Biofouling Removal Using a Novel Electronic System for Driving an Array of High Power Marinised Transducers

Abstract

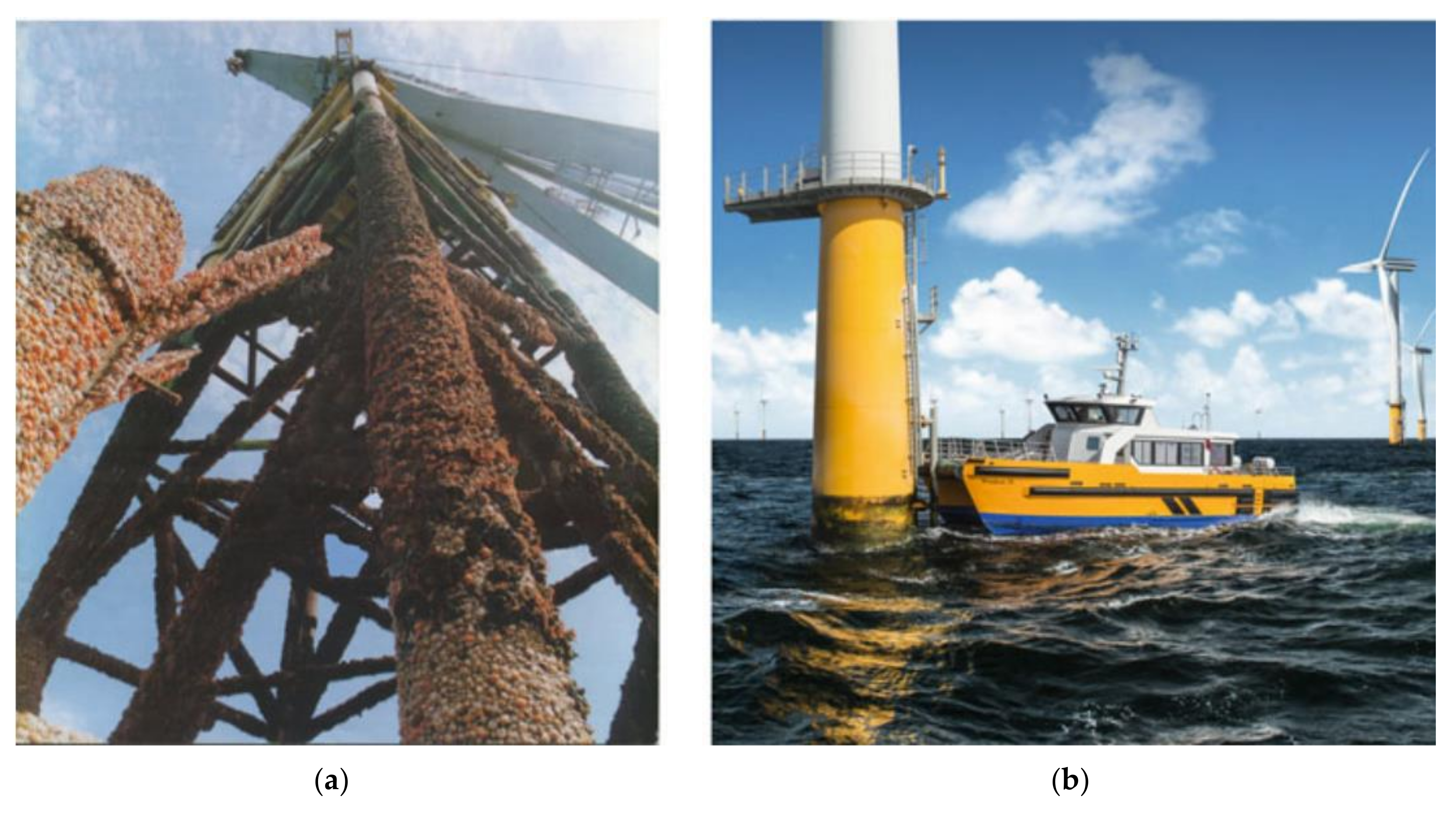

1. Introduction

2. Electrical Equipment and Assembly to Power the Transducer

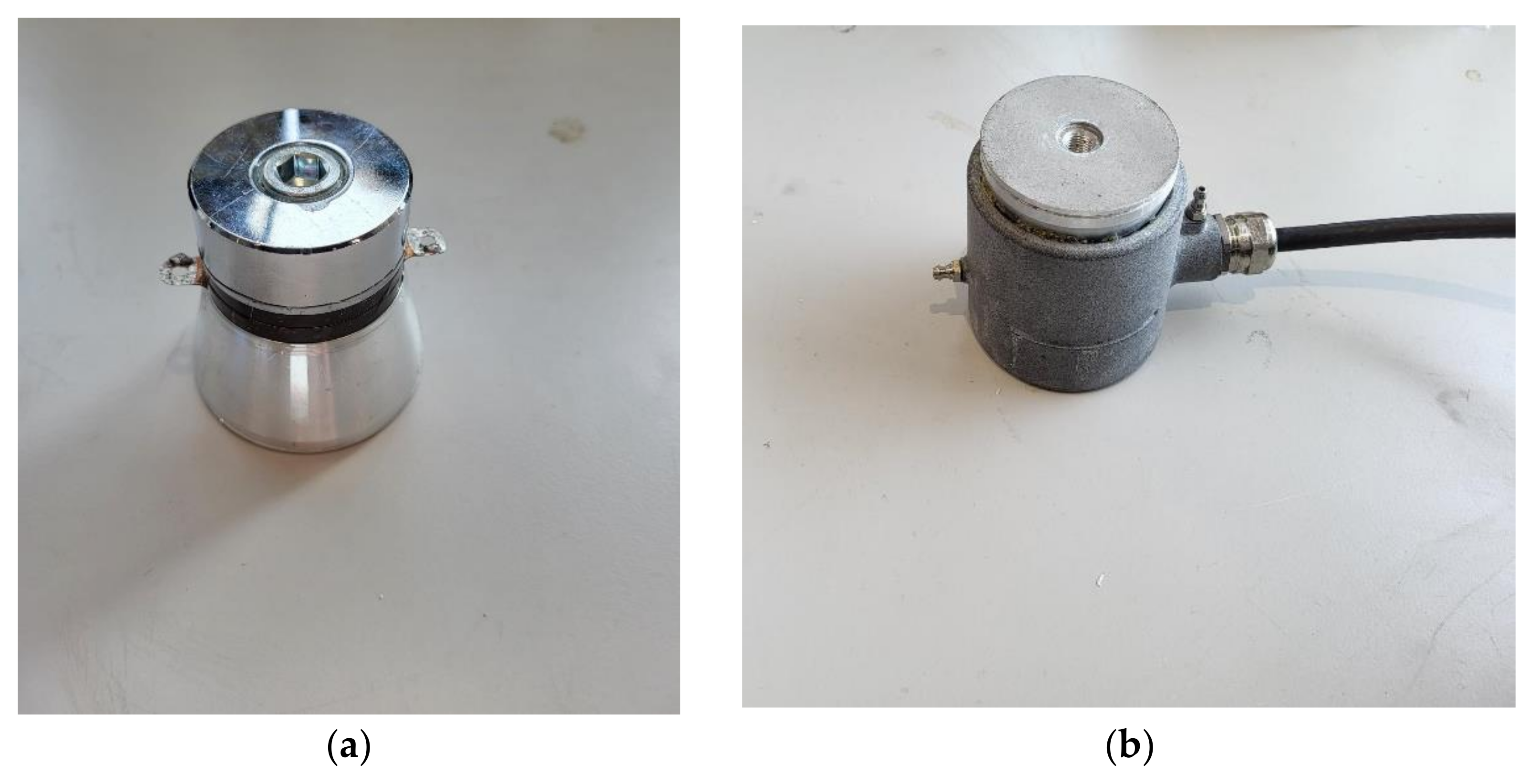

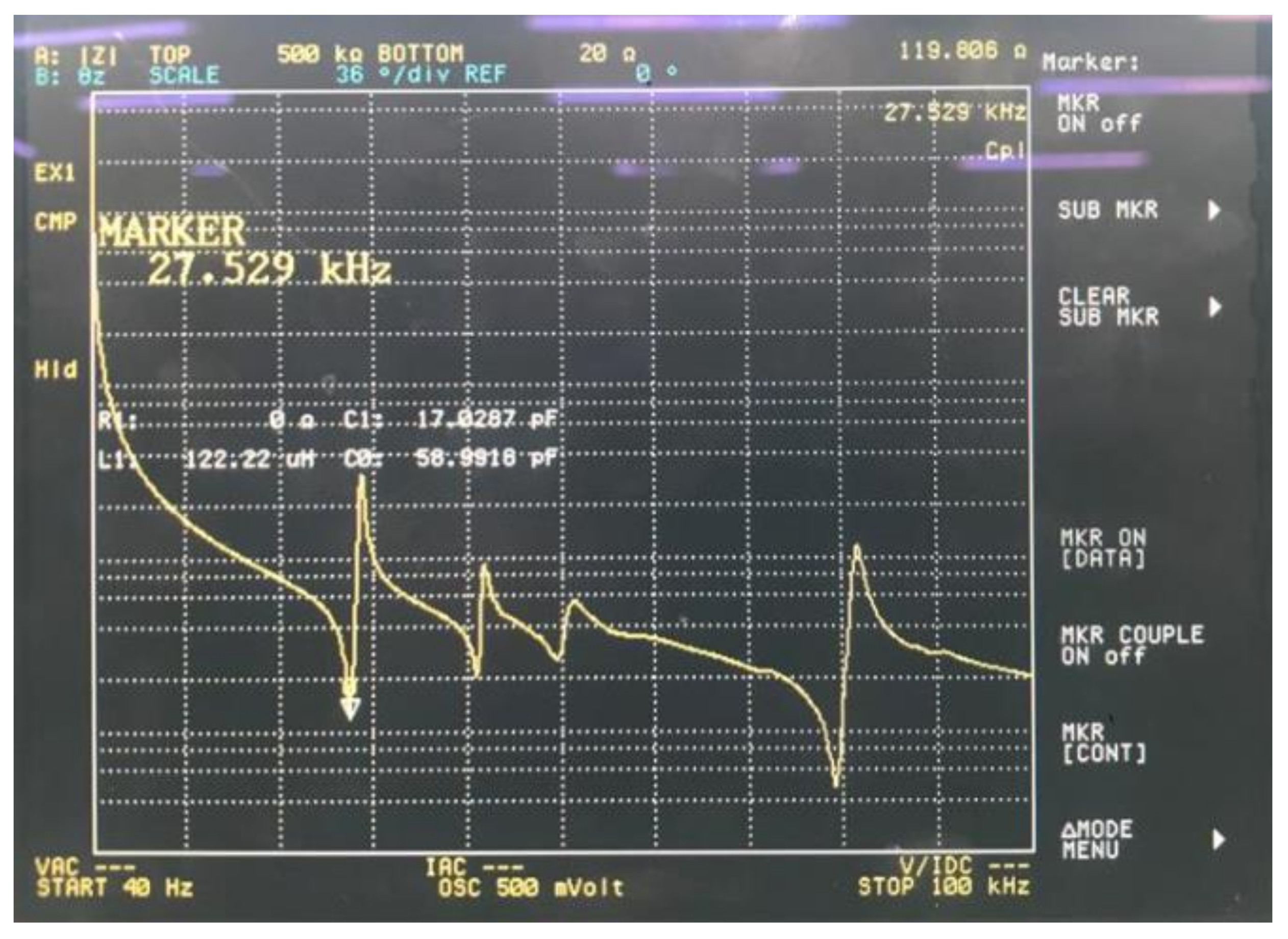

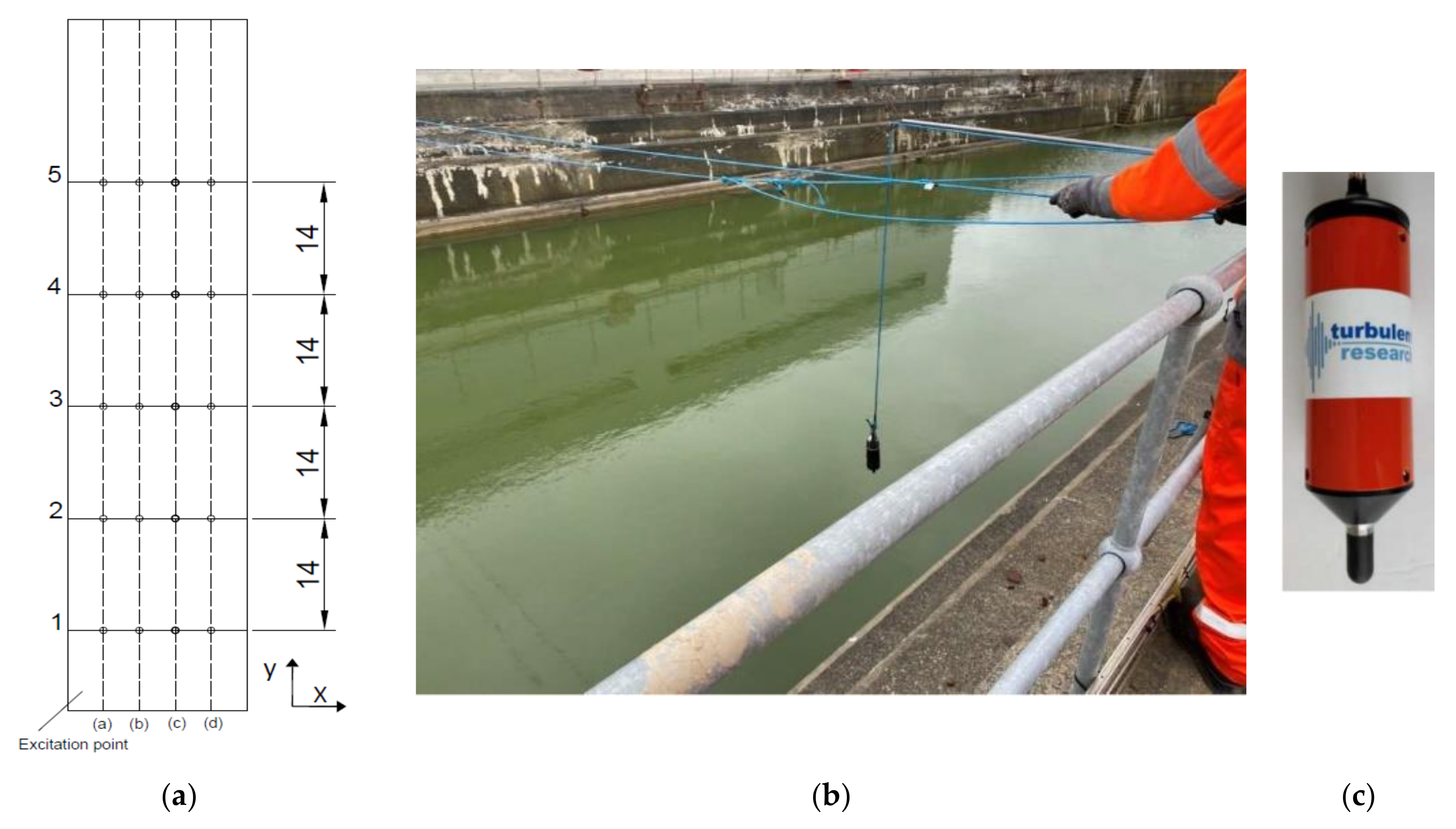

2.1. Marinised Power Ultrasonic Transducers

2.2. Power Generator Specification

- Fixed power generation, 160 Wrms (or over 1400 W peak), with 300 Vpp (100 Vrms), 4.5 App (1.6 Arms, fuse protection) transducer drive capability.

- High power gain bandwidth (200 kHz)

- Module provides two single channels or one Bridge mode channel.

- Supports a step-up transformer to further increase voltage drive and isolation for transducers that require ground isolation to operate safely.

- System can drive any UT (Ultrasonic Transducers) at frequencies between 20–200 kHz.

2.3. Signal Generator Specification

- Digital Signal Generators provide maximum flexibility like

- Dual independent signal output channels.

- Digitally synthesized waveforms for maximum flexibility.

- Uses 12-bit DACs running up to 2 MHz sampling frequency.

- Selection of any frequency (20–200 kHz)

- Sweep mode, any rate and frequency range.

- Pulse mode with duty cycle control for all signals generated.

- Arbitrary signal generation by importing synthesized signals from a file (useful for research purposes).

- Bespoke firmware supported by BIC and can be upgraded with new features and bug fixes.

2.4. Transducer Design Electrical Connection Precautions

3. Proposing a Sweep Sine to Cool down the Transducer Automatically

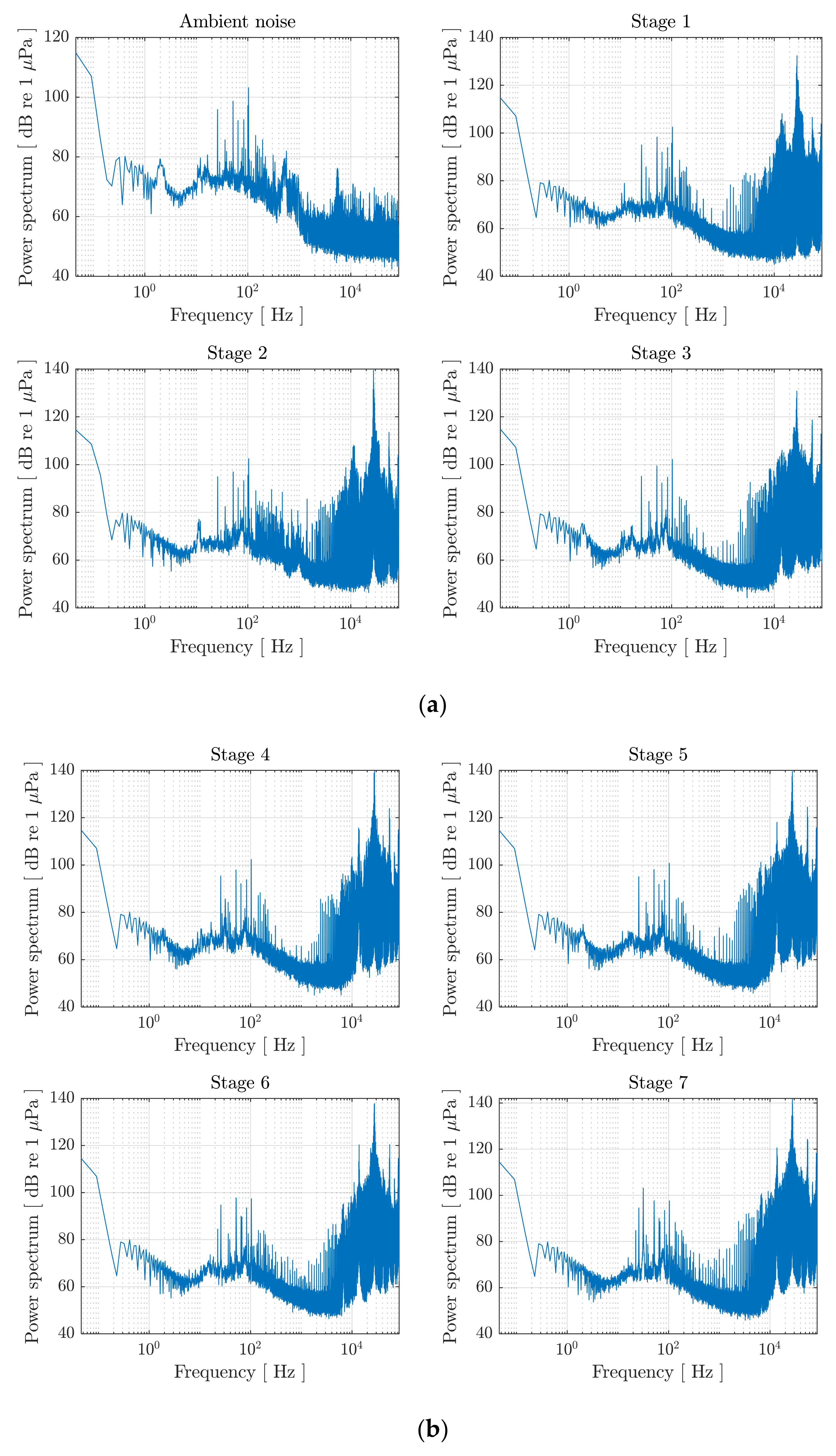

4. Noise Levels in the Ocean Generated by Horn and Non-Horn Marinised Transducers

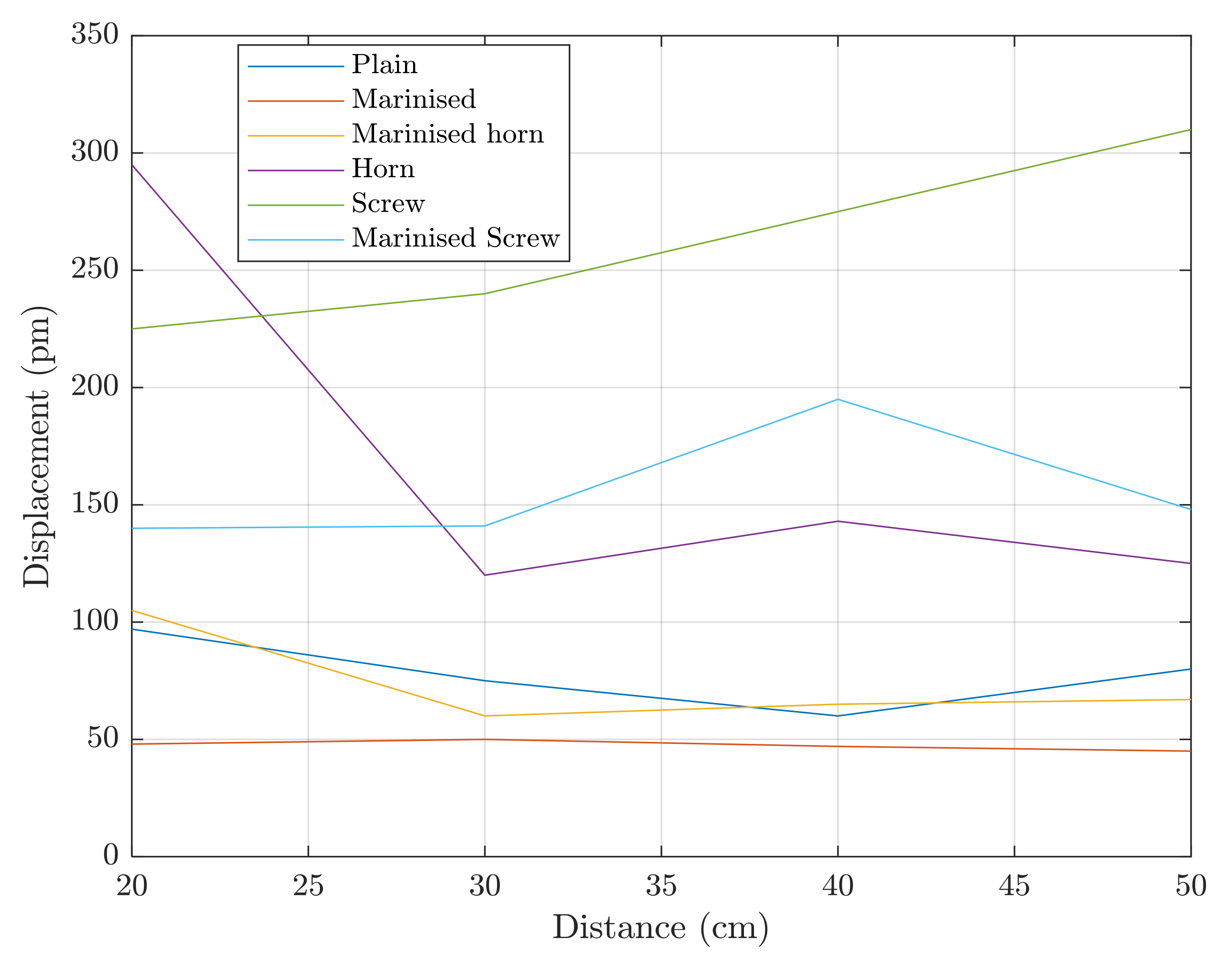

5. The Effect of HPUT Vibration on Removing Biofouling from a Plate

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alternative Methods for Environmentally Friendly Fouling Control. Available online: https://eurofishmagazine.com/sections/technology/item/676-alternative-methods-for-environmentally-friendly-fouling-control (accessed on 20 December 2022).

- Seo, E.; Lee, J.W.; Lee, D.; Seong, M.R.; Kim, G.H.; Hwang, D.S.; Lee, S.J. Eco-Friendly Erucamide–Polydimethylsiloxane Coatings for Marine Anti-Biofouling. Colloids Surf. B Biointerfaces 2021, 207, 112003. [Google Scholar] [CrossRef] [PubMed]

- Swain, G.W.; Nelson, W.G.; Preedeekanit, S. The Influence of Biofouling Adhesion and Biotic Disturbance on the Development of Fouling Communities on Non-toxic Surfaces. Biofouling 1998, 12, 257–269. [Google Scholar] [CrossRef]

- Hao, H.-H.; Liu, P.; Su, P.; Chen, T.; Zhu, M.; Jiang, Z.-B.; Li, J.-P.; Feng, D.-Q. Sea-Trial Research on Natural Product-Based Antifouling Paint Applied to Different Underwater Sensor Housing Materials. Int. Biodeterior. Biodegrad. 2022, 170, 105400. [Google Scholar] [CrossRef]

- Kalumuck, K.M.; Chahine, G.L.; Frederick, G.S.; Aley, P.D. Development of a DYNAJET Cavitating Water Jet Cleaning Tool for Underwater Marine Fouling Removal. In Proceedings of the 9th American Waterjet Conference, Dearborn, MI, USA, 23–26 August 1997. [Google Scholar]

- Ning, D.; Wang, Q.; Tian, J.; Gong, Y.; Du, H.; Chen, S.; Hou, J. Experimental Study on the Coating Removing Characteristics of High-Pressure Water Jet by Micro Jet Flow. Micromachines 2021, 12, 173. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Liu, Y.; Ma, C.; Muhammad, T.; Zhou, B.; Zhou, Y.; Song, P.; Li, Y. Using Electromagnetic Fields to Inhibit Biofouling and Scaling in Biogas Slurry Drip Irrigation Emitters. J. Hazard. Mater. 2021, 401, 123265. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Seo, Y.; Lin, Y.; Li, L.; Muhammad, T.; Ma, C.; Li, Y. Electromagnetic Fields for Biofouling Mitigation in Reclaimed Water Distribution Systems. Water Res. 2020, 173, 115562. [Google Scholar] [CrossRef]

- Guo, S.; Khoo, B.C.; Teo, S.L.M.; Lee, H.P. The Effect of Cavitation Bubbles on the Removal of Juvenile Barnacles. Colloids Surf. B Biointerfaces 2013, 109, 219–227. [Google Scholar] [CrossRef] [PubMed]

- Vyas, N.; Manmi, K.; Wang, Q.; Jadhav, A.J.; Barigou, M.; Sammons, R.L.; Kuehne, S.A.; Walmsley, A.D. Which Parameters Affect Biofilm Removal with Acoustic Cavitation? A Review. Ultrasound Med. Biol. 2019, 45, 1044–1055. [Google Scholar] [CrossRef]

- Louisnard, O.; González-García, J. Acoustic Cavitation. In Ultrasound Technologies for Food and Bioprocessing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 13–64. [Google Scholar]

- Miller, M.W.; Miller, D.L.; Brayman, A.A. A Review of in vitro Bioeffects of Inertial Ultrasonic Cavitation from a Mechanistic Perspective. Ultrasound Med. Biol. 1996, 22, 1131–1154. [Google Scholar] [CrossRef]

- Ashokkumar, M. The Characterization of Acoustic Cavitation Bubbles–An Overview. Ultrason. Sonochem. 2011, 18, 864–872. [Google Scholar] [CrossRef]

- Mustonen, J.; Tommiska, O.; Holmström, A.; Rauhala, T.; Moilanen, P.; Gritsevich, M.; Salmi, A.; Hæggström, E. FEM-Based Time-Reversal Enhanced Ultrasonic Cleaning. Ultrason. Sonochem. 2021, 79, 105798. [Google Scholar] [CrossRef]

- Church, C.C.; Carstensen, E.L. “Stable” Inertial Cavitation. Ultrasound Med. Biol. 2001, 27, 1435–1437. [Google Scholar] [CrossRef] [PubMed]

- Fuchs, F.J. 19-Ultrasonic Cleaning and Washing of Surfaces. In Power Ultrasonics; Gallego-Juárez, J.A., Graff, K.F., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 577–609. ISBN 978-1-78242-028-6. [Google Scholar]

- Aktij, S.A.; Taghipour, A.; Rahimpour, A.; Mollahosseini, A.; Tiraferri, A. A Critical Review on Ultrasonic-Assisted Fouling Control and Cleaning of Fouled Membranes. Ultrasonics 2020, 108, 106228. [Google Scholar] [CrossRef] [PubMed]

- Rassweiler, J.J.; Knoll, T.; Köhrmann, K.-U.; McAteer, J.A.; Lingeman, J.E.; Cleveland, R.O.; Bailey, M.R.; Chaussy, C. Shock Wave Technology and Application: An Update. Eur. Urol. 2011, 59, 784–796. [Google Scholar] [CrossRef]

- Lais, H.; Lowe, P.S.; Gan, T.-H.; Wrobel, L.C. Numerical Investigation of Design Parameters for Optimization of the In-Situ Ultrasonic Fouling Removal Technique for Pipelines. Ultrason. Sonochem. 2019, 56, 94–104. [Google Scholar] [CrossRef]

- Agarwal, A.; Jern Ng, W.; Liu, Y. Removal of Biofilms by Intermittent Low-Intensity Ultrasonication Triggered Bursting of Microbubbles. Biofouling 2014, 30, 359–365. [Google Scholar] [CrossRef] [PubMed]

- Lais, H.; Lowe, P.S.; Wrobel, L.C.; Gan, T.-H. Investigation of Ultrasonic Sonotrode Design to Improve the Performance of Ultrasonic Fouling Removal. IEEE Access 2019, 7, 148897–148912. [Google Scholar] [CrossRef]

- da Cunha, T.V.; Bohórquez, C.E.N. Ultrasound in Arc Welding: A Review. Ultrasonics 2015, 56, 201–209. [Google Scholar] [CrossRef]

- Teyeb, A.; Silva, J.; Kanfoud, J.; Carr, P.; Gan, T.-H.; Balachandran, W. Improvements in the Microstructure and Mechanical Properties of Aluminium Alloys Using Ultrasonic-Assisted Laser Welding. Metals 2022, 12, 1041. [Google Scholar] [CrossRef]

- Teyeb, A.; Salimi, M.; el Masri, E.; Balachandran, W.; Gan, T.-H. Analytical Simulation of the Microbubble Collapsing in a Welding Fusion Pool. Materials 2023, 16, 410. [Google Scholar] [CrossRef]

- Mason, T.J. Industrial Sonochemistry: Potential and Practicality. Ultrasonics 1992, 30, 192–196. [Google Scholar] [CrossRef]

- Harvey, G.; Gachagan, A.; Mutasa, T. Review of High-Power Ultrasound-Industrial Applications and Measurement Methods. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 481–495. [Google Scholar] [CrossRef]

- Escrig, J.; Woolley, E.; Rangappa, S.; Simeone, A.; Watson, N.J. Clean-in-Place Monitoring of Different Food Fouling Materials Using Ultrasonic Measurements. Food Control 2019, 104, 358–366. [Google Scholar] [CrossRef]

- Kumar, S.; Wu, C.S.; Padhy, G.K.; Ding, W. Application of Ultrasonic Vibrations in Welding and Metal Processing: A Status Review. J. Manuf. Process. 2017, 26, 295–322. [Google Scholar] [CrossRef]

- Gallego-Juarez, J.A. High-Power Ultrasonic Processing: Recent Developments and Prospective Advances. Phys. Procedia 2010, 3, 35–47. [Google Scholar] [CrossRef]

- Saalbach, K.-A.; Twiefel, J.; Wallaschek, J. Self-Sensing Cavitation Detection in Ultrasound-Induced Acoustic Cavitation. Ultrasonics 2019, 94, 401–410. [Google Scholar] [CrossRef]

- Uchida, T.; Sato, H.; Takeuchi, S.; Kikuchi, T. Investigation of Output Signal from Cavitation Sensor by Dissolved Oxygen Level and Sonochemical Luminescence. Jpn. J. Appl. Phys. 2010, 49, 07HE03. [Google Scholar] [CrossRef]

- Uchida, T.; Takeuchi, S.; Kikuchi, T. Measurement of Amount of Generated Acoustic Cavitation: Investigation of Spatial Distribution of Acoustic Cavitation Generation Using Broadband Integrated Voltage. Jpn. J. Appl. Phys. 2011, 50, 07HE01. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Asakura, Y.; Koda, S.; Yasuda, K. Dependence of Cavitation, Chemical Effect, and Mechanical Effect Thresholds on Ultrasonic Frequency. Ultrason. Sonochem. 2017, 39, 301–306. [Google Scholar] [CrossRef]

- Heikkola, E.; Miettinen, K.; Nieminen, P. Multiobjective Optimization of an Ultrasonic Transducer Using NIMBUS. Ultrasonics 2006, 44, 368–380. [Google Scholar] [CrossRef]

- Lin, S.; Xu, L.; Wenxu, H. A New Type of High Power Composite Ultrasonic Transducer. J. Sound Vib. 2011, 330, 1419–1431. [Google Scholar] [CrossRef]

- Zhong, X.; Dong, J.; Liu, M.; Meng, R.; Li, S.; Pan, X. Experimental Study on Ship Fouling Cleaning by Ultrasonic-Enhanced Submerged Cavitation Jet: A Preliminary Study. Ocean Eng. 2022, 258, 111844. [Google Scholar] [CrossRef]

- Mazue, G.; Viennet, R.; Hihn, J.Y.; Carpentier, L.; Devidal, P.; Albaïna, I. Large-Scale Ultrasonic Cleaning System: Design of a Multi-Transducer Device for Boat Cleaning (20 KHz). Ultrason. Sonochem. 2011, 18, 895–900. [Google Scholar] [CrossRef]

- Guo, S.; Lee, H.P.; Teo, S.L.M.; Khoo, B.C. Inhibition of Barnacle Cyprid Settlement Using Low Frequency and Intensity Ultrasound. Biofouling 2012, 28, 131–141. [Google Scholar] [CrossRef] [PubMed]

- Scherba, G.; Weigel, R.M.; O’Brien Jr, W.D. Quantitative Assessment of the Germicidal Efficacy of Ultrasonic Energy. Appl. Environ. Microbiol. 1991, 57, 2079–2084. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.J.; Nakano, K.; Matsumara, M. Ultrasonic Irradiation for Blue-Green Algae Bloom Control. Environ. Technol. 2001, 22, 383–390. [Google Scholar] [CrossRef] [PubMed]

- McKenna, M.F.; Gabriele, C.; Kipple, B. Effects of Marine Vessel Management on the Underwater Acoustic Environment of Glacier Bay National Park, AK. Ocean Coast Manag. 2017, 139, 102–112. [Google Scholar] [CrossRef]

- Tyack, P.L. Implications for Marine Mammals of Large-Scale Changes in the Marine Acoustic Environment. J. Mammal. 2008, 89, 549–558. [Google Scholar] [CrossRef]

- Lais, H.; Lowe, P.S.; Kanfoud, J.; Gan, T.-H. Application of High Power Ultrasonics for Fouling Removal in Submerged Structures. In Proceedings of the OCEANS 2017, Aberdeen, UK, 19–22 June 2017; pp. 1–8. [Google Scholar]

- Sullivan, K.D. Technical Guidance for Assessing the Effects of Anthropogenic Sound on Marine Mammal Hearing: Underwater Acoustic Thresholds for Onset of Permanent and Temporary Threshold Shifts. National Marine Fisheries Service, Office of Protected Resources: Washington, DC, USA,, 2016; Volume 178. [Google Scholar] [CrossRef]

- Available online: https://www.bjultrasonic.com/category/ultrasonic-transducer/ (accessed on 9 January 2023).

- Legg, M.; Yücel, M.K.; de Carellan, I.G.; Kappatos, V.; Selcuk, C.; Gan, T.H. Acoustic Methods for Biofouling Control: A Review. Ocean Eng. 2015, 103, 237–247. [Google Scholar] [CrossRef]

- Aganin, A.A.; Ilgamov, M.A.; Kosolapova, L.A.; Malakhov, V.G. Dynamics of a Cavitation Bubble near a Solid Wall. Thermophys. Aeromech. 2016, 23, 211–220. [Google Scholar] [CrossRef]

- Fisher, F.H.; Simmons, V.P. Sound Absorption in Sea Water. J. Acoust. Soc. Am. 1977, 62, 558–564. [Google Scholar] [CrossRef]

- Warburton, G.B. The Vibration of Rectangular Plates. Proc. Inst. Mech. Eng. 1954, 168, 371–384. [Google Scholar] [CrossRef]

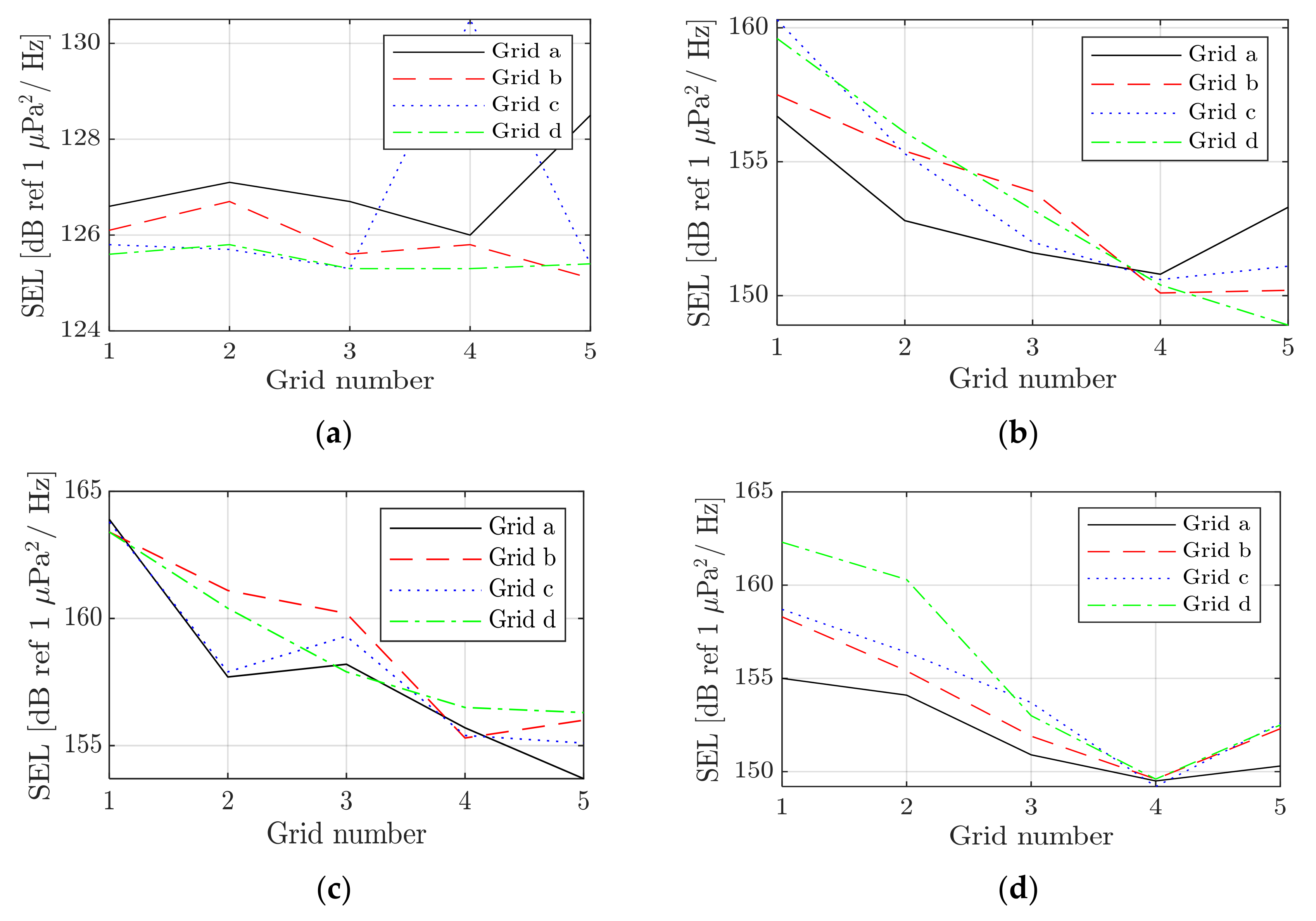

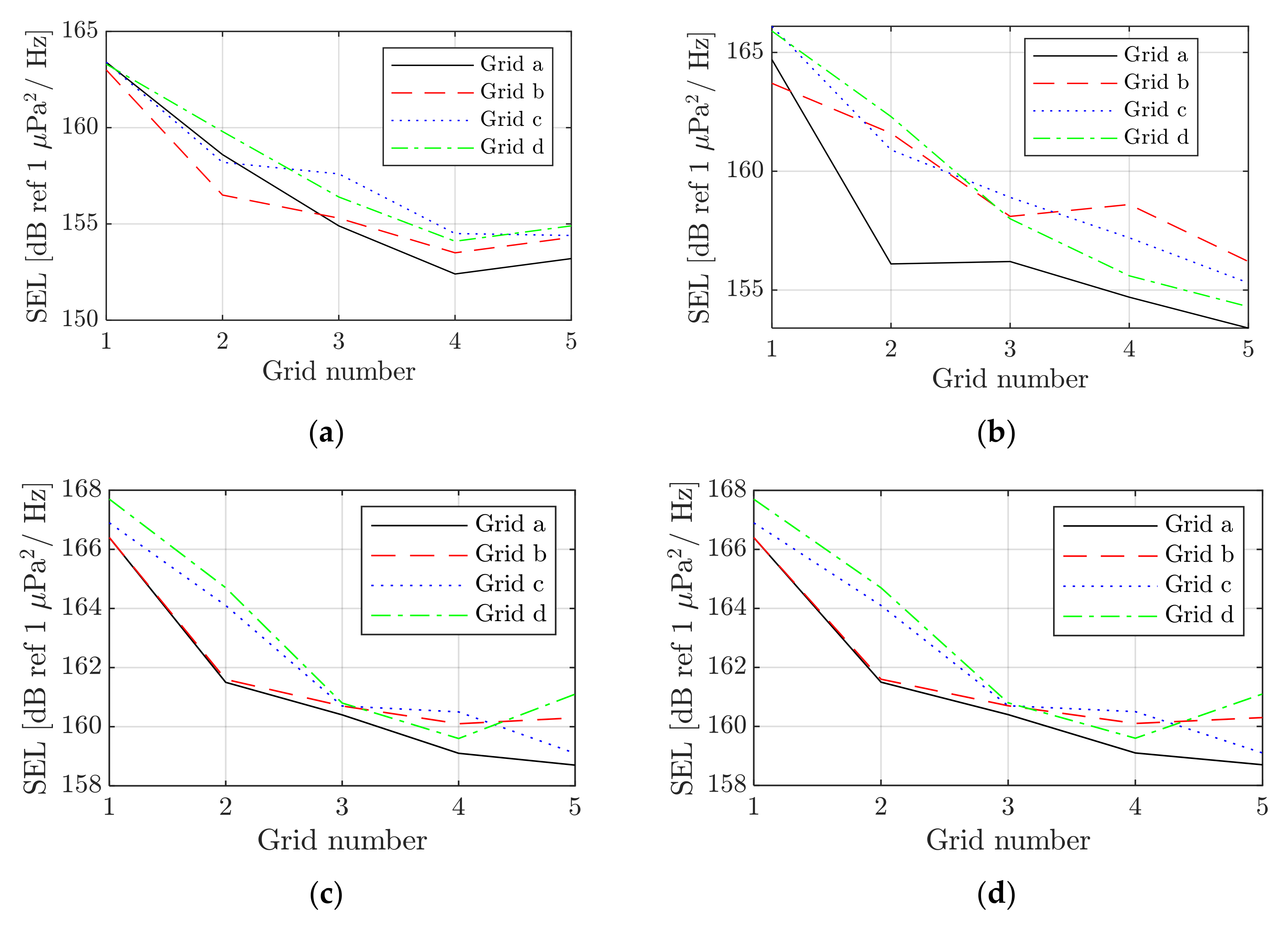

| Stage Number | Max SEL (dB) ref 1 μPa | Min SEL (dB) ref 1 μPa | Max SPL (dB) ref 1 μPa | Min SPL (dB) ref 1 μPa |

|---|---|---|---|---|

| 1 | 160.3 (dB)—grid point 1 c | 148.9 (dB)—grid point 5d | 142.5 (dB)—grid 1c | 131.1—grid point 5d |

| 2 | 163.9 (dB)—grid point 1a | 155.1 (dB)—grid point 5c | 146.7 (dB)—grid 1 a | 137.4 (dB)—grid point 5c |

| 3 | 162.3 (dB)—grid point 1d | 149.2 (dB)—grid point 4c | 144.5 (dB)—grid 1 d | 131.4 (dB)—grid point 4c |

| 4 | 163.4 (dB)—grid point 1a and 1c | 152.4 (dB)—grid point 4a | 145.6 (dB)—grid 1 a and c | 134.7 (dB)—grid point 4a |

| 5 | 167.7 (dB)—grid point 1d | 158.7 (dB)—grid point 5a | 149.9 (dB)—grid 1 d | 140.9 (dB)—grid point 5a |

| 6 | SEL: 166.1 (dB)—grid point 1c | 153.4 (dB)—grid point 5a | 148.3 (dB)—grid 1c | 135.6 (dB)—grid point 5a |

| 7 | SEL: 169.4 (dB)—grid point 1d | 159 (dB)—grid point 4a and 5a | 151.6 (dB)—grid 1 d | 141.2 (dB)—grid point 4a and 5a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salimi, M.; Livadas, M.; Teyeb, A.; El Masri, E.; Gan, T.-H. Biofouling Removal Using a Novel Electronic System for Driving an Array of High Power Marinised Transducers. Appl. Sci. 2023, 13, 3749. https://doi.org/10.3390/app13063749

Salimi M, Livadas M, Teyeb A, El Masri E, Gan T-H. Biofouling Removal Using a Novel Electronic System for Driving an Array of High Power Marinised Transducers. Applied Sciences. 2023; 13(6):3749. https://doi.org/10.3390/app13063749

Chicago/Turabian StyleSalimi, Mohamad, Makis Livadas, Ahmed Teyeb, Evelyne El Masri, and Tat-Hean Gan. 2023. "Biofouling Removal Using a Novel Electronic System for Driving an Array of High Power Marinised Transducers" Applied Sciences 13, no. 6: 3749. https://doi.org/10.3390/app13063749

APA StyleSalimi, M., Livadas, M., Teyeb, A., El Masri, E., & Gan, T.-H. (2023). Biofouling Removal Using a Novel Electronic System for Driving an Array of High Power Marinised Transducers. Applied Sciences, 13(6), 3749. https://doi.org/10.3390/app13063749