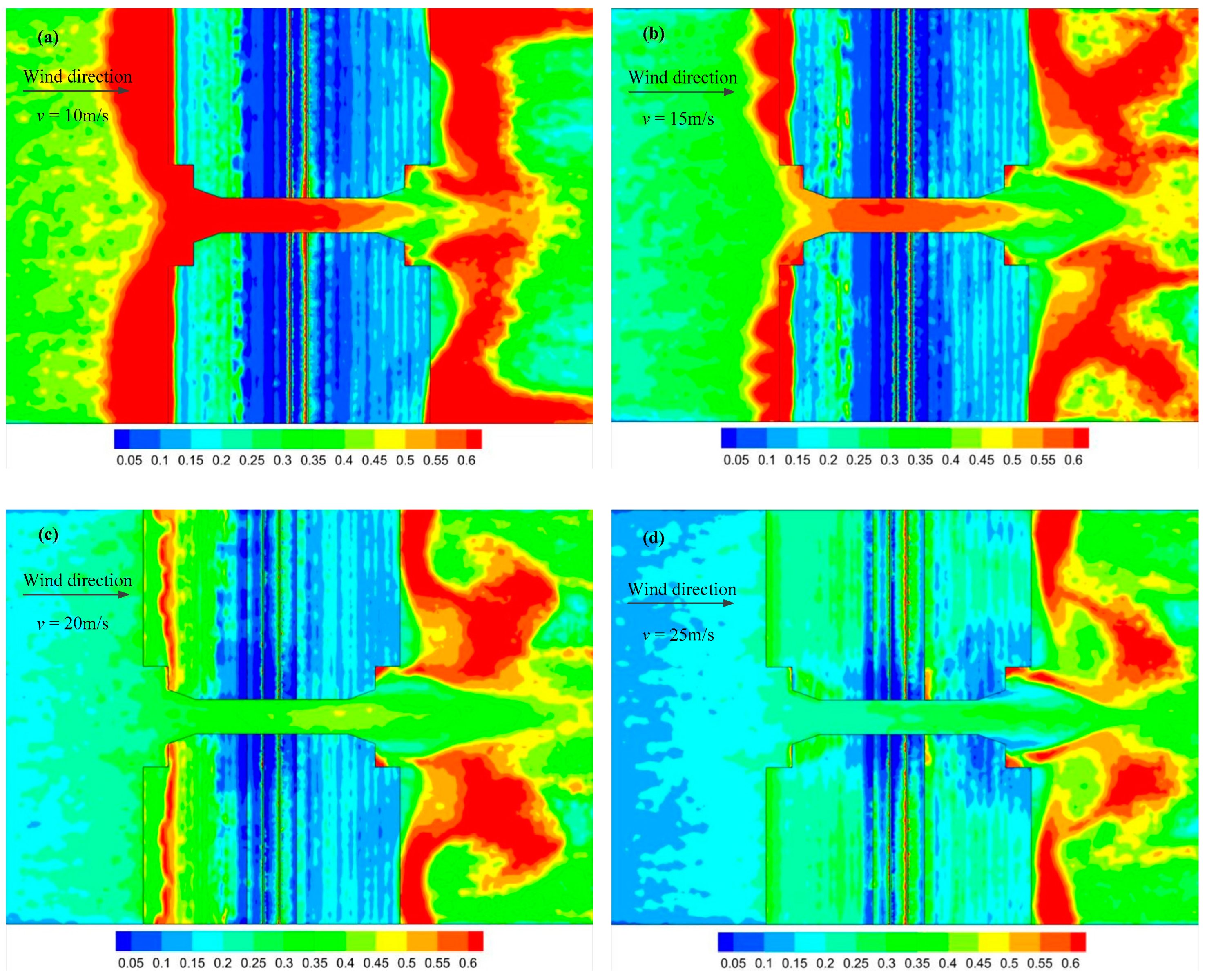

3.3. Influence of Inflow Velocity on Sand Distribution in Culvert

4. Discussion

4.1. Sand Sedimentation Mechanism in the Railway Culvert

4.2. Optimization and Design of Railway Culvert

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| CFD | Computational fluid dynamics |

| CWE | Computational wind engineering |

| αg | volume fractions of the air phase (%) |

| αs | volume fractions of the sand phase (%) |

| ρg | density of the air phase (kg/m3) |

| ρs | density of the sand phase (kg/m3) |

| vg | velocity vectors of the air phase |

| vs | velocity vectors of the sand phase |

| ug | velocity of the air phase (m/s) |

| us | velocity of the sand phase (m/s) |

| τg | surface stress tensors of the air phase (Pa) |

| τs | surface stress tensors of the sand phase (Pa) |

| p | pressure of an ideal fluid (Pa) |

| ps | solid pressure of the sand phase (Pa) |

| g | acceleration of gravity (m/s²) |

| fsg | interaction force between the air and sand phases (N) |

| CD | drag coefficient |

| d | equivalent diameter of the sand particle (m) |

| ur | relative velocity between the air and sand phases (m/s) |

| RANS | Reynolds Average Navier-Stokes method |

| k | turbulent kinetic energy |

| ε | turbulent dissipation rate |

| ui | velocity components in the x-direction (m/s) |

| uj | velocity components in the y-direction (m/s) |

| σk | Prandtl constant corresponding to the turbulent kinetic energy |

| σε | Prandtl constant corresponding to the turbulent dissipation rate |

| Gk | turbulent kinetic energy caused by the average velocity gradient |

| turbulent kinetic energy caused by particle motion | |

| turbulent dissipation rate caused by particle motion | |

| μt | turbulent viscosity |

| C1 | model constant |

| C2 | model constant |

| Cμ | model constant |

| u(y) | horizontal wind speed at height y (m/s) |

| u* | friction wind speed (m/s) |

| κ | Karman constant |

| y0 | surface roughness (m) |

| v | inflow velocity (m/s) |

References

- Niu, B.C.; Tan, L.H.; Zhang, X.C.J.; Qu, J.J.; An, Z.S.; Wang, J.Z.; Liu, B.L.; Wang, T.; Li, K.C. Targeted control of sand hazards for a railway in extremely arid regions using fingerprinting approaches. Geomorphology 2020, 361, 107189. [Google Scholar] [CrossRef]

- Paz, C.; Suarez, E.; Gil, C.; Concheiro, M. Numerical study of the impact of windblown sand particles on a high-speed train. J. Wind Eng. Ind. Aerodyn. 2015, 145, 87–93. [Google Scholar] [CrossRef]

- Shu, K.; Ding, H.H.; Mazzù, A.; Lin, Q.; Guo, J.; Meli, E.; Liu, Q.Y.; Wang, W.J. Effect of dynamic windblown sand environments on the wear and damage of wheel-rail under different slip ratios. Wear 2022, 500–501, 204349. [Google Scholar] [CrossRef]

- Deng, G.X.; Ma, W.; Peng, Y.; Wang, S.M.; Yao, S.; Peng, S. Experimental study on laminated glass responses of high-speed trains subject to windblown sand particles loading. Constr. Build. Mater. 2021, 300, 124332. [Google Scholar] [CrossRef]

- Mehdipour, R.; Baniamerian, Z. A new approach in reducing sand deposition on railway tracks to improve transportation. Aeolian Res. 2019, 41, 100537. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, Z.H.; Chi, Y.H.; Wang, M.; Wang, H.Y. Experimental study and discrete element analysis on dynamic mechanical behaviour of railway ballast bed in windblown sand areas. Constr. Build. Mater. 2021, 304, 124669. [Google Scholar] [CrossRef]

- Marko, H.; Luca, B.; Sami, K. Receiver Sand Mitigation Measures along railways: CWE-based conceptual design and preliminary performance assessment. J. Wind Eng. Ind. Aerodyn. 2022, 228, 105109. [Google Scholar] [CrossRef]

- Lorenzo, R.; Luca, B. Windblown sand action on civil structures: Definition and probabilistic modeling. Eng. Struct. 2019, 178, 88–101. [Google Scholar] [CrossRef]

- Lorenzo, R.; Luca, B. Windblown sand mitigation along railway megaprojects: A comparative study. Struct. Eng. Int. 2020, 30, 355–364. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, N.; Dun, H.C. Experimental study on sand/bed collision over the Gobi surface. J. Geophys. Res. Atmos. 2022, 127, e2021JD035766. [Google Scholar] [CrossRef]

- Wang, T.; Qu, J.J.; Tan, L.H.; Gao, Y.; Zhang, K.; Shi, B.Y. Aeolian sediment transport over the Gobi with high gravel coverage under extremely strong winds in the Hundred Miles windy area along the Lanzhou-Xinjiang High-Speed Railway. J. Wind Eng. Ind. Aerodyn. 2022, 220, 104857. [Google Scholar] [CrossRef]

- Cheng, J.J.; Jiang, F.Q.; Xue, C.X.; Xin, G.W.; Li, K.C.; Yang, Y.H. Characteristics of the disastrous wind-sand environment along railways in the Gobi area of Xinjiang, China. Atmos. Environ. 2015, 102, 344–354. [Google Scholar] [CrossRef]

- Cheng, J.J.; Lei, J.Q.; Li, S.Y.; Wang, H.F. Disturbance of the inclined inserting-type sand fence to wind-sand flow fields and Its sand control characteristics. Aeolian Res. 2016, 21, 139–150. [Google Scholar] [CrossRef]

- Xin, G.W.; Huang, N.; Zhang, J.; Dun, H.C. Investigations into the design of sand control fence for Gobi buildings. Aeolian Res. 2021, 49, 100662. [Google Scholar] [CrossRef]

- Wang, T.; Qu, J.J.; Ling, Y.Q.; Liu, B.L.; Xiao, J.H. Shelter effect efficacy of sand fences: A comparison of systems in a wind tunnel. Aeolian Res. 2018, 30, 32–40. [Google Scholar] [CrossRef]

- Zhang, K.; Zhao, P.W.; Zhao, J.C.; Zhang, X.X. Protective effect of multi-row HDPE board sand fences: A wind tunnel study. Int. Soil Water Conse. 2021, 9, 103–115. [Google Scholar] [CrossRef]

- Huang, N.; Gong, K.; Xu, B.; Zhao, J.; Xin, G.W. Investigations into the law of sand particle accumulation over railway subgrade with wind-break wall. Eur. Phys. J. E 2019, 42, 145. [Google Scholar] [CrossRef]

- Cui, X.N. Study of Sand Damage in Culvert and Mechanism of Sand Blocking in New Sand Barrier Network of Geku Railway; Lanzhou Jiaotong University: Gansu, China, 2019. [Google Scholar]

- Luca, B.; Marko, H.; Lorenzo, R. Windblown sand along railway infrastructures: A review of challenges and mitigation measures. J. Wind Eng. Ind. Aerodyn. 2018, 177, 340–365. [Google Scholar] [CrossRef]

- Zhi, L.Y.; Cheng, J.J.; Wang, L.; Xin, L.G. Study on flow field around culvert of desert road and characteristics of sand accumulation. Railw. Stand. Des. 2018, 62, 62–67. [Google Scholar]

- Li, K.C.; Shi, L.; Zhang, F.; Jiang, F.Q. Research on the dynamic response of sand flow and railway culvert. J. Railw. Eng. Soc. 2015, 32, 14–17+48. [Google Scholar]

- Shi, L.; Jiang, F.Q.; Li, K.C.; Xue, X.C.; Kong, L.W. Three-dimensional simulation analysis of response law of wind-blown sand flow around the railway culvert. J. Railw. Eng. Soc. 2016, 33, 14–18. [Google Scholar]

- Yang, X.M.; Jia, H.F.; Zhou, Y.L. Numerical analysis on formation mechanism of sand damage around culvert of Qinghai Tibet Railway. Railw. Eng. 2021, 61, 109–111+133. [Google Scholar]

- Yuan, Z.L.; Zhu, L.P.; Geng, F.; Peng, Z.B. Gas Solid Two Phase Flow and Numerical Simulation; Southeast University Press: Nanjing, China, 2013; pp. 61–63, 68. [Google Scholar]

- TB 10002-2017; Code for Design of Railway Bridges and Culvert. National Railway Administration of the People’s Republic of China: Shenyang, China, 29 September 2017.

- Liu, S.M.; Pan, W.X.; Zhao, X.W.; Zhang, H.; Cheng, X.L.; Long, Z.W.; Chen, Q.Y. Influence of surrounding buildings on wind flow around a building predicted by CFD simulations. Build. Environ. 2018, 140, 1–10. [Google Scholar] [CrossRef]

- Dun, H.C.; Xin, G.W.; Huang, N.; Shi, G.T.; Zhang, J. Wind-tunnel studies on sand sedimentation around wind-break walls of Lanxin High-Speed Railway II and its prevention. Appl. Sci. 2021, 11, 5989. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Huang, N.; Dun, H.; Shi, G.; Zhang, X. Sand Sedimentation Mechanism in and around the Railway Culvert and Its Structural Optimization of Sediment Reduction. Appl. Sci. 2023, 13, 5585. https://doi.org/10.3390/app13095585

Xu J, Huang N, Dun H, Shi G, Zhang X. Sand Sedimentation Mechanism in and around the Railway Culvert and Its Structural Optimization of Sediment Reduction. Applied Sciences. 2023; 13(9):5585. https://doi.org/10.3390/app13095585

Chicago/Turabian StyleXu, Jiangang, Ning Huang, Hongchao Dun, Guangtian Shi, and Xiaoan Zhang. 2023. "Sand Sedimentation Mechanism in and around the Railway Culvert and Its Structural Optimization of Sediment Reduction" Applied Sciences 13, no. 9: 5585. https://doi.org/10.3390/app13095585

APA StyleXu, J., Huang, N., Dun, H., Shi, G., & Zhang, X. (2023). Sand Sedimentation Mechanism in and around the Railway Culvert and Its Structural Optimization of Sediment Reduction. Applied Sciences, 13(9), 5585. https://doi.org/10.3390/app13095585