Equivalent Stress Intensity Factor: The Consequences of the Lack of a Unique Definition

Abstract

1. Introduction

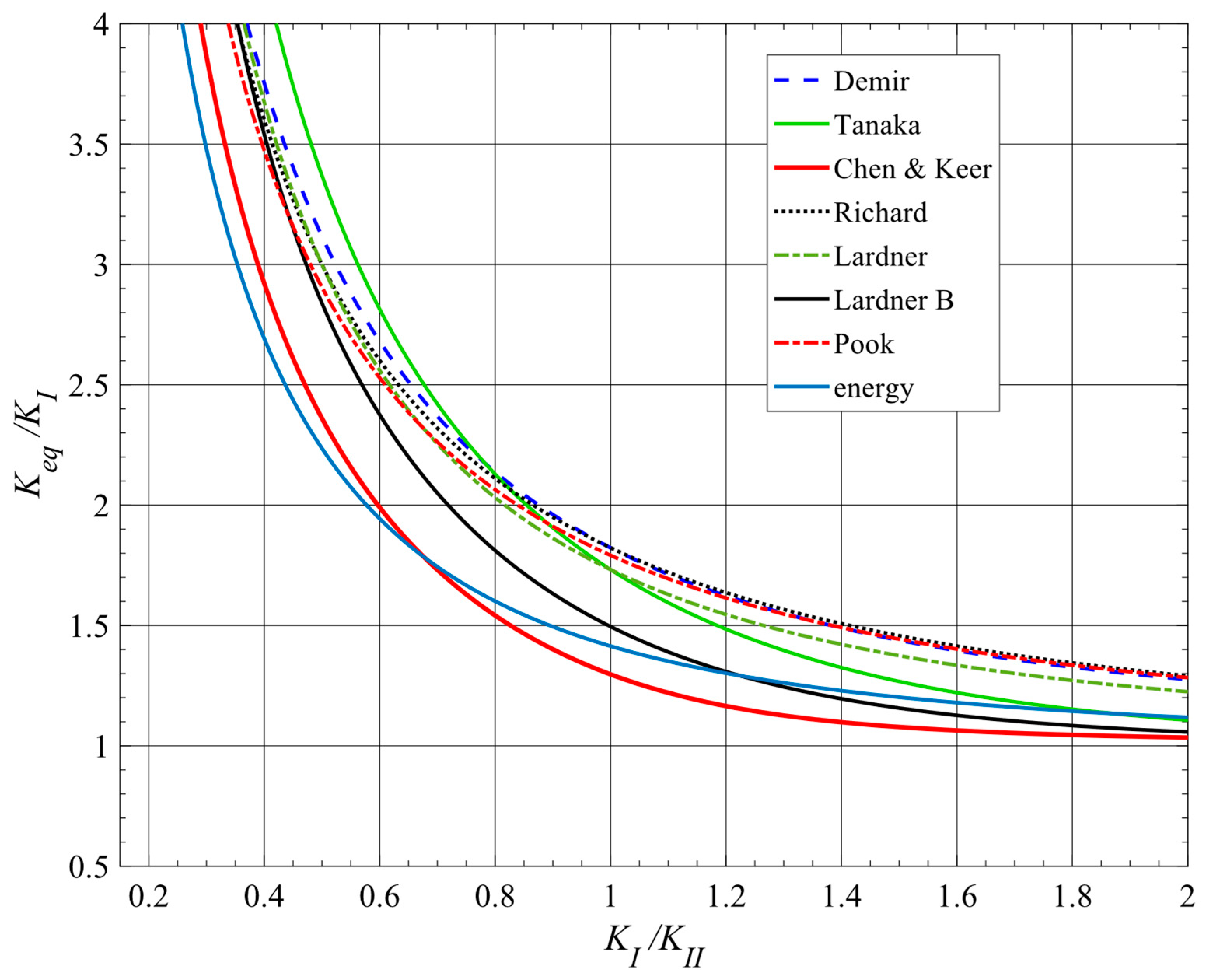

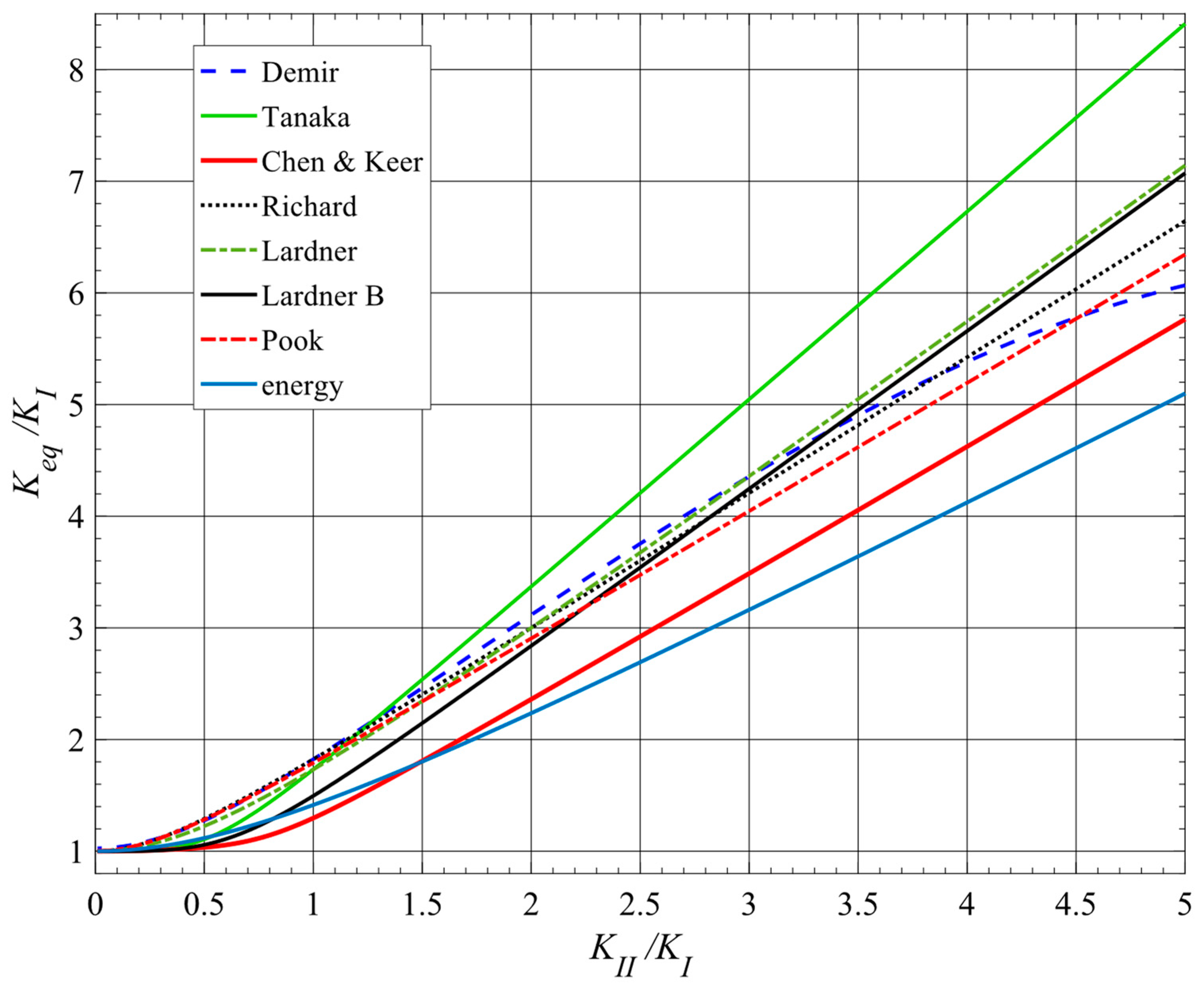

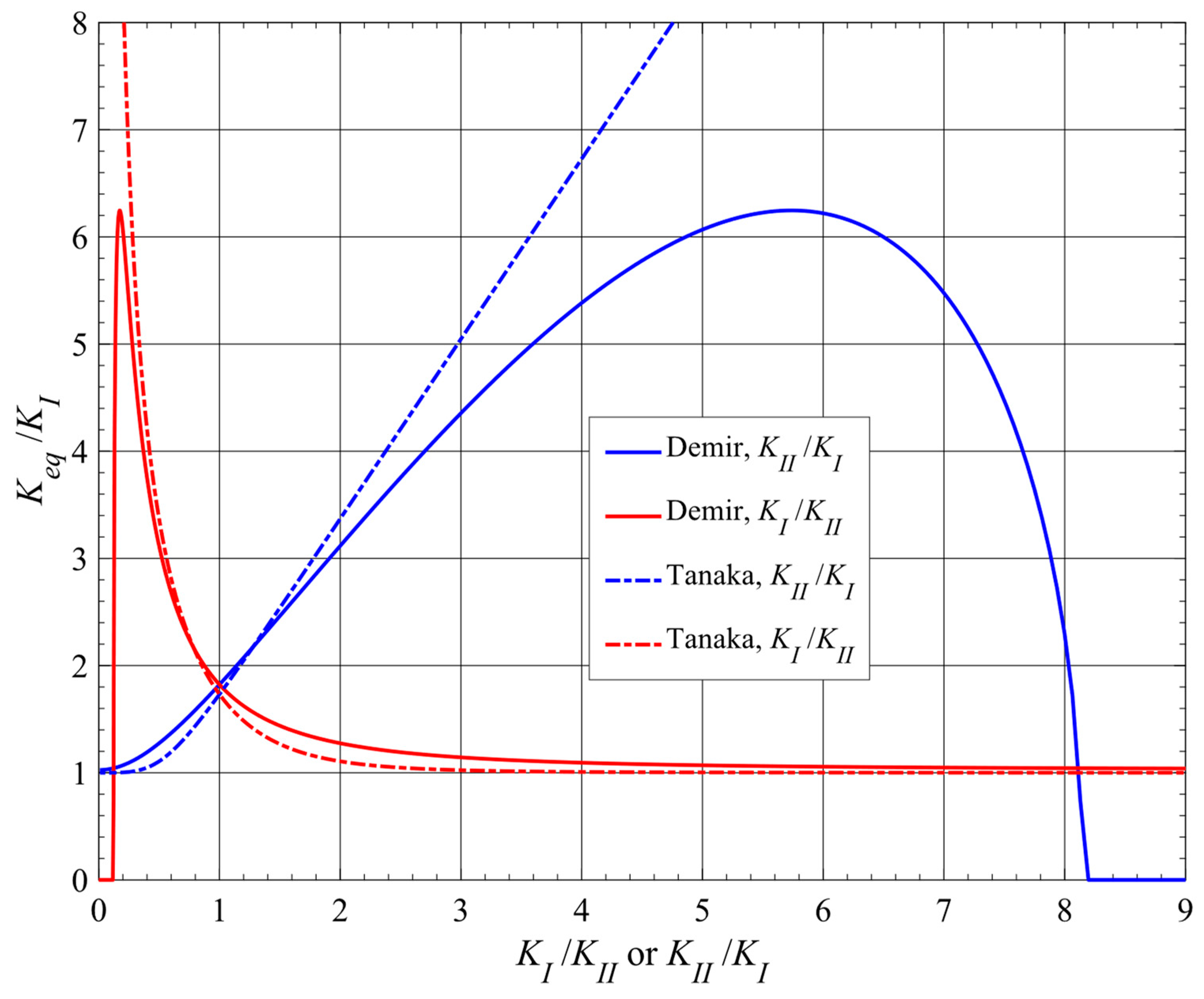

2. The Equivalent Stress Intensity Factor Keq

2.1. Energy Approach

2.2. Tanaka’s Approach

2.3. Lardner’s Approach

2.4. Chen and Keer Approach

2.5. Pook’s Approach

2.6. Demir’s Approach

2.7. Richard/Henn Approach

3. Comparisons

4. Experimental Data and Discussion

5. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zehnder, A.T. Fracture Mechanics; Springer Science + Business Media, B.V.: London, UK, 2012. [Google Scholar]

- Perez, N. Fracture Mechanics, 2nd ed.; Springer International Publishing AG: Cham, Switzerland, 2017. [Google Scholar]

- Paris, P.C.; Gomez, M.P.; Anderson, W.E. A rational analytic theory of fatigue. Trend Eng. 1961, 13, 9–14. [Google Scholar]

- Paris, P.C. Fracture mechanics and fatigue: A historical perspective. Fatigue Fract. Eng. Mater. Struct. 1998, 21, 535–540. [Google Scholar] [CrossRef]

- Baganha-Marques, J.; Tavares, S.M.O.; de Castro, P.M.S.T. Analysis of mode II and mixed mode I-II in fracture and fatigue: A numerical and experimental study. In Materials Design and Applications II; da Silva, L.F.M., Ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 403–423. [Google Scholar]

- Tavares, S.M.O.; Reis, L.; de Freitas, M.; de Castro, P.M.S.T. Mixed mode fatigue and fracture in planar geometries: Observations on Keq and crack path modelling. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2441–2456. [Google Scholar] [CrossRef]

- ABAQUS. Abaqus/Standard Analysis User’s Manual; Dassault Systems Simulia Corporation: Providence, RI, USA, 2017. [Google Scholar]

- Butler, K.T.; Davies, D.W.; Cartwright, H.; Isayev, O.; Walsh, A. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; He, X.; Tu, Z.C. Prediction of fatigue–crack growth with neural network-based increment learning scheme. Eng. Fract. Mech. 2021, 241, 107402. [Google Scholar] [CrossRef]

- Mortazavi, S.N.S.; Ince, A. An artificial neural network modeling approach for short and long fatigue crack propagation. Comput. Mater. Sci. 2020, 185, 109962. [Google Scholar] [CrossRef]

- Raja, A.; Chukka, S.T.; Jayaganthan, R. Prediction of fatigue crack growth behaviour in ultrafine grained Al 2014 alloy using machine learning. Metals 2020, 10, 1349. [Google Scholar] [CrossRef]

- Zafar, M.H.; Younis, H.B.; Mansoor, M.; Moosavi, S.K.R.; Khan, N.M.; Akhtar, N. Training deep neural networks with novel metaheuristic algorithms for fatigue crack growth prediction in aluminum aircraft alloys. Materials 2022, 15, 6198. [Google Scholar] [CrossRef]

- Irwin, G.R. Analysis of stresses and strains near the end of a crack traversing a plate. J. Appl. Mech. 1957, 24, 361–364. [Google Scholar] [CrossRef]

- Radaj, D. Extended stress intensity factor concepts. In Advanced Methods of Fatigue Assessment; Radaj, D., Vormwald, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 101–265. [Google Scholar]

- Ramulu, M.; Kobayashi, A.S. Numerical and experimental study of mixed mode fatigue crack propagation. In Handbook of Fatigue Crack Propagation in Metallic Structures; Carpinteri, A., Ed.; Elsevier: Amsterdam, The Netherlands, 1994; Volume 2, pp. 1073–1123. [Google Scholar]

- Réthoré, J.; Gravouil, A.; Morestin, F.; Combescure, A. Estimation of mixed-mode stress intensity factors using digital image correlation and an interaction integral. Int. J. Fract. 2005, 132, 65–79. [Google Scholar] [CrossRef]

- Rhee, H.C.; Salama, M.M. Mixed-mode stress intensity factor solutions of a warped surface flaw by three-dimensional finite element analysis. Eng. Fract. Mech. 1987, 28, 203–209. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, Z.M.; Liu, H.J. On the I–II mixed mode fracture of granite using four-point bend specimen. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1193–1203. [Google Scholar] [CrossRef]

- Bezensek, B.; Hancock, J.W. Mode I and mixed-mode I/II crack tip fields unified by constraint. In Proceedings of the ECF15, Stockholm, Sweden, 11–13 August 2004. [Google Scholar]

- Tanaka, K. Fatigue crack propagation from a crack inclined to the cyclic tensile axis. Eng. Fract. Mech. 1974, 6, 493–507. [Google Scholar] [CrossRef]

- Qian, J.; Fatemi, A. Mixed mode fatigue crack growth: A literature survey. Eng. Fract. Mech. 1996, 55, 969–990. [Google Scholar] [CrossRef]

- Liu, L. Modeling of Mixed-Mode Fatigue Crack Propagation; Vanderbilt University: Nashville, TN, USA, 2008. [Google Scholar]

- Kim, J.-K.; Kim, C.-S. Fatigue crack growth behavior of rail steel under mode I and mixed mode loadings. Mater. Sci. Eng. A 2002, A338, 191–201. [Google Scholar] [CrossRef]

- Lardner, R.W. A dislocation model for fatigue crack growth in metals. Philos. Mag. A J. Theor. Exp. Appl. Phys. 1968, 17, 71–82. [Google Scholar] [CrossRef]

- Chen, W.R.; Keer, L.M. Fatigue crack growth in mixed mode loading. J. Eng. Mater. Technol. ASME Trans. 1991, 113, 222–227. [Google Scholar] [CrossRef]

- Pook, L.P. Crack Paths; WIT Press: Southampton, UK, 2002. [Google Scholar]

- Demir, O.; Ayhan, A.O.; Iriç, S. A new specimen for mixed mode-I/II fracture tests: Modeling, experiments and criteria development. Eng. Fract. Mech. 2017, 178, 457–476. [Google Scholar] [CrossRef]

- Demir, O.; Ayhan, A.O.; Iric, S.; Lekesiz, H. Evaluation of mixed mode-I/II criteria for fatigue crack propagation using experiments and modeling. Chin. J. Aeronaut. 2018, 31, 1525–1534. [Google Scholar] [CrossRef]

- Richard, H.A. Grundlagen und Anwendungen der Bruchmechaninik. Tech. Mech. 1990, 11, 69–80. [Google Scholar]

- Richard, H.A.; Linning, W.; Henn, K. Fatigue crack propagation under combined loading. Forensic Eng. 1991, 3, 99–109. [Google Scholar]

- Henn, K.; Richard, H.A. Some aspects of fatigue crack growth under mixed mode loading. In Proceedings of the 7th International Conference on Fracture—ICF7, Houston, TX, USA, 20–24 March 1989; Salama, K., Taplin, D.M.R., Rama-Rao, P., Ravi-Chandar, K., Eds.; Elsevier: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Borrego, L.P.; Antunes, F.V.; Costa, J.M.; Ferreira, J.M. Mixed-mode fatigue crack growth behaviour in aluminium alloy. Int. J. Fatigue 2006, 28, 618–626. [Google Scholar] [CrossRef]

- Peixoto, D.F.C.; de Castro, P.M.S.T. Fatigue crack growth of a railway wheel. Eng. Fail. Anal. 2017, 82, 420–434. [Google Scholar] [CrossRef]

- Richard, H.-A. Bruchvorhersagen bei überlagerter Normal- und Schubbeanspruchung von Rissen; VDI Forschungsheft; VDI-Verlag: Düsseldorf, Germany, 1985; pp. 1–60. [Google Scholar]

- Richard, H.A. Safety estimation for construction units with cracks under complex loading. In Proceedings of the Second International Conference on ‘Structural Failure, Product Liability and Technical Insurance’, Vienna, Austria, 1–3 July 1986; Rossmanith, H.P., Ed.; Inderscience: Geneva, Switzerland, 1986; pp. 423–437. [Google Scholar]

- Sander, M.; Richard, H.A. Lifetime predictions for real loading situations—Concepts and experimental results of fatigue crack growth. Int. J. Fatigue 2003, 25, 999–1005. [Google Scholar] [CrossRef]

- Richard, H.A. Crack problems under complex loading. In Proceedings of the International Conference on the Role of Fracture Mechanics in Modern Technology, Fukuoka, Japan, 2–6 June 1986; Sih, G.C., Nisitani, H., Ishihara, T., Eds.; North-Holland, 1987; pp. 577–588. [Google Scholar]

- Richard, H.A.; Fulland, M.; Buchholz, F.G.; Schöllmann, M. 3D fracture criteria for structures with cracks. Steel Res. 2003, 74, 491–497. [Google Scholar] [CrossRef]

- Richard, H.A.; Fulland, M.; Sander, M. Theoretical crack path prediction. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 3–12. [Google Scholar] [CrossRef]

- Richard, H.A.; Sander, M.; Fulland, M.; Kullmer, G. Development of fatigue crack growth in real structures. Eng. Fract. Mech. 2008, 75, 331–340. [Google Scholar] [CrossRef]

- Richard, H.A.; Sander, M. Ermüdungsrisse—Erkennen, Sicher Beurteilen, Vermeiden, 3rd ed.; Springer Vieweg: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Amato, D.; Yarullin, R.; Shlyannikov, V.; Citarella, R. Numerical and experimental investigation of mixed-mode crack growth in aluminum alloys. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 2854–2872. [Google Scholar] [CrossRef]

- Carvalho, D.; Silva, A.L.L.; Jesus, A.M.P.; Fernandes, A.A. Fatigue behaviour of structural steels. Comparison of strain-life and fatigue crack propagation data. Mec. Exp. 2015, 25, 67–78. [Google Scholar]

- Silva, A.L.L.; Jesus, A.M.P.; Xavier, J.; Correia, J.A.F.O.; Fernandes, A.A. Combined analytical-numerical methodologies for the evaluation of mixed-mode (I + II) fatigue crack growth rates in structural steels. Eng. Fract. Mech. 2017, 185, 124–138. [Google Scholar] [CrossRef]

- Akama, M. Fatigue crack growth under non-proportional mixed mode loading in rail and wheel steel. Part 1: Sequential mode I and mode II loading. Appl. Sci. 2019, 9, 2006. [Google Scholar] [CrossRef]

- Heirani, H.; Farhangdoost, K. Mixed mode I/II fatigue crack growth under tensile or compressive far-field loading. Mater. Res. Express 2017, 4, 116506. [Google Scholar] [CrossRef]

- Hong, S.; Kim, S.; Kim, J. Effects of mixed mode loading conditions on fatigue crack growth rate. Key Eng. Mater. 2019, 814, 176–181. [Google Scholar] [CrossRef]

- Alshoaibi, A.M.; Fageehi, Y.A. 3D modelling of fatigue crack growth and life predictions using ANSYS. Ain Shams Eng. J. 2022, 13, 101636. [Google Scholar] [CrossRef]

- Alshoaibi, A.M.; Fageehi, Y.A. Simulation of quasi-static crack propagation by adaptive finite element method. Metals 2021, 11, 16. [Google Scholar] [CrossRef]

- Alshoaibi, A.M. Fatigue crack growth analysis under constant amplitude loading using finite element method. Materials 2022, 15, 2937. [Google Scholar] [CrossRef]

- Ferreira, M.A.C.; Tavares, S.M.O.; Belinha, J.; de Castro, P.M.S.T. Mixed mode crack propagation: Numerical and experimental study. In Proceedings of the 7th International Conference on Mechanics and Materials in Design, Albufeira, Portugal, 25 April 2017; Silva-Gomes, J.F., Meguid, S.A., Eds.; INEGI-FEUP: Albufeira, Portugal, 2017. [Google Scholar]

- Alshoaibi, A.M. Computational simulation of 3D fatigue crack growth under mixed-mode loading. Appl. Sci. 2021, 11, 5953. [Google Scholar] [CrossRef]

- Alshoaibi, A.M. Numerical modeling of crack growth under mixed-mode loading. Appl. Sci. 2021, 11, 2975. [Google Scholar] [CrossRef]

- Sajith, S.; Shukla, S.S.; Murthy, K.S.R.K.; Robi, P.S. Mixed mode fatigue crack growth studies in AISI 316 stainless steel. Eur. J. Mech./A Solids 2020, 80, 103898. [Google Scholar] [CrossRef]

- Sajith, S.; Murthy, K.S.R.K.; Robi, P.S. Prediction of accurate mixed mode fatigue crack growth curves using the paris’ law. J. Inst. Eng. (India) Ser. C 2019, 100, 165–174. [Google Scholar] [CrossRef]

- Mueller, T.; Kusne, A.G.; Ramprasad, R. Machine learning in materials science: Recent progress and emerging applications. Rev. Comput. Chem. 2016, 29, 186–273. [Google Scholar]

- Shah, S.; Sarath, S.; Reddy, S. Similarity driven unsupervised learning for materials science terminology extraction. Comput. Sist. 2019, 23, 1005–1013. [Google Scholar] [CrossRef]

- Wang, Z. The investigation into the failure criteria of concrete based on the BP neural network. Eng. Fract. Mech. 2022, 275, 108835. [Google Scholar] [CrossRef]

- Younes, K.; Grasset, L. Carbohydrates as proxies in ombrotrophic peatland: DFRC molecular method coupled with PCA. Chem. Geol. 2022, 606, 120994. [Google Scholar] [CrossRef]

- Baptista, R.; Moita, P.; Infante, V. Fatigue crack growth on modified CT specimens using artificial neural networks. Int. J. Fatigue 2023, 167, 107357. [Google Scholar] [CrossRef]

- Athanasiou, C.E.; Padture, N.P.; Sheldon, B.W.; Gao, H. A machine learning approach to fracture mechanics problems. Acta Mater. 2020, 190, 105–112. [Google Scholar]

- Jin, H.; Zhang, E.; Espinosa, H.D. Recent advances and applications of machine learning in experimental solid mechanics: A review. arXiv 2023, arXiv:2303.07647. [Google Scholar]

| da/dN [mm/cycle] | KI, max [MPamm−1/2] | KII, max [MPamm−1/2] | |

|---|---|---|---|

| spec. #1 | 0.00015 | 172.3 | 512.9 |

| 5.9 × 10−5 | 738.6 | 9.6 | |

| 0.001 | 834.6 | 51 | |

| 0.01 | 1.08 × 103 | 83.7 | |

| spec. #3 | 9.70 × 10−5 | 344,7 | 258.9 |

| 0.0014 | 574.9 | 100.5 | |

| 0.00041 | 840 | 50.6 | |

| 0.006 | 919.4 | 183.5 | |

| 0.019 | 1169.8 | 132.3 |

| Keq = 400 MPamm−1/2 | Keq = 800 MPamm−1/2 | |

|---|---|---|

| Chen & Keer | 3.16 × 10−5 | 5.12 × 10−3 |

| Pook | 3.40 × 10−5 | 4.75 × 10−3 |

| Richard | 4.15 × 10−5 | 4.52 × 10−3 |

| Lardner | 5.62 × 10−5 | 4.14 × 10−3 |

| Tanaka | 8.76 × 10−5 | 4.27 × 10−3 |

| Energy/Irwin | 1.54 × 10−4 | 3.78 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tavares, S.M.O.; de Castro, P.M.S.T. Equivalent Stress Intensity Factor: The Consequences of the Lack of a Unique Definition. Appl. Sci. 2023, 13, 4820. https://doi.org/10.3390/app13084820

Tavares SMO, de Castro PMST. Equivalent Stress Intensity Factor: The Consequences of the Lack of a Unique Definition. Applied Sciences. 2023; 13(8):4820. https://doi.org/10.3390/app13084820

Chicago/Turabian StyleTavares, Sérgio M. O., and Paulo M. S. T. de Castro. 2023. "Equivalent Stress Intensity Factor: The Consequences of the Lack of a Unique Definition" Applied Sciences 13, no. 8: 4820. https://doi.org/10.3390/app13084820

APA StyleTavares, S. M. O., & de Castro, P. M. S. T. (2023). Equivalent Stress Intensity Factor: The Consequences of the Lack of a Unique Definition. Applied Sciences, 13(8), 4820. https://doi.org/10.3390/app13084820