Mechanical Properties of NiTi Rotary Files Fabricated through Gold-Wire, CM-Wire, T-Wire, and R-Phase Heat Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Mechanical Tests

2.2. Statistical Analysis

2.3. DSC

3. Results

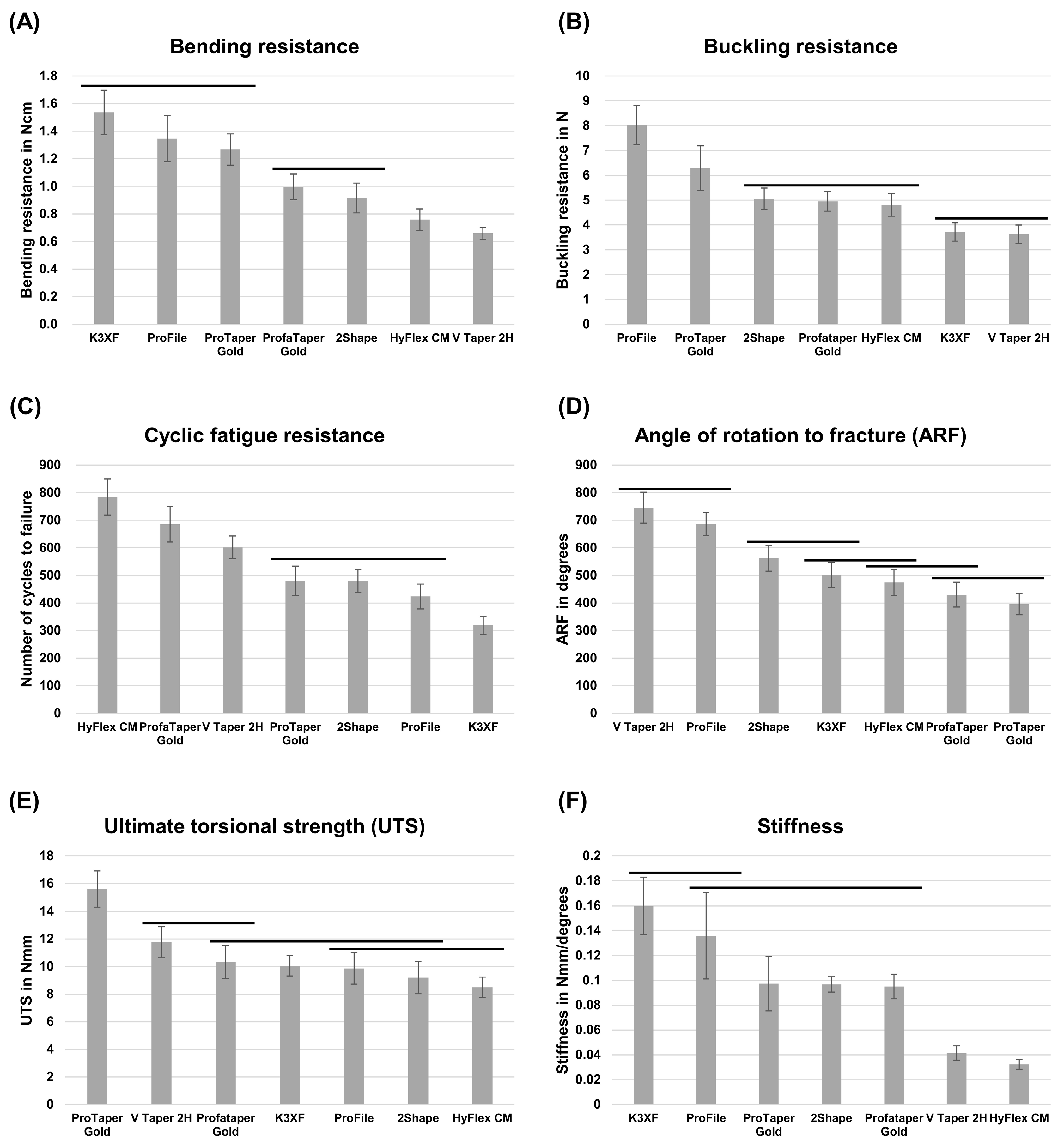

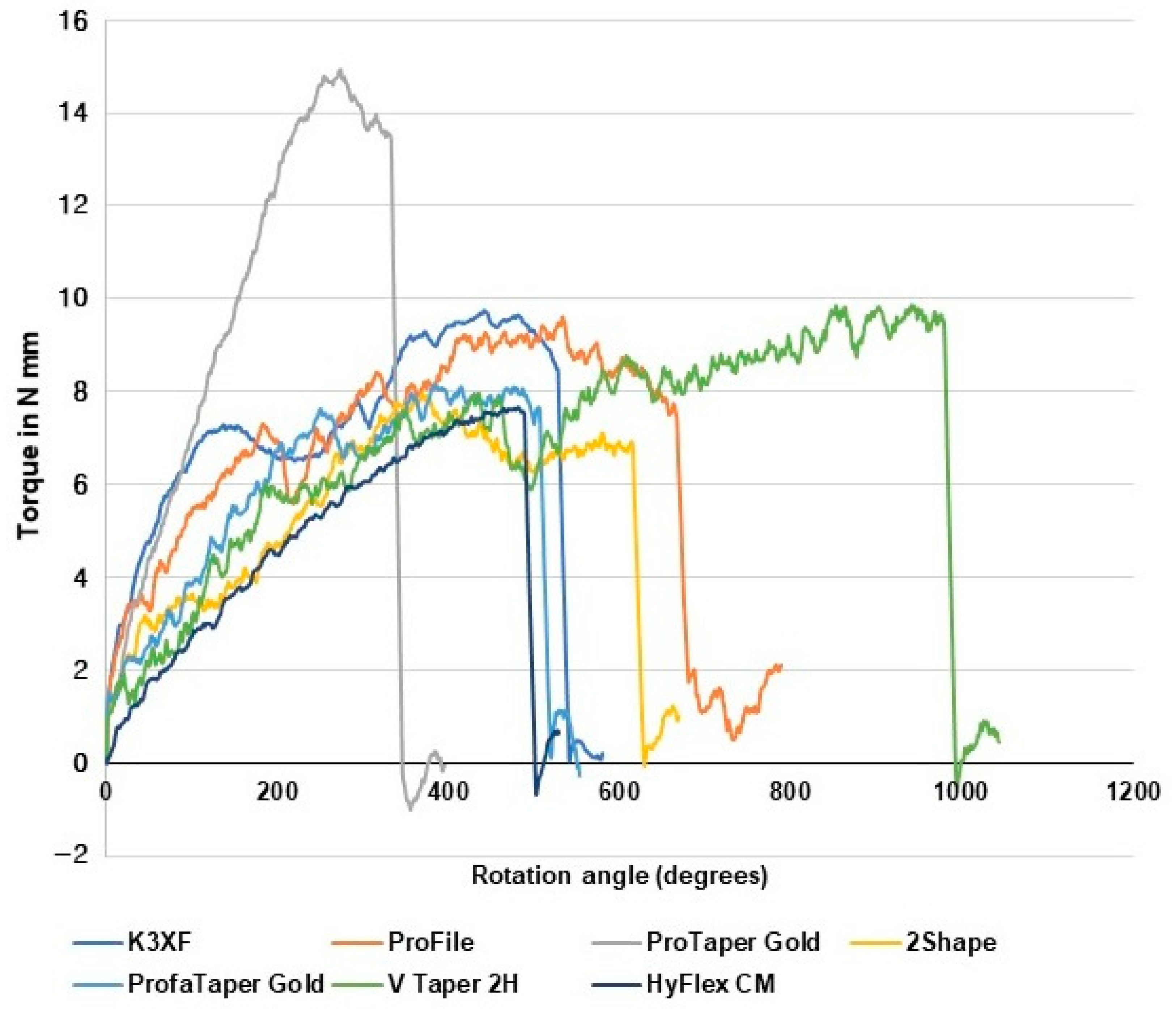

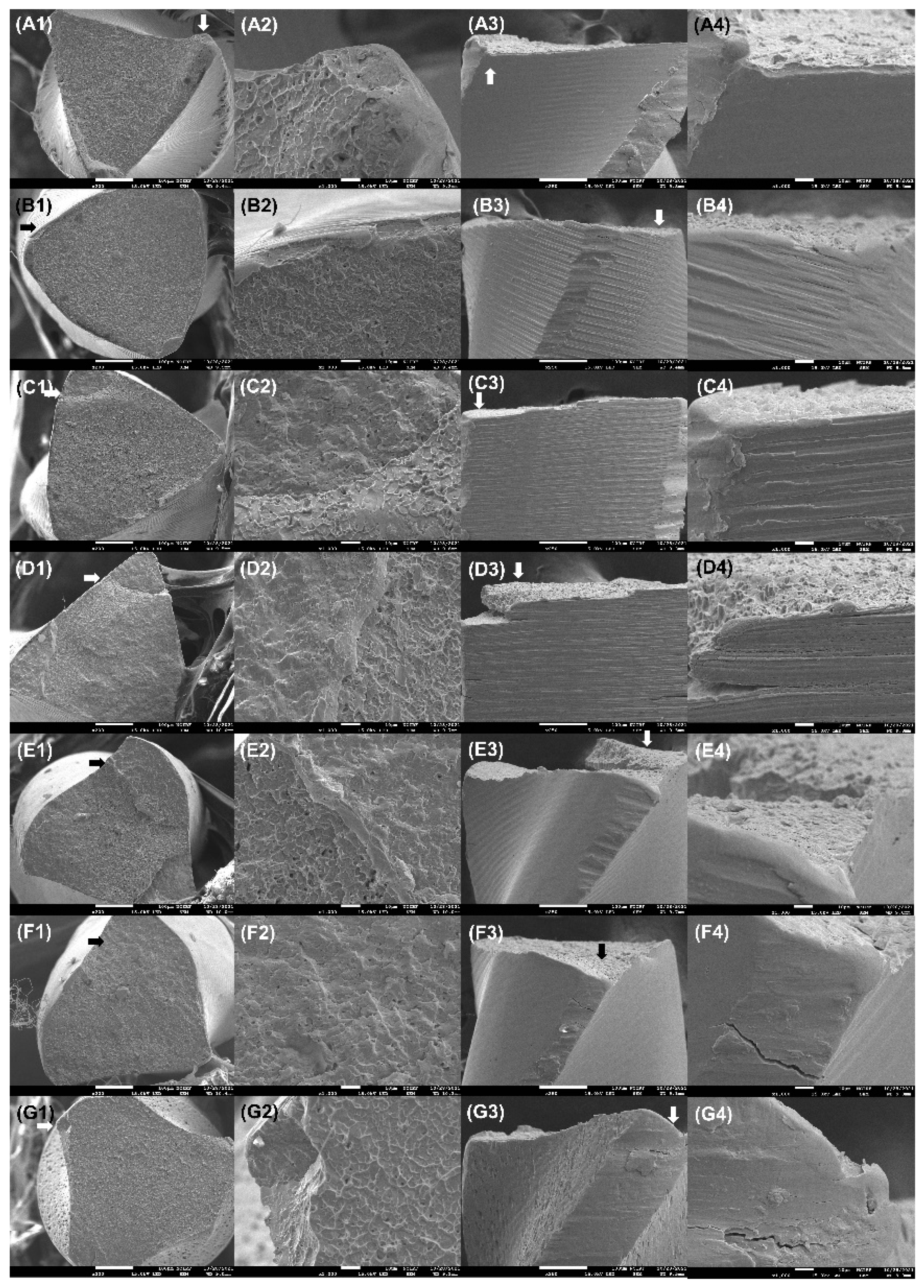

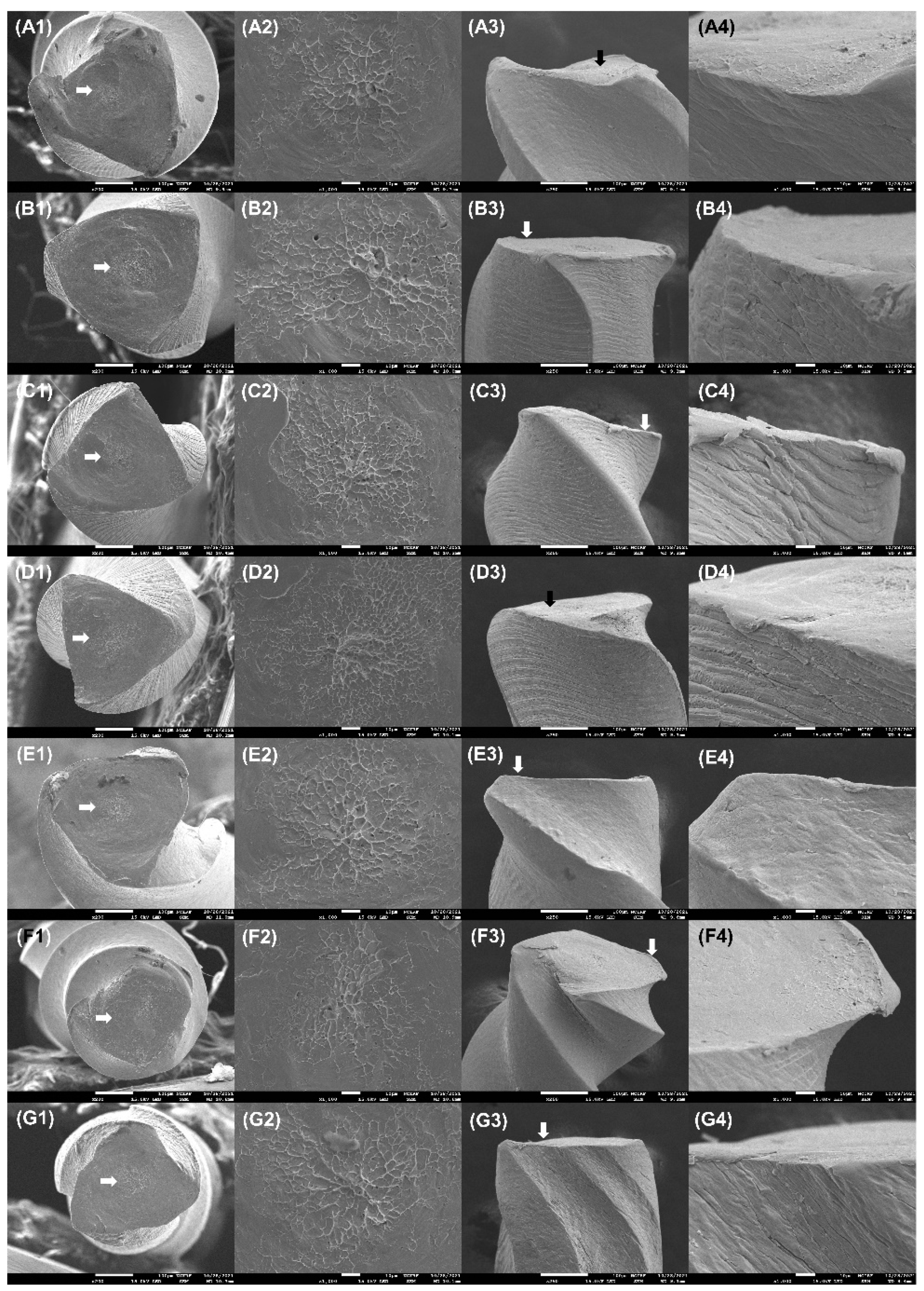

3.1. Mechanical Tests

3.2. Pearson Correlation Analysis

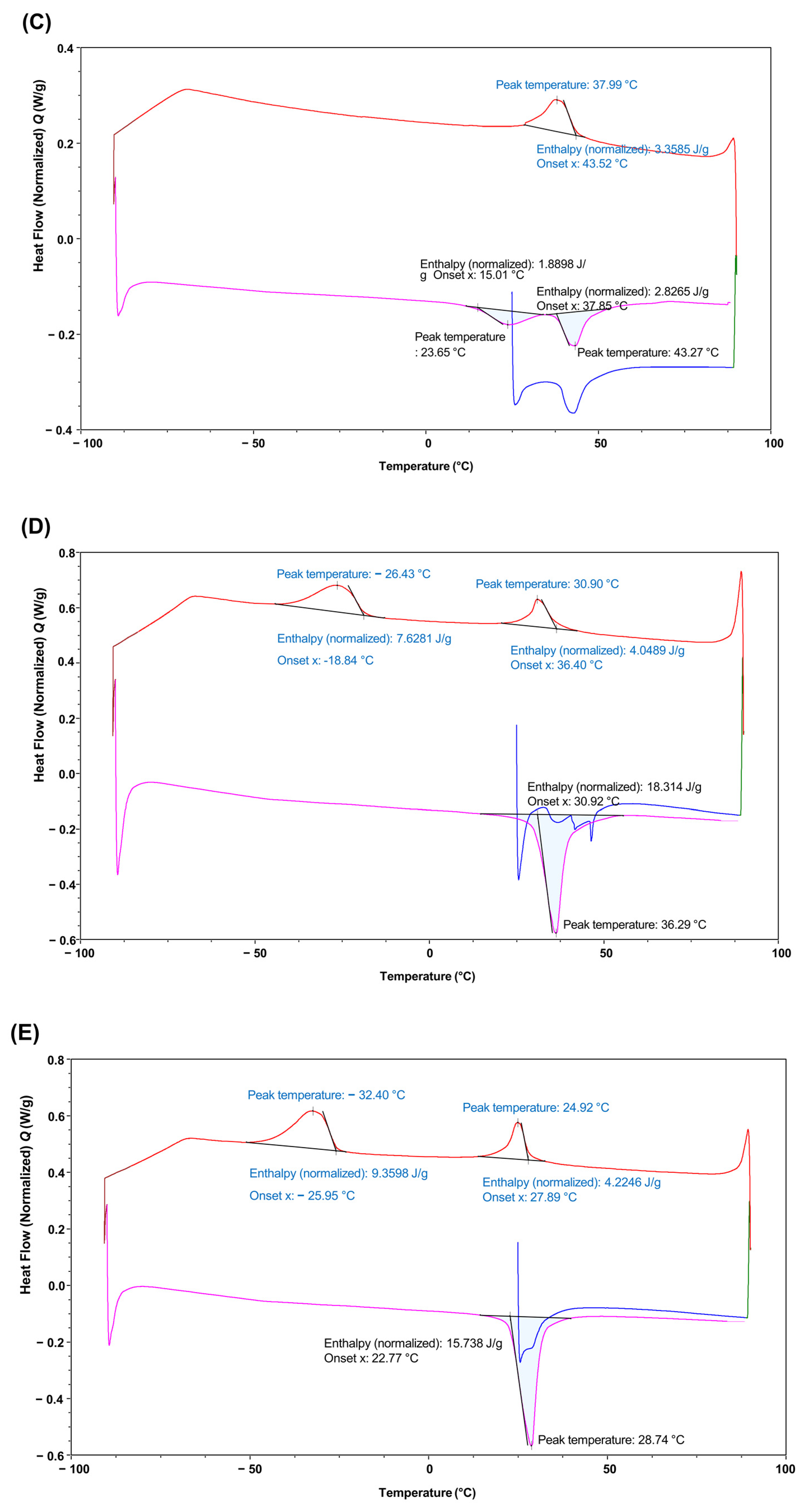

3.3. DSC

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Celik, D.; Taşdemir, T.; Er, K. Comparative study of 6 rotary nickel-titanium systems and hand instrumentation for root canal preparation in severely curved root canals of extracted teeth. J. Endod. 2013, 39, 278–282. [Google Scholar] [CrossRef]

- Cheung, G.S.; Liu, C.S. A retrospective study of endodontic treatment outcome between nickel-titanium rotary and stainless steel hand filing techniques. J. Endod. 2009, 35, 938–943. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Lei, G.; Yan, M.; Yu, Y.; Yu, J.; Zhang, G. Instrument separation analysis of multi-used ProTaper Universal rotary system during root canal therapy. J. Endod. 2011, 37, 758–763. [Google Scholar] [CrossRef]

- Caballero-Flores, H.; Nabeshima, C.K.; Binotto, E.; Machado, M.E.L. Fracture incidence of instruments from a single-file reciprocating system by students in an endodontic graduate programme: A cross-sectional retrospective study. Int. Endod. J. 2019, 52, 13–18. [Google Scholar] [CrossRef] [PubMed]

- Gambarini, G.; Grande, N.M.; Plotino, G.; Somma, F.; Garala, M.; De Luca, M.; Testarelli, L. Fatigue resistance of engine-driven rotary nickel-titanium instruments produced by new manufacturing methods. J. Endod. 2008, 34, 1003–1005. [Google Scholar] [CrossRef] [PubMed]

- Keskin, N.B.; Inan, U. Cyclic fatigue resistance of rotary NiTi instruments produced with four different manufacturing methods. Microsc. Res. Tech. 2019, 82, 1642–1648. [Google Scholar] [CrossRef]

- Tabassum, S.; Zafar, K.; Umer, F. Nickel-Titanium rotary file systems: What’s new? Eur. Endod. J. 2019, 4, 111–117. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, H.M.; Zheng, Y.F.; Peng, B.; Haapasalo, M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J. Endod. 2013, 39, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Braga, L.C.; Silva, A.C.F.; Buono, V.T.; de Azevedo Bahia, M.G. Impact of heat treatments on the fatigue resistance of different rotary nickel-titanium instruments. J. Endod. 2014, 40, 1494–1497. [Google Scholar] [CrossRef]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New thermomechanically treated NiTi alloys—A review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef] [PubMed]

- Thompson, S.A. An overview of nickel-titanium alloys used in dentistry. Int. Endod. J. 2000, 33, 297–310. [Google Scholar] [CrossRef]

- de Vasconcelos, R.A.; Murphy, S.; Carvalho, C.A.; Govindjee, R.G.; Govindjee, S.; Peters, O.A. Evidence for reduced fatigue resistance of contemporary rotary instruments exposed to body temperature. J. Endod. 2016, 42, 782–787. [Google Scholar] [CrossRef] [PubMed]

- Pereira, E.S.; Gomes, R.O.; Leroy, A.M.; Singh, R.; Peters, O.A.; Bahia, M.G.; Buono, V.T. Mechanical behavior of M-Wire and conventional NiTi wire used to manufacture rotary endodontic instruments. Dent. Mater. 2013, 29, e318–e324. [Google Scholar] [CrossRef] [PubMed]

- Goo, H.J.; Kwak, S.W.; Ha, J.H.; Pedullà, E.; Kim, H.C. Mechanical properties of various heat-treated nickel-titanium rotary instruments. J. Endod. 2017, 43, 1872–1877. [Google Scholar] [CrossRef] [PubMed]

- Bouska, J.; Justman, B.; Williamson, A.; DeLong, C.; Qian, F. Resistance to cyclic fatigue failure of a new endodontic rotary file. J. Endod. 2012, 38, 667–669. [Google Scholar] [CrossRef] [PubMed]

- Gambarini, G.; Plotino, G.; Grande, N.M.; Al-Sudani, D.; De Luca, M.; Testarelli, L. Mechanical properties of nickel-titanium rotary instruments produced with a new manufacturing technique. Int. Endod. J. 2011, 44, 337–341. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Zhou, H.M.; Wang, Z.; Campbell, L.; Zheng, Y.F.; Haapasalo, M. Phase transformation behavior and mechanical properties of thermomechanically treated K3XF nickel-titanium instruments. J. Endod. 2013, 39, 919–923. [Google Scholar] [CrossRef]

- Shim, K.S.; Oh, S.; Kum, K.; Kim, Y.C.; Jee, K.K.; Chang, S.W. Mechanical and metallurgical properties of variou nickel-titanium rotary instruments. Biomed. Res. Int. 2017, 2017, 4528601. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.M.; Shen, Y.; Zheng, W.; Li, L.; Zheng, Y.F.; Haapasalo, M. Mechanical properties of controlled memory and superelastic nickel-titanium wires used in the manufacture of rotary endodontic instruments. J. Endod. 2012, 38, 1535–1540. [Google Scholar] [CrossRef]

- Testarelli, L.; Plotino, G.; Al-Sudani, D.; Vincenzi, V.; Giansiracusa, A.; Grande, N.M.; Gambarini, G. Bending properties of a new nickel-titanium alloy with a lower percent by weight of nickel. J. Endod. 2011, 37, 1293–1295. [Google Scholar] [CrossRef]

- Zinelis, S.; Eliades, T.; Eliades, G. A metallurgical characterization of ten endodontic Ni-Ti instruments: Assessing the clinical relevance of shape memory and superelastic properties of Ni-Ti endodontic instruments. Int. Endod. J. 2010, 43, 125–134. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, H.M.; Zheng, Y.F.; Campbell, L.; Peng, B.; Haapasalo, M. Metallurgical characterization of controlled memory wire nickel-titanium rotary instruments. J. Endod. 2011, 37, 1566–1571. [Google Scholar] [CrossRef]

- Chang, S.W.; Shim, K.S.; Kim, Y.C.; Jee, K.K.; Zhu, Q.; Perinpanayagam, H.; Kum, K.Y. Cyclic fatigue resistance, torsional resistance, and metallurgical characteristics of V taper 2 and V taper 2H rotary NiTi files. Scanning 2016, 38, 564–570. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Qian, W.; Abtin, H.; Gao, Y.; Haapasalo, M. Fatigue testing of controlled memory wire nickel-titanium rotary instruments. J. Endod. 2011, 37, 997–1001. [Google Scholar] [CrossRef] [PubMed]

- Pereira, É.S.; Viana, A.C.; Buono, V.T.; Peters, O.A.; Bahia, M.G. Behavior of nickel-titanium instruments manufactured with different thermal treatments. J. Endod. 2015, 41, 67–71. [Google Scholar] [CrossRef]

- Ninan, E.; Berzins, D.W. Torsion and bending properties of shape memory and superelastic nickel-titanium rotary instruments. J. Endod. 2013, 39, 101–104. [Google Scholar] [CrossRef]

- De Arruda Santos, L.; Bahia, M.G.; de Las Casas, E.B.; Buono, V.T. Comparison of the mechanical behavior between controlled memory and superelastic nickel-titanium files via finite element analysis. J. Endod. 2013, 39, 1444–1447. [Google Scholar] [CrossRef] [PubMed]

- Nehme, W.; Naaman, A.; Diemer, F.; Leotta, M.L.; La Rosa, G.R.M.; Pedullà, E. Influence of different heat treatments and temperatures on the cyclic fatigue resistance of endodontic instruments with the same design. Clin. Oral Investig. 2022, in press. [Google Scholar] [CrossRef] [PubMed]

- Alghamdi, S.; Huang, X.; Haapasalo, M.; Mobuchon, C.; Hieawy, A.; Hu, J.; Wang, Z.; Sobotkiewicz, T.; Shen, Y. Effect of curvature location on fatigue resistance of five nickel-titanium files determined at body temperature. J. Endod. 2020, 46, 1682–1688. [Google Scholar] [CrossRef]

- Silva, E.; Giraldes, J.F.N.; de Lima, C.O.; Vieira, V.T.L.; Elias, C.N.; Antunes, H.S. Influence of heat treatment on torsional resistance and surface roughness of nickel-titanium instruments. Int. Endod. J. 2019, 52, 1645–1651. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.; Kum, K.Y.; Kim, H.J.; Moon, S.Y.; Kim, H.C.; Chaniotis, A.; Perinpanayagam, H.; Pedullá, E.; Chang, S.W. Bending resistance and cyclic fatigue resistance of WaveOne Gold, Reciproc Blue, and HyFlex EDM instruments. J. Dent. Sci. 2020, 15, 472–478. [Google Scholar] [CrossRef] [PubMed]

- Martins, J.N.R.; Silva, E.; Marques, D.; Belladonna, F.G.; Simões-Carvalho, M.; da Costa, R.P.; Ginjeira, A.; Braz Fernandes, F.M.; Versiani, M.A. Comparison of five rotary systems regarding design, metallurgy, mechanical performance, and canal preparation-a multimethod research. Clin. Oral Investig. 2022, 26, 3299–3310. [Google Scholar] [CrossRef] [PubMed]

- Uygun, A.D.; Kol, E.; Topcu, M.K.; Seckin, F.; Ersoy, I.; Tanriver, M. Variations in cyclic fatigue resistance among ProTaper Gold, ProTaper Next and ProTaper Universal instruments at different levels. Int. Endod. J. 2016, 49, 494–499. [Google Scholar] [CrossRef]

- MicroMega, 2Shape. Available online: https://micro-mega.com/wp-content/uploads/2018/03/60301807-C_Brochure-2Shape_EN_WEB.pdf (accessed on 1 November 2022).

- International Organization for Standardization. International Standard ISO 3630-1:2019(E): Root-Canal Instruments—Part 1: General Requirements and Test Methods. 2019. Available online: https://www.iso.org/obp/ui/#iso:std:iso:3630:-1:ed-3:v1:en (accessed on 1 September 2022).

- Oh, S.; Jeon, B.K.; Chang, S.W. Mechanical properties and torque/force generation of XP-Endo Shaper, Trunatomy, Spring Endo File, and Spring Endo Heated Finish File, Part 1. Appl. Sci. 2022, 12, 10393. [Google Scholar] [CrossRef]

- Lopes, H.P.; Elias, C.N.; Siqueira, J.F., Jr.; Soares, R.G.; Souza, L.C.; Oliveira, J.C.; Lopes, W.S.; Mangelli, M. Mechanical behavior of pathfinding endodontic instruments. J. Endod. 2012, 38, 1417–1421. [Google Scholar] [CrossRef]

- Ha, J.H.; Kwak, S.W.; Versluis, A.; Kim, H.C. Buckling resistance of various nickel-titanium glide path preparationinstruments in dynamic or static mode. J. Endod. 2020, 46, 1125–1129. [Google Scholar] [CrossRef]

- Bürklein, S.; Börjes, L.; Schäfer, E. Comparison of preparation of curved root canals with Hyflex CM and Revo-S rotary nickel-titanium instruments. Int. Endod. J. 2014, 47, 470–476. [Google Scholar] [CrossRef]

- Marceliano-Alves, M.F.; Sousa-Neto, M.D.; Fidel, S.R.; Steier, L.; Robinson, J.P.; Pécora, J.D.; Versiani, M.A. Shaping ability of single-file reciprocating and heat-treated multifile rotary systems: A micro-CT study. Int. Endod. J. 2015, 48, 1129–1136. [Google Scholar] [CrossRef]

- McGuigan, M.B.; Louca, C.; Duncan, H.F. Endodontic instrument fracture: Causes and prevention. Br. Dent. J. 2013, 214, 341–348. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Huang, X.; Wang, Z.; Wei, X.; Haapasalo, M. Low environmental temperature influences the fatigue resistance of nickel-titanium files. J. Endod. 2018, 44, 626–629. [Google Scholar] [CrossRef]

- Oh, S.; Kum, K.Y.; Cho, K.; Lee, S.H.; You, S.H.; Go, J.; Jeon, B.K.; Kim, S.W.; Kim, T.H.; Jang, J.H.; et al. Torsional and bending properties of V Taper 2H, ProTaper NEXT, NRT, and One Shape. BioMed Res. Int. 2019, 2019, 6368958. [Google Scholar] [CrossRef]

- Lopes, H.P.; Gambarra-Soares, T.; Elias, C.N.; Siqueira, J.F., Jr.; Inojosa, I.F.; Lopes, W.S.; Vieira, V.T. Comparison of the mechanical properties of rotary instruments made of conventional nickel-titanium wire, M-wire, or nickel-titanium alloy in R-phase. J. Endod. 2013, 39, 516–520. [Google Scholar] [CrossRef] [PubMed]

- Ha, J.H.; Lee, C.J.; Kwak, S.W.; El Abed, R.; Ha, D.; Kim, H.C. Geometric optimization for development of glide path preparation nickel-titanium rotary instrument. J. Endod. 2015, 41, 916–919. [Google Scholar] [CrossRef] [PubMed]

- Alqedairi, A.; Alfawaz, H.; Abualjadayel, B.; Alanazi, M.; Alkhalifah, A.; Jamleh, A. Torsional resistance of three ProTaper rotary systems. BMC Oral Health 2019, 19, 124. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Yue, L. Evolution and development: Engine-driven endodontic rotary nickel-titanium instruments. Int. J. Oral. Sci. 2022, 14, 12. [Google Scholar] [CrossRef]

- Amine, M.; Merdma, W.; El Boussiri, K. Electrogalvanism in Oral Implantology: A Systematic Review. Int. J. Dent. 2022, 2022, 4575416. [Google Scholar] [CrossRef] [PubMed]

- Sfondrini, M.F.; Cacciafesta, V.; Maffia, E.; Scribante, A.; Alberti, G.; Biesuz, R.; Klersy, C. Nickel release from new conven tional stainless steel, recycled, and nickel-free orthodontic brackets: An in vitro study. Am. J. Orthod. Dentofac. Orthop. 2010, 137, 809–815. [Google Scholar] [CrossRef]

| NiTi File | Manufacturer | Tip Size, Taper | Heat Treatment |

|---|---|---|---|

| ProFile | Dentsply Maillefer, Ballaigues, Switzerland | #25, 6% | Conventional wire (no heat treatment) |

| ProTaper Gold | Dentsply Maillefer, Ballaigues, Switzerland | #25, variable 8% (F2) | Gold-wire |

| ProfaTaper Gold | Shenzhen Perfect Medical Instruments Co., Ltd., Guangdong, China | #25, variable 8% (T2) | Gold-wire |

| HyFlex CM | Coltene/Whaledent AG, Altstätten, Switzerland | #25, 6% | CM-wire |

| V Taper 2H | SS White Dental, Lakewood, NJ, USA | #25, variable 6% | CM-wire |

| 2Shape | Micro-Mega, Besançon, France | #25, 6% (TS2) | T-wire |

| K3XF | Kerr Dental, Orange, CA, USA | #25, 6% | R-phase |

| ProFile | ProTaper Gold | ProfaTaper Gold | HyFlex CM | 2Shape | V Taper 2H | K3XF | |

|---|---|---|---|---|---|---|---|

| Bending resistance (N cm) | 1.3 ± 0.2 d | 1.3 ± 0.1 d | 1 ± 0.1 c | 0.8 ± 0.1 b | 0.9 ± 0.1 c | 0.7 ± 0.04 a | 1.5 ± 0.2 d |

| Buckling resistance (N) | 8 ± 0.8 d | 6.3 ± 0.9 c | 5 ± 0.4 b | 4.8 ± 0.5 b | 5.1 ± 0.4 b | 3.6 ± 0.4 a | 3.7 ± 0.4 a |

| Number of cycles to failure | 424 ± 45 b | 480 ± 53 b | 686 ± 64 d | 784 ± 65 e | 480 ± 42 b | 602 ± 41 c | 319 ± 33 a |

| Angle of rotation to fracture (degrees) | 686 ± 42 e | 396 ± 39 a | 430 ± 45 a, b | 474 ± 47 b, c | 562 ± 47 d | 745 ± 56 e | 501 ± 45 c,d |

| Ultimate torsional strength (N mm) | 9.9 ± 1.1 a, b | 15.6 ± 1.3 d | 10.3 ± 1.2 b, c | 8.5 ± 0.7 a | 9.2 ± 1.2 a, b | 11.8 ± 1.1 c | 10.1 ± 0.7 b |

| Stiffness (N mm/degrees) | 0.14 ± 0.03 c,d | 0.1 ± 0.02 c | 0.1 ± 0.01 c | 0.03 ± 0.004 a | 0.1 ± 0.006 c | 0.04 ± 0.006 b | 0.16 ± 0.02 d |

| Heating (Endothermic) Curve | ||||||

| Rs (°C) | Rf (°C) | ΔH (J/g) | As (°C) | Af (°C) | ΔH (J/g) | |

| ProFile | –3.06 | 19.27 | 2.37 | |||

| ProTaper Gold | 35.20 | 47.92 | 4.77 | |||

| ProfaTaper Gold | 15.01 | 36.46 | 1.89 | 37.85 | 56.25 | 2.83 |

| HyFlex CM | 30.92 | 58.33 | 18.31 | |||

| V Taper 2H | 22.77 | 41.67 | 15.74 | |||

| 2Shape | 1.27 | 29.69 | 2.64 | |||

| K3XF | 2.08 | 18.43 | 18.43 | 30.21 | 11.44 * | |

| Cooling (Exothermic) Curve | ||||||

| Rs (°C) | Rf (°C) | ΔH (J/g) | Ms (°C) | Mf (°C) | ΔH (J/g) | |

| ProFile | 10.13 | –13.54 | 1.98 | |||

| ProTaper Gold | 40.55 | 19.79 | 4.68 | |||

| ProfaTaper Gold | 43.52 | 29.17 | 3.36 | |||

| HyFlex CM | 36.40 | 21.35 | 4.05 | –18.84 | –46.35 | 7.63 |

| V Taper 2H | 27.89 | 14.58 | 4.22 | –25.95 | –53.44 | 9.36 |

| 2Shape | 16.00 | –11.46 | 2.07 | |||

| K3XF | 18.11 | 6.77 | 3.07 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, S.; Kim, T.-H.; Chang, S.W. Mechanical Properties of NiTi Rotary Files Fabricated through Gold-Wire, CM-Wire, T-Wire, and R-Phase Heat Treatment. Appl. Sci. 2023, 13, 3604. https://doi.org/10.3390/app13063604

Oh S, Kim T-H, Chang SW. Mechanical Properties of NiTi Rotary Files Fabricated through Gold-Wire, CM-Wire, T-Wire, and R-Phase Heat Treatment. Applied Sciences. 2023; 13(6):3604. https://doi.org/10.3390/app13063604

Chicago/Turabian StyleOh, Soram, Tae-Hwan Kim, and Seok Woo Chang. 2023. "Mechanical Properties of NiTi Rotary Files Fabricated through Gold-Wire, CM-Wire, T-Wire, and R-Phase Heat Treatment" Applied Sciences 13, no. 6: 3604. https://doi.org/10.3390/app13063604

APA StyleOh, S., Kim, T.-H., & Chang, S. W. (2023). Mechanical Properties of NiTi Rotary Files Fabricated through Gold-Wire, CM-Wire, T-Wire, and R-Phase Heat Treatment. Applied Sciences, 13(6), 3604. https://doi.org/10.3390/app13063604