Probabilistic Models for the Shear Strength of RC Deep Beams

Abstract

1. Introduction

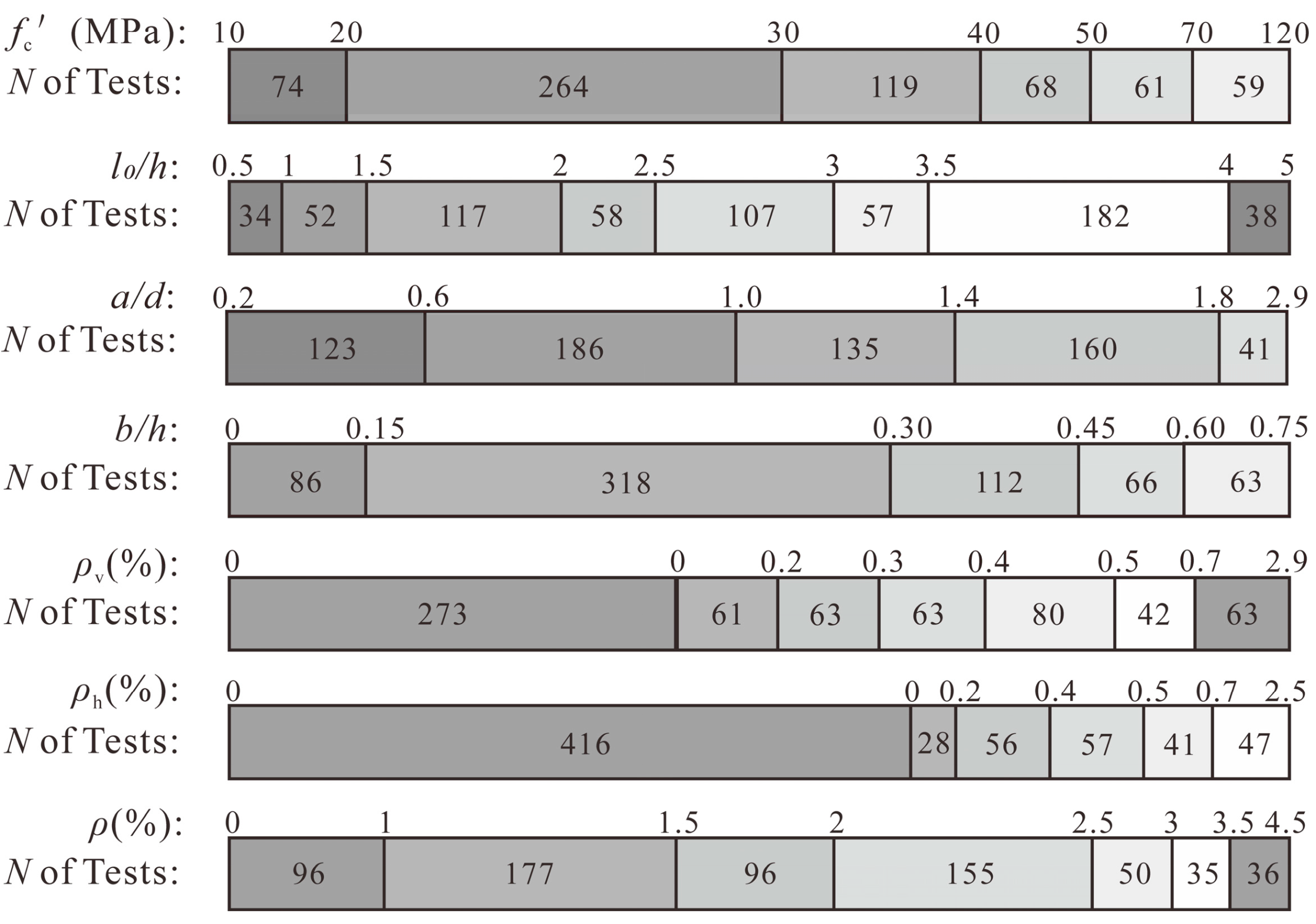

2. Database

3. Bayesian–MCMC Method

3.1. Bayesian Method

3.1.1. Probabilistic Model

3.1.2. Bayesian Parameter Estimation

3.1.3. The Prior Distribution

3.1.4. Likelihood Functions

- (1)

- “failure datum”: the demand Vi was measured at the instant of the failure, i.e., σε = lnVi − lnVd − γ(xi, θ);

- (2)

- “lower bound datum”: the component did not fail up to the demand level Vi, i.e., σε > lnVi − lnVd − γ(xi, θ);

- (3)

- “upper bound datum”: the component has failed under a lower demand than measured Vi, i.e., σε < lnVi − lnVd − γ(xi, θ). The likelihood function for the univariate model has the general form

3.2. MCMC Method

4. Probabilistic Shear Strength Models

4.1. Operation of Probabilistic Models

4.1.1. Selection of Explanatory Functions

4.1.2. Parameter Removal Process

- (1)

- Calculate the posterior estimation values of parameters θ = [θ1, θ2, …, θp] and σ.

- (2)

- Calculate the coefficient of variation COV for θi:The Coefficient of Variation of each parameter is calculated aswhere σi and μi are the standard deviations and the mean value of the ith parameter, respectively.

- (3)

- Remove hi(x) with the highest coefficient of variation COV. If the COV for the θi is the largest, it is considered that the hi(x) has the most negligible impact and is removed. It is continuing the adjustment with the remaining term h(x).

- (4)

- Repeat the parameter removal process until a significant increase occurs in the prediction model’s standard deviation (SD).

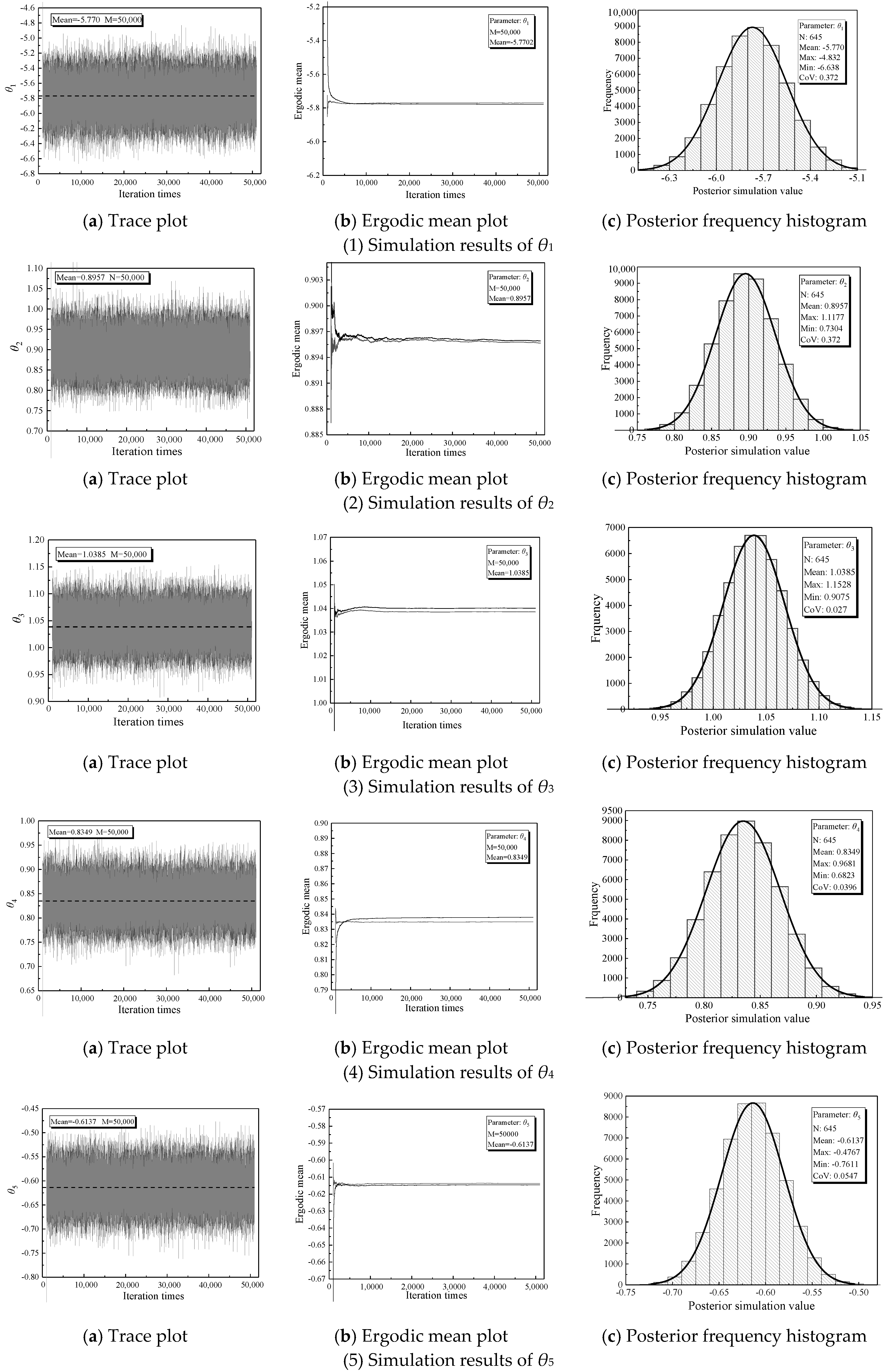

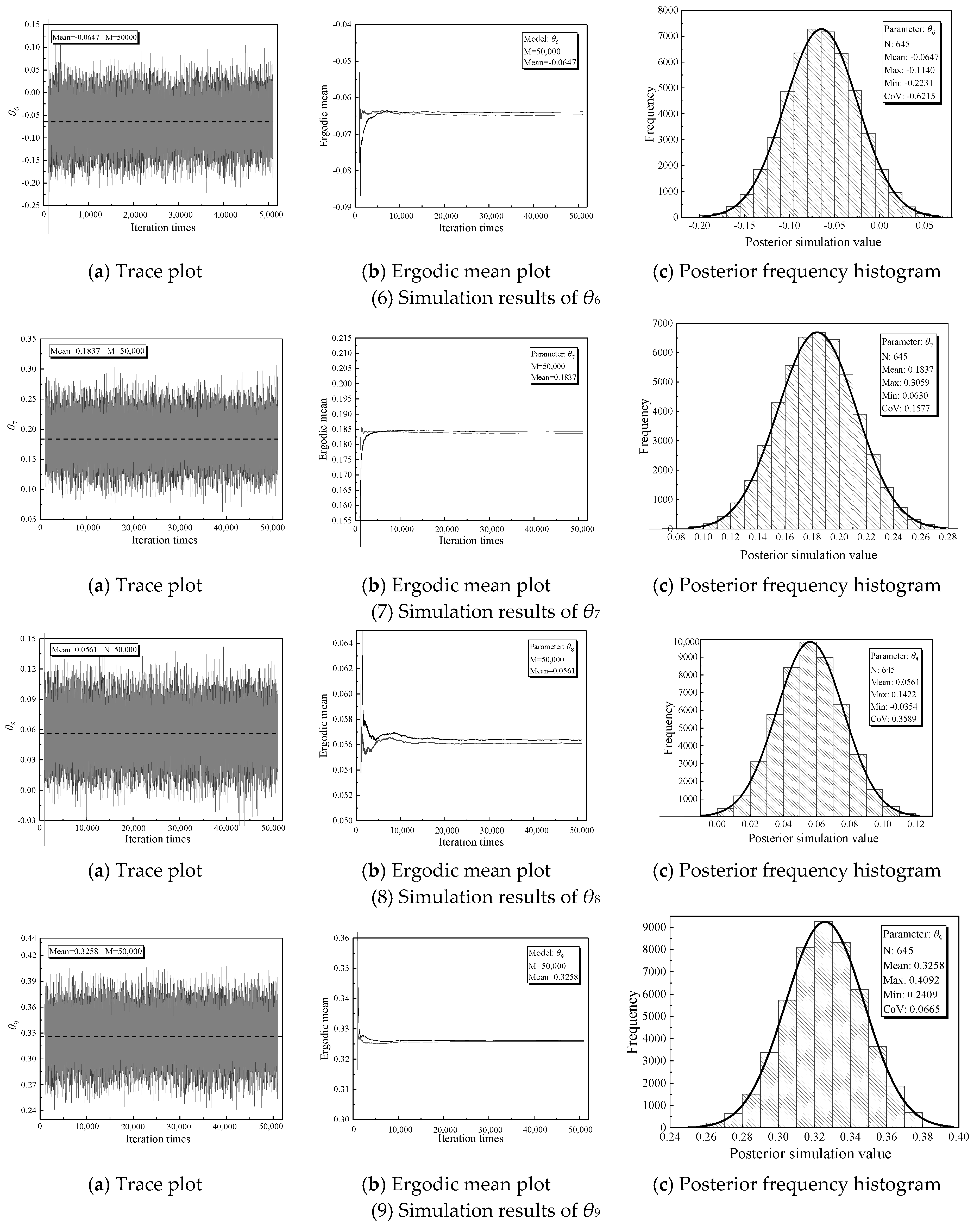

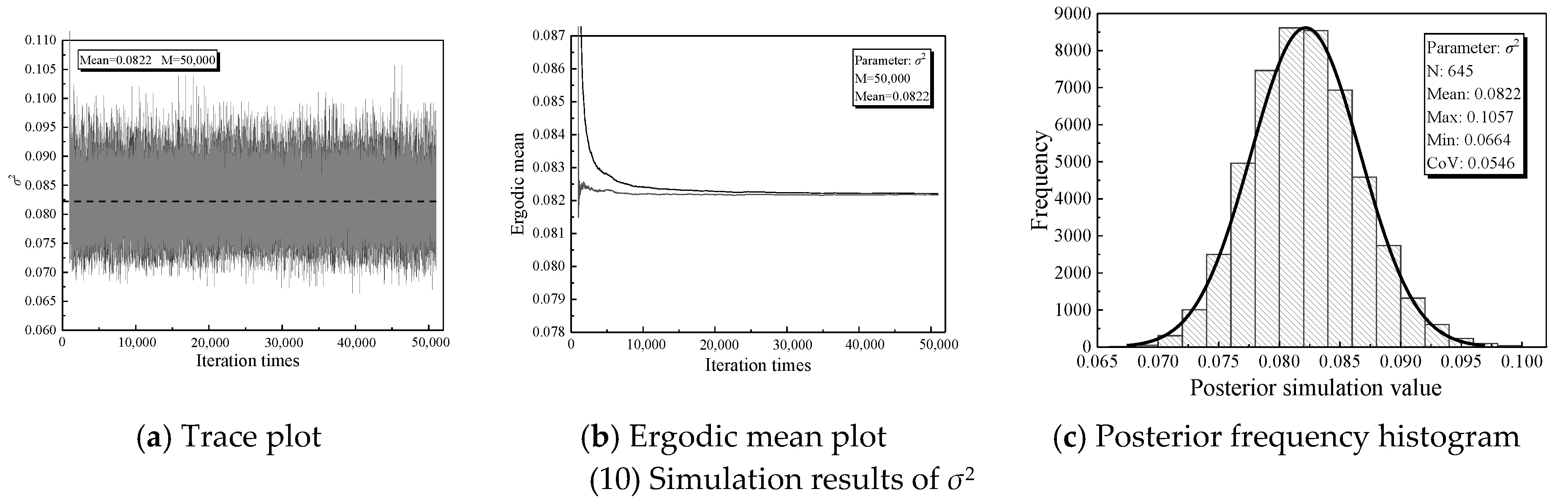

4.1.3. Gibbs Sampling

- (1)

- was sampled from the full conditional distribution

- (2)

- was sampled from the full conditional distribution

- (3)

- was sampled from the full conditional distribution

4.2. Development of Probabilistic Models

4.2.1. Existing Shear Strength Models

4.2.2. Calculation Results

4.2.3. Probabilistic Models

5. Discussion

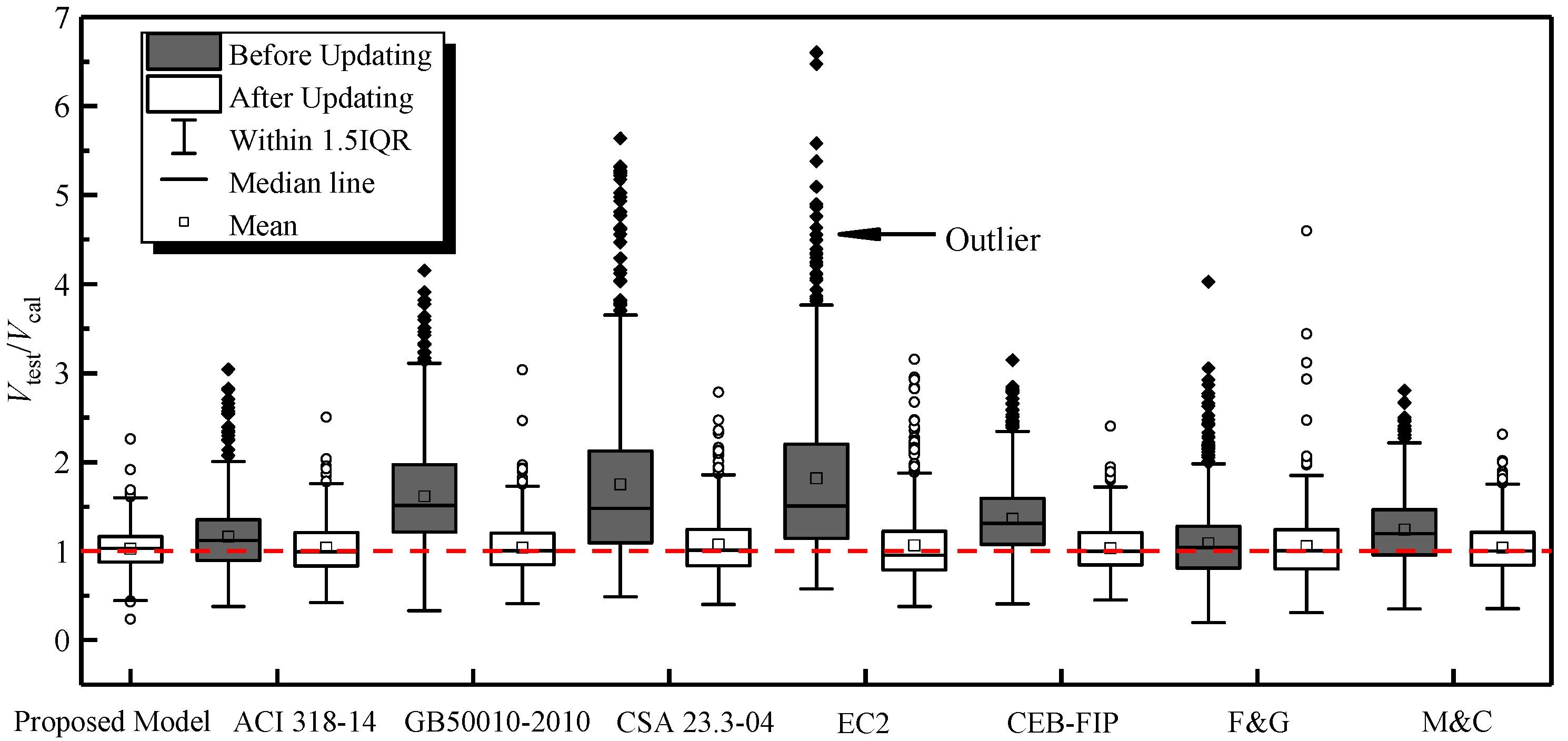

5.1. Comparison with Existing Models

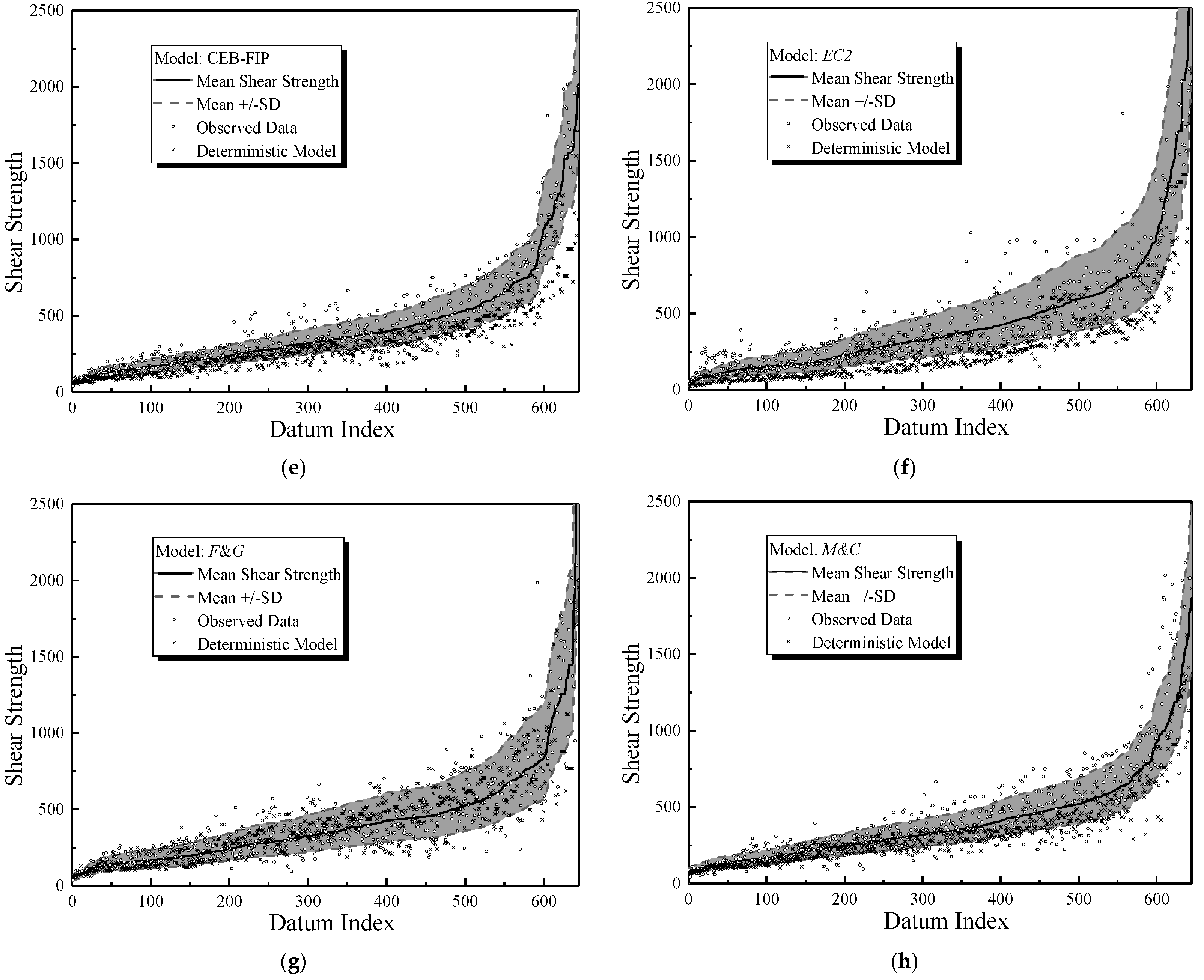

5.2. Comparison with Experimental Observations

5.3. Continuity and Uncertainty

- 1.20~1.35 for whole database (γRd ≈ 1.25, β = 0.38)

- 1.18~1.32 for normal-strength members (γRd ≈ 1.25, β = 0.38)

- 1.21~1.35 for high-strength members (γRd ≈ 1.27, β = 0.38)

- 1.30~1.52 for ultra-strength members (γRd ≈ 1.41, β = 0.38)

- 1.20~1.37 for 0 < ρ ≤ 1.0 members (γRd ≈ 1.28, β = 0.38)

- 1.23~1.39 for 1.0 < ρ ≤ 2.0 members (γRd ≈ 1.31, β = 0.38)

- 1.17~1.30 for 2.0 < ρ ≤ 5.0 members (γRd ≈ 1.21, β = 0.38)

6. Conclusions

- The deterministic methods improved by the Bayesian–MCMC method showed more accurate and robust predictions with experiment-to-prediction ratios between 1.0322 and 1.0744 and CoVs between 0.2540 and 0.3879.

- The proposed model developed without prior models had higher accuracy (the mean was 1.0357) and lower discreteness (the CoV was 0.2312) than other modified probabilistic models. Uncertainties related to the proposed model were described by the following statistical characteristics and partial factors: whole database (β = 0.38, μ = 1.0357, V = 0.2263, and γRd ≈ 1.25).

- Gibbs sampling method was introduced to solve high-dimensional and complex integration problems by which the sampling progress was simplified, improving the optimization and reliability of model parameters.

- Explanatory functions such as fc′/fy, l0/h, a/h0, b/h, ρv, ρh, and ρ were identified by different removal processes, which improves the modified probabilistic models.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Glossary

| a = shear span; |

| a/d = the shear span-to-depth ratio; |

| Asv = the total area of vertical web reinforcement in the same section; |

| Ash = the total area of horizontal web reinforcement in the same section; |

| b = the width of specimens; |

| bw = the width of web; |

| d = the effective depth of beam; |

| E[f(x)] = the expectation of arbitrary function; |

| f(x) = the arbitrary function; |

| fc′ = the specified compressive strength of concrete; |

| fcd = the design value of cylinder compressive strength of concrete; |

| fck = the compressive cylinder strength of concrete; |

| fcu = the cube compressive strength of concrete; |

| ft = the tensile strength of concrete; |

| fy = the yield strength of longitudinal reinforcement; |

| fyh = the yield stress for horizontal web reinforcement in beam; |

| fyv = the yield stress for vertical web reinforcement in beam; |

| f(Θ) = the posterior distribution; |

| h = the depth of specimens; |

| h0 = the effective depth of beam; |

| hi(x) = the explanatory functions; |

| L(θ, σ|Y, X) = the likelihood function; |

| L(Θ) = the likelihood function; |

| l0/h = the shear–depth ratio; |

| (lp)E = the width of the bottom loading plate; |

| (lp)P = the width of the top loading plate; |

| Sh = the spacing of horizontal web reinforcement; |

| Sn= the variance of arbitrary function; |

| Sv = the spacing of vertical web reinforcement; |

| M = iteration times |

| m = the number of samples when the Markov chain reaches stationary distribution; |

| n = the total number of samples generated by simulation; |

| p = the number of explanatory functions; |

| p(Θ) = the joint probability density function of a prior distribution; |

| VAR[f(x)] = the variance of arbitrary function; |

| V(X, Θ) = a probabilistic model; |

| Vd = an existing deterministic model; |

| Vi = calculation of probability model of ith test; |

| Vn = the shear strength of deep beams with different calculation models; |

| ws = the width of a strut perpendicular to the axis of the strut; |

| wt = the effective height of the bottom nodal zone |

| wt′ = the effective height of the top nodal zone; |

| X= the vector of input parameters; |

| αR = FORM (First Order Reliability Method) sensitivity factor; |

| β = the elected target reliability index; |

| βs = the factor used to account for the effect of cracking and confining reinforcement on the effective compressive strength of the concrete in a strut; |

| γRd = the partial factor; |

| γ(X, θ) = the correction term for the bias; |

| ε = the normal random variable with the zero mean and unit variance; |

| ε1 = the main tensile strain; |

| εs = the longitudinal tensile strain in mid span of beams; |

| θ= the vector of uncertain model parameters; |

| θ(−i) = the vector of uncertain model parameters excluding eighth parameter; |

| = the ith iterative value of the kth parameter; |

| θs = the smallest angle between the strut and the adjoining ties; |

| = the mean value of each uncertain model parameter; |

| κ = the normalizing factor; |

| λ = the shear span-to-depth ratio; |

| μi = the mean value of the ith parameter; |

| π(θ, σ) = the prior distribution of parameters; |

| π(θ, σ|Y, X) = a posteriori distribution function; |

| ρ = longitudinal reinforcement ratio; |

| ρh= the horizontal web reinforcement ratio; |

| ρv= the vertical web reinforcement ratio; |

| σ = the unknown model parameter representing the magnitude of the model error; |

| σi = the standard deviation of the ith parameter; |

| σ2 = the variance; |

| υ = coefficient of the experiment-prediction ratios; |

| φ(·) = the joint probability density function (PDF) of the standard normal; |

| Φ(·) = the cumulative distribution function (CDF) of the standard normal distribution; |

| Θ = a set of model parameters introduced to fit the model to the test results. |

Appendix A

References

- Gandomi, A.H.; Alavi, A.H.; Shadmehri, D.M.; Sahab, M.G. An empirical model for shear capacity of RC deep beams using genetic-simulated annealing. Arch. Civ. Mech. Eng. 2013, 13, 354–369. [Google Scholar] [CrossRef]

- Chou, J.S.; Ngo, N.T.; Pham, A.D. Shear strength prediction in reinforced concrete deep beams using nature-inspired metaheuristic support vector regression. J. Comput. Civ. Eng. 2015, 30, 04015002. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Cao, M.T. Evolutionary multivariate adaptive regression splines for estimating shear strength in reinforced-concrete deep beams. Eng. Appl. Artif. Intell. 2014, 28, 86–96. [Google Scholar] [CrossRef]

- Todisco, L.; Reineck, K.H.; Bayrak, O. Database with shear tests on non-slender reinforced concrete beams with vertical stirrups. Aci. Struct. J. 2015, 112, 761–770. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Tran, M.T.; Kim, S.; Bakhshpoori, T.; Deo, R.C. Shear strength prediction of steel fiber reinforced concrete beam using hybrid intelligence models: A new approach. Eng. Struct. 2018, 177, 244–255. [Google Scholar] [CrossRef]

- Tuchscherer, R.G.; Birrcher, D.B.; Williams, C.S.; Deschenes, D.J.; Bayrak, O. Evaluation of existing strut-and-tie methods and recommended improvements. ACI Struct. J. 2014, 111, 1451–1460. [Google Scholar] [CrossRef]

- Ismail, K.S.; Guadagnini, M.; Pilakoutas, K. Strut-and-Tie modelling of reinforced concrete deep beams. J. Struct. Eng. 2017, 144, 04017216. [Google Scholar] [CrossRef]

- Liu, J.; Mihaylov, B.I. A comparative study of models for shear strength of reinforced concrete deep beams. Eng. Struct. 2016, 112, 81–89. [Google Scholar] [CrossRef]

- Kassem, W. Shear strength of deep beams: A mathematical model and design formula. Struct. Concr. 2015, 16, 184–194. [Google Scholar] [CrossRef]

- Chen, H.; Yi, W.J.; Ma, Z.J.; Hwang, H.J. Shear strength of reinforced concrete simple and continuous deep beams. ACI Struct. J. 2019, 116, 31–40. [Google Scholar] [CrossRef]

- Song, J.; Kang, W.H.; Kim, K.S.; Jung, S. Probabilistic shear strength models for reinforced concrete beams without shear reinforcement. Struct. Eng. Mech. 2010, 11, 15–38. [Google Scholar] [CrossRef]

- Han, M. Bayesian Statistics and Its Applications; Tongji University Press: Shanghai, China, 2015. [Google Scholar]

- Lyathakula, K.R.; Yuan, F.G. A probabilistic fatigue life prediction for adhesively bonded joints via ANNs-based hybrid model. Int. J. Fatigue 2021, 151, 106352. [Google Scholar] [CrossRef]

- Magni, P.; Bellazzi, R.; De, N.G. Bayesian function learning using MCMC methods. IEEE Trans. Pattern Anal. 1998, 20, 1319–1331. [Google Scholar] [CrossRef]

- Andrieu, C.; De, F.N.; Doucet, A.; Jordan, M.I. An introduction to MCMC for machine learning. Mach. Learn. 2003, 50, 5–43. [Google Scholar] [CrossRef]

- Gelman, A.; Carlin, J.B.; Stern, H.S.; Rubin, D.B. Bayesian Data Analysis; Chapman and Hall/CRC: New York, NY, USA, 1995. [Google Scholar]

- Reis, D.S.; Stedinger, J.R. Bayesian MCMC flood frequency analysis with historical information. J. Hydrol. 2005, 313, 97–116. [Google Scholar] [CrossRef]

- Papaioannou, I.; Betz, W.; Straub, D. Bayesian model updating of a tunnel in soft soil with settlement. In Proceedings of the Geotechnical Safety and Risk IV, Hong Kong, China, 4–6 December 2013; pp. 351–356. [Google Scholar] [CrossRef]

- Sorensen, D.; Gianola, D. Likelihood, Bayesian, and MCMC Methods in Quantitative Genetics; Springer Science and Business Media: New York, NY, USA, 2007. [Google Scholar]

- Mensah, K.K. Reliability Assessment of Structural Concrete with Special Reference to Shear Resistance. Ph.D. Dissertation, Stellenbosch University, Stellenbosch, South Africa, 2012. [Google Scholar]

- Krejsa, J.; Holicky, M.; Sykora, M. Uncertainty in shear resistance of reinforced concrete beams with stirrups-comparison of EN 1992-1-1 and fib MC 2010 approaches. Trans. VŠB-Tech. Univ. Ostrav. Civ. Eng. Ser. 2014, 14, 48–56. [Google Scholar] [CrossRef]

- Sykora, M.; Krejsa, J.; Mlcoch, J.; Prieto, M.; Tanner, P. Uncertainty in shear resistance models of reinforced concrete beams according to fib MC 2010. Struct. Concr. 2018, 19, 284–295. [Google Scholar] [CrossRef]

- ACI 318; Building Code Requirement for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- GB50011-2010; Code for Seismic Design of Buildings. China Architectural and Building Press: Beijing, China, 2010.

- CSA. Design of Concrete Structures; Canadian Standards Association: Mississauga, ON, Canada, 2004. [Google Scholar]

- EC2; Design of Concrete Structures. British Standards Institution: London, UK, 2004.

- CEB-FIP. fib Model Code for Concrete Structures 2010; International Federation for Structural Concrete: Lausanne, Switzerland, 2013. [Google Scholar]

- Foster, S.J.; Gilbert, R.I. Experimental studies on high-strength concrete deep beams. ACI Struct. J. 1998, 95, 382–390. [Google Scholar] [CrossRef]

- Mitchell, D.; Collins, M.P. Diagonal compression field theory-a rational model for structural concrete in pure torsion. ACI J. Proc. 1974, 71, 396–408. [Google Scholar] [CrossRef]

- Kong, F.K.; Robins, P.J.; Cole, D.P. Web reinforcement effects on deep beams. ACI Struct. J. 1970, 67, 1010–1017. [Google Scholar] [CrossRef]

- Tan, K.H.; Kong, F.K.; Teng, S.; Weng, L.M. Effect of web reinforcement on high-strength concrete deep beams. ACI Struct. J. 1997, 94, 572–582. [Google Scholar] [CrossRef]

- Liu, L.X.; Xie, L.L.; Chen, M. The shear strength capability of reinforced concrete deep flexural member. Build. Struct. 2000, 30, 19–22. [Google Scholar] [CrossRef]

- Manuel, R.F.; Slight, B.W.; Suter, G.T. Deep beam behaviour affected by length and shear span variations. ACI J. 1971, 68, 366–379. [Google Scholar] [CrossRef]

- Smith, K.N.; Vantsiotis, A.S. Shear strength of deep beams. ACI J. 1982, 79, 201–213. [Google Scholar] [CrossRef]

- Gong, S.X. The shear strength capability of reinforced concrete deep beam under symmetric concentrated loads. J. Zhengzhou Technol. Inst. 1982, 1, 52–68. [Google Scholar]

- Mphonde, A.G.; Frantz, G.C. Shear tests of high-and low-strength concrete beams without stirrups. ACI J. 1984, 81, 350–357. [Google Scholar] [CrossRef]

- Fang, J.W. Experimental study of reinforced concrete deep on shear strength. J. ShiJiazhuang Railw. Inst. 1990, 3, 15–24. [Google Scholar]

- Tan, K.H.; Kong, F.K.; Teng, S.; Guan, L. High-strength concrete deep beams with effective span and shear span variations. ACI Mater. J. 1995, 92, 395–405. [Google Scholar] [CrossRef]

- Tan, K.H.; Teng, S.; Kong, F.K.; Lu, H. Main tension steel in high strength concrete deep and short beams. ACI Struct. J. 1997, 94, 752–768. [Google Scholar] [CrossRef]

- Shin, S.W.; Lee, L.S.; Moon, J.I.; Ghosh, S.K. Shear strength of reinforced high-strength concrete beams with shear span-to-depth ratios between 1.5 and 2.5. ACI Struct. J. 1999, 96, 549–556. [Google Scholar] [CrossRef]

- Tan, K.H.; Lu, H.Y. Shear behavior of large reinforced concrete deep beams and code comparisons. ACI Struct. J. 1999, 96, 836–845. [Google Scholar] [CrossRef]

- Tan, K.H.; Cheng, G.H.; Zhang, N. Experiment to mitigate size effect on deep beams. Mag. Concr. Res. 2008, 60, 709–723. [Google Scholar] [CrossRef]

- Oh, J.K.; Shin, S.W. Shear strength of reinforced high-strength concrete deep beams. ACI Struct. J. 2001, 98, 164–173. [Google Scholar] [CrossRef]

- Kani, G.N.J. How safe are our large reinforced concrete beams. ACI J. Proc. 1967, 64, 128–141. [Google Scholar] [CrossRef]

- Rogowsky, D.M.; MacGregor, J.G.; Ong, S.Y. Tests of reinforced concrete deep beams. ACI Struct. J. 1983, 83, 614–623. [Google Scholar] [CrossRef]

- Lu, W.Y.; Lin, I.J.; Hwang, S.J. Shear strength of reinforced concrete deep beams. ACI Struct. J. 2013, 110, 671–680. [Google Scholar] [CrossRef]

- Teng, S.; Ma, W.; Wang, F. Shear strength of concrete deep beams under fatigue loading. ACI Struct. J. 2000, 97, 572–580. [Google Scholar] [CrossRef]

- Moody, K.G.; Viest, I.M.; Elstner, R.C.; Hognestad, E. Shear strength of reinforced concrete beams, part 1-tests of simple beams. ACI J. 1954, 26, 317–332. [Google Scholar] [CrossRef]

- Laupa, A.; Siess, C.P.; Newmark, N.M. Strength in Shear of Reinforced Concrete Beams; Engineering Experiment Station, University of Illinois: Champaign, IL, USA, 1955. [Google Scholar]

- Morrow, J.D.; Viest, I.M. Shear strength of reinforced concrete frame member without web reinforcement. ACI J. 1957, 53, 833–869. [Google Scholar] [CrossRef]

- Ramakrishnan, V.; Ananthanarayana, Y. Ultimate strength of deep beams in shear. ACI J. 1968, 65, 87–98. [Google Scholar] [CrossRef]

- Lee, D. An Experimental Investigation in the Effects of Detailing on the Shear Behaviour of Deep Beams. Ph.D. Dissertation, University of Toronto, Toronto, ON, Canada, 1982. [Google Scholar]

- Mathey, R.G.; Watstein, D. Shear strength of beams without web reinforcement containing deformed bars of different yield strengths. ACI J. 1963, 60, 183–208. [Google Scholar] [CrossRef]

- Leonhardt, F.; Walther, R. The Stuttgart shear tests. Cem. Concr. Assoc. Libr. 1961, 11, 49–54. [Google Scholar]

- Subedi, N.K. Reinforced concrete deep beams: A method of analysis. Proc. Inst. Civ. Eng. 1988, 85, 1–30. [Google Scholar] [CrossRef]

- Walravena, J.; Lehwalter, N. Size effects in short beams loaded in shear. ACI Struct. J. 1994, 91, 585–593. [Google Scholar] [CrossRef]

- Adebar, P. One way shear strength of large footings. Can. J. Civ. Eng. 2000, 27, 553–562. [Google Scholar] [CrossRef]

- Yang, K.H.; Chung, H.S.; Lee, E.T. Shear characteristics of high-strength concrete deep beams without shear reinforcements. Eng. Struct. 2003, 25, 1343–1352. [Google Scholar] [CrossRef]

- Tanimura, Y.; Sato, T. Evaluation of shear strength of deep beams with stirrups. Q. Rep. RTRI 2005, 46, 53–58. [Google Scholar] [CrossRef]

- Salamy, M.R.; Kobayashi, H.; Unjoh, S. Experimental and analytical study on RC deep beams. Asian J. Civ. Eng. 2005, 104, 409–422. [Google Scholar]

- Zhang, N.; Tan, K.H. Size effect in RC deep beams: Experimental investigation and STM verification. Eng. Struct. 2007, 29, 3241–3254. [Google Scholar] [CrossRef]

- Garay, J.D.; Lu, A.S. Behavior of concrete deep beams with high strength reinforcement. Struct. Congr. 2008, 4, 1–10. [Google Scholar] [CrossRef]

- Brena, S.F.; Roy, N.C. Evaluation of load transfer and strut strength of deep beams with short longitudinal bar anchorages. ACI Struct. J. 2009, 106, 678–689. [Google Scholar] [CrossRef]

- Kosa, K. Discussion on experimental analysis of reinforced concrete deep beams. J. JSCE 2009, 65, 368–383. [Google Scholar]

- Zhang, N.; Tan, K.H.; Leong, C.L. Single-span deep beams subjected to unsymmetrical loads. J. Struct. Eng. 2009, 135, 239–252. [Google Scholar] [CrossRef]

- Sagaseta, J.; Vollum, R.L. Shear design of short-span beams. Mag. Concr. Res. 2010, 62, 267–282. [Google Scholar] [CrossRef]

- Sahoo, D.K.; Sagi, M.V.; Singh, B. Effect of detailing of web reinforcement on the behavior of bottle-shaped struts. J. Adv. Concr. Technol. 2010, 8, 303–314. [Google Scholar] [CrossRef]

- Senturk, A.E.; Higgins, C. Valuation of reinforced concrete deck girder bridge bent caps with 1950s vintage details: Laboratory Tests. ACI Struct. J. 2010, 107, 534–543. [Google Scholar]

- Mihaylov, B.I.; Bentz, E.C.; Collins, M.P. Behavior of large deep beam subjected to monotonic and reversed cyclic shear. ACI Struct. J. 2010, 107, 726–734. [Google Scholar] [CrossRef]

- Lin, Y. Experimental Investigation and Finite Element Analysis of RC Simple Supported Deep Beam; Hunan University: Changsha, China, 2011. [Google Scholar]

- Hanifi, G.Y.; Nakamura, H.; Yamamoto, Y. Effect of stirrups on the shear failure mechanism of deep beams. J. Adv. Concr. Technol. 2012, 10, 14–30. [Google Scholar] [CrossRef]

- Aguilar, G.; Matamoros, A.B.; Parra-Montesinos, G.; Ramírez, J.A.; Wight, J.K. Experimental evaluation of design procedures for shear strength of deep reinforced concrete beams. ACI Struct. J. 2002, 99, 539–548. [Google Scholar] [CrossRef]

- Quintero-Febres, C.G.; Parra-Montesinos, G.; Wight, J.K. Strength of struts in deep concrete members designed using strut-and-tie method. ACI Struct. J. 2006, 103, 577–586. [Google Scholar] [CrossRef]

- Box, G.E.P.; Tiao, G.C. Bayesian Inference in Statistical Analysis; Wiley Classics Library: New York, NY, USA, 2011. [Google Scholar]

- Gardoni, P.; Der Kiureghian, A.; Mosalam, K.M. Probabilistic capacity models and fragility estimates for reinforced concrete columns based on experimental observations. J. Eng. Mech. 2002, 128, 1024–1038. [Google Scholar] [CrossRef]

- Chib, S.; Greenberg, E. Understanding the Metropolis-Hastings algorithm. Am. Stat. 1995, 49, 327–335. [Google Scholar]

- Alan, E.G. Gibbs sampling. J. Am. Stat. Assoc. 2000, 95, 1300–1304. [Google Scholar]

- Chetchotisak, P.; Teerawong, J.; Chetchotsak, D.; Yindeesuk, S. Efficiency factors for reinforced concrete deep beams: Part 1-Improved models. Adv. Mater. Res. 2014, 931, 506–513. [Google Scholar] [CrossRef]

- Schueller, G.I. Efficient Monte Carlo simulation procedures in structural uncertainty and reliability analysis-recent advances. Struct. Eng. Mech. 2009, 32, 1–20. [Google Scholar] [CrossRef]

- Caspeele, R.; Sykora, M.; Allaix, D.L.; Steenbergen, R. The design value method and adjusted partial factor approach for existing structures. Struct. Eng. Int. 2013, 23, 386–393. [Google Scholar] [CrossRef]

- Sykora, M.; Holicky, M.; Krejsa, J. Model uncertainty for shear resistance of reinforced concrete beams with shear reinforcement according to EN 1992-1-1. Trans. VŠB-Tech. Univ. Ostrav. Civ. Eng. Ser. 2013, 13, 150–159. [Google Scholar] [CrossRef]

- Sykora, M.; Holicky, M.; Markova, J. Verification of existing reinforced concrete bridges using the semi-probabilistic approach. Eng. Struct. 2013, 56, 1419–1426. [Google Scholar] [CrossRef]

- ISO 2394; General Principles on Reliability for Structures. International Organization for Standardization: Geneva, Switzerland, 2015.

- fib COM3 TG3.1; Partial Factor Methods for Existing Structures (fib Bulletin 80, Recommendation). International Federation for Structural Concrete: Lausanne, Switzerland, 2016.

| Literature | Quantity | fc′/MPa | a/d | Vtest/kN |

|---|---|---|---|---|

| Kong et al., 1970 [30] | 33 | 18.6~26.8 | 0.35–0.18 | 78.0–308.0 |

| Tan et al., 1997 [31] | 18 | 86.3~56.2 | 0.85–1.69 | 185.0–775.0 |

| Liu et al., 2000 [32] | 5 | 19.6~26.1 | 0.5–2.50 | 64.7–180.2 |

| Manuel et al., 1971 [33] | 12 | 30.1~44.8 | 0.30–1.00 | 226.9–258.0 |

| Smith et al., 1982 [34] | 52 | 20.4~28.7 | 0.77–2.01 | 73.4–178.5 |

| Gong 1982 [35] | 39 | 18.3~30.1 | 0.36–1.94 | 67.6–411.6 |

| Mphonde et al., 1984 [36] | 10 | 20.6~83.8 | 1.50–2.94 | 87.700–558.1 |

| Fang 1990 [37] | 5 | 33.7~37.0 | 0.75–0.84 | 434.0–472.0 |

| Tan et al., 1995 [38] | 19 | 41.1~58.8 | 0.27–2.70 | 105.0–675.0 |

| Tan et al., 1997 [39] | 15 | 72.1~64.6 | 0.28~1.28 | 150.0~925.0 |

| Foster et al., 1998 [28] | 5 | 120.0~89.0 | 0.87~0.88 | 950.0~2000.0 |

| Shin et al., 1999 [40] | 13 | 52.0~73.0 | 1.50~2.00 | 90.0~287.1 |

| Tan et al., 1999 [41] | 12 | 30.8~49.1 | 0.56~1.13 | 435.0~1636.0 |

| Tan et al., 2008 [42] | 4 | 32.7~37.6 | 0.42~0.84 | 331.5~1305.0 |

| Oh et al., 2001 [43] | 53 | 23.7~73.6 | 0.50~2.00 | 112.5~745.6 |

| Kani 1967 [44] | 5 | 26.7~31.4 | 1.00~1.03 | 155.2~585.4 |

| Rogowsky et al., 1986 [45] | 16 | 26.1~43.2 | 1.02~2.08 | 185.0~875.0 |

| Lu et al., 2013 [46] | 13 | 34.6~67.8 | 0.61~0.83 | 1156.0~2018.0 |

| Teng et al., 2000 [47] | 6 | 34.0~41.0 | 1.71 | 225.0~450.0 |

| Moody et al., 1954 [48] | 14 | 17.2~25.4 | 1.52 | 267.6~507.1 |

| Laupa 1955 [49] | 9 | 23.5~26.2 | 1.17~0.56 | 94.2~260.0 |

| Morrow et al., 1957 [50] | 21 | 11.3~46.8 | 0.95~1.00 | 129.0~900.7 |

| Ramakrishnan et al., 1968 [51] | 20 | 10.8~28.4 | 0.30~1.00 | 40.0~193.0 |

| Lee 1982 [52] | 3 | 28.0–33.5 | 1.56–1.70 | 840.0–967.5 |

| Mathey et al., 1963 [53] | 16 | 21.9–27.0 | 1.51 | 179.5–312.9 |

| Leonhardt et al., 1961 [54] | 3 | 32.4 | 1.00–2.00 | 80.2–120.3 |

| Subedi 1988 [55] | 5 | 29.6–41.6 | 0.31–1.53 | 175.0–797.5 |

| Walraven et al., 1994 [56] | 25 | 13.9–26.4 | 0.97–1.01 | 109.0–669.1 |

| Adebar 2000 [57] | 6 | 19.5–21.0 | 1.43–2.20 | 330.0–771.0 |

| Yang et al., 2003 [58] | 19 | 31.4–78.5 | 0.36–1.41 | 192.1–1029.0 |

| Tanimura et al., 2005 [59] | 41 | 22.5–97.5 | 0.50–1.50 | 184.23–739.77 |

| Salamy et al., 2005 [60] | 12 | 29.2–37.8 | 0.50–1.50 | 308.0–980.0 |

| Zhang et al., 2007 [61] | 12 | 24.8~32.4 | 1.10 | 85.0~775.0 |

| Garay et al., 2008 [62] | 2 | 43.0~44.0 | 1.19~1.78 | 1027.5~1373.5 |

| Brena et al., 2009 [63] | 7 | 27.0~34.1 | 1.00~1.50 | 211.0~371.0 |

| Kosa 2009 [64] | 18 | 23.0~42.3 | 1.00 | 195.0~4198.0 |

| Zhang et al., 2009 [65] | 11 | 38.3~41.2 | 0.57~1.42 | 240.1~665.4 |

| Sagaseta et al., 2010 [66] | 6 | 68.4~80.2 | 1.51 | 326.0~602.0 |

| Sahoo et al., 2010 [67] | 11 | 36.3~45.2 | 0.50 | 303.2~371.2 |

| Senturk et al., 2010 [68] | 2 | 24.4~26.2 | 1.37 | 1307.0~1809.0 |

| Mihaylov et al., 2010 [69] | 6 | 29.1~37.8 | 1.55~2.29 | 416.0~1162.0 |

| Lin 2011 [70] | 4 | 25.8~30.1 | 0.86~1.02 | 260.0~460.0 |

| Hanifi et al., 2012 [71] | 8 | 22.1~35.7 | 0.50~2.00 | 65.0~329.0 |

| Aguilar et al., 2002 [72] | 4 | 28.0~32.0 | 1.14~1.27 | 1134.0~1357.0 |

| Quintero et al., 2006 [73] | 12 | 22.0~50.3 | 0.81~1.57 | 196.0~484.0 |

| Subedi 1988 [74] | 12 | 22.4~29.2 | 0.43~1.56 | 78.0~485.0 |

| Design Provisions | Shear Calculation Model | Mean | SD | CoV |

|---|---|---|---|---|

| ACI318-14 (2014) [23] | 1.1637 | 0.4148 | 0.3565 | |

| GB 50010-10 (2010) [24] | 1.6164 | 0.6075 | 0.3758 | |

| CSA A23.3-04 (2004) [25] | 1.2327 | 0.6464 | 0.3690 | |

| EC2 (2004) [26] | 1.2179 | 0.6310 | 0.5181 | |

| CEB-FIP (2010) [27] | 1.3641 | 0.4302 | 0.3154 | |

| Foster and Gilbert (1998) [28] | 1.0900 | 0.4594 | 0.4215 | |

| Mitchell and Collins (1974) [29] | 1.2440 | 0.4015 | 0.3228 |

| Model Parameter | θ1 | θ2 | θ3 | θ4 | θ5 | θ6 | θ7 | θ8 | θ9 | σ2 |

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | −5.770 | 0.896 | 1.039 | 0.835 | −0.614 | −0.065 | 0.184 | 0.056 | 0.326 | 0.082 |

| SD | 0.221 | 0.040 | 0.029 | 0.033 | 0.034 | 0.040 | 0.029 | 0.020 | 0.022 | 0.005 |

| CoV | 0.038 | 0.045 | 0.028 | 0.040 | 0.054 | 0.621 | 0.158 | 0.358 | 0.067 | 0.055 |

| Naive SE (×10−4) | 9.880 | 1.809 | 1.299 | 1.479 | 1.501 | 1.797 | 1.295 | 9.002 | 0.969 | 0.201 |

| Time-series SE (×10−4) | 9.880 | 1.809 | 1.305 | 1.468 | 1.797 | 1.797 | 1.295 | 9.002 | 0.969 | 0.204 |

| 2.5% quantile | −6.202 | 0.817 | 0.981 | 0.769 | −0.680 | −0.143 | 0.127 | 0.017 | 0.283 | 0.074 |

| 97.5% quantile | −5.333 | 0.975 | 1.095 | 0.899 | −0.548 | 0.014 | 0.240 | 0.096 | 0.368 | 0.092 |

| Step | Posterior CoV of the Corresponding θi | |||||||||

| θ1 | θ2 | θ3 | θ4 | θ5 | θ6 | θ7 | θ8 | θ9 | σ | |

| (Constant) | (lnft) | (lnb) | (lnh) | (lna/d) | (lnl0/h) | (ρv) | (ρh) | (lnρ) | ||

| Initial | 0.0383 | 0.0492 | 0.028 | 0.0396 | 0.0547 | 0.6214 | 0.3677 | 0.3589 | 0.0665 | 0.0546 |

| 1st | 0.0373 | 0.0441 | 0.0280 | 0.0390 | 0.0412 | × | 0.3552 | 0.3514 | 0.0674 | 0.0545 |

| 2nd | 0.0394 | 0.0450 | 0.0292 | 0.0408 | 0.0419 | × | × | 0.3374 | 0.0647 | 0.0545 |

| 3sd | 0.0399 | 0.0450 | 0.0290 | 0.0403 | 0.0419 | × | × | × | 0.0646 | 0.0542 |

| 4th | 0.2166 | 0.1187 | 0.2603 | 0.1192 | 0.0789 | × | × | × | × | 0.0544 |

| Step | Posterior Mean of the Corresponding θi | |||||||||

| θ1 | θ2 | θ3 | θ4 | θ5 | θ6 | θ7 | θ8 | θ9 | SD | |

| (Constant) | (lnft) | (lnb) | (lnh) | (lna/d) | (lnl0/h) | (ρv) | (ρh) | (lnρ) | ||

| Initial | −5.7707 | 0.8957 | 1.0385 | 0.8349 | −0.6137 | −0.0647 | 0.1837 | 0.0561 | 0.3258 | 0.2249 |

| 1st | −5.8362 | 0.8761 | 1.0359 | 0.8412 | −0.6469 | × | 0.1860 | 0.0578 | 0.3205 | 0.2276 |

| 2nd | −5.5820 | 0.8796 | 1.0122 | 0.8256 | −0.6523 | × | × | 0.0618 | 0.3385 | 0.2379 |

| 3sd | −5.5223 | 0.8829 | 0.9899 | 0.8354 | −0.6567 | × | × | × | 0.3418 | 0.2396 |

| 4th | 1.8175 | 0.5812 | 0.1994 | −0.4868 | 0.3363 | × | × | × | × | 0.2914 |

| Prior Model | Posterior Mean of the Corresponding θi | |||||||

|---|---|---|---|---|---|---|---|---|

| Constant | fc′/fy (fcu/fy) | a/d | l0/h | b/h | ρv | ρh | ρ | |

| GB50010-2010 | 1.3460 | × 1 | −0.2506 | × 3 | × 2 | −0.0894 | −0.1960 | 0.4416 |

| ACI 318-14 | 0.6310 | −0.2403 | × 2 | −0.4193 | −0.1992 | × 3 | × 1 | 0.1905 |

| CSA 23.3-04 | 1.3209 | × 3 | 0.8291 | × 2 | −0.1432 | 0.1116 | × 1 | 0.0031 |

| EC2 | 1.4215 | −0.1016 | 0.6843 | −0.1672 | × 1 | 0.1652 | × 2 | × 3 |

| CEB-FIP | 1.2508 | × 3 | −0.1324 | −0.2691 | −0.1659 | × 1 | × 2 | 0.2033 |

| Foster and Gilbert | 0.7606 | −0.1244 | × 3 | −0.5332 | −0.2717 | × 1 | × 2 | 0.2932 |

| Mitchell and Collins | 1.2960 | 0.1484 | × 2 | × 3 | −0.1780 | 0.1729 | 0.0693 | × 1 |

| Model | Bias Correction Term | Mean | SD | COV |

|---|---|---|---|---|

| The Proposed Model | 1.0357 | 0.2396 | 0.2312 | |

| GB50010-2010 | 1.0384 | 0.2908 | 0.2803 | |

| ACI 318-14 | 1.0387 | 0.2906 | 0.2798 | |

| CSA 23.3-04 | 1.0744 | 0.3421 | 0.3184 | |

| EC2 | 1.0647 | 0.4129 | 0.3879 | |

| CEB-FIP | 1.0322 | 0.2622 | 0.2540 | |

| Foster and Gilbert | 1.0557 | 0.3729 | 0.3542 | |

| Mitchell and Collins | 1.0396 | 0.2866 | 0.2756 |

| Level of Approximation | n | Proposed Model | ACI | ACI.MCMC | ||||

|---|---|---|---|---|---|---|---|---|

| Description of Sample | Mean | CoV | Mean | CoV | Mean | CoV | ||

| Whole Databases | 645 | 1.0357 | 0.2263 | 1.1637 | 0.3565 | 1.0387 | 0.2798 | |

| Concrete compressive strength | Normal strength 10~40 MPa | 457 | 1.0402 | 0.2169 | 1.2491 | 0.3437 | 1.0733 | 0.2812 |

| High strength 40~70 MPa | 129 | 1.0201 | 0.2156 | 1.0210 | 0.2865 | 0.9941 | 0.2570 | |

| Ultra strength 70~120 MPa | 59 | 1.0356 | 0.3101 | 0.8140 | 0.2704 | 0.8686 | 0.2173 | |

| Reinforcement ratio | 0 < ρ ≤ 1.0 | 96 | 1.0558 | 0.2494 | 1.3640 | 0.4725 | 1.0827 | 0.3050 |

| 1.0 < ρ ≤ 2.0 | 273 | 1.0177 | 0.2346 | 1.1250 | 0.3442 | 1.0441 | 0.2694 | |

| 2.0 < ρ ≤ 5.0 | 276 | 1.0466 | 0.2092 | 1.1325 | 0.2728 | 1.0182 | 0.2795 | |

| Component section size | 0 < b/h ≤ 0.2 | 156 | 1.0408 | 0.2752 | 1.5299 | 0.3259 | 1.1142 | 0.2662 |

| 0.2 < b/h ≤ 0.4 | 296 | 1.0537 | 0.2082 | 1.0485 | 0.2769 | 0.9683 | 0.2565 | |

| 0.4 < b/h ≤ 0.7 | 193 | 1.0029 | 0.2106 | 1.0630 | 0.3184 | 1.0935 | 0.2945 | |

| Shear span ratio | 0 < a/d ≤ 1.0 | 246 | 1.0367 | 0.2320 | 1.3359 | 0.3608 | 1.0558 | 0.2746 |

| 1.0 < a/d ≤ 2.0 | 211 | 1.0991 | 0.1838 | 1.0971 | 0.2688 | 0.9950 | 0.2337 | |

| 2.0 < a/d ≤ 5.0 | 188 | 0.9633 | 0.2495 | 1.0129 | 0.3477 | 1.0654 | 0.3209 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Liu, X.; Kou, D.; Hu, Y.; Zhang, Q.; Yuan, Q. Probabilistic Models for the Shear Strength of RC Deep Beams. Appl. Sci. 2023, 13, 4853. https://doi.org/10.3390/app13084853

Li Z, Liu X, Kou D, Hu Y, Zhang Q, Yuan Q. Probabilistic Models for the Shear Strength of RC Deep Beams. Applied Sciences. 2023; 13(8):4853. https://doi.org/10.3390/app13084853

Chicago/Turabian StyleLi, Zhenjun, Xi Liu, Dawei Kou, Yi Hu, Qingrui Zhang, and Qingxi Yuan. 2023. "Probabilistic Models for the Shear Strength of RC Deep Beams" Applied Sciences 13, no. 8: 4853. https://doi.org/10.3390/app13084853

APA StyleLi, Z., Liu, X., Kou, D., Hu, Y., Zhang, Q., & Yuan, Q. (2023). Probabilistic Models for the Shear Strength of RC Deep Beams. Applied Sciences, 13(8), 4853. https://doi.org/10.3390/app13084853