Abstract

Non-conventional machining processes offer various advantages, including the capability of processing hard-to-cut materials with a reasonable cost and sufficient productivity. However, depending on the application, different machining strategies need to be employed, in order to increase the flexibility of the process and produce parts with a better quality. In this study, experimental work was conducted and the use of a multipass strategy during slot milling of titanium alloy with abrasive water jet milling (AWJM) was explored, by comparing the effect of different numbers of passes under different process conditions, such as the jet pressure and traverse feed rate. The performance was evaluated by means of the kerf characteristics, and the productivity through material removal rate (MRR) values. The results indicated that the use of a multipass strategy had a considerable impact on the kerf taper angle, apart from the depth of penetration; and although it leads to reduced MRR and cutting efficiency, choosing appropriate values of process parameters, such as a higher jet pressure and moderate traverse feed, in combination with a moderate amount of passes, can be beneficial for AWJM from different points of view.

1. Introduction

Abrasive waterjet (AWJ) technology is a well-known and unconventional manufacturing method, in which a high-pressure fluid jet containing abrasive particles acts on the machined material, causing an erosion process and removing its fractions. This method has significant advantages, such as being environmentally-friendly, the possibility to machine all kinds of materials, especially hard-to-machine materials [1], and not causing a heat affected zone [2]. The method needs to be modernized in order to achieve a level of quality and efficiency that is in line with the requirements of new products in high end industries, such as the automotive and aerospace industries. Thus, research has been performed to enable the creation of more complex geometries in novel materials and composites through unconventional techniques such as AWJ. In order to control the process and find the best solutions, it is necessary to select appropriate process parameters and machining strategies [3,4,5].

The cutting capability of the AWJM process has been a major obstacle limiting its application to relatively thick materials, because of the depth-of-cut (DoC) or depth of penetration and kerf quality obtained [6,7,8]. Thus, an alternative multipass cutting strategy was introduced, in an attempt to increase the efficiency of the AWJM process and to improve the kerf quality. Multipass AWJM refers to the process in which the jet or cutting head travels over the same kerf many times during the cutting process. Multipass cutting has been found to be superior to single-pass cutting if the number of passes and the cutting parameters are properly selected [9]. By cutting the material at almost the same time with higher traverse speeds (vf) and lower mass flow rates (ma), multipass cutting offers better cutting performance and lower energy consumption than single pass cutting. Wang and Guo [10] were among the first who took into consideration the possibility of improving technological performance using multipass strategies, as compared to single pass cutting. In their research, an 87% alumina ceramic sample was used and machined using the chosen process parameters. The jet traverse direction and jet traverse speed in each pass of a multipass operation were included in the design of the experiment. In the first and second parts of the tests, the first pass was able to cut through the sample, while in the third part more than one pass was needed to penetrate the material. It has been shown that multipass AWJM can be used to reduce the total actual cutting time and cost.

Shipway, Fowler, and Pashby [11] investigated parameters in controlled-depth AWJM process, such as the jet impingement angle, traverse speed, waterjet pressure, and size of the garnet abrasive particles, to determine their influence on the roughness, waviness, and level of grit embedment of the titanium alloy sample. It was found that for achieving low waviness on the machined part, a high jet traverse speed, a small grit size, a low waterjet pressure, and a low jet impingement angle should be employed. The same research team completed experiments to determine the correlation between different abrasive properties and the quality of the surface in AWJ controlled-depth milling (AWJ-CDM) [12]. It was concluded that the material removal rate and surface roughness increase if the particle hardness is increased, that the shape factor and particle hardness have no significant effect on surface waviness, and the shape factor may have an effect on material removal and roughness. Srinivasu et al. [13] experimentally investigated the milling of a SiC ceramic plate, with a hardness level evaluated as 2500 HV under specific conditions. The influence of the jet feed rate, jet impingement angle, and the number of passes was investigated. It was concluded that real jet penetration does not follow a pure factorial rule (penetration depth × number of passes). The research of Alberdi et al. [14] considered the abrasive water jet slot milling in a 7075-T651 aluminum sample and analysis of the pressure, abrasive mass flow rate, stand-off distance (SoD), and traverse feed rate influencing the kerf profile. The results showed that for machining deeper grooves, the stand-off distance and the traverse feed rate should be reduced and the jet pressure increased. On the other hand, for increasing the width of the cut, an increase of the stand-off distance is required.

Since several studies have performed investigations of the material removable mechanism and improving the machining quality, researchers are trying to define the optimal cutting process parameters by applying different strategies, such as a multipass strategy and optimization techniques. Miao et al. [15] defined two different strategies using multipass AWJM technology. In the first, the jet passes through the material at maximum depth, while the second utilizes changing process parameters to deepen material penetration of every pass until achieving the desired depth of the cut. Τhe optimal cutting time for cutting AISI 304 stainless steel with both strategies was two passes, but to obtain a better kerf taper, the optimal cutting time changed to three passes. The deep-cutting strategy had better results regarding the surface quality and geometrical output. In general, a multipass strategy can improve both the roughness and kerf taper, as shown by Doreswamy et al. [16]. Wang and Zhong [17] proposed the use of oscillation at the nozzle as well as a multipass strategy, in order to further increase the depth of cut in a single pass with the same machining time. Xiong et al. [18] performed tests with two machining passes with different directions, under different traverse rates and stand-off distance values, in order to reduce roughness. They concluded that increasing the SoD at the second pass improved the quality, but reducing the SoD improved the kerf taper. In a similar study, Miao et al. [19] tested four different multipass strategies, such as machining in the opposite direction or using a reduced traverse speed. They revealed that an opposite secondary pass provided better results. Klocke et al. [20] introduced simulation and CAM generated tool path, in order to minimalize undesired deviations of the programmed feed rate, such as feed rate drops at sharp corners. Experiments on cutting carbon fiber-reinforced plastics using multipass AWJM were conducted by Xiao et al. [21], as a method that increases surface quality. Their work enabled the reduction of kerf taper by 53% and the improvement of efficiency by 13%. Regarding the surface quality in the smooth cutting zone (SCZ), the former did not show any advantage over the latter, unless a highly increased pressure was employed for the second-pass cutting. It was also found from the experimental results that arranging a low traverse speed in the first-pass cutting was superior to using it in the second-pass cutting.

In another work, Hejjaji et al. [22] examined the fatigue behavior of carbon/epoxy composites after using a controlled depth abrasive water jet milling method. A new parameter named “crater volume (Cv)” was defined as a proposition for quantifying and qualifying the machining quality in terms of induced damage, and the result confirmed that the new parameter was a more realistic indicator in the case of CFRP composites. Yuvaraj, Pavithra, and Shamli [23] considered the machining of a biomedical implant surface pattern on stainless steel 304 using controlled deposition of AWJM. The use of a multicriteria technique for creating this particular pattern was enabled. Multipass methods can be used for the waterjet technique, not only for cutting the material but can also find other applications. Nawi et al. [24] implemented a multipass method for an experiment in which the team analyzed the feasibility of using plain water jet cleaning in the paint removal process. The conclusions of the study referred to the influence of the process parameters on the paint removal level and surface roughness. Another research work considered the influence on the quality of the machined material with the use of different strategies based on single, double, and multi-cutting passes with different traverse speeds and direction strategies [25]. El Mesalamy and Youssef [25] used a response surface method (RSM) for their analysis, and their experiments revealed significant conclusions, e.g., that the multipass AWJM process improves the surface quality in contrast to single-pass cutting. Changing the cutting direction in the multipass method allowed obtaining better results for surface quality compared to cutting in one direction, and the results also showed that the impact of posterior passes decreased. Yuan et al. [26] examined machining circular pockets using AWJM in titanium alloy Ti-6Al-4V samples. The Box–Behnken design method was implemented, and the results of the experiment showed that well-selected process parameters can enhance the average milling depth by 47.8% and reduce the surface roughness by 38.1%.

Uhlmann, Männel, and Braun [27] conducted an experiment in which hard-to-cut titanium aluminide TNM-B1 was machined using two kerfs, to realize the shape of a turbine blade. Two new quality parameters were introduced to describe the difference between the constant and variable kerf depths: a concave geometry factor fa, and a convex geometry factor fx. Karmiris-Obratański et al. [28] studied multipass AWJM efficiency when working on chromium molybdenum-vanadium (60CrMoV18-5) steel alloy as a workpiece material. It was concluded that the effect of the multipass strategy was highly related to the process conditions and that the multipass cutting technique enables achieving a markedly higher efficiency. Another non-conventional study with the use of AWJM was introduced by Yuvaraj et al. [29]. Experiments on polishing a stainless steel workpiece were conducted, where both single and multipass techniques were used. The results showed that the most appropriate process parameters for gaining the best quality of polished surface were a double-pass strategy, abrasive mesh 300, and a traverse rate of 39.96 mm/min. Barabas and Florescu [30] studied statistical possibilities for enhancing AWJM performance. The Taguchi method was used, which permitted focusing on the process parameters that had the most effect on the process. The conclusions showed that the stochastic effects resulting from the marble structure could be reduced, and the statistical methods used for the experiments allowed decreasing the number of cracks in the material after the machining process.

The importance of adopting alternatives strategies to improve AWJM is even more significant in the case of the processing of hard-to-cut materials, such as hardened steel, titanium, and nickel alloys. In particular, Ti-6Al-4V has a high strength-to-weight ratio, is more common than any other titanium alloys, represents more than 50% of the world’s supply, and belongs to the α + β alloy group [31,32]. It is a common choice for applications such as compressor blades, airframe components, rocket engine cases, and rings used in jet engines. Approximately 155,000 kg of titanium will be consumed in 2020 by the aviation sector, the largest consumer of titanium [33]. This alloy can be divided into two phases at usual atmospheric pressure and temperature: the α phase with hexagonal close packed (HCP) crystallographic structure, and the β phase with body centered cubic (BCC) structure [34]. Τhe Al, O, and N elements play a significant role in the stability of the α phase, but the vanadium and iron elements stabilize the β phase [35]. Due to the superior characteristics of Ti-6Al-4V, several authors have studied the machining of this alloy using AWJM. Huang, Kinnell, and Shipway [36] studied the effect of abrasive waterjet cleaning on the grit embedment and surface quality of this titanium alloy. They found that the use of pure WJ could remove embedded abrasives more effectively with specific process conditions. Perec [37] compared the use of three different abrasive types, namely garnet, olivine, and crushed glass during the AWJM of Ti-6Al-4V. He found that garnet was the most effective for obtaining a greater depth of penetration, followed by olivine and crushed glass, but olivine led to larger focusing tube wear, followed by garnet and crushed glass. Seo, Ramulu, and Kim [38] studied the surface roughness of slots produced by AWJM on a Ti-6Al-4V workpiece, as well as grit embedment; and Hascalik, Caydas, and Gürün [39] thoroughly explored the effect of traverse speed during the AWJM of the same alloy, finding that traverse speed considerably affects the surface morphology and kerf taper ratio.

As can be seen from the above literature review, although some authors investigated various aspects of the multipass AWJM strategy, there have been no relevant studies that thoroughly analyzed the influence of the multipass strategy on the formation of slots under different AWJM parameters. Using a constant abrasive mass flow rate and SoD, and by changing the traverse speed, the jet pressure, and the number of passes (up to 4), this study aimed to define the changes of the depth of penetration and slot geometry, as well as the impact on productivity and cutting efficiency of a challenging and difficult to machine material, such as Ti-6Al-4V. Therefore, in this study, the effect of multiple passes was investigated in relation to the depth of cut, kerf width, kerf taper angle, material removal rate, and cutting efficiency during the AWJM of a Ti-6Al-4V alloy, and various useful conclusions were drawn.

2. Materials and Methods

AWJM experiments under varying process conditions were conducted in the present study, with the intention of determining whether using more than one pass to mill an object had a significant impact on the kerf characteristics and whether or not it improved the process efficiency in a positive way. In the current study, a Ti-6Al-4V alloy was used, also called titanium grade 5. Table 1 contains the chemical composition of the workpiece.

Table 1.

Chemical Composition (in wt. %).

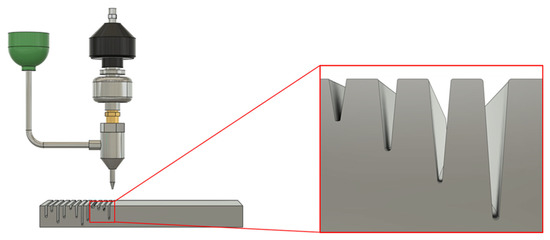

This study was carried out on a model HWE-1520 H.G. RIDDER Automatisierungs GmbH machine (H.G. RIDDER H., Hamm, Germany), on which the AWJ milling experiments were conducted. This machine has the capability to employ a wide range of jet pressure values, ranging from 50 to 400 MPa, abrasive mass flow rates from 10 g/min to 600 g/min, as well as a wide range of traverse feeds, and is operated using Siemens SINUMERIK software. Twenty experiments were conducted, with four levels of passes, three levels of traverse speed, Jet pressure at a content abrasive mass flow rate (ma), and a constant standoff distance. In the case of multiple passes, the alternating direction strategy was adopted. The abrasive used was garnet of mesh size 80. The following Figure 1 shows a graphical representation of the multipass AWJM setup and the H.G. RIDDER AWJ center model HWE-1520 AWJ machine. In order to avoid undesired effects of nozzle wear on the results, a new nozzle was employed at the beginning of the experiments, and the wear was checked after a few passes. However, given that the abrasive was garnet, which is less hard than the nozzle material, moderate wear was expected with respect to the number of experiments performed in the current study.

Figure 1.

Graphical representation of the AWJM process and the influence of the process parameters on the slot’s geometry.

The slot dimensions were measured using a VHX-7000 ultra-deep-field microscope (KEYENCE, Mechelen, Belgium). The microscope was a focus variation microscope (FVM), which uses 20–2000× lenses. The measuring method of the FV microscope is similar to confocal microscopy, and the source of white light is an LED, which passed through a semi-transparent mirror and a lens before reaching the measuring surface. A beam splitter directed the reflected light from the focused areas back through the lens to an optical detector, where it was registered geometrically and photometrically using a photonic detector. By combining the small depth of a classical optical system with vertical scanning, FV is able to provide colorful, high-resolution 3D surface measurements at a low cost. As a 4K camera was used, the resolution of the produced images was 4096 × 2160. Based on the technique mentioned above, it was then possible to measure the kerf width and depth from the 2D images and to generate the 3D slot surface from the 2D images using the kerf width and depth measurements. The measurements were conducted with IMAGE-J software, based on the obtained images from the microscope. The measurements of the depth of penetration and kerf width were conducted at various positions of the slot length (6 measurements), and so average and standard deviation values could be calculated. The following Figure 1 is a graphical representation of the AWJM process, as well as the influence of the multi-pass method on the slot’s geometry.

The purpose of this study was to examine the potential benefits that multipass AWJM method applications could generate. Thus, experiments were conducted to generate slots, in which the geometric characteristics were measured and analyzed. Twenty experiments were conducted with four levels of number of passes, three levels of traverse speed, and with the jet pressure at a constant abrasive mass flow rate and stand-off distance. The penetration depth, top kerf width, and kerf taper angle were considered relevant parameters for describing the groove’s geometric properties. As a result, they can be used for further development of the method in the future. The following Table 2 contains the experimental combinations, and each of them was repeated for four different numbers of passes; namely, from 1 to 4 passes, for a total of 20 experiments.

Table 2.

Experimental parameters.

These experiments were chosen on the basis of a one-factor-at-a-time (OFAT) strategy, which is simpler than the usual DOE methods, as it considers the effect of a single parameter for every sequence of experiments, rather than a combination [40]. As the number of experiments required if a fractional design had been adopted would be large, because every experiment was repeated four times for 1, 2, 3, and 4 passes, it was decided that this experimental strategy would be favorable to investigate the effect of multiple passes under various process conditions, so as to find out whether multiple passes were more effective under specific conditions or in general.

The experimental parameters presented in Table 2 can be explained as follows: for a constant value of jet pressure, namely 150 MPa, three different values of traverse feed were used; for a constant value of traverse feed, namely 500 mm/min, two values of jet pressure are used. In order to enhance the understanding of this method, the different levels of the two parameters are presented in bold letters in Table 2. Although this method cannot be employed to study all the interactions between the two parameters and is considered less effective that fractional or full factorial designs [41,42], it was sufficient to indicate some important trends [43].

In Figure 2a, indicative incision profiles are depicted for different jet pressures and traverse feed values for 1 pass. As can be observed, different depths of penetration and kerf shapes were obtained as expected, in order to evaluate the effect of the multipass strategy in different cases. Moreover, in Figure 2b, an indicative 3D representation of a produced slot is depicted.

Figure 2.

Indicative images of the produced slots: (a) 2D image of the produced slots under various process conditions, (b) 3D representation of the produced slot.

3. Results and Discussion

Machining slots in hard-to-machine titanium alloys is a challenging task. Thus, in this study, we focused on multipass strategy applications and the benefits they could bring. The conducted experiments resulted in generating slots in which the geometric characteristics were measured and analyzed. In this section, the results regarding the penetration depth, top kerf width, and kerf taper angle, which are regarded as important parameters for the description of slot geometry, are presented, as well as results regarding the productivity and cutting efficiency of the process.

3.1. The Effect of the Multipass Strategy on the Depth of Penetration

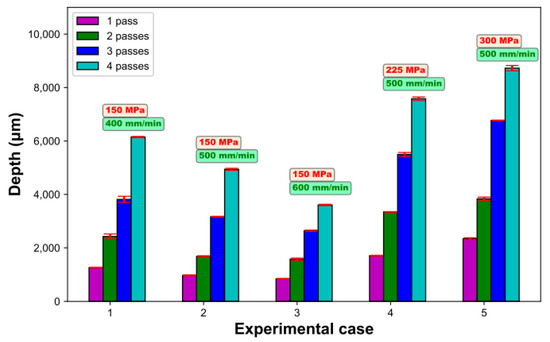

In this subsection, the research focused on checking the influence of the jet pressure, traverse feed rate, and the number of passes on the depth of penetration, with constant stand-off distance and abrasive mass flow rate values. Figure 3 shows the influence of machining one slot multiple times and other parameters on the depth. Grouping the input into five cases made it easier to separate the influence of particular parameters on the multipass method results. Different colors represent different numbers of passes, and for every case, 1 to 5, the pressure and traverse feed rate values were changed as shown in Table 2.

Figure 3.

Influence of multipass strategy on the depth of penetration.

In each case, the first three slots were machined using a 150 MPa jet pressure; and for the next two, the jet pressure was increased to 225 and 300 MPa, respectively. For the first slot, the traverse feed rate was 400 mm/min, for the third 600 mm/min, and the rest of the slots were machined using a 500 mm/min traverse feed rate. As we can see on the graph, all parameters were significant and influenced the results. The slots in the first case were deeper than in the second and third cases, due to the smaller value of the traverse feed rate. A slower movement of the nozzle above the workpiece material caused the removal of more material in the area per time unit and consequently deeper slots [6,7]. In the fourth and fifth cases, the slots were deeper, because of the higher jet pressure [7]. Every additional pass through the slot generated deeper grooves [26]. This effect can be observed in each of the five cases.

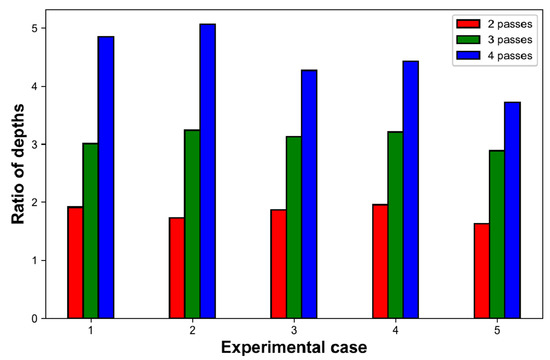

In the experiment, the mass flow rate was constant, the pressure increased, and the variation in the traverse feed rate values was not large. Despite the beam energy loss connected to the rising stand-off distance in every pass, the ratio of depths, calculated as the ratio of depths between each pass and the first one and featured in Figure 4, increased for each additional pass. The correlation between passes and depth was not thought to be directly linear. The values obtained by dividing the multipass results by the one pass result allowed us to approximate the increase in the depth of the slots after machining them repeatedly. Despite the change in parameters such as the jet pressure or nozzle feed rate, the changes for subsequent transitions between the indicated cases did not differ significantly. Using the multipass method we could predict that, after a second pass, the penetration depth will practically double; after a third, the depth of the slots will reach about three times the original value; and after four passes, it will reach values between four and five times higher than with a single cut. This can be probably attributed to the fact that, after each pass, the geometry of the slot bottom surface becomes more irregular and non-flat compared to the first pass [13]. Thus, it is possible that in some cases, such as those with a lower traverse feed rate and lower pressure, the final pass can aggravate the variance of the slot geometry to a such a considerable extent that a larger depth of penetration is achieved. It can be concluded that as a rule of thumb, the correlation of number of passes and depth of penetration is almost linear up to three passes, and then, depending on the case, a further increase in the number of passes can lead to larger increase of the depth of cut, especially for the cases with lower pressure, as can be seen in Figure 4, whereas for cases with higher pressures, the relationship between the depth of cut and number of passes can be linear, up to four passes.

Figure 4.

Ratio of depth obtained with 2, 3, or 4 passes, with respect to the depth of the first pass under various experimental conditions.

The multipass method can be thus used to control the depth of the cut, while keeping the machining parameters at lower levels. A change in the number of passes could be used, for example, when selecting a softer abrasive would be beneficial. The difference between the depth of the slots after one pass, using 150 and 300 MPa in cases 2 and 5, was about 1370 µm, which is almost 1.5 times more. On the other hand, the average deepening of the slot after the second pass was above 1.8, so that an additional pass could produce deeper slots in the titanium alloy than doubling the pressure value. This alternative can also be evaluated in terms of energy consumption, in order to determine whether the additional machining time for two passes is less expensive than increasing the power consumption by doubling the jet pressure for a single step.

3.2. The Effect of the Multipass Method on the Top Width of the Slots

In all five experimental cases, one can see that the output values varied in different ranges. The most significant parameter influencing the top kerf width was the stand-off distance [7], which in this case was constant; however, other parameters such as the traverse feed rate caused some variations between slots. In most tests, increasing the number of passes led to an increase in the kerf width, at least for the average value. In Figure 5, there is a visible trend in some cases, in which after the third pass, the results approached a relatively high level. This might have been due to the curvature of the stream during each pass and the influence of the other machining parameters to varying degrees during the different passes. On the other hand, the results from different input parameters did not differ significantly, something that can be attributed on the fact that the traverse feed rate and especially the jet pressure were less significant in regulating the kerf width than the stand-off distance. Based on the presented graph, it can be concluded that, although in most cases a greater number of passes widened the top kerf, direct control of the width of the grooves using the tested parameters was not possible.

Figure 5.

Variation of the top kerf width with an increasing number of passes and different process conditions.

Figure 6 shows the ratio of widths, which was created by dividing the value of the top kerf width after four passes by the value obtained after one pass. This operation was repeated for each case. This ratio informs us about how often the slot would be wider after four passes, as compared to with one pass. In this case, the results show that the ratio value oscillated around 1.1–1.2, which means that the multipass strategy did not have a significant influence on the top kerf width of the slots, as was also observed in another study of multipass AWJM [10]. On the other hand, in every case, the ratio value exceeded one, therefore increasing the number of passes four times tended to generate wider slots.

Figure 6.

Ratio of top kerf width obtained with four passes, with respect to the width of the first pass under various experimental conditions.

It can be concluded that in the case of the top kerf width, a direct trend between the top kerf width and number of passes could not be established in every case. In some cases, the widening of the kerf occurred after two passes and remained practically constant after the third pass, whereas in some cases, such as 1 and 2, a considerable increase of the kerf width occurred only after the third pass. Finally, after four passes, the increase of top kerf width, with respect to its value after the first pass, was clear. Thus, the only clear trend that could be established was that after four passes, the top kerf width increased independently from the other conditions.

3.3. The Effect of a Multipass Strategy on the Kerf Taper Angle

One of the important quality parameters for cutting a workpiece material and also for creating more complex geometries is the kerf taper angle. It would be highly desirable to produce machine elements, parts, and geometries in a way that would enable the processing of their edges such that they were perfectly perpendicular to the face of the element. It can therefore be concluded that the challenge for engineering is to reduce the kerf taper angle. As previous studies showed, this parameter is strongly affected by all variable process parameters [9,13]. In Figure 7, for cases 1–3, where lower pressure values were selected, one pass of the nozzle generated explicitly higher values of the kerf taper angle, whereas subsequent passes reduced this value, something that was also observed in the relevant literature [10,15,16,21]. Among the input variables that can reduce the angle when their values are increased, we can indicate the jet pressure and the number of passes, whereas the jet traverse rate, in most cases, increases the kerf taper angle. In one case out of the five, it can be seen that the fourth pass increased the angle value, but this might have been an exception related to measurement error or the impact of the other process parameters. Choosing adequate process parameters could reduce the taper angle, without the need to use a multipass strategy [13]. For example similar or better results could be achieved after machining twice using a 150 MPa jet pressure and 500 or 600 mm/min traverse feed rate, instead of machining using once using a 300 MPa jet pressure and 500 mm/min traverse feed rate. The reduction in kerf angle is probably partially related to the increasing distance between the nozzle and the workpiece. In general, the water beam enters the already created slot, deepening it and also removing more material on the sides of the slot, which makes the angle sharper. There is also an undeniable relationship between the groove depth and diminishing kerf taper angle.

Figure 7.

Variation of the kerf taper angle for an increasing number of passes and different process conditions.

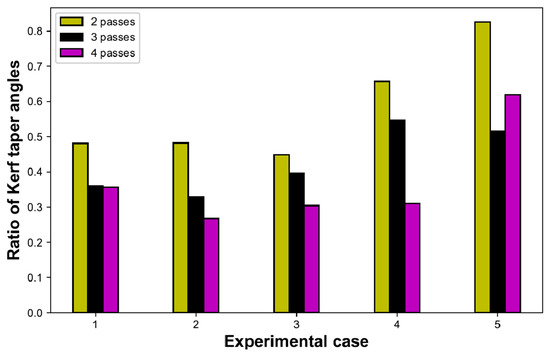

For a better comparison, the ratio between one and multiple passes was generated and is featured in Figure 8. The measurement results indicated that the ratio between one and several passes was less than one, thus indicating a decreasing trend of kerf taper angle with a higher number of passes. It can be deduced that there was a clear trend that caused the reduction of kerf taper angle after conducting additional passes [28]. In most cases, the successive passes had less and less impact on the result. Additionally, we can conclude that the other parameters, such as jet pressure and traverse feed rate, also visibly affected variations in the angle values. In the graphs, the differences between cases changed, so this means the values of the ratio of kerf taper angle differed in the studied cases. The smallest difference existed in the first case, between 3 and 4 passes, and then, after changing the pressure to 225 MPa, the difference increased. After using a jet pressure value of 300 MPa, the previously obtained effect of reducing the angle when increasing the number of passes no longer occurred; thus, as can be seen in the last case, the kerf taper angle increased when increasing the number of passes from three to four.

Figure 8.

Ratio of kerf taper angle obtained with 2, 3, or 4 passes, with respect to the taper angle of the first pass under various experimental conditions.

From the aforementioned discussion, it can be concluded that there was a direct effect of multiple passes on the kerf taper angle, with the increase of passes leading directly to a smaller kerf taper angle and a sharper shape of the incision profile of the slots. This was attributed to the gradual erosion of material on the slot walls, which reduced its width, especially in the region close to the bottom of the slots. The reduction of kerf taper angle was less intense as the number of passes increased; and in the cases with the longest exposure time or highest kinetic energy, the final pass led to a negligible difference in the kerf taper angle value or even a small increase.

Finally, from the obtained results, it can be deduced that a suitable combination of process parameters and the number of passes can lead to desirable values of kerf taper angle, and thus by choosing the multipass method, the quality of the slot, associated with the minimum kerf width and taper angle can also be improved.

3.4. The Effect of Multipass Strategy on Material Removal Rate and Cutting Efficiency

Apart from the kerf characteristics, which are related to the desired slot geometry and quality, it is important to estimate other crucial quantities of the AWJM process, such as the productivity, which is also essential from a different point of view. By altering process parameters or using a different number of passes, it is possible that the productivity, represented by material removal rate (MRR), can be regulated. From the observations of the slot geometry, it was deduced that during single pass milling, the amount of the removed material was decreased at higher traverse feed rates and increased at higher jet pressure values, as was anticipated due to the different energy values and contact time between the jet and the workpiece surface. Although this trend was still evident in the case of multiple passes, it was clear that the amount of removed material did not increase proportionally. Thus, as aforementioned, although the depth of penetration increased after each pass, the fact that the kerf width was almost unaffected and kerf taper was reduced, as well as the reduction of energy of the beam at higher depths, led to a less efficient material removal. Moreover, the previous interaction between the beam and material caused an increase in the residual compressive stress and difficulty with detaching the material during the erosion process. The time needed for removing the same quantity of material for every additional pass became longer.

If the average MRR values are calculated, taking into consideration the different number of passes in each case, the results in Figure 9 clearly illustrate the previous observations about removed material and confirm the variation of MRR after multiple passes. It can be seen that the single-pass AWJM led to a greater MRR in all cases, with the MRR being reduced at higher traverse feed rates and increased at higher jet pressure values. In the case of multiple passes, at lower jet pressures, the effect of multiple passes on the MRR was less important, as the variation of MRR values was minimal. In some cases, the MRR increased under more passes and a faster feed rate, but this increase was rather small compared to the cases with a higher jet pressure. At higher jet pressures, a clear trend can be observed regarding MRR, as it was gradually decreasing, eventually being reduced to almost half the value of MRR for the single-pass milling. These results show that, although the process parameters and number of passes can alter kerf characteristics, it is essential to also consider the effect of these choices on the productivity and to avoid parameter combinations that render AWJM inefficient.

Figure 9.

Variation of MRR for the increasing number of passes and different process conditions.

It can be concluded that, in cases with a longer exposure time such as case 1, or higher kinetic energy, such as cases 4 and 5, the correlation between average MRR and number of passes was more evident, especially in the cases with higher kinetic energy, as the subsequent passes led to a lower overall MRR. On the contrary, when the exposure was shorter, the number of passes did not affect the MRR. As a rule of thumb, single pass cutting leads to higher MRR, but the final decision should take into account the values of kerf characteristics, in order to reach a compromise between productivity and slot quality.

Finally, in order to quantify the cutting efficiency of AWJM, it is estimated as the ratio of the removed material per unit mass of abrasive removed [28]. The results in Figure 10 indicate generally similar trends to those for MRR, as the cutting efficiency is shown to decrease at higher traverse feed rates and increase at higher jet pressures for single-pass milling. The maximum efficiency was obtained for cases with a single pass. Moreover, for multipass milling at lower pressures, the variation of cutting efficiency was minimal, and in most cases, a higher traverse feed was slightly better than lower values. A clear decreasing trend for cutting efficiency was established for higher jet pressures; however, in almost every case, machining at higher pressures was more efficient, indicating that a successful trade-off between sufficient kerf quality and cutting efficiency can be found by adopting higher jet pressures and a moderate number of passes.

Figure 10.

Variation of the cutting efficiency when increasing the number of passes and with different process conditions.

4. Conclusions

The presented research was conducted to investigate the impact of the use of the multipass method on the geometric characteristics of slots produced in a Ti-6Al-4V workpiece by AWJM, as well as the productivity and cutting performance variation, with respect to the number of passes. In order to conduct a comprehensive study, the effect of multiple passes was also evaluated on cases with different traverse feed rates and jet pressure values. After the experimental work was conducted and the results were properly analyzed, various conclusions were drawn.

It was determined that the multipass strategy made it possible to generate deeper slots in the sample, without changing other machining parameters. Using the multipass method for machining Ti-6Al-4V, the penetration depth was shown to have an almost linear dependence up to three passes in most cases. Jet pressure plays a significant role, as it can increase the depth considerably at higher values. Moreover, the anticipated correlation with jet pressure and traverse feed rate was also observed, due to the increased kinetic energy or decrease of the exposure time of the jet.

Regarding the top kerf width, the findings confirmed that both of the other parameters and the multipass method did not have a large impact on the width of the slots under a constant abrasive mass flow rate and stand-off distance. The lack of a direct rule, according to which the kerf width varied, was noted, whereas for the highest number of passes, a slight increase of kerf width was observed in every case.

The multipass method was confirmed to be a rather convenient and effective way to reduce the kerf taper angle. It was observed that, by increasing the jet pressure and number of passes, the kerf angle decreased. Due to the decreasing beam energy and the limitations of the method in reducing the angle, the influence of successive passes became smaller and smaller.

Regarding MRR and cutting efficiency, it was shown that they are decreased with an increasing number of passes, thus it becomes evident that single-pass AWJM leads to a higher MRR and cutting efficiency compared to a multipass strategy in every case.

From the obtained results, it becomes evident that in some cases, similar results can be obtained either by regulating crucial process parameters, such as jet pressure and traverse rate, or by using a different number of passes. In order to obtain both high productivity and favorable kerf characteristics, it is suggested that a value of jet pressure higher than 150 MPa, a moderate value of traverse feed, e.g., 500 mm/min, and a moderate number of passes are employed, as the use of a relatively high pressure and moderate traverse feed ensures a sufficient depth and MRR, and reduced kerf taper angle, whereas the use of two or three passes can maintain the top kerf width and kerf taper angle at acceptable levels without compromising the MRR.

Author Contributions

Conceptualization, N.E.K. and P.K.-O.; methodology, N.E.K., P.K.-O. and L.D.; software, L.D.; validation, N.E.K., P.K.-O. and L.D.; formal analysis, L.D.; investigation, L.D.; resources, P.K.-O. and L.D.; data curation, N.E.K. and L.D.; writing—original draft preparation, L.D., N.E.K. and P.K.-O.; writing—review and editing, A.P.M.; visualization, P.K.-O., N.E.K. and L.D.; supervision, A.P.M.; project administration, A.P.M.; funding acquisition, N.E.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ness, N.; Zibbell, R. Abrasion and erosion of hard materials related to wear in the abrasive waterjet. Wear 1996, 196, 120–125. [Google Scholar] [CrossRef]

- Kovacevic, R.; Hashish, M.; Mohan, R.; Ramulu, M.; Kim, T.J.; Geskin, E.S. State of the Art of Research and Development in Abrasive Waterjet Machining. J. Manuf. Sci. Eng. 1997, 119, 776–785. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Pradeep, K.M.; Mugilvalavan, M.; Shakeel, A.L.A.K. Abrasive Water Jet Machining process: A state of art of review. J. Manuf. Process. 2020, 49, 271–322. [Google Scholar] [CrossRef]

- Jani, S.P.; Kumar, A.S.; Khan, M.A.; AJose, S. Design and optimization of unit production cost for AWJ process on machining hybrid natural fibre composite material. Int. J. Lightweight Mater. Manuf. 2021, 4, 491–497. [Google Scholar] [CrossRef]

- Thakur, R.K.; Singh, K.K. Abrasive waterjet machining of fiber-reinforced composites: A state-of-the-art review. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 381. [Google Scholar] [CrossRef]

- Hashish, M. Three-Dimensional Machining with Abrasive-Waterjets. In Jet Cutting Technology; Fluid Mechanics and Its Applications; Lichtarowicz, A., Ed.; Springer: Dordrecht, The Netherlands, 1992; Volume 13, pp. 605–620. [Google Scholar] [CrossRef]

- Axinte, D.A.; Karpuschewski, B.; Kong, M.C.; Beaucamp, A.T.; Anwar, S.; Miller, D.; Petzel, M. High Energy Fluid Jet Machining (HEFJet-Mach): From scientific and technological advances to niche industrial applications. CIRP Ann. 2014, 63, 751–771. [Google Scholar] [CrossRef]

- Karakurt, I.; Aydin, G.; Aydiner, K. An Experimental Study on the Depth of Cut of Granite in Abrasive Waterjet Cutting. Mater. Manuf. Process. 2012, 27, 538–544. [Google Scholar] [CrossRef]

- Chen, J.; Yuan, Y.; Gao, H.; Zhou, T.; Wu, Z. Predictive modeling approach for the jet lag in multi-pass cutting of thick materials using abrasive waterjet. J. Manuf. Process. 2022, 83, 143–156. [Google Scholar] [CrossRef]

- Wang, J.; Guo, D.M. The cutting performance in multipass abrasive waterjet machining of industrial ceramics. J. Mater. Process. Technol. 2003, 133, 371–377. [Google Scholar] [CrossRef]

- Shipway, P.H.; Fowler, G.; Pashby, I.R. Characteristics of the surface of a titanium alloy following milling with abrasive waterjets. Wear 2005, 258, 123–132. [Google Scholar] [CrossRef]

- Fowler, G.; Pashby, I.R.; Shipway, P.H. The effect of particle hardness and shape when abrasive water jet milling titanium alloy Ti6Al4V. Wear 2009, 266, 613–620. [Google Scholar] [CrossRef]

- Srinivasu, D.S.; Axinte, D.A.; Shipway, P.H.; Folkes, J. Influence of kinematic operating parameters on kerf geometry in abrasive waterjet machining of silicon carbide ceramics. Int. J. Mach. Tools Manuf. 2009, 49, 1077–1088. [Google Scholar] [CrossRef]

- Alberdi, A.; Rivero, A.; López de Lacalle, L.N.; Exteberria, I.; Suárez, A. Effect of process parameter on the kerf geometry in abrasive water jet milling. Int. J. Adv. Manuf. Technol. 2010, 51, 467–480. [Google Scholar] [CrossRef]

- Miao, X.; Qiang, Z.; Wu, M.; Song, L.; Ye, F. The optimal cutting times of multipass abrasive water jet cutting. Int. J. Adv. Manuf. Technol. 2018, 97, 1779–1786. [Google Scholar] [CrossRef]

- Doreswamy, D.; Akash, V.; Natt, W.; Anjaiah, D. Machining of D2 heat treated steel using abrasive waterjet: The effect of standoff distance and feed rate on kerf width and surface roughness. Int. J. Res. Eng. Technol. 2014, 3, 417–421. [Google Scholar]

- Wang, J.; Zhong, Y. Enhancing the depth of cut in abrasive waterjet cutting of alumina ceramics by using multipass cutting with nozzle oscillation. Mach. Sci. Technol. 2009, 13, 76–91. [Google Scholar] [CrossRef]

- Xiong, J.; Wan, L.; Qian, Y.; Sun, S.; Li, D.; Wu, S. A new strategy for improving the surface quality of Ti6Al4V machined by abrasive water jet: Reverse cutting with variable standoff distances. Int. J. Adv. Manuf. Technol. 2022, 120, 5339–5350. [Google Scholar] [CrossRef]

- Miao, X.; Qiang, Z.; Wu, M.; Song, L.; Ye, F. Research on quality improvement of the cross section cut by abrasive water jet based on secondary cutting. Int. J. Adv. Manuf. Technol. 2018, 97, 71–80. [Google Scholar] [CrossRef]

- Klocke, F.; Schreiner, T.; Schüler, M.; Zeis, M. Material Removal Simulation for Abrasive Water Jet Milling. Procedia CIRP 2018, 68, 541–546. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, P.; Gao, H.; Soulat, D. A study of abrasive waterjet multi-pass cutting on kerf quality of carbon fiber-reinforced plastics. Int. J. Adv. Manuf. Technol. 2019, 105, 4527–4537. [Google Scholar] [CrossRef]

- Hejjaji, A.; Zitoune, R.; Toubal, L.; Crouzeix, L.; Collombet, F. Influence of controlled depth abrasive water jet milling on the fatigue behavior of carbon/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 397–410. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Pavithra, E.; Shamli, C.S. Investigation of surface morphology and topography features on abrasive water jet milled surface pattern of SS 304. J. Test. Eval. 2019, 48, 2981–2997. [Google Scholar] [CrossRef]

- Nawi, M.N.M.; Husin, H.; Gebremariam, M.A.; Azhari, A. Optimization of paint removal operation using waterjet cleaning process. In Recent Trends in Manufacturing and Materials towards Industry 4.0; Osman Zahid, M.N., Abdul Sani, A.S., Mohamad Yasin, M.R., Ismail, Z., Che Lah, N.A., Mohd Turan, F., Eds.; Springer: Singapore, 2021; pp. 485–494. [Google Scholar]

- El Mesalamy, A.S.; Youssef, A. Enhancement of cutting quality of abrasive waterjet by using multipass cutting strategy. J. Manuf. Process. 2020, 60, 530–543. [Google Scholar] [CrossRef]

- Yuan, Y.; Chen, J.; Gao, H.; Wang, X. An investigation into the abrasive waterjet milling circular pocket on titanium alloy. Int. J. Adv. Manuf. Technol. 2020, 107, 4503–4515. [Google Scholar] [CrossRef]

- Uhlmann, E.; Männel, C.; Braun, T. Efficient abrasive water jet milling for near-net-shape fabrication of difficult-to-cut materials. Int. J. Adv. Manuf. Technol. 2020, 111, 685–693. [Google Scholar] [CrossRef]

- Karmiris-Obratański, P.; Karkalos, N.E.; Kudelski, R.; Papazoglou, E.L.; Markopoulos, A.P. On the Effect of Multiple Passes on Kerf Characteristics and Efficiency of Abrasive Waterjet Cutting. Metals 2021, 11, 74. [Google Scholar] [CrossRef]

- Yuvaraj, N. Experimental investigation on abrasive water jet polishing of stainless steel: A preliminary study. Int. J. Surf. Sci. Eng. 2021, 15, 67–86. [Google Scholar]

- Barabas, S.; Florescu, A. Reduction of Cracks in Marble Appeared at Hydro-Abrasive Jet Cutting Using Taguchi Method. Materials 2022, 15, 486. [Google Scholar] [CrossRef]

- Vasanth, S.; Muthuramalingam, T.; Vinothkumar, P.; Geethapriyan, T.; Murali, G. Performance Analysis of Process Parameters on Machining Titanium (Ti-6Al-4V) Alloy Using Abrasive Water Jet Machining Process. Procedia CIRP 2016, 46, 139–142. [Google Scholar] [CrossRef]

- Arrazola, P.J.; Garay, A.; Iriarte, L.M.; Armendia, M.; Marya, S.; Le Maître, F. Machinability of titanium alloys (Ti6Al4V and Ti555.3). J. Mater. Process. Technol. 2009, 209, 2223–2230. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F. Additive Manufacturing of Titanium Alloys, 1st ed.; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta. Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Tungala, V.; Dutt, A.K.; Choudhuri, D.; Mishra, R.S.; Tamirisakandala, S.A.; Cho, K.C.; Brennan, R.E. Friction Stir Processing of Beta C and Ti-185: A Unique Pathway to Engineer Microstructures for Exceptional Properties in β Titanium Alloys. Metall. Mater. Trans. A 2019, 50, 4075–4084. [Google Scholar] [CrossRef]

- Huang, L.; Kinnell, P.; Shipway, P.H. Parametric effects on grit embedment and surface morphology in an innovative hybrid waterjet cleaning process for alpha case removal from titanium alloys. Procedia CIRP 2013, 6, 594–599. [Google Scholar] [CrossRef]

- Perec, A. Experimental research into alternative abrasive material for the abrasive water-jet cutting of titanium. Int. J. Adv. Manuf. Technol. 2018, 97, 1529–1540. [Google Scholar] [CrossRef]

- Seo, Y.W.; Ramulu, M.; Kim, D. Machinability of titanium alloy (Ti-6Al-4V) by abrasive waterjets. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2003, 217, 1709–1721. [Google Scholar] [CrossRef]

- Hascalik, A.; Çaydaş, U.; Gürün, H. Effect of traverse speed on abrasive waterjet machining on Ti-6Al-4V alloy. Mat. Des. 2007, 28, 1953–1957. [Google Scholar] [CrossRef]

- Kraber, S. Augmenting one-factor-at-a-time data to build a DOE. J. Plast. Film. Sheeting 2023, 39, 15–18. [Google Scholar] [CrossRef]

- Czitrom, V. One-Factor-at-a-Time versus designed experiments. Am. Stat. 1999, 53, 126–131. [Google Scholar]

- Astakhov, V.P. Design of experiment methods in Manufacturing: Basics and Practical Applications. In Statistical and Computational Techniques in Manufacturing; Davim, J.P., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–54. [Google Scholar]

- Banu, A.; Ali, M.Y.; Rahman, M.A.; Konneh, M. Stability of micro dry wire EDM: OFAT and DOE method. Int. J. Adv. Manuf. Technol. 2020, 106, 4247–4261. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).