Direct Fabrication of Ultrahydrophobic Laser-Induced Graphene for Strain Sensors

Abstract

1. Introduction

2. Materials and Methods

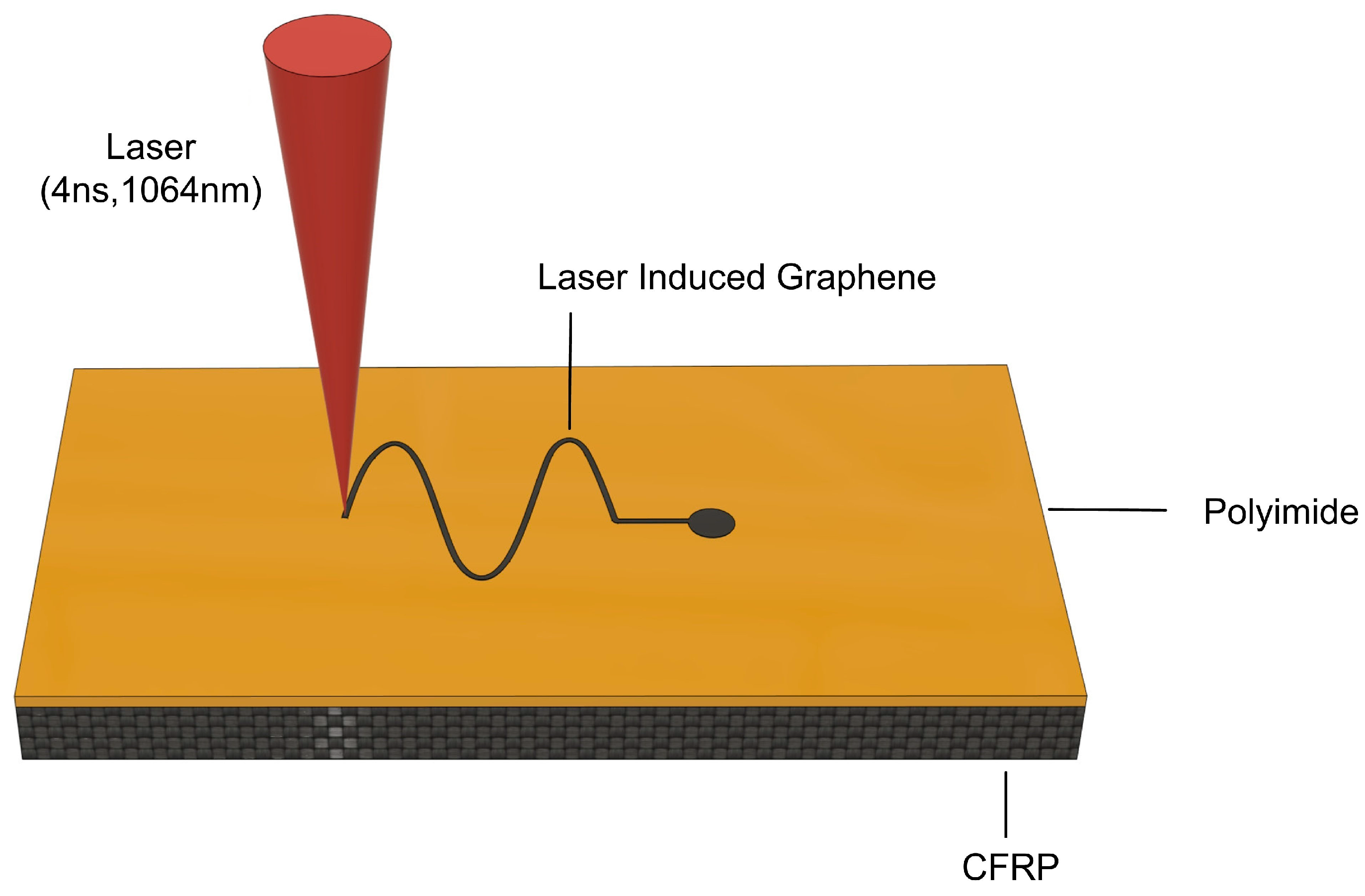

2.1. LIG Fabrication

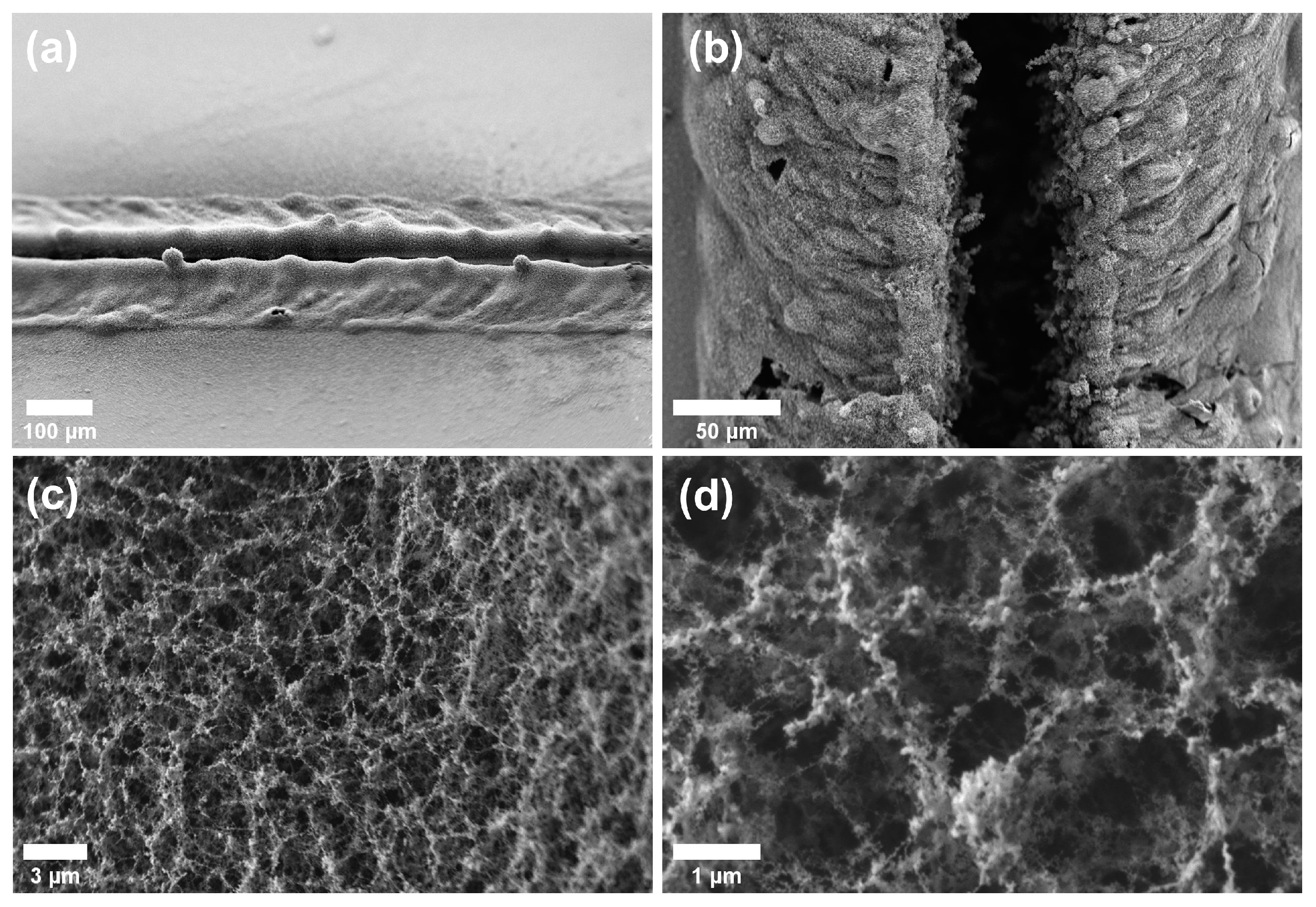

2.2. Surface Morphology and Chemical Composition Analysis

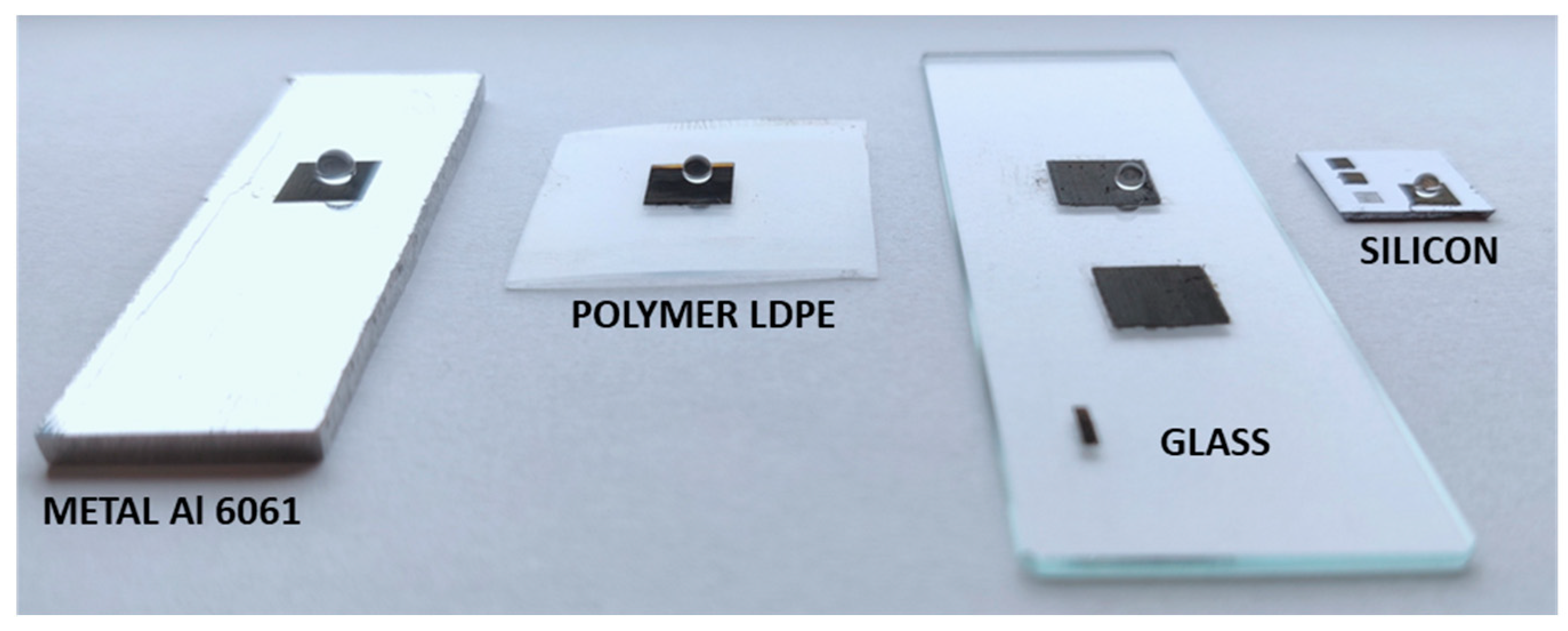

2.3. Sensor Fabrication and Analysis

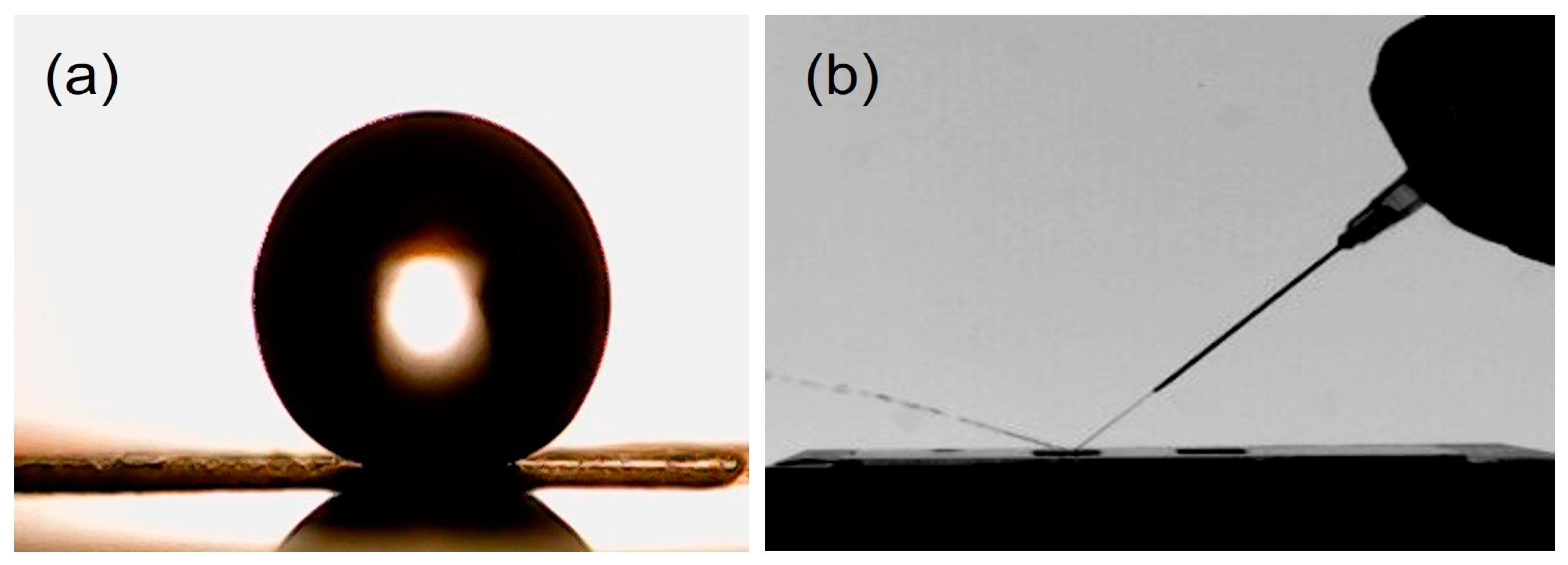

2.4. Superhydrophobic Surface Characterization

3. Results and Discussion

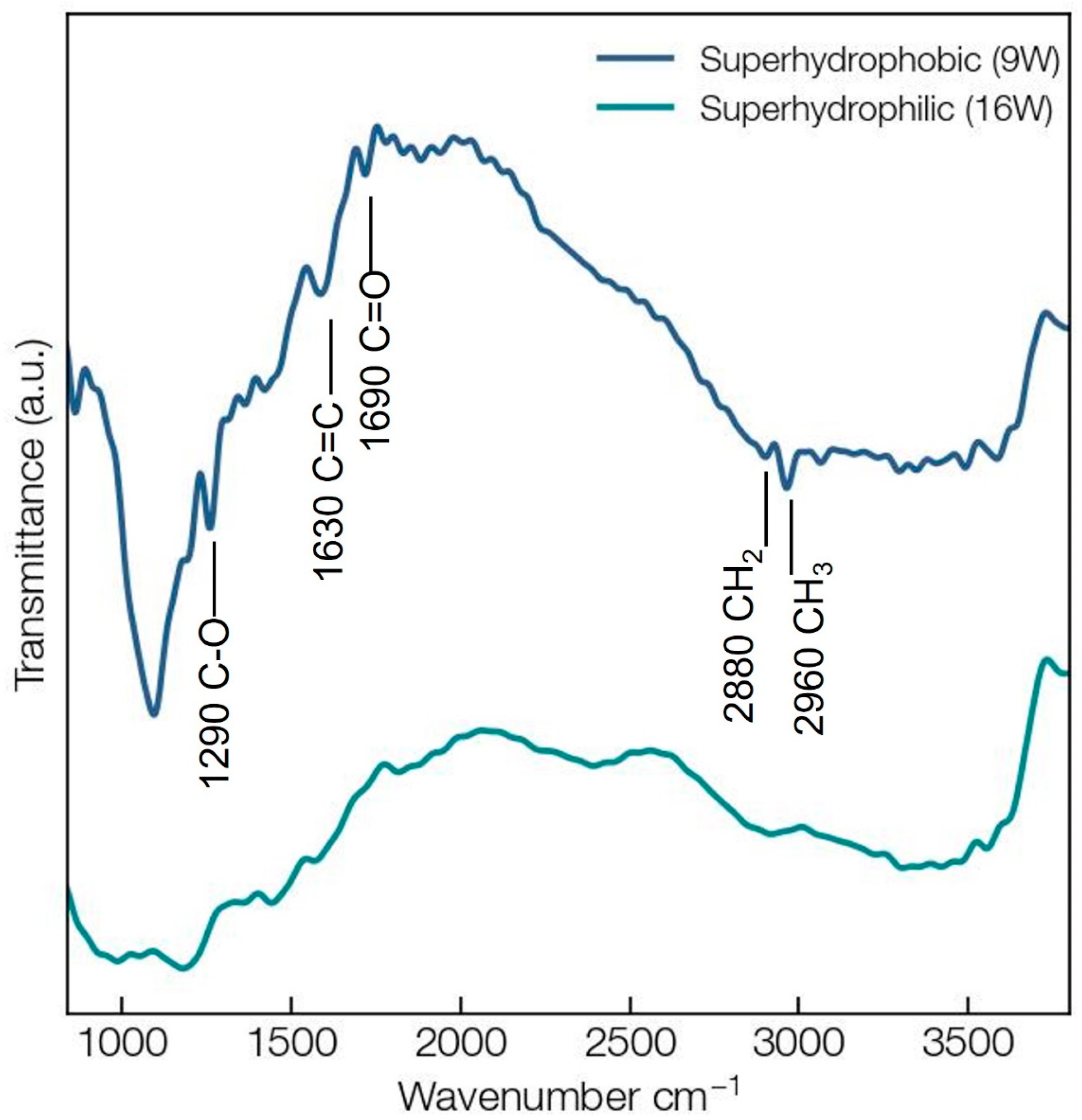

3.1. Surface Material Characterization

3.2. Piezoresistive Properties

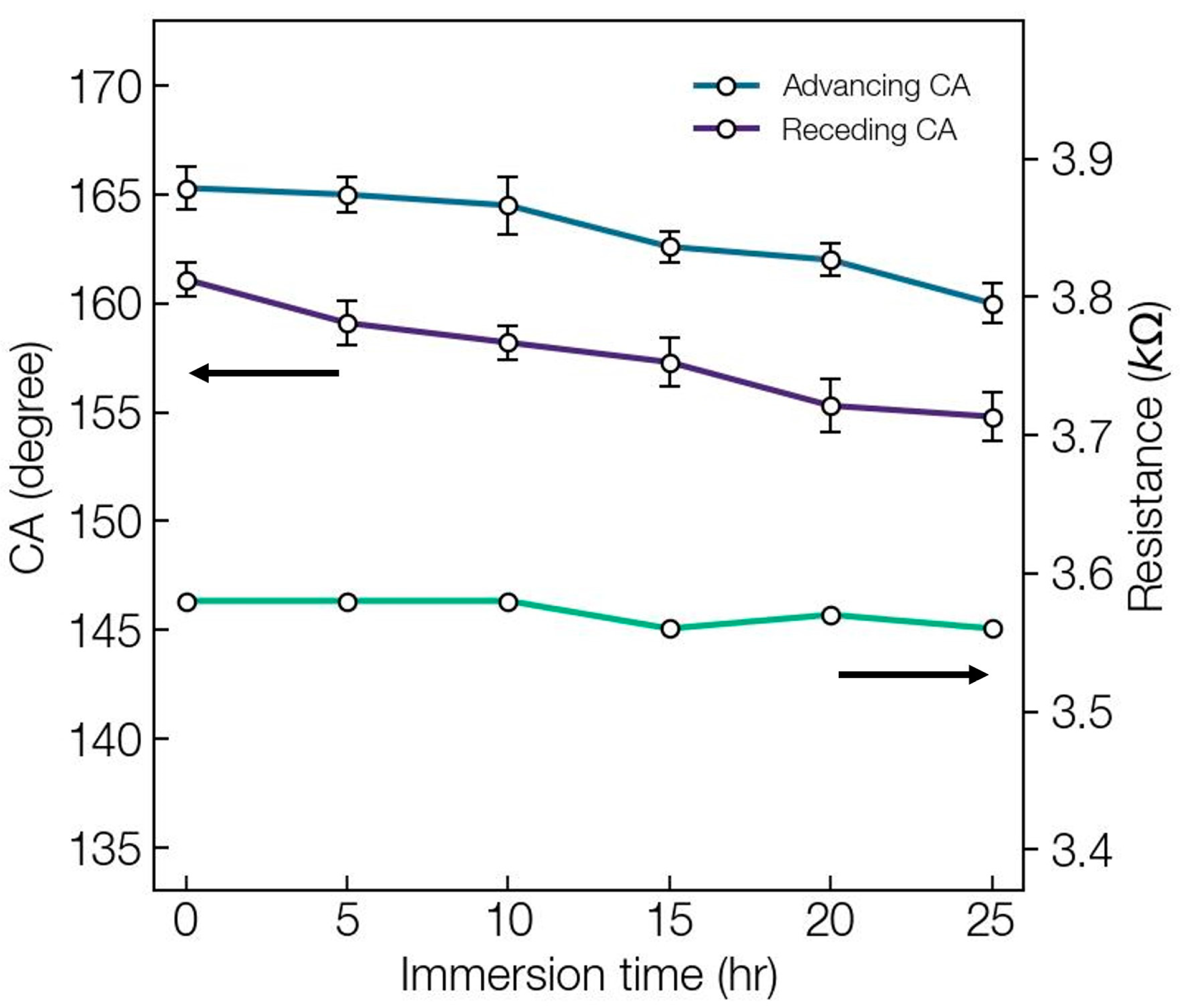

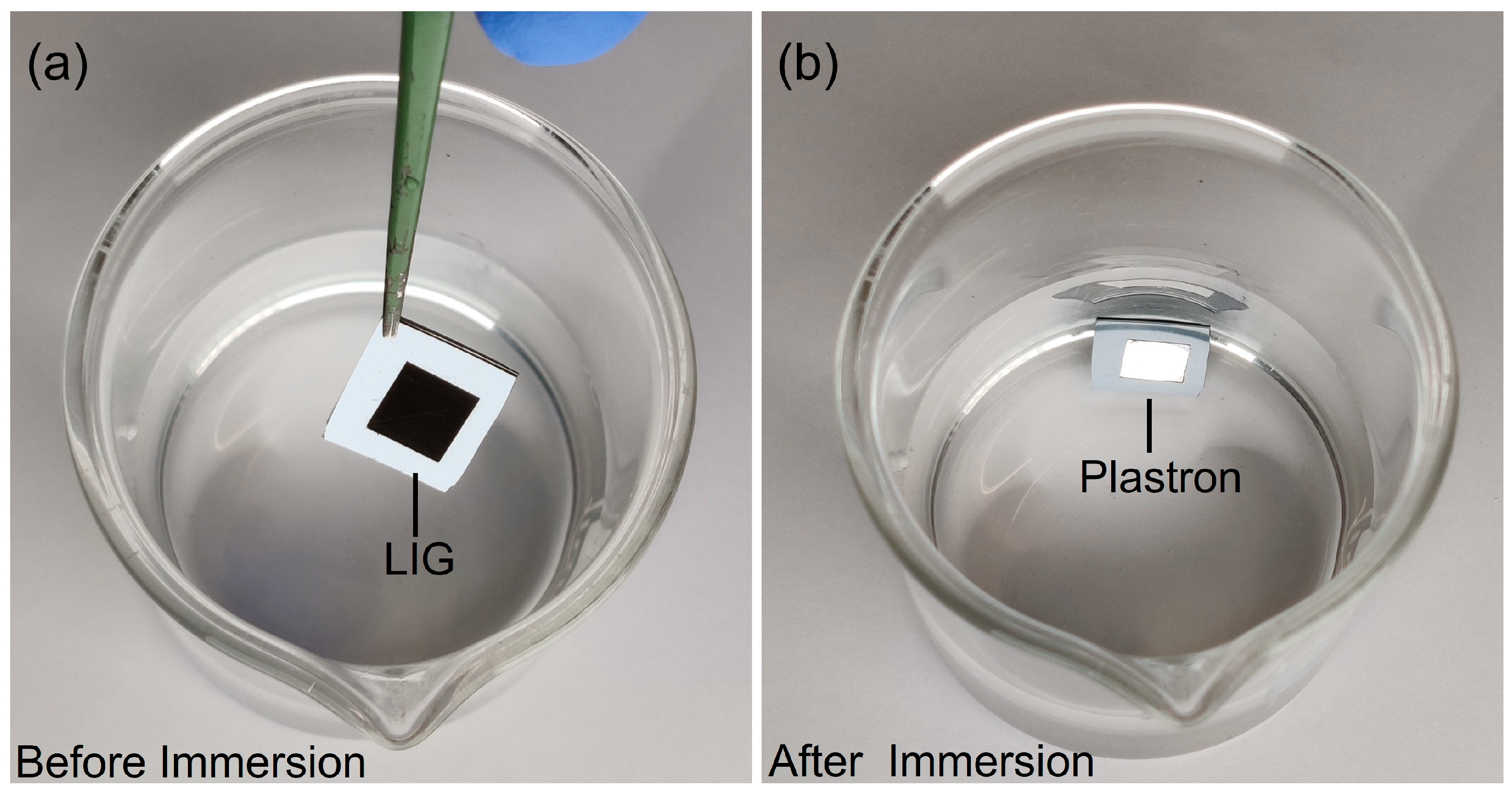

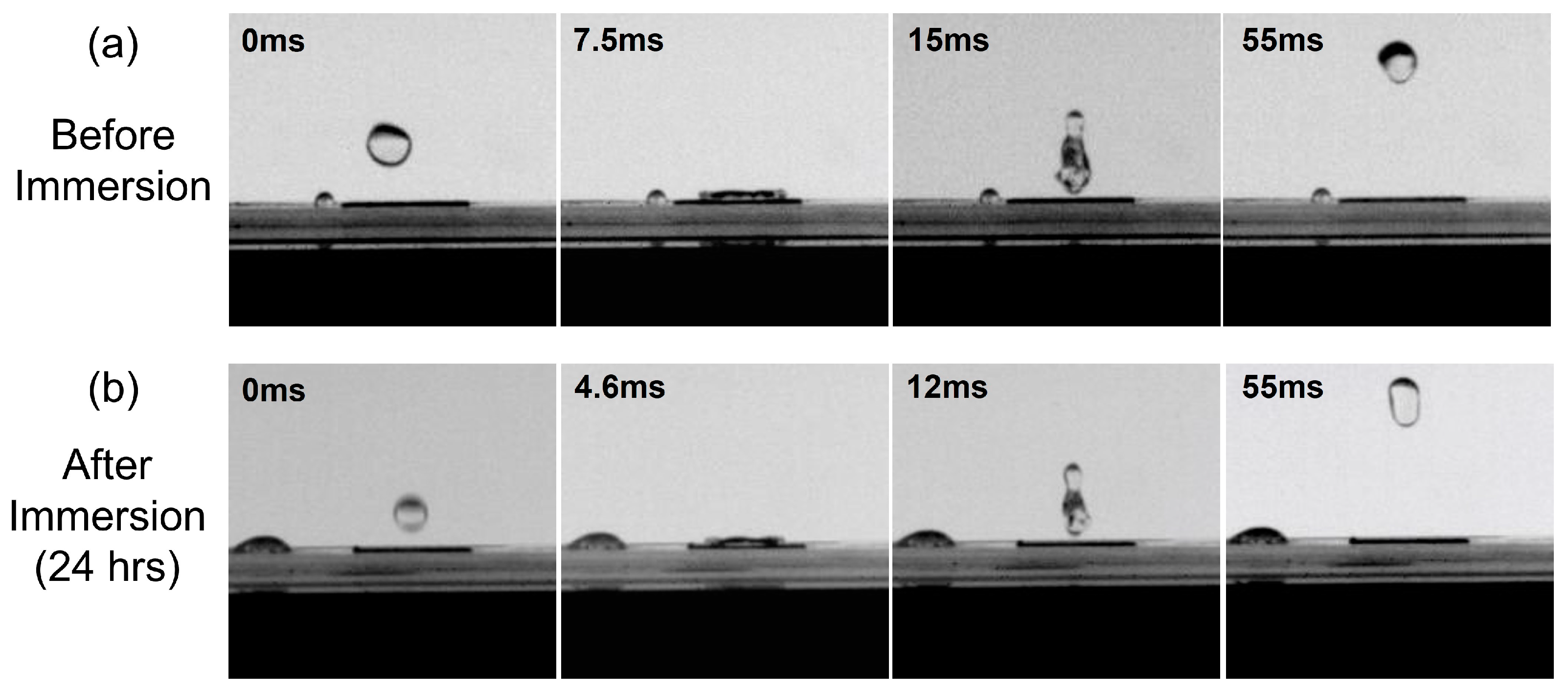

3.3. Superhydrophobic Property

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koumoulos, E.; Trompeta, A.-F.; Santos, R.-M.; Martins, M.; Santos, C.; Iglesias, V.; Böhm, R.; Gong, G.; Chiminelli, A.; Verpoest, I.; et al. Research and Development in Carbon Fibers and Advanced High-Performance Composites Supply Chain in Europe: A Roadmap for Challenges and the Industrial Uptake. J. Compos. Sci. 2019, 3, 86. [Google Scholar] [CrossRef]

- Scattareggia Marchese, S.; Epasto, G.; Crupi, V.; Garbatov, Y. Tensile Response of Fibre-Reinforced Plastics Produced by Additive Manufacturing for Marine Applications. JMSE 2023, 11, 334. [Google Scholar] [CrossRef]

- Zhang, C.; Ling, Y.; Zhang, X.; Liang, M.; Zou, H. Ultra-Thin Carbon Fiber Reinforced Carbon Nanotubes Modified Epoxy Composites with Superior Mechanical and Electrical Properties for the Aerospace Field. Compos. Part A Appl. Sci. Manuf. 2022, 163, 107197. [Google Scholar] [CrossRef]

- Jani, S.P.; Sajith, S.; Rajaganapathy, C.; Adam Khan, M. Mechanical and Thermal Insulation Properties of Surface-Modified Agave Americana/Carbon Fibre Hybrid Reinforced Epoxy Composites. Mater. Today Proc. 2021, 37, 1648–1653. [Google Scholar] [CrossRef]

- Bartkowiak, M.; Kizak, M.; Liebig, W.V.; Weidenmann, K.A. Fatigue Behavior of Hybrid Continuous-Discontinuous Fiber-Reinforced Sheet Molding Compound Composites under Application-Related Loading Conditions. Compos. Part C Open Access 2022, 8, 100265. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, W.; Li, B.; Zhu, J.; Wang, C.; Song, G.; Wu, G.; Yang, X.; Huang, Y.; Ma, L. Recent Advances of Interphases in Carbon Fiber-Reinforced Polymer Composites: A Review. Compos. Part B Eng. 2022, 233, 109639. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Paramsamy Kannan, V. Damage Monitoring of Carbon Fibre Reinforced Polymer Composites Using Acoustic Emission Technique and Deep Learning. Compos. Struct. 2022, 292, 115629. [Google Scholar] [CrossRef]

- Sun, Q.; Zhou, G.; Meng, Z.; Jain, M.; Su, X. An Integrated Computational Materials Engineering Framework to Analyze the Failure Behaviors of Carbon Fiber Reinforced Polymer Composites for Lightweight Vehicle Applications. Compos. Sci. Technol. 2021, 202, 108560. [Google Scholar] [CrossRef]

- Forintos, N.; Sarkadi, T.; Czigany, T. Electric Resistance Measurement–Based Structural Health Monitoring with Multifunctional Carbon Fibers: Predicting, Sensing, and Measuring Overload. Compos. Commun. 2021, 28, 100913. [Google Scholar] [CrossRef]

- Li, H.; Zhang, J.; Chen, J.; Luo, Z.; Zhang, J.; Alhandarish, Y.; Liu, Q.; Tang, W.; Wang, L. A Supersensitive, Multidimensional Flexible Strain Gauge Sensor Based on Ag/PDMS for Human Activities Monitoring. Sci. Rep. 2020, 10, 4639. [Google Scholar] [CrossRef]

- Ahuja, P.; Akiyama, S.; Ujjain, S.K.; Kukobat, R.; Vallejos-Burgos, F.; Futamura, R.; Hayashi, T.; Kimura, M.; Tomanek, D.; Kaneko, K. A Water-Resilient Carbon Nanotube Based Strain Sensor for Monitoring Structural Integrity. J. Mater. Chem. A 2019, 7, 19996–20005. [Google Scholar] [CrossRef]

- Sun, R.; Gao, L.; Liu, F.; Su, H.; Wu, L.; Zou, Z.; Wu, L.; Zhang, H.; Liao, C. Magnetically Induced Robust Anisotropic Structure of Multi-Walled Carbon Nanotubes/Ni for High-Performance Flexible Strain Sensor. Carbon 2022, 194, 185–196. [Google Scholar] [CrossRef]

- Fu, Y.-F.; Li, Y.-Q.; Liu, Y.-F.; Huang, P.; Hu, N.; Fu, S.-Y. High-Performance Structural Flexible Strain Sensors Based on Graphene-Coated Glass Fabric/Silicone Composite. ACS Appl. Mater. Interfaces 2018, 10, 35503–35509. [Google Scholar] [CrossRef]

- Qian, C.; Xiao, T.; Chen, Y.; Wang, N.; Li, B.; Gao, Y. 3D Printed Reduced Graphene Oxide/Elastomer Resin Composite with Structural Modulated Sensitivity for Flexible Strain Sensor. Adv. Eng. Mater. 2021, 24, 2101068. [Google Scholar] [CrossRef]

- Lei, M.; Feng, K.; Ding, S.; Wang, M.; Dai, Z.; Liu, R.; Gao, Y.; Zhou, Y.; Xu, Q.; Zhou, B. Breathable and Waterproof Electronic Skin with Three-Dimensional Architecture for Pressure and Strain Sensing in Nonoverlapping Mode. ACS Nano 2022, 16, 12620–12634. [Google Scholar] [CrossRef]

- Smeacetto, F.; Zanchi, E.; Menon, D.M.N.; Janner, D.; Lamnini, S.; Salvo, M.; De La Pierre, S.; Javed, H.; Ferraris, M. Torsional Behaviour of Glass-Joined, Laser-Processed Crofer 22 APU Interconnect: Unravelling the Effect of Surface Roughness on the Shear Strength. Ceram. Int. 2022, 48, 32837–32843. [Google Scholar] [CrossRef]

- Menon, D.M.N.; Pugliese, D.; Janner, D. Infrared Nanosecond Laser Texturing of Cu-Doped Bioresorbable Calcium Phosphate Glasses. Appl. Sci. 2022, 12, 3516. [Google Scholar] [CrossRef]

- Zhu, J.; Huang, X.; Song, W. Physical and Chemical Sensors on the Basis of Laser-Induced Graphene: Mechanisms, Applications, and Perspectives. ACS Nano 2021, 15, 18708–18741. [Google Scholar] [CrossRef]

- Liu, K.; Yang, C.; Zhang, S.; Wang, Y.; Zou, R.; Alamusi; Deng, Q.; Hu, N. Laser Direct Writing of a Multifunctional Superhydrophobic Composite Strain Sensor with Excellent Corrosion Resistance and Anti-Icing/Deicing Performance. Mater. Des. 2022, 218, 110689. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, C.; Chen, Y.; Nie, Z. Research Progress on the Preparation and Applications of Laser-Induced Graphene Technology. Nanomaterials 2022, 12, 2336. [Google Scholar] [CrossRef]

- Wang, W.; Lu, L.; Li, Z.; Lin, L.; Liang, Z.; Lu, X.; Xie, Y. Fingerprint-Inspired Strain Sensor with Balanced Sensitivity and Strain Range Using Laser-Induced Graphene. ACS Appl. Mater. Interfaces 2022, 14, 1315–1325. [Google Scholar] [CrossRef]

- Zhao, J.; Gui, J.; Luo, J.; Gao, J.; Zheng, C.; Xu, R. Highly Responsive Screen-Printed Asymmetric Pressure Sensor Based on Laser-Induced Graphene. J. Micromech. Microeng. 2022, 32, 015002. [Google Scholar] [CrossRef]

- Li, Q.; Wu, T.; Zhao, W.; Ji, J.; Wang, G. Laser-Induced Corrugated Graphene Films for Integrated Multimodal Sensors. ACS Appl. Mater. Interfaces 2021, 13, 37433–37444. [Google Scholar] [CrossRef] [PubMed]

- Hui, X.; Sharifuzzaman, M.; Sharma, S.; Park, C.I.; Yoon, S.; Kim, D.H.; Park, J.Y. A Nanocomposite-Decorated Laser-Induced Graphene-Based Multi-Functional Hybrid Sensor for Simultaneous Detection of Water Contaminants. Anal. Chim. Acta 2022, 1209, 339872. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Luo, J.; Huang, X.; Lin, L.; Wang, L.; Hu, M.; Tang, L.; Xue, H.; Gao, J.; Mai, Y.-W. A Highly Stretchable, Super-Hydrophobic Strain Sensor Based on Polydopamine and Graphene Reinforced Nanofiber Composite for Human Motion Monitoring. Compos. Part B Eng. 2020, 181, 107580. [Google Scholar] [CrossRef]

- Gao, W.-C.; Wu, W.; Chen, C.-Z.; Zhao, H.; Liu, Y.; Li, Q.; Huang, C.-X.; Hu, G.; Wang, S.-F.; Shi, D.; et al. Design of a Superhydrophobic Strain Sensor with a Multilayer Structure for Human Motion Monitoring. ACS Appl. Mater. Interfaces 2022, 14, 1874–1884. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, J.; Chen, Z.; Song, Z.; Meng, X.; Chen, X. Porous Graphene-Based Photothermal Superhydrophobic Surface for Robust Anti-Icing and Efficient De-Icing. Adv. Mater. Interfaces 2022, 9, 2201758. [Google Scholar] [CrossRef]

- Li, Y.; Luong, D.X.; Zhang, J.; Tarkunde, Y.R.; Kittrell, C.; Sargunaraj, F.; Ji, Y.; Arnusch, C.J.; Tour, J.M. Laser-Induced Graphene in Controlled Atmospheres: From Superhydrophilic to Superhydrophobic Surfaces. Adv. Mater. 2017, 29, 1700496. [Google Scholar] [CrossRef]

- Lee, Y.A.; Lim, J.; Cho, Y.; Lee, H.; Park, S.; Lee, G.-W.; Yoo, C.-Y.; Park, S.H.; Matham Murukeshan, V.; Kim, S.; et al. Attachable Micropseudocapacitors Using Highly Swollen Laser-Induced-Graphene Electrodes. Chem. Eng. J. 2020, 386, 123972. [Google Scholar] [CrossRef]

- Liu, F.; Wang, G.; Ding, X.; Luo, S. Multifunctional Laser-Induced Graphene Enabled Polymeric Composites. Compos. Commun. 2021, 25, 100714. [Google Scholar] [CrossRef]

- Wang, W.; Lu, L.; Li, Z.; Xie, Y. Laser Induced 3D Porous Graphene Dots: Bottom-up Growth Mechanism, Multi-Physics Coupling Effect and Surface Wettability. Appl. Surf. Sci. 2022, 592, 153242. [Google Scholar] [CrossRef]

- Wakabayashi, S.; Arie, T.; Akita, S.; Nakajima, K.; Takei, K. A Multitasking Flexible Sensor via Reservoir Computing. Adv. Mater. 2022, 34, 2201663. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Z.; Bakhtiyari, A.N.; Zheng, H. A Comparative Study of Laser-Induced Graphene by CO2 Infrared Laser and 355 Nm Ultraviolet (UV) Laser. Micromachines 2020, 11, 1094. [Google Scholar] [CrossRef] [PubMed]

- Stanford, M.G.; Yang, K.; Chyan, Y.; Kittrell, C.; Tour, J.M. Laser-Induced Graphene for Flexible and Embeddable Gas Sensors. ACS Nano 2019, 13, 3474–3482. [Google Scholar] [CrossRef]

- Gupta, A.; Sharma, C.P.; Thamaraiselvan, C.; Pisharody, L.; Powell, C.D.; Arnusch, C.J. Low-Voltage Bacterial and Viral Killing Using Laser-Induced Graphene-Coated Non-Woven Air Filters. ACS Appl. Mater. Interfaces 2021, 13, 59373–59380. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Xie, B.; Long, J.; Kuang, Y.; Chen, X.; Hou, M.; Gao, J.; Zhou, S.; Fan, B.; He, Y.; et al. Interfacial Laser-Induced Graphene Enabling High-Performance Liquid−Solid Triboelectric Nanogenerator. Adv. Mater. 2021, 33, 2104290. [Google Scholar] [CrossRef]

- Du, Q.; Chen, T.; Liu, J.; Zeng, X. Surface Microstructure and Chemistry of Polyimide by Single Pulse Ablation of Picosecond Laser. Appl. Surf. Sci. 2018, 434, 588–595. [Google Scholar] [CrossRef]

- Bounos, G.; Selimis, A.; Georgiou, S.; Rebollar, E.; Castillejo, M.; Bityurin, N. Dependence of Ultraviolet Nanosecond Laser Polymer Ablation on Polymer Molecular Weight: Poly (Methyl Methacrylate) at 248 Nm. J. Appl. Phys. 2006, 100, 114323. [Google Scholar] [CrossRef]

- Ma, W.; Zhu, J.; Wang, Z.; Song, W.; Cao, G. Recent Advances in Preparation and Application of Laser-Induced Graphene in Energy Storage Devices. Mater. Today Energy 2020, 18, 100569. [Google Scholar] [CrossRef]

- Peng, Z.; Lin, J.; Ye, R.; Samuel, E.L.G.; Tour, J.M. Flexible and Stackable Laser-Induced Graphene Supercapacitors. ACS Appl. Mater. Interfaces 2015, 7, 3414–3419. [Google Scholar] [CrossRef]

- Malyshev, A.Y.; Bityurin, N.M. Laser Swelling Model for Polymers Irradiated by Nanosecond Pulses. Quantum Electron. 2005, 35, 825–830. [Google Scholar] [CrossRef]

- Marla, D.; Zhang, Y.; Hattel, J.H.; Spangenberg, J. Modeling of Nanosecond Pulsed Laser Processing of Polymers in Air and Water. Model. Simul. Mater. Sci. Eng. 2018, 26, 055005. [Google Scholar] [CrossRef]

- Han, C.; Zahid, M.A.; Lee, B.; Oh, J.-Y.; Kim, Y.; Yi, J. Ultraviolet Nanosecond Laser Ablation of Polyimide with Thermal and Nonthermal Effects near Threshold Fluence. J. Laser Appl. 2022, 34, 032004. [Google Scholar] [CrossRef]

- Bityurin, N. 8 Studies on Laser Ablation of Polymers. Annu. Rep. Prog. Chem. Sect. C 2005, 101, 216. [Google Scholar] [CrossRef]

- Cardoso, A.R.; Marques, A.C.; Santos, L.; Carvalho, A.F.; Costa, F.M.; Martins, R.; Sales, M.G.F.; Fortunato, E. Molecularly-Imprinted Chloramphenicol Sensor with Laser-Induced Graphene Electrodes. Biosens. Bioelectron. 2019, 124–125, 167–175. [Google Scholar] [CrossRef]

- Wahab, H.; Jain, V.; Tyrrell, A.S.; Seas, M.A.; Kotthoff, L.; Johnson, P.A. Machine-Learning-Assisted Fabrication: Bayesian Optimization of Laser-Induced Graphene Patterning Using in-Situ Raman Analysis. Carbon 2020, 167, 609–619. [Google Scholar] [CrossRef]

- Sehat, A.A.; Khodadadi, A.A.; Shemirani, F.; Mortazavi, Y. Fast Immobilization of Glucose Oxidase on Graphene Oxide for Highly Sensitive Glucose Biosensor Fabrication. Int. J. Electrochem. Sci. 2015, 10, 272–286. [Google Scholar]

- Hazra, K.S.; Rafiee, J.; Rafiee, M.A.; Mathur, A.; Roy, S.S.; McLauhglin, J.; Koratkar, N.; Misra, D.S. Thinning of Multilayer Graphene to Monolayer Graphene in a Plasma Environment. Nanotechnology 2011, 22, 025704. [Google Scholar] [CrossRef]

- Nag, A.; Alahi, M.E.E.; Mukhopadhyay, S.C. Recent Progress in the Fabrication of Graphene Fibers and Their Composites for Applications of Monitoring Human Activities. Appl. Mater. Today 2021, 22, 100953. [Google Scholar] [CrossRef]

- Ebrahimi, G.; Pakchin, P.S.; Shamloo, A.; Mota, A.; de la Guardia, M.; Omidian, H.; Omidi, Y. Label-Free Electrochemical Microfluidic Biosensors: Futuristic Point-of-Care Analytical Devices for Monitoring Diseases. Microchim. Acta 2022, 189, 252. [Google Scholar] [CrossRef]

- Zelenková, G.; Zelenka, T.; Almáši, M.; Soldánová, M. Graphene as a Promising Additive to Hierarchically Porous Carbon Monoliths for Enhanced H2 and CO2 Sorption. J. CO2 Util. 2023, 68, 102371. [Google Scholar] [CrossRef]

- Selim, M.S.; Fatthallah, N.A.; Higazy, S.A.; Chen, X.; Hao, Z. Novel Blade-like Structure of Reduced Graphene Oxide/α-Mn2O3 Nanocomposite as an Antimicrobial Active Agent against Aerobic and Anaerobic Bacteria. Mater. Chem. Phys. 2023, 298, 127436. [Google Scholar] [CrossRef]

- Barahuie, F.; Saifullah, B.; Dorniani, D.; Fakurazi, S.; Karthivashan, G.; Hussein, M.Z.; Elfghi, F.M. Graphene Oxide as a Nanocarrier for Controlled Release and Targeted Delivery of an Anticancer Active Agent, Chlorogenic Acid. Mater. Sci. Eng. C 2017, 74, 177–185. [Google Scholar] [CrossRef]

- Gao, X.; Yokota, N.; Oda, H.; Tanaka, S.; Hokamoto, K.; Chen, P.; Xu, M. Preparation of Few-Layer Graphene by Pulsed Discharge in Graphite Micro-Flake Suspension. Crystals 2019, 9, 150. [Google Scholar] [CrossRef]

- Ye, R.; James, D.K.; Tour, J.M. Laser-Induced Graphene. Acc. Chem. Res. 2018, 51, 1609–1620. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, T.; Wu, M.; Wei, W. Durable Superhydrophobic Surface with Hierarchical Microstructures for Efficient Water Collection. Surf. Coat. Technol. 2021, 419, 127279. [Google Scholar] [CrossRef]

- Ivvala, J.; Arora, H.S.; Grewal, H.S. Towards Development of Sustainable Metallic Superhydrophobic Materials. Colloids Surf. A Physicochem. Eng. Asp. 2023, 663, 131047. [Google Scholar] [CrossRef]

- Menon, D.M.N.; Giardino, M.; Janner, D. Tunable Pulsewidth Nanosecond Laser Texturing: From Environment Friendly Superhydrophobic to Superamphiphobic Surfaces. Appl. Surf. Sci. 2023, 610, 155356. [Google Scholar] [CrossRef]

- Sharifikolouei, E.; Najmi, Z.; Cochis, A.; Scalia, A.C.; Aliabadi, M.; Perero, S.; Rimondini, L. Generation of Cytocompatible Superhydrophobic Zr–Cu–Ag Metallic Glass Coatings with Antifouling Properties for Medical Textiles. Mater. Today Bio. 2021, 12, 100148. [Google Scholar] [CrossRef]

- Liu, Y.; Moevius, L.; Xu, X.; Qian, T.; Yeomans, J.M.; Wang, Z. Pancake Bouncing on Superhydrophobic Surfaces. Nat. Phys. 2014, 10, 515–519. [Google Scholar] [CrossRef]

- Li, H.; Zhang, K. Dynamic Behavior of Water Droplets Impacting on the Superhydrophobic Surface: Both Experimental Study and Molecular Dynamics Simulation Study. Appl. Surf. Sci. 2019, 498, 143793. [Google Scholar] [CrossRef]

- Elzaabalawy, A.; Meguid, S.A. Development of Novel Icephobic Surfaces Using Siloxane-Modified Epoxy Nanocomposites. Chem. Eng. J. 2022, 433, 133637. [Google Scholar] [CrossRef]

| Substrate | Roughness [Sa (µm)] |

|---|---|

| Al 6061 | 6.22 |

| Silicon | 1.81 |

| Glass | 4.58 |

| Atomic % | |||

|---|---|---|---|

| Element | Al 6061 | Silicon | Glass |

| Al | 40.5 | - | - |

| Si | - | 69.2 | 18.7 |

| C | 28.5 | 23.3 | 45.9 |

| O | 29.1 | 7.4 | 35.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menon, D.M.N.; Giardino, M.; Janner, D. Direct Fabrication of Ultrahydrophobic Laser-Induced Graphene for Strain Sensors. Appl. Sci. 2023, 13, 4935. https://doi.org/10.3390/app13084935

Menon DMN, Giardino M, Janner D. Direct Fabrication of Ultrahydrophobic Laser-Induced Graphene for Strain Sensors. Applied Sciences. 2023; 13(8):4935. https://doi.org/10.3390/app13084935

Chicago/Turabian StyleMenon, Devanarayanan Meena Narayana, Matteo Giardino, and Davide Janner. 2023. "Direct Fabrication of Ultrahydrophobic Laser-Induced Graphene for Strain Sensors" Applied Sciences 13, no. 8: 4935. https://doi.org/10.3390/app13084935

APA StyleMenon, D. M. N., Giardino, M., & Janner, D. (2023). Direct Fabrication of Ultrahydrophobic Laser-Induced Graphene for Strain Sensors. Applied Sciences, 13(8), 4935. https://doi.org/10.3390/app13084935