Development of Geospatial Data Acquisition, Modeling, and Service Technology for Digital Twin Implementation of Underground Utility Tunnel

Abstract

1. Introduction

2. Literature Review

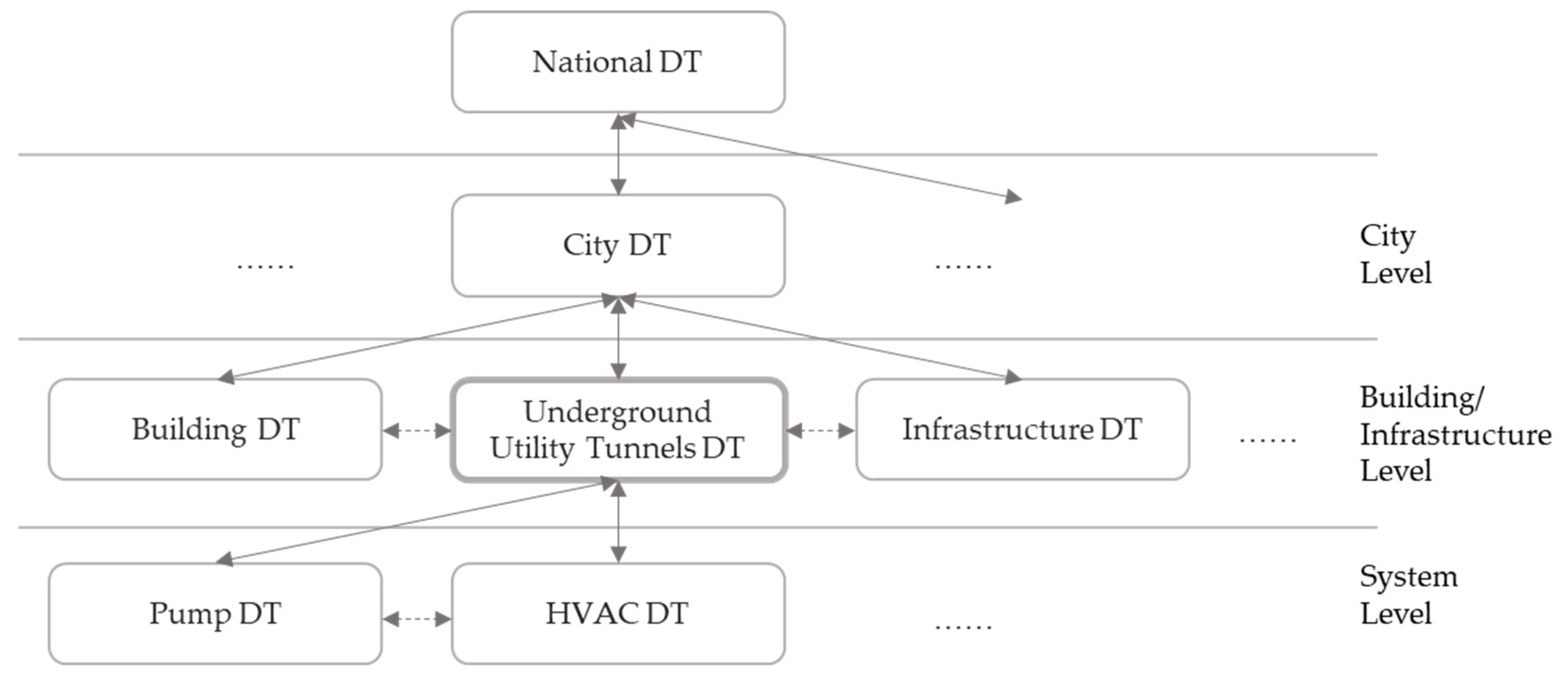

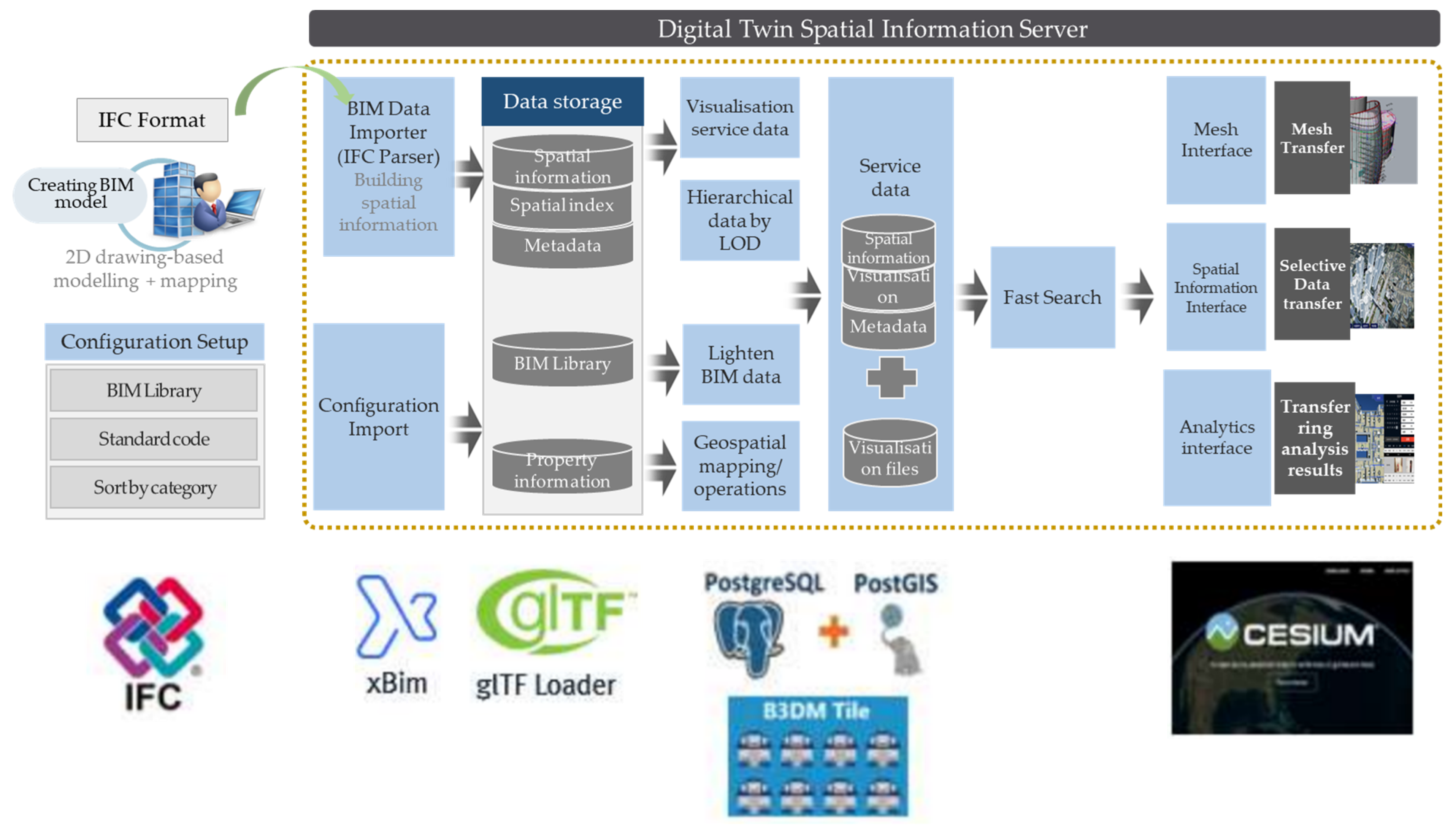

2.1. Digital Twin Field

2.2. Digital Twin Application

2.2.1. Data

2.2.2. Modeling for Digital Twins

2.2.3. Services for Digital Twins

3. Methods

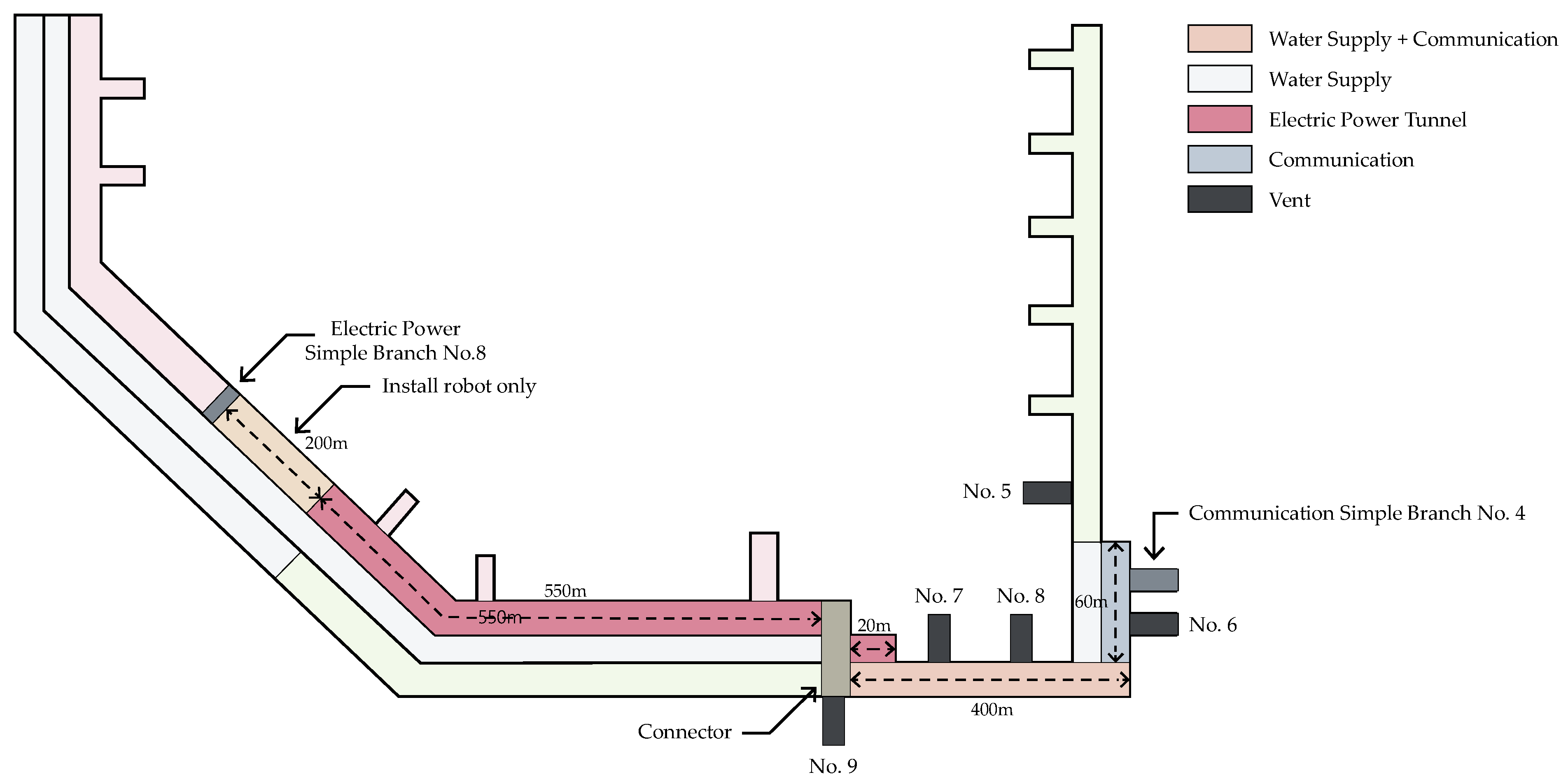

3.1. Status of the Selected Underground Utility Tunnel

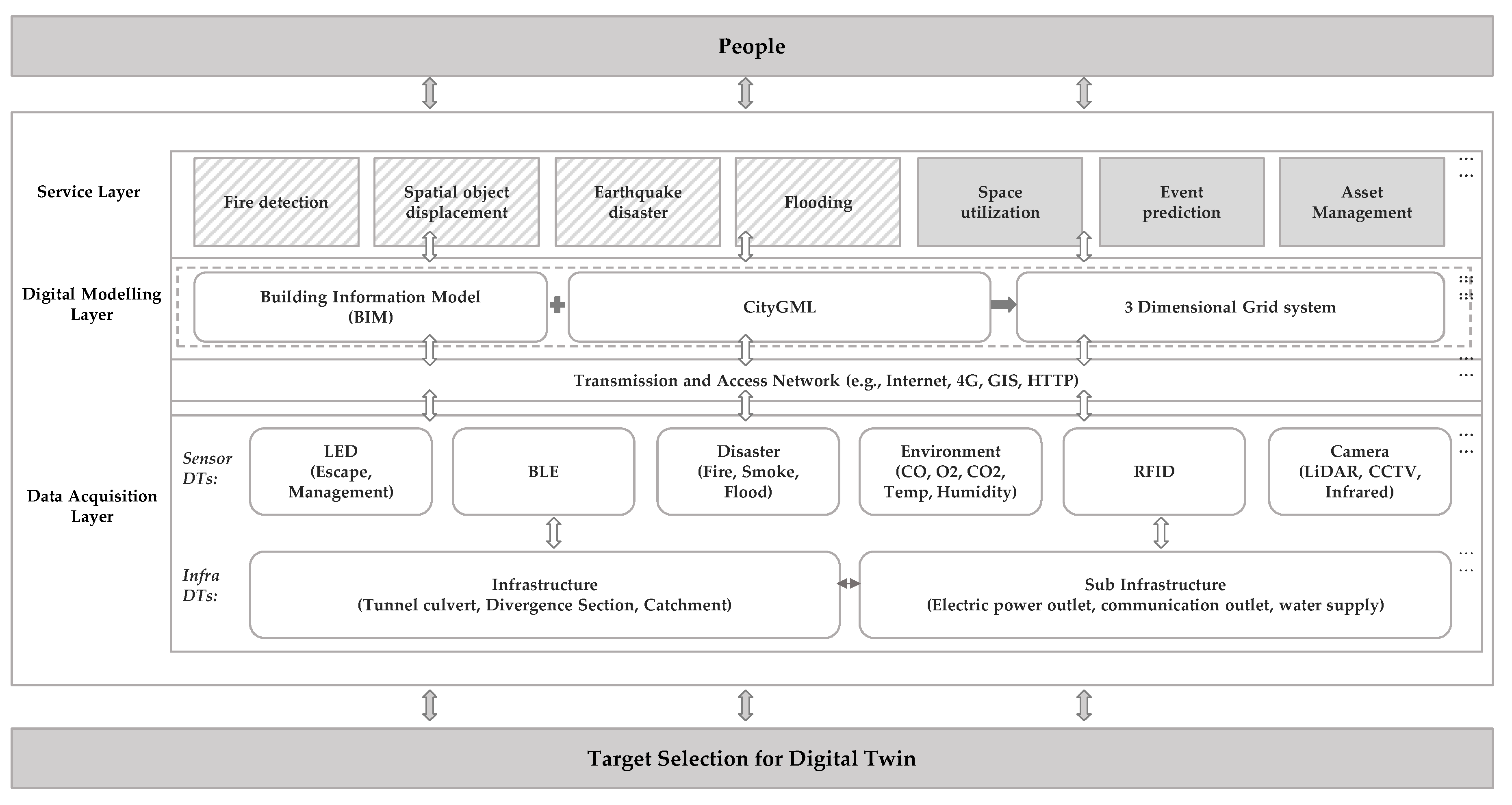

3.2. Key Methodologies for the UTU Digital Twin

4. Results

4.1. Data Acquisition Layer

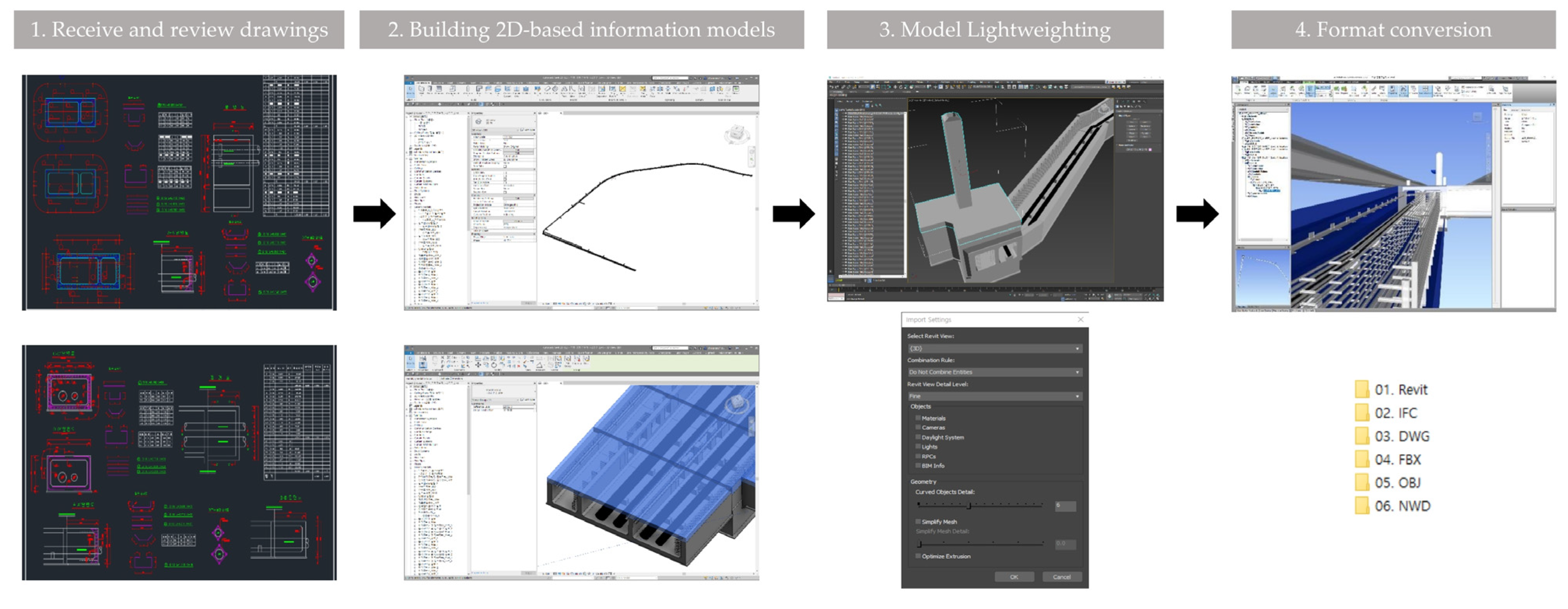

4.1.1. Collecting Pre-Established Information

- -

- Accessibility: 2D-based modeling is often easier and more accessible than LiDAR-based modeling as it can be created using basic software and traditional drawing tools.

- -

- Cost-effective: 2D-based modeling can be less expensive than LiDAR-based modeling as it does not require specialized equipment such as LiDAR scanners.

- -

- Simple: 2D-based modeling is simpler and easier to learn than LiDAR-based modeling, making it accessible to a wider range of users.

- -

- High accuracy: LiDAR-based modeling can provide highly accurate 3D models of the underground utility tunnel, capturing details such as the precise location and geometry of objects and structures.

- -

- High level of detail: LiDAR-based modeling can provide a high level of detail, including the position, size, and orientation of objects, which is important for simulating the operation and maintenance of the tunnel.

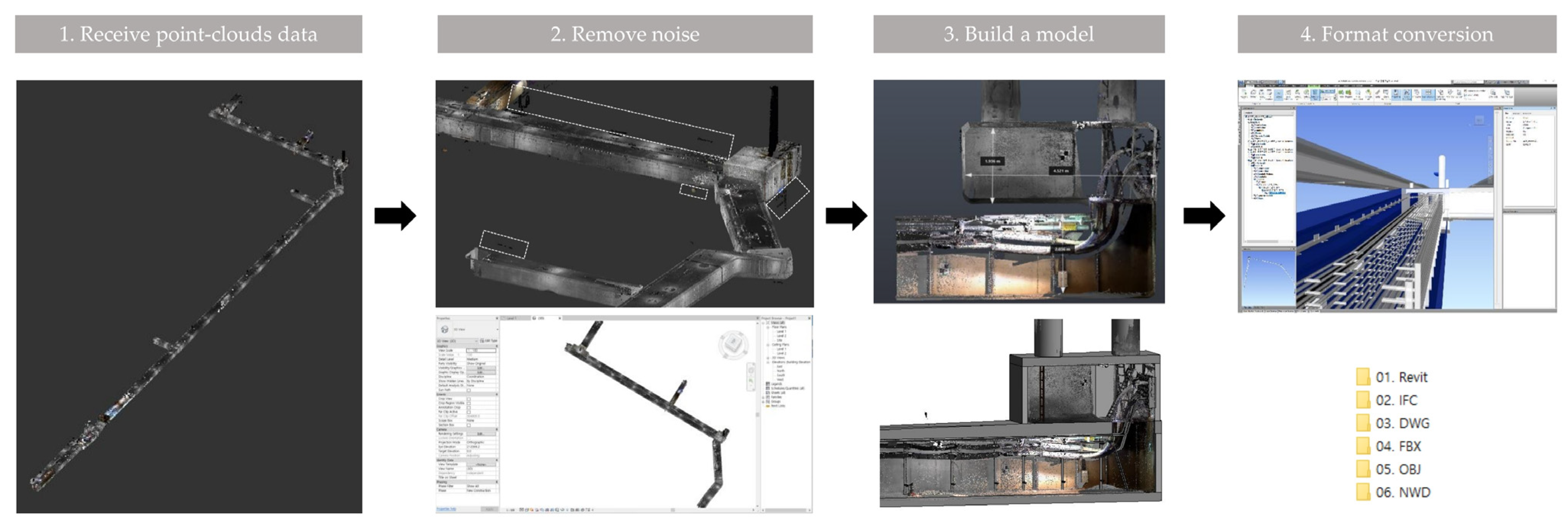

4.1.2. Site Information Collection

4.2. Modeling Layer

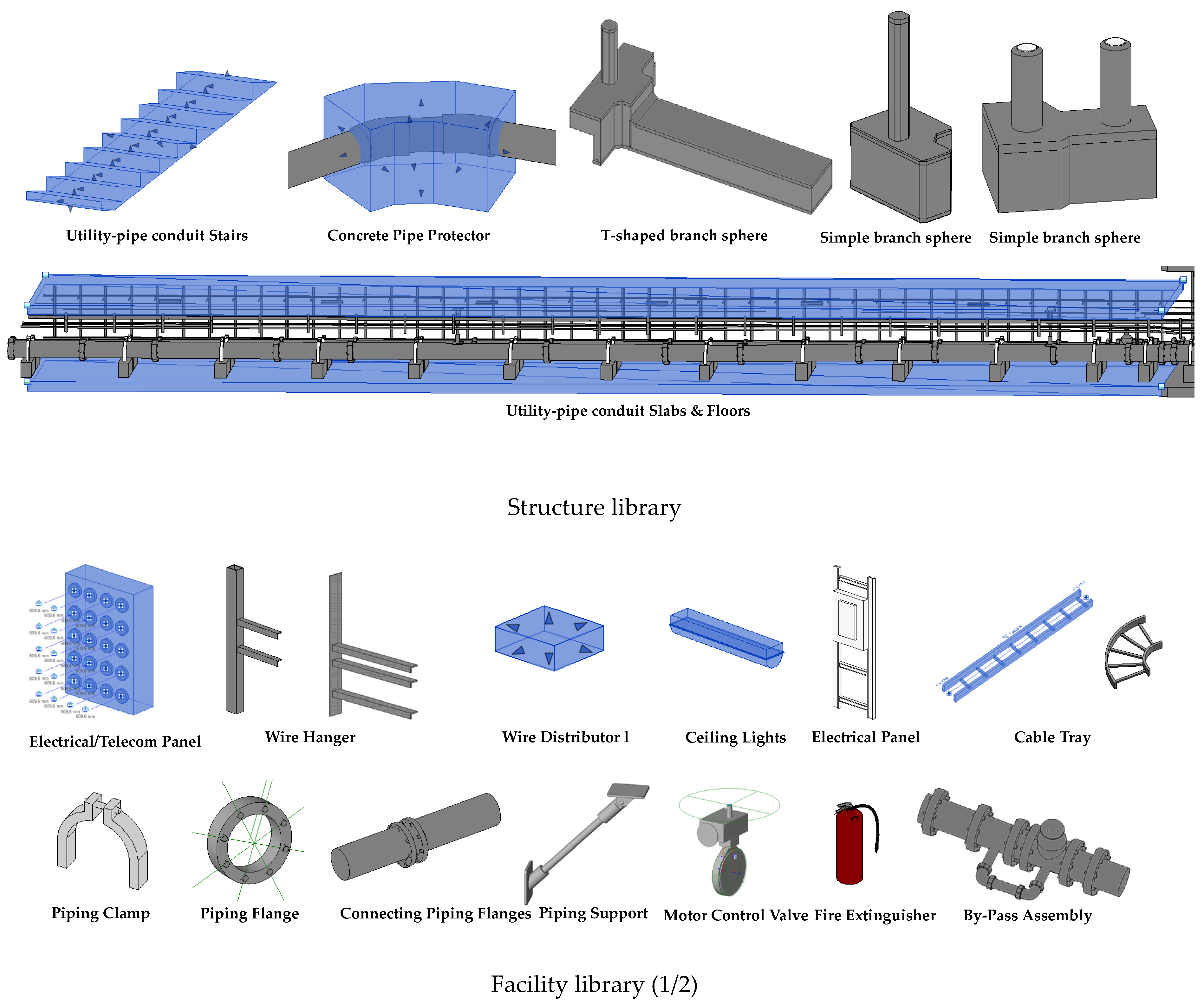

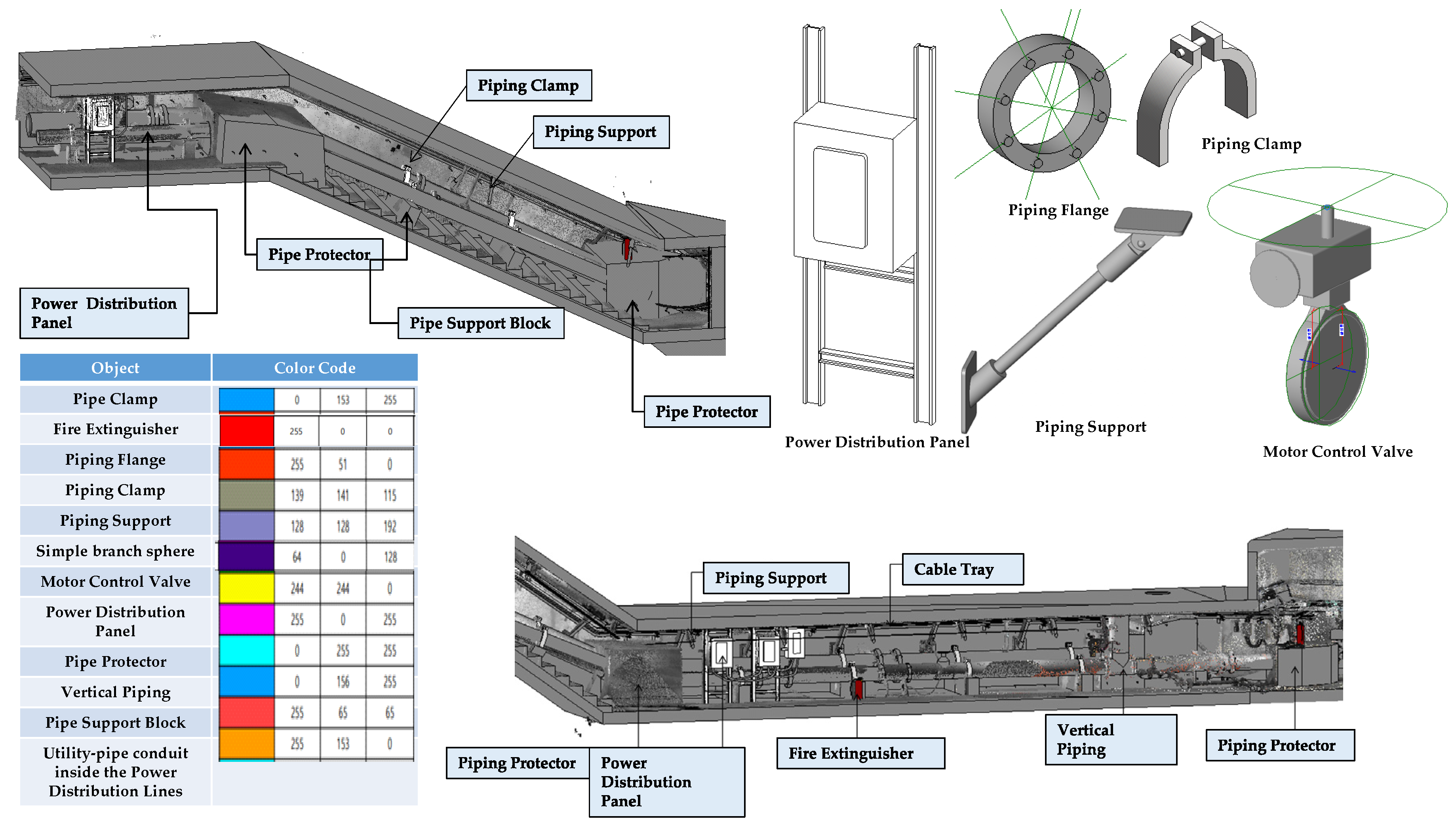

4.2.1. BIM Modeling

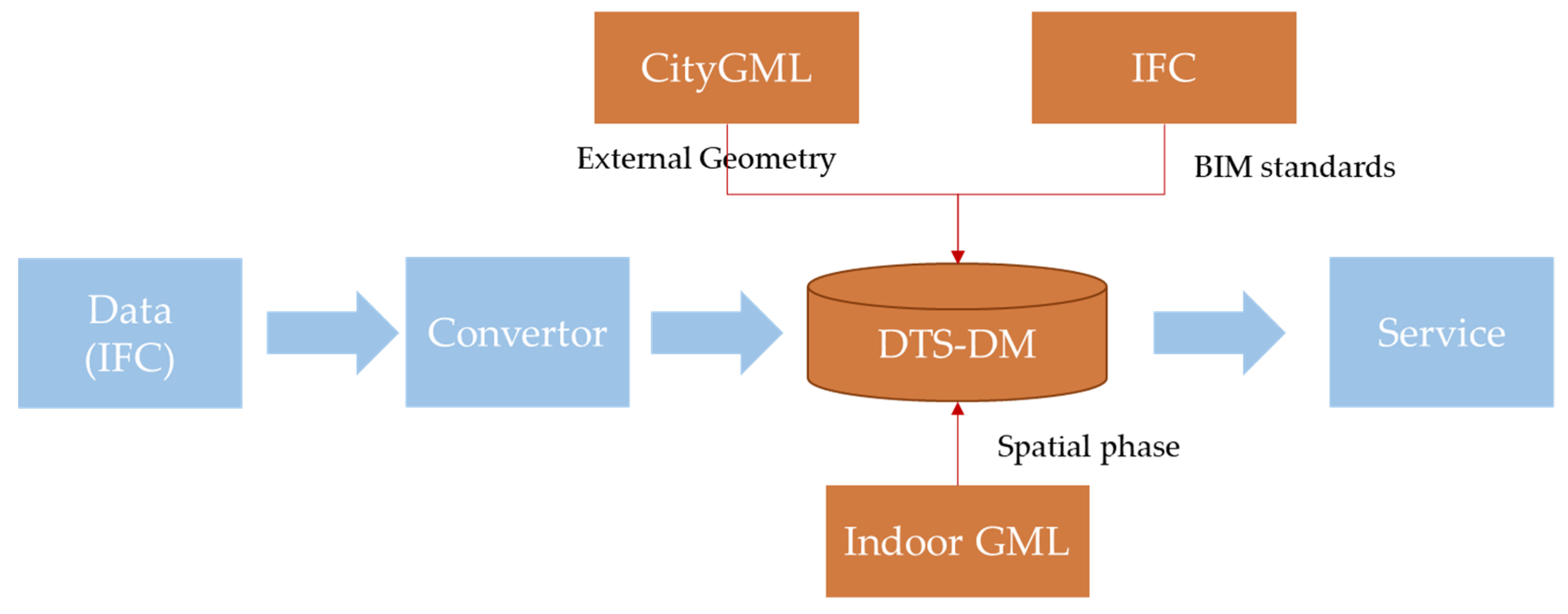

4.2.2. Building and Operating System of a Digital Twin Space

4.3. Service Layer

4.3.1. Service Items of an Underground Utility Tunnel

4.3.2. Service Functional Requirements of an Underground Utility Tunnel

5. Conclusions

- -

- Data acquisition: The key role of the data acquisition layer is collecting facility data, sensor data, and general information. Facility data can be acquired based on existing 2D or 3D drawings or through a scanning process using LiDAR technology.

- -

- Modeling: Modeling is proceeded based on data building. The key role of the modeling layer is to model the underground utility tunnel by using BIM (infrastructure and sensor data) and GIS (spatial information). Additionally, modeling was efficiently performed by configuring a DB architecture for storing and linking relevant data and for providing services.

- -

- Service: Lastly, underground utility tunnel management technology using a digital twin consists of an underground utility tunnel management service and a response service for abnormal situations. An underground utility tunnel management service provides manned and unmanned surveillance, diagnoses, and risk inference services through a digital twin. In particular, abnormal situations in underground facilities include fire detection, spatial object displacement, earthquake disaster, and flooding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Yevu, S.K.; Ann, T.; Darko, A. Digitalization of construction supply chain and procurement in the built environment: Emerging technologies and opportunities for sustainable processes. J. Clean. Prod. 2021, 322, 129093. [Google Scholar] [CrossRef]

- Osunsanmi, T.O.; Aigbavboa, C.; Oke, A. Construction 4.0: The future of the construction industry in South Africa. Int. J. Civ. Environ. Eng. 2018, 12, 206–212. [Google Scholar]

- Agnusdei, G.P.; Elia, V.; Gnoni, M.G. Is digital twin technology supporting safety management? A bibliometric and systematic review. Appl. Sci. 2021, 11, 2767. [Google Scholar] [CrossRef]

- Turner, C.J.; Oyekan, J.; Stergioulas, L.; Griffin, D. Utilizing industry 4.0 on the construction site: Challenges and opportunities. IEEE Trans. Ind. Inform. 2020, 17, 746–756. [Google Scholar] [CrossRef]

- Johari, S.; Jha, K.N. Impact of work motivation on construction labor productivity. J. Manag. Eng. 2020, 36, 04020052. [Google Scholar] [CrossRef]

- Costa, D.G.; Peixoto, J.P.J. COVID-19 pandemic: A review of smart cities initiatives to face new outbreaks. IET Smart Cities 2020, 2, 64–73. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Jacoby, M.; Usländer, T. Digital twin and internet of things—Current standards landscape. Appl. Sci. 2020, 10, 6519. [Google Scholar] [CrossRef]

- Singh, M.; Srivastava, R.; Fuenmayor, E.; Kuts, V.; Qiao, Y.; Murray, N.; Devine, D. Applications of Digital Twin across industries: A review. Appl. Sci. 2022, 12, 5727. [Google Scholar] [CrossRef]

- Xue, F.; Lu, W.; Chen, Z.; Webster, C.J. From LiDAR point cloud towards digital twin city: Clustering city objects based on Gestalt principles. ISPRS J. Photogramm. Remote Sens. 2020, 167, 418–431. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Tan, W.; Sepasgozar, S.M. Digital twin and CyberGIS for improving connectivity and measuring the impact of infrastructure construction planning in smart cities. ISPRS Int. J. Geo-Inf. 2020, 9, 240. [Google Scholar] [CrossRef]

- Wang, M.; Yin, X. Construction and maintenance of urban underground infrastructure with digital technologies. Autom. Constr. 2022, 141, 104464. [Google Scholar] [CrossRef]

- Rosen, R.; Von Wichert, G.; Lo, G.; Bettenhausen, K.D. About the importance of autonomy and digital twins for the future of manufacturing. Ifac-Papersonline 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Boschert, S.; Rosen, R. Digital twin—The simulation aspect. In Mechatronic Futures: Challenges and Solutions for Mechatronic Systems and Their Designers; Hehenberger, P., Bradley, D., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 59–74. [Google Scholar]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems; Springer: Berlin/Heidelberg, Germany, 2017; pp. 85–113. [Google Scholar]

- Meierhofer, J.; Schweiger, L.; Lu, J.; Züst, S.; West, S.; Stoll, O.; Kiritsis, D. Digital twin-enabled decision support services in industrial ecosystems. Appl. Sci. 2021, 11, 11418. [Google Scholar] [CrossRef]

- Pang, T.Y.; Pelaez Restrepo, J.D.; Cheng, C.-T.; Yasin, A.; Lim, H.; Miletic, M. Developing a digital twin and digital thread framework for an ‘Industry 4.0’Shipyard. Appl. Sci. 2021, 11, 1097. [Google Scholar] [CrossRef]

- Shah, K.; Prabhakar, T.; Sarweshkumar, C.; Abhishek, S. Construction of a digital twin framework using free and open-source software programs. IEEE Internet Comput. 2021, 26, 50–59. [Google Scholar] [CrossRef]

- Lu, Q.; Parlikad, A.K.; Woodall, P.; Don Ranasinghe, G.; Xie, X.; Liang, Z.; Konstantinou, E.; Heaton, J.; Schooling, J. Developing a digital twin at building and city levels: Case study of West Cambridge campus. J. Manag. Eng. 2020, 36, 05020004. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.H.; Masoud, N.; Krishnan, M.; Li, V.C. Integrated digital twin and blockchain framework to support accountable information sharing in construction projects. Autom. Constr. 2021, 127, 103688. [Google Scholar] [CrossRef]

- Zhuang, C.; Miao, T.; Liu, J.; Xiong, H. The connotation of digital twin, and the construction and application method of shop-floor digital twin. Robot. Comput. Integr. Manuf. 2021, 68, 102075. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Ma, W.; Phil-Ebosie, O. Digital twin aided vulnerability assessment and risk-based maintenance planning of bridge infrastructures exposed to extreme conditions. Sustainability 2021, 13, 2051. [Google Scholar] [CrossRef]

- Borth, M.; Verriet, J.; Muller, G. Digital twin strategies for SoS 4 challenges and 4 architecture setups for digital twins of SoS. In Proceedings of the 2019 14th Annual Conference System of Systems Engineering (SoSE), Anchorage, AK, USA, 19–22 May 2019; pp. 164–169. [Google Scholar]

- Kaewunruen, S.; Lian, Q. Digital twin aided sustainability-based lifecycle management for railway turnout systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Majumdar, P.K.; FaisalHaider, M.; Reifsnider, K. Multi-physics response of structural composites and framework for modeling using material geometry. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; p. 1577. [Google Scholar]

- Soon, K.; Khoo, V. CityGML modelling for Singapore 3d national mapping. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, 42, 37. [Google Scholar] [CrossRef]

- Akroyd, J.; Mosbach, S.; Bhave, A.; Kraft, M. Universal digital twin-a dynamic knowledge graph. Data-Cent. Eng. 2021, 2, e14. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmström, J. Digital twin: Vision, benefits, boundaries, and creation for buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Yu, G.; Wang, Y.; Mao, Z.; Hu, M.; Sugumaran, V.; Wang, Y.K. A digital twin-based decision analysis framework for operation and maintenance of tunnels. Tunn. Undergr. Space Technol. 2021, 116, 104125. [Google Scholar] [CrossRef]

- Ye, Z.; Ye, Y.; Zhang, C.; Zhang, Z.; Li, W.; Wang, X.; Wang, L.; Wang, L. A digital twin approach for tunnel construction safety early warning and management. Comput. Ind. 2023, 144, 103783. [Google Scholar] [CrossRef]

- Shao, F.; Wang, Y. Intelligent overall planning model of underground space based on digital twin. Comput. Electr. Eng. 2022, 104, 108393. [Google Scholar] [CrossRef]

- Kim, I.; Lee, Y.; Choi, J. BIM-based hazard recognition and evaluation methodology for automating construction site risk assessment. Appl. Sci. 2020, 10, 2335. [Google Scholar] [CrossRef]

- Chen, Y.; Lin, H.; Liu, B. Review of Research Progresses and Application of Geothermal Disaster Prevention on Large-Buried Tunnels. Appl. Sci. 2022, 12, 10950. [Google Scholar] [CrossRef]

- Park, J.; Lee, H.; Kim, H.Y. Risk factor recognition for automatic safety management in construction sites using fast deep convolutional neural networks. Appl. Sci. 2022, 12, 694. [Google Scholar] [CrossRef]

- Tomar, R.; Piesk, J.; Sprengel, H.; Isleyen, E.; Duzgun, S.; Rostami, J. Digital twin of tunnel construction for safety and efficiency. In Tunnels and Underground Cities: Engineering and Innovation Meet Archaeology, Architecture and Art; CRC Press: Boca Raton, FL, USA, 2019; pp. 3224–3234. [Google Scholar]

| REF | Year | Field | Application | ||||

|---|---|---|---|---|---|---|---|

| Infra | Arch | City | Data Acquisition | Modeling | Service | ||

| [18] | 2021 | - | - | ● | QR codes, radio-frequency identification (RFID), IPC, sensors | 3D geometric model | Simulation Optimization |

| [19] | 2020 | ● | - | ● | GIS, sensing images, sensors, building management system (BMS) data | BIM | Monitoring, controlling the physical city |

| [20] | 2021 | ● | - | ● | Sensors, QR codes, space management system | BIM | Anomaly detection in operation and maintenance Blockchain |

| [21] | 2021 | ● | - | - | Geospatial datasets, demographic and climate conditions | BIM | Monitoring |

| [22] | 2021 | ● | - | - | Thermal imaging camera, sensors, AI | CIM, BIM, thermography map | Energy planning, simulation |

| [23] | 2019 | - | ● | ● | Sensors, financial compensation | 3D geometric model | Architecture for a cyber-physical system |

| [24] | 2019 | ● | - | - | Climate conditions, drawing data, geology data | BIM | Greenhouse gas emission, time schedule, cost data |

| [25] | 2013 | ● | - | Magnitude of electrical current | 3D geometric model | Structural stability | |

| [10] | 2020 | - | ● | - | LiDAR | 3D geometric model | City digital twin model |

| Category | Major Services |

|---|---|

| General situations | Maintenance efficiency improvement |

| Process optimization | |

| Cause analysis | |

| Multi-party decision-making | |

| Disaster and abnormal situations | Predictive maintenance |

| Proactive control |

| Main Features | Key Methodologies | |

|---|---|---|

| Data acquisition layer | Information collection: infrastructure DT | LiDAR scan 2D documents 3D documents Geospatial datasets |

| Information collection: sensor DT | Sensor data and image QR codes | |

| Information collection: general | Climate datasets Demographic information Maintenance datasets | |

| Modeling layer | Infrastructure and sensor modeling | BIM: library creation and color code designation |

| Geospatial modeling | GIS | |

| Information storage and linkage measures | Database and linkage | |

| Service layer | Abnormal situation management | Fire detection Spatial object displacement Earthquake disaster Flooding |

| General situation management | Space utilization Event prediction Asset management |

| Work Procedure | Major Details |

|---|---|

| Drawing printing | Check the work location on a numerical map Prepare for a site inspection and survey |

| Site 3D scan | Site inspection and survey of facilities Site inspection facility properties Site exploration and survey before project launch |

| Select a survey position on the drawing | Select a survey position in CAD program according to the site inspection survey results |

| Survey ground-level reference point | Survey a precise reference point on the ground connected to the utility tunnel |

| Survey underground reference point | Link with the precise reference point surveyed on the ground |

| Reference point data mapping | Mapping between 3D scan data and reference point survey data |

| Point cloud matching | Connect 3D scan data to each station according to the site |

| Monitoring Location | Monitoring Means and Method | Collected Data |

|---|---|---|

| Inside the underground utility tunnel | Fixed sensor: multisensors and cameras are repeatedly arranged at certain intervals in tens of km along the utility tunnel, and information is collected in real time | Temperature, humidity, oxygen, carbon dioxide, carbon monoxide, smoke, flame, vibration sensor, low-luminance image, thermal image |

| Fixed sensor: sensor is arranged in facilities with a high risk | Vibration sensor of a water supply line, partial discharge sensor of a power line, water level sensor of a collection well, acoustic sensor | |

| Movable robot: robot moves on the ceiling rate over tens of km along the utility tunnel to collect information in real time | Temperature, humidity, oxygen, carbon dioxide, carbon monoxide, hydrogen sulfide, nitrogen dioxide, low-luminance image, thermal image, LiDAR sensor | |

| Manned patrol: patrol moves on foot and visually observes tens of km along the utility tunnel | Abnormalities in structures, firefighting facilities, power facilities, and communications facilities | |

| Outside the underground utility tunnel | Fixed sensor: sensors and cameras are arranged at the entrance/exit of the management office and underground utility tunnel to collect information | Access security sensor, detection sensor of safety device |

| Connection with external systems: regional and critical situation information is collected via the Meteorological Administration | Weather information such as temperature, humidity, precipitation, wind direction, wind speed, earthquake of a certain region, construction information, and terrorism risk information of the nearby areas |

| Category | Description |

|---|---|

| Database management | Collect and store databases |

| Convert and transmit databases | |

| Statistical analysis of databases | |

| Facility management | Status inquiry of management and accommodation facilities |

| Inspection of management and accommodation facilities | |

| State information display of management and accommodation facilities | |

| Search firefighting facility control data | |

| CCTV control | |

| Register field situations | |

| Inquiry of workers’ locations | |

| Safety management | Check for abnormalities |

| Request on-site support | |

| Abnormal signal management | Check for abnormal situations |

| Propagate situations | |

| Simulation management | Guide evacuation routes |

| Suppress disaster spread | |

| Predict damage spread | |

| Visualization of analysis results |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Lee, Y.; Hong, C. Development of Geospatial Data Acquisition, Modeling, and Service Technology for Digital Twin Implementation of Underground Utility Tunnel. Appl. Sci. 2023, 13, 4343. https://doi.org/10.3390/app13074343

Lee J, Lee Y, Hong C. Development of Geospatial Data Acquisition, Modeling, and Service Technology for Digital Twin Implementation of Underground Utility Tunnel. Applied Sciences. 2023; 13(7):4343. https://doi.org/10.3390/app13074343

Chicago/Turabian StyleLee, Jaewook, Yonghwan Lee, and Changhee Hong. 2023. "Development of Geospatial Data Acquisition, Modeling, and Service Technology for Digital Twin Implementation of Underground Utility Tunnel" Applied Sciences 13, no. 7: 4343. https://doi.org/10.3390/app13074343

APA StyleLee, J., Lee, Y., & Hong, C. (2023). Development of Geospatial Data Acquisition, Modeling, and Service Technology for Digital Twin Implementation of Underground Utility Tunnel. Applied Sciences, 13(7), 4343. https://doi.org/10.3390/app13074343