A Technique for Multi-Parameter Signal Processing of an Eddy-Current Probe for Measuring the Thickness of Non-Conductive Coatings on Non-Magnetic Electrically Conductive Base Metals

Abstract

:Featured Application

Abstract

1. Introduction

1.1. Amplitude-Sensitive Eddy-Current Method for Measuring the Thickness of Coating

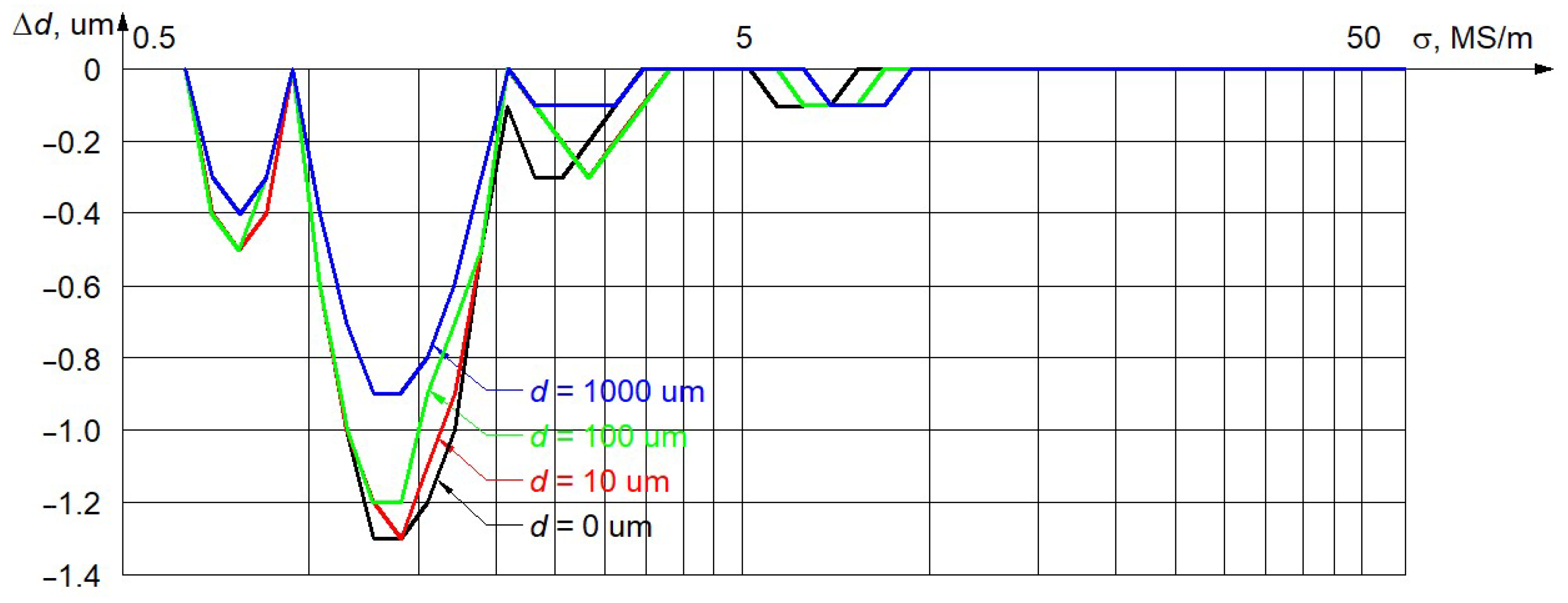

1.2. Stray Parameters When Measuring d by Using the Amplitude-Sensitive Eddy-Current Method

- -

- Geometric: curvature and roughness of a base metal and coating surfaces; the tilt of ECP; contamination of the coating and ECP surfaces resulting in a gap between the ECP and the test object; edge effect.

- -

- Technological: the pressure of ECP on the coating; intermediate coatings; the influence of temperature and external electromagnetic fields.

- -

- Electromagnetic: the specific electrical conductivity σ of the base metal.

- -

- The thickness is measured on a fully painted product, and removing the coating from a part of the surface (for ECP calibration) is not possible;

- -

- σ changes considerably on the surface of base metal;

- -

- The test object has different temperatures on the surface. In this case, a deviation of σ is observed.

1.3. A Review of the Methods for a Suppression of the Influence of σ Deviation

2. Materials and Methods

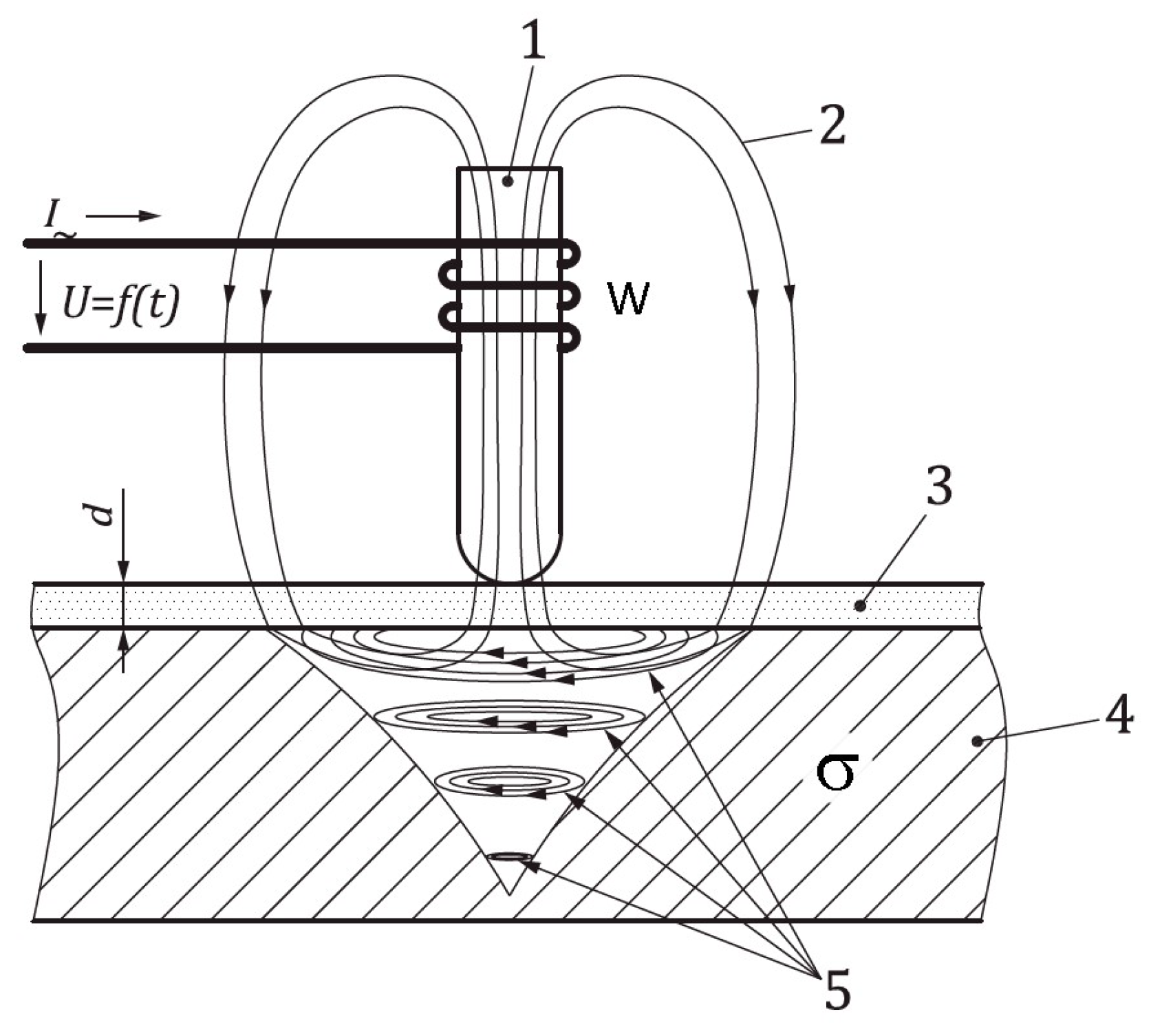

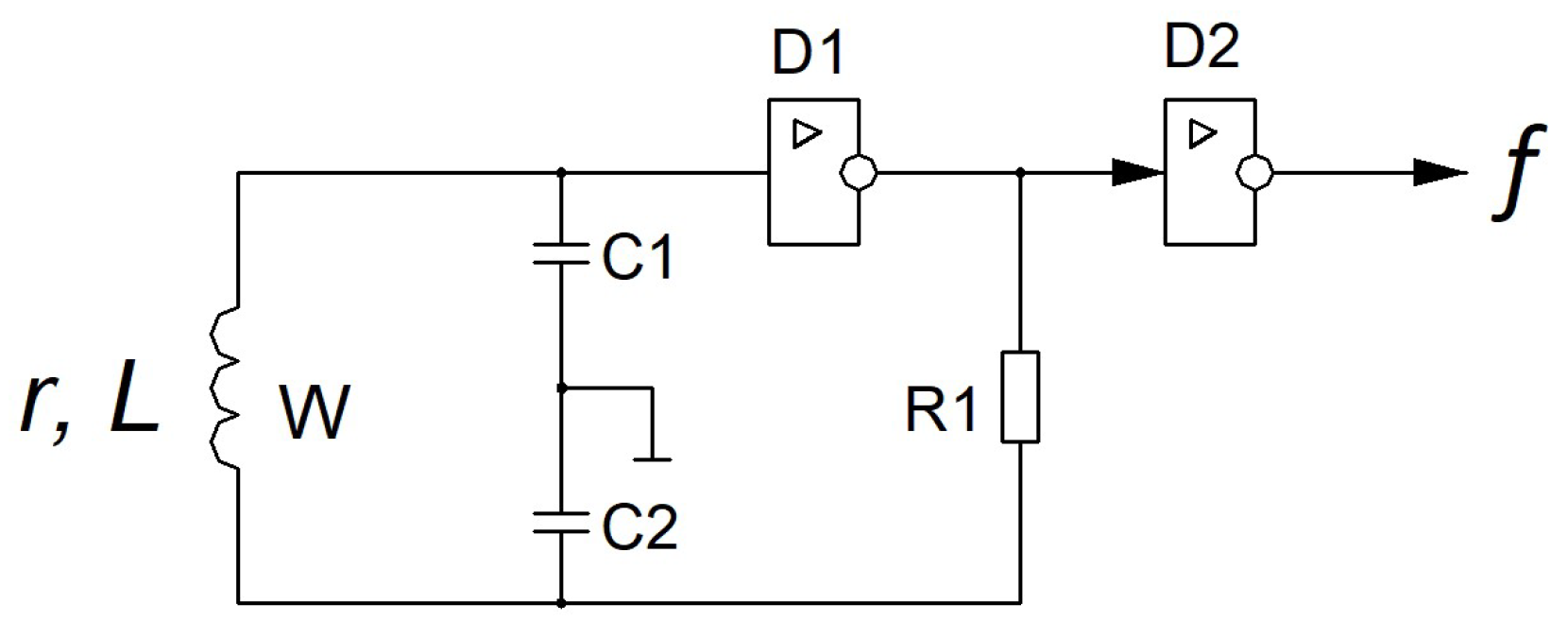

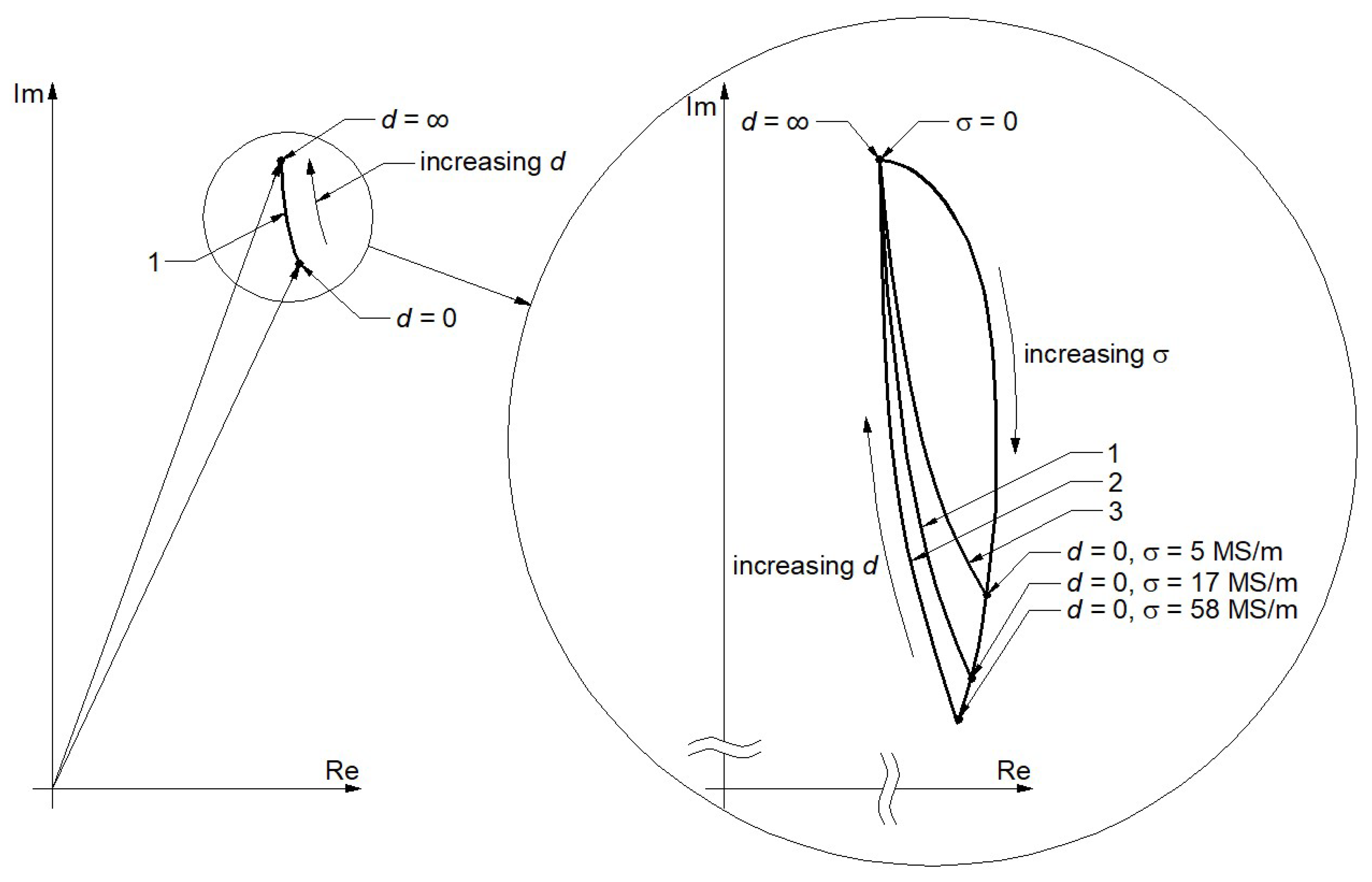

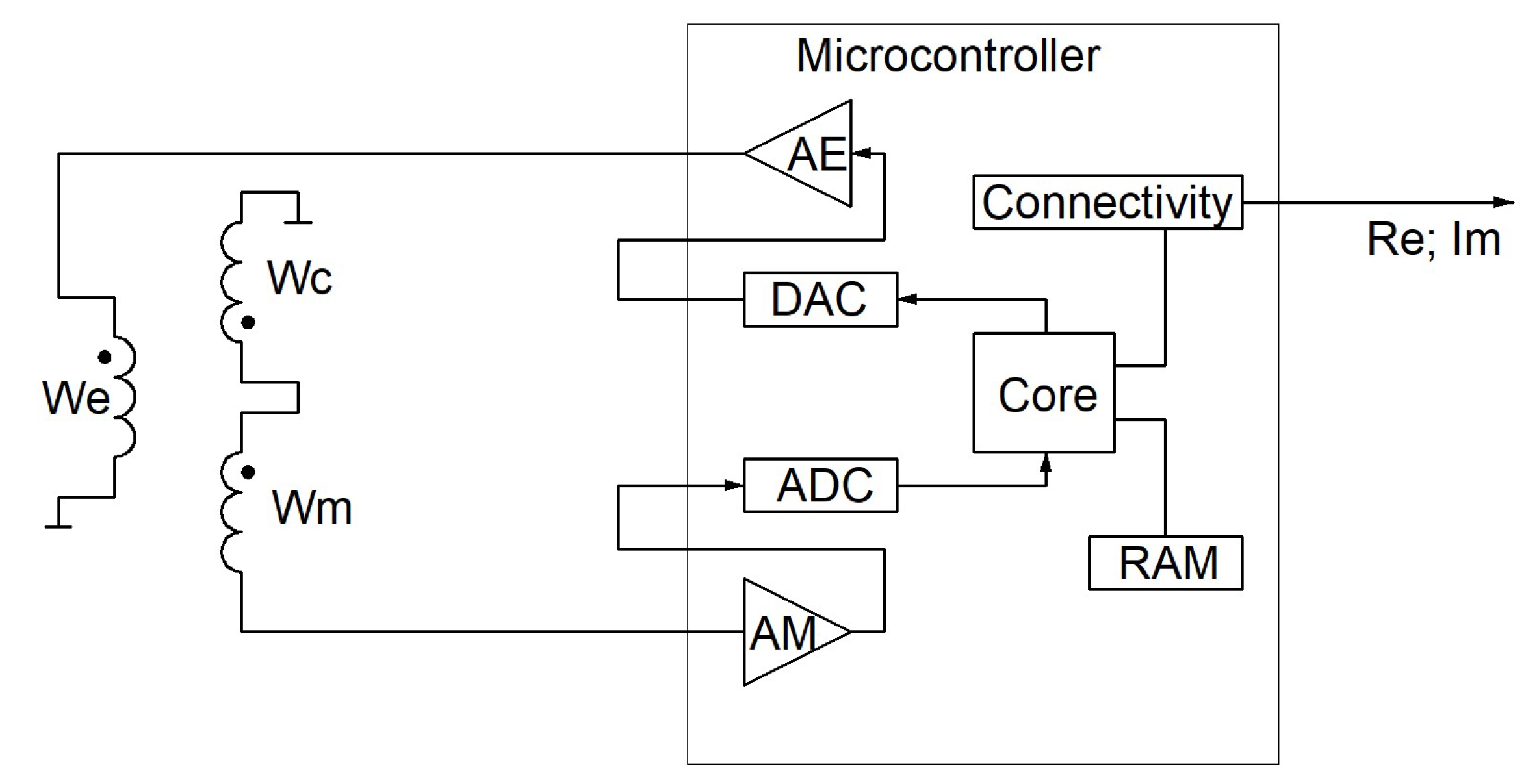

2.1. Description of an Amplitude-Phase Probe

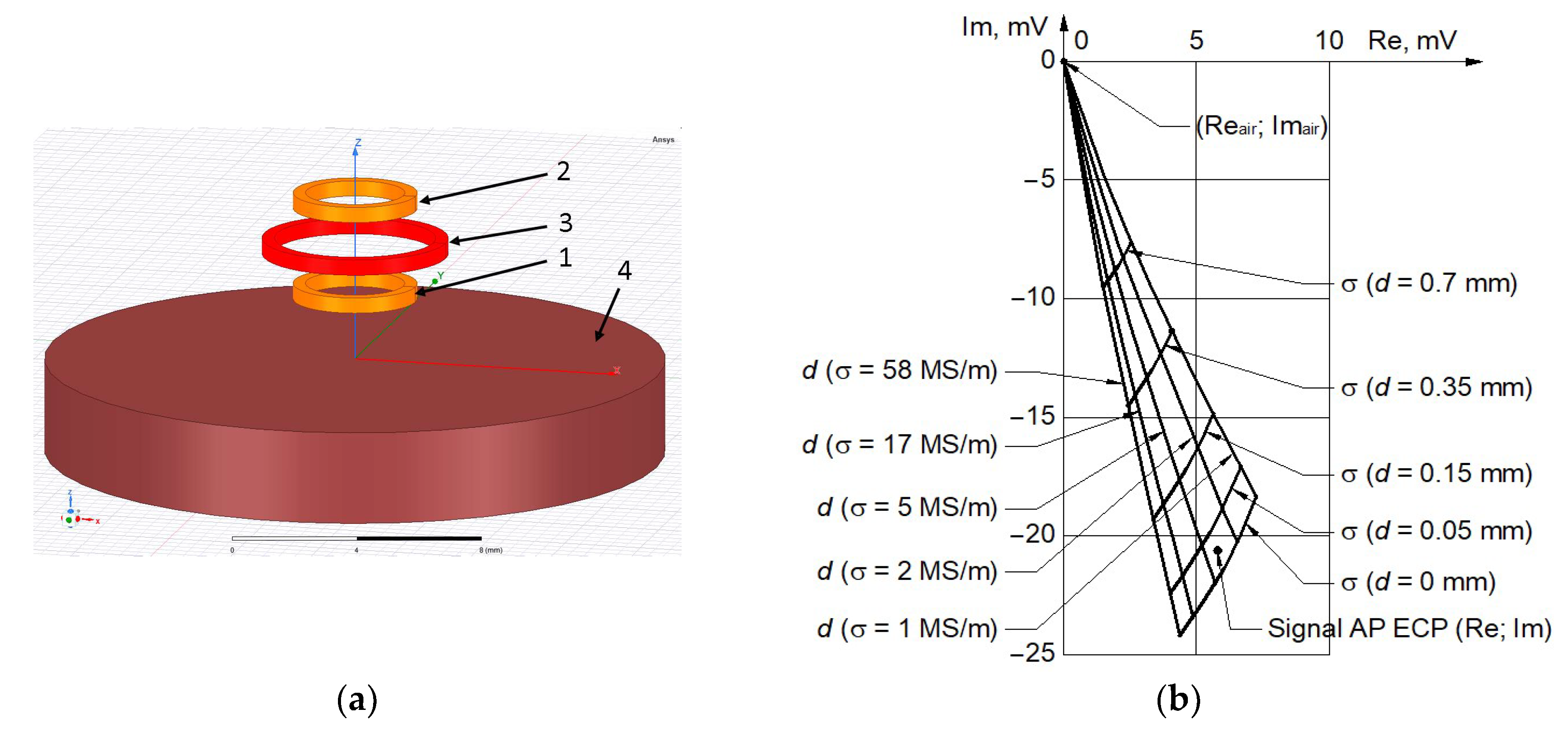

2.2. Description of the Finite Element Model of AP ECP

2.3. Overview of Two-Parameter Measurement Methods

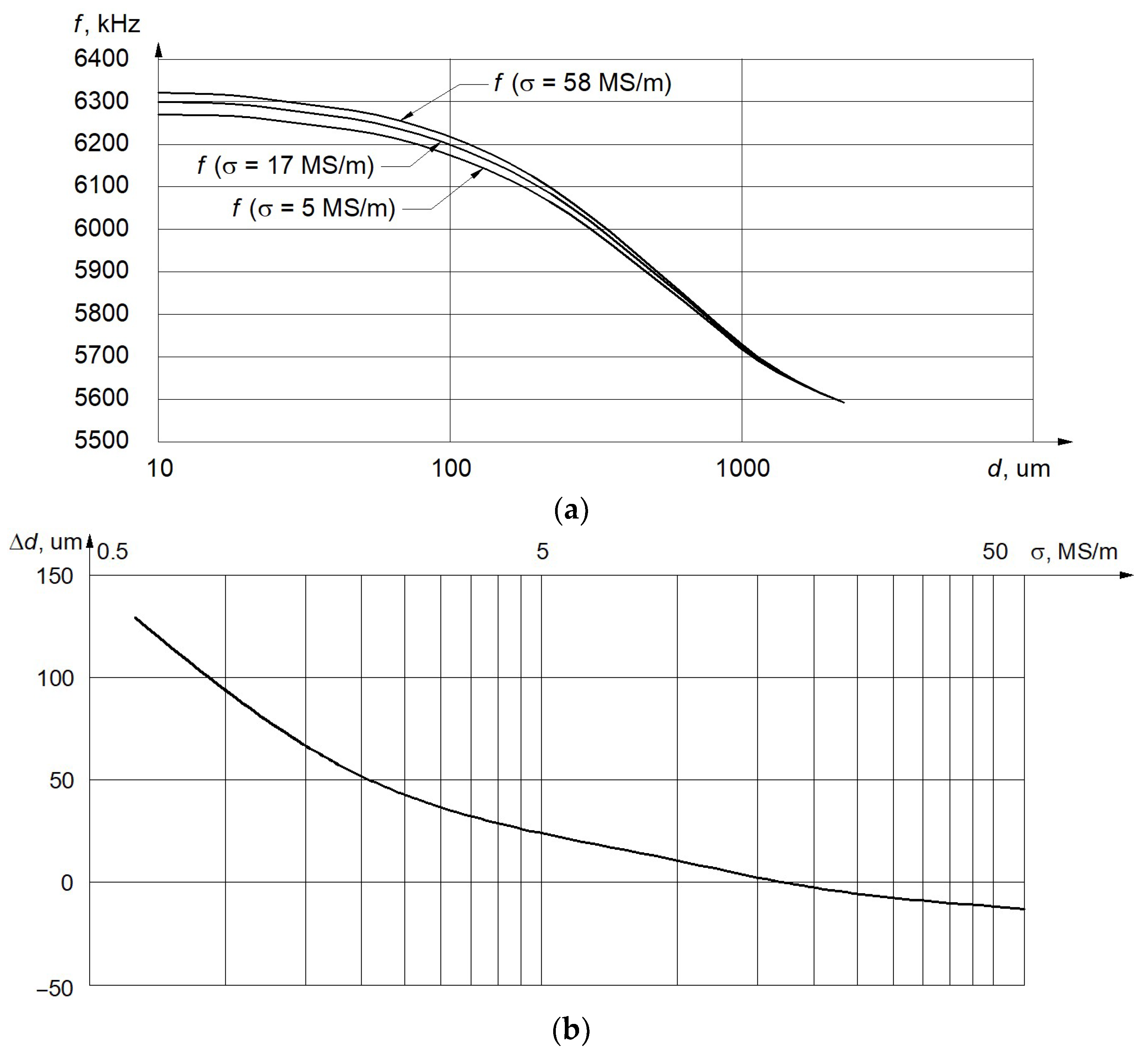

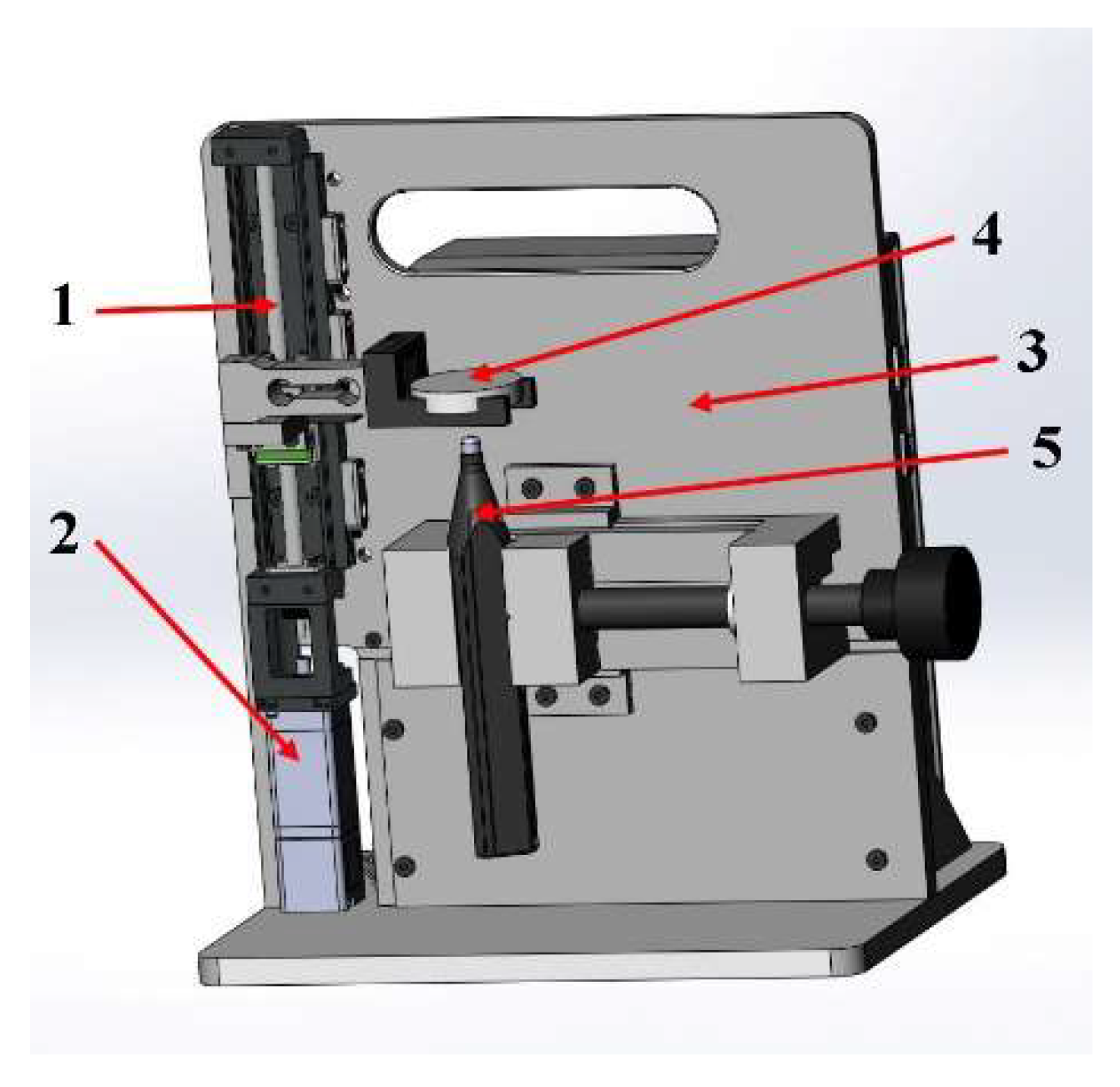

2.4. Description of the Proposed Graduation Technique

2.5. Description of the Proposed Measurement Technique

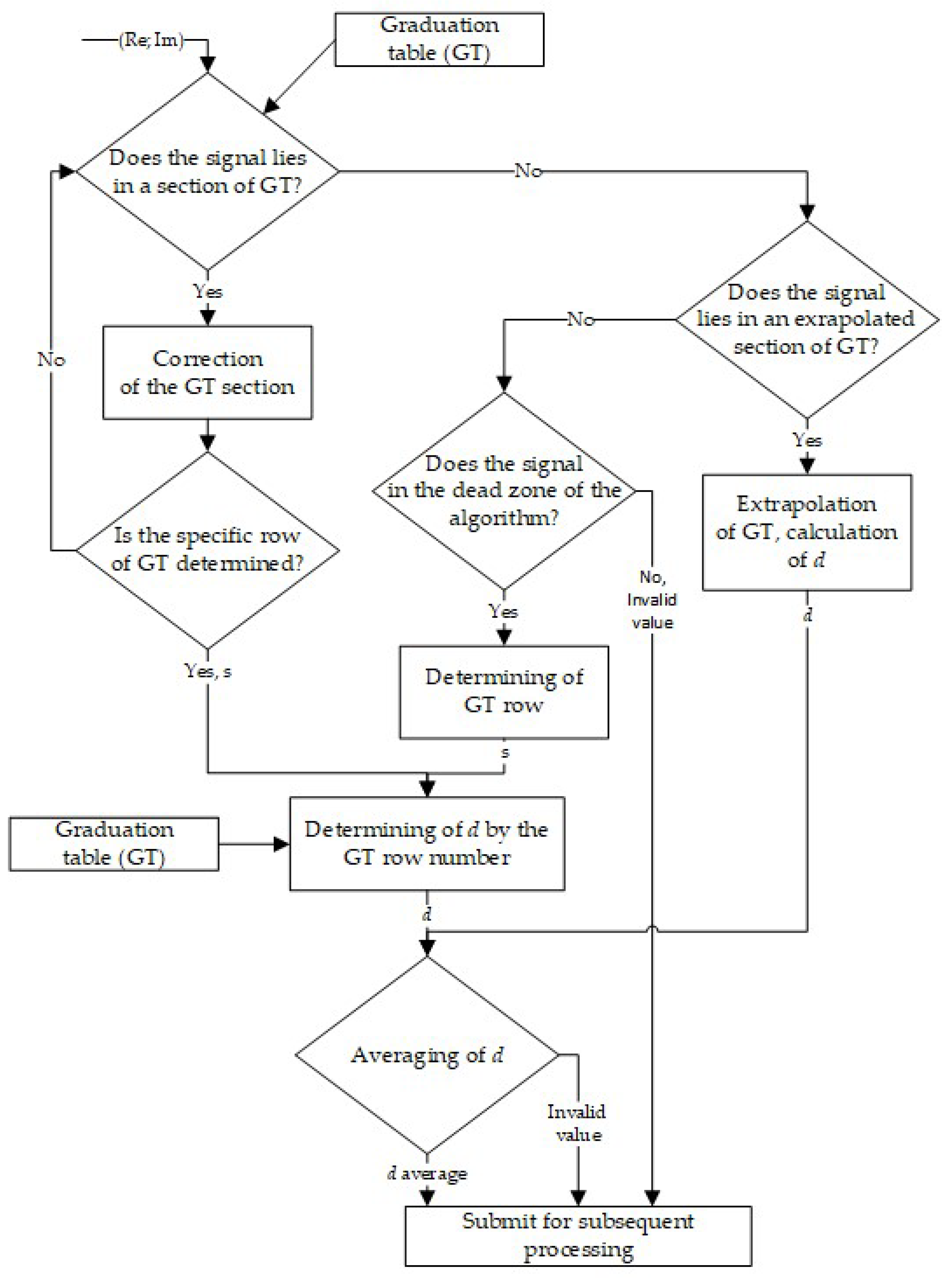

2.5.1. General Description of Two-Dimensional Algorithm for the Calculation σ and d

2.5.2. “Signal-in-Section” Check

- If the condition is met for d = 0, then the signal belongs to the upper half of the table. In this case, for the next iteration, points from the upper half of the table (d = 0, d = row/4 and d = row/2) are selected;

- If the condition is met for d = row/2, then the signal belongs to the lower half of the table. In this case, for the next iteration, points from the lower half of the table (d = 0, d = row3/4 and d = row) are selected;

- If the condition is not met neither for d = 0, nor for d = row/2, then either the signal belongs to one of the extrapolated sections, or the signal is in one of the dead zones of the algorithm. In this case, the signal is checked for belonging to one of the extrapolated sections of the table;

- If the condition is met for none of the interpolated sections of the graduation characteristic, then the signal belongs to one of “dead zones” of the algorithm; in this case, the signal is checked for belonging to “dead zones”;

- If the condition is met for none of “dead zones” of the algorithm, then the signal is an error and is not subject to further processing.

2.5.3. Extrapolation of the Graduation Characteristic and “Dead Zones” of the Algorithm

- Example 1. The measure σmax is taken for copper, σ ≈ 58 MS/m. If we measure d on a copper base at low temperature of the test object, the value of σ may exceed the σmax.

- Example 2. As was mentioned before, in practice, the curvature of the surface of the test object is a non-excluded stray parameter. When graduating, we use only measures for flat surfaces. If measurements are taken on an object with a concave surface, the d readings decrease. With a small d value, the readings may be negative.

3. Results

4. Discussion

- Measurement of the thickness of a non-conductive coating on a magnetic and non-magnetic conductive base metal and non-metal base;

- Simultaneous measurement of the thickness of layers of a non-conductive coating with a sublayer of a conductive non-magnetic coating on a conductive magnetic base metal, for example, a paint coating applied to a steel base with a zinc underlayer;

- Measurement of the thickness of non-magnetic conductive sheet with suppression of its specific electrical conductivity;

- Measurement of the specific electrical conductivity of the base metal with suppression of the influence of the lift-off or the thickness of the paint coating in a wide range of the base metal specific electrical conductivity values.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ISO 2360:2017; Non-Conductive Coatings on Non-Magnetic Electrically Conductive Base Metals—Measurement of Coating Thickness—Amplitude-Sensitive Eddy-Current Method. ISO: Geneva, Switzerland, 2017.

- GOST R ISO 2360-2021; Non-Conductive Coatings on Non-Magnetic Electrically Conductive Base Metals. Measurement of Coating Thickness. Amplitude-Sensitive Eddy-Current Method. Russian Technical Standard: Moscow, Russia, 2021.

- Syasko, V.A. Measuring the thicknesses of nonferromagnetic metal coatings on nonferrous metal products using the eddy-current frequency method. Russ. J. Nondestruct. Test. 2010, 46, 898–905. [Google Scholar] [CrossRef]

- GOST R 8.673-2009; State System for Ensuring the Uniformity of Measurements. Intelligent Sensors and Intelligent Measuring Systems. Basic Terms and Definitions. Federal Agency for Technical Regulation and Metrology: Moscow, Russian, 2009.

- GOST R 8.734-2011; State System for Ensuring the Uniformity of Measurements. Intelligent Sensors and Intelligent Measuring Systems. Methods of Metrological Self-Checking. Federal Agency for Technical Regulation and Metrology: Moscow, Russian, 2011.

- Tian, Y.; Rebinsky, D.A.; Kinney, C.A.; Luick, K. Eddy Current Based Method for Coating Thickness Measurement. U.S. Patent 9,377,287 B2, 28 January 2016. [Google Scholar]

- Cheng, W. Thickness Measurement of Metal Plates Using Swept-Frequency Eddy Current Testing and Impedance Normalization. IEEE Sens. J. 2017, 17, 4558–4569. [Google Scholar] [CrossRef]

- Yin, W.; Peyton, A.; Dickinson, S. Simultaneous Measurement of Distance and Thickness of a Thin Metal Plate With an Electromagnetic Sensor Using a Simplified Model. IEEE Trans. Instrum. Meas. 2004, 53, 1335–1338. [Google Scholar] [CrossRef]

- Meng, X.; Lu, M.; Yin, W.; Bennecer, A.; Kirk, K.J. Evaluation of Coating Thickness Using Lift-Off Insensitivity of Eddy Current Sensor. Sensors 2021, 21, 419. [Google Scholar] [CrossRef] [PubMed]

- Syasko, V. Optimization of structure and operation algorithms for electromagnetic plated coatings thickness meters with the use of digital technologies. In Proceedings of the BINDT/45th Annual British Conference on Non-Destructive Testing 2006, Shanghai, China, 25–28 October 2008. [Google Scholar]

- Potapov, A.I.; Syasko, V.A. Non-Destructive Methods and Means of Thickness Control of Coatings and Products/SCIENTIFIC, Methodological and Reference Manual; Humanistic Studies: Saint Petersburg, Russia, 2009; pp. 203–213. [Google Scholar]

- Egorov, A.V.; Polyakov, V.V. Eddy Current Testing of Metallic Materials Using Projection Methods. Russ. J. Nondestruct. Test. 2018, 54, 377–384. [Google Scholar] [CrossRef]

- Nerush, M.N. Eddy current method of measuring the thickness of an electrically conductive plate and the thickness of a non-conductive coating. In Proceedings of the Collection of Scientific Papers of the II International Conference of Schoolchildren, Students, Post-Graduates, Young Scientists “Resource-Efficient Systems in Management and Control: A look into the Future”, Tomsk, Russia, 18–19 September 2013; pp. 164–168. [Google Scholar]

- Gromyka, D.S.; Gogolinskiy, K.V. Method of State and Residual Resource Assessment of Excavator Bucket Tooth Caps. Russ. J. Nondestruct. Test. 2022, 58, 381–390. [Google Scholar] [CrossRef]

- Goldstein, A.E.; Belyankov, V.Y. An eddy-current gauge for measuring the wall thickness of light-alloy drill pipes. Russ. J. Nondestruct. Test. 2017, 53, 588–595. [Google Scholar] [CrossRef]

- Syasko, V.; Polacek, A. Electromagnetic thickness measurement of coatings. Situation and prospects. In Proceedings of the 11 European Conference on Non-Destructive Testing (ECNDT 2014), Prague, Czech Republic, 6–11 October 2014. [Google Scholar]

- Laszlo, M. Computational Geometry and Computer Graphics in C++ BINOM; Prentice Hall: Moscow, Russia, 1997; p. 304. [Google Scholar]

- Litovka, Y.V. Obtaining Optimal Design Solutions and Their Analysis Using Mathematical Models; Tambov State Technical University: Tambov, Russia, 2012; p. 161. [Google Scholar]

| d | Σ | |||

|---|---|---|---|---|

| σ1 | σ2 | -//- | σcolumn | |

| d0 | (Re d0, σ1; Im d0, σ1) | (Re d0, σ2; Im d0, σ2) | -//- | (Re d0, σcolumn; Im d0, σcolumn) |

| d1 | (Re d1, σ1; Im d1, σ1) | (Re d1, σ2; Im d1, σ2) | -//- | (Re d1, σcolumn; Im d1, σcolumn) |

| d2 | (Re d2, σ1; Im d2, σ1) | (Re d2, σ2; Im d2, σ2) | -//- | (Re d2, σcolumn; Im d2, σcolumn) |

| -//- | -//- | -//- | -//- | -//- |

| d row | (Re d row, σ1; Im d row, σ1) | (Re d row, σ2; Im d row, σ2) | -//- | (Re d row, σcolumn; Im d row, σcolumn) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Syasko, M.; Solomenchuk, P.; Soloviev, I.; Ampilova, N. A Technique for Multi-Parameter Signal Processing of an Eddy-Current Probe for Measuring the Thickness of Non-Conductive Coatings on Non-Magnetic Electrically Conductive Base Metals. Appl. Sci. 2023, 13, 5144. https://doi.org/10.3390/app13085144

Syasko M, Solomenchuk P, Soloviev I, Ampilova N. A Technique for Multi-Parameter Signal Processing of an Eddy-Current Probe for Measuring the Thickness of Non-Conductive Coatings on Non-Magnetic Electrically Conductive Base Metals. Applied Sciences. 2023; 13(8):5144. https://doi.org/10.3390/app13085144

Chicago/Turabian StyleSyasko, Michael, Pavel Solomenchuk, Igor’ Soloviev, and Natalia Ampilova. 2023. "A Technique for Multi-Parameter Signal Processing of an Eddy-Current Probe for Measuring the Thickness of Non-Conductive Coatings on Non-Magnetic Electrically Conductive Base Metals" Applied Sciences 13, no. 8: 5144. https://doi.org/10.3390/app13085144

APA StyleSyasko, M., Solomenchuk, P., Soloviev, I., & Ampilova, N. (2023). A Technique for Multi-Parameter Signal Processing of an Eddy-Current Probe for Measuring the Thickness of Non-Conductive Coatings on Non-Magnetic Electrically Conductive Base Metals. Applied Sciences, 13(8), 5144. https://doi.org/10.3390/app13085144