Influence of Microwave Radiation on Pollutant Removal and Biomethane Production Efficiency in Anaerobic Treatment of High-Load Poultry Wastewater

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Design

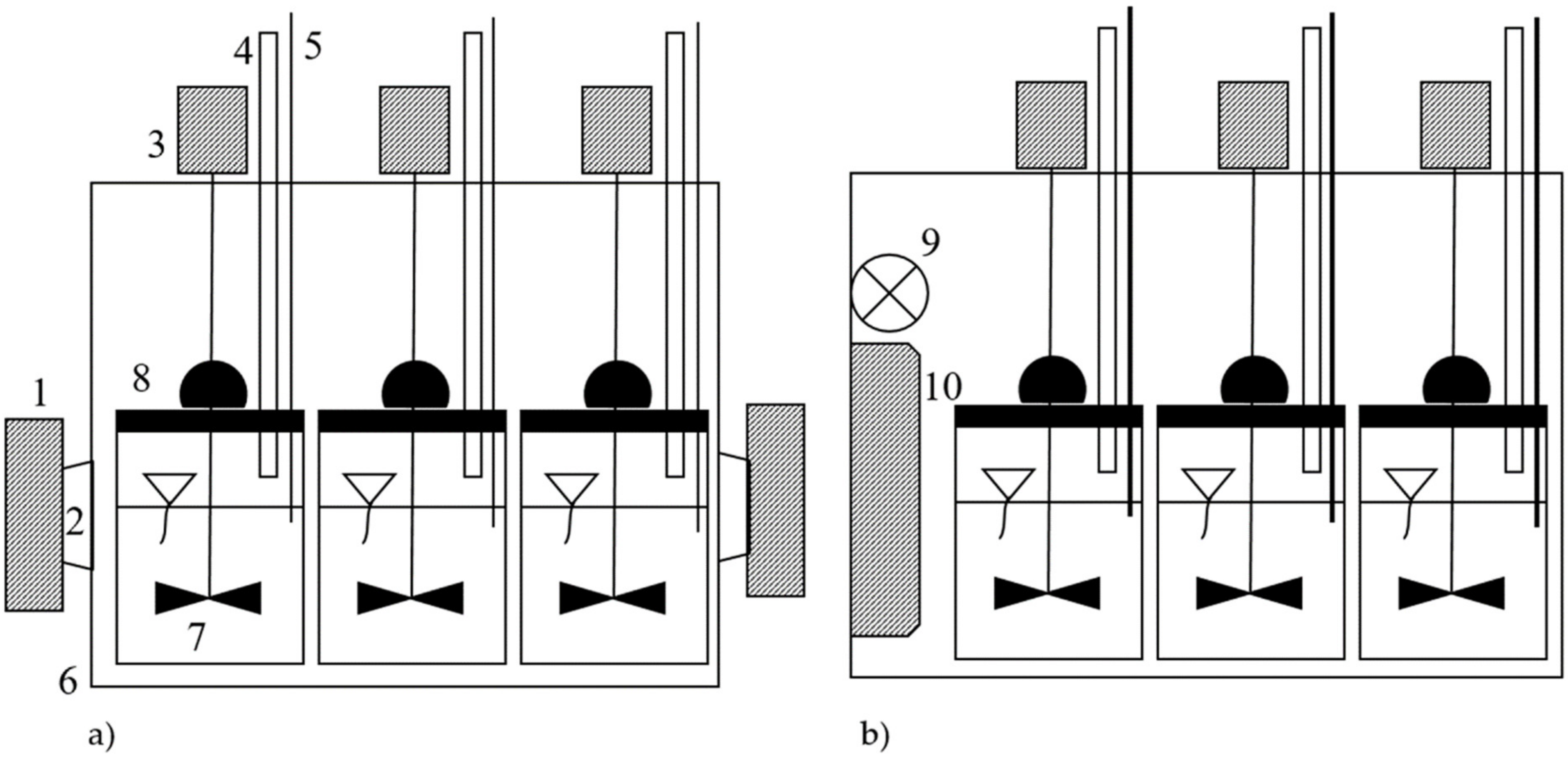

2.3. Laboratory Equipment

2.4. Analytical Methods

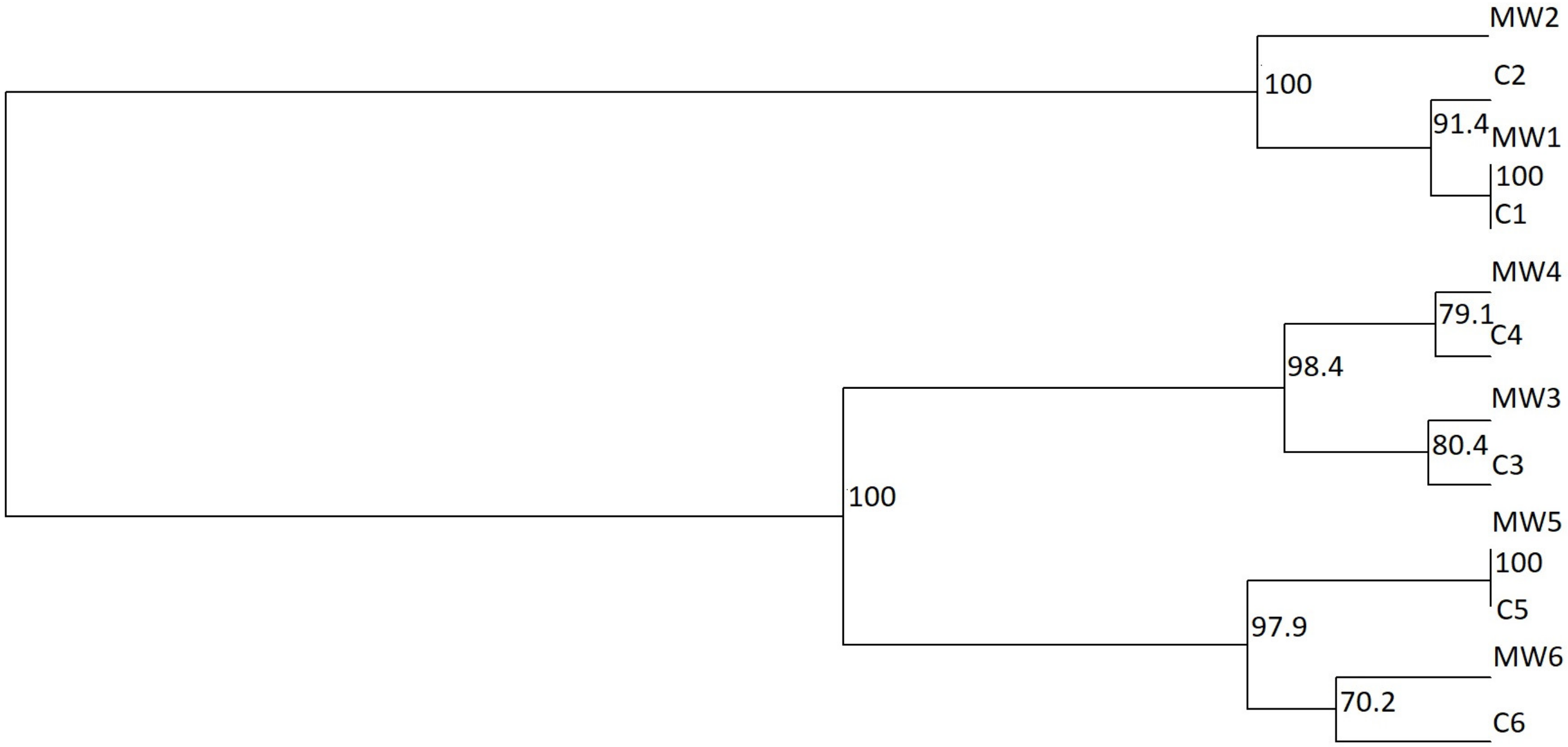

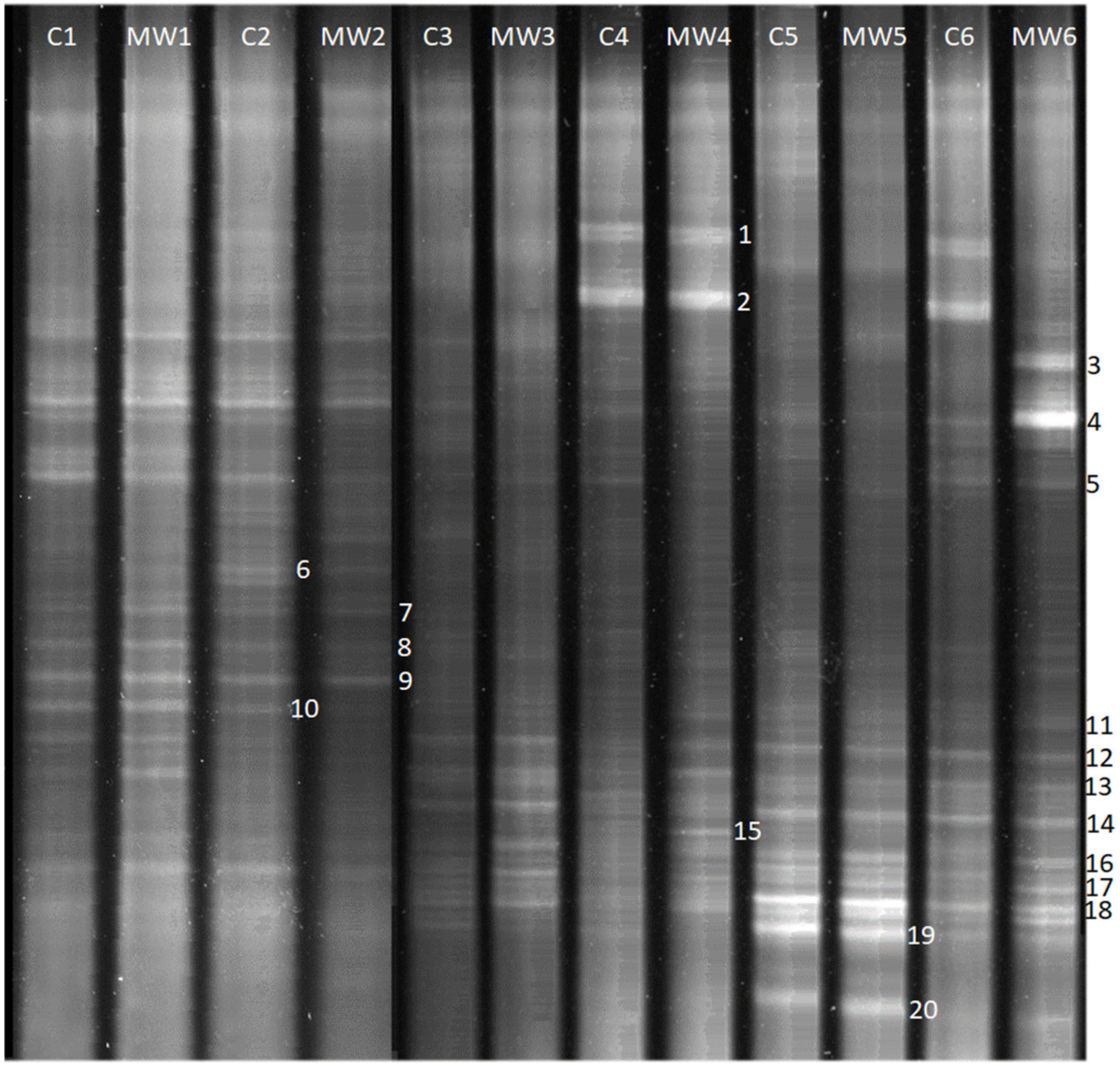

2.5. PCR-DGGE

2.6. Statistical Methods

3. Results

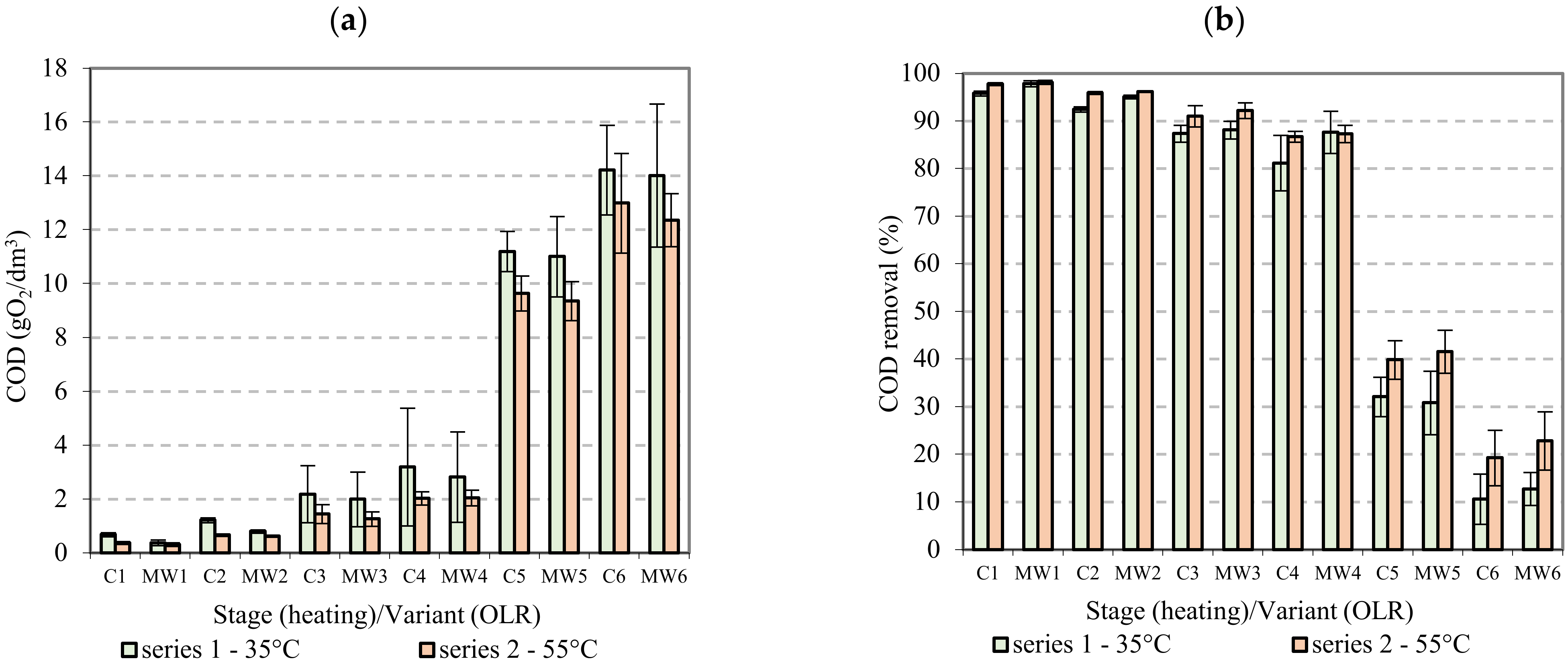

3.1. Organic Compounds

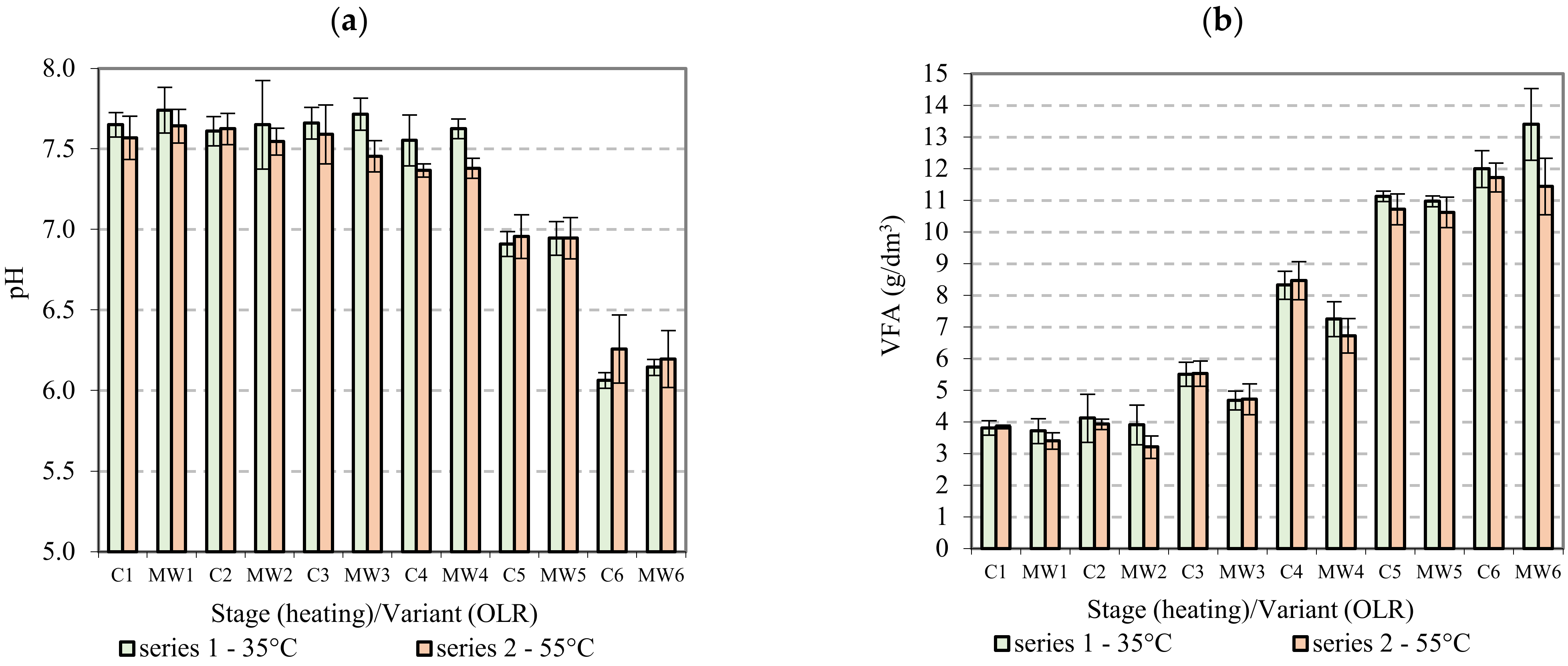

3.2. pH and VFA

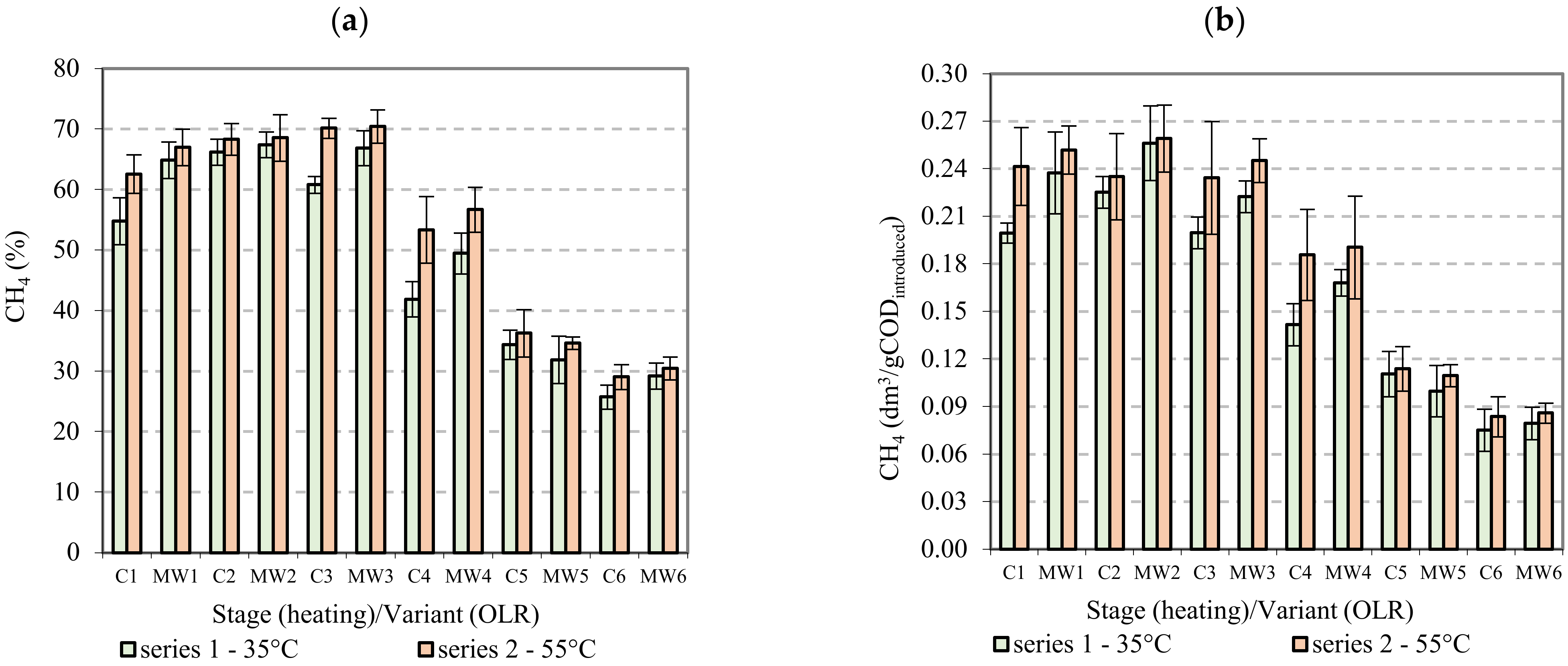

3.3. Biogas and Methane

3.4. Nitrogen and Phosphorus

3.5. Bacterial Community

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Karwacka, M.; Ciurzyńska, A.; Lenart, A.; Janowicz, M. Sustainable Development in the Agri-Food Sector in Terms of the Carbon Footprint: A Review. Sustainability 2020, 12, 6463. [Google Scholar] [CrossRef]

- Eryuruk, K.; Tezcan Un, U.; Bakır Ogutveren, U. Electrochemical treatment of wastewaters from poultry slaughtering and processing by using iron electrodes. J. Clean. Prod. 2018, 172, 1089–1095. [Google Scholar] [CrossRef]

- Hilares, R.T.; Atoche-Garay, D.F.; Pagaza, D.A.P.; Ahmed, M.A.; Andrade, G.J.C.; Santos, J.C. Promising physicochemical technologies for poultry slaughterhouse wastewater treatment: A critical review. J. Environ. Chem. Eng. 2021, 9, 105174. [Google Scholar] [CrossRef]

- Ng, M.; Dalhatou, S.; Wilson, J.; Kamdem, B.P.; Temitope, M.B.; Paumo, H.K.; Djelal, H.; Assadi, A.A.; Nguyen-Tri, P.; Kane, A. Characterization of Slaughterhouse Wastewater and Development of Treatment Techniques: A Review. Processes 2022, 10, 1300. [Google Scholar] [CrossRef]

- Njoya, M.; Basitere, M.; Ntwampe, S.K.O. High Rate Anaerobic Treatment of Poultry Slaughterhouse Wastewater (PSW). New Horizons Wastewaters Manag. 2019, 38, 173–210. [Google Scholar]

- Kazimierowicz, J.; Dzienis, L.; Dębowski, M.; Zieliński, M. Optimisation of methane fermentation as a valorisation method for food waste products. Biomass Bioenergy 2021, 144, 105913. [Google Scholar] [CrossRef]

- Ghaleb, A.A.S.; Kutty, S.R.M.; Salih, G.H.A.; Jagaba, A.H.; Noor, A.; Kumar, V.; Almahbashi, N.M.Y.; Saeed, A.A.H.; Saleh Al-dhawi, B.N. Sugarcane Bagasse as a Co-Substrate with Oil-Refinery Biological Sludge for Biogas Production Using Batch Mesophilic Anaerobic Co-Digestion Technology: Effect of Carbon/Nitrogen Ratio. Water 2021, 13, 590. [Google Scholar] [CrossRef]

- Vinardell, S.; Astals, S.; Mata-Alvarez, J.; Dosta, J. Techno-economic analysis of combining forward osmosis-reverse osmosis and anaerobic membrane bioreactor technologies for municipal wastewater treatment and water production. Bioresour. Technol. 2020, 297, 122395. [Google Scholar] [CrossRef]

- Khitous, M.; Saber, M.; Tirichine, N.; Aiouaz, F. Investigation of slaughterhouse waste anaerobic digestion in a pilot-scale mesophilic reactor. Environ. Prog. Sustain. Energy 2022, 41, e13904. [Google Scholar] [CrossRef]

- Zhang, L.; Loh, K.C.; Sarvanantharajah, S.; Tong, Y.W.; Wang, C.H.; Dai, Y. Mesophilic and thermophilic anaerobic digestion of soybean curd residue for methane production: Characterizing bacterial and methanogen communities and their correlations with organic loading rate and operating temperature. Bioresour. Technol. 2019, 288, 121597. [Google Scholar] [CrossRef]

- Ingersoll, J.G. Thermophilic Co-Fermentation of Wood Wastes and High in Nitrogen Animal Manures into Bio-Methane with the Aid of Fungi and its Potential in the USA. Energies 2020, 13, 4257. [Google Scholar] [CrossRef]

- RATUSHNIAK, G.; BIKS, Y.; LYALYUK, O.; RATUSHNYAK, O.; LYALYUK, A. Modeling of Environmental-Energy Efficiency of the Biogas Installation with Heat Supplying of the Biomass Fermentation Process. Archit. Civ. Eng. Environ. 2020, 13, 115–124. [Google Scholar] [CrossRef]

- Maurer, C.; Müller, J. Drying Characteristics of Biogas Digestate in a Hybrid Waste-Heat/Solar Dryer. Energies 2019, 12, 1294. [Google Scholar] [CrossRef]

- Augustyn, G.; Mikulik, J.; Rumin, R.; Szyba, M. Energy Self-Sufficient Livestock Farm as the Example of Agricultural Hybrid Off-Grid System. Energies 2021, 14, 7041. [Google Scholar] [CrossRef]

- Hiloidhari, M.; Kumari, S. Biogas upgrading and life cycle assessment of different biogas upgrading technologies. In Emerging Technologies and Biological Systems for Biogas Upgrading; Academic Press: Cambridge, MA, USA, 2021; pp. 413–445. [Google Scholar] [CrossRef]

- Zhen, G.; Pan, Y.; Lu, X.; Li, Y.Y.; Zhang, Z.; Niu, C.; Kumar, G.; Kobayashi, T.; Zhao, Y.; Xu, K. Anaerobic membrane bioreactor towards biowaste biorefinery and chemical energy harvest: Recent progress, membrane fouling and future perspectives. Renew. Sustain. Energy Rev. 2019, 115, 109392. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Kazimierowicz, J. The Effect of Electromagnetic Microwave Radiation on Methane Fermentation of Selected Energy Crop Species. Processes 2021, 10, 45. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, S.; Jin, H.; Luo, Y.; Zheng, Z.; Gao, F.; Zheng, Y. Noninvasive Electromagnetic Wave Sensing of Glucose. Sensors 2019, 19, 1151. [Google Scholar] [CrossRef]

- Li, H.; Zhao, Z.; Xiouras, C.; Stefanidis, G.D.; Li, X.; Gao, X. Fundamentals and applications of microwave heating to chemicals separation processes. Renew. Sustain. Energy Rev. 2019, 114, 109316. [Google Scholar] [CrossRef]

- Nigar, H.; Sturm, G.S.J.; Garcia-Baños, B.; Peñaranda-Foix, F.L.; Catalá-Civera, J.M.; Mallada, R.; Stankiewicz, A.; Santamaría, J. Numerical analysis of microwave heating cavity: Combining electromagnetic energy, heat transfer and fluid dynamics for a NaY zeolite fixed-bed. Appl. Therm. Eng. 2019, 155, 226–238. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Zieliński, M.; Dębowski, M. Influence of the Heating Method on the Efficiency of Biomethane Production from Expired Food Products. Fermentation 2021, 7, 12. [Google Scholar] [CrossRef]

- Sharifvaghefi, S.; Zheng, Y. Microwave vs conventional heating in hydrogen production via catalytic dry reforming of methane. Resour. Chem. Mater. 2022, 1, 290–307. [Google Scholar] [CrossRef]

- Yellezuome, D.; Zhu, X.; Wang, Z.; Liu, R. Mitigation of ammonia inhibition in anaerobic digestion of nitrogen-rich substrates for biogas production by ammonia stripping: A review. Renew. Sustain. Energy Rev. 2022, 157, 112043. [Google Scholar] [CrossRef]

- Braguglia, C.M.; Gallipoli, A.; Gianico, A.; Pagliaccia, P. Anaerobic bioconversion of food waste into energy: A critical review. Bioresour. Technol. 2018, 248, 37–56. [Google Scholar] [CrossRef] [PubMed]

- Volschan Junior, I.; de Almeida, R.; Cammarota, M.C. A review of sludge pretreatment methods and co-digestion to boost biogas production and energy self-sufficiency in wastewater treatment plants. J. Water Process Eng. 2021, 40, 101857. [Google Scholar] [CrossRef]

- Muyzer, G.; De Waal, E.C.; Uitterlinden, A.G. Profiling of complex microbial populations by denaturing gradient gel electrophoresis analysis of polymerase chain reaction-amplified genes coding for 16S rRNA. Appl. Environ. Microbiol. 1993, 59, 695–700. [Google Scholar] [CrossRef]

- Jaranowska, P.; Cydzik-Kwiatkowska, A.; Zielińska, M. Configuration of biological wastewater treatment line and influent composition as the main factors driving bacterial community structure of activated sludge. World J. Microbiol. Biotechnol. 2013, 29, 1145–1153. [Google Scholar] [CrossRef] [PubMed]

- Directive (European Union). Council Directive of 21 May 1991 concerning urban waste water treatment (91/271/EEC). J. Eur. Commun. 1991, 34, 40. [Google Scholar]

- U.S. Environmental Protection Agency. Federal Register Effluent Limitations Guidelines and New Source Performance Standards for the Meat and Poultry Products Point Source Category. Fed. Register. 2004, 69, 54475–54555. [Google Scholar]

- GB 8978-1996; Integrated Wastewater Disposal Standard. FAO: Rome, Italy, 1996.

- European Commission Integrated Pollution Prevention and Control Reference Document on Best Available Techniques in the Slaughterhouses and Animal By-products Industries; European Commission: Brussels, Belgium, 2005.

- Directive 2000/60/EC of the European Parliament and of the Council of 23 October 2000 Establishing a Framework for Community Action in the Field of Water Policy. Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX%3A32000L0060 (accessed on 3 January 2023).

- de Nardi, I.R.; Fuzi, T.P.; Del Nery, V. Performance evaluation and operating strategies of dissolved-air flotation system treating poultry slaughterhouse wastewater. Resour. Conserv. Recycl. 2008, 52, 533–544. [Google Scholar] [CrossRef]

- Avula, R.Y.; Nelson, H.M.; Singh, R.K. Recycling of poultry process wastewater by ultrafiltration. Innov. Food Sci. Emerg. Technol. 2009, 10, 1–8. [Google Scholar] [CrossRef]

- Malmali, M.; Askegaard, J.; Sardari, K.; Eswaranandam, S.; Sengupta, A.; Wickramasinghe, S.R. Evaluation of ultrafiltration membranes for treating poultry processing wastewater. J. Water Process Eng. 2018, 22, 218–226. [Google Scholar] [CrossRef]

- Paulista, L.O.; Presumido, P.H.; Theodoro, J.D.P.; Pinheiro, A.L.N. Efficiency analysis of the electrocoagulation and electroflotation treatment of poultry slaughterhouse wastewater using aluminum and graphite anodes. Environ. Sci. Pollut. Res. 2018, 25, 19790–19800. [Google Scholar] [CrossRef] [PubMed]

- Zarei, A.; Biglari, H.; Mobini, M.; Dargahi, A.; Ebrahimzadeh, G.; Narooie, M.R.; Mehrizi, E.A.; Yari, A.R.; Mohammadi, M.J.; Baneshi, M.M.; et al. Disinfecting Poultry Slaughterhouse Wastewater Using Copper Electrodes in the Electrocoagulation Process. Polish J. Environ. Stud. 2018, 27, 1907–1912. [Google Scholar] [CrossRef]

- Coskun, T.; Debik, E.; Kabuk, H.A.; Manav Demir, N.; Basturk, I.; Yildirim, B.; Temizel, D.; Kucuk, S. Treatment of poultry slaughterhouse wastewater using a membrane process, water reuse, and economic analysis. New Pub Balaban 2015, 57, 4944–4951. [Google Scholar] [CrossRef]

- Racar, M.; Dolar, D.; Špehar, A.; Košutić, K. Application of UF/NF/RO membranes for treatment and reuse of rendering plant wastewater. Process Saf. Environ. Prot. 2017, 105, 386–392. [Google Scholar] [CrossRef]

- Abdelhay, A.; Jum’h, I.; Abdulhay, E.; Al-Kazwini, A.; Alzubi, M. Anodic oxidation of slaughterhouse wastewater on boron-doped diamond: Process variables effect. Water Sci. Technol. 2017, 76, 3227–3235. [Google Scholar] [CrossRef]

- Ghazouani, M.; Akrout, H.; Jellali, S.; Bousselmi, L. Comparative study of electrochemical hybrid systems for the treatment of real wastewaters from agri-food activities. Sci. Total Environ. 2019, 647, 1651–1664. [Google Scholar] [CrossRef]

- Keskes, S.; Hmaied, F.; Gannoun, H.; Bouallagui, H.; Godon, J.J.; Hamdi, M. Performance of a submerged membrane bioreactor for the aerobic treatment of abattoir wastewater. Bioresour. Technol. 2012, 103, 28–34. [Google Scholar] [CrossRef]

- Rajab, A.R.; Salim, M.R.; Sohaili, J.; Anuar, A.N.; Salmiati; Lakkaboyana, S.K. Performance of integrated anaerobic/aerobic sequencing batch reactor treating poultry slaughterhouse wastewater. Chem. Eng. J. 2017, 313, 967–974. [Google Scholar] [CrossRef]

- Akizuki, S.; Cuevas-Rodríguez, G.; Toda, T. Microalgal-nitrifying bacterial consortium for energy-saving ammonia removal from anaerobic digestate of slaughterhouse wastewater. J. Water Process Eng. 2019, 31, 100753. [Google Scholar] [CrossRef]

- Terán Hilares, R.; Garcia Bustos, K.A.; Sanchez Vera, F.P.; Colina Andrade, G.J.; Pacheco Tanaka, D.A. Acid precipitation followed by microalgae (Chlorella vulgaris) cultivation as a new approach for poultry slaughterhouse wastewater treatment. Bioresour. Technol. 2021, 335, 125284. [Google Scholar] [CrossRef] [PubMed]

- Arutselvy, B.; Rajeswari, G.; Jacob, S. Sequential valorization strategies for dairy wastewater and water hyacinth to produce fuel and fertilizer. J. Food Process Eng. 2021, 44, e13585. [Google Scholar] [CrossRef]

- Philipp, M.; Jabri, K.M.; Wellmann, J.; Akrout, H.; Bousselmi, L.; Geißen, S.U. Slaughterhouse Wastewater Treatment: A Review on Recycling and Reuse Possibilities. Water 2021, 13, 3175. [Google Scholar] [CrossRef]

- Gannoun, H.; Bouallagui, H.; Okbi, A.; Sayadi, S.; Hamdi, M. Mesophilic and thermophilic anaerobic digestion of biologically pretreated abattoir wastewaters in an upflow anaerobic filter. J. Hazard. Mater. 2009, 170, 263–271. [Google Scholar] [CrossRef]

- Rajakumar, R.; Meenambal, T.; Banu, J.R.; Yeom, I.T. Treatment of poultry slaughterhouse wastewater in upflow anaerobic filter under low upflow velocity. Int. J. Environ. Sci. Technol. 2011 81 2010, 8, 149–158. [Google Scholar] [CrossRef]

- Musa, M.A.; Idrus, S. Physical and Biological Treatment Technologies of Slaughterhouse Wastewater: A Review. Sustainability 2021, 13, 4656. [Google Scholar] [CrossRef]

- Chávez, P.C.; Castillo, L.R.; Dendooven, L.; Escamilla-Silva, E.M. Poultry slaughter wastewater treatment with an up-flow anaerobic sludge blanket (UASB) reactor. Bioresour. Technol. 2005, 96, 1730–1736. [Google Scholar] [CrossRef]

- Musa, M.A.; Idrus, S. Effect of Hydraulic Retention Time on the Treatment of Real Cattle Slaughterhouse Wastewater and Biogas Production from HUASB Reactor. Water 2020, 12, 490. [Google Scholar] [CrossRef]

- Musa, M.A.; Idrus, S.; Hasfalina, C.M.; Daud, N.N.N. Effect of Organic Loading Rate on Anaerobic Digestion Performance of Mesophilic (UASB) Reactor Using Cattle Slaughterhouse Wastewater as Substrate. Int. J. Environ. Res. Public Heal. 2018, 15, 2220. [Google Scholar] [CrossRef]

- Loganath, R.; Mazumder, D. Performance study on organic carbon, total nitrogen, suspended solids removal and biogas production in hybrid UASB reactor treating real slaughterhouse wastewater. J. Environ. Chem. Eng. 2018, 6, 3474–3484. [Google Scholar] [CrossRef]

- Chollom, M.N.; Rathilal, S.; Swalaha, F.M.; Bakare, B.F.; Tetteh, E.K. Comparison of response surface methods for the optimization of an upflow anaerobic sludge blanket for the treatment of slaughterhouse wastewater. Environ. Eng. Res. 2020, 25, 114–122. [Google Scholar] [CrossRef]

- Dutta, A.; Davies, C.; Ikumi, D.S. Performance of upflow anaerobic sludge blanket (UASB) reactor and other anaerobic reactor configurations for wastewater treatment: A comparative review and critical updates. J. Water Supply Res. Technol. 2018, 67, 858–884. [Google Scholar] [CrossRef]

- Crone, B.C.; Garland, J.L.; Sorial, G.A.; Vane, L.M. Significance of dissolved methane in effluents of anaerobically treated low strength wastewater and potential for recovery as an energy product: A review. Water Res. 2016, 104, 520–531. [Google Scholar] [CrossRef] [PubMed]

- Mainardis, M.; Buttazzoni, M.; Goi, D. Up-Flow Anaerobic Sludge Blanket (UASB) Technology for Energy Recovery: A Review on State-of-the-Art and Recent Technological Advances. Bioengineering 2020, 7, 43. [Google Scholar] [CrossRef] [PubMed]

- Ellacuriaga, M.; García-Cascallana, J.; Gómez, X. Biogas Production from Organic Wastes: Integrating Concepts of Circular Economy. Fuels 2021, 2, 144–167. [Google Scholar] [CrossRef]

- Procházka, J.; Dolejš, P.; MácA, J.; Dohányos, M. Stability and inhibition of anaerobic processes caused by insufficiency or excess of ammonia nitrogen. Appl. Microbiol. Biotechnol. 2012, 93, 439–447. [Google Scholar] [CrossRef]

- Angelidaki, I.; Ahring, B.K. Thermophilic anaerobic digestion of livestock waste: The effect of ammonia. Appl. Microbiol. Biotechnol. 1993, 38, 560–564. [Google Scholar] [CrossRef]

- Kayhanian, M. Ammonia Inhibition in High-Solids Biogasification: An Overview and Practical Solutions. Environ. Technol. 2010, 20, 355–365. [Google Scholar] [CrossRef]

- Ozturk, B. Evaluation of Biogas Production Yields of Different Waste Materials. Earth Sci. Res. 2013, 2, 165–174. [Google Scholar] [CrossRef]

- Nazifa, T.H.; Cata Saady, N.M.; Bazan, C.; Zendehboudi, S.; Aftab, A.; Albayati, T.M. Anaerobic Digestion of Blood from Slaughtered Livestock: A Review. Energies 2021, 14, 5666. [Google Scholar] [CrossRef]

- Zieliński, M.; Zielińska, M.; Debowski, M. Application of microwave radiation to biofilm heating during wastewater treatment in trickling filters. Bioresour. Technol. 2013, 127, 223–230. [Google Scholar] [CrossRef] [PubMed]

- Zieliński, M.; Dębowski, M.; Kazimierowicz, J. Microwave Radiation Influence on Dairy Waste Anaerobic Digestion in a Multi-Section Hybrid Anaerobic Reactor (M-SHAR). Processes 2021, 9, 1772. [Google Scholar] [CrossRef]

- Feng, R.Z.; Zaidi, A.A.; Zhang, K.; Shi, Y. Optimisation of Microwave Pretreatment for Biogas Enhancement through Anaerobic Digestion of Microalgal Biomass. Period. Polytech. Chem. Eng. 2019, 63, 65–72. [Google Scholar] [CrossRef]

- Aguilar-Reynosa, A.; Romaní, A.; Ma. Rodríguez-Jasso, R.; Aguilar, C.N.; Garrote, G.; Ruiz, H.A. Microwave heating processing as alternative of pretreatment in second-generation biorefinery: An overview. Energy Convers. Manag. 2017, 136, 50–65. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Rusanowska, P. Influence of microwave heating on biogas production from Sida hermaphrodita silage. Bioresour. Technol. 2017, 245, 1290–1293. [Google Scholar] [CrossRef]

- Zaidi, A.A.; Feng, R.; Malik, A.; Khan, S.Z.; Shi, Y.; Bhutta, A.J.; Shah, A.H. Combining Microwave Pretreatment with Iron Oxide Nanoparticles Enhanced Biogas and Hydrogen Yield from Green Algae. Process. 2019, 7, 24. [Google Scholar] [CrossRef]

- Bozkurt, Y.C.; Apul, O.G. Critical review for microwave pretreatment of waste-activated sludge prior to anaerobic digestion. Curr. Opin. Environ. Sci. Heal. 2020, 14, 1–9. [Google Scholar] [CrossRef]

- Shahriari, H.; Warith, M.; Hamoda, M.; Kennedy, K.J. Anaerobic digestion of organic fraction of municipal solid waste combining two pretreatment modalities, high temperature microwave and hydrogen peroxide. Waste Manag. 2012, 32, 41–52. [Google Scholar] [CrossRef]

- Khan, M.U.; Lee, J.T.E.; Bashir, M.A.; Dissanayake, P.D.; Ok, Y.S.; Tong, Y.W.; Shariati, M.A.; Wu, S.; Ahring, B.K. Current status of biogas upgrading for direct biomethane use: A review. Renew. Sustain. Energy Rev. 2021, 149, 111343. [Google Scholar] [CrossRef]

- Zieliński, M.; Karczmarczyk, A.; Kisielewska, M.; Dębowski, M. Possibilities of Biogas Upgrading on a Bio-Waste Sorbent Derived from Anaerobic Sewage Sludge. Energies 2022, 15, 6461. [Google Scholar] [CrossRef]

- Hu, Y.; Jia, G. Non-thermal effect of microwave in supercritical water: A molecular dynamics simulation study. Phys. A Stat. Mech. its Appl. 2021, 564, 125275. [Google Scholar] [CrossRef]

- Komarov, V.V. A review of radio frequency and microwave sustainability-oriented technologies. Sustain. Mater. Technol. 2021, 28, e00234. [Google Scholar] [CrossRef]

- Debowski, M.; Zielinski, M.; Kisielewska, M.; Kazimierowicz, J. Evaluation of Anaerobic Digestion of Dairy Wastewater in an Innovative Multi-Section Horizontal Flow Reactor. Energies 2020, 13, 2392. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Szwarc, D.; Szwarc, K.; Rokicka, M. Impact Of Microwave Heating On The Efficiency Of Methane Fermentation Of Algae Biomass. Abbrev. Pol. J. Natur. Sc 2017, 32, 561–571. [Google Scholar]

- Zielińska, M.; Cydzik-Kwiatkowska, A.; Zieliński, M.; Debowski, M. Impact of temperature, microwave radiation and organic loading rate on methanogenic community and biogas production during fermentation of dairy wastewater. Bioresour. Technol. 2013, 129, 308–314. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Krzemieniewski, M.; Brudniak, A.; Kisielewska, M. Possibility of improving technological effectiveness of dairy wastewater treatment through application of active fillings and microwave rabiation. J. Water Chem. Technol. 2016, 38, 6. [Google Scholar] [CrossRef]

- Nowicka, A.; Zieliński, M.; Dębowski, M.; Dudek, M.; Rusanowska, P. Progress in the production of biogas from Virginia mallow after alkaline-heat pretreatment. Biomass Bioenergy 2019, 126, 174–180. [Google Scholar] [CrossRef]

- Bichot, A.; Lerosty, M.; Radoiu, M.; Méchin, V.; Bernet, N.; Delgenès, J.P.; García-Bernet, D. Decoupling thermal and non-thermal effects of the microwaves for lignocellulosic biomass pretreatment. Energy Convers. Manag. 2020, 203, 112220. [Google Scholar] [CrossRef]

- Guo, C.; Wang, Y.; Luan, D. Non-thermal effects of microwave processing on inactivation of Clostridium Sporogenes inoculated in salmon fillets. LWT 2020, 133, 109861. [Google Scholar] [CrossRef]

- Kostas, E.T.; Beneroso, D.; Robinson, J.P. The application of microwave heating in bioenergy: A review on the microwave pre-treatment and upgrading technologies for biomass. Renew. Sustain. Energy Rev. 2017, 77, 12–27. [Google Scholar] [CrossRef]

- Zhang, L.; Loh, K.C.; Zhang, J. Jointly reducing antibiotic resistance genes and improving methane yield in anaerobic digestion of chicken manure by feedstock microwave pretreatment and activated carbon supplementation. Chem. Eng. J. 2019, 372, 815–824. [Google Scholar] [CrossRef]

- Mwene-Mbeja, T.M.; Dufour, A.; Lecka, J.; Kaur, B.S.; Vaneeckhaute, C. Enzymatic reactions in the production of biomethane from organic waste. Enzyme Microb. Technol. 2020, 132, 109410. [Google Scholar] [CrossRef] [PubMed]

- Czatzkowska, M.; Harnisz, M.; Korzeniewska, E.; Koniuszewska, I. Inhibitors of the methane fermentation process with particular emphasis on the microbiological aspect: A review. Energy Sci. Eng. 2020, 8, 1880–1897. [Google Scholar] [CrossRef]

- Cantero, D.; Jara, R.; Navarrete, A.; Pelaz, L.; Queiroz, J.; Rodríguez-Rojo, S.; Cocero, M.J. Pretreatment Processes of Biomass for Biorefineries: Current Status and Prospects. Annu. Rev. Chem. Biomol. Eng. 2019, 10, 289–310. [Google Scholar] [CrossRef] [PubMed]

- Pakhomov, A.G.; Akyel, Y.; Pakhomova, O.N.; Stuck, B.E.; Murphy, M.R. Current state and implications of research on biological effects of millimeter waves: A review of the literature. Bioelectromagnetics 1998, 19, 393–413. [Google Scholar] [CrossRef]

- Banik, S.; Bandyopadhyay, S.; Ganguly, S. Bioeffects of microwave––A brief review. Bioresour. Technol. 2003, 87, 155–159. [Google Scholar] [CrossRef]

- Banik, S.; Bandyopadhyay, S.; Ganguly, S.; Dan, D. Effect of microwave irradiated Methanosarcina barkeri DSM-804 on biomethanation. Bioresour. Technol. 2006, 97, 819–823. [Google Scholar] [CrossRef]

- Deepanraj, B.; Sivasubramanian, V.; Jayaraj, S. Effect of substrate pretreatment on biogas production through anaerobic digestion of food waste. Int. J. Hydrog. Energy 2017, 42, 26522–26528. [Google Scholar] [CrossRef]

| Parameter | Unit | Mean |

|---|---|---|

| Total organic carbon (TOC) | g/dm3 | 5.9 ± 1.9 |

| Chemical oxygen demand (COD) | gO2/dm3 | 15.6 ± 1.6 |

| Volatile fatty acids (VFA) | g/dm3 | 0.98 ± 0.31 |

| Total nitrogen (TN) | gTN/dm3 | 0.512 ± 0.042 |

| Ammonia nitrogen (NNH4) | gN-NH4/dm3 | 0.034 ± 0.008 |

| Total phosphorus (TP) | gTP/dm3 | 0.115 ± 0.012 |

| pH | - | 6.83 ± 0.06 |

| Total solids (TS) | g/dm3 | 1.04 ± 0.28 |

| Volatile solids (VS) | g/dm3 | 0.88 ± 0.02 |

| Mineral solids (MS) | g/dm3 | 0.12 ± 0.015 |

| Protein | g/dm3 | 4.92 ± 0.46 |

| Lipids | g/dm3 | 3.92 ± 0.11 |

| Carbohydrates | g/dm3 | 0.016 ± 0.007 |

| Parameter | Unit | Value |

|---|---|---|

| TS | % | 6.2 ± 1.3 |

| VS | % TS | 77.1 ± 2.1 |

| MS | % TS | 22.9 ± 1.9 |

| TN | mg/gTS | 69.7 ± 7.2 |

| TP | mg/gTS | 10.3 ± 1.4 |

| TC | mg/gTS | 869 ± 92 |

| TOC | mg/gTS | 671 ± 41 |

| C:N | - | 12.4 ± 0.7 |

| pH | - | 7.02 ± 0.11 |

| protein | % DM | 42.1 ± 4.3 |

| lipids | % DM | 15.2 ± 1.7 |

| saccharides | % DM | 3.1 ± 0.4 |

| Variant | Target OLR (gCOD/dm3·d) | COD in the H-LPW (gO2/dm3) | Volume of H-LPW (dm3/day) | Reactor Volume (dm3) | HRT (day) |

|---|---|---|---|---|---|

| 1 | 1.0 | 15.6 ± 1.6 | ≈0.26 | 4.0 | ≈15.4 |

| 2 | 2.0 | ≈0.52 | ≈7.7 | ||

| 3 | 3.0 | ≈0.78 | ≈5.1 | ||

| 4 | 4.0 | ≈1.04 | ≈3.8 | ||

| 5 | 5.0 | ≈1.30 | ≈3.1 | ||

| 6 | 6.0 | ≈1.56 | ≈2.6 |

| S/V | Chemical Oxygen Demand (COD) | S/V | Total Organic Carbon (TOC) | ||||

|---|---|---|---|---|---|---|---|

| Parameter | Series | Parameter | Series | ||||

| SER1—35 °C | SER2—55 °C | SER1—35 °C | SER2—55 °C | ||||

| C1 | g/dm3 | 0.68 ± 0.08 | 0.37 ± 0.05 | C1 | g/dm3 | 0.1 ± 0.07 | 0.06 ± 0.01 |

| % rem. | 95.7 ± 0.5 | 97.7 ± 0.3 | % rem. | 92.2 ± 1.2 | 98.2 ± 0.4 | ||

| MW1 | g/dm3 | 0.38 ± 0.1 | 0.30 ± 0.07 | MW1 | g/dm3 | 0.22 ± 0.13 | 0.05 ± 0.02 |

| % rem. | 97.8 ± 0.6 | 98.1 ± 0.4 | % rem. | 95.3 ± 4.1 | 98.1 ± 0.3 | ||

| C2 | g/dm3 | 1.21 ± 0.09 | 0.66 ± 0.05 | C2 | g/dm3 | 0.3 ± 0.16 | 0.2 ± 0.06 |

| % rem. | 92.4 ± 0.5 | 95.9 ± 0.3 | % rem. | 89.5 ± 2.7 | 93.2 ± 1 | ||

| MW2 | g/dm3 | 0.8 ± 0.06 | 0.62 ± 0.03 | MW2 | g/dm3 | 0.25 ± 0.15 | 0.17 ± 0.04 |

| % rem. | 95 ± 0.4 | 96.1 ± 0.2 | % rem. | 91.3 ± 1.1 | 94.4 ± 1.8 | ||

| C3 | g/dm3 | 2.18 ± 1.06 | 1.44 ± 0.35 | C3 | g/dm3 | 0.5 ± 0.12 | 0.25 ± 0.03 |

| % rem. | 87.3 ± 1.8 | 91 ± 2.2 | % rem. | 82.9 ± 4.1 | 91.5 ± 1.3 | ||

| MW3 | g/dm3 | 1.99 ± 1.01 | 1.26 ± 0.27 | MW3 | g/dm3 | 0.45 ± 0.19 | 0.27 ± 0.05 |

| % rem. | 88.1 ± 1.9 | 92.1 ± 1.7 | % rem. | 84.6 ± 3.5 | 90.8 ± 0.8 | ||

| C4 | g/dm3 | 3.19 ± 2.19 | 2.02 ± 0.24 | C4 | g/dm3 | 0.68 ± 0.28 | 0.47 ± 0.03 |

| % rem. | 81.1 ± 5.8 | 86.7 ± 1.1 | % rem. | 76.4 ± 3.6 | 83.7 ± 1.8 | ||

| MW4 | g/dm3 | 2.82 ± 1.68 | 2.04 ± 0.29 | MW4 | g/dm3 | 0.64 ± 0.22 | 0.46 ± 0.06 |

| % rem. | 87.6 ± 4.4 | 87.2 ± 1.8 | % rem. | 77.3 ± 5.1 | 84.2 ± 0.9 | ||

| C5 | g/dm3 | 11.19 ± 0.75 | 9.63 ± 0.65 | C5 | g/dm3 | 2.43 ± 0.26 | 2.15 ± 0.01 |

| % rem. | 32.1 ± 4.1 | 39.8 ± 4.1 | % rem. | 16 ± 10 | 26.2 ± 10 | ||

| MW5 | g/dm3 | 11 ± 1.49 | 9.35 ± 0.72 | MW5 | g/dm3 | 2.16 ± 0.27 | 1.98 ± 0.26 |

| % rem. | 30.8 ± 6.7 | 41.6 ± 4.5 | % rem. | 27.3 ± 6.6 | 31.4 ± 4.4 | ||

| C6 | g/dm3 | 14.22 ± 1.66 | 12.98 ± 1.85 | C6 | g/dm3 | 2.59 ± 0.19 | 2.6 ± 0.25 |

| % rem. | 10.6 ± 5.3 | 19.2 ± 5.8 | % rem. | 10.4 ± 4.7 | 10.7 ± 3.1 | ||

| MW6 | g/dm3 | 14.01 ± 2.66 | 12.35 ± 0.98 | MW6 | g/dm3 | 2.56 ± 0.12 | 2.49 ± 0.06 |

| % rem. | 12.7 ± 3.5 | 22.8 ± 6.1 | % rem. | 11.8 ± 5.3 | 13.8 ± 6.5 | ||

| S/V | Total Nitrogen (TN) | S/V | Total Phosphorus (TP) | ||||

|---|---|---|---|---|---|---|---|

| Parameter | Series | Parameter | Series | ||||

| SER1—35 °C | SER2—55 °C | SER1—35 °C | SER2—55 °C | ||||

| C1 | g/dm3 | 0.283 ± 0.033 | 0.291 ± 0.029 | C1 | g/dm3 | 0.080 ± 0.010 | 0.074 ± 0.005 |

| % rem. | 44.7 ± 6.4 | 47.5 ± 5.7 | % rem. | 30.2 ± 8.3 | 35.8 ± 4.3 | ||

| MW1 | g/dm3 | 0.263 ± 0.029 | 0.273 ± 0.027 | MW1 | g/dm3 | 0.068 ± 0.006 | 0.067 ± 0.007 |

| % rem. | 48.5 ± 3.7 | 49.2 ± 5.2 | % rem. | 40.5 ± 4.0 | 41.6 ± 4.1 | ||

| C2 | g/dm3 | 0.351 ± 0.026 | 0.343 ± 0.016 | C2 | g/dm3 | 0.082 ± 0.004 | 0.075 ± 0.005 |

| % rem. | 31.5 ± 5.0 | 34.3 ± 3.2 | % rem. | 28.3 ± 3.6 | 34.5 ± 4.1 | ||

| MW2 | g/dm3 | 0.349 ± 0.024 | 0.322 ± 0.049 | MW2 | g/dm3 | 0.074 ± 0.003 | 0.069 ± 0.003 |

| % rem. | 31.7 ± 4.7 | 39.6 ± 9.5 | % rem. | 35.1 ± 3.2 | 39.7 ± 2.4 | ||

| C3 | g/dm3 | 0.364 ± 0.026 | 0.365 ± 0.017 | C3 | g/dm3 | 0.093 ± 0.007 | 0.088 ± 0.004 |

| % rem. | 28.8 ± 5.1 | 28.7 ± 3.3 | % rem. | 18.9 ± 4.0 | 22.9 ± 4.9 | ||

| MW3 | g/dm3 | 0.347 ± 0.033 | 0.339 ± 0.032 | MW3 | g/dm3 | 0.089 ± 0.006 | 0.090 ± 0.003 |

| % rem. | 32.2 ± 6.4 | 32.1 ± 6.3 | % rem. | 22.4 ± 3.3 | 21.7 ± 5.3 | ||

| C4 | g/dm3 | 0.404 ± 0.032 | 0.401 ± 0.030 | C4 | g/dm3 | 0.089 ± 0.007 | 0.091 ± 0.004 |

| % rem. | 21.1 ± 6.3 | 21.5 ± 4.2 | % rem. | 22.1 ± 3.4 | 20.3 ± 5.4 | ||

| MW4 | g/dm3 | 0.389 ± 0.022 | 0.386 ± 0.034 | MW4 | g/dm3 | 0.090 ± 0.006 | 0.091 ± 0.005 |

| % rem. | 24.0 ± 6.7 | 24.6 ± 5.9 | % rem. | 21.7 ± 4.7 | 20.7 ± 3.6 | ||

| C5 | g/dm3 | 0.443 ± 0.030 | 0.444 ± 0.042 | C5 | g/dm3 | 0.096 ± 0.005 | 0.079 ± 0.004 |

| % rem. | 13.5 ± 8.2 | 13.3 ± 9.1 | % rem. | 16.4 ± 5.6 | 31.3 ± 3.8 | ||

| MW5 | g/dm3 | 0.426 ± 0.047 | 0.419 ± 0.013 | MW5 | g/dm3 | 0.097 ± 0.008 | 0.096 ± 0.003 |

| % rem. | 15.9 ± 2.4 | 16.9 ± 4.5 | % rem. | 15.4 ± 4.0 | 16.0 ± 3.3 | ||

| C6 | g/dm3 | 0.445 ± 0.023 | 0.470 ± 0.032 | C6 | g/dm3 | 0.102 ± 0.004 | 0.103 ± 0.004 |

| % rem. | 11.3 ± 6.3 | 8.1 ± 5.4 | % rem. | 10.9 ± 5.2 | 10.5 ± 5.6 | ||

| MW6 | g/dm3 | 0.436 ± 0.021 | 0.437 ± 0.018 | MW6 | g/dm3 | 0.101 ± 0.007 | 0.100 ± 0.005 |

| % rem. | 14.7 ± 6.1 | 14.3 ± 5.6 | % rem. | 11.4 ± 5.8 | 12.6 ± 4.1 | ||

| Substrate | Optimal Conditions | Effects | Ref. | |

|---|---|---|---|---|

| Pretreatment Conditions | Batch Test Conditions | |||

| Expired food products: bread (12%), meat waste (35%), fish (9%), vegetables (10%), fruit (16%), and dairy products (18%) | 300 W, 2.45 GHz | 35 ± 1 °C, Time = 80 d, HRT = 40 d, OLR = 2.0 kgVS/dm3·d | Increase of 4.57% in biogas production * | [21] |

| Dairy wastewater | 1600 W, 2.45 GHz | 35 °C, HRT = 24 h, OLR = 1.0 kgCOD/m3·d | Increase of 4.65% in biogas production * | [79] |

| Dairy wastewater | 800 W, 2.45 GHz | 35 °C, HRT = 120 h | Increase of 14.0 to 24.0% in biogas production * | [80] |

| Dairy wastewater | 90 W, 20 kHz | 38 ± 1 °C, Time = 30 d, HRT = 24 h, OLR = 2.0 kgCOD/dm3·d | Increase of 7.5% in biogas production * | [77] |

| Alga biomass | 600 W, 2.45 GHz | 35 ± 1 °C, HRT = 20 d, OLR = 2.0 kgVS/dm3·d | Increase of 2.88% in biogas production * | [78] |

| Sida hermaphrodita silage | 1600 W, 2.45 GHz | HRT = 33.3 d, Time = 45 d | Increase of 8% in biogas production * | [69] |

| Virginia mallow | 1600 W, 2.45 GHz | 36 °C, HRT = 40 d, OLR = 5.0 g VS/dm3 | Increase of 8% in biogas production * | [81] |

| Virginia mallow | 600 W, 2.45 GHz | 36 °C, HRT = 40 d, OLR = 5.0 g VS/dm3 | Increase of 18% in CH4 production * | [17] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zieliński, M.; Dębowski, M.; Rusanowska, P.; Kazimierowicz, J. Influence of Microwave Radiation on Pollutant Removal and Biomethane Production Efficiency in Anaerobic Treatment of High-Load Poultry Wastewater. Appl. Sci. 2023, 13, 3553. https://doi.org/10.3390/app13063553

Zieliński M, Dębowski M, Rusanowska P, Kazimierowicz J. Influence of Microwave Radiation on Pollutant Removal and Biomethane Production Efficiency in Anaerobic Treatment of High-Load Poultry Wastewater. Applied Sciences. 2023; 13(6):3553. https://doi.org/10.3390/app13063553

Chicago/Turabian StyleZieliński, Marcin, Marcin Dębowski, Paulina Rusanowska, and Joanna Kazimierowicz. 2023. "Influence of Microwave Radiation on Pollutant Removal and Biomethane Production Efficiency in Anaerobic Treatment of High-Load Poultry Wastewater" Applied Sciences 13, no. 6: 3553. https://doi.org/10.3390/app13063553

APA StyleZieliński, M., Dębowski, M., Rusanowska, P., & Kazimierowicz, J. (2023). Influence of Microwave Radiation on Pollutant Removal and Biomethane Production Efficiency in Anaerobic Treatment of High-Load Poultry Wastewater. Applied Sciences, 13(6), 3553. https://doi.org/10.3390/app13063553