Three-Dimensional Film Image Classification Using an Optimal Width of Histogram

Abstract

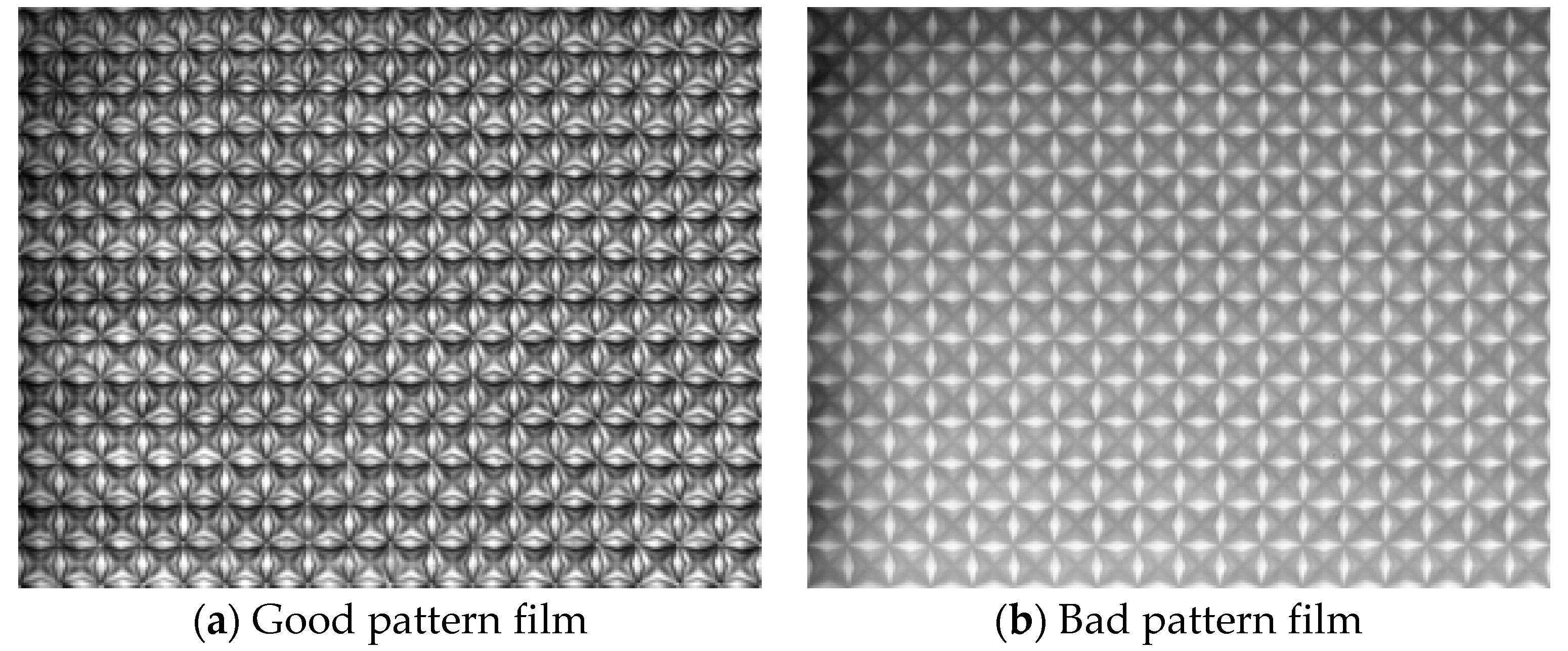

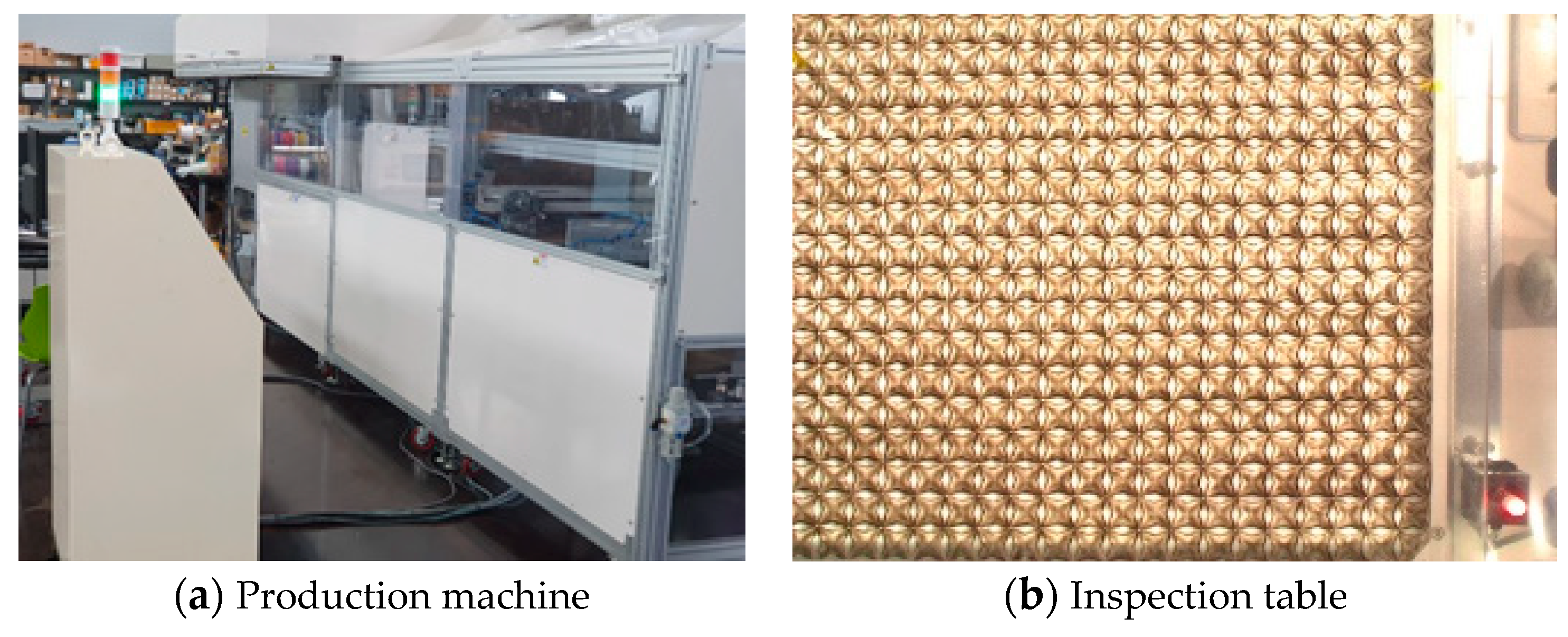

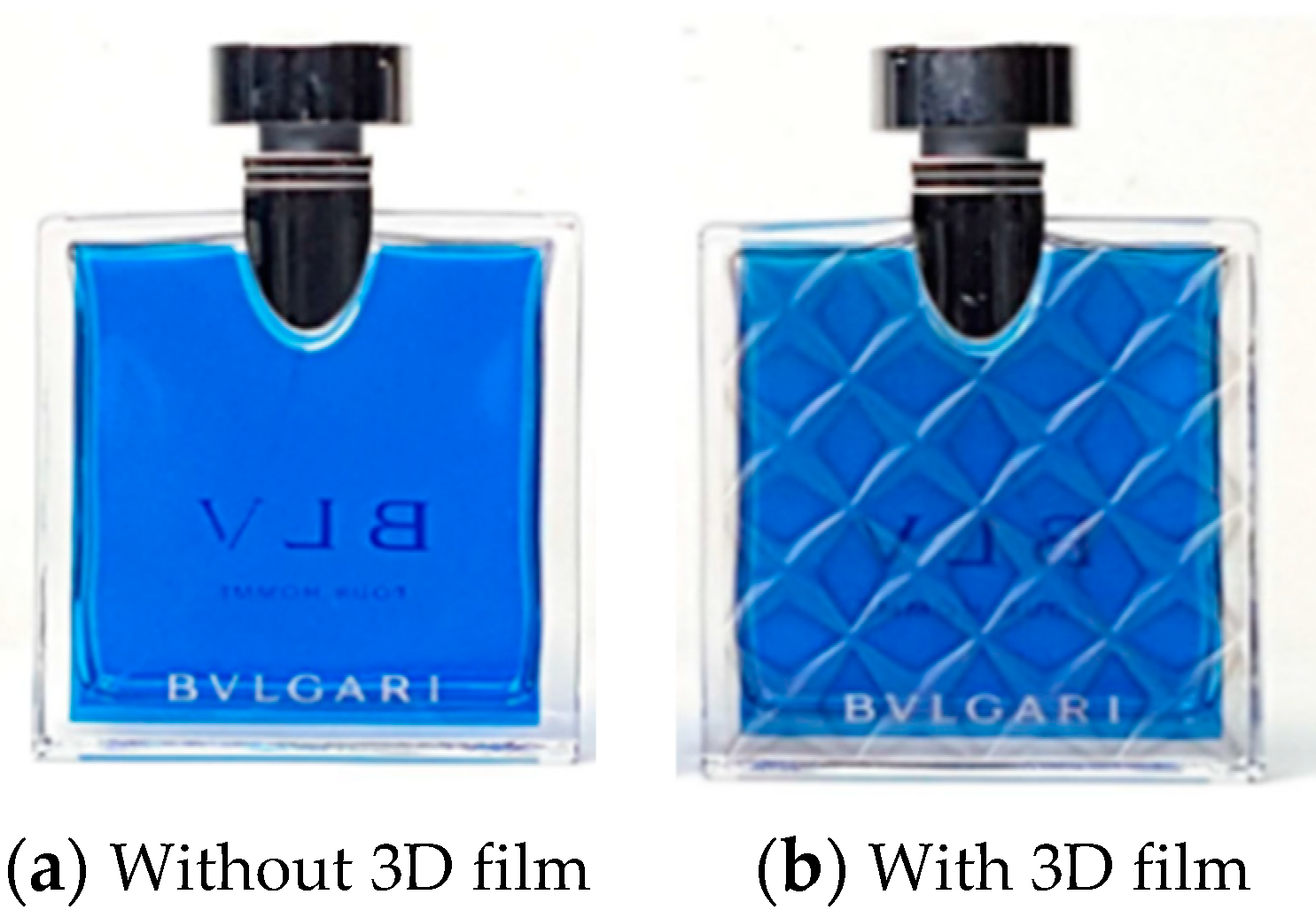

1. Introduction

2. Related Methods

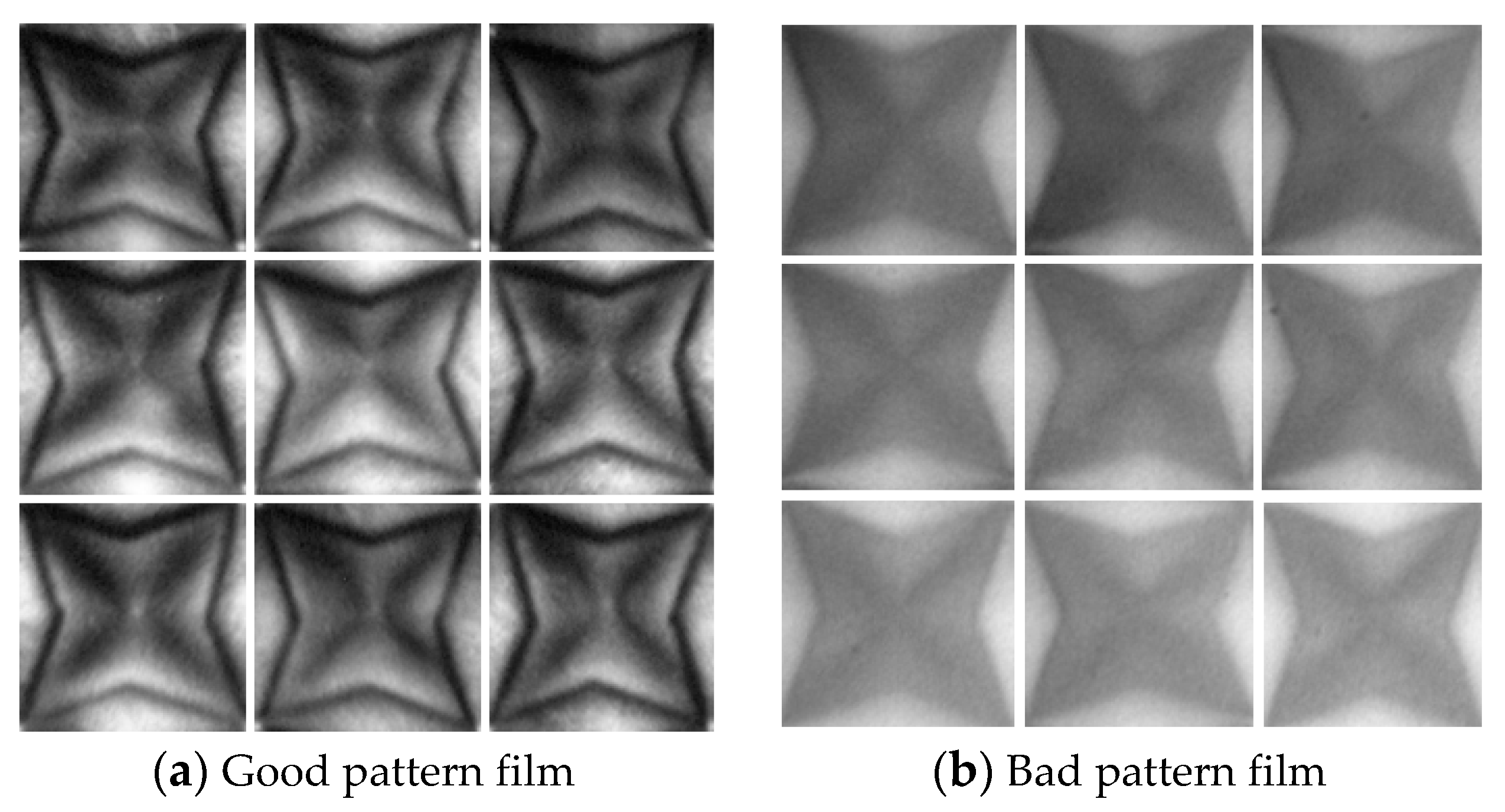

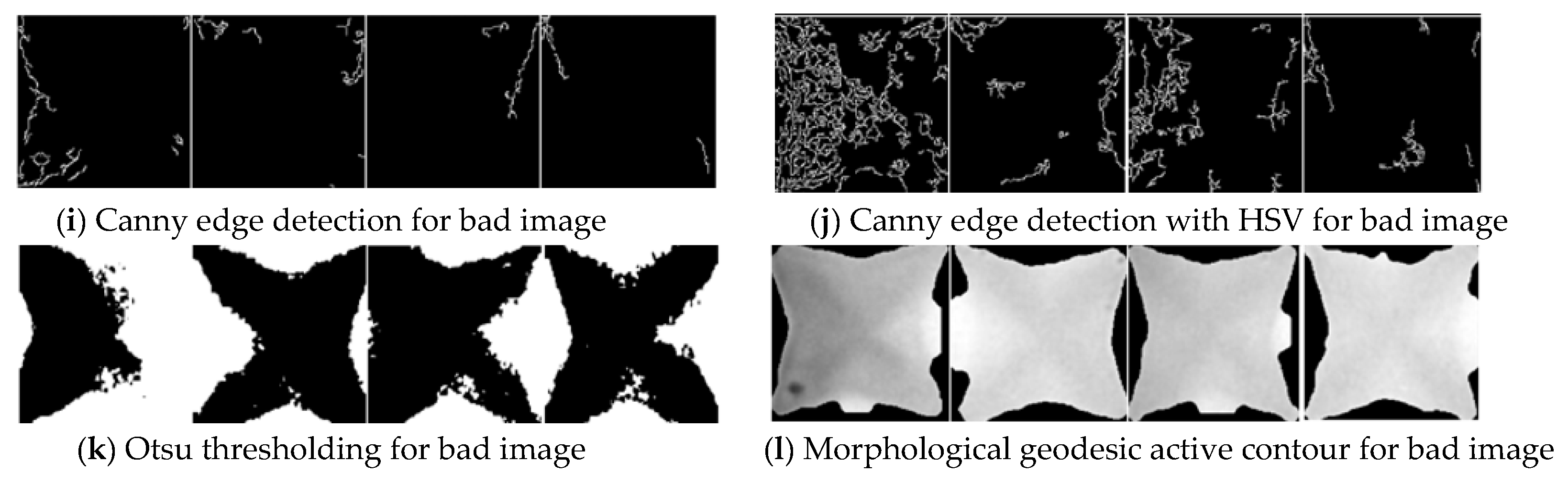

3. Proposed Algorithm

3.1. Cropping Pattern Images on Film Using Fast Fourier Transform Algorithm

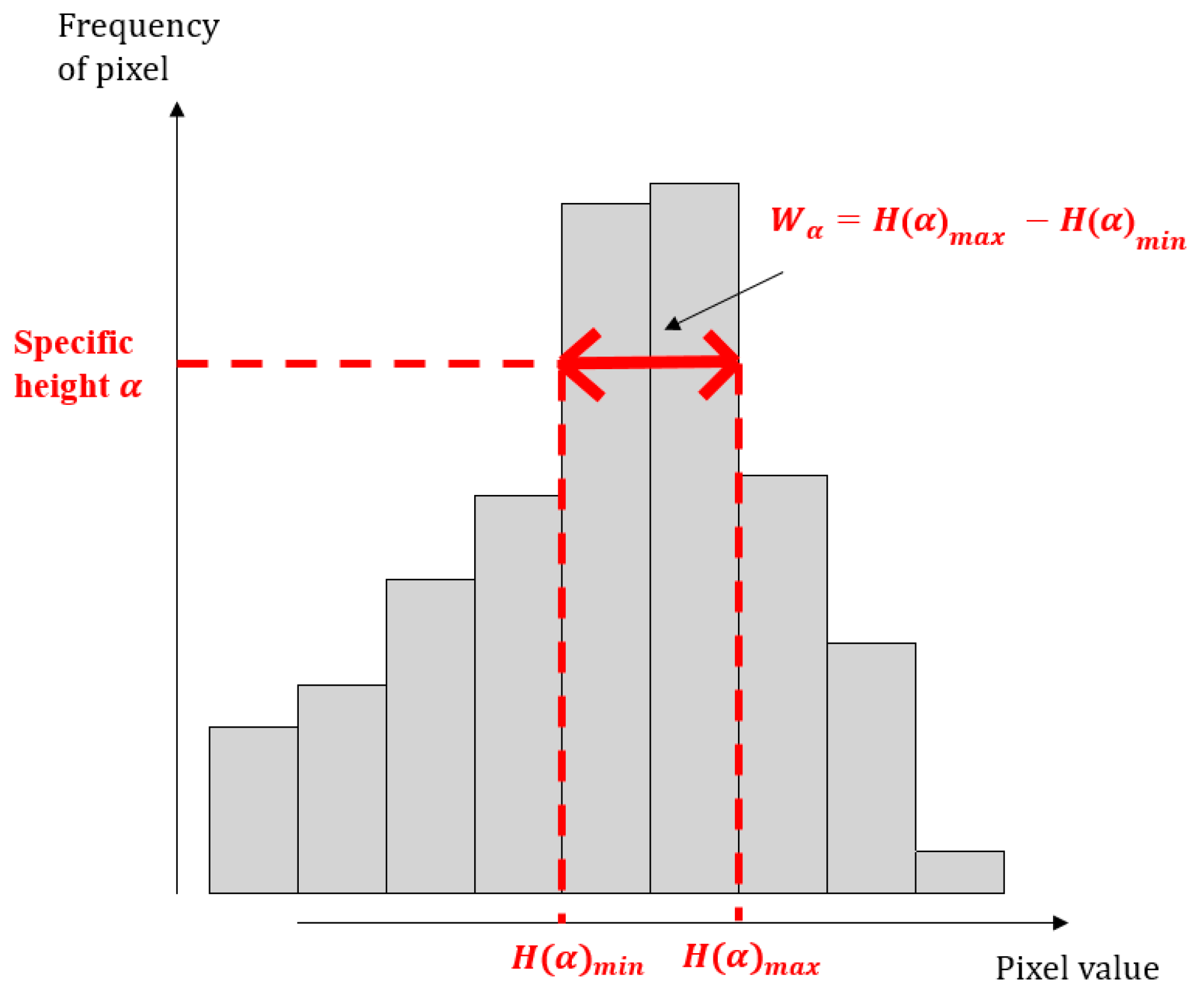

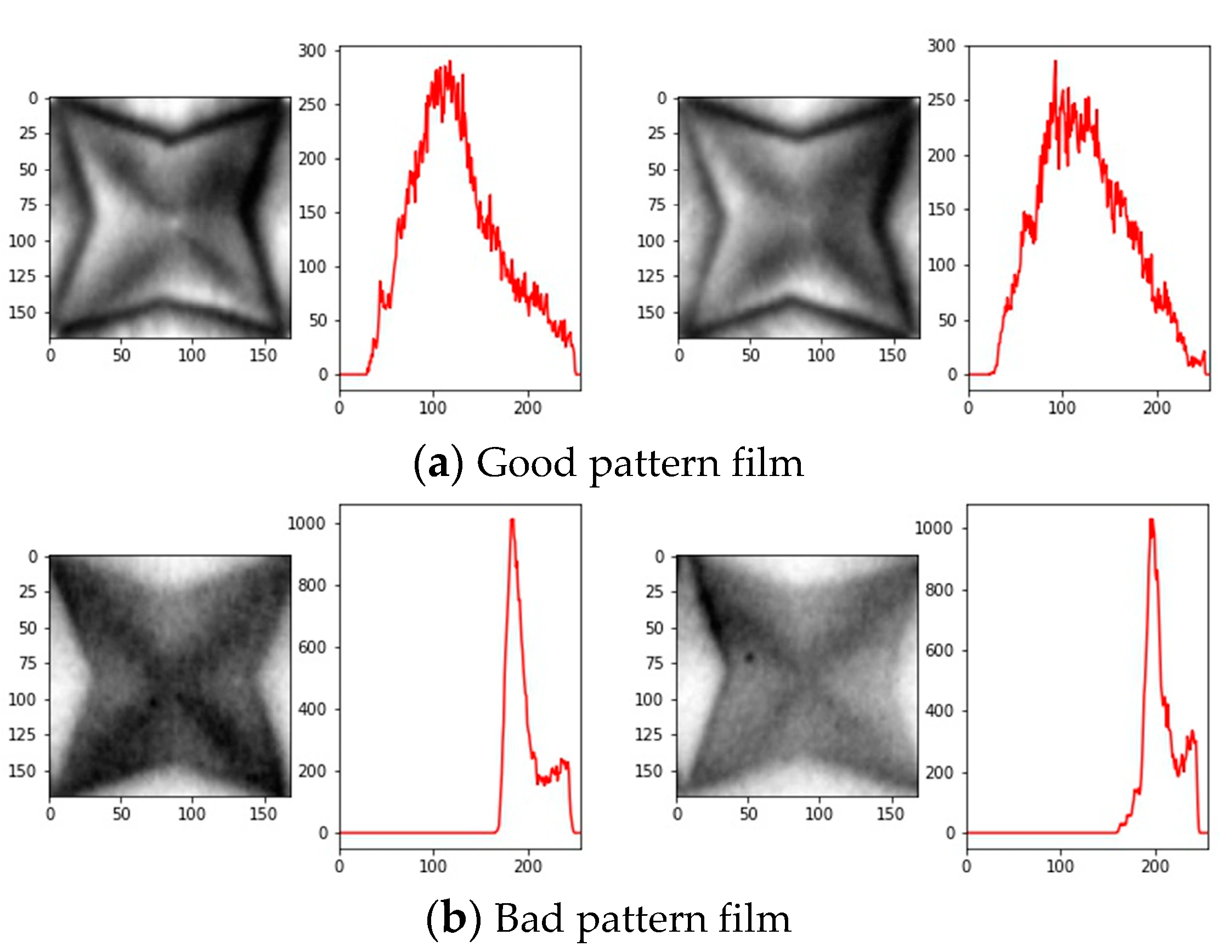

3.2. Classification Using an Optimal width of Image Histogram

4. Experimental Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.; Chen, Y.; Wei, Y.; Li, Y. 3D Printing of shape memory polymer for functional part fabrication. Int. J. Adv. Manuf. Technol. 2015, 84, 2079–2095. [Google Scholar] [CrossRef]

- Ugur, M.D.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The role of additive manufacturing in the era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar]

- Colman, I.L.; Bedding, T.R.; Huber, D.; Kjeldsen, H. The kepler IRIS catalog: Image subtraction light curves for 9150 stars in and around the open clusters NGC 6791 and NGC 6819. Astrophys. J. Suppl. Ser. 2022, 258, 39–53. [Google Scholar] [CrossRef]

- Hu, L.; Wang, L.; Chen, X.; Yang, J. Image Subtraction in Fourier Space. Astrophys. J. 2022, 936, 157. [Google Scholar] [CrossRef]

- Fang, C.; Liu, Y.; Liu, Y.; Liu, M.; Qiu, X.; Li, Y.; Wen, J.; Yang, Y. Label-free coronavirus disease 2019 lesion segmentation based on synthetic healthy lung image subtraction. Med. Phys. 2022, 49, 4632–4641. [Google Scholar] [CrossRef]

- Cao, Y.; Nugent, P.E.; Kasliwal, M.M. Intermediate palomar transient factory: Realtime image subtraction pipeline. Publ. Astron. Soc. Pac. 2016, 128, 114502. [Google Scholar] [CrossRef]

- Masci, F.J.; Laher, R.R.; Rebbapragada, U.D.; Doran, G.B.; Miller, A.A.; Bellm, E.; Kasliwal, M.; Ofek, E.O.; Surace, J.; Shupe, D.L.; et al. The IPAC image subtraction and discovery pipeline for the Intermediate Palomar Transient Factory. Publ. Astron. Soc. Pac. 2016, 129, 014002. [Google Scholar] [CrossRef]

- Mustafa, W.A.; Kader, M.A. Binarization of document images: A comprehensive review. In Proceedings of the International Conference on Green and Sustainable Computing (ICoGeS), Kuching, Malaysia, 25–27 November 2017; p. 012023. [Google Scholar]

- Tensmeyer, C.; Martinez, T. Historical document image binarization: A review. SN Comput. Sci. 2020, 1, 173. [Google Scholar] [CrossRef]

- Fan, R.; Bocus, M.J.; Zhu, Y.; Jiao, J.; Wang, L.; Ma, F.; Cheng, S.; Liu, M. Road crack detection using deep convolutional neural network and adaptive thresholding. In Proceedings of the 2019 IEEE Intelligent Vehicles Symposium (IV), Paris, France, 9–12 June 2019; pp. 474–479. [Google Scholar]

- Hoang, N.D. Detection of surface crack in building structures using image processing technique with an improved Otsu method for image thresholding. Adv. Civ. Eng. 2018, 2018, 3924120. [Google Scholar] [CrossRef]

- Owotogbe, Y.S.; Ibiyemi, T.S.; Adu, B.A. Edge detection techniques on digital images-a review. Int. J. Innov. Sci. Res. Technol. 2019, 4, 329–332. [Google Scholar]

- Jing, J.; Liu, S.; Wang, G.; Zhang, W.; Sun, C. Recent advances on image edge detection: A comprehensive review. Neurocomputing 2022, 503, 259–271. [Google Scholar] [CrossRef]

- Lorencin, I.; Anđelić, N.; Španjol, J.; Car, Z. Using multi-layer perceptron with Laplacian edge detector for bladder cancer diagnosis. Artif. Intell. Med. 2020, 102, 101746. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Li, G.; Zhang, Y.; Li, C.; Yu, L. Application of static gesture segmentation based on an improved canny operator. J. Eng. 2019, 2019, 543–546. [Google Scholar] [CrossRef]

- Bansal, R.; Raj, G.; Choudhury, T. Blur image detection using Laplacian operator and Open-CV. In Proceedings of the 2016 International Conference System Modeling & Advancement in Research Trends (SMART), Moradabad, India, 25–27 November 2016; pp. 63–67. [Google Scholar]

- Septiarini, A.; Hamdani, H.; Sari, S.U.; Hatta, H.R.; Puspitasari, N.; Hadikurniawati, W. Image processing techniques for tomato segmentation applying k-means clustering and edge detection approach. In Proceedings of the International Seminar on Machine Learning, Optimization, and Data Science, jakarta, Indonesia, 29–30 January 2021; pp. 92–96. [Google Scholar]

- Ma, J.; Wang, D.; Wang, X.P.; Yang, X. A fast algorithm for geodesic active contours with applications to medical image segmentation. arXiv 2020, arXiv:2007.00525v1. [Google Scholar]

- Álvarez, L.; Baumela, L.; Neila, P.M.; Henríquez, P. A real time morphological snakes algorithm. Image Process. Online 2014, 2, 1–7. [Google Scholar] [CrossRef]

- Mlyahilu, J.N.; Mlyahilu, J.N.; Lee, J.E.; Kim, Y.B.; Kim, J.N. Morphological geodesic active contour algorithm for the segmentation of the histogram-equalized welding bead image edges. IET Image Process. 2022, 16, 2680–2696. [Google Scholar] [CrossRef]

- Wang, R.; Li, W.; Li, R.; Zhang, L. Automatic blur type classification via ensemble SVM. Signal Process. Image Commun. 2019, 71, 24–35. [Google Scholar] [CrossRef]

- Hsu, P.; Chen, B.Y. Blurred image detection and classification. In Proceedings of the International Conference on Multimedia Modeling, Kyoto, Japan, 9–11 January 2008; pp. 277–286. [Google Scholar]

- Salman, A.; Semwal, A.; Bhatt, U.; Thakkar, V.M. Leaf classification and identification using canny edge detector and SVM classifier. In Proceedings of the International Conference on Inventive Systems and Control, Coimbatore, India, 19–20 January 2017; pp. 1–4. [Google Scholar]

- Hemamalini, V.; Rajarajeswari, S.; Nachiyappan, S.; Sambath, M.; Devi, T.; Singh, B.K.; Raghuvanshi, A. Food quality inspection and grading using efficient image segmentation and machine learning-based system. J. Food Qual. 2022, 2022, 1–6. [Google Scholar] [CrossRef]

- Thomas, M.V.; Kanagasabapthi, C.; Yellampalli, S.S. VHDL implementation of pattern based template matching in satellite images. In Proceedings of the International Conference on Smart Technologies for Smart Nation, Bengaluru, India, 17–19 August 2017; pp. 820–824. [Google Scholar]

- Satish, B.; Jayakrishnan, P. Hardware implementation of template matching algorithm and its performance evaluation. In Proceedings of the International Conferences on Microelectronic Devices and Technologies, Vellore, India, 10–12 August 2017; pp. 1–7. [Google Scholar]

- Mlyahilu, J.; Kim, J. A Fast Fourier Transform with Brute Force Algorithm for Detection and Localization of White Points on 3D Film Pattern Images. J. Imaging Sci Technol. 2021, 66, 030506. [Google Scholar] [CrossRef]

- Joseph, J.; Jayaraman, S.; Periyasamy, R.; Renuka, S.V. An edge preservation index for evaluating nonlinear spatial restoration in MR images. Curr. Med. Imaging Rev. 2017, 13, 58–65. [Google Scholar] [CrossRef]

- Sara, U.; Morium, A.; Uddin, M.S. Image quality assessment through FSIM, SSIM, MSE and PSNR—A comparative study. J. Comput. Commun. 2019, 7, 8–18. [Google Scholar] [CrossRef]

| Specific Height | 1/10 | 2/10 | 3/10 | 4/10 | 5/10 | 6/10 | 7/10 | 8/10 | 9/10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Good Pattern | Min | 85 | 63 | 29 | 23 | 20 | 12 | 9 | 2 | 1 |

| Max | 241 | 240 | 229 | 195 | 190 | 158 | 128 | 99 | 89 | |

| Bad Pattern | Min | 43 | 22 | 17 | 12 | 9 | 6 | 5 | 3 | 1 |

| Max | 133 | 106 | 86 | 70 | 66 | 58 | 55 | 53 | 40 | |

| Threshold | 120 | 95 | 65 | 55 | 35 | 30 | 20 | 15 | 5 | |

| Accuracy (%) | 99.23 | 99.27 | 99.34 | 99.13 | 99.09 | 98.78 | 97.55 | 73.42 | 82.40 | |

| Algorithm | Good Pattern Film Images | Bad Pattern Film Images | ||||||

|---|---|---|---|---|---|---|---|---|

| Img1 | Img2 | Img3 | Img4 | Img1 | Img2 | Img3 | Img4 | |

| Image subtraction | 0.5445 | 0.4736 | 0.5171 | 0.5040 | 0.2477 | 0.2735 | 0.2372 | 0.2694 |

| Canny edge detection | 3.9533 | 3.9257 | 4.6248 | 3.9869 | 2.0604 | 2.1220 | 1.9288 | 2.0198 |

| Canny edge detection with HSV [17] | 3.6100 | 3.5531 | 3.8108 | 3.6666 | 1.8198 | 2.0888 | 1.8439 | 1.9961 |

| Otsu thresholding | 4.3954 | 4.3134 | 4.6248 | 4.4331 | 2.0672 | 2.1133 | 1.9076 | 1.9919 |

| Morphological geodesic active contour [20] | 13.4196 | 13.1801 | 14.1203 | 13.5010 | 6.2879 | 6.4296 | 5.8185 | 6.0841 |

| Algorithm | Accuracy (%) | Computation Time (sec) |

|---|---|---|

| Proposed algorithm | 99.34 | 3240.225 |

| Image subtraction | 76.75 | 12.126 |

| Canny edge detection | 22.62 | 12.158 |

| Canny edge detection with HSV [17] | 25.05 | 54.869 |

| Otsu thresholding | 39.28 | 8.135 |

| Morphological geodesic active contour [20] | 72.07 | 2074.59 |

| SVM with Canny edge detection [23] | 76.58 | 21.314 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Kim, J. Three-Dimensional Film Image Classification Using an Optimal Width of Histogram. Appl. Sci. 2023, 13, 4949. https://doi.org/10.3390/app13084949

Lee J, Kim J. Three-Dimensional Film Image Classification Using an Optimal Width of Histogram. Applied Sciences. 2023; 13(8):4949. https://doi.org/10.3390/app13084949

Chicago/Turabian StyleLee, Jaeeun, and Jongnam Kim. 2023. "Three-Dimensional Film Image Classification Using an Optimal Width of Histogram" Applied Sciences 13, no. 8: 4949. https://doi.org/10.3390/app13084949

APA StyleLee, J., & Kim, J. (2023). Three-Dimensional Film Image Classification Using an Optimal Width of Histogram. Applied Sciences, 13(8), 4949. https://doi.org/10.3390/app13084949