Study on Interface Mechanical Properties of Graphene/Copper Matrix Composites

Abstract

1. Introduction

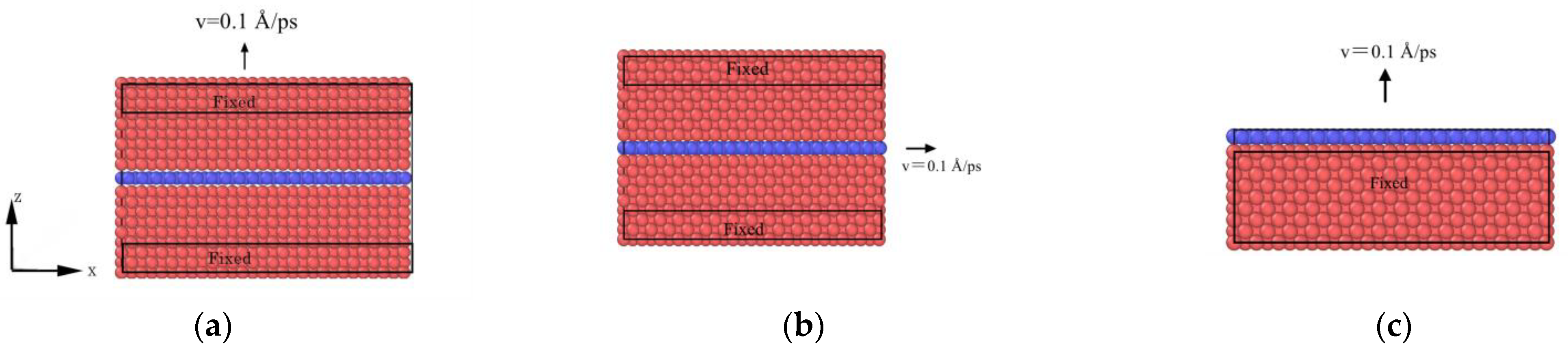

2. Calculation Model and Method

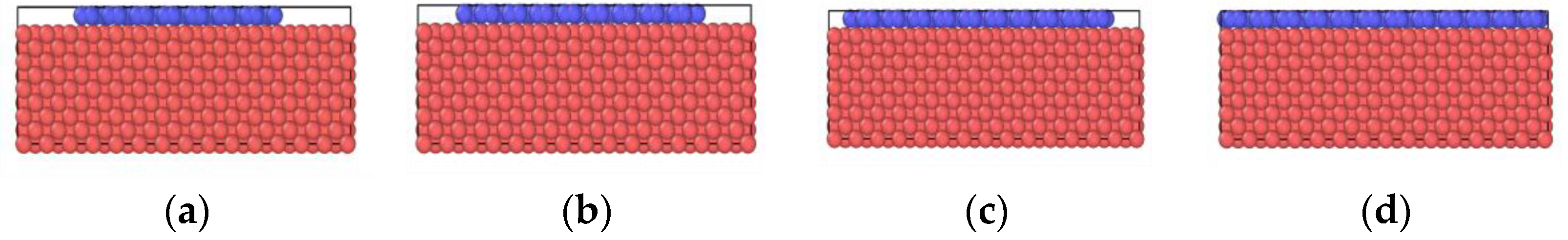

2.1. Computational Model

2.2. Calculation Method

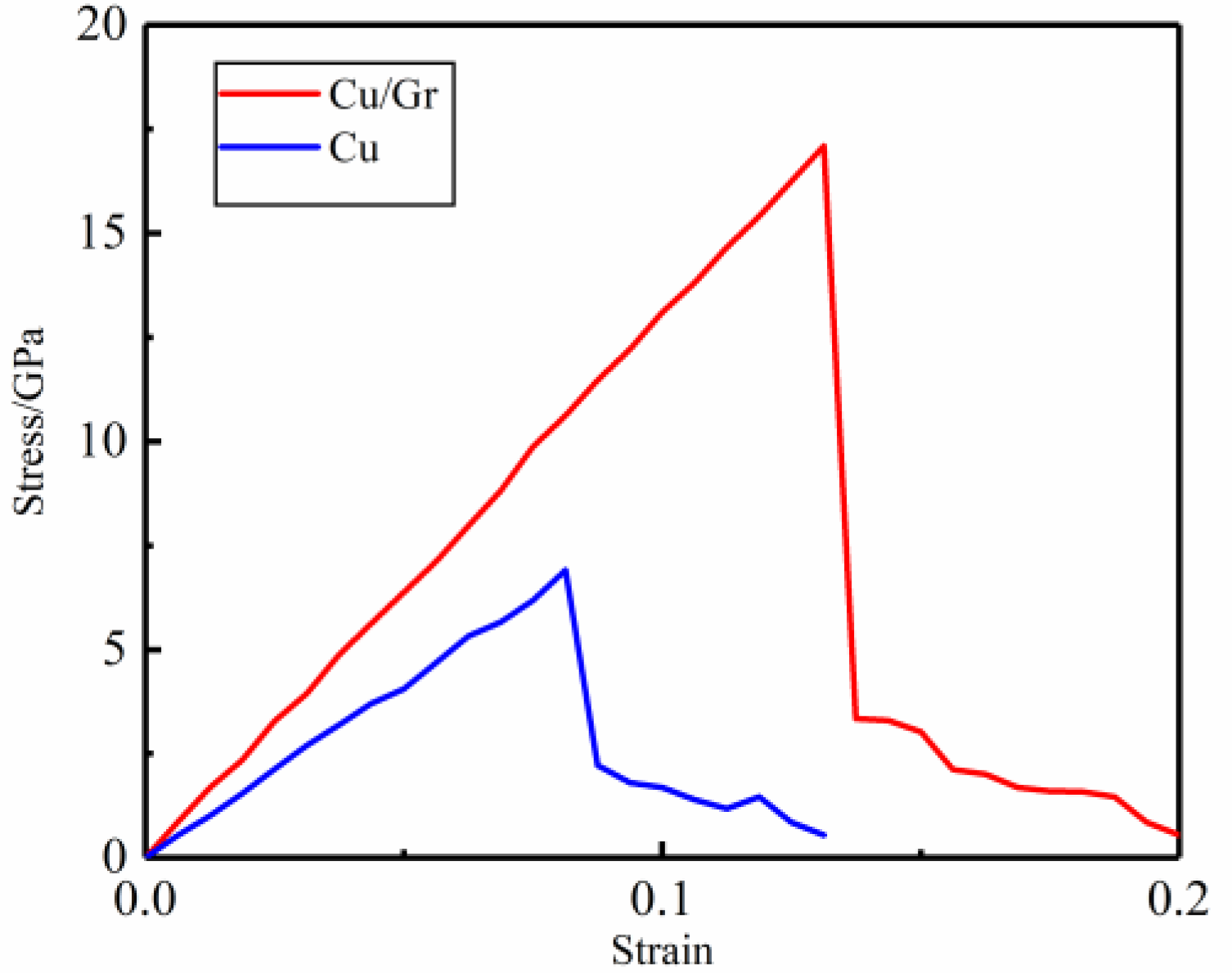

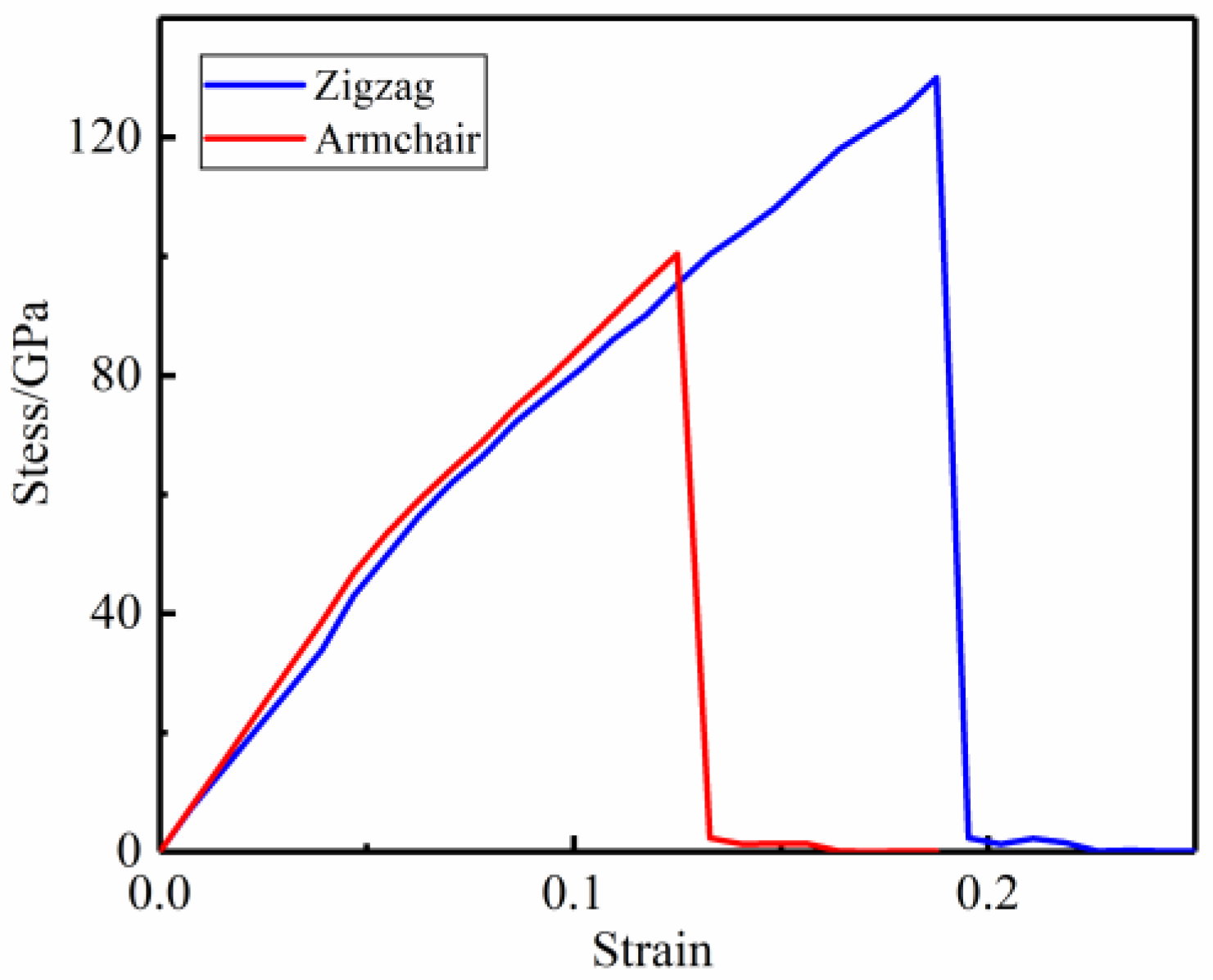

2.3. Model and Method Verification

3. Calculation Results and Discussion

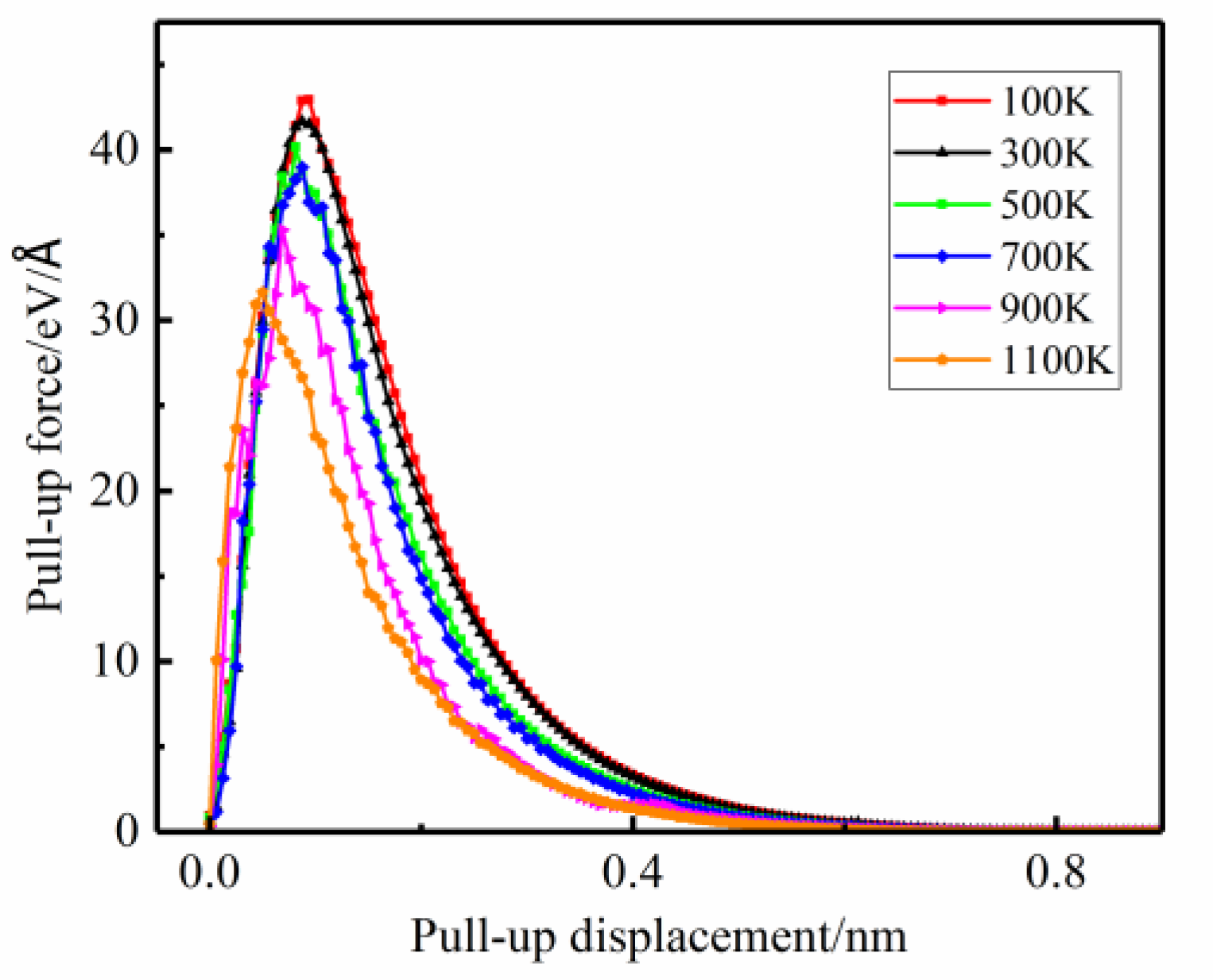

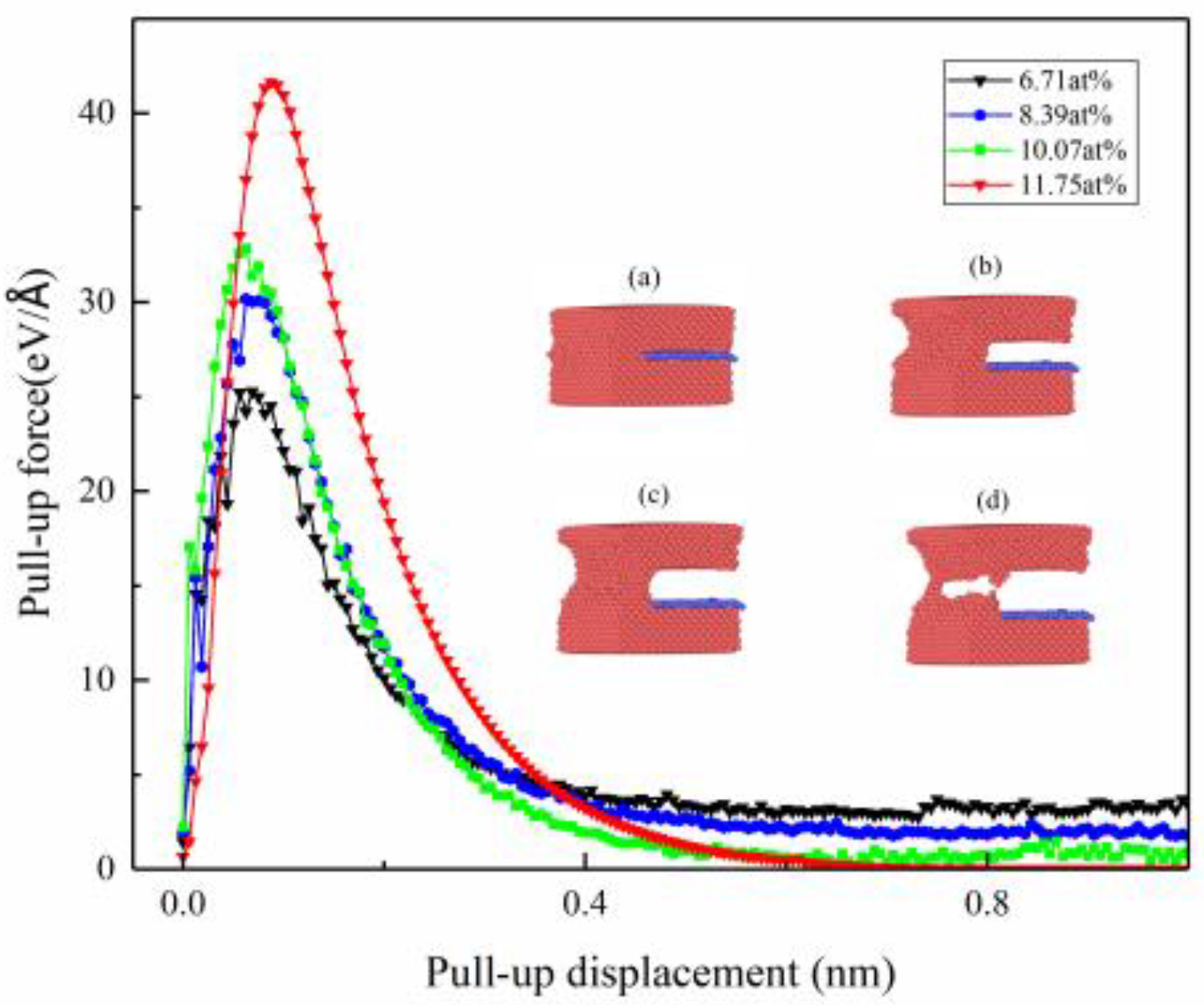

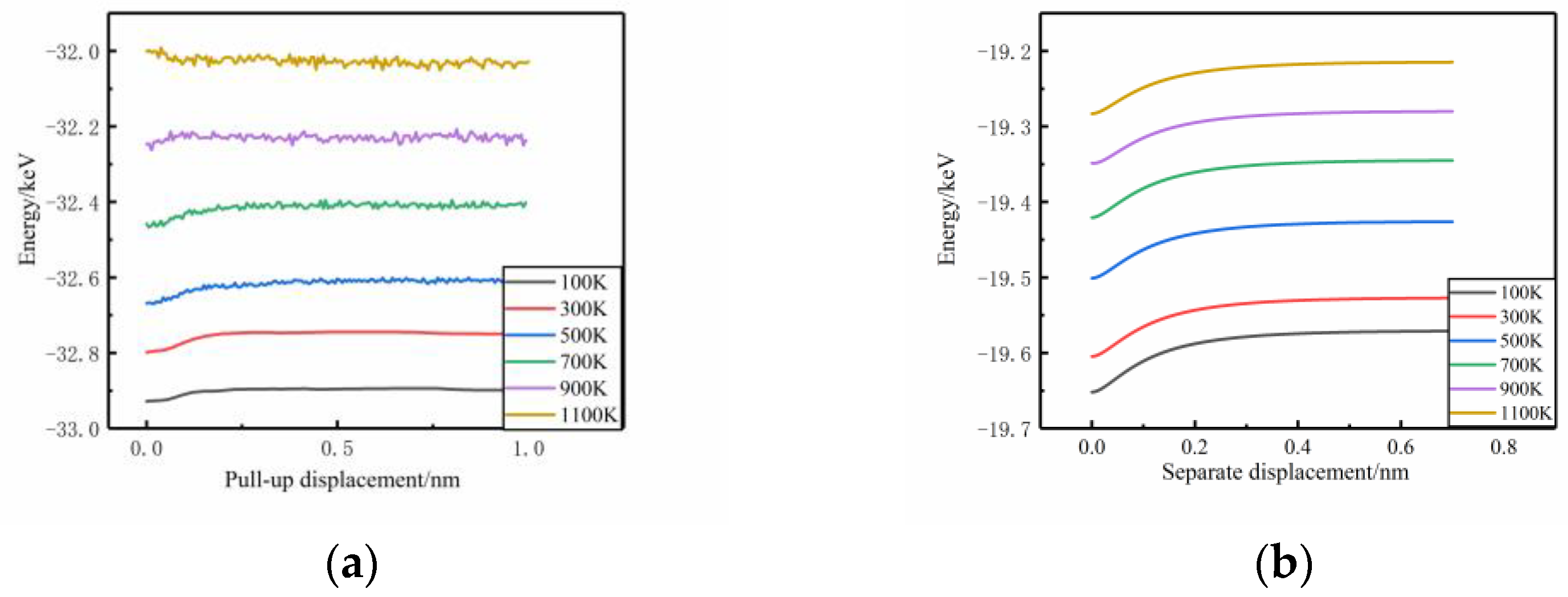

3.1. Mechanical Behavior Analysis of Interface Pull-Up

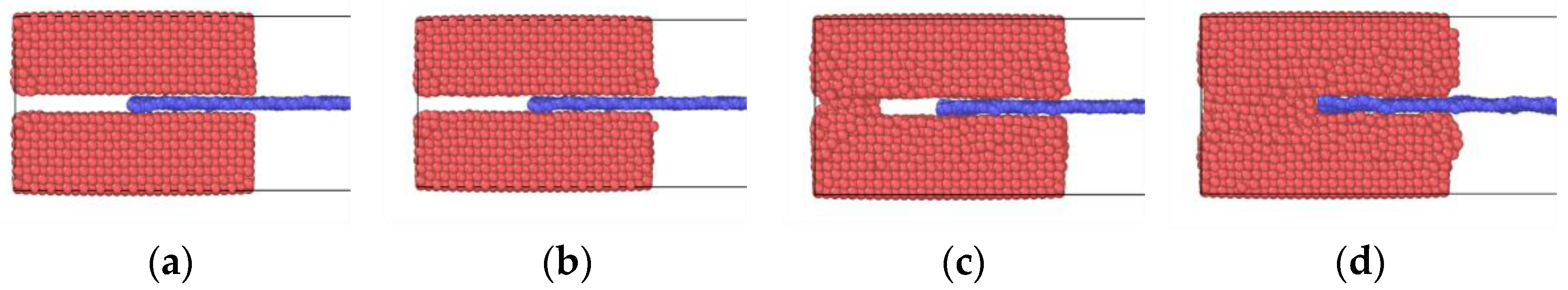

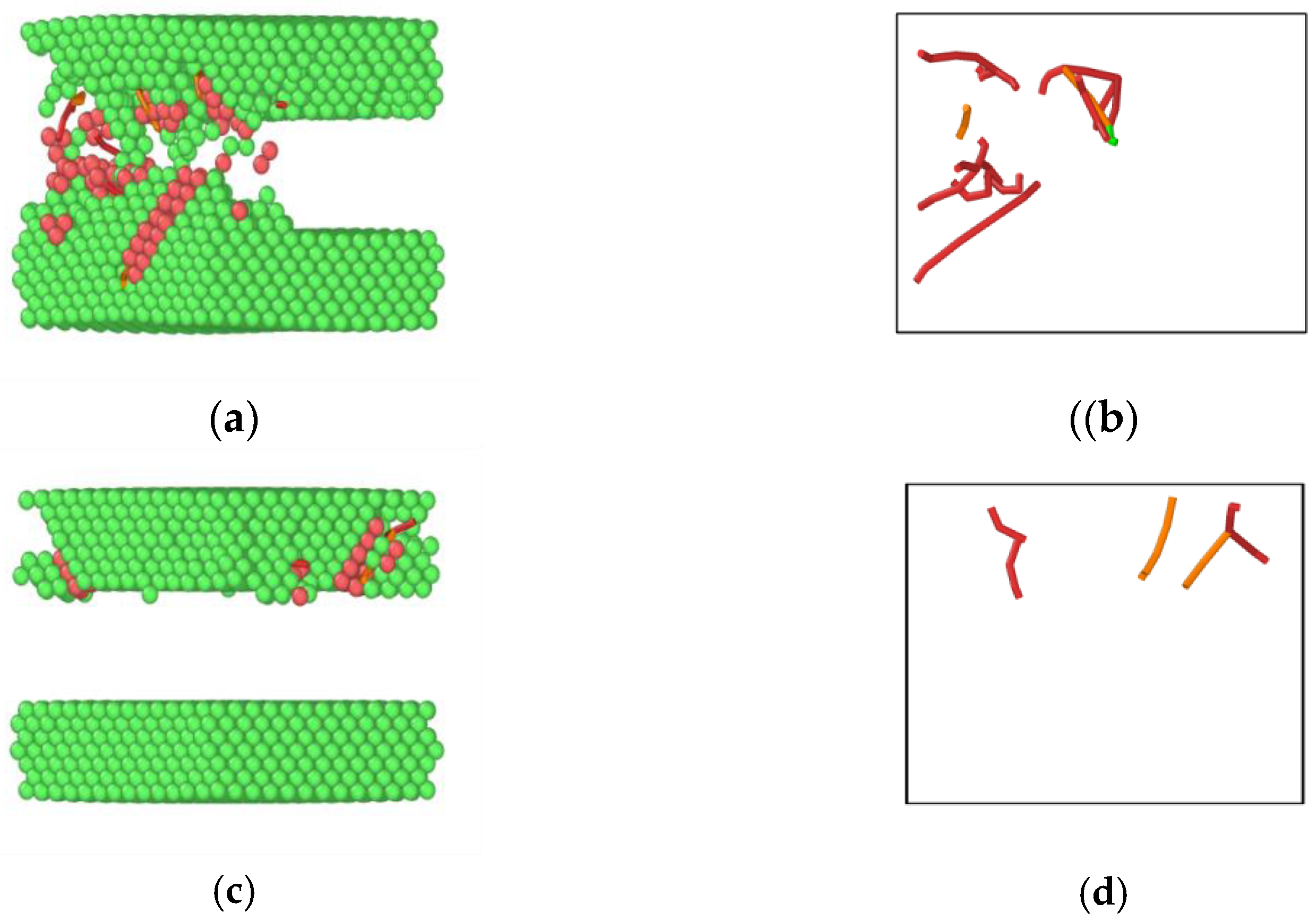

3.2. Mechanical Behavior Analysis of Interface Pulling Out

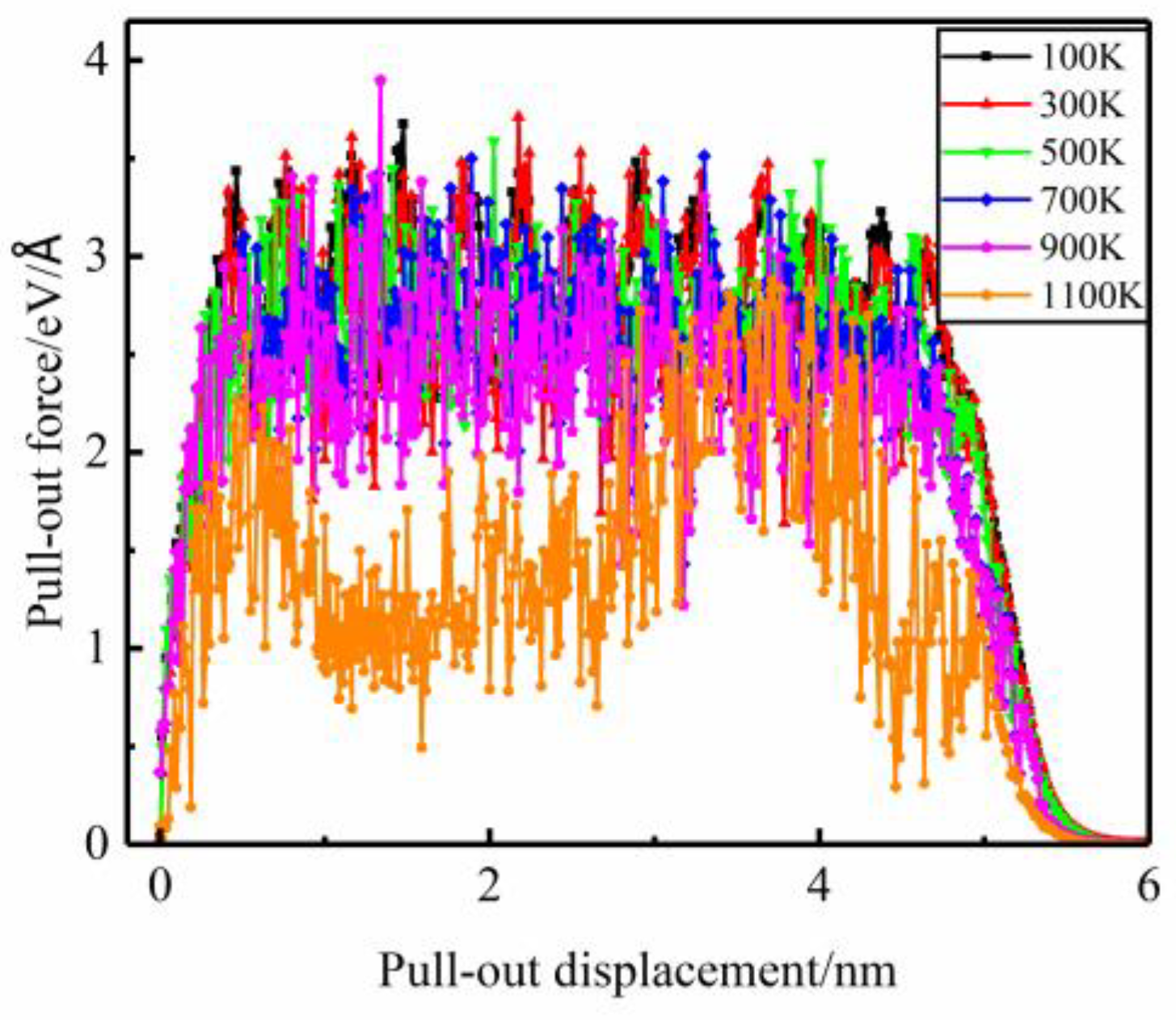

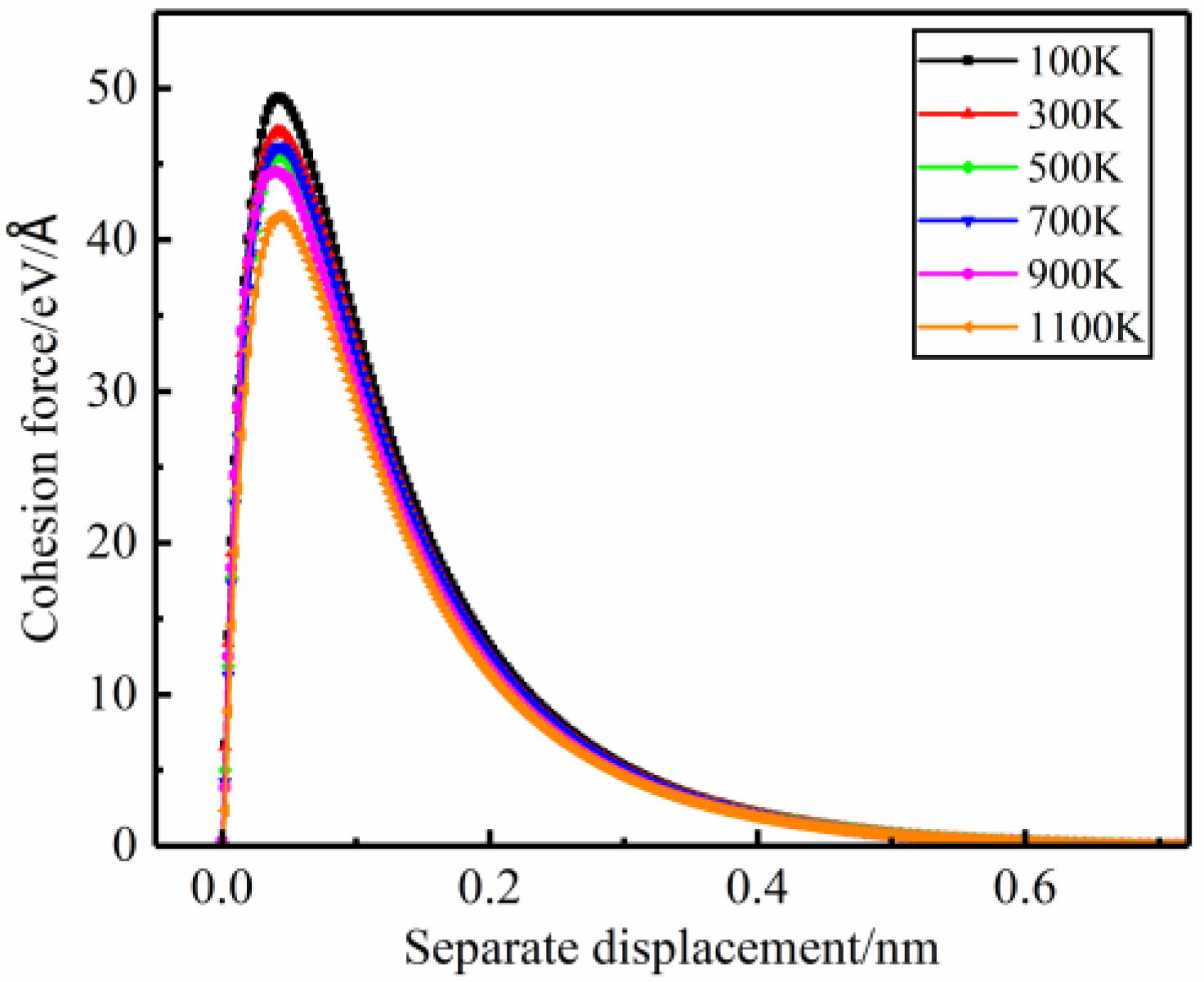

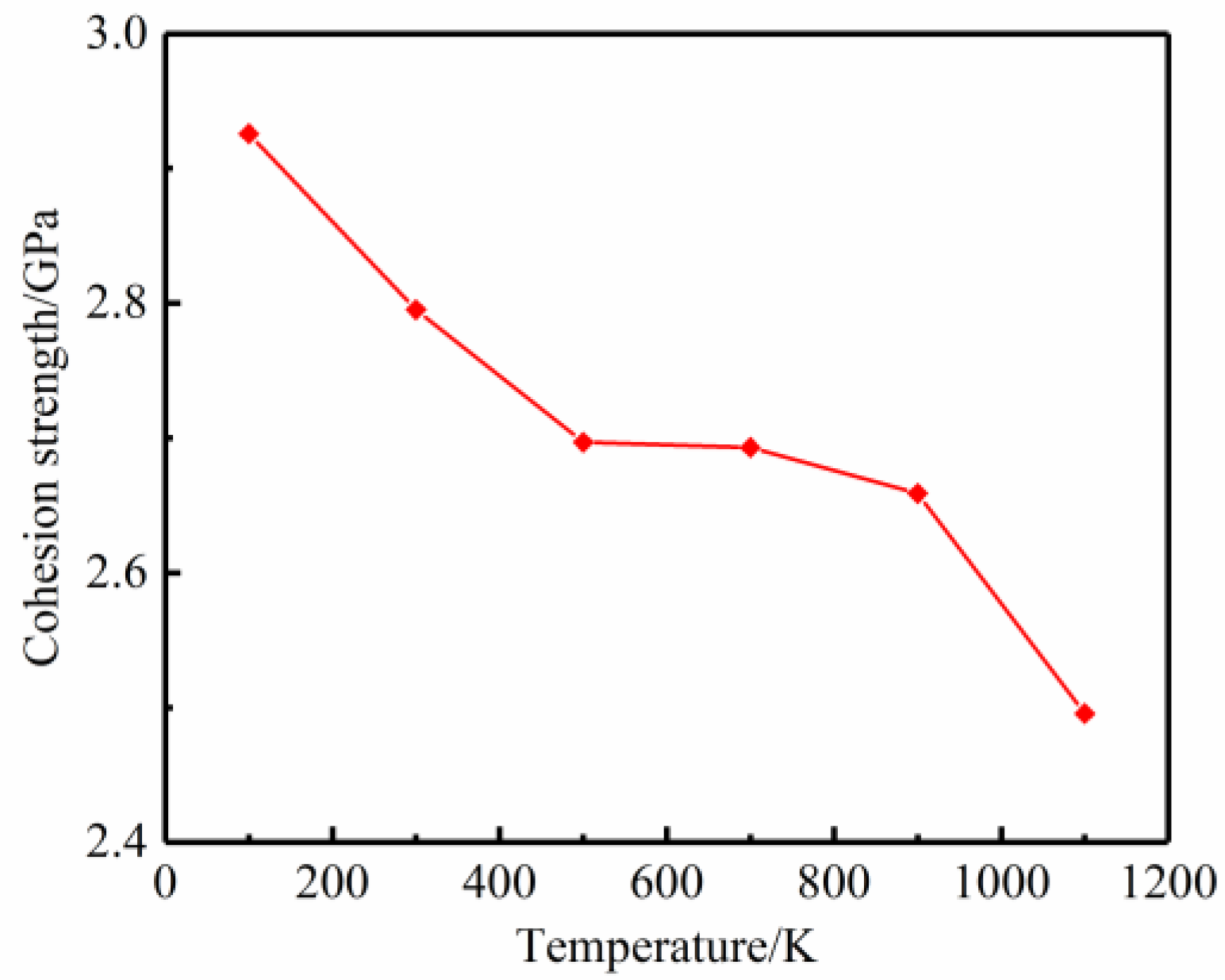

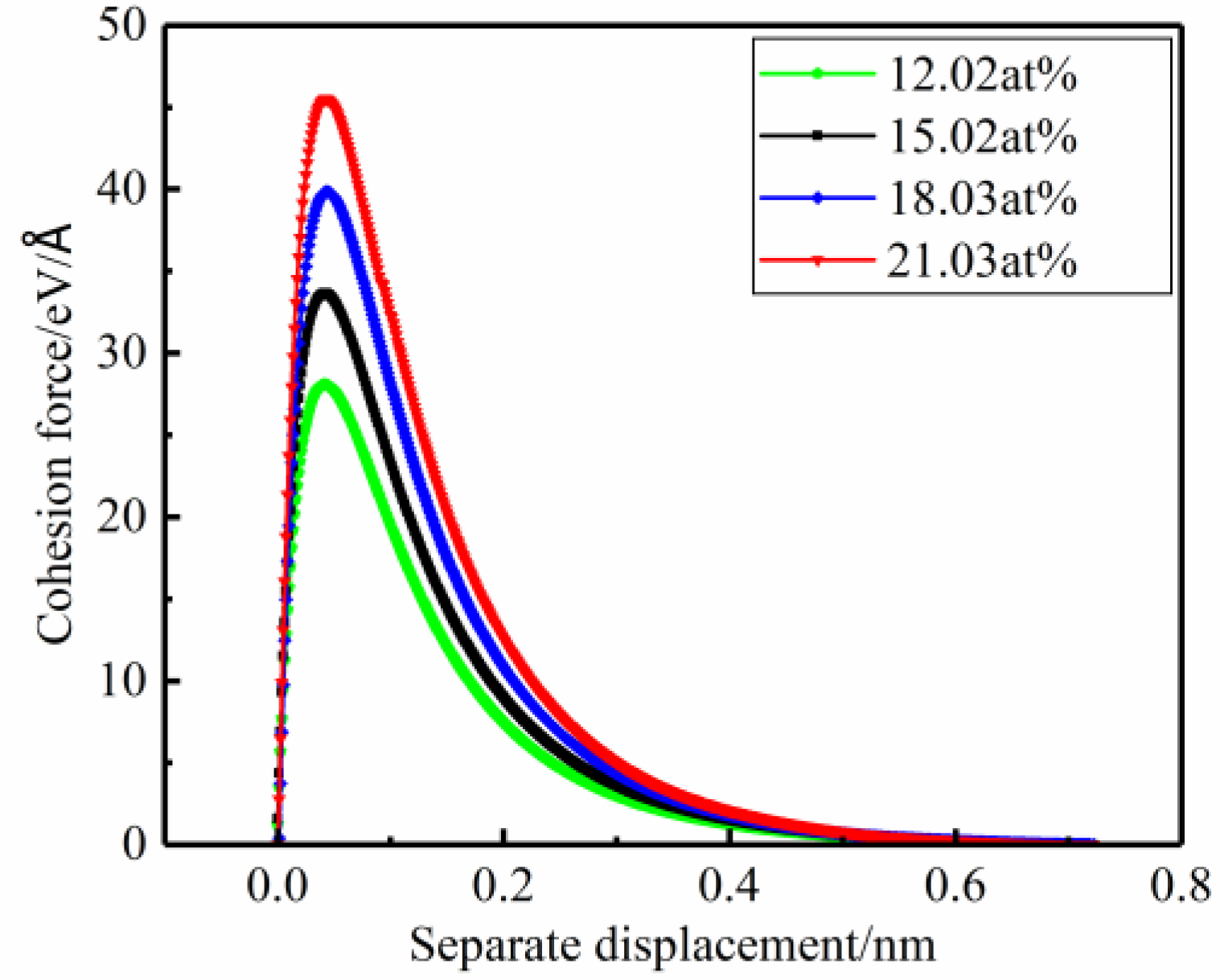

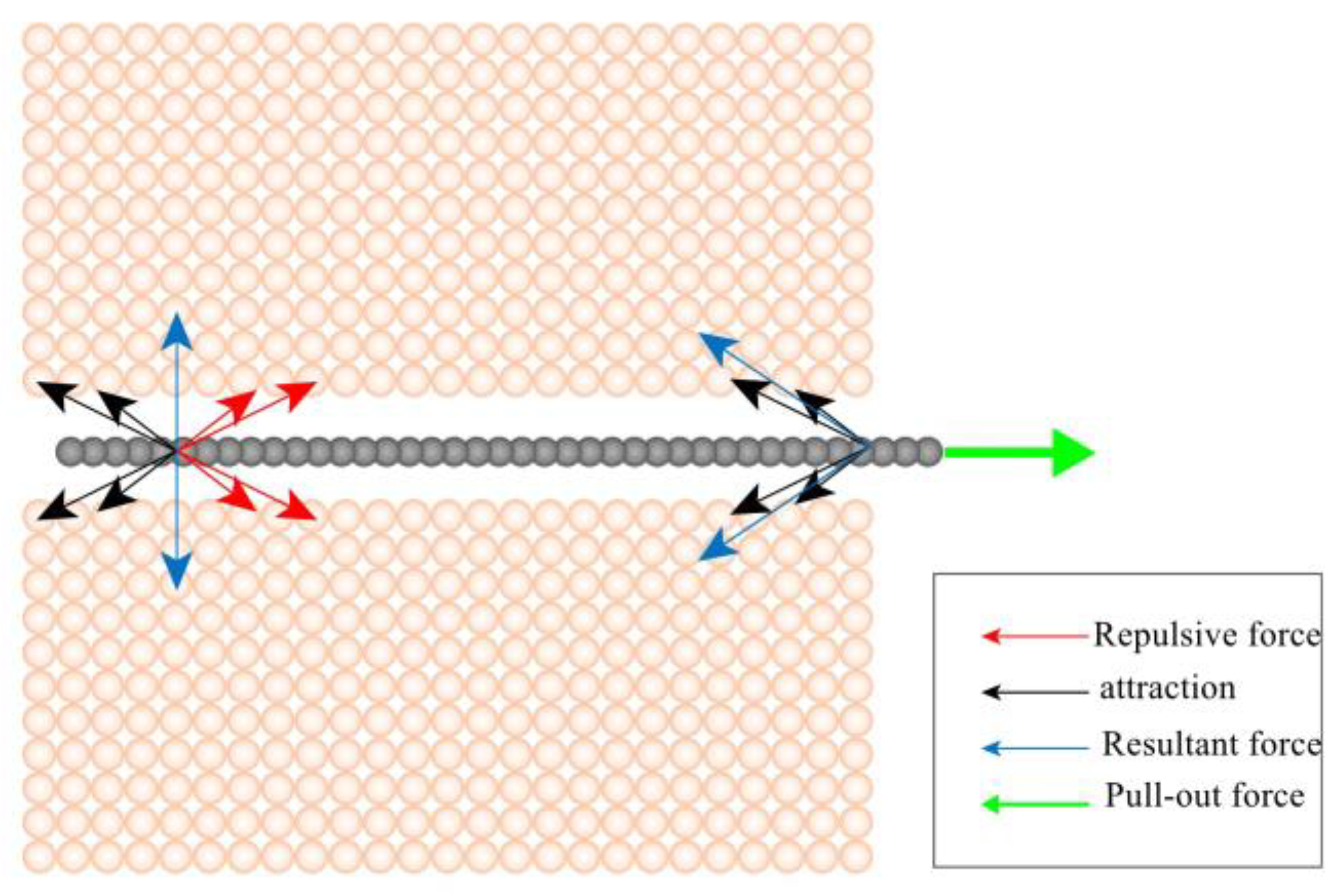

3.3. Analysis of Interface Cohesion

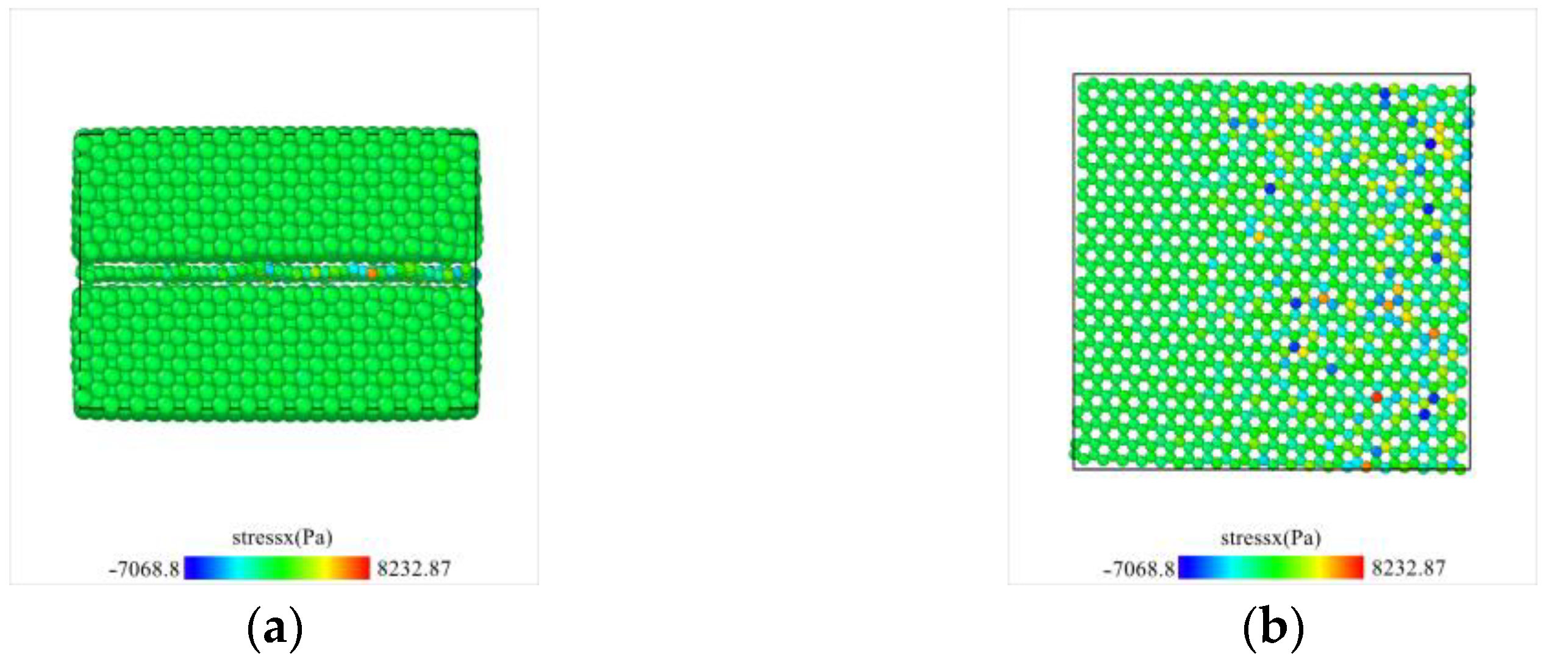

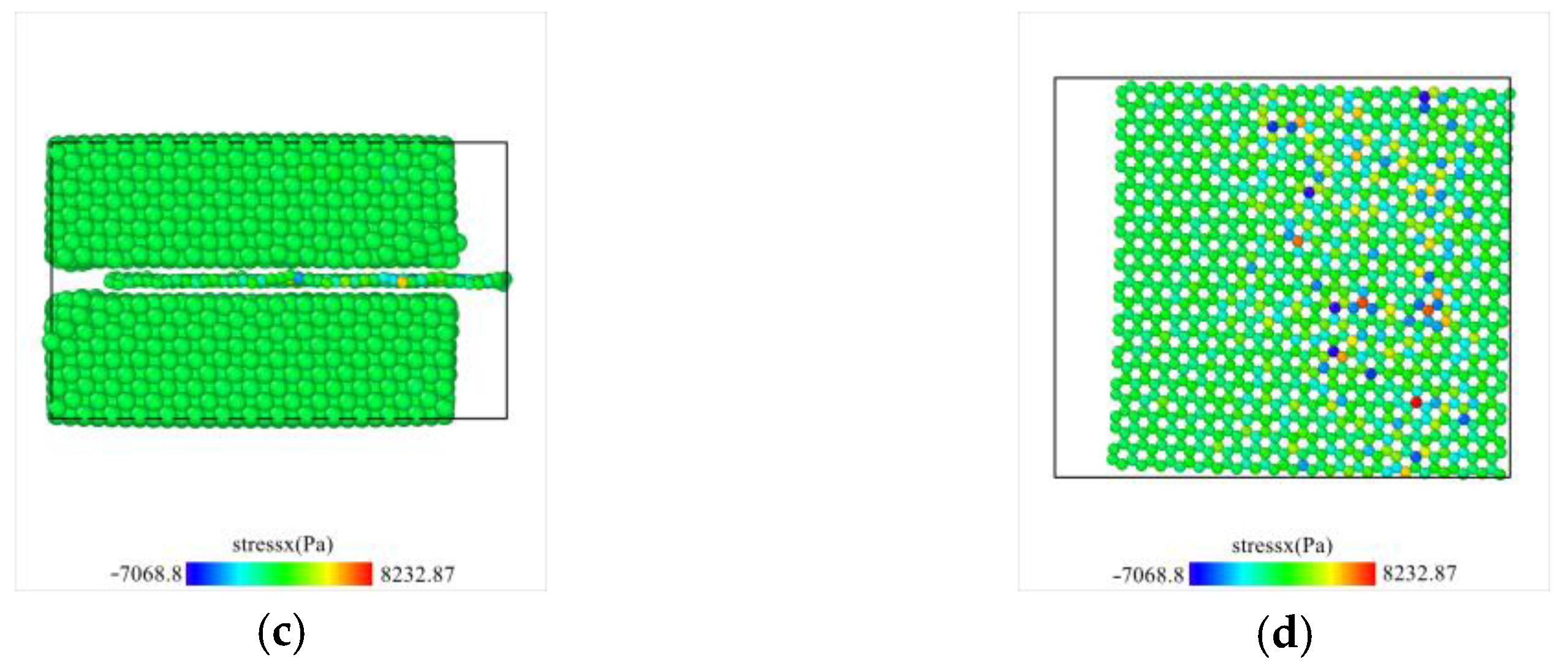

3.4. Influence Mechanism Analysis

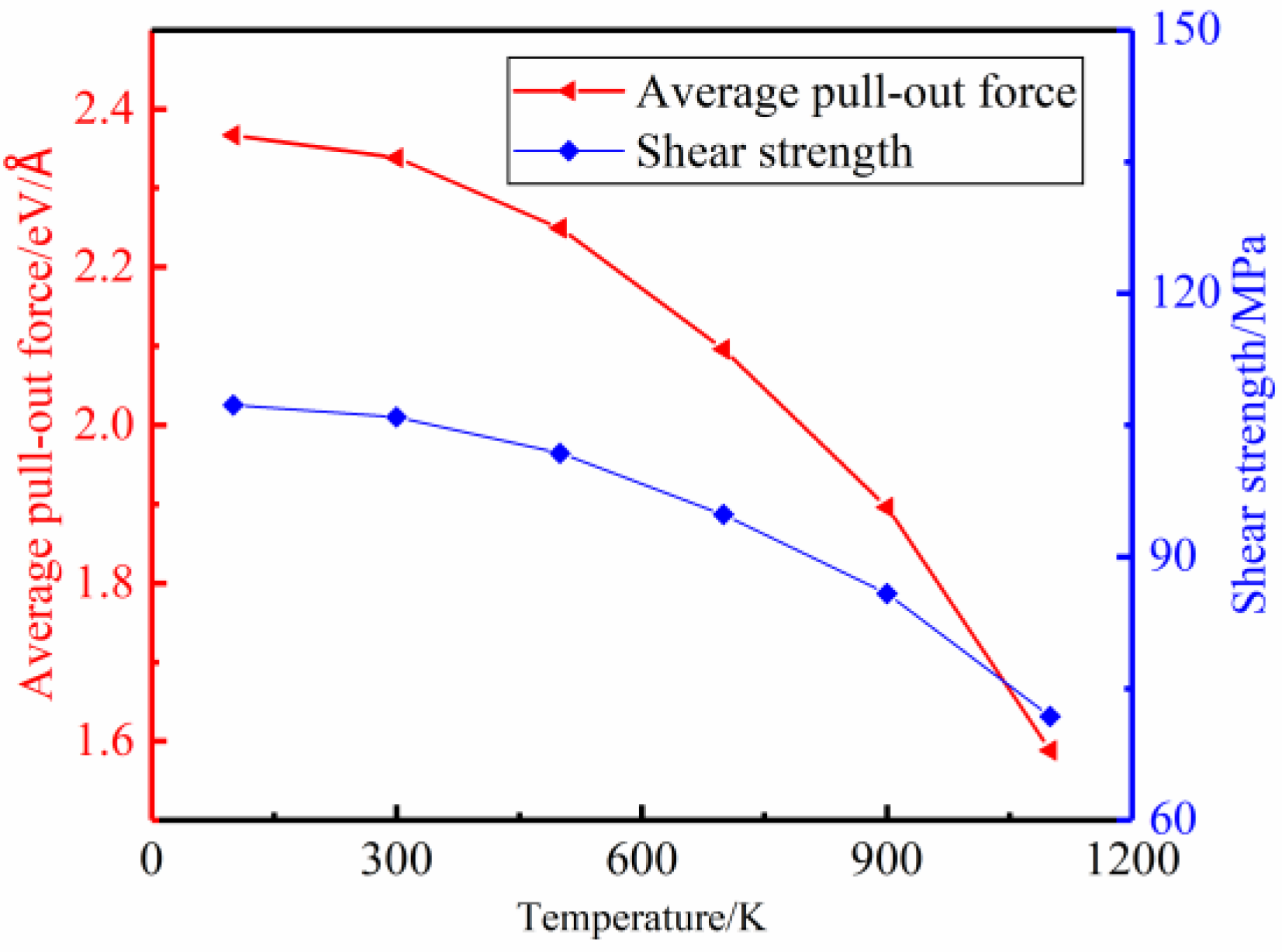

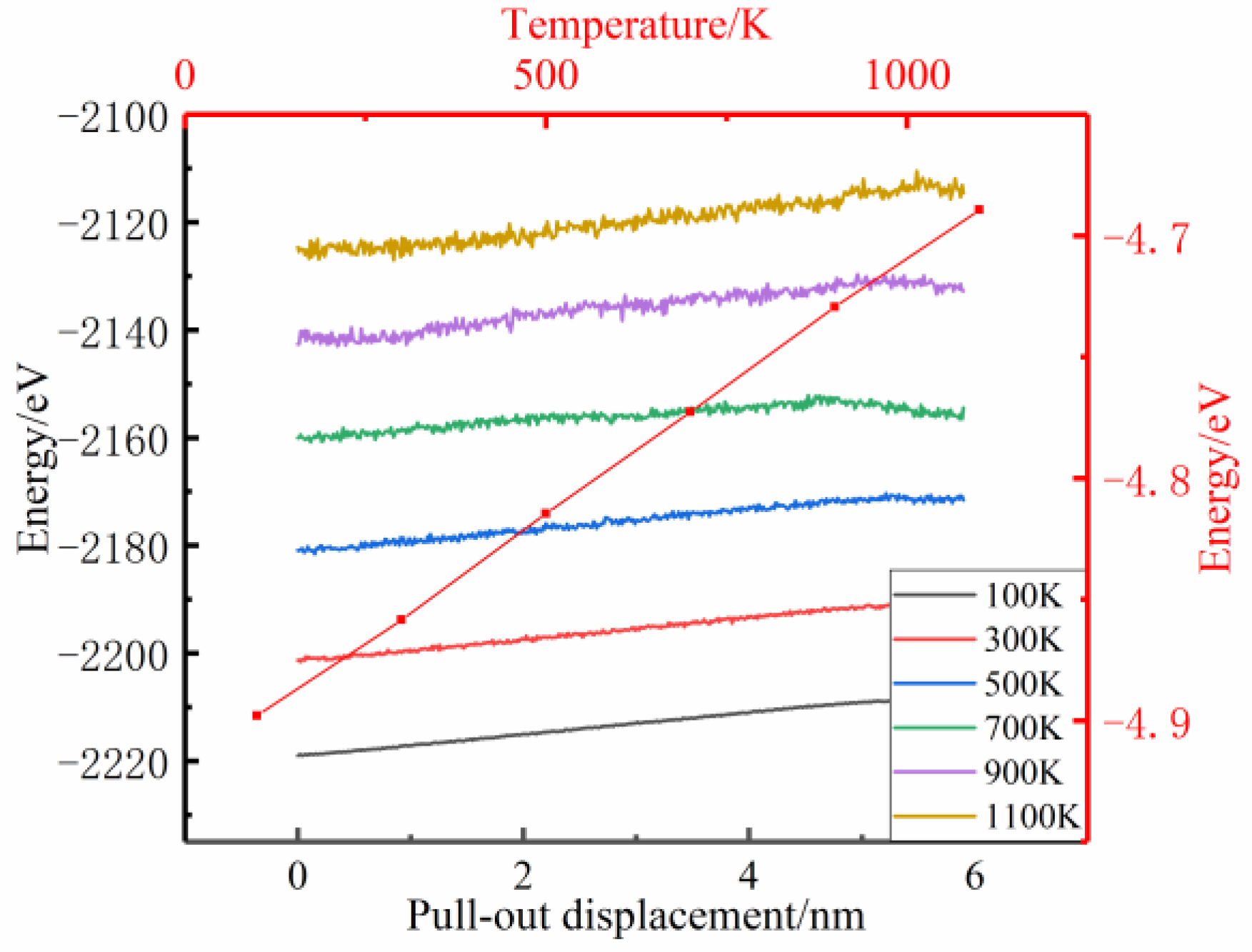

3.4.1. Temperature Effect

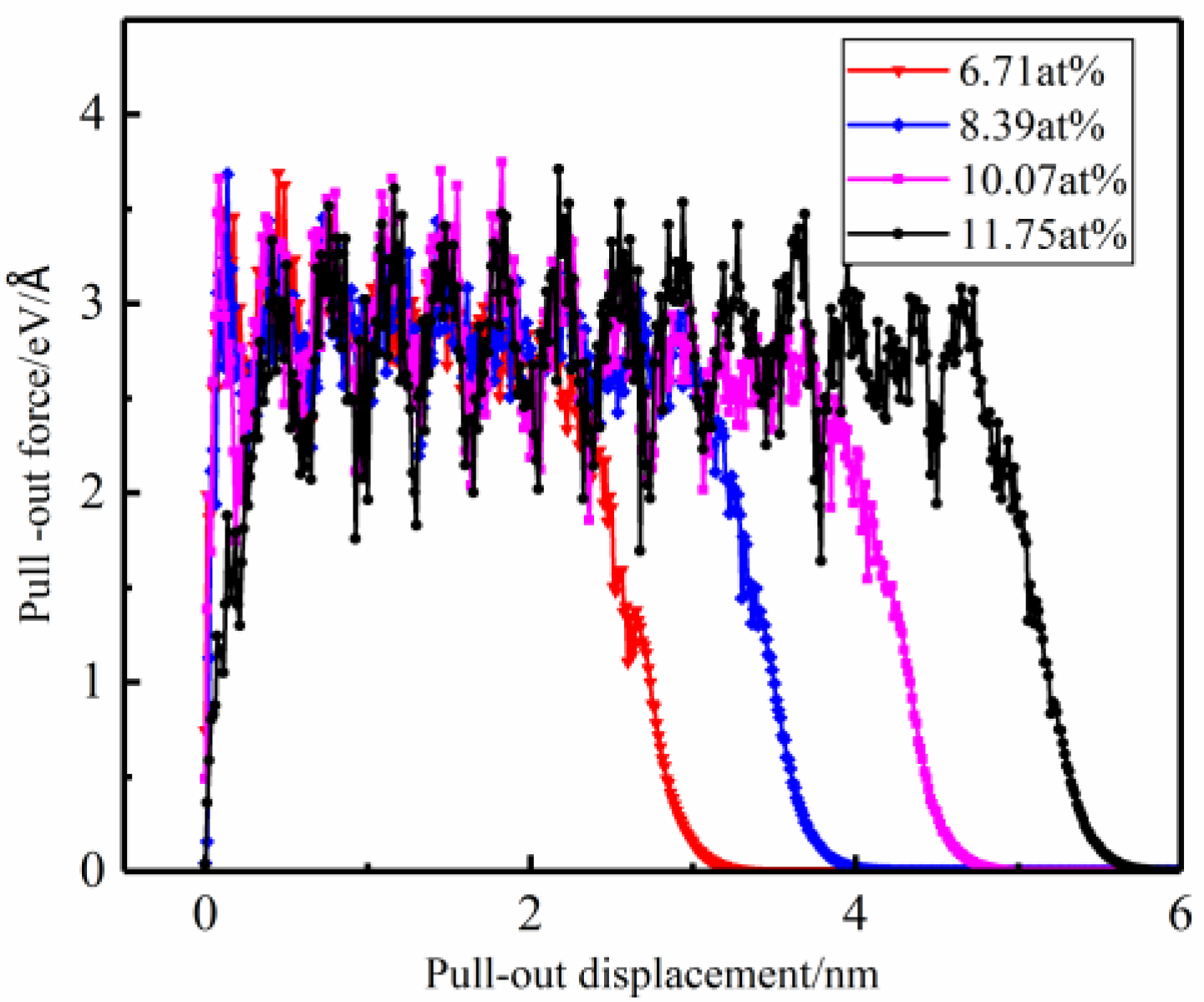

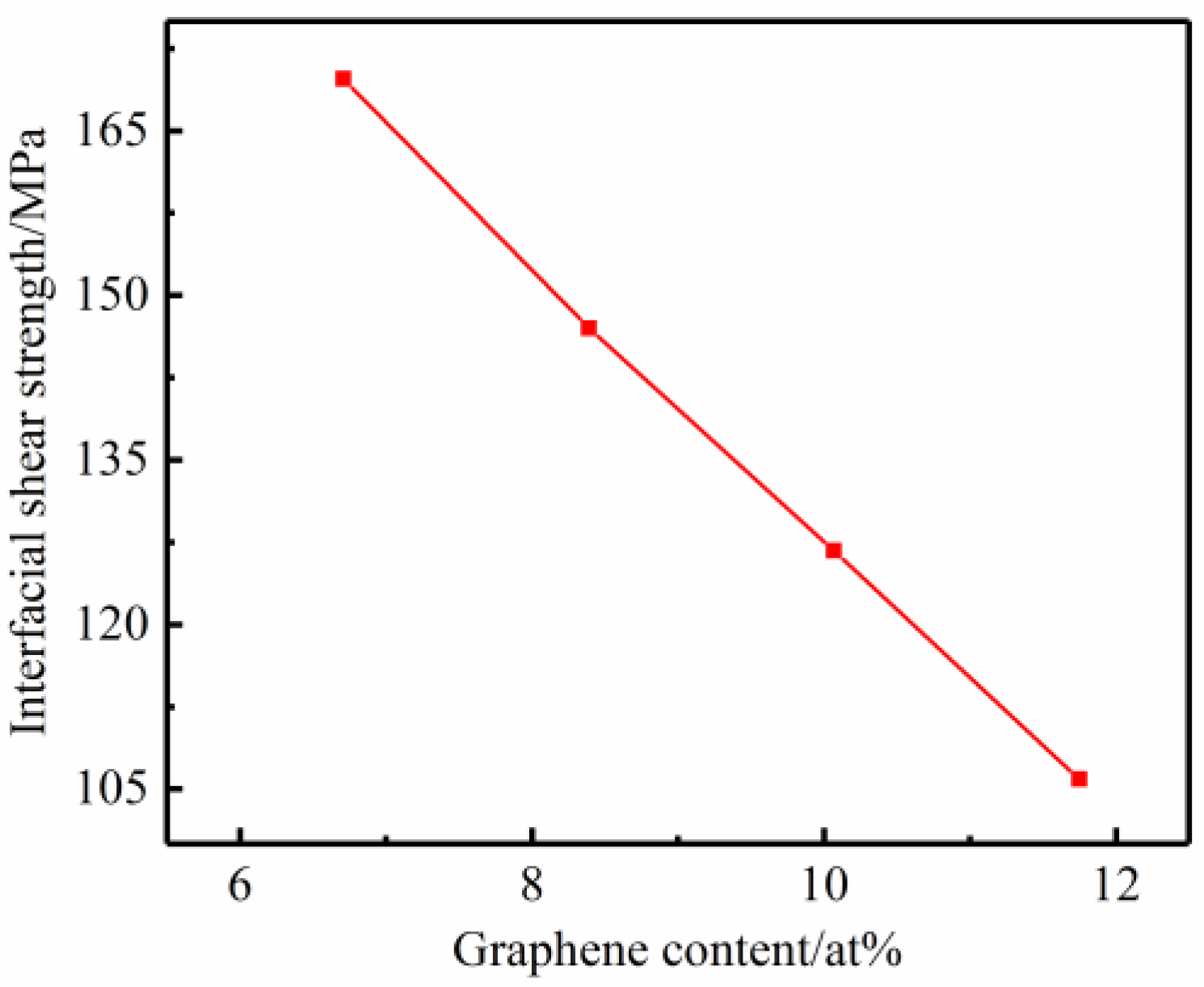

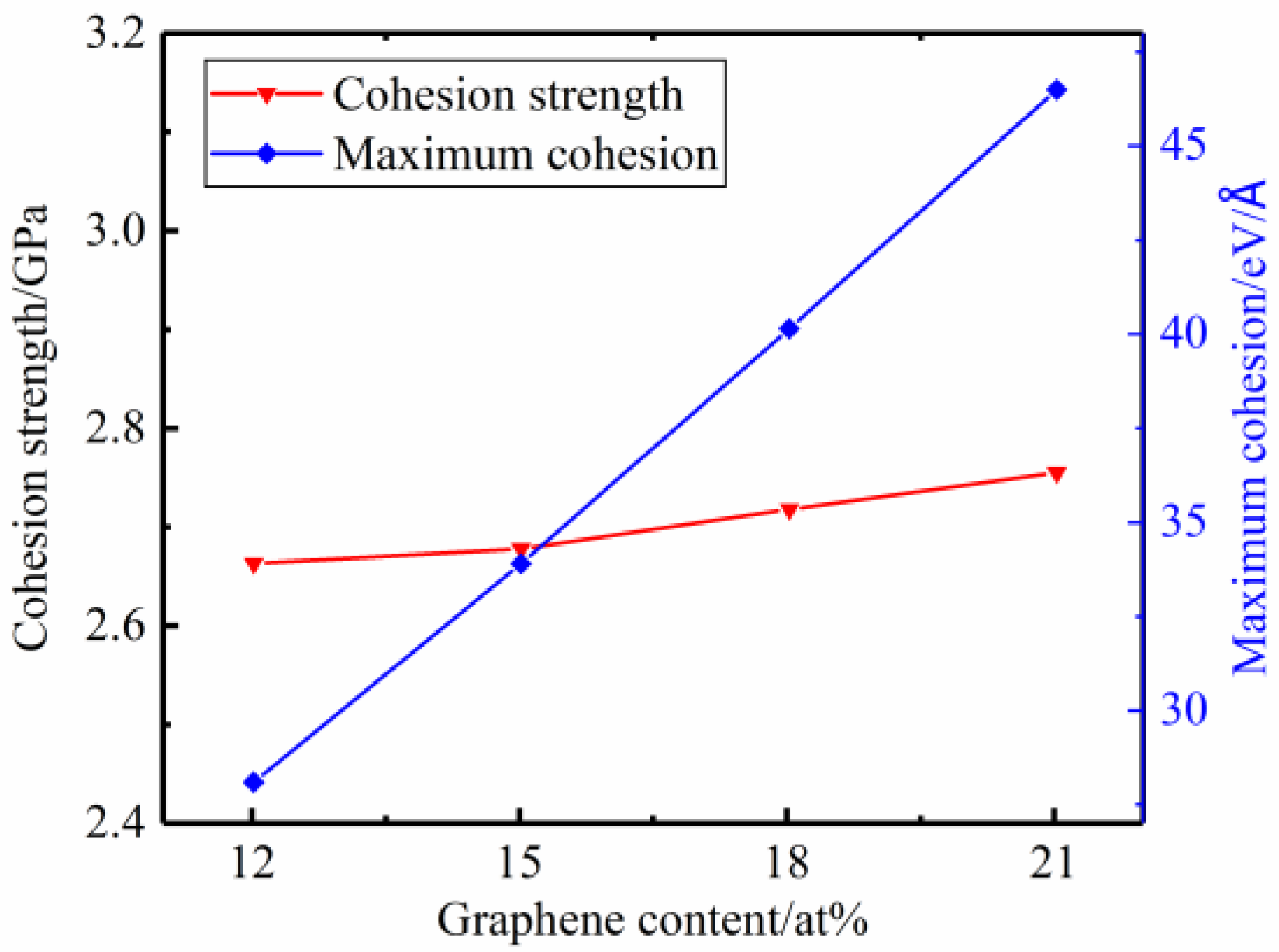

3.4.2. Graphene Content Effect

4. Conclusions

- (1)

- During the simulation process, the pulling force increased first and then decreased. The normal strength and pulling force decreased with the increase in temperature. The influence of graphene content on the normal strength was obvious, and the normal strength of 6.71 at% decreased by 6.8% compared with that of the composite containing intact single graphene;

- (2)

- During the pull-out process, the pull-out force first increased rapidly, then fluctuated continuously, and finally decreased to zero. The pull-out force and interfacial shear strength decreased with the increase in temperature and had a large decreasing trend between 700 K and 1100 K. The graphene content had little effect on the pull-out force but a significant effect on the interfacial shear strength;

- (3)

- The interface cohesion increased rapidly with the simulation and then decreased to 0. The maximum cohesion and cohesion strength decreased with the increase in temperature, and the cohesion strength was almost not affected by the graphene content;

- (4)

- The analysis of the effect of temperature and graphene content shows that temperature will affect atomic activity. The increase in temperature leads to a decrease in the attraction between carbon atoms and copper atoms and the softening of the copper matrix, which reduces the interface strength. The presence of graphene sheets will hinder the dislocation expansion of the copper matrix, so the normal strength increases with the increase in graphene content, and the pull-out force is only affected by the number of carbon atoms at the critical pull-out surface, so the maximum pull-out force remains basically unchanged.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Berman, D.; Deshmukh, S.A.; Sankaranarayanan, S.K.R.S.; Erdemir, A.; Sumant, A.V. Macroscale superlubricity enabled by gra-phene nanoscroll formation. Science 2015, 348, 6239. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Tonks, D.L.; Alexanderl, D.J.; Sheffield, S.A.; Zurek, A.K.; Thissell, W.R. Spallation strength of single crystal and polycrys-talline copper. J. Phys. IV 2000, 10, 787–792. [Google Scholar]

- Zhai, W.; Lu, W.; Chen, Y.; Liu, X.; Zhou, L.; Lin, D. Gas-atomized copper-based particles encapsulated in graphene oxide for high wear-resistant composites. Compos. Part B Eng. 2019, 157, 131–139. [Google Scholar] [CrossRef]

- Zhang, P.C.; Jie, J.C.; Gao, Y.; Li, H.; Cao, Z.Q.; Wang, T.M. Preparation and properties of TiB2 particles reinforced Cu-Cr matrix composite. Mater. Sci. Eng. Struct. Mater. Propert. Misrostruct. Process. 2015, 642, 398–405. [Google Scholar] [CrossRef]

- Xue, Z.; Wang, L.; Zhao, P.; Xu, S.; Qi, J.; Fei, W. Microstructures and tensile behavior of carbon nanotubes reinforced Cu matrix composites with molecular-level dispersion. Mater. Des. 2012, 34, 298–301. [Google Scholar] [CrossRef]

- Hua, J.; Zhang, Y.; Wu, X. Vibration analysis of defective graphene based on the molecular structural mechanics method. Int. J. Comput. Mater. Sci. Eng. 2016, 5, 16500020. [Google Scholar] [CrossRef]

- Wang, C.; Lan, L.; Liu, Y.; Tan, H. Multiple component correlation model for elastic modulus of single layer graphene sheets. Phys. E Low-Dimens. Syst. Nanostruct. 2013, 56, 372–376. [Google Scholar] [CrossRef]

- Ren, Y.; Cao, G. Effect of geometrical defects on the tensile properties of graphene. Carbon 2016, 103, 125–133. [Google Scholar] [CrossRef]

- Cui, J.; Song, Z.; Xin, L.; Zhao, S.; Yan, Y.; Liu, G. Exfoliation of graphite to few-layer graphene in aqueous media with vinylimidazole-based polymer as high-performance stabilizer. Carbon 2016, 99, 249–260. [Google Scholar] [CrossRef]

- Wang, H.; Xie, G.Y.; Fang, M.; Ying, Z.; Tong, Y.; Zeng, Y. Electrical and mechanical properties of antistatic PVC films con-taining multi-layer graphene. Compos. Part B 2015, 79, 444–450. [Google Scholar] [CrossRef]

- Yao, W.; Fan, L.; Liu, G. Advance in Properties of Graphene and Graphene/Metal Layered Composite After Irradiation Damage. Rare Metal Mater. Eng. 2019, 48, 3130–3135. [Google Scholar]

- Cha, S.I.; Kim, K.T.; Arshad, S.N.; Mo, C.B.; Hong, S.H. Extraordinary Strengthening Effect of Carbon Nanotubes in Metal-Matrix Nanocomposites Processed by Molecular-Level Mixing. Adv. Mater. 2005, 17, 1377–1381. [Google Scholar] [CrossRef] [PubMed]

- Hwang, J.; Yoon, T.; Jin, S.H.; Lee, J.; Kim, T.-S.; Hong, S.H.; Jeon, S. Enhanced Mechanical Properties of Graphene/Copper Nanocomposites Using a Molecular-Level Mixing Process. Adv. Mater. 2013, 25, 6724–6729. [Google Scholar] [CrossRef] [PubMed]

- Hua, J.; Song, C.; Duan, Z.R.; Xiao, P. Molecular dynamics simulation of shear properties of graphene/copper compo-sites. J. Compos. Mater. 2018, 35, 632–639. [Google Scholar]

- Hua, J.; Ren, X.L.; Zhao, D. Friction properties of graphene-coated copper substrates based on molecular dynamics. Chin. J. Appl. Mech. 2021, 38, 1485–1492. [Google Scholar]

- Zhang, J.; Xu, Q.; Gao, L.; Ma, T.B.; Qiu, M.; Hu, Y.Z.; Wang, H.; Luo, J.B. A molecular dynamics study of lubricating mechanism of graphene nanoflakes embedded in Cu-based nanocomposite. Appl. Surf. Sci. 2020, 511, 145620.1–145620.9. [Google Scholar] [CrossRef]

- Bian, J.J.; Nicola, L. On the lubrication of rough copper surfaces with graphene. Tribol. Int. 2021, 156, 106837. [Google Scholar] [CrossRef]

- Shi, X.; Yin, Q.; Wei, Y. A theoretical analysis of the surface dependent binding, peeling and folding of graphene on single crystal copper. Carbon 2012, 50, 3055–3063. [Google Scholar] [CrossRef]

- Jiang, R.; Zhou, X.; Fang, Q.; Liu, Z. Copper–graphene bulk composites with homogeneous graphene dispersion and enhanced mechanical properties. Mater. Sci. Eng. A 2016, 654, 124–130. [Google Scholar] [CrossRef]

- Sadowski, P.; Kowalczyk-Gajewska, K.; Stupkiewicz, S. Classical estimates of the effective thermoelastic properties of copper–graphene composites. Compos. Part B Eng. 2015, 80, 278–290. [Google Scholar] [CrossRef]

- Ji, B.; Gao, H. Mechanical properties of nanostructure of biological materials. J. Mech. Phys. Solids 2004, 52, 1963–1990. [Google Scholar] [CrossRef]

- Liu, X.; Wang, F.; Wang, W.; Wu, H. Interfacial strengthening and self-healing effect in graphene-copper nanolayered composites under shear deformation. Carbon 2016, 107, 680–688. [Google Scholar] [CrossRef]

- Plimptoni, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 15012. [Google Scholar] [CrossRef]

- Foiles, S.M.; Baskes, M.I.; Daw, M.S. Erratum: Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys. Rev. B Condens. Matter. 1986, 33, 7983–7991. [Google Scholar] [CrossRef]

- Muller, S.E.; Nair, A.K. Dislocation Nucleation in Nickel-Graphene Nanocomposites under Mode I Loading. Jom 2016, 68, 1909–1914. [Google Scholar] [CrossRef]

- Stuart, S.J.; Tutein, A.B.; Harrison, J.A. A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 2000, 112, 6472–6486. [Google Scholar] [CrossRef]

- Duan, Z.R. Study on the Mechanical Properties of Tensile and Indentation of Graphene/Cu Nanocomposites; Xi’an University of Architecture and Technology: Xi’an, China, 2017. (In Chinese) [Google Scholar]

- Yao, W.P. Molecular Dynamics-Based Tensile Mechanical Behavior of Metal Nanowires; Xi’an University of Technology: Xi’an, China, 2018. (In Chinese) [Google Scholar]

- Gregory, V.L.; Christian, V.A.; Vic, V.D.; Paul, G. Ab initio study of the elastic properties of single-walled carbon nanotubes and graphene. Chem. Phys. Lett. 2000, 326, 181–185. [Google Scholar]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Lv, C.; Xue, Q.; Xia, D.; Ma, M.; Xie, J.; Chen, H. Effect of Chemisorption on the Interfacial Bonding Characteristics of Graphene Polymer Composites. J. Phys. Chem. C 2010, 114, 6588–6594. [Google Scholar] [CrossRef]

- Duan, K.; Zhu, F.; Tang, K.; He, L.; Chen, Y.; Liu, S. Effects of chirality and number of graphene layers on the mechanical properties of graphene-embedded copper nanocomposites. Comput. Mater. Sci. 2016, 117, 294–299. [Google Scholar] [CrossRef]

- Nam, D.H.; Cha, S.I.; Lim, B.K.; Park, H.M.; Han, D.S.; Hong, S.H. Synergistic strengthening by load transfer mechanism and grain refinement of CNT/Al–Cu composites. Carbon 2012, 50, 2417–2423. [Google Scholar] [CrossRef]

| Pure Copper | Graphene/Copper Composites | |||

|---|---|---|---|---|

| Parameter | Ultimate Strain | Modulus of Elasticity/GPa | Ultimate Strain | Modulus of Elasticity/GPa |

| Textual data | 0.0858 | 87.65 | 0.13 | 215.88 |

| Literature data | 0.0825 | 84.049 | 0.127 | 210.2 |

| Error | 4.1% | 4.3% | 2.6% | 2.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Liu, Y.; Liu, Q. Study on Interface Mechanical Properties of Graphene/Copper Matrix Composites. Appl. Sci. 2023, 13, 3559. https://doi.org/10.3390/app13063559

Li D, Liu Y, Liu Q. Study on Interface Mechanical Properties of Graphene/Copper Matrix Composites. Applied Sciences. 2023; 13(6):3559. https://doi.org/10.3390/app13063559

Chicago/Turabian StyleLi, Dongbo, Yongkun Liu, and Qinlong Liu. 2023. "Study on Interface Mechanical Properties of Graphene/Copper Matrix Composites" Applied Sciences 13, no. 6: 3559. https://doi.org/10.3390/app13063559

APA StyleLi, D., Liu, Y., & Liu, Q. (2023). Study on Interface Mechanical Properties of Graphene/Copper Matrix Composites. Applied Sciences, 13(6), 3559. https://doi.org/10.3390/app13063559