1. Introduction

For the process of production of mineral resources in underground mines to proceed smoothly, it is necessary to ensure the functionality and stability of the underground rooms. Sometimes, to ensure both functionality and stability of the underground roadways, which are directly related, it is necessary to install a suitable support substructure. The support takes static and dynamic loads from the rock mass and begins to deform over time. For the unhindered passage of loading and transport machinery, it is necessary to design the underground roadway considering the minimum dimensions of the free cross-section of the underground roadway, including the legally defined minimum safety distances from the equipment to the walls and roof of the roadway. As time passes, the underground support suffers deformations, and it can happen that the minimum dimensions are violated, after which the transportation and export of useful mineral resources are suspended. In such cases, it is necessary to proceed with the reconstruction of the underground roadway, which can have a significant impact on the economic operation of the mine, because the reconstruction is both a financially and time-consuming process that impairs continuous production. To avoid such situations, it is necessary to conduct systematic monitoring of deformations of the support construction and provide a forecast of deformations. With proper forecasting, mining engineers can react in a timely manner and plan the replacement of the underground support in the necessary sections of the underground roadway. In this way, strategic management of the functionality of underground rooms and continuous production is achieved. The use of a laser scanner or similar instrument with the possibility of gathering high-accuracy data is necessary to obtain deformation data that can be used for analysis and forecasting the future states of the support construction.

Various approaches can be used to obtain future states of support construction. Deformation forecast has been the subject of research by many authors, with different approaches for prediction of tunnel surrounding rock displacement, structural deformations prediction, deformations of the lake bottom, landslide deformations, slope deformations, displacements of mining roadways, and so on. Wu et al. [

1] used two methodologies, support vector machines and artificial neural networks, to predict tunnels surrounding rock displacements; though the support vector machine gave more accurate predictions, it was more time-consuming than the artificial neural network. Luo et al. [

2] proposed a model based on temporal convolutional networks in their study for structural deformation prediction, which they verified with the cumulative strain data of the upper steel beam in the foundation pit in China as well as the structural subsidence data on the same location. Luan et al. [

3] showed that the grey model GM(1,1) could be used for the prediction of the deformations on the lake bottom. Ma et al. [

4] used tunnel geological information as well as monitoring measurement data to determine factor weights, and extension theory was used for the prediction model of tunnel deformations. In their study, Rao et al. [

5] used the grey model theory for the prediction of the large deformation of the tunnel. Guo et al. [

6] established a grey forecast model for rock deformation in a big tunnel cross section and concluded that it could be used in engineering practice. Prediction of the final displacement of underground structures based on the improved no equidistant grey Verhulst model was used by Han et al. [

7]. Xiong [

8] predicted displacements in tunnels surrounding rock using the grey system theory. For landslide deformations, displacements were predicted by a model combining extreme learning machines and grey wolf optimization by Zhang et al. [

9], and by using a new grey model prediction by Wu et al. [

10] as well as Li and Wu [

11]. Slope deformation prediction was calculated using the grey model by Li et al. [

12] and Zhang et al. [

13]. In the mining environment, multivariate singular spectrum analysis was used by Crnogorac et al. [

14] for accurate gate road support deformation forecasting. Zhu et al. [

15] proposed mining roadway displacement forecasting using the support vector machine theory. Xie et al. [

16] used a grey algebraic curve model for the prediction of the roof fall.

The aim of this paper is to develop an accurate grey forecasting algorithm for coal mines where large deformations of support constructions occur in a relatively short period of time. These deformations are the result of high underground pressure which occurs around the underground roadways, and the main factors for the occurrence of high underground pressure are bad geological conditions and poor physic-mechanical properties of the surrounding rock mass, as well as the presence of the clay which swells when in contact with water, adding additional pressure to support construction. In underground coal mines in the Republic of Serbia, the most used support for underground roadways is steel arch supports, followed by steel circular and wooden supports. Because of this, in our paper, we will focus on the deformations forecast in the case of the application of steel arch supports in underground roadways.

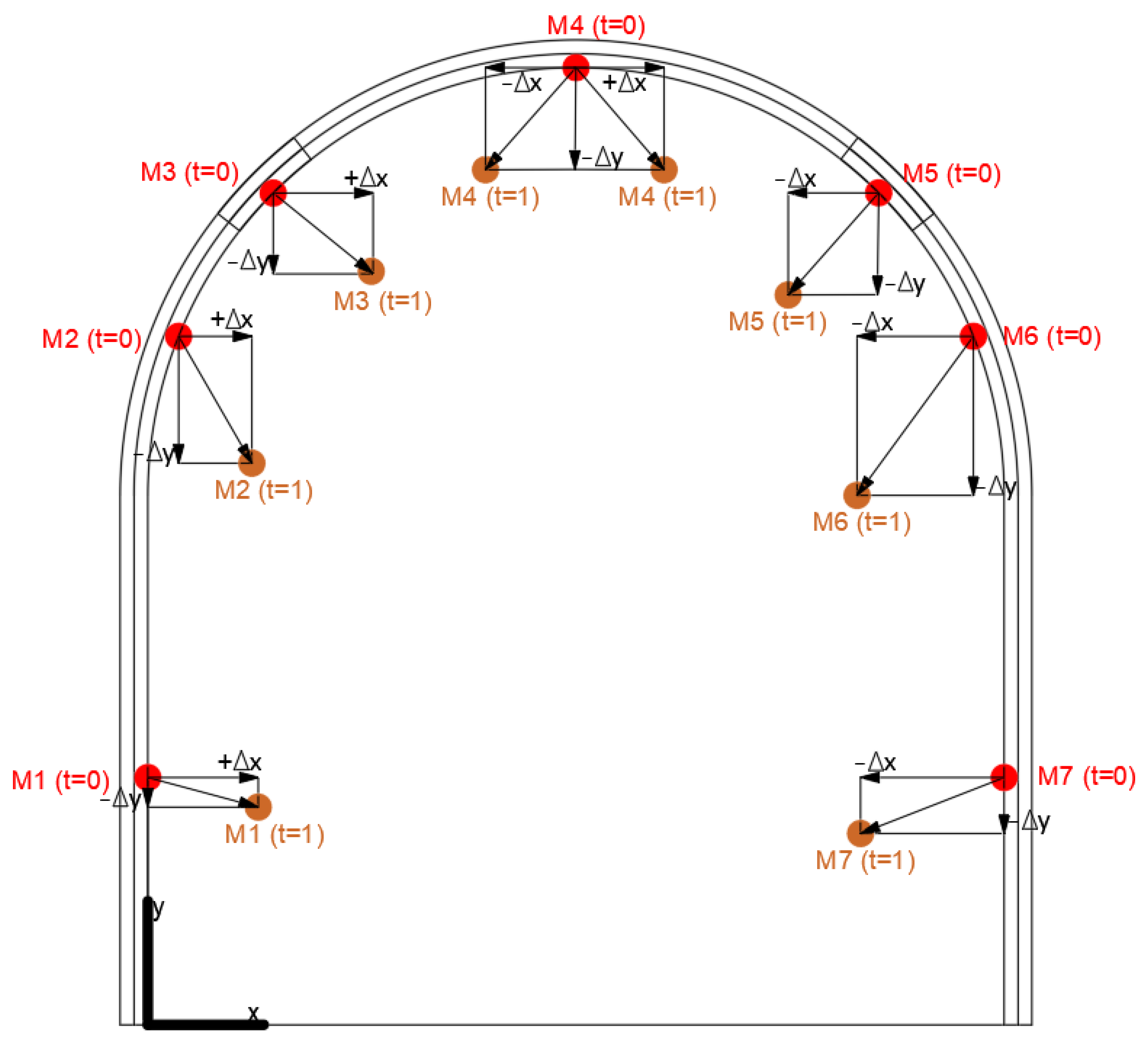

This paper has four sections. In the section Materials and Methods, the forecasting model of displacements of the steel arch support based on the grey system (1,1) and stochastic theory is described. A novel approach is used that considers the displacements of the markers along the steel arch support that better describes the real situation (an example was given for marker M4 and its movement along the x coordinate in both directions). Using grey–stochastic simulation and the autoregressive process, the configuration of the steel arch support was described and forecasted based on the observed data. For error estimation of the model due to the nature of the problem we described, besides the usual MAPE error approach, which deals with displacements of the marker along the x and y axes as two separated time series and does not consider the fitted position of the marker, we introduced the novel approach of model accuracy dealing with the analysis of the closeness between fitted and observed position of the marker. The calculation process is shown in the section Numerical Example to represent the possibilities of this model. All steps of the calculation in the section Numerical Example are discussed, and the results, efficiency, and the area of implementation of the model are represented. Results show that the model is capable, and it can be used, to solve real-time problems concerning the forecasting deformations of the steel arch support in underground coal mines.

3. Numerical Example

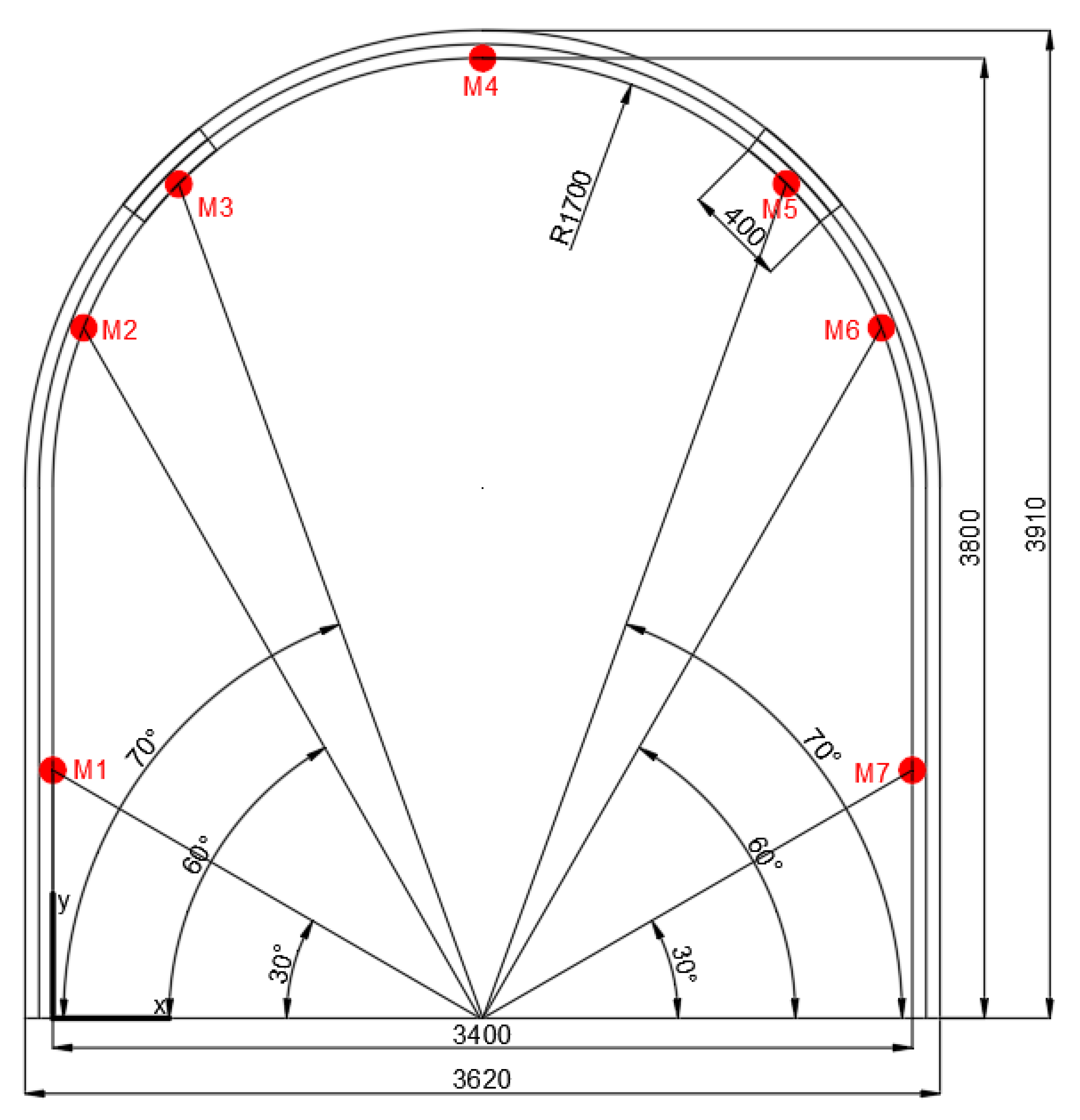

The hypothetical data used in this paper include daily values of displacements of markers along the

x- and

y-axis, respectively. The period of monitoring is thirty days. This set of displacements is divided into two subsets, fitting and forecasting subsets. The period ranging from the first to the twenty-fifth day (25 values) was used as the fitting subset, and within this interval, we checked the model accuracy by comparing the fitted and monitored values of displacements. The second subset ranging from twenty-six to thirty days (5 values) was used as the validity subset, and in this period, we made a comparison between forecasted and monitored displacements. The positions of seven markers are defined around the internal rim of the steel arch support; see

Figure 4.

Figure 4.

Steel arch support with positions of the markers.

Figure 4.

Steel arch support with positions of the markers.

The coordinates of markers during the monitoring period are presented in

Table 6, while the corresponding displacements are shown in

Table 7.

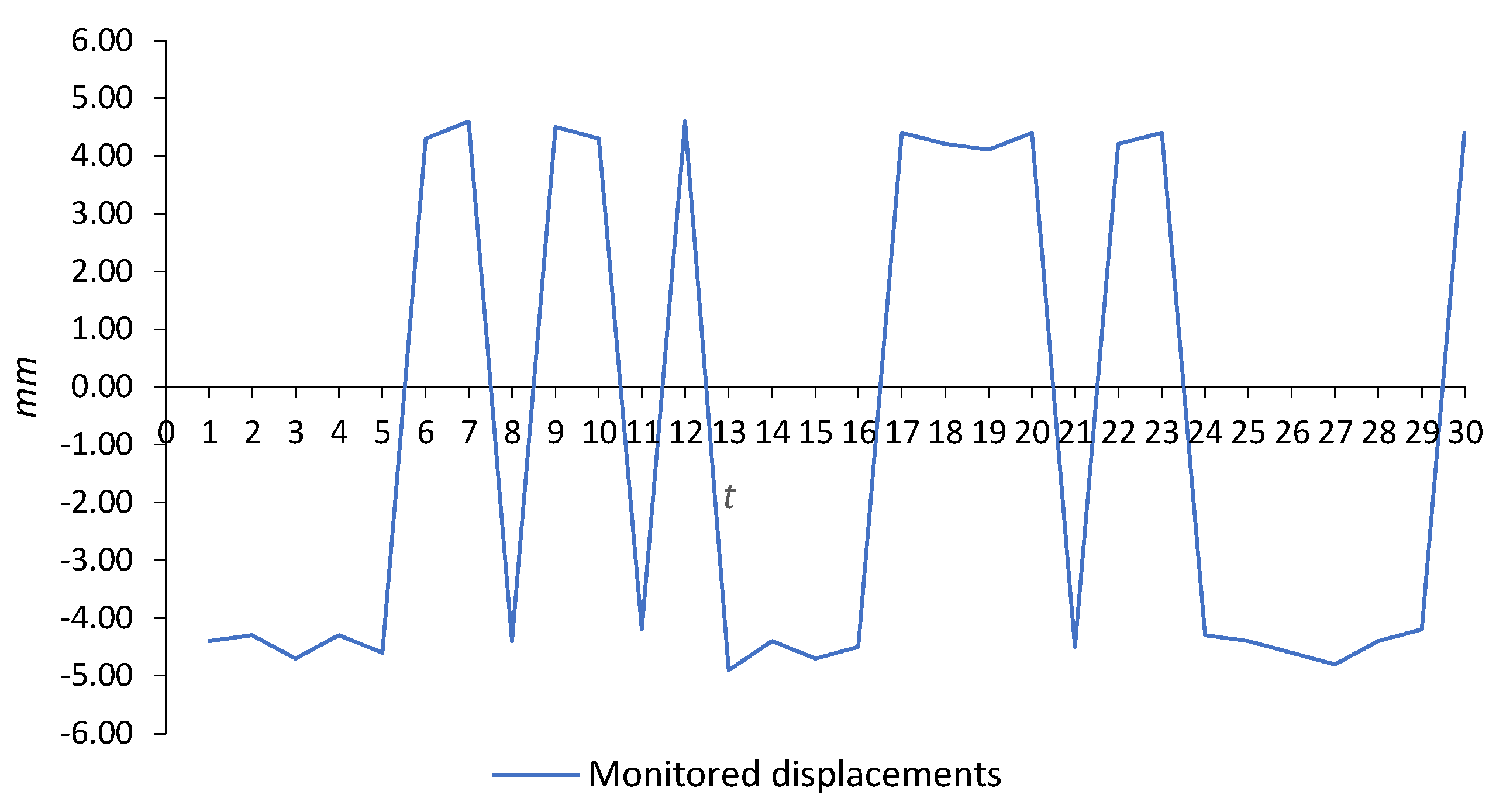

Time series related to displacements of marker M4 along the

x-axis was used to show how the model works.

Figure 5 presents displacements of marker M4 along the

x-axis.

Despite the randomness in displacement series, there are always some kinds of governing laws. From the previous plot, we can see that the displacement series is too complex and cannot be considered a regular one. According to Equation (3), the series belongs to a mixed time series (

MD state). Vector of transformation coefficients for the

MD state, and transformation from the

MD state to the

NN state, are shown in

Table 8 and

Figure 6.

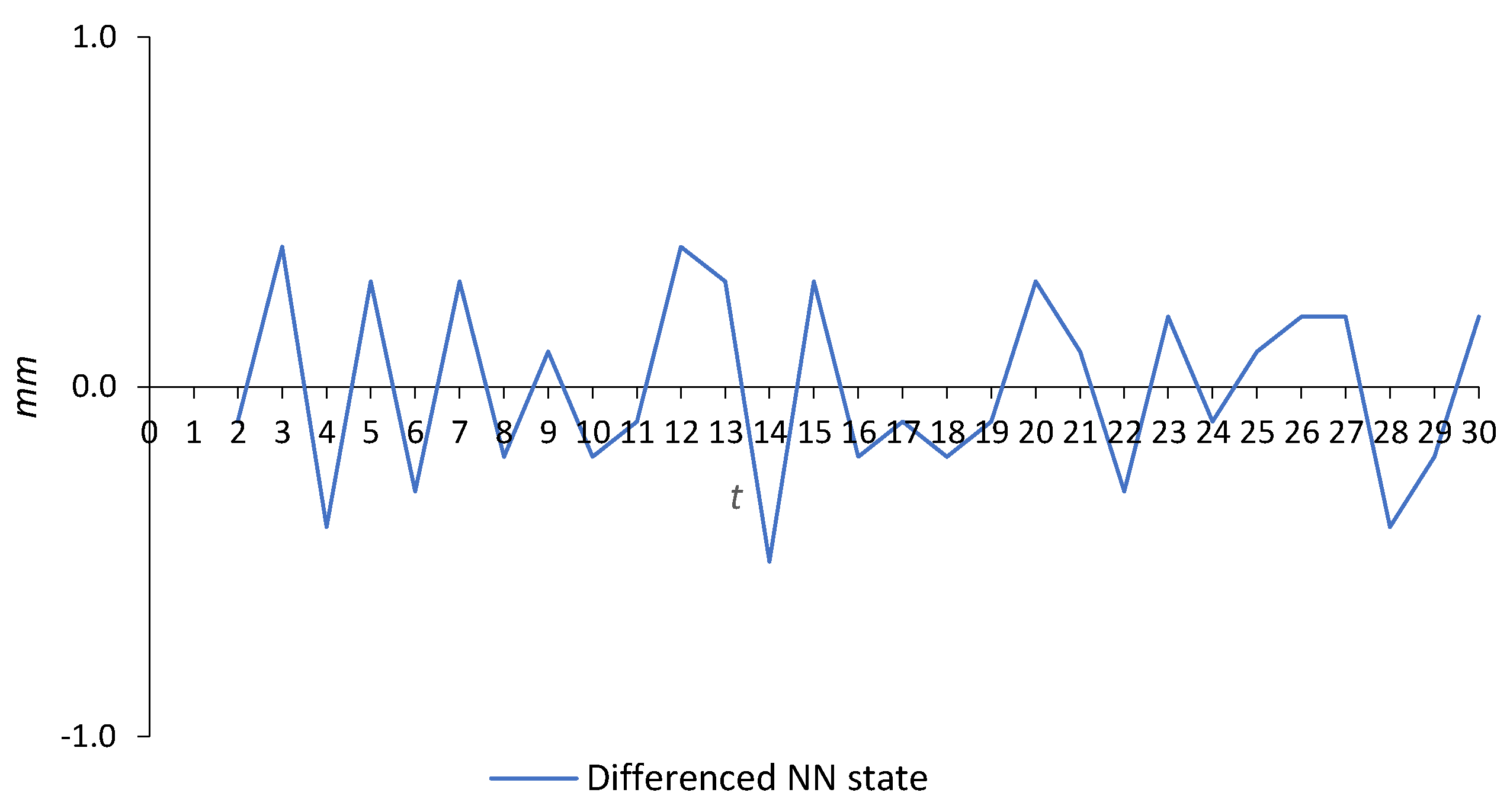

By the first difference of the

NN state of the series, we obtain stationary time series, as is shown in

Table 9 and

Figure 7.

Obviously, the stationary time series belongs to the

MD state of the series, so we must transform it to the

NN state of the series. The way of transformation is presented in

Table 10 and

Figure 8.

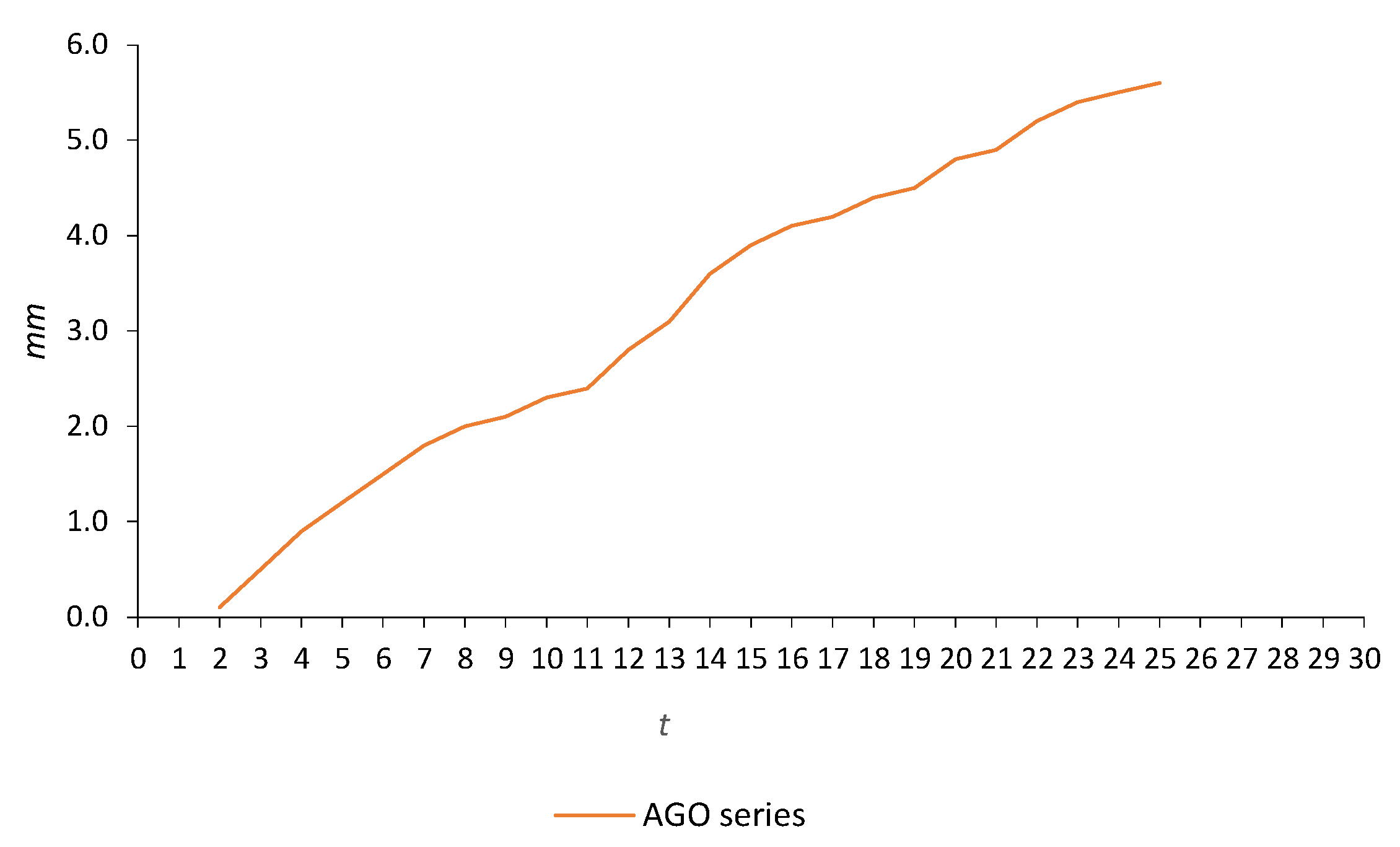

Elements of the transformed stationary series can now be accumulated, and the results of the AGO process are shown in

Table 11 and

Figure 9. Accumulation is performed only on values from

t = 2 to

t = 25 (fitting period).

The following matrices are used to calculate parameters

a and

b of the grey modeling:

According to Equation (12), we obtain

a = 0.03454 and

b = 0.35021. The parameters of the grey stochastic process are presented in

Table 12.

Numerical approximation of

is based on the following Euler–Maruyama discretization:

Figure 10 shows simulations obtained by Equation (53).

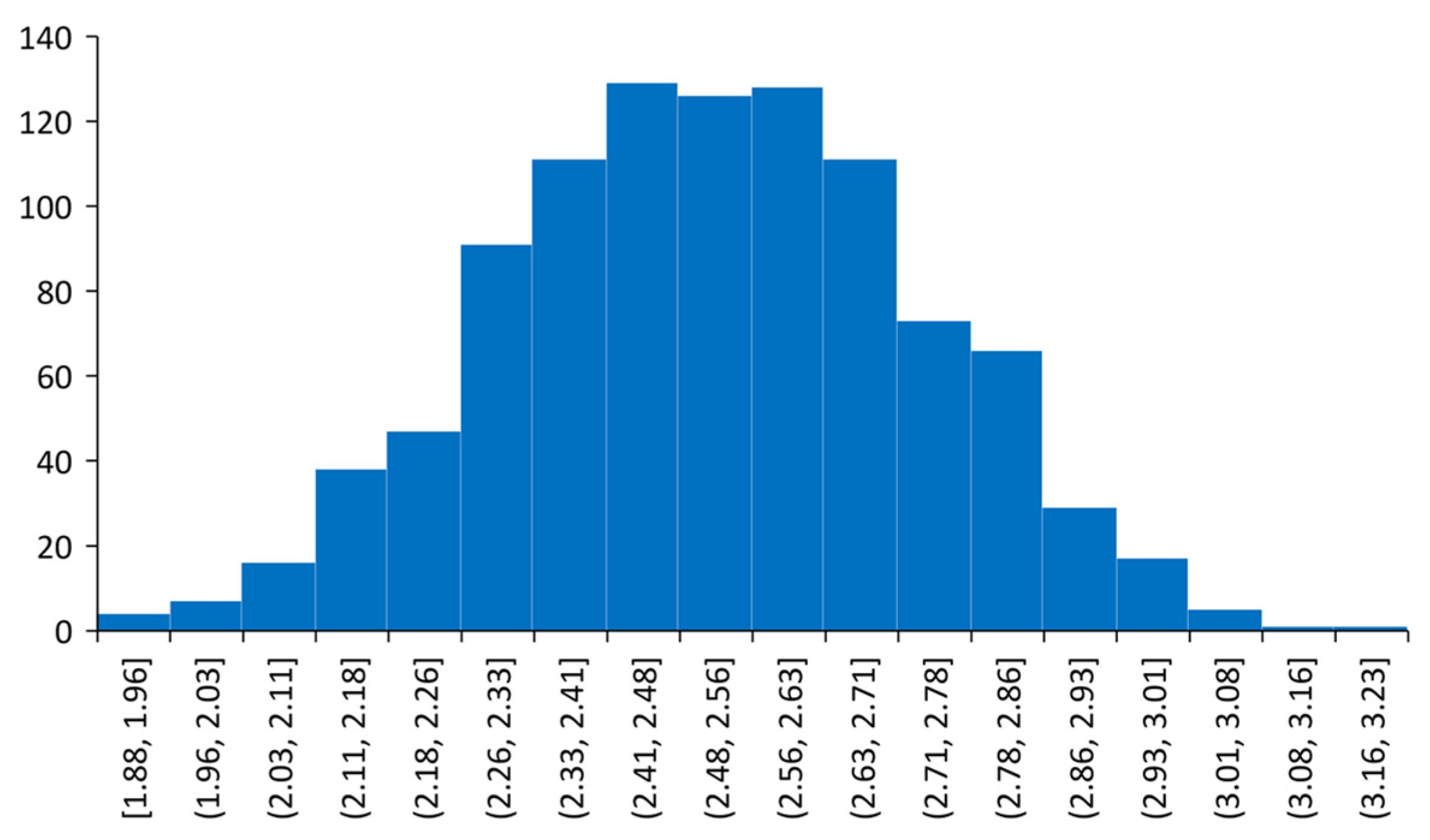

After one thousand simulations of Equation (53), the following expected AGO and corresponding IAGO outcomes are presented in

Table 13.

Figure 11 presents the probability distribution function of the AGO series for

t = 10.

Applying Equation (5) on the expected IAGO outcomes, we obtain the first difference series of displacements for

t = 2, 3, …, 25 reconstructed; see

Table 14.

To obtain the reconstructed (fitted)

MD state of the series of displacements, we applied Equation (27), and the results with the corresponding absolute percentage errors are shown in

Table 15 and

Figure 12.

The mean absolute percentage error (MAPE) is 1.88%, and according to

Table 1, the fitting model of the displacement of marker M4 along the

x-axis belongs to a highly accurate class. Fitting errors of displacement for all markers along the

x- and

y-axis are presented in

Table 16.

The MAPE of the model is

, which points out that the model is capable of forecasting future values of displacement. AGO series beyond

T = 25 are forecasted by simulation of Equation (52), for

t = 26, 27, 28, 29, 30; and outcomes of expected AGO and corresponding IAGO series are shown in

Table 17.

Application of Equation (5) for the forecasting period requires the transformation coefficient series

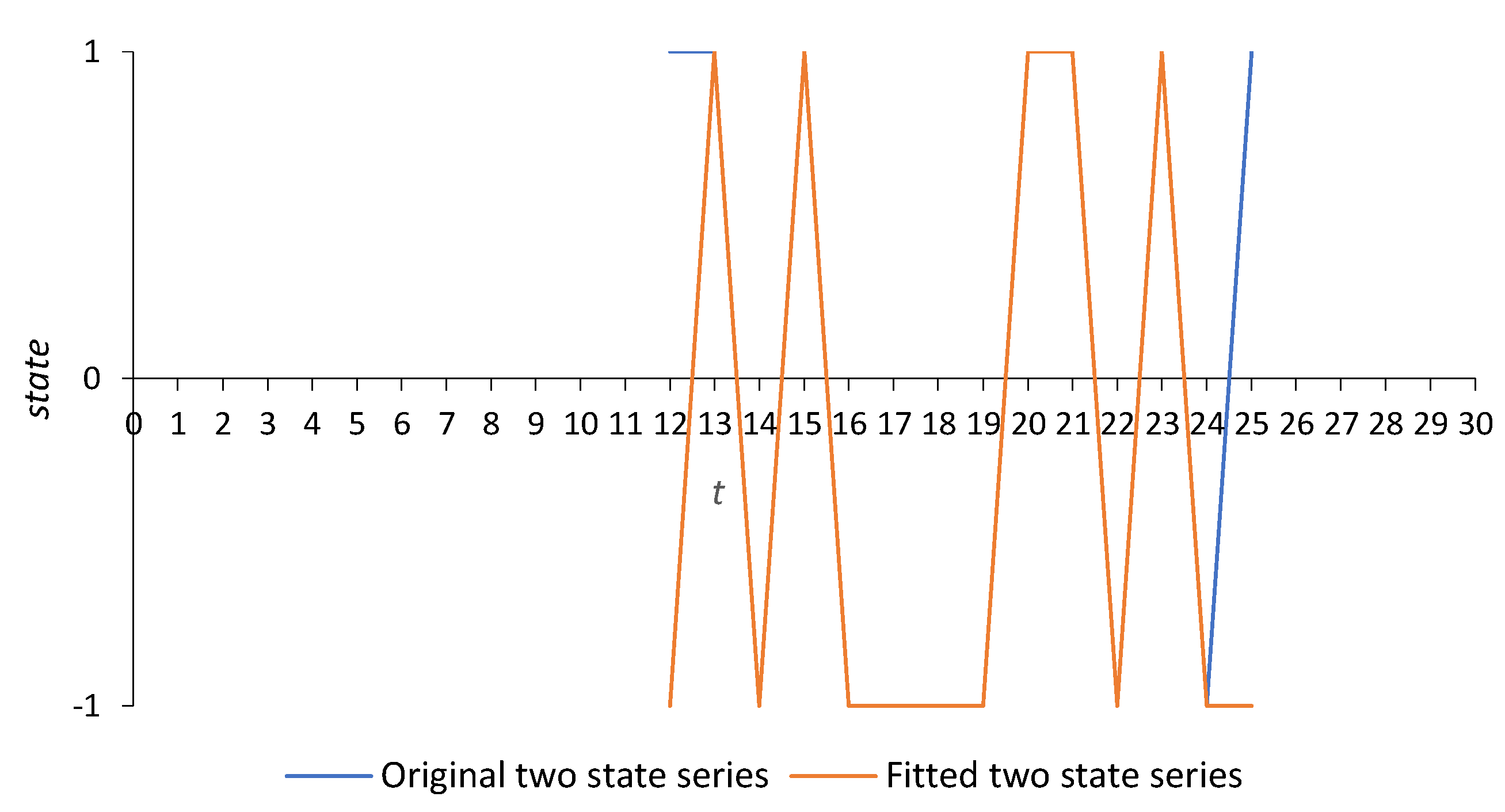

to also be forecasted. The two-state time series of the first difference monitored data is presented in

Table 18.

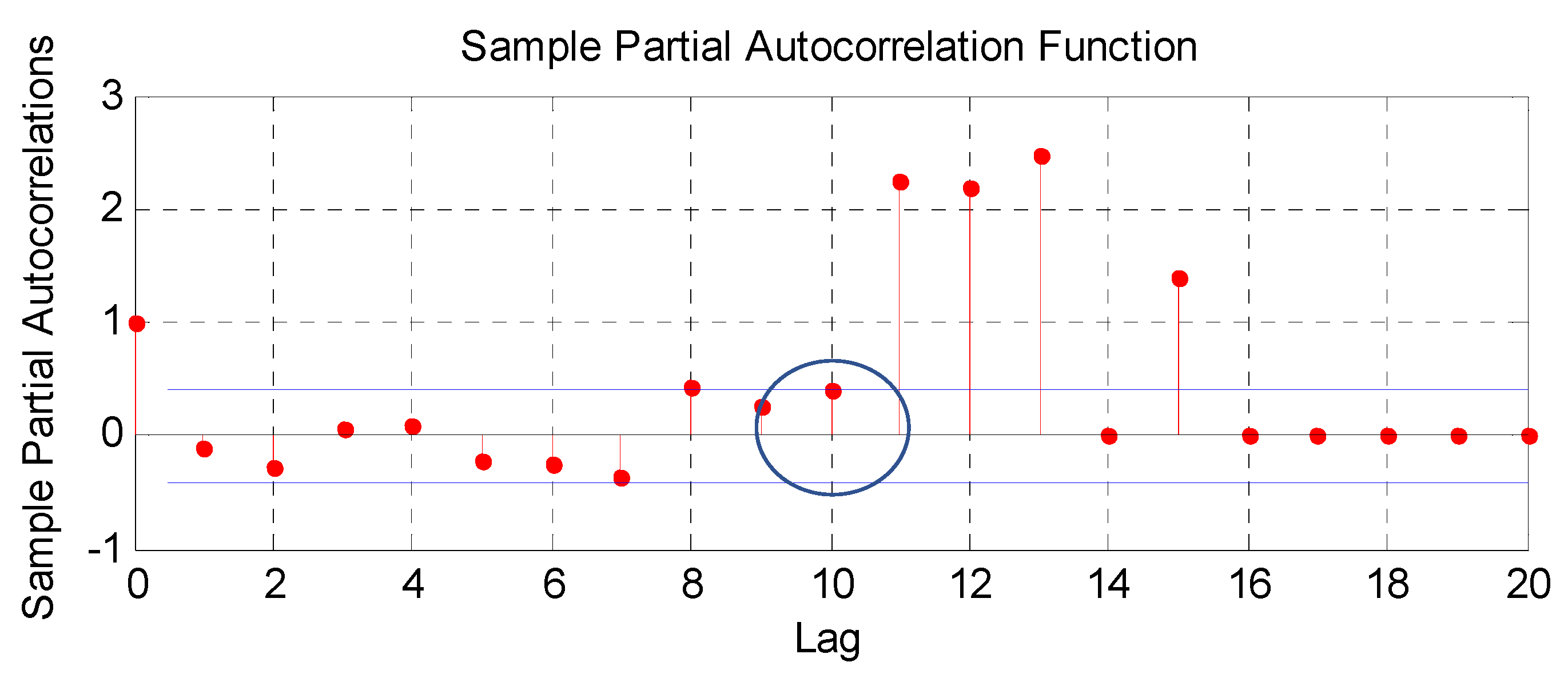

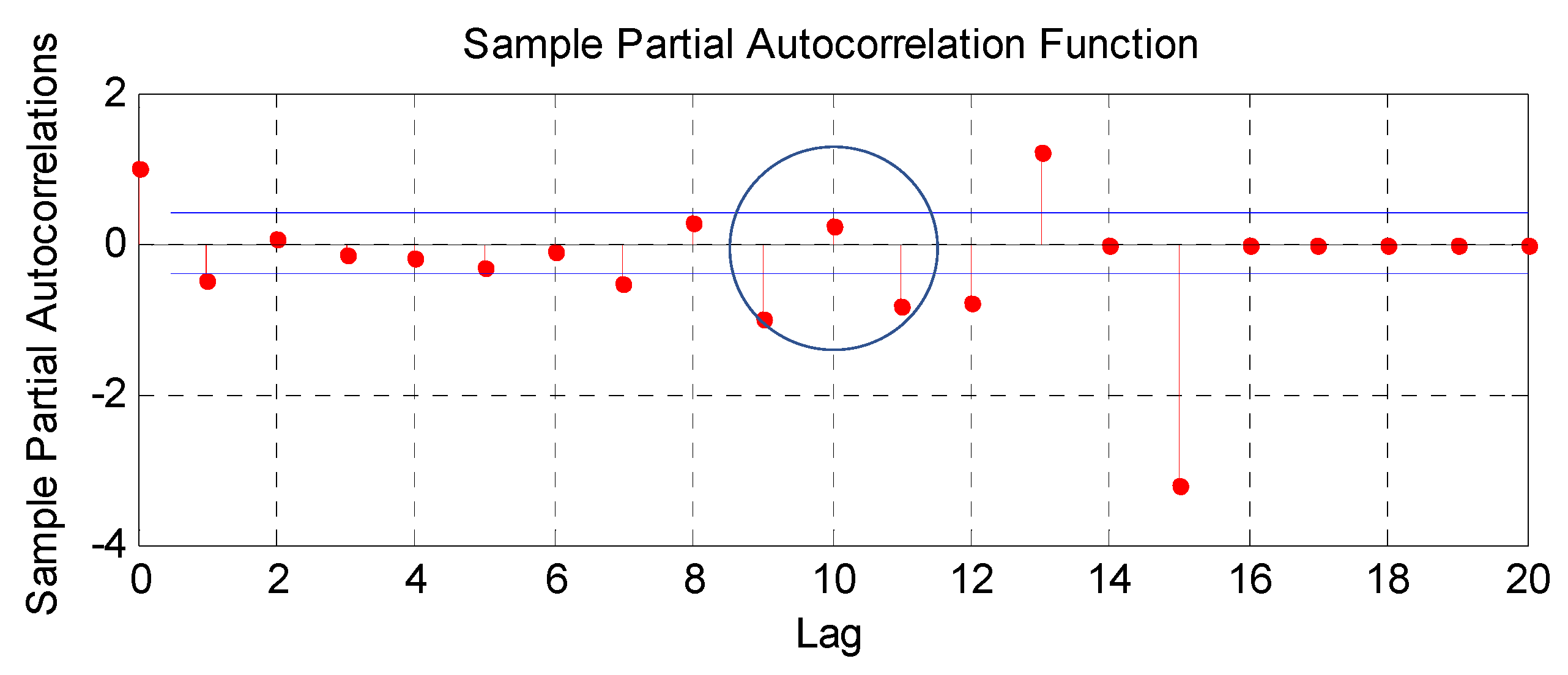

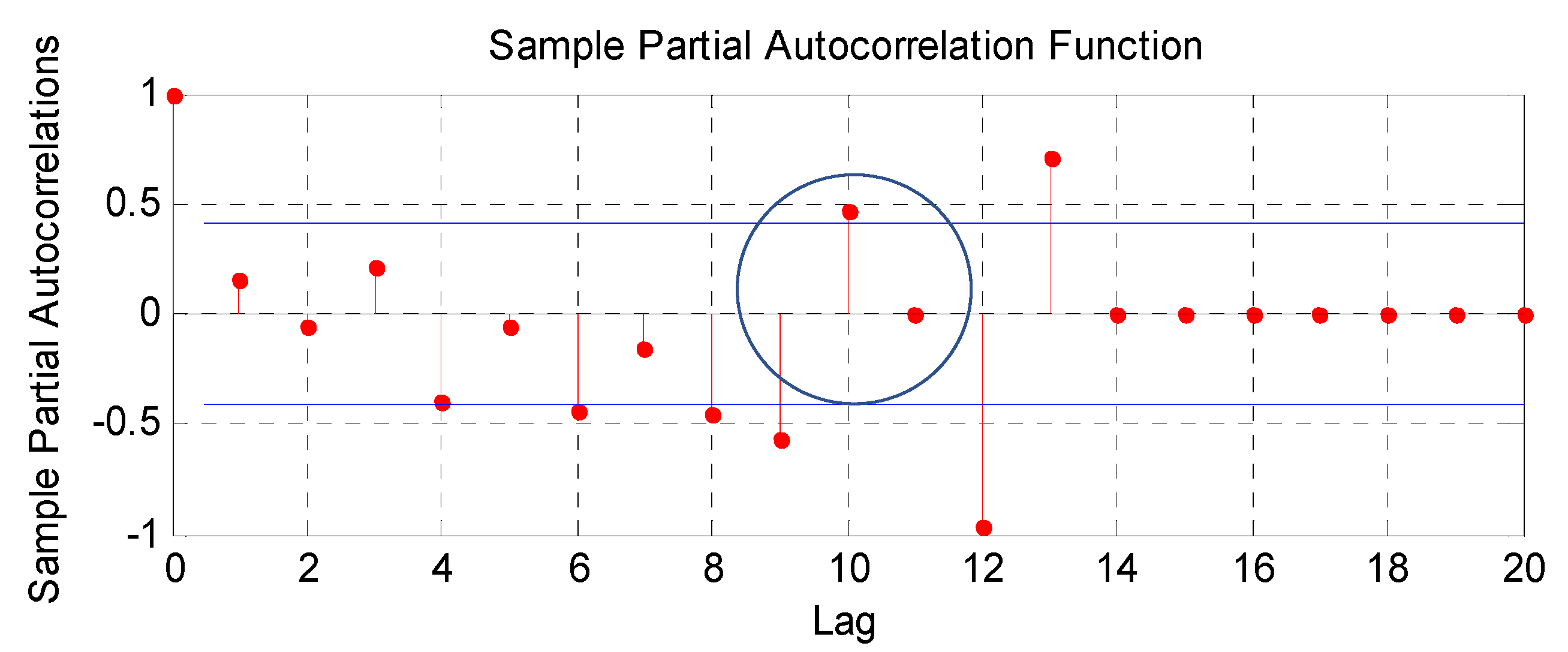

The order of the AR process equals

. The plot of the partial autocorrelation function for two-state time series, which is presented in

Table 16, is shown in

Figure 13. The parameters of the AR(10) process are presented in

Table 19.

Reconstructed (fitted) time series of M4

x, corresponding states (see Equation (34)), and model accuracy are shown in

Table 20 and

Figure 14.

Table 21 shows the accuracy of the AR(10) process for all markers separately.

The expected accuracy of the AR(10) model is 92.34%. Besides the transformation coefficient series

that related to the first difference, the original series of displacements of marker M4 along the

x-axis is also related to the transformation coefficient series

; see

Table 6 (transformation from the

MD to

NN state of series). The order of the AR process for series

equals

, and we adopt the value of 10. The plot of the partial autocorrelation function for two state time series, which is presented in

Table 10, is shown in

Figure 15. The parameters of the AR(10) process for the

series are presented in

Table 22.

The fitted time series of original displacements of marker M4 along the

x-axis, corresponding states (see Equation (34)), and model accuracy are shown in

Table 23 and

Figure 16.

The accuracy of the model for forecasting two-state series of marker M4

x, using the AR(10) process, is presented in

Table 24.

We proposed

Table 25 to express the accuracy of the AR(

) two-state model in a linguistic way.

The accuracy of the forecasted two-state series for all markers, regarding the first difference, is shown in

Table 26.

The expected accuracy of the AR(10) model, for the first difference, is 57.14%. According to

Table 26, we can conclude the model is classified as good, and can be applied to forecast the first difference two-state series.

Furthermore, outcomes of forecasting beyond

t = 25 for displacements of marker M4 along the

x-axis are presented in

Table 27.

Mean absolute percentage error equals 85.41%. That is to be expected; if the model gets just one state wrong, then the forecast error increases significantly. Forecasted displacements for all markers and corresponding errors are presented in

Table 28.

The MAPE of the forecasting model is 11.75%, and the model belongs to the good accuracy class (see

Table 1), even though the error of M4

x is 85.41%. Suppose the model got all the states wrong; in that case, the MAPE of M4

x is 197.84%, and the MAPE of the forecasting model is 19.78%.

The application of APE to express the efficiency of the model only in the context of a time series is a very rigorous approach, with respect to the environment of forecasting displacements of markers. From a mining engineering point of view, the position forecasting of a marker presents a desired target. Accordingly, the mean absolute percentage error of marker position is a more suitable way to estimate the accuracy of the forecasting model.

Table 29 contains coordinates of markers obtained by the model for

t = 25, 26, …, 30 (forecasting-validity phase).

The comparison of steel arch support between the monitored, fitted, and forecasted shapes is presented in

Figure 17.

Calculation of model efficiency, which is based on the position error of a marker, is presented in a few successive steps, and we also used marker M4 as an illustrative marker for t = 10:

Step 1: input data:

- -

monitored position of marker M4, defined by coordinates, is M(x,y) = (1691.0, 3753.4);

- -

fitted position of marker M4, defined by coordinates, is M(x,y) = (1735.7, 3754.0);

- -

monitored position vector of marker M4 is ;

- -

fitted position vector of marker M4 is .

Step 2: the projection of fitted position vector on monitored position vector

Step 3: magnitude of the vector

and

Step 4: Absolute percentage error of marker position

Applying the same calculation on all markers, we obtain the following errors in

Table 30.

The MAPE of the fitting and forecasting model is 0.113% and 0.2143%, respectively.

4. Conclusions

The stability of the underground roadways (headings, galleries, drifts, gate roads, and drives) is crucial for the smooth operation of a mine. When underground roadways are constructed in complex geological conditions and in a weak rock mass, installation of adequate support construction is necessary for the stability maintenance of the roadways in order to provide its functionality during exploitation time. Even then, mostly due to the influence of the dynamic loads from the rock mass, the deformations of the walls and arch of the underground roadways occur. These deformations are also represented in the support construction. Steel arch support is the most used support construction in the headings and gate roads in underground coal mines. As the deformations of the steel arch support cause the shrinking of the cross-section area of the underground roadways, it is important to monitor and forecast the deformations of the sections that can jeopardize the planned work cycle.

In this paper, we presented a forecasting model based on the grey system theory, which observes the deformations of markers placed on a steel arch support. By measuring the coordinates of the marker in a defined period (25 days), data on the position of the marker are obtained, as well as the increment of the deformations along the x- and y-axis each day. Increments of the deformations along the x- and y-axis are observed as two univariate time series, which are later used for the forecasting of the future states of the markers, i.e., the steel arch support.

The previous chapter detailed our model, which gave a MAPE of forecasting of 11.75% in the case when the error was analyzed from a time series point of view. With such an error, the model accuracy is described as good. As the nature of the described problem is such that the position of the marker, i.e., the future position of the underground construction, is of importance to mining engineers, we introduced the analysis of the error of the marker position to evaluate the effectiveness of the model. The MAPE of the forecasting model is 0.2143%, and in that term, the model accuracy is described as high. For the autoregressive model, the proposed window length of showed high accuracy (92.34%) for the AR(10) model for fitted data of corresponding states, while it showed reasonable accuracy (57.14%) for the same model for the validity (forecasting) phase. One of the focuses of future research will be the definition of the optimal window length for an autoregressive model to achieve greater accuracy of the model in general. The development of a smart rolling model is also planned to make the model more user-friendly.

This model can be used by mining engineers in underground coal mines for accurate forecasting of the future states of the steel arch support. Using this model, it is possible to plan the maintenance of underground roadways more efficiently, which further results in fewer stoppages in the process of coal production and lower operating costs of the mine.