Prediction of the Bearing Capacity of Composite Grounds Made of Geogrid-Reinforced Sand over Encased Stone Columns Floating in Soft Soil Using a White-Box Machine Learning Model

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Methodology

2.2. Multivariate Polynomial Regression

2.3. Sofware Implementation

2.4. K-Fold Cross Validation

- Random shuffling of the dataset.

- Splitting the dataset into k number of groups.

- For every distinct k-group:

- Use one group as a validation set;

- Use the remaining groups as a train set.;

- Use the train set for model training and the test set for model validation;

- Preserve the results from each fold and discard the predictive model.

- Using a sample of model assessment scores to summarize the skills of the model.

2.5. Performance Metrics

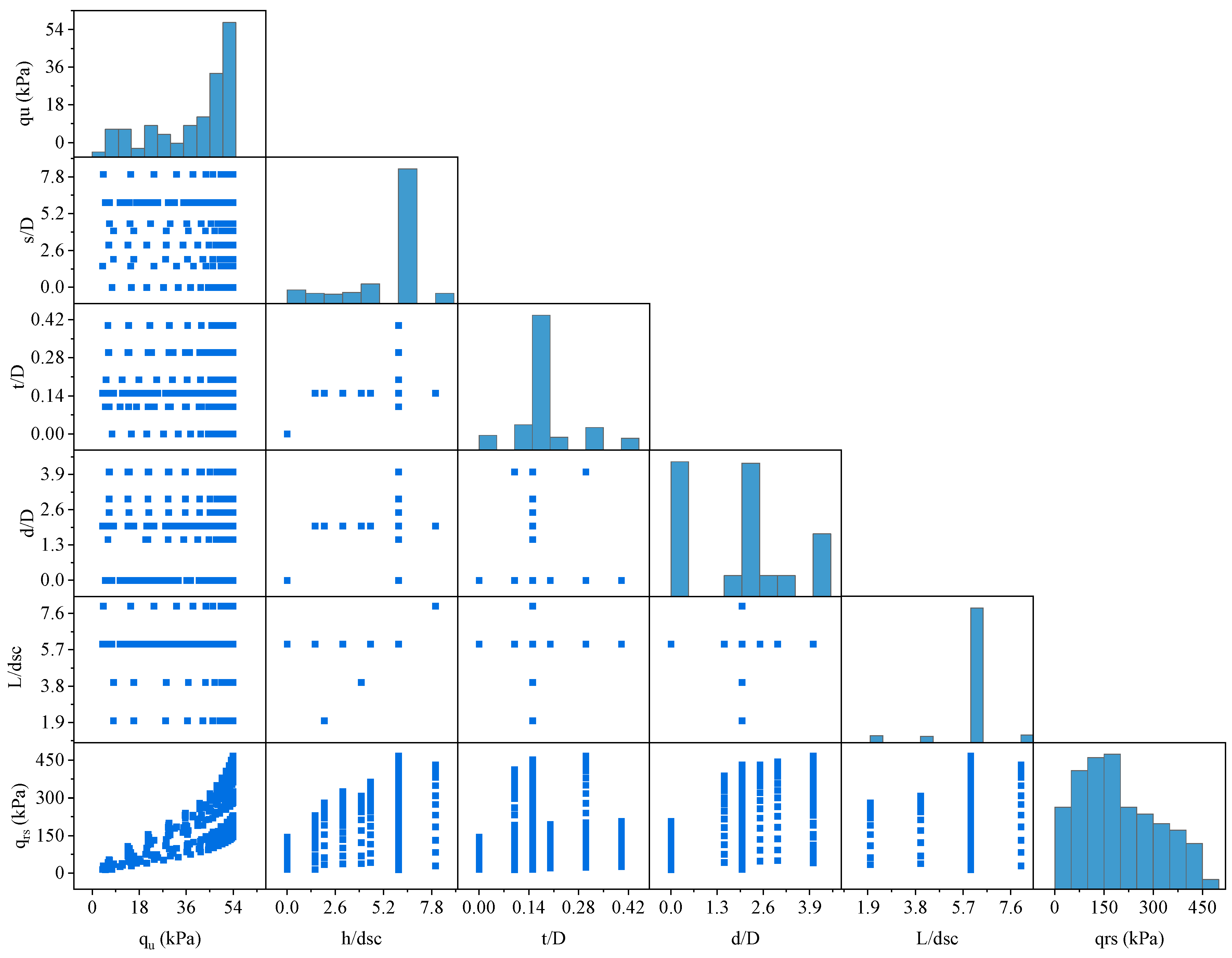

3. Database Used

| Data Category | Statistics | qu (kPa) | t/D | d/D | L/dsc | h/dsc | qrs (kPa) |

|---|---|---|---|---|---|---|---|

| Training data | Standard deviation | 15.05 | 0.08 | 1.42 | 0.96 | 2.02 | 118.33 |

| Mean | 38.89 | 0.16 | 1.64 | 5.88 | 5.01 | 197.26 | |

| Median | 45.02 | 0.15 | 2.00 | 6.00 | 6.00 | 178.81 | |

| Maximum | 53.82 | 0.40 | 4.00 | 8.00 | 8.00 | 452.21 | |

| Minimum | 3.86 | 0.00 | 0.00 | 2.00 | 0.00 | 15.44 | |

| Kurtosis | −0.52 | 1.97 | −1.13 | 8.58 | 0.80 | −0.87 | |

| Testing data | Standard deviation | 17.35 | 0.09 | 1.38 | 1.26 | 1.93 | 120.11 |

| Mean | 36.66 | 0.19 | 1.85 | 5.67 | 4.89 | 195.44 | |

| Median | 44.24 | 0.15 | 2.00 | 6.00 | 6.00 | 178.40 | |

| Maximum | 53.82 | 0.40 | 4.00 | 8.00 | 8.00 | 467.01 | |

| Minimum | 4.99 | 0.00 | 0.00 | 2.00 | 0.00 | 14.11 | |

| Kurtosis | −1.03 | 0.63 | −0.89 | 4.44 | −0.17 | −0.65 |

4. Model Results

4.1. K-Fold Cross-Validation

4.2. Evaluation of the RF Model

| Point | qu (kPa) | t/D | d/D | L/dsc | L/dsc | Actual qrs (kPa) | Predicted qrs (kPa) | Individual Error (kPa) |

|---|---|---|---|---|---|---|---|---|

| 1 | 7.46 | 0 | 0 | 6 | 0 | 15.8 | 9.36 | 6.44 |

| 2 | 4.99 | 0.1 | 0 | 6 | 6 | 14.11 | 11.65 | 2.46 |

| 3 | 48.48 | 0.1 | 0 | 6 | 6 | 127.82 | 135.92 | −8.10 |

| 4 | 49.95 | 0.1 | 0 | 6 | 6 | 135.24 | 143.89 | −8.65 |

| 5 | 5.18 | 0.2 | 0 | 6 | 6 | 20.99 | 23.75 | −2.76 |

| 6 | 30.69 | 0.2 | 0 | 6 | 6 | 94.57 | 86.28 | 8.29 |

| 7 | 42.6 | 0.3 | 0 | 6 | 6 | 134.5 | 132.15 | 2.35 |

| 8 | 48.8 | 0.3 | 0 | 6 | 6 | 166.92 | 160.31 | 6.61 |

| 9 | 5.9 | 0.4 | 0 | 6 | 6 | 26.07 | 49.19 | −23.12 |

| 10 | 13.89 | 0.4 | 0 | 6 | 6 | 50.71 | 73.66 | −22.95 |

| 11 | 48.26 | 0.4 | 0 | 6 | 6 | 168.28 | 168.84 | −0.56 |

| 12 | 52.84 | 0.4 | 0 | 6 | 6 | 196.5 | 195.44 | 1.06 |

| 13 | 53.55 | 0.4 | 0 | 6 | 6 | 203.37 | 200.12 | 3.25 |

| 14 | 41.8 | 0.1 | 4 | 6 | 6 | 233.57 | 254.81 | −21.24 |

| 15 | 47.63 | 0.1 | 4 | 6 | 6 | 297.8 | 322.93 | −25.13 |

| 16 | 51.24 | 0.1 | 4 | 6 | 6 | 349.63 | 372.72 | −23.09 |

| 17 | 21.62 | 0.15 | 4 | 6 | 6 | 143.78 | 125.27 | 18.51 |

| 18 | 53.22 | 0.15 | 4 | 6 | 6 | 436.17 | 419.78 | 16.39 |

| 19 | 29.28 | 0.3 | 4 | 6 | 6 | 201.08 | 189.21 | 11.87 |

| 20 | 41.07 | 0.3 | 4 | 6 | 6 | 279.93 | 285.72 | −5.79 |

| 21 | 45.02 | 0.3 | 4 | 6 | 6 | 317.3 | 329.10 | −11.80 |

| 22 | 53.82 | 0.3 | 4 | 6 | 6 | 467.01 | 450.68 | 16.33 |

| 23 | 5.9 | 0.15 | 1.5 | 6 | 6 | 42.79 | 30.53 | 12.26 |

| 24 | 52.34 | 0.15 | 1.5 | 6 | 6 | 348.15 | 327.30 | 20.85 |

| 25 | 53.16 | 0.15 | 1.5 | 6 | 6 | 369.38 | 336.75 | 32.63 |

| 26 | 53.82 | 0.15 | 2 | 6 | 6 | 420.44 | 381.51 | 38.93 |

| 27 | 6.36 | 0.15 | 2.5 | 6 | 6 | 49.12 | 43.82 | 5.30 |

| 28 | 14.03 | 0.15 | 2.5 | 6 | 6 | 92.69 | 82.57 | 10.12 |

| 29 | 21.62 | 0.15 | 2.5 | 6 | 6 | 135.77 | 121.82 | 13.95 |

| 30 | 21.3 | 0.15 | 3 | 6 | 6 | 137.76 | 123.92 | 13.84 |

| 31 | 36.4 | 0.15 | 2 | 2 | 2 | 154.23 | 147.24 | 6.99 |

| 32 | 48.77 | 0.15 | 2 | 2 | 2 | 239.71 | 237.26 | 2.45 |

| 33 | 51.07 | 0.15 | 2 | 2 | 2 | 255.44 | 259.59 | −4.15 |

| 34 | 53.82 | 0.15 | 2 | 2 | 2 | 281.26 | 289.04 | −7.78 |

| 35 | 8.15 | 0.15 | 2 | 4 | 4 | 37.84 | 43.34 | −5.50 |

| 36 | 36.71 | 0.15 | 2 | 4 | 4 | 171.08 | 176.82 | −5.74 |

| 37 | 32.21 | 0.15 | 2 | 8 | 8 | 185.72 | 207.77 | −22.05 |

| 38 | 46.2 | 0.15 | 2 | 8 | 8 | 309.6 | 336.94 | −27.34 |

| 39 | 14.68 | 0.15 | 2 | 6 | 1.5 | 44.38 | 35.71 | 8.67 |

| 40 | 23.56 | 0.15 | 2 | 6 | 1.5 | 70.44 | 61.65 | 8.79 |

| 41 | 43.46 | 0.15 | 2 | 6 | 1.5 | 147.23 | 158.34 | −11.11 |

| 42 | 51.55 | 0.15 | 2 | 6 | 1.5 | 204.22 | 227.99 | −23.77 |

| 43 | 52.7 | 0.15 | 2 | 6 | 1.5 | 215.15 | 239.88 | −24.73 |

| 44 | 52.08 | 0.15 | 2 | 6 | 3 | 291.01 | 275.32 | 15.69 |

| 45 | 29.82 | 0.15 | 2 | 6 | 4.5 | 154.14 | 135.63 | 18.51 |

| 46 | 47.96 | 0.15 | 2 | 6 | 4.5 | 273.42 | 272.09 | 1.33 |

| 47 | 51.51 | 0.15 | 2 | 6 | 4.5 | 316.7 | 310.61 | 6.09 |

| 48 | 53.39 | 0.15 | 2 | 6 | 4.5 | 352.47 | 333.01 | 19.46 |

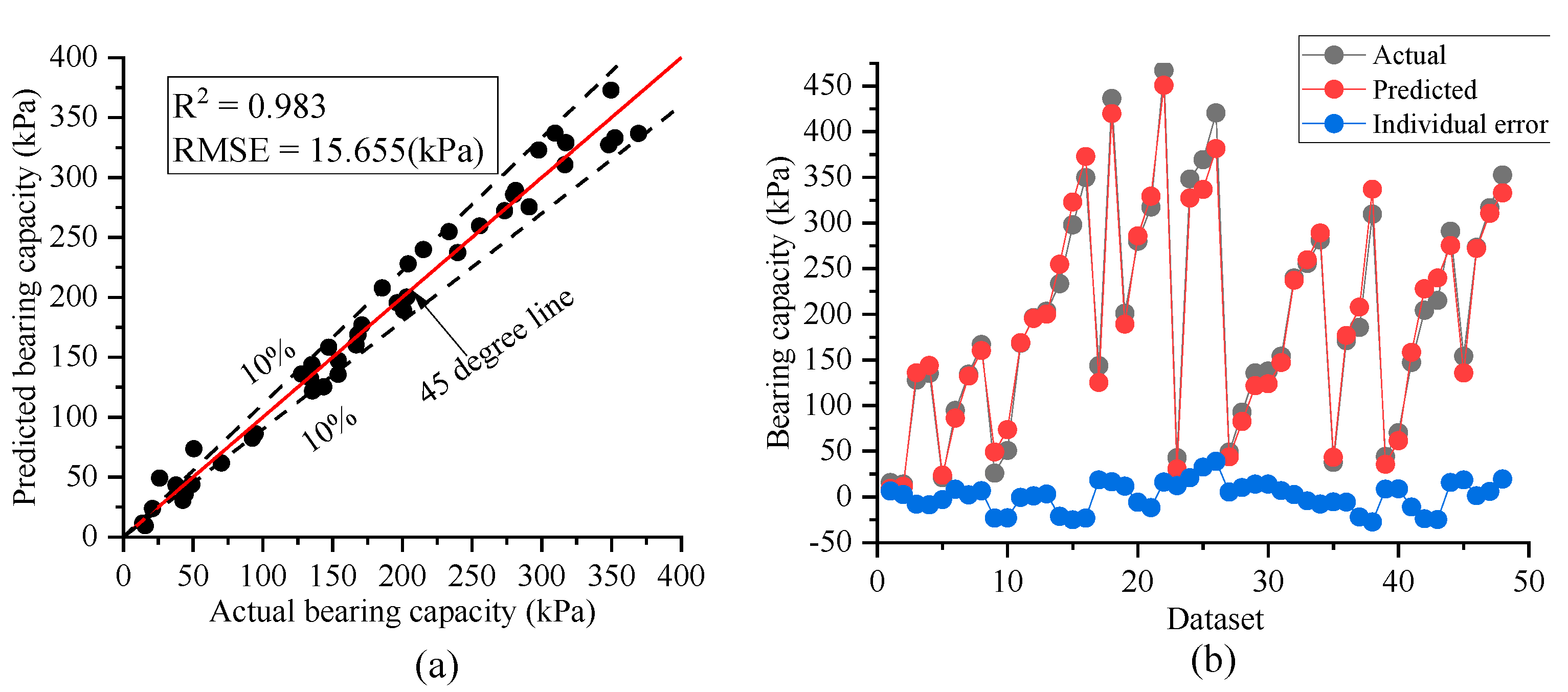

4.3. Comparison of the MPR Model with Previously Developed Models

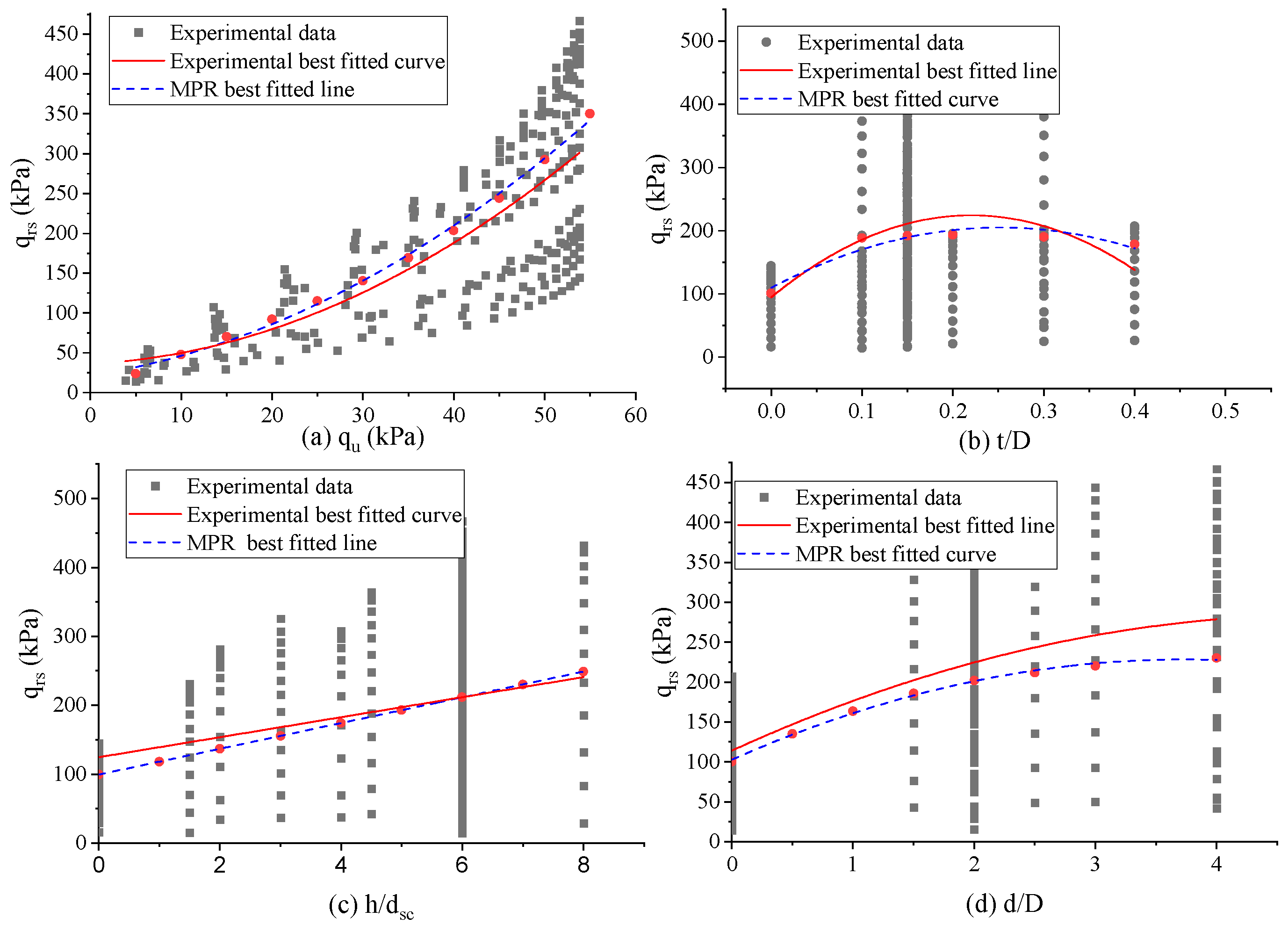

4.4. Parametric Analysis

5. Conclusions

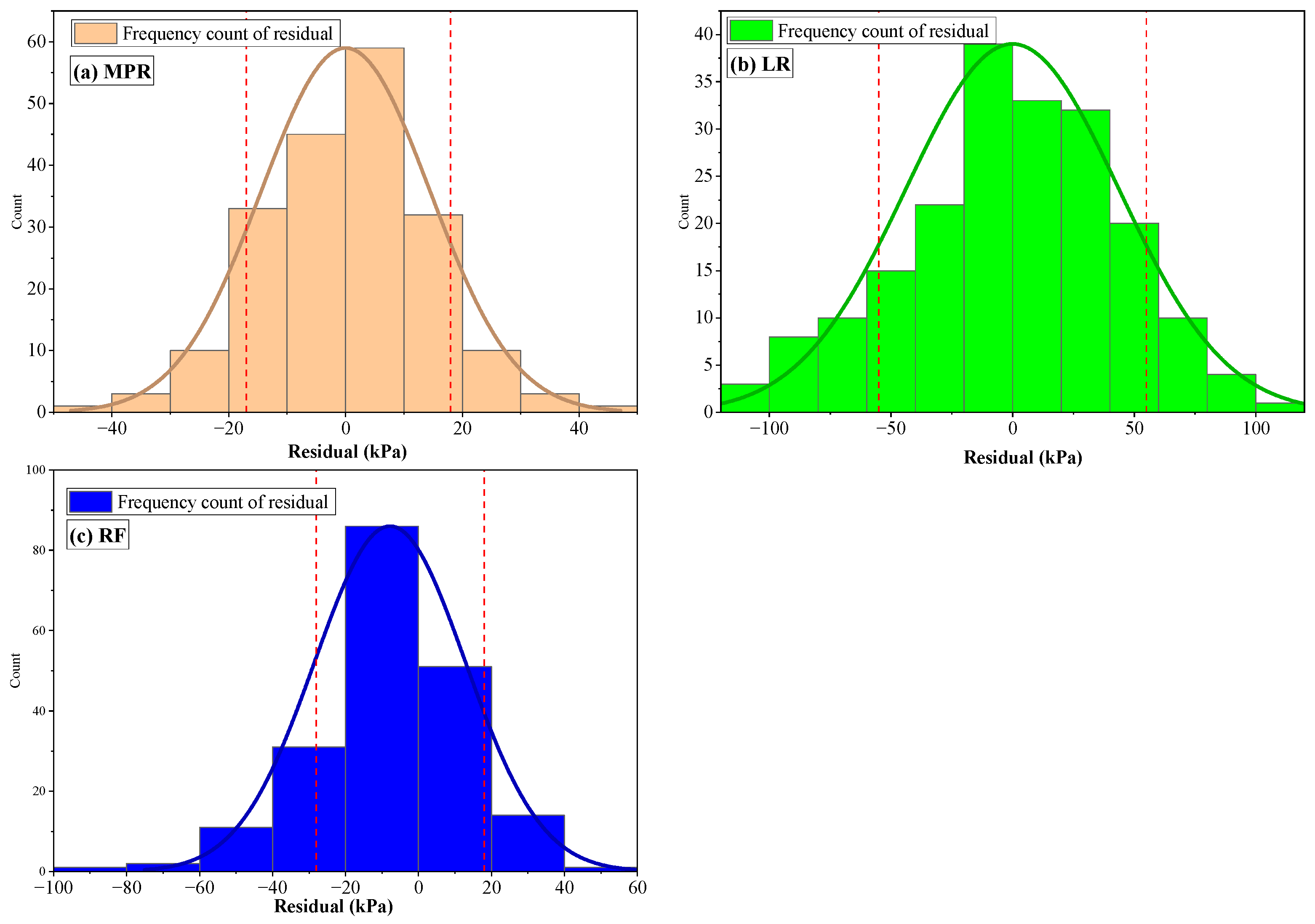

- When tested using a cross-validation approach, the MPR model outperformed both the traditional LR (white-box) and RF (black-box) models in terms of R2 and RMSE. The MPR model showed average prediction performances of 0.9850 for R2 and 13.9161 for RMSE, while the RF model showed performances of 0.9820 for R2 and 19.2054 for RMSE. The LR model performed the worst among all the tested models;

- Further, the MPR model was successfully used to predict the bearing capacity (qrs) for the testing dataset, with results closely aligned to the experimental values;

- Comparing new and existing models is important in ML. The MPR model performed well, achieving high accuracy and interpretability when compared to traditional white-box and black-box models, which require specialized knowledge;

- In addition, a parametric analysis was performed to assess the impact of increasing the predictors on qrs. The findings revealed that the MPR predictions align well with laboratory results, indicating that an increase in qu values leads to an increase in qrs values. Similarly, an increase in both d/D and h/dsc ratios also results in an increase in qrs values. However, an increase in the t/D ratio shows a different effect on qu values, which initially increase but then decrease. These findings can help in understanding how different factors impact the bearing capacity of composite foundation systems, such as the one studied in this research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Li, T.; Wang, Y. Theoretical elastic solutions for foundations improved by geosynthetic-encased columns. Geosynth. Int. 2011, 18, 12–20. [Google Scholar] [CrossRef]

- Raithel, M.; Kempfert, H.; Kirchner, A. Geotextile-encased columns (GEC) for foundation of a dike on very soft soils. In Proceedings of the 7th International Conference on Geosynthetics, Paris, France, 22–27 September 2002; pp. 1025–1028. [Google Scholar]

- Murugesan, S.; Rajagopal, K. Model tests on geosynthetic-encased stone columns. Geosynth. Int. 2007, 14, 346–354. [Google Scholar] [CrossRef]

- Murugesan, S.; Rajagopal, K. Geosynthetic-encased stone columns: Numerical evaluation. Geotext. Geomembr. 2006, 24, 349–358. [Google Scholar] [CrossRef]

- Miranda, M.; Da Costa, A. Laboratory analysis of encased stone columns. Geotext. Geomembr. 2016, 44, 269–277. [Google Scholar] [CrossRef]

- Hosseinpour, I.; Almeida, M.; Riccio, M. Full-scale load test and finite-element analysis of soft ground improved by geotextile-encased granular columns. Geosynth. Int. 2015, 22, 428–438. [Google Scholar] [CrossRef]

- Gu, M.; Zhao, M.; Zhang, L.; Han, J. Effects of geogrid encasement on lateral and vertical deformations of stone columns in model tests. Geosynth. Int. 2016, 23, 100–112. [Google Scholar] [CrossRef]

- Ghazavi, M.; Afshar, J.N. Bearing capacity of geosynthetic encased stone columns. Geotext. Geomembr. 2013, 38, 26–36. [Google Scholar] [CrossRef]

- Fattah, M.Y.; Zabar, B.S.; Hassan, H.A. Experimental analysis of embankment on ordinary and encased stone columns. Int. J. Geomech. 2016, 16, 04015102. [Google Scholar] [CrossRef]

- Almeida, M.; Hosseinpour, I.; Riccio, M. Performance of a geosynthetic-encased column (GEC) in soft ground: Numerical and analytical studies. Geosynth. Int. 2013, 20, 252–262. [Google Scholar] [CrossRef]

- Ali, K.; Shahu, J.; Sharma, K. Model tests on geosynthetic-reinforced stone columns: A comparative study. Geosynth. Int. 2012, 19, 292–305. [Google Scholar] [CrossRef]

- Dey, A.; Debnath, P. Empirical approach for bearing capacity prediction of geogrid-reinforced sand over vertically encased stone columns floating in soft clay using support vector regression. Neural Comput. Appl. 2020, 32, 6055–6074. [Google Scholar] [CrossRef]

- Fattah, M.Y.; Zabar, B.S.; Hassan, H.A. Soil arching analysis in embankments on soft clays reinforced by stone columns. Struct. Eng. Mech. 2015, 56, 507–534. [Google Scholar] [CrossRef]

- Fattah, M.Y.; Majeed, Q.G. A study on the behaviour of geogrid encased capped stone columns by the finite element method. GEOMATE J. 2012, 3, 343–350. [Google Scholar] [CrossRef]

- Fattah, M.Y.; Majeed, Q.G. Finite element analysis of Geogrid encased stone columns. Geotech. Geol. Eng. 2012, 30, 713–726. [Google Scholar] [CrossRef]

- Kwa, S.F.; Kolosov, E.; Fattah, M.Y. Ground improvement using stone column construction encased with geogrid. Constr. Unique Build. Struct. 2018, 3, 69. [Google Scholar]

- Malarvizhi, S.; Ilamparuthi, K. Load versus settlement of clay bed stabilized with stone and reinforced stone columns. In Proceedings of the 3rd Asian Regional Conference on Geosynthetics, Seoul, Korea, 21–22 June 2004; pp. 322–329. [Google Scholar]

- Orekanti, E.R.; Dommaraju, G.V. Load-settlement response of geotextile encased laterally reinforced granular piles in expansive soil under compression. Int. J. Geosynth. Ground Eng. 2019, 5, 17. [Google Scholar] [CrossRef]

- Hajiazizi, M.; Nasiri, M. Experimental and numerical investigation of reinforced sand slope using geogird encased stone column. Civ. Eng. Infrastruct. J. 2019, 52, 85–100. [Google Scholar]

- Yoo, C.; Lee, D. Performance of geogrid-encased stone columns in soft ground: Full-scale load tests. Geosynth. Int. 2012, 19, 480–490. [Google Scholar] [CrossRef]

- Ayadat, T.; Hanna, A. Encapsulated stone columns as a soil improvement technique for collapsible soil. Proc. Inst. Civ. Eng.-Ground Improv. 2005, 9, 137–147. [Google Scholar] [CrossRef]

- Almeida, M.S.; Hosseinpour, I.; Riccio, M.; Alexiew, D. Behavior of geotextile-encased granular columns supporting test embankment on soft deposit. J. Geotech. Geoenviron. Eng. 2015, 141, 04014116. [Google Scholar] [CrossRef]

- Mitchell, J.K. Soil improvement-state of the art report. In Proceedings of the 11th International Conference on SMFE, Stockholm, Sweden, 15–19 June 1981; pp. 509–565. [Google Scholar]

- Shahu, J.; Madhav, M.; Hayashi, S. Analysis of soft ground-granular pile-granular mat system. Comput. Geotech. 2000, 27, 45–62. [Google Scholar] [CrossRef]

- Deb, K. Modeling of granular bed-stone column-improved soft soil. Int. J. Numer. Anal. Methods Geomech. 2008, 32, 1267–1288. [Google Scholar] [CrossRef]

- Das, M.; Dey, A.K. Prediction of Bearing Capacity of Stone Columns Using Type-2 Fuzzy Logic. In Recent Developments in Sustainable Infrastructure (ICRDSI-2020)—GEO-TRA-ENV-WRM; Springer: Berlin/Heidelberg, Germany, 2022; pp. 413–437. [Google Scholar]

- Das, M.; Dey, A.K. Prediction of bearing capacity of stone columns placed in soft clay using SVR model. Arab. J. Sci. Eng. 2019, 44, 4681–4691. [Google Scholar] [CrossRef]

- Das, M.; Dey, A.K. Determination of bearing capacity of stone column with application of neuro-fuzzy system. KSCE J. Civ. Eng. 2018, 22, 1677–1683. [Google Scholar] [CrossRef]

- Chik, Z.; Aljanabi, Q.A.; Kasa, A.; Taha, M.R. Tenfold cross validation artificial neural network modeling of the settlement behavior of a stone column under a highway embankment. Arab. J. Geosci. 2014, 7, 4877–4887. [Google Scholar] [CrossRef]

- Al-Obaidy, N.K.; Al-Shueli, A. Utilizing an artificial neural network model to predict bearing capacity of stone. Int. J. Emerg. Technol. 2020, 11, 124–129. [Google Scholar]

- Aljanabi, Q.A.; Chik, Z.; Allawi, M.F.; El-Shafie, A.H.; Ahmed, A.N.; El-Shafie, A. Support vector regression-based model for prediction of behavior stone column parameters in soft clay under highway embankment. Neural Comput. Appl. 2018, 30, 2459–2469. [Google Scholar] [CrossRef]

- Shatnawi, A.; Alkassar, H.M.; Al-Abdaly, N.M.; Al-Hamdany, E.A.; Bernardo, L.F.A.; Imran, H. Shear Strength Prediction of Slender Steel Fiber Reinforced Concrete Beams Using a Gradient Boosting Regression Tree Method. Buildings 2022, 12, 550. [Google Scholar] [CrossRef]

- Al-Abdaly, N.M.; Al-Taai, S.R.; Imran, H.; Ibrahim, M. Development of prediction model of steel fiber-reinforced concrete compressive strength using random forest algorithm combined with hyperparameter tuning and k-fold cross-validation. East.-Eur. J. Enterp. Technol. 2021, 5, 113. [Google Scholar] [CrossRef]

- Imran, H.; Ibrahim, M.; Al-Shoukry, S.; Rustam, F.; Ashraf, I. Latest concrete materials dataset and ensemble prediction model for concrete compressive strength containing RCA and GGBFS materials. Constr. Build. Mater. 2022, 325, 126525. [Google Scholar] [CrossRef]

- Ghanizadeh, A.R.; Ghanizadeh, A.; Asteris, P.G.; Fakharian, P.; Armaghani, D.J. Developing bearing capacity model for geogrid-reinforced stone columns improved soft clay utilizing MARS-EBS hybrid method. Transp. Geotech. 2023, 38, 100906. [Google Scholar] [CrossRef]

- Su, M.; Zhong, Q.; Peng, H. Regularized multivariate polynomial regression analysis of the compressive strength of slag-metakaolin geopolymer pastes based on experimental data. Constr. Build. Mater. 2021, 303, 124529. [Google Scholar] [CrossRef]

- Sinha, P. Multivariate polynomial regression in data mining: Methodology, problems and solutions. Int. J. Sci. Eng. Res. 2013, 4, 962–965. [Google Scholar]

- Wei, J.; Chen, T.; Liu, G.; Yang, J. Higher-order multivariable polynomial regression to estimate human affective states. Sci. Rep. 2016, 6, 1–13. [Google Scholar] [CrossRef]

- Weka, W. 3: Data mining software in Java. Univ. Waikato Hamilt. N. Z. (Www. Cs. Waikato. Ac. Nz/Ml/Weka) 2011, 19, 52. [Google Scholar]

- El Morr, C.; Jammal, M.; Ali-Hassan, H.; Walid, E.-H. Machine Learning for Practical Decision Making: A Multidisciplinary Perspective with Applications from Healthcare, Engineering and Business Analytics; Springer Nature: Berlin/Heidelberg, Germany, 2022; Volume 334. [Google Scholar]

- Tvedskov, T.; Meretoja, T.; Jensen, M.; Leidenius, M.; Kroman, N. Cross-validation of three predictive tools for non-sentinel node metastases in breast cancer patients with micrometastases or isolated tumor cells in the sentinel node. Eur. J. Surg. Oncol. 2014, 40, 435–441. [Google Scholar] [CrossRef]

- Shao, C.; Paynabar, K.; Kim, T.H.; Jin, J.J.; Hu, S.J.; Spicer, J.P.; Wang, H.; Abell, J.A. Feature selection for manufacturing process monitoring using cross-validation. J. Manuf. Syst. 2013, 32, 550–555. [Google Scholar] [CrossRef]

- Jiang, P.; Chen, J. Displacement prediction of landslide based on generalized regression neural networks with K-fold cross-validation. Neurocomputing 2016, 198, 40–47. [Google Scholar] [CrossRef]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning; Springer: Berlin/Heidelberg, Germany, 2013; Volume 112. [Google Scholar]

- Debnath, P.; Dey, A.K. Bearing capacity of geogrid reinforced sand over encased stone columns in soft clay. Geotext. Geomembr. 2017, 45, 653–664. [Google Scholar] [CrossRef]

| Statistics | MPR | RF | LR | |||

|---|---|---|---|---|---|---|

| RMSE | R2 | RMSE | R2 | RMSE | R2 | |

| Mean | 13.9161 | 0.9850 | 19.2054 | 0.9820 | 42.1545 | 0.8697 |

| Median | 13.6817 | 0.9856 | 17.0350 | 0.9814 | 42.5097 | 0.8674 |

| Maximum | 16.0838 | 0.9902 | 31.8202 | 0.9900 | 44.7245 | 0.8902 |

| Minimum | 11.3142 | 0.9784 | 11.7660 | 0.9764 | 39.6920 | 0.8472 |

| Models | MPR | SVR-ERBF | SVR-RBF | SVR-POLY | ANFIS | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Metrics | Train | Test | Train | Test | Train | Test | Train | Test | Train | Test |

| R2 | 0.994 | 0.983 | 0.999 | 0.989 | 0.980 | 0.975 | 0.976 | 0.965 | 0.996 | 0.981 |

| RMSE | 13.010 | 15.655 | 4.30 | 11.45 | 17.63 | 17.51 | 20.63 | 23.93 | 7.90 | 13.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeini, H.A.; Lwti, N.K.; Imran, H.; Henedy, S.N.; Bernardo, L.F.A.; Al-Khafaji, Z. Prediction of the Bearing Capacity of Composite Grounds Made of Geogrid-Reinforced Sand over Encased Stone Columns Floating in Soft Soil Using a White-Box Machine Learning Model. Appl. Sci. 2023, 13, 5131. https://doi.org/10.3390/app13085131

Zeini HA, Lwti NK, Imran H, Henedy SN, Bernardo LFA, Al-Khafaji Z. Prediction of the Bearing Capacity of Composite Grounds Made of Geogrid-Reinforced Sand over Encased Stone Columns Floating in Soft Soil Using a White-Box Machine Learning Model. Applied Sciences. 2023; 13(8):5131. https://doi.org/10.3390/app13085131

Chicago/Turabian StyleZeini, Husein Ali, Nabeel Katfan Lwti, Hamza Imran, Sadiq N. Henedy, Luís Filipe Almeida Bernardo, and Zainab Al-Khafaji. 2023. "Prediction of the Bearing Capacity of Composite Grounds Made of Geogrid-Reinforced Sand over Encased Stone Columns Floating in Soft Soil Using a White-Box Machine Learning Model" Applied Sciences 13, no. 8: 5131. https://doi.org/10.3390/app13085131

APA StyleZeini, H. A., Lwti, N. K., Imran, H., Henedy, S. N., Bernardo, L. F. A., & Al-Khafaji, Z. (2023). Prediction of the Bearing Capacity of Composite Grounds Made of Geogrid-Reinforced Sand over Encased Stone Columns Floating in Soft Soil Using a White-Box Machine Learning Model. Applied Sciences, 13(8), 5131. https://doi.org/10.3390/app13085131