TSDNet: A New Multiscale Texture Surface Defect Detection Model †

Abstract

1. Introduction

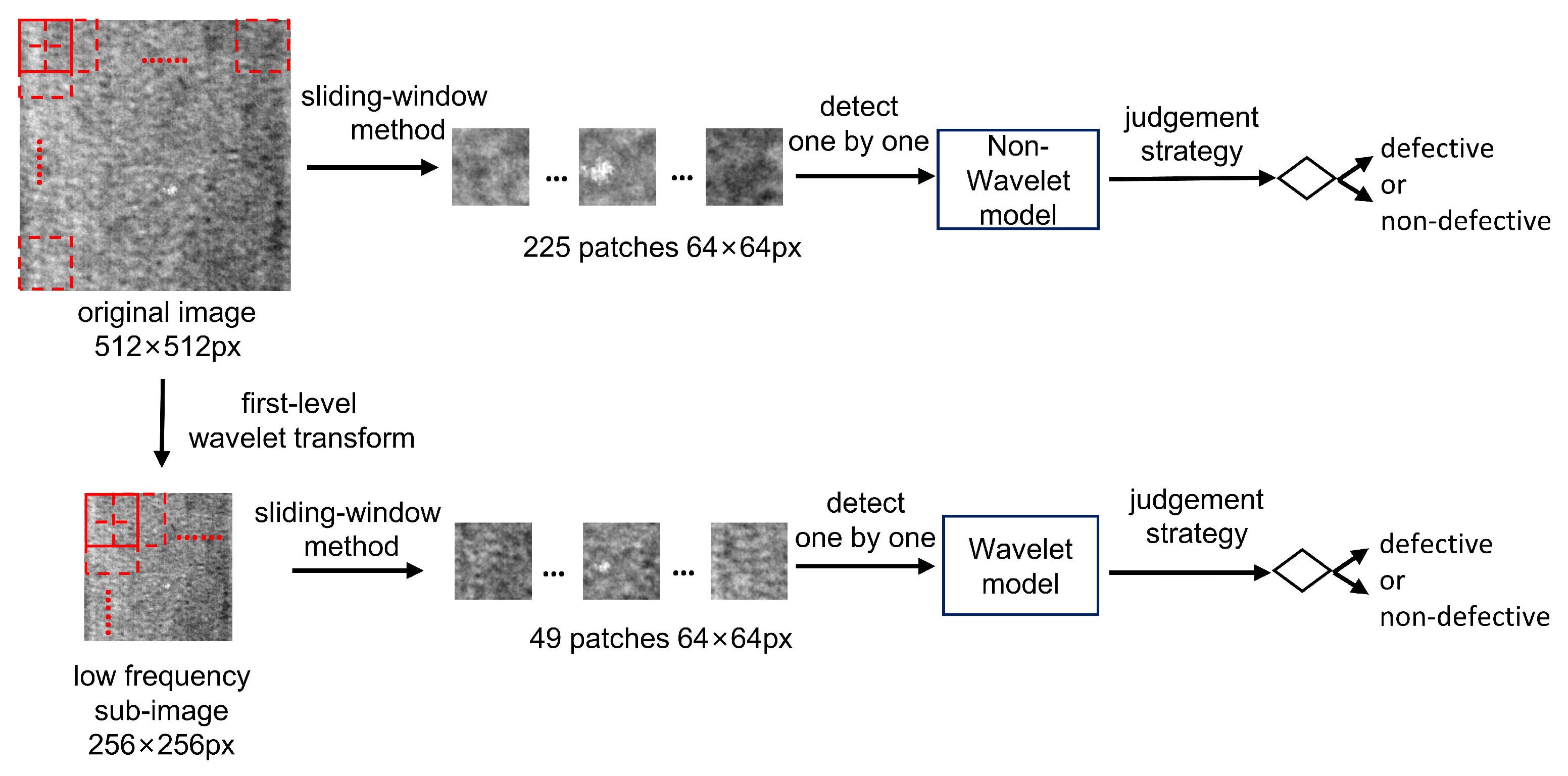

- To solve the problem of tiny defect detection, a new method based on wavelet analysis and patch extraction is proposed, which can detect and locate many kinds of tiny defects in complex texture backgrounds with only a small amount of training data. Experimental results have verified its good performance.

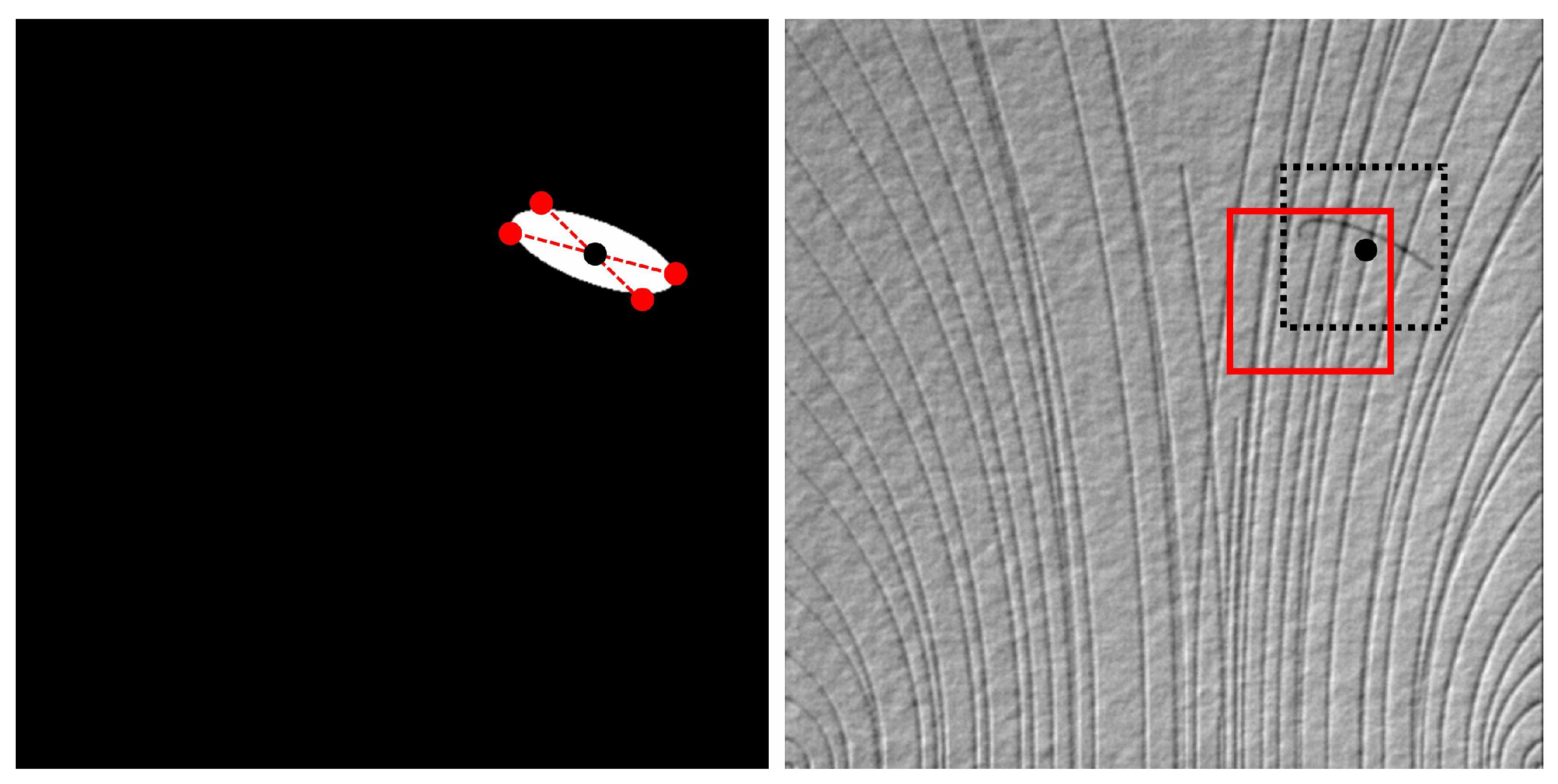

- In the data preprocessing phase of our method, we propose a method which can automatically extract defective patches based on binary label images. Experiments show that this method can greatly reduce the workload of building a defective training dataset;

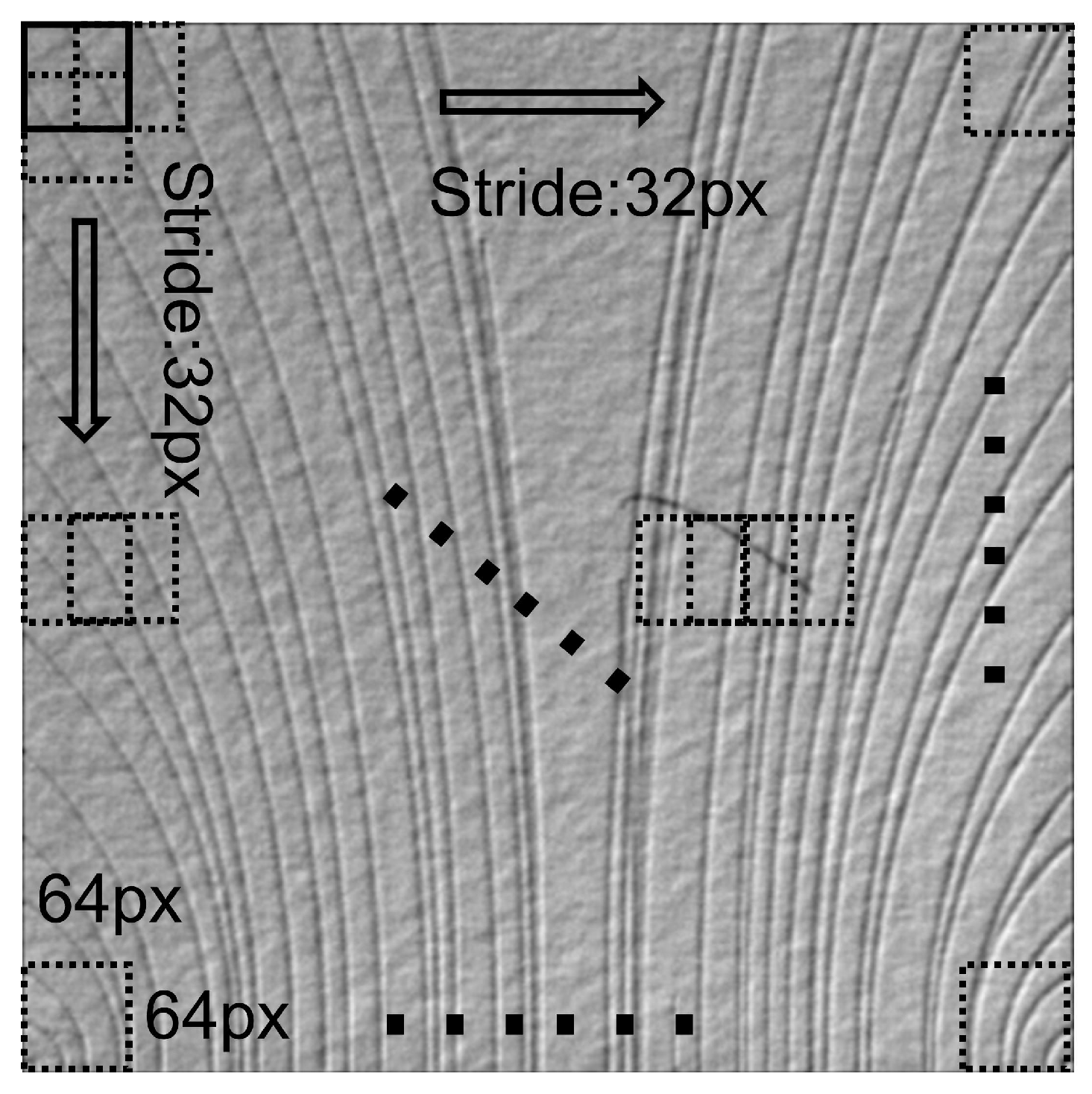

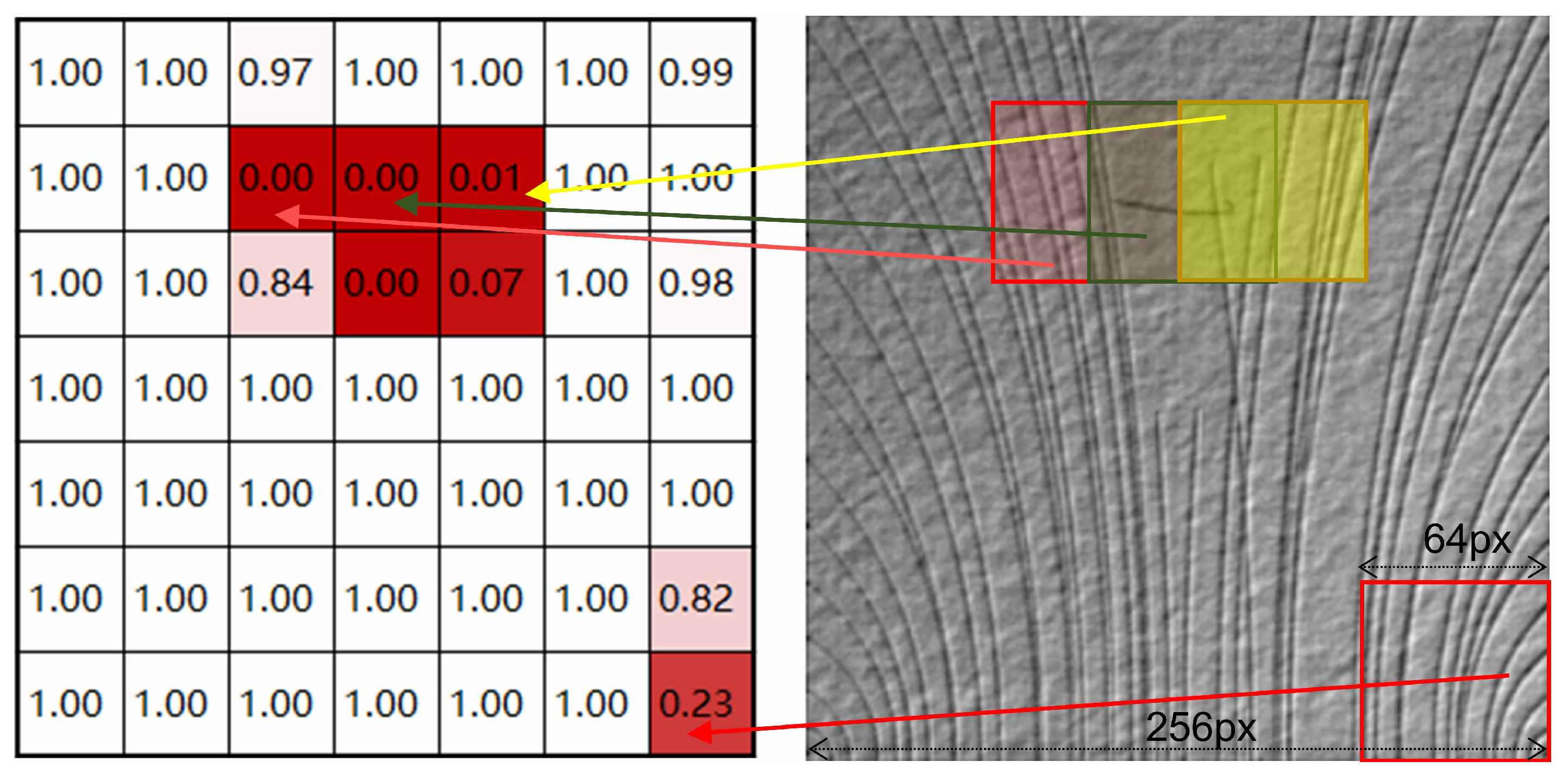

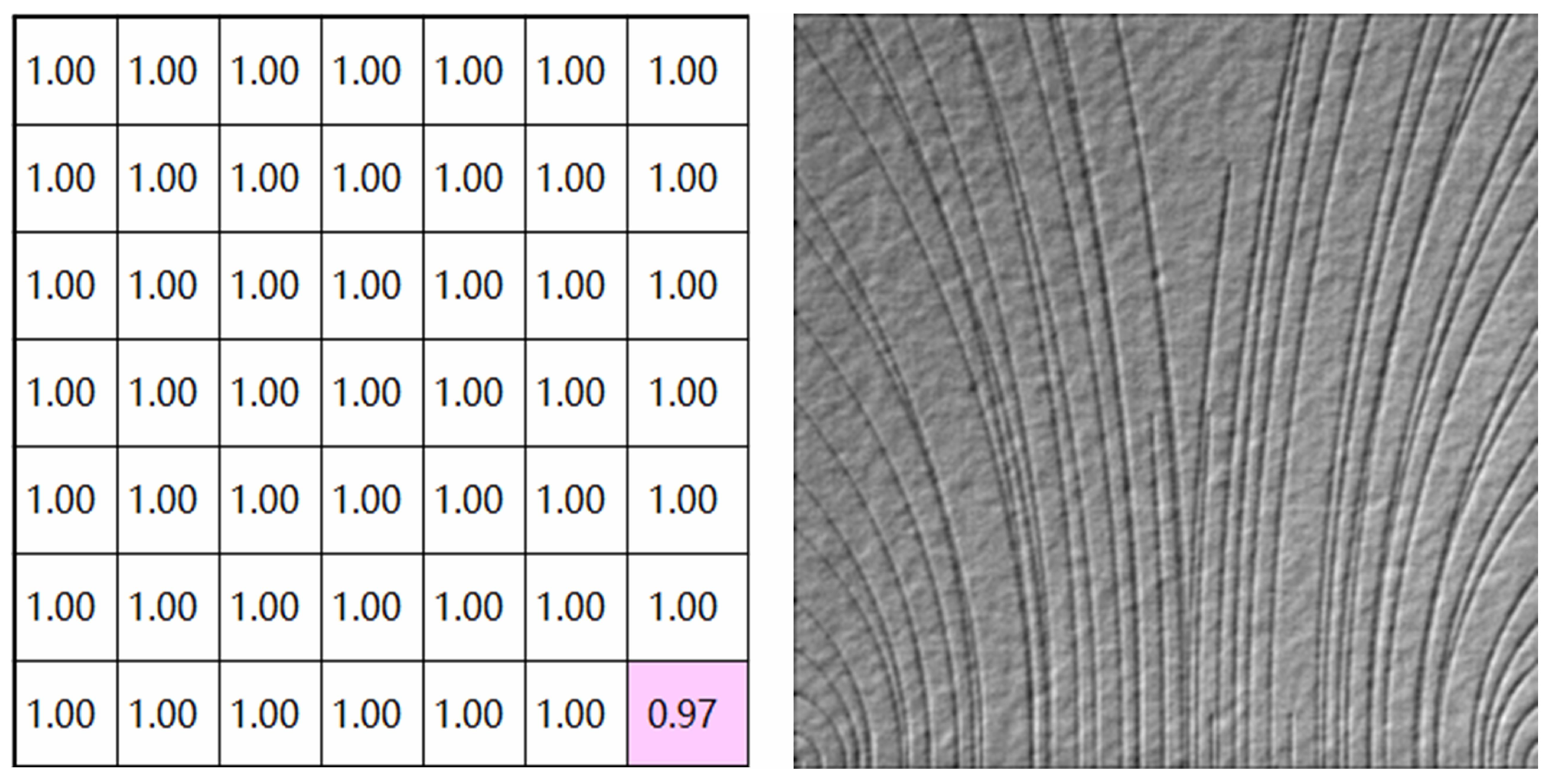

- A judgment strategy based on the sliding-window is proposed, which can improve the robustness of CNN networks. It can reduce the detection error probability in complex backgrounds.

2. Related Work

2.1. Defect Detection

2.2. Convolutional Neural Network

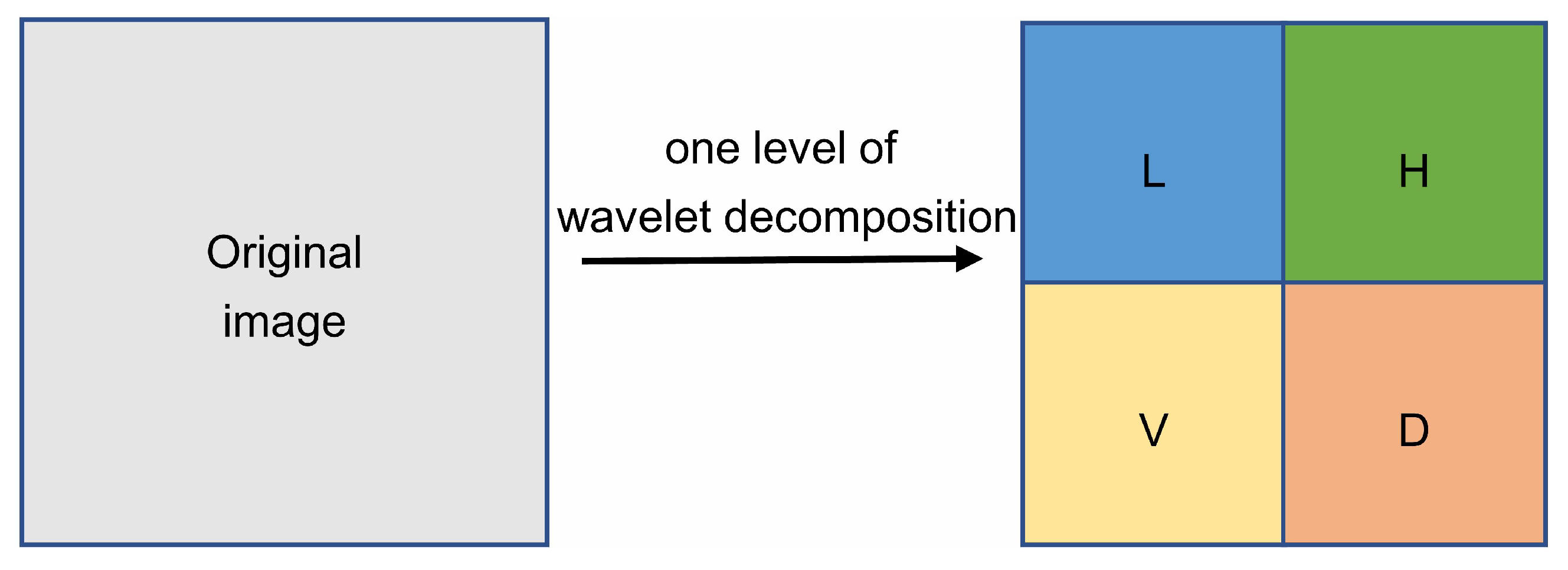

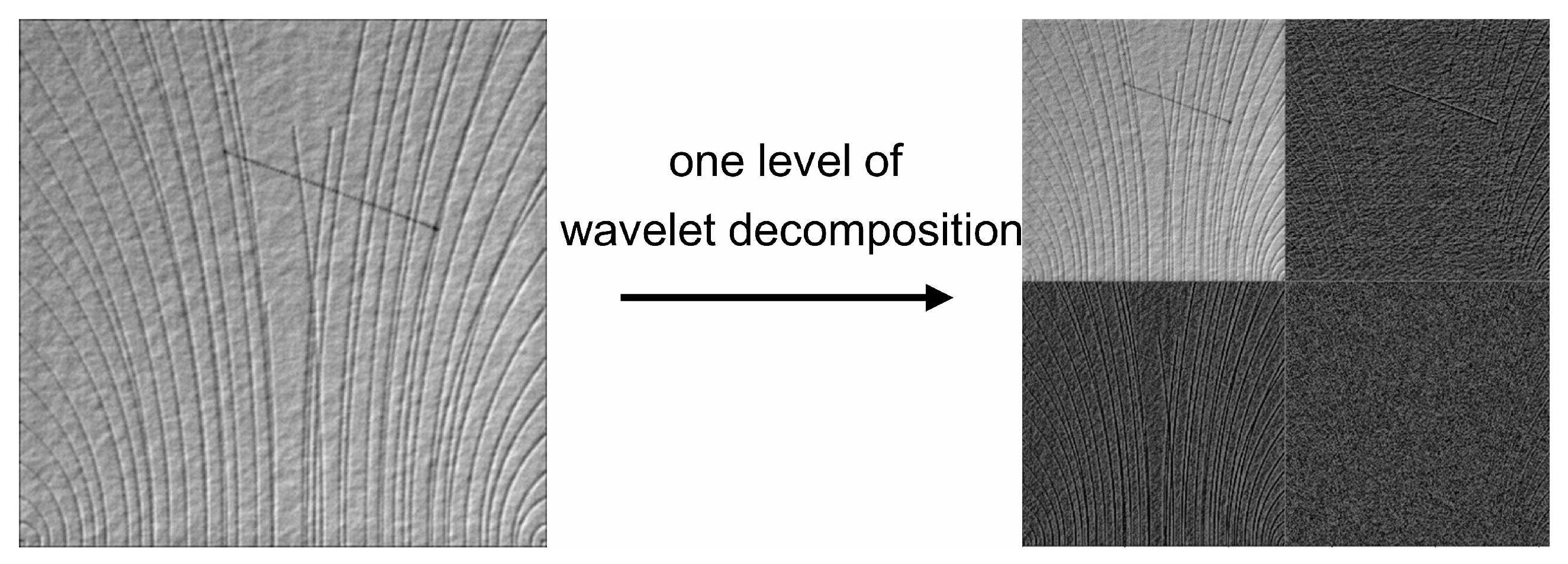

2.3. Wavelet Analysis

3. Method

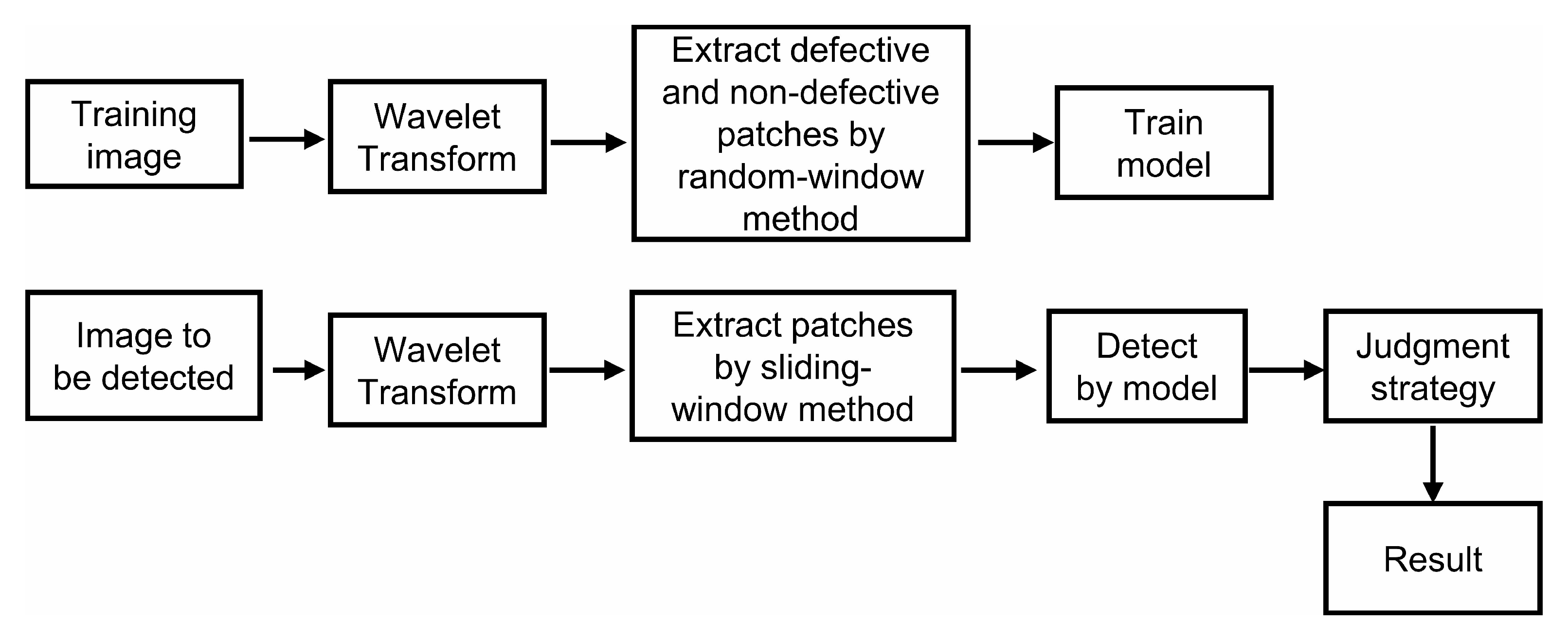

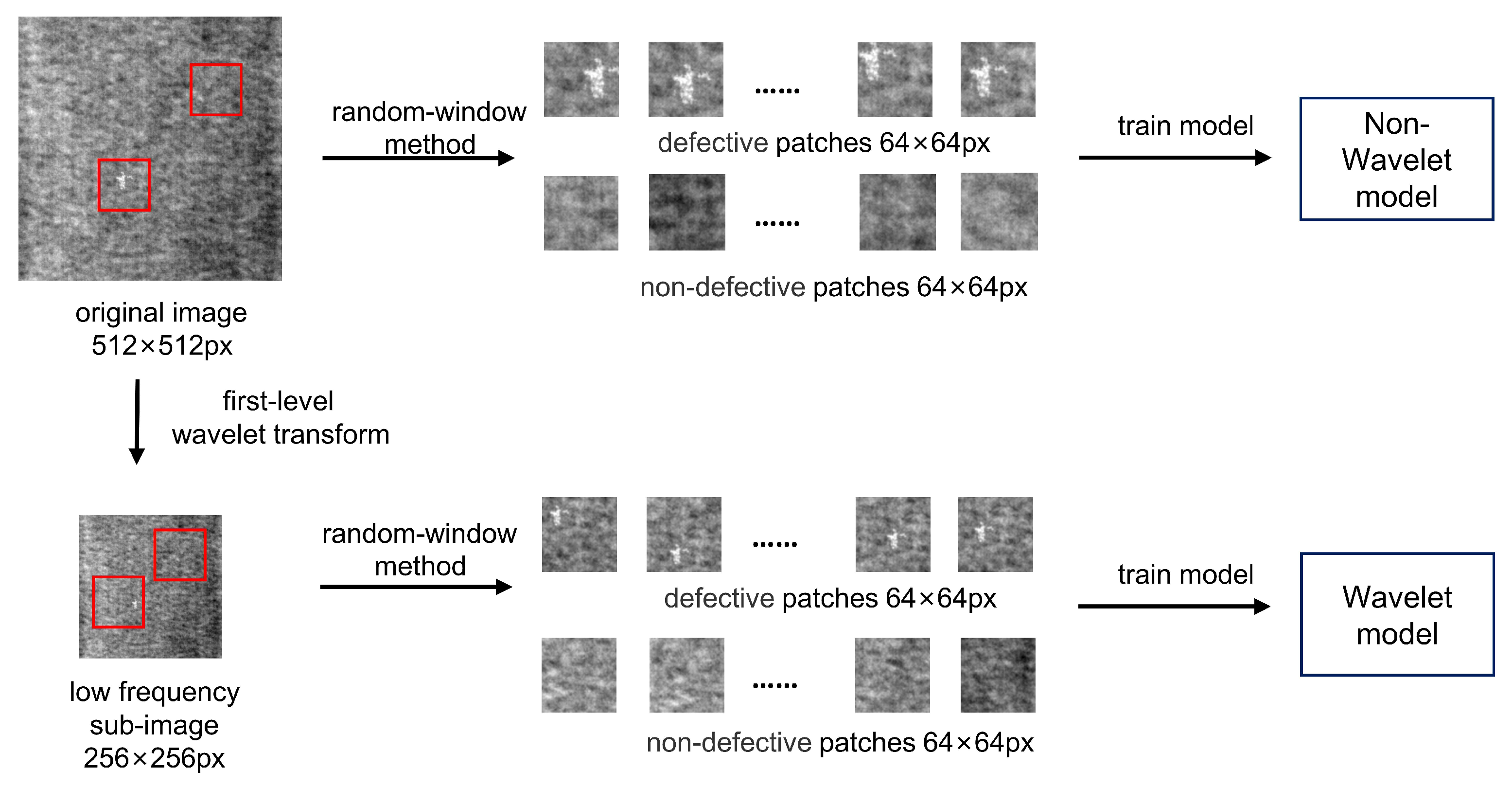

3.1. System Overview

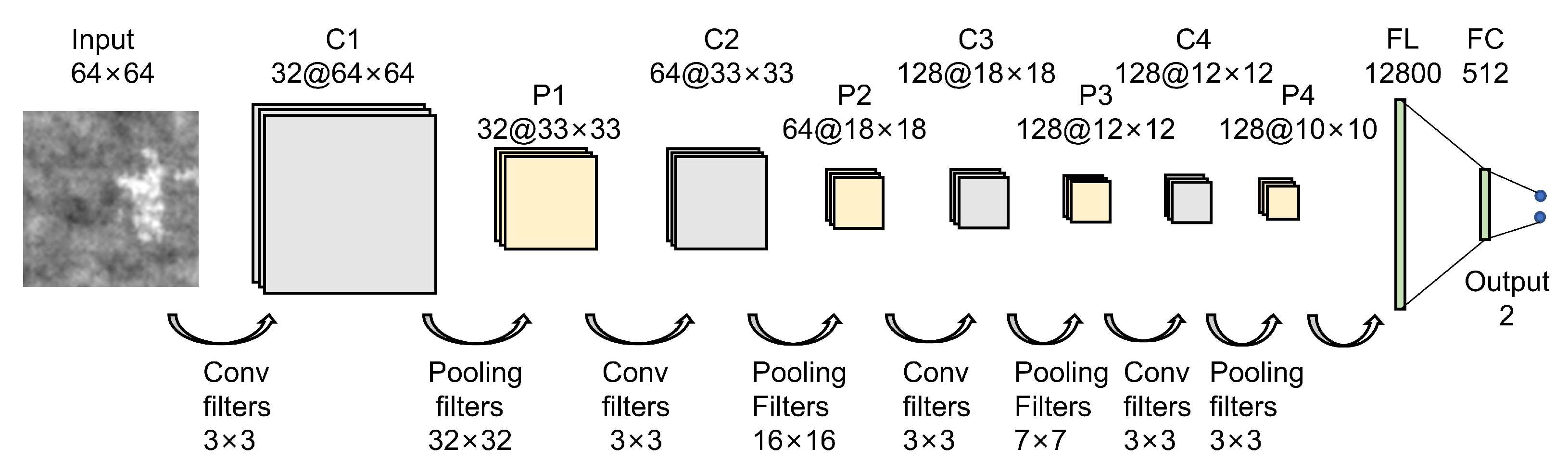

3.2. CNN for Defect Detection

3.3. Random-Window Method

3.4. Sliding-Window Method

3.5. Judgment Strategy

4. Experiments

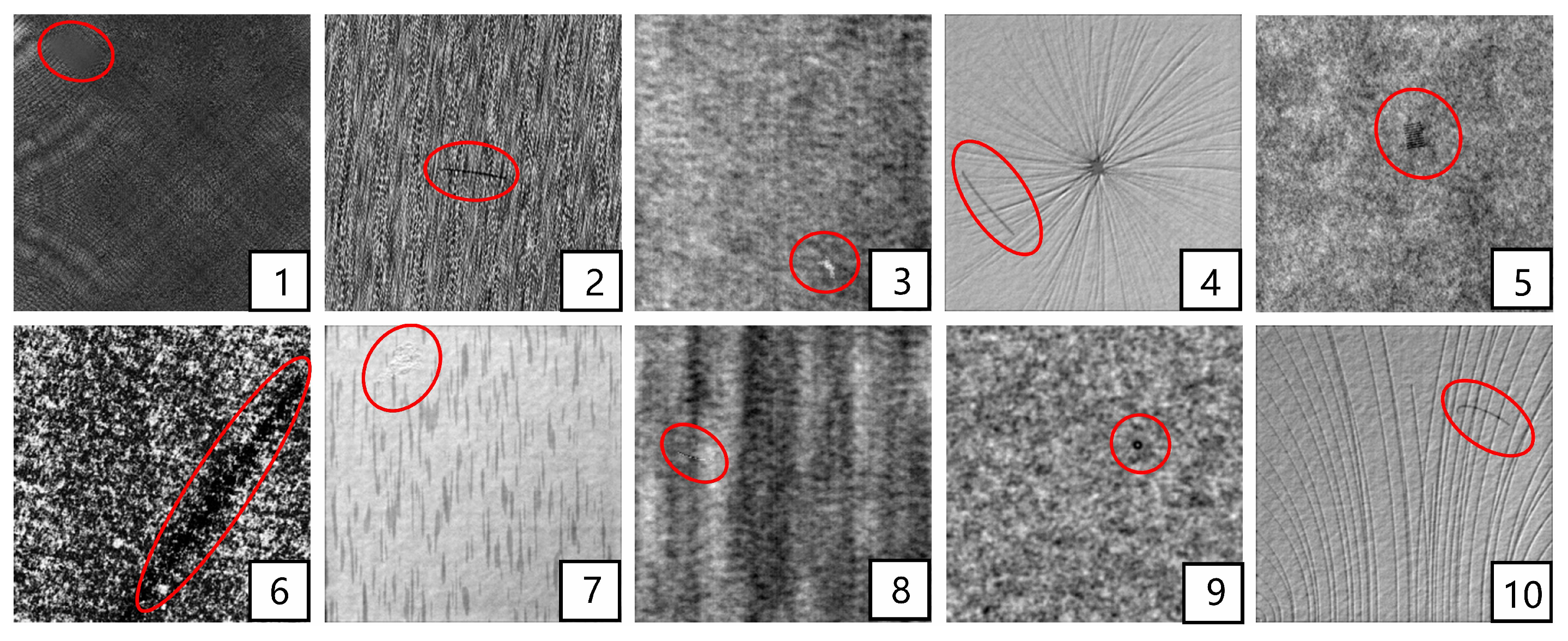

4.1. Dataset

4.1.1. DAGM2007

4.1.2. Micro-Surface Defect Database

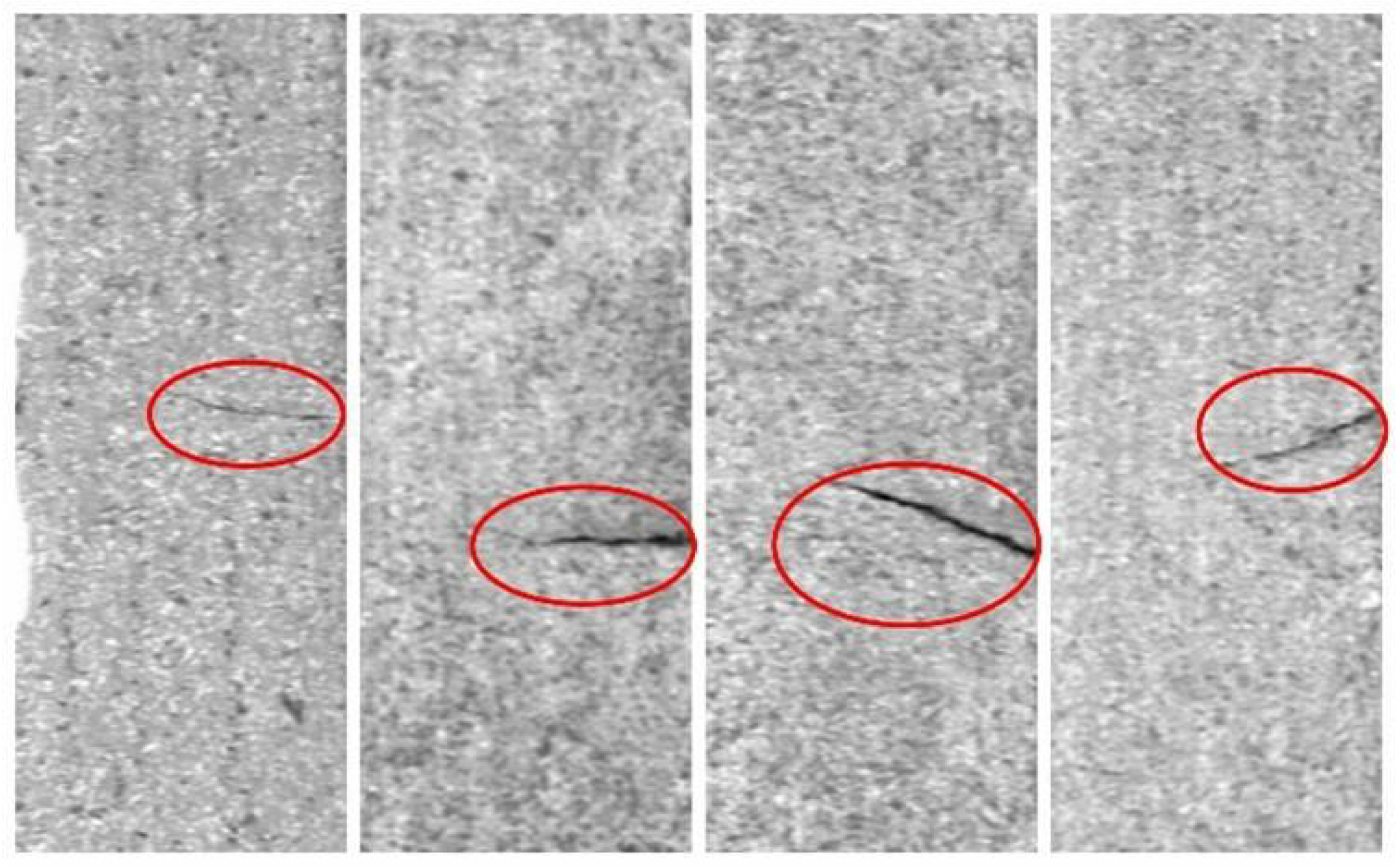

4.1.3. KolektorSDD Dataset

4.2. Experiment Settings

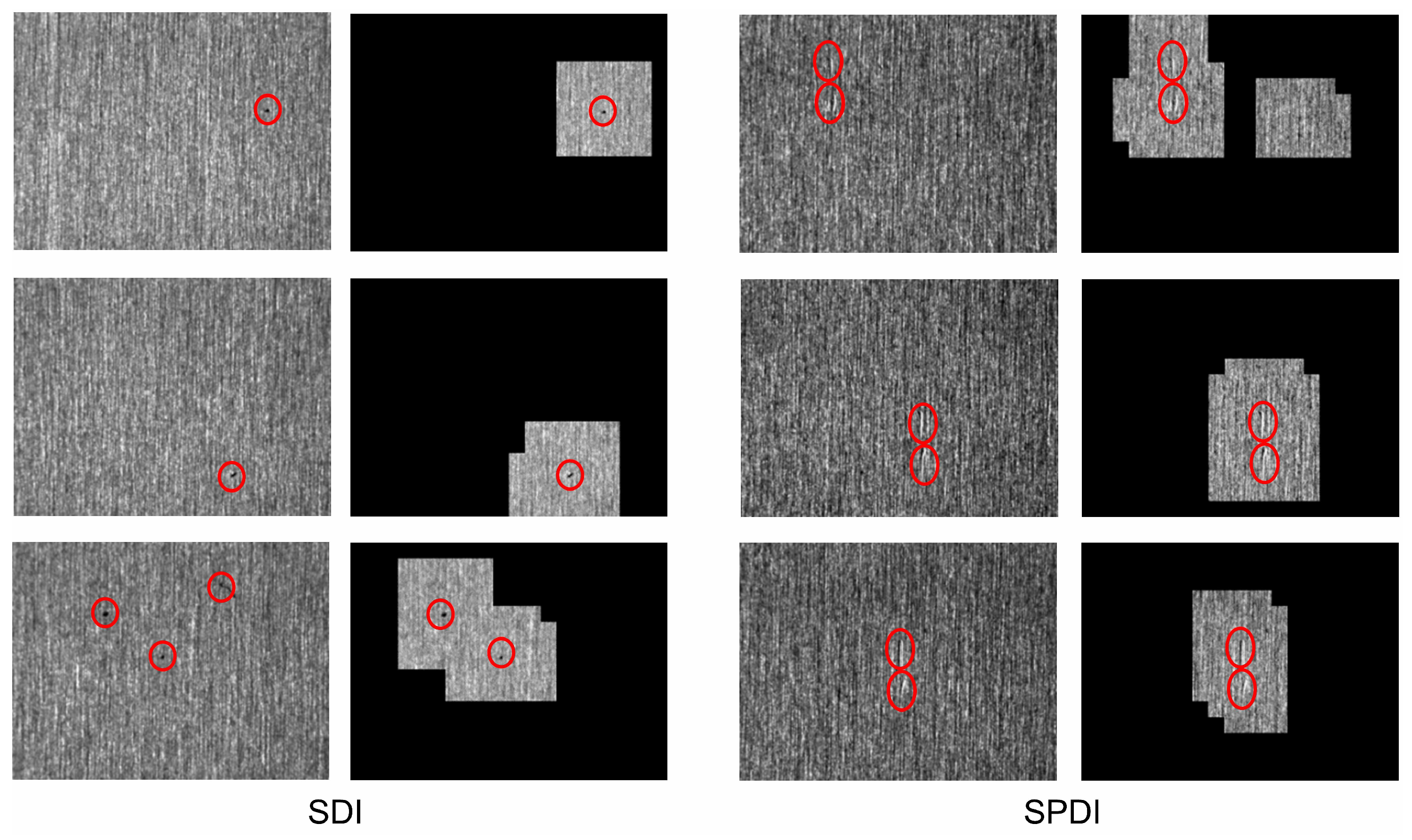

4.2.1. DAGM2007

4.2.2. Micro-Surface Defect Database

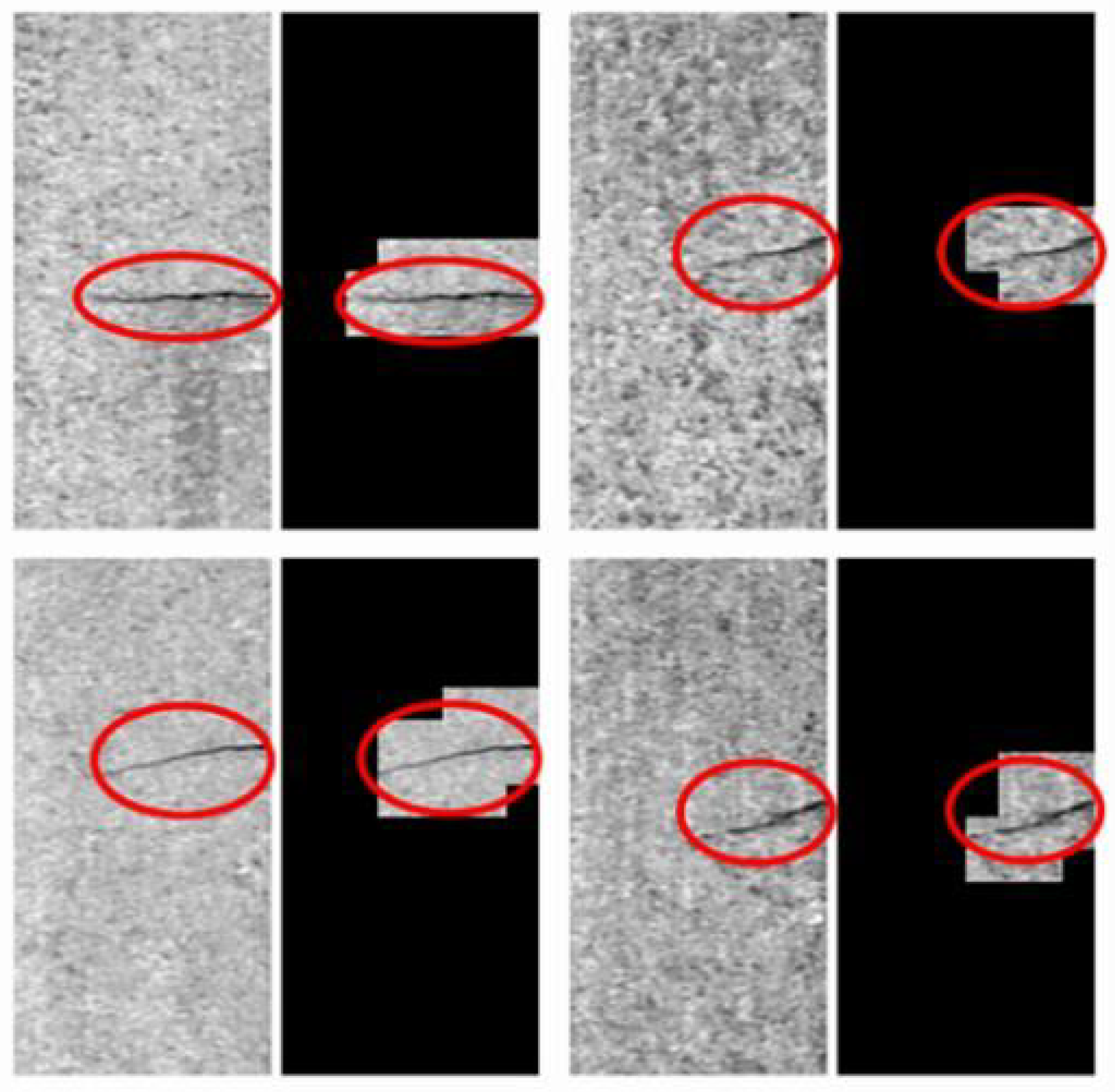

4.2.3. KolektorSDD Dataset

4.3. Results and Discussion

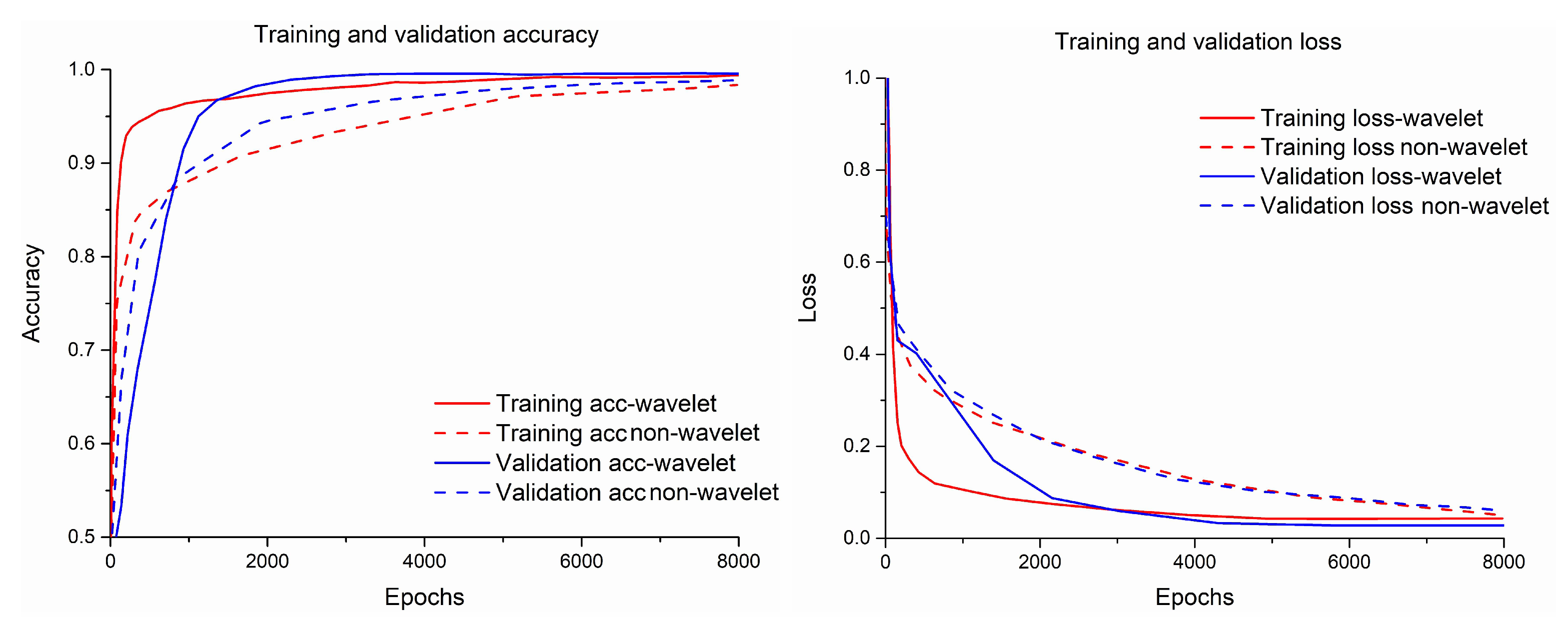

4.3.1. DAGM2007

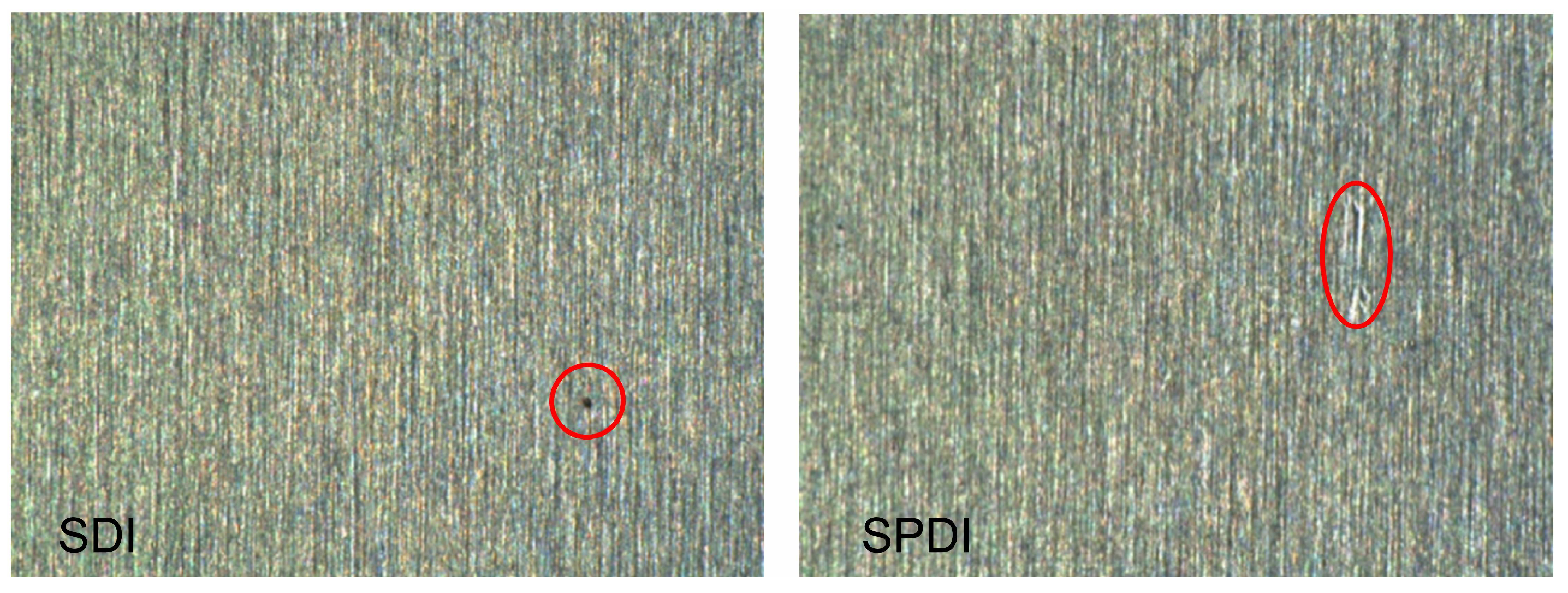

4.3.2. Micro-Surface Defect Database

4.3.3. KolektorSDD Dataset

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Racki, D.; Tomazevic, D.; Skocaj, D. A Compact Convolutional Neural Network for Textured Surface Anomaly Detection. In Proceedings of the 2018 IEEE Winter Conference on Applications of Computer Vision (WACV), Lake Tahoe, NV, USA, 12–15 March 2018; pp. 1331–1339. [Google Scholar]

- Wang, T.; Chen, Y.; Qiao, M.; Snoussi, H. A fast and robust convolutional neural network-based defect detection model in product quality control. Int. J. Adv. Manuf. Technol. 2018, 94, 3465–3471. [Google Scholar] [CrossRef]

- Weimer, D.; Scholz-Reiter, B.; Shpitalni, M. Design of deep convolutional neural network architectures for automated feature extraction in industrial inspection. CIRP Ann. 2016, 65, 417–420. [Google Scholar] [CrossRef]

- Li, P.; Liang, J.; Shen, X.; Zhao, M.; Sui, L. Textile fabric defect detection based on low-rank representation. Multimed. Tools Appl. 2019, 78, 99–124. [Google Scholar] [CrossRef]

- Ma, S.; Liu, W.; You, C.; Jia, S.; Wu, Y. An improved defect detection algorithm of jean fabric based on optimized Gabor filter. J. Inf. Process. Syst. 2020, 16, 1008–1014. [Google Scholar]

- Di, L.; Long, H.; Liang, J. Fabric defect detection based on illumination correction and visual salient features. Sensors 2020, 20, 5147. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Ma, J.; Jing, J.; Li, P. Fabric defect detection using L0 gradient minimization and fuzzy C-means. Appl. Sci. 2019, 9, 3506. [Google Scholar] [CrossRef]

- Jia, L.; Zhang, J.; Chen, S.; Hou, Z. Fabric defect inspection based on lattice segmentation and lattice templates. J. Frankl. Inst. 2018, 355, 7764–7798. [Google Scholar] [CrossRef]

- Shi, K.; Wang, J.; Wang, L.; Pan, R.; Gao, W. Objective evaluation of fabric wrinkles based on 2-D Gabor transform. Fibers Polym. 2020, 21, 2138–2146. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Constant, T.; Colin, F. An innovative and automated method for characterizing wood defects on trunk surfaces using high-density 3D terrestrial LiDAR data. Ann. For. Sci. 2021, 78, 1–18. [Google Scholar] [CrossRef]

- Ibrahim, M.; Headland, D.; Withayachumnankul, W.; Wang, C. Nondestructive Testing of Defects in Polymer-Matrix Composite Materials for Marine Applications Using Terahertz Waves. J. Nondestruct. Eval. 2021, 40, 1–11. [Google Scholar] [CrossRef]

- Liu, K.; Wang, H.; Chen, H.; Qu, E.; Tian, Y.; Sun, H. Steel surface defect detection using a new Haar–Weibull-variance model in unsupervised manner. IEEE Trans. Instrum. Meas. 2017, 66, 2585–2596. [Google Scholar] [CrossRef]

- Zhao, X.; He, Z.; Zhang, S.; Liang, D. A sparse-representation-based robust inspection system for hidden defects classification in casting components. Neurocomputing 2015, 153, 1–10. [Google Scholar] [CrossRef]

- Xiang, S.; Liang, D.; Kaneko, S.; Asano, H. Robust defect detection in 2D images printed on 3D micro-textured surfaces by multiple paired pixel consistency in orientation codes. IET Image Process. 2020, 14, 3373–3384. [Google Scholar] [CrossRef]

- Alzubaidi, L.; Zhang, J.; Humaidi, A.J.; Al-Dujaili, A.; Duan, Y.; Al-Shamma, O.; Santamaría, J.; Fadhel, M.A.; Al-Amidie, M.; Farhan, L. Review of deep learning: Concepts, CNN architectures, challenges, applications, future directions. J. Big Data 2021, 8, 1–74. [Google Scholar]

- Gu, J.; Wang, Z.; Kuen, J.; Ma, L.; Shahroudy, A.; Shuai, B.; Liu, T.; Wang, X.; Wang, G.; Cai, J.; et al. Recent advances in convolutional neural networks. Pattern Recognit. 2018, 77, 354–377. [Google Scholar] [CrossRef]

- Donahue, J.; Anne Hendricks, L.; Guadarrama, S.; Rohrbach, M.; Venugopalan, S.; Saenko, K.; Darrell, T. Long-term recurrent convolutional networks for visual recognition and description. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Boston, MA, USA, 7–12 June 2015; pp. 2625–2634. [Google Scholar]

- Cha, Y.J.; Choi, W.; Büyüköztürk, O. Deep learning-based crack damage detection using convolutional neural networks. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Raghavendra, U.; Fujita, H.; Bhandary, S.V.; Gudigar, A.; Tan, J.H.; Acharya, U.R. Deep convolution neural network for accurate diagnosis of glaucoma using digital fundus images. Inf. Sci. 2018, 441, 41–49. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, D.; Lee, D.J. Automatic fabric defect detection with a wide-and-compact network. Neurocomputing 2019, 329, 329–338. [Google Scholar] [CrossRef]

- Zhao, Y.; Hao, K.; He, H.; Tang, X.; Wei, B. A visual long-short-term memory based integrated CNN model for fabric defect image classification. Neurocomputing 2020, 380, 259–270. [Google Scholar] [CrossRef]

- Mei, S.; Yang, H.; Yin, Z. An unsupervised-learning-based approach for automated defect inspection on textured surfaces. IEEE Trans. Instrum. Meas. 2018, 67, 1266–1277. [Google Scholar] [CrossRef]

- Fortuna-Cervantes, J.M.; Ramírez-Torres, M.T.; Martínez-Carranza, J.; Murguía-Ibarra, J.; Mejía-Carlos, M. Object detection in aerial navigation using wavelet transform and convolutional neural networks: A first approach. Program. Comput. Softw. 2020, 46, 536–547. [Google Scholar] [CrossRef]

- Cui, L.; Jiang, X.; Xu, M.; Li, W.; Lv, P.; Zhou, B. SDDNet: A fast and accurate network for surface defect detection. IEEE Trans. Instrum. Meas. 2021, 70, 1–13. [Google Scholar] [CrossRef]

- Xie, X.; Zhang, R.; Peng, L.; Peng, S. A Four-Stage Product Appearance Defect Detection Method With Small Samples. IEEE Access 2022, 10, 83740–83754. [Google Scholar] [CrossRef]

- Zhang, N.; Zhong, Y.; Dian, S. Rethinking unsupervised texture defect detection using PCA. Opt. Lasers Eng. 2023, 163, 107470. [Google Scholar] [CrossRef]

- Yan, S.; Shao, H.; Xiao, Y.; Liu, B.; Wan, J. Hybrid robust convolutional autoencoder for unsupervised anomaly detection of machine tools under noises. Robot. -Comput.-Integr. Manuf. 2023, 79, 102441. [Google Scholar] [CrossRef]

- He, Z.; Zeng, Y.; Shao, H.; Hu, H.; Xu, X. Novel motor fault detection scheme based on one-class tensor hyperdisk. Knowl.-Based Syst. 2023, 262, 110259. [Google Scholar] [CrossRef]

- Rezaei, Z.; Ebrahimpour-Komleh, H.; Eslami, B.; Chavoshinejad, R.; Totonchi, M. Adverse drug reaction detection in social media by deep learning methods. Cell J. 2020, 22, 319. [Google Scholar]

- Liu, S.; Tang, B.; Chen, Q.; Wang, X. Drug-drug interaction extraction via convolutional neural networks. Comput. Math. Methods Med. 2016, 2016, 6918381. [Google Scholar] [CrossRef]

- Kooi, T.; Litjens, G.; Van Ginneken, B.; Gubern-Mérida, A.; Sánchez, C.I.; Mann, R.; den Heeten, A.; Karssemeijer, N. Large scale deep learning for computer aided detection of mammographic lesions. Med. Image Anal. 2017, 35, 303–312. [Google Scholar] [CrossRef]

- Lin, T.Y.; Dollár, P.; Girshick, R.; He, K.; Hariharan, B.; Belongie, S. Feature pyramid networks for object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017; pp. 2117–2125. [Google Scholar]

- Quan, W.; Wang, K.; Yan, D.M.; Zhang, X. Distinguishing between natural and computer-generated images using convolutional neural networks. IEEE Trans. Inf. Forensics Secur. 2018, 13, 2772–2787. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, Y.; Huang, W.; Liu, L. Sitcom-star-based clothing retrieval for video advertising: A deep learning framework. Neural Comput. Appl. 2019, 31, 7361–7380. [Google Scholar] [CrossRef]

- He, K.; Gkioxari, G.; Dollár, P.; Girshick, R. Mask r-cnn. In Proceedings of the IEEE International Conference on Computer Vision, Venice, Italy, 22–29 October 2017; pp. 2961–2969. [Google Scholar]

- Kamnitsas, K.; Ledig, C.; Newcombe, V.F.; Simpson, J.P.; Kane, A.D.; Menon, D.K.; Rueckert, D.; Glocker, B. Efficient multi-scale 3D CNN with fully connected CRF for accurate brain lesion segmentation. Med. Image Anal. 2017, 36, 61–78. [Google Scholar] [CrossRef] [PubMed]

- Liang, D.; Kang, B.; Liu, X.; Gao, P.; Tan, X.; Kaneko, S. Cross-scene foreground segmentation with supervised and unsupervised model communication. Pattern Recognit. 2021, 117, 107995. [Google Scholar] [CrossRef]

- Rhif, M.; Ben Abbes, A.; Farah, I.R.; Martínez, B.; Sang, Y. Wavelet transform application for/in non-stationary time-series analysis: A review. Appl. Sci. 2019, 9, 1345. [Google Scholar] [CrossRef]

- Song, K.; Yan, Y. micro-surface defect detection method for silicon steel strip based on saliency convex active contour model. Math. Probl. Eng. 2013, 2013, 429094. [Google Scholar] [CrossRef]

- Tabernik, D.; Šela, S.; Skvarč, J.; Skočaj, D. Segmentation-based deep-learning approach for surface-defect detection. J. Intell. Manuf. 2020, 31, 759–776. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Delving deep into rectifiers: Surpassing human-level performance on imagenet classification. In Proceedings of the IEEE International Conference on Computer Vision, Santiago, Chile, 7–13 December 2015; pp. 1026–1034. [Google Scholar]

- Jiang, X.; Scott, P.; Whitehouse, D. Wavelets and their applications for surface metrology. CIRP Ann. 2008, 57, 555–558. [Google Scholar] [CrossRef]

- Siebel, N.T.; Sommer, G. Learning defect classifiers for visual inspection images by neuro-evolution using weakly labelled training data. In Proceedings of the 2008 IEEE Congress on Evolutionary Computation (IEEE World Congress on Computational Intelligence), Hong Kong, China, 1–6 June 2008; pp. 3925–3931. [Google Scholar]

- Timm, F.; Barth, E. Non-parametric texture defect detection using Weibull features. In Image Processing: Machine Vision Applications IV; Society of Photo-Optical Instrumentation Engineers (SPIE): Bellingham, WA, USA, 2011; Volume 7877, pp. 150–161. [Google Scholar]

| Class | Class2 | Class3 | Class6 | Class7 | Class8 | Class9 | Class10 | Total |

|---|---|---|---|---|---|---|---|---|

| Train(P/N) 1 | 120/970 | 100/800 | 100/800 | 200/1800 | 200/800 | 200/1800 | 200/1800 | 1120/9770 |

| Test(P/N) 1 | 30/30 | 50/200 | 50/200 | 100/200 | 100/200 | 100/200 | 100/200 | 530/1230 |

| Class | Class2 | Class3 | Class6 | Class7 | Class8 | Class9 | Class10 | Total |

|---|---|---|---|---|---|---|---|---|

| Defective patches | 1503 | 1758 | 2370 | 3690 | 2814 | 2930 | 4504 | 19,589 |

| Non-defective patches | 3880 | 3200 | 2400 | 7200 | 7200 | 6000 | 5400 | 35,280 |

| Class | Our Non-Wavelet Model | Our Wavelet Mode | Xie’s Model [25] | Racki’s CNN [1] | Wang’s CNN [2] | Weimer’s CNN [3] | Statistical Features [42] | SIFT and ANN [43] | Weibull [44] | Zhang’s Model [26] |

|---|---|---|---|---|---|---|---|---|---|---|

| TPR (%) | ||||||||||

| 2 | 95.8 | 97.5 | 100 | 100 | 100 | 100 | 94.3 | 95.7 | - * | 92.5 |

| 3 | 87.0 | 100 | 100 | 100 | 100 | 95.5 | 99.5 | 98.5 | 99.8 | 89.6 |

| 6 | 100 | 99 | 100 | 100 | 100 | 100 | 100 | 99.8 | 94.9 | 93.8 |

| 7 | 66.5 | 97.5 | 100 | 100 | - | - | - | - | - | 95.9 |

| 8 | 100 | 96.5 | 100 | 100 | - | - | - | - | - | 95.9 |

| 9 | 74 | 99.5 | 100 | 100 | - | - | - | - | - | - |

| 10 | 51 | 92 | 100 | 100 | - | - | - | - | - | - |

| TNR (%) | ||||||||||

| 2 | 97.5 | 99.4 | 100 | 99.8 | 100 | 97.3 | 80 | 91.3 | - | - |

| 3 | 98.8 | 99 | 100 | 96.3 | 100 | 100 | 100 | 100 | 100 | - |

| 6 | 100 | 99.9 | 100 | 100 | 100 | 99.5 | 96.1 | 100 | 100 | - |

| 7 | 100 | 99.5 | 100 | 100 | - | - | - | - | - | - |

| 8 | 100 | 98.9 | 100 | 100 | - | - | - | - | - | - |

| 9 | 95.9 | 100 | 100 | 99.9 | - | - | - | - | - | - |

| 10 | 99.9 | 99.8 | 100 | 100 | - | - | - | - | - | - |

| AVEACC (%) | ||||||||||

| 96.1 | 99.3 | 100 | 99.7 | 99.8 | 99.2 | 95.9 | 98.2 | 97.1 | - |

| Class | Our Wavelet Model | Racki’s CNN [1] | Wang’s CNN [2] | Weimer’S CNN [3] |

|---|---|---|---|---|

| Class1–6 | 20,631,552 px | 209,190,912 px | 867,631,104 px | 221,729,792 px |

| (5037 × 64 × 64) * | (798 × 512 × 512) | (52,956 × 128 × 128) | (216,533 × 32 × 32) | |

| Class7–10 | 40,710,144 px | 419,430,400 px | - | - |

| (9939 × 64 × 64) | (1600 × 512 × 512) | - | - | |

| Ratio | 1 | 10.24 | 42.05 | 10.75 |

| AVEACC (%) | 99.3 | 99.7 | 99.8 | 99.2 |

| Class | TP | FP | FN | Recall (%) | Precession (%) |

|---|---|---|---|---|---|

| SDI * | 24 | 0 | 2 | 92.3 | 100 |

| SDPI * | 24 | 1 | 1 | 96 | 96 |

| TP | FP | FN | Recall (%) | Precession (%) |

|---|---|---|---|---|

| 16 | 0 | 4 | 80 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, M.; Li, D.; Li, K.; Xu, J. TSDNet: A New Multiscale Texture Surface Defect Detection Model. Appl. Sci. 2023, 13, 3289. https://doi.org/10.3390/app13053289

Dong M, Li D, Li K, Xu J. TSDNet: A New Multiscale Texture Surface Defect Detection Model. Applied Sciences. 2023; 13(5):3289. https://doi.org/10.3390/app13053289

Chicago/Turabian StyleDong, Min, Dezhen Li, Kaixiang Li, and Junpeng Xu. 2023. "TSDNet: A New Multiscale Texture Surface Defect Detection Model" Applied Sciences 13, no. 5: 3289. https://doi.org/10.3390/app13053289

APA StyleDong, M., Li, D., Li, K., & Xu, J. (2023). TSDNet: A New Multiscale Texture Surface Defect Detection Model. Applied Sciences, 13(5), 3289. https://doi.org/10.3390/app13053289