1. Introduction

As industries develop and the population grows, the amount of energy consumption also grows. Currently, most energy comes from fossil fuels such as oil, gas, coal, etc. The use of fossil fuels not only causes a lot of environmental pollution (such as the release of a lot of CO

2, solid particles, etc.) but the amount of this type of fuel is also limited. In addition, countries that do not have fossil fuel sources become dependent on other countries that have this type of fuel source. Such a situation is unacceptable because countries without resources are strongly dependent on external partners [

1,

2,

3,

4]. In addition, the continuous exploitation of fossil fuel sources causes hard-to-repair damage to the environment and various ecosystems. In order to change this situation, more and more energy needed for both industry and the population is being generated using renewable energy sources such as solar and wind power plants, “green” hydrogen, etc. Solar power plants are increasingly used to generate electricity by installing them on the roofs of buildings and designing and installing solar parks on the ground. The producer can store the electricity obtained using solar power plants using batteries made of, e.g., LiFePO

4 or use the inventories to supply electricity to the general electricity distribution network. Solar power plants have a number of advantages over other sources of renewable electricity: they do not emit noise, they are durable (20 years or more), they are easier to maintain than, for example, wind power plants, they are easy enough to install on the roofs of buildings of various shapes or in fields on the ground, etc. In addition, it has recently been proposed that the electricity obtained from renewable energy sources (e.g., electricity produced in solar parks, etc.) should be stored on the basis of thermal energy, the operation of which is based on exothermic and endothermic reactions. Thermal energy accumulated in this way, using chemical reactions, can be used for heating or electricity generation in the dark. This technology is based on different types of energy transformations. The electricity obtained from solar power plants, during daylight hours, is proposed to be used by applying various heat exchanger systems through which electricity is converted into thermal energy. To implement this method, various thermal capacities are used, the basis of which can be molten salt or liquid metals. Such systems are also implemented in combination with nuclear power. Such a hybrid method, when heat obtained from a solar power plant is used, using heat exchangers, and during nuclear reactions in thermonuclear power plants, makes it possible to ensure the optimal overall operation of the energy system. The most reliably functioning hybrid energy systems are ones in which the unified system consists of a park of solar power plants, a park of wind power plants, and a nuclear power plant. For such a system, it is recommended to apply a hybrid energy storage system in which the components are a heat exchanger system, a thermal storage system and batteries (for example made on the basis of Li ions), and an MXene electrochemical energy storage system. By optimizing both the work of the energy production part and the operation of the energy storage system, it is possible to attain the most optimally functioning energy system based on the principle of hybrid production [

5,

6,

7,

8,

9,

10].

As the number of solar power parks increase and the solar power network expands, more and more personnel are needed for their operation and maintenance. Increasing human resources have to be devoted to this purpose. In addition, more and more time is spent on training qualified personnel. In order to make the maintenance and monitoring processes of solar power plants and parks more efficient, auxiliary and intelligent tools such as various environmental sensors (temperature, light flux, humidity, etc.) are increasingly being used. Voltage, current and power sensors are used to monitor the operating parameters of individual solar power batteries. Such type sensors can be attached to each module, so that in the case of a large solar park, the number of these modules and the amount of information they send are very large [

11,

12,

13]. IoT technology is often used to ensure reliable information transmission and processing of these sensors. For using this technology and ensuring a stable data flow, a high internet speed, which can be provided by Wi-Fi or quality GSM mobile communication networks with 4G or 5G generation technology, is required. The greater the number of different sensors, the greater the need for a fast information transmission network. Many solar power parks are located outside the city limits in remote areas where it is not possible to provide a very fast internet connection provided by the GSM network [

14,

15,

16,

17]. Therefore, in order to ensure a stable data transmission process, it is necessary to design a hybrid data transmission network using RF modules connected to each sensor and transmitting information to the central server. Meanwhile, the received information on the central server is analysed, stored and transmitted centrally to a remote data center using e.g., a GSM network if the solar park is built in a remote area. Data can be stored directly on a central-server-contained database (e.g., MySQL) or using cloud technology. Specialized software tools such as, e.g., SKADA, the Aix-layer detection algorithm or others, built and installed on the central server, perform data analysis and make appropriate decisions (e.g., send a message to the operator about a solar panel whose electrical parameters do not fall within the permitted range). Analysing the received information, the operator makes relevant decisions related to the operation of solar panels, such as sending a drone with a camera that would allow to evaluate the general image of a specific solar module or a brigade composed of qualified personnel able to eliminate the problems [

18,

19,

20]. Ensuring a unified monitoring process for individual modules of a solar power plant or park is a difficult task, as it is necessary to simultaneously evaluate a large amount of information received from individual sensors or unmanned monitoring devices [

21,

22,

23,

24]. When evaluating this information and making relevant decisions, it is impossible to avoid errors related to the human factor. Therefore, in order to avoid problems related to decision-making as much as possible, efforts are being made to create the most intelligent self-control systems that are as independent of human intervention as possible. In order to achieve this goal, various applications (software tools for mobile devices, etc.) are often developed that allow the operator to transmit information to the mobile device about an event that has occurred (e.g., a decision made by artificial intelligence related to the information sent by the sensors of the solar power plant, etc.) if the operator is not present in the stationary control panel. Software applications can be adapted to various mobile devices (e.g., smartphones or laptops) with operating systems such as Windows Phone OS, Android, etc. [

24,

25,

26,

27,

28,

29,

30].

Following an analysis of the literature, it has become clear that there is no universal hybrid data transmission network concept for monitoring the working parameters of solar power parks. Meanwhile, solar parks are often built in remote areas where the speed of the external internet connection, which operates on the basis of the GSM network, is insufficient. In addition, in order to monitor the operating parameters of individual solar panels and conduct monitoring, a very dense IoT network is required, the speed of which may not be sufficient to ensure data transmission and communication between individual components. In order to solve this problem, the aim of this work is to design and test a hybrid data transmission network and its concept with extended capabilities, making it possible to simultaneously transmit data from solar power plant sensors and various monitoring subsystems using RF modules, Wi-Fi technology, GSM networks, etc., and monitoring and evaluating the operating parameters of the solar power plant using various software subsystems (e.g., mobile applications).

3. Results and Discussion

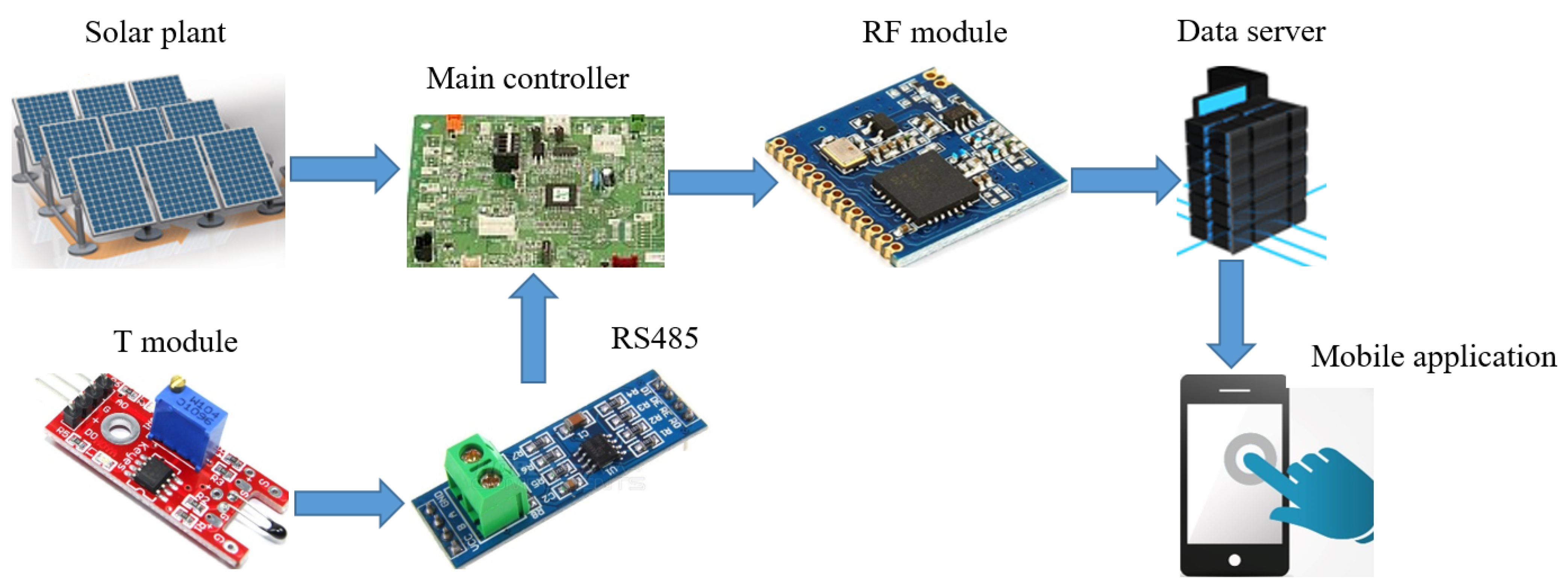

Using 3 solar batteries with a total power of 870 W, a solar power plant was installed on the flat roof of a building. The modules of the solar power plant were oriented towards the south at an angle of 35 degrees (such installation conditions are recommended according to the area). Since it is well known that the power of solar power plants depends on the temperature of the environment and the batteries, the temperature of the surface of each module was monitored in order to evaluate its influence on the generated electricity power. 15 August 2022, was chosen to monitor the parameters of the solar power plant because it is one of the hottest days of the year according to meteorological observations. Such a day was chosen so that there would be as large a temperature difference between the light and dark time of the day as possible, in order to assess the influence of the ambient temperature on the operation of the solar power plant as accurately as possible. A hybrid data transmission network consisting of various data transmission chains was created for data transmission and processing. The concept of the hybrid data transmission network is presented in

Figure 1. RS 485 modules with an interface to the main controller board were used to transmit the information of the surface temperature of the batteries and sensors. A simple shielded cable directly connected to the main controller board was used to transmit the electrical parameters of the solar modules.

The processing of received data and formation of information packets was carried out using a PIC series microcontroller on the main controller board. An RF module capable of transmitting and receiving information using radio communication was used to transmit information packets to the data server. The use of RF modules allows stable transmission of digital information packets regardless of the stability of the external internet connection. Using the GSM network, the information related to the parameters of the solar power plant can be transferred from the central server to the mobile device used by the system operator, who evaluates the system (solar power plant) operation based on the received data and makes decisions as needed.

A one-month hybrid data network speed measurement was performed, the results of which are presented in

Figure 2. Network speed fluctuations are partly caused by the fact that the monitoring system was in different parts of the building on different days of the month. As we can see, the data network speed is slightly different, within the range 15.5–16 Mbps. Such a data network is fully sufficient to transmit data from various sensors to a central server. With the already mentioned data rate, it is possible to transmit the operating parameters of each solar panel (obtained from voltage, current and other sensors) to the data server. When designing the network, it is possible to create a separate data transmission channel from each solar module with a data rate of approximately 16 Mbps. It is worth noting that the speed of the data network is greatly influenced by the technical characteristics of the RF modules and the specific choice according to the needs.

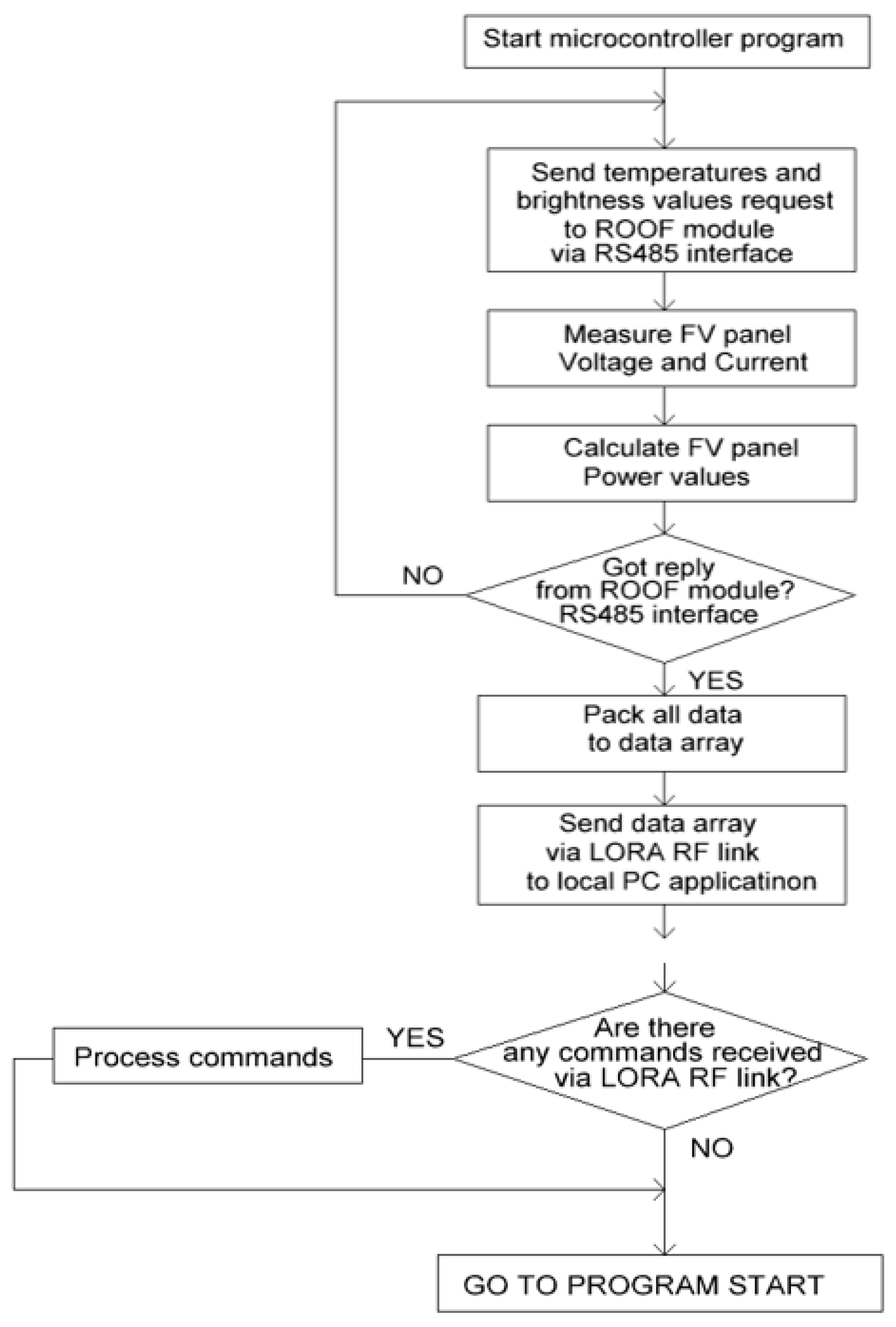

A central controller was developed using a PIC series microcontroller to monitor solar electrical parameters and surface temperature. The algorithm scheme of program code (using the C programming language) which was created to analyze and evaluate information and to form information packets is presented in

Figure 3. The program starts by booting the microcontroller.

Temperature values are obtained from the temperature sensors located on the surface of the solar batteries. Next, the voltage and current measurements of the solar batteries are performed and transmitted to the central controller. Based on the obtained values, the electric power is calculated. The data are processed and an information package is formed. The formed information package is transmitted to the RF module, with the help of which the information is sent to the data server. After receiving a command from the data server that the package is successfully received, the microcontroller program is restarted and a new cycle of the program is repeated.

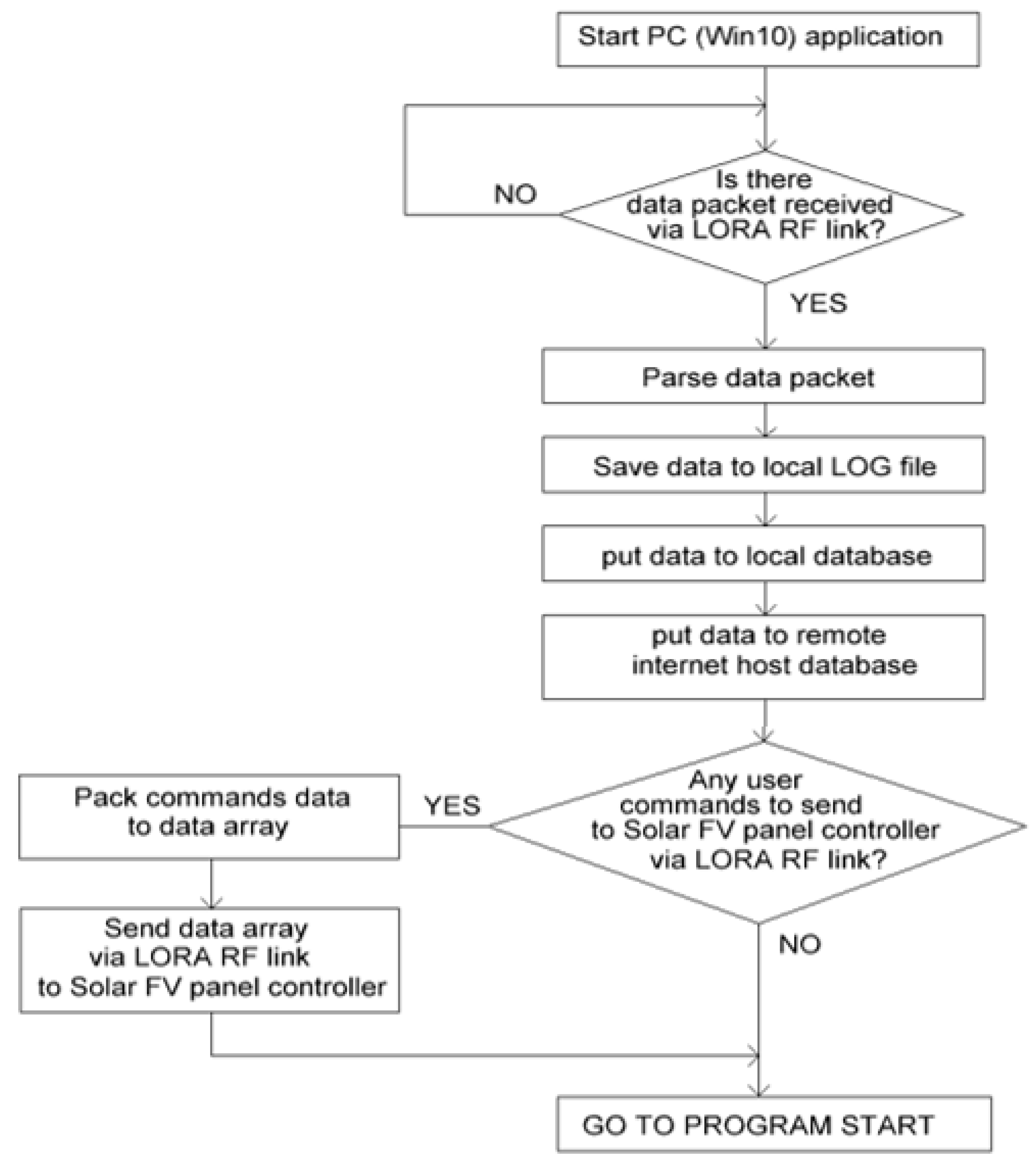

The received data from the central controller using the RF module is analysed in the data server and decisions are made whether the system is working properly. The scheme of the data server program code algorithm is presented in

Figure 4. The program starts with the Start program command. Reception of the digital data packet from the first stage with the help of the RF module is performed. The next step involves the analysis and evaluation of digital data. After analysing the data, the data are stored into the database. A MySQL software tool was used to create the database. An application was developed using the HTML and Delphi programming languages to display the data graphically on the output device of the central server. This application is intended for process evaluation by the system operator at the control panel. The application provides values of solar electrical parameters (voltage, current and power) over time.

The operator can also evaluate the surface temperature of each module and its influence on the operating parameters of the solar batteries. In the output device of the server, it is also possible to monitor the size of incoming and outgoing information packets and the duration of transmission, as well as the status of network communication (whether information packets have been successfully exchanged between the individual hybrid network devices).

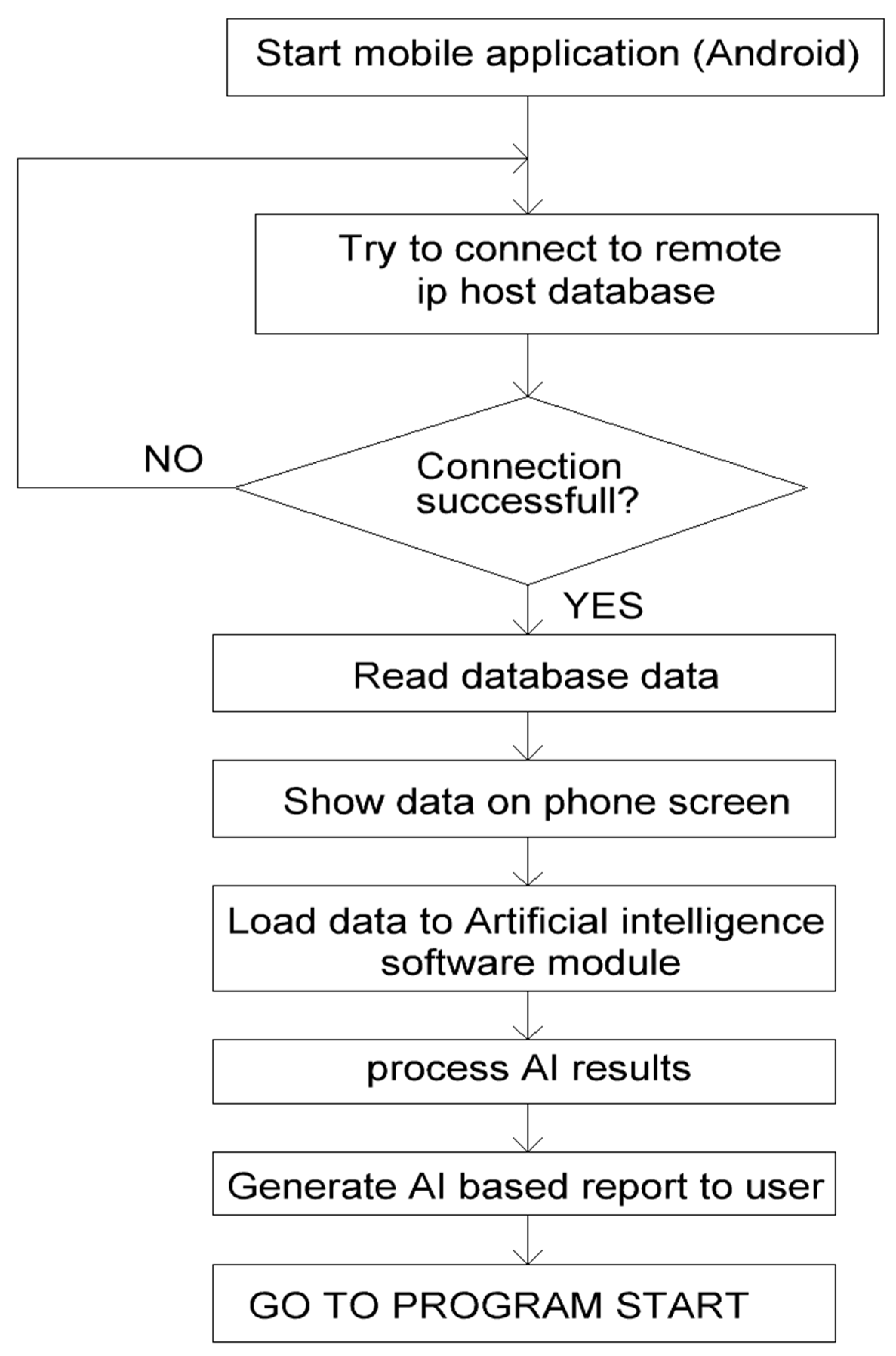

When there is no system operator at the control panel, basic system information can be transferred to the mobile application on mobile devices (such as mobile phones or tablets, etc.) with the Android operating system. In this case, the GSM network is used to transmit and send the data packets (internet connection provided by the GSM network). In this system, a mobile data monitoring application was developed using the Java programming language. The mobile application algorithm is presented in

Figure 5. The program starts after launching the mobile application and checking whether the bandwidth of the GSM network connection is sufficient. The next step is connecting to the server database. The message is received whether the connection is successful. Data scanning and retrieval, as well as the graphical representation process, are in progress. If the data is received successfully and its graphic image is formed, then the data are displayed on the screen of the mobile device. For the mobile application, it is possible to choose an artificial intelligence subsystem that can perform analysis and evaluation of the incoming data in case of an unforeseen event (e.g., in the event of a voltage spike in the solar battery, etc.) or the need to inform the system administration performing operator. Later, the next request to the data server takes place and the next data packet is received, and in this way the program cycle is repeated again.

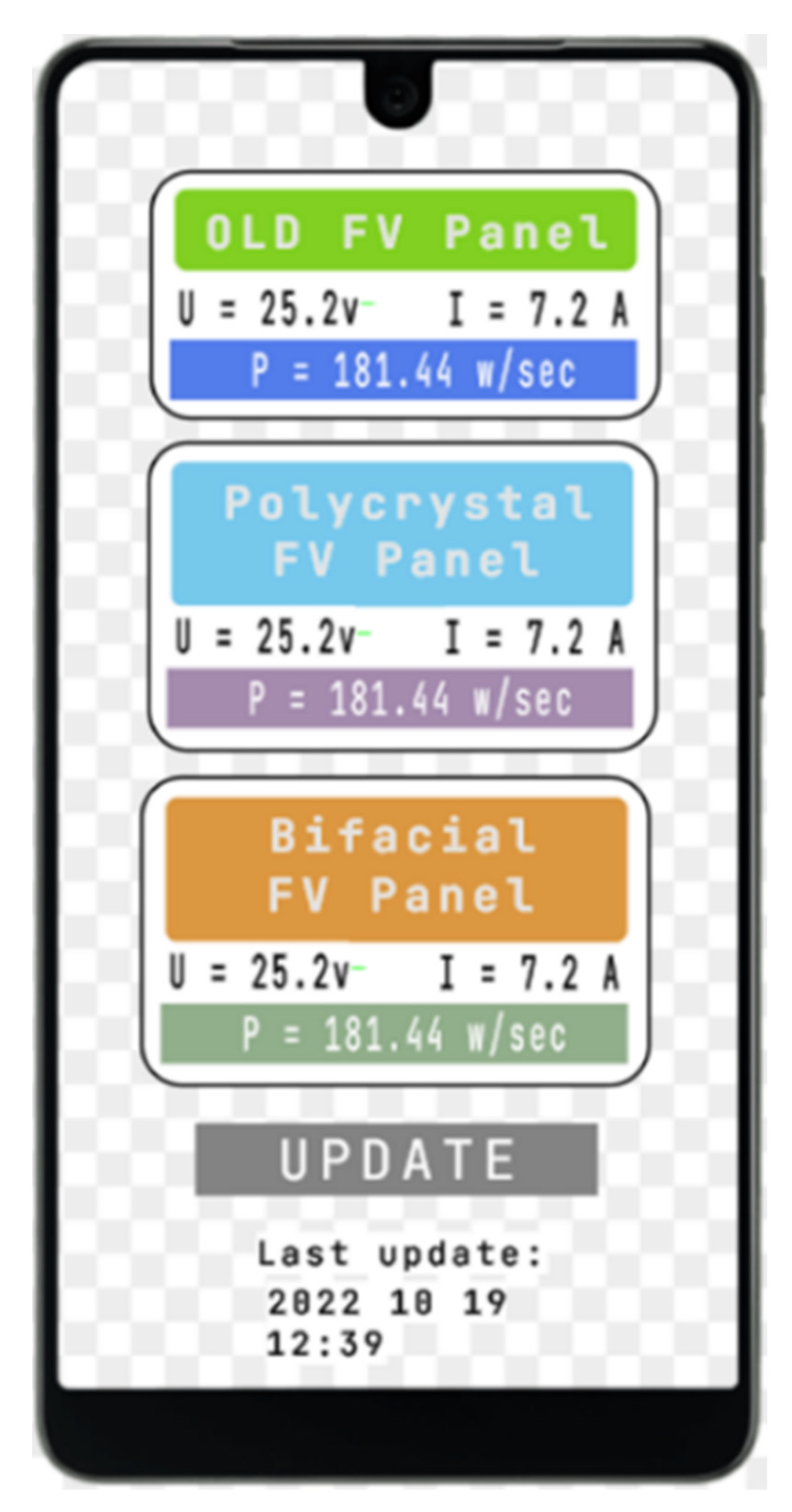

The general graphic image of the mobile application is presented in

Figure 6. The values of the electrical parameters of individual solar panels such as voltage, current and power can be seen on the screen of the mobile device. As already mentioned, the solar power plant consists of three solar batteries, one of which is of the bifacial type, the other is a tracytic polycrystalline solar cell made of silicon. The third battery had already been used for 10 years and is also made of a silicon base (it was used so that its wear and tear can be assessed compared to the first two, which had not been used before). In the mobile application, the time of the received data can be seen and, if required, update of the data can be initiated. The use of these applications is quite convenient: since the operator is not at the control panel, but only has a mobile device, it is possible to quickly assess the state of the system and make decisions accordingly.

In order to test the hybrid data transmission network and the performance of the corresponding developed software tools and the process of graphical representation of the information, pilot observations of the solar power plant were carried out. The test observations of the individual modules of the solar power plant were graphically displayed based on the data collected on the server [

10].

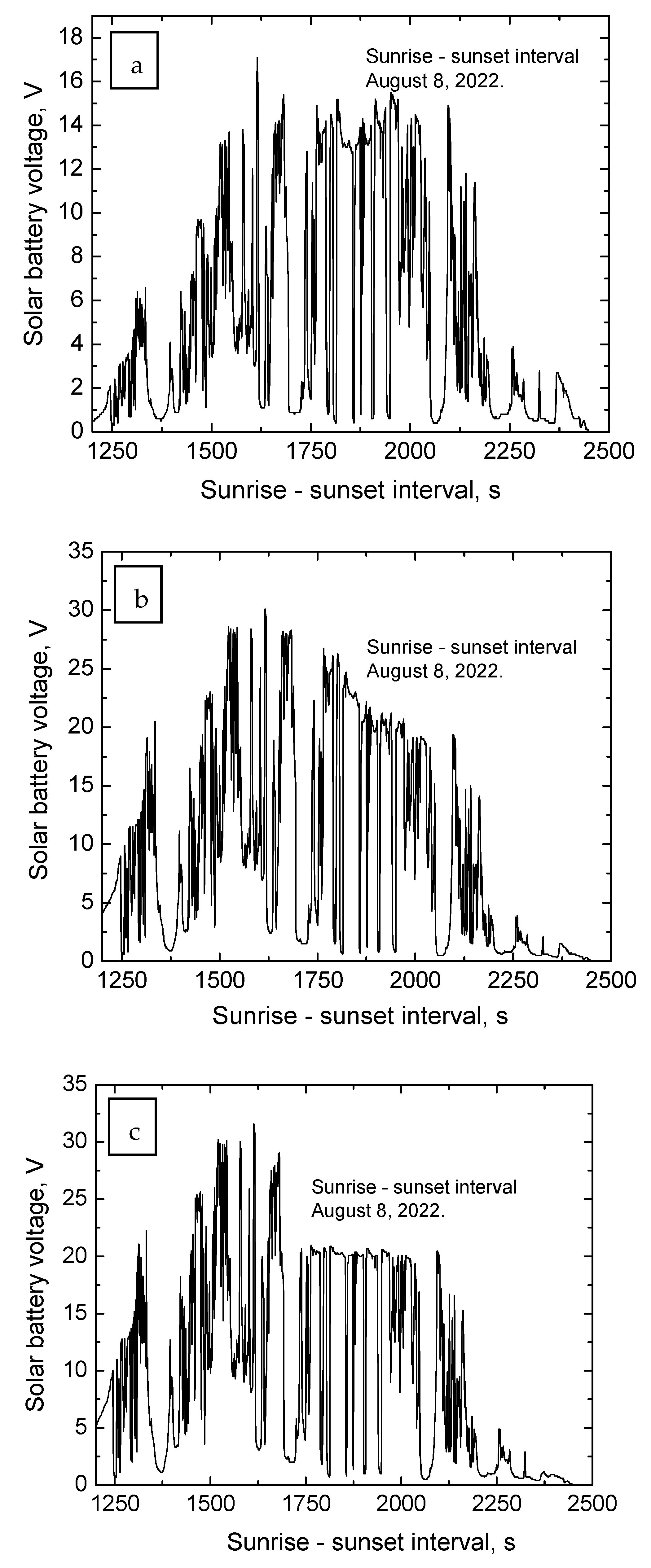

Figure 7 shows the instantaneous voltage values of three solar panels over time. Analysing the data, it can be seen that the maximum voltage value is about 33 V, which was generated by a bifacial solar cell. Meanwhile, the maximum voltage value of a used 10-year-old solar battery was about 17 V. Such a result is possible due to mechanical damage of the individual silicon segments of the battery. In addition, very sharp spikes in instantaneous values of voltage are observed for all three solar batteries. This occurred for two reasons: first, due to the erratic sunlight in cloudy conditions; second, due to the angle variation between the incident sunlight and the surface of the batteries.

Figure 8 presents the instantaneous values of electric current strength over time. The current strength was measured for all 3 solar panels (10 years old, silicon polycrystalline and bifacial). The trends of the current measurement curves are very similar to those of the voltage measurements.

The lowest maximum current value was observed for the used solar battery and reached about 6.5 A, while the maximum current value of the bifacial type solar battery reached up to 9 A. It is worth mentioning that both voltage and current measurements were carried out under the same environmental conditions (ambient temperature, etc.). In the electric current curves it is possible to see sudden changes in the instantaneous values, which are related to changes in sunlight intensity due to cloudiness and the angle variation between the sunrays and the surface of the batteries.

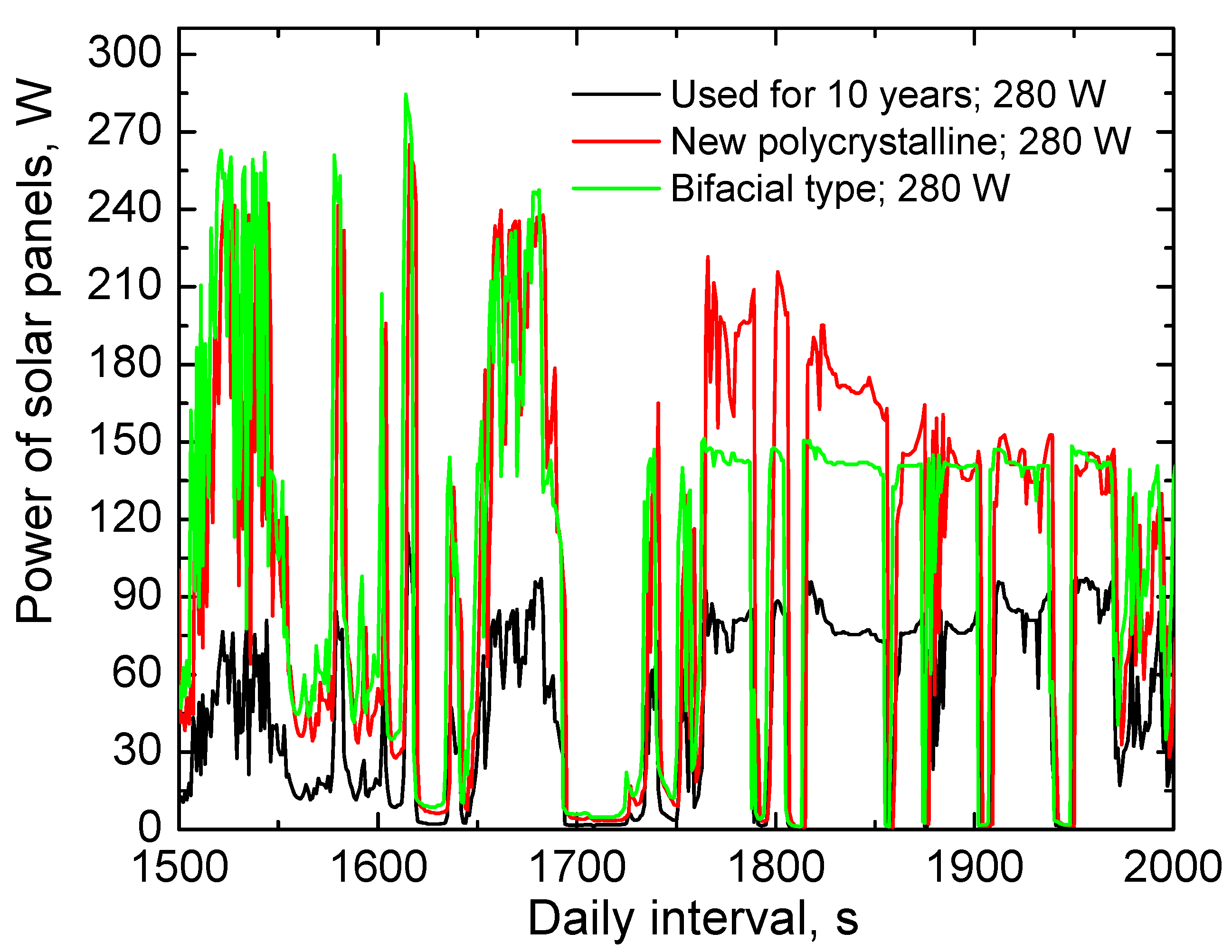

After measuring the voltage and current of the solar panels, the instantaneous values of electric power were calculated with the help of the software code located on the server (

Figure 9). Maximum power instantaneous values were fixed for a bifacial solar battery. As can be seen, the maximum generated power of bifacial type batteries can reach up to 290 W (this is the maximum possible power for a solar battery). Meanwhile, the maximum instantaneous power value of a used solar battery of the same capacity reached just about 90 W. Meanwhile, it is worth mentioning that bifacial type batteries are about 15–20% more efficient than traditional solar batteries made on the basis of polycrystalline silicon. This trend is also reflected in the measurements, since the instantaneous maximum power of the new solar cell (made on the basis of silicon) is about 15% lower than that of the bifacial type solar battery.

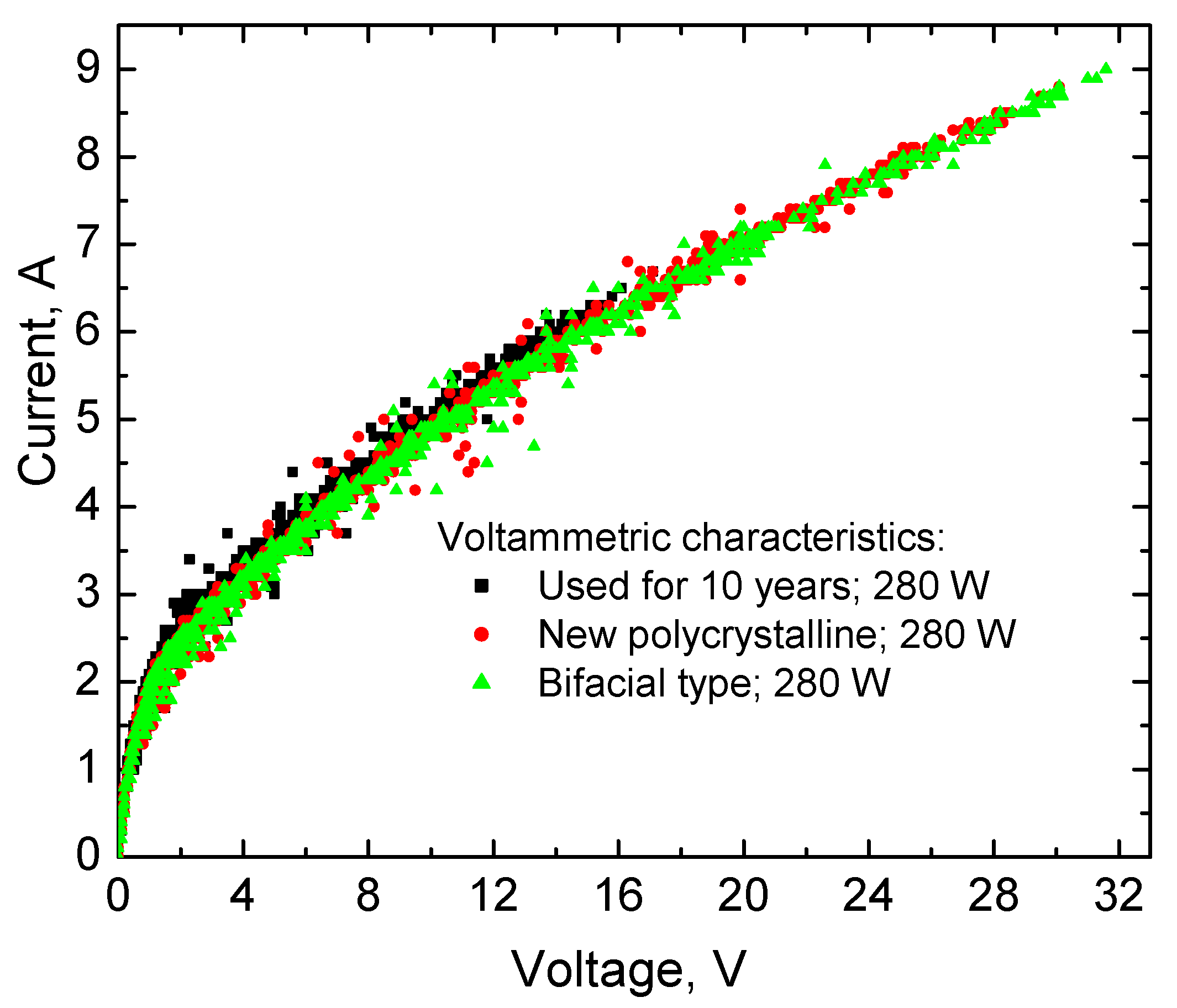

In order to evaluate the degradation process of silicon segments of solar cells consisting of P-N junctions in the old battery and to compare it with the new ones, the volt-ampere characteristics of all three batteries are presented in

Figure 10. As we can see, the volt-ampere curves of the bifacial-type battery, the silicon-based new battery and the battery used for 10 years basically match. Observing the trends of volt-ampere characteristics, it can be said that the active material of all three types of batteries—silicon—has a similar degree of alloying and the same internal resistance. Meanwhile, the matching of the volt-ampere characteristic curve of the old battery with the volt-ampere curves of new batteries (bifacial type and polycrystalline new) shows that the degradation of silicon segments over time is insignificant.

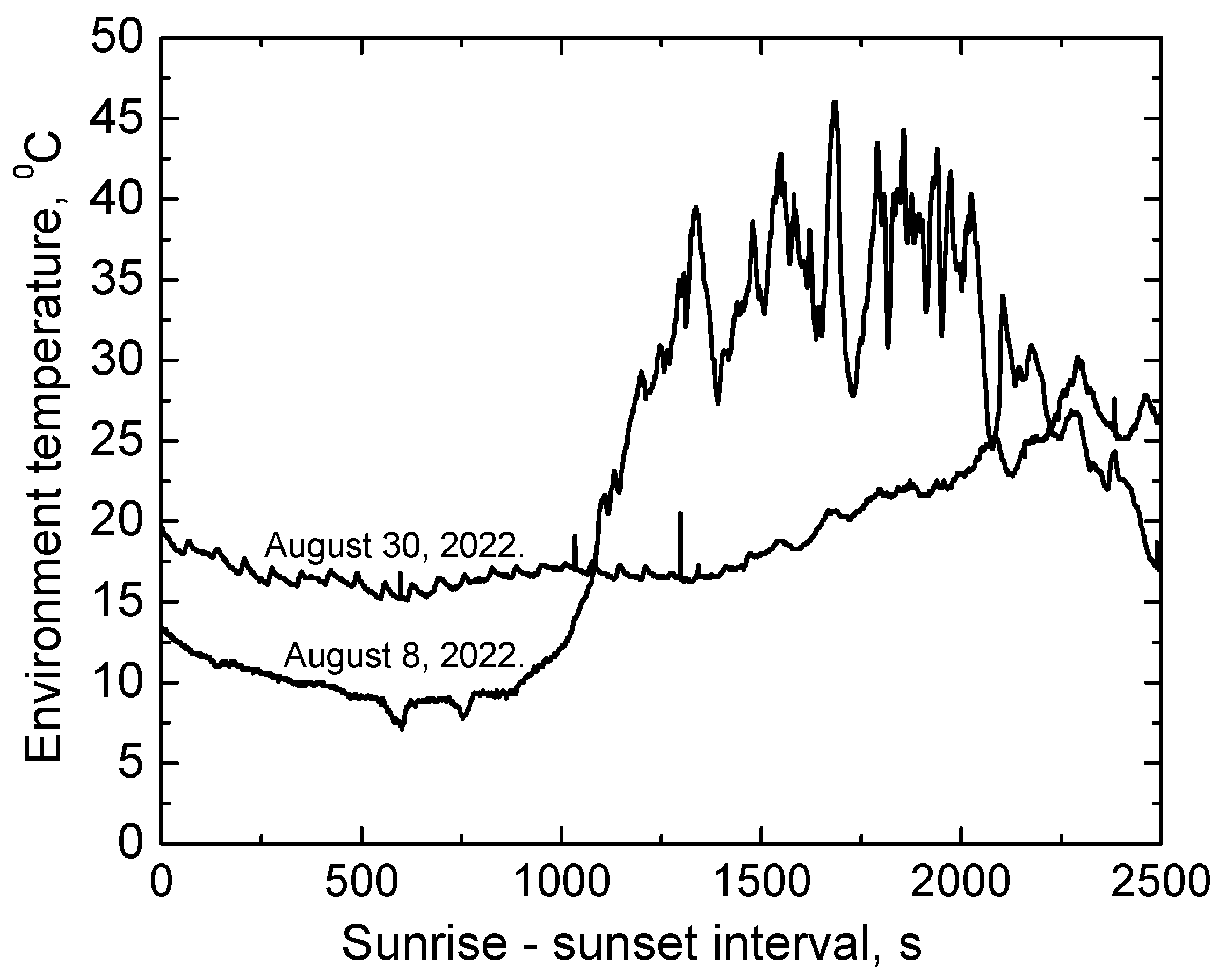

Observations of the surface temperature of the solar cells over time are presented in

Figure 11. Temperature measurements took place during daylight hours when the solar power plant actively produced electricity. For the measurements, 2 days with sufficiently different temperatures were chosen (the temperature difference sometimes reached up to 20 °C). Although the temperature differences were quite large, the amount of sunlight was similar, based on the meteorological statements. Observing the data of temperature measurements (2 days) on the surface of the solar modules, the temperature reached the maximum values around noon (about 25 and 45 °C, respectively) when the sun is at its highest point. At this moment, the most intensive production of electricity takes place in the solar power plant.

It is known that temperature has a slight influence on the efficiency of a solar power plant, barely 0.5–1% (under ideal laboratory conditions). In real conditions, it is almost impossible to accurately determine the influence of temperature on the efficiency of a solar power plant, since the efficiency of a solar power plant depends not only on the temperature difference, but also on the angle of the sun between the surface of the battery and the radiation. In addition, the efficiency of a solar power plant strongly depends on the intensity of solar radiation. All the aforementioned factors (angle, radiation intensity, etc.) on which the efficiency of the solar power plant depends, have an incomparably greater influence than the ambient temperature, so that reliably assessing the influence of temperature on the efficiency of the solar power plant in real conditions is a difficult task.