Biochar from Agro-Forest Residue: Application Perspective Based on Decision Support Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Used Biomass

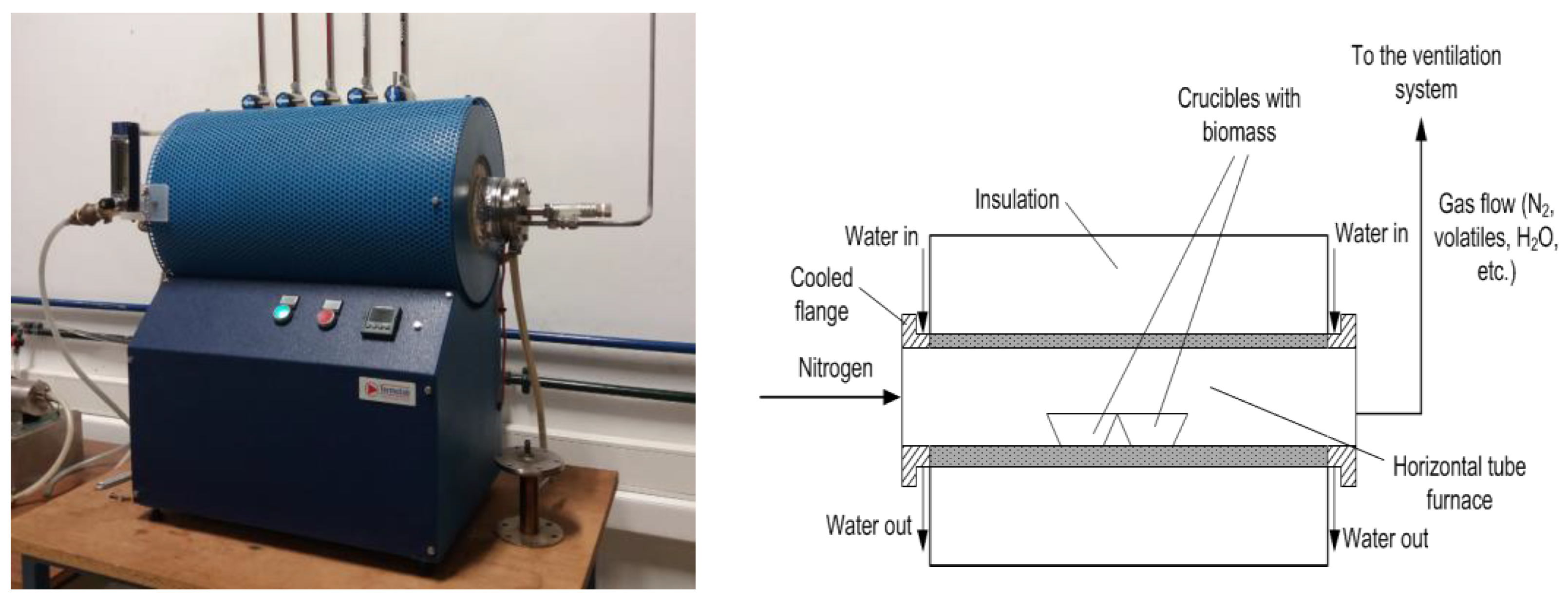

2.2. Horizontal Tube Furnace and Test Conditions

2.3. Experimental Methods Used for Biochar Characterization

2.4. Kinetic Analysis

2.5. Decision Support Analysis

2.5.1. Pareto Dominance Analysis

2.5.2. Compromise Programming Approach

3. Results and Discussion

3.1. Biochar Yield

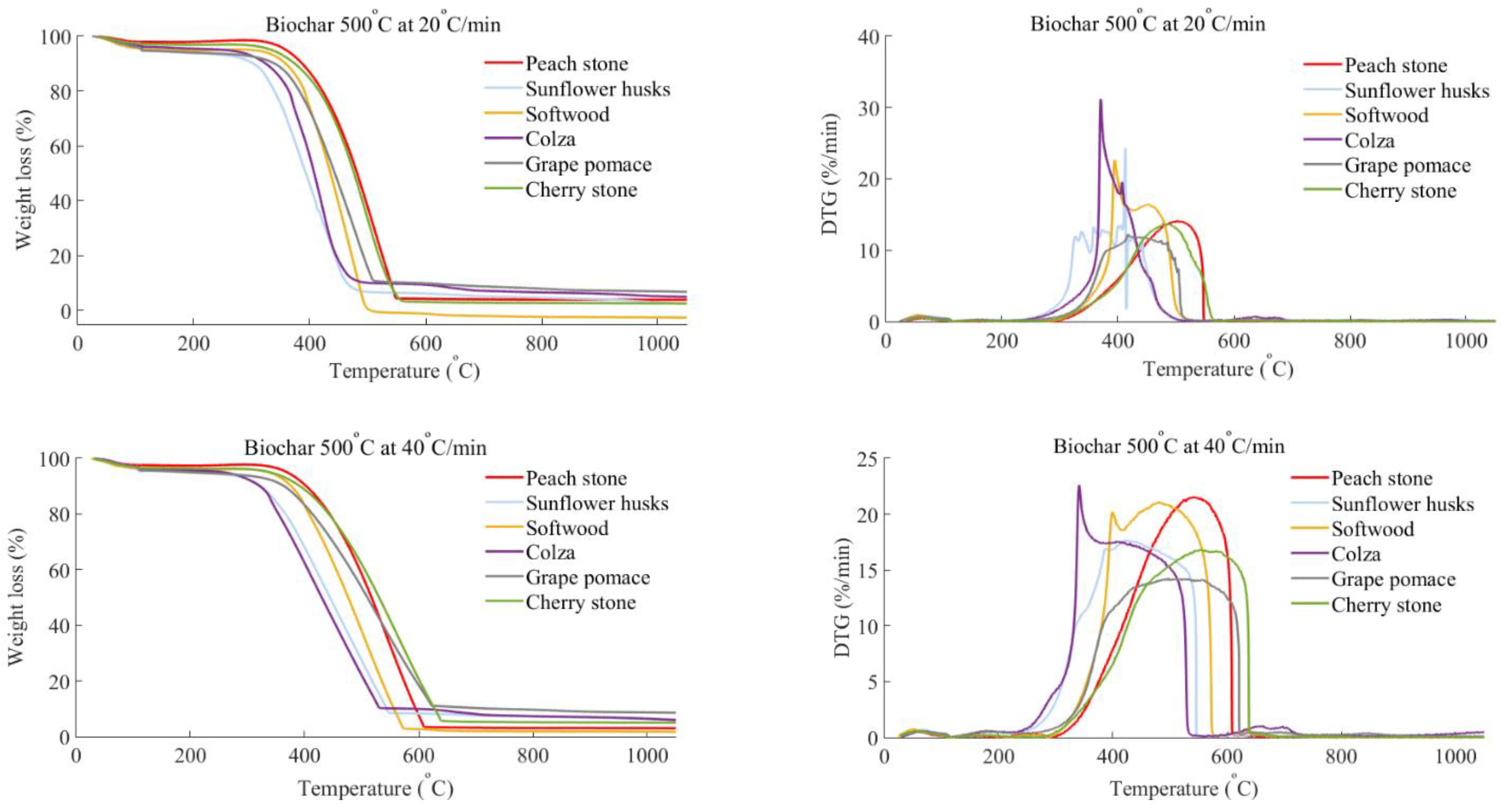

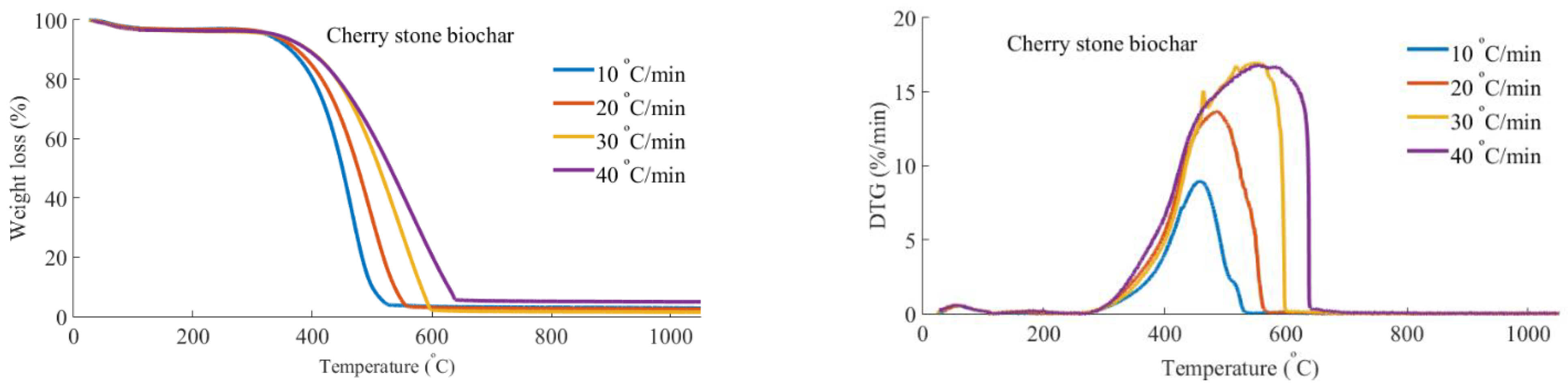

3.2. Thermogravimetric Analysis of Biochar

3.3. Kinetic Analysis

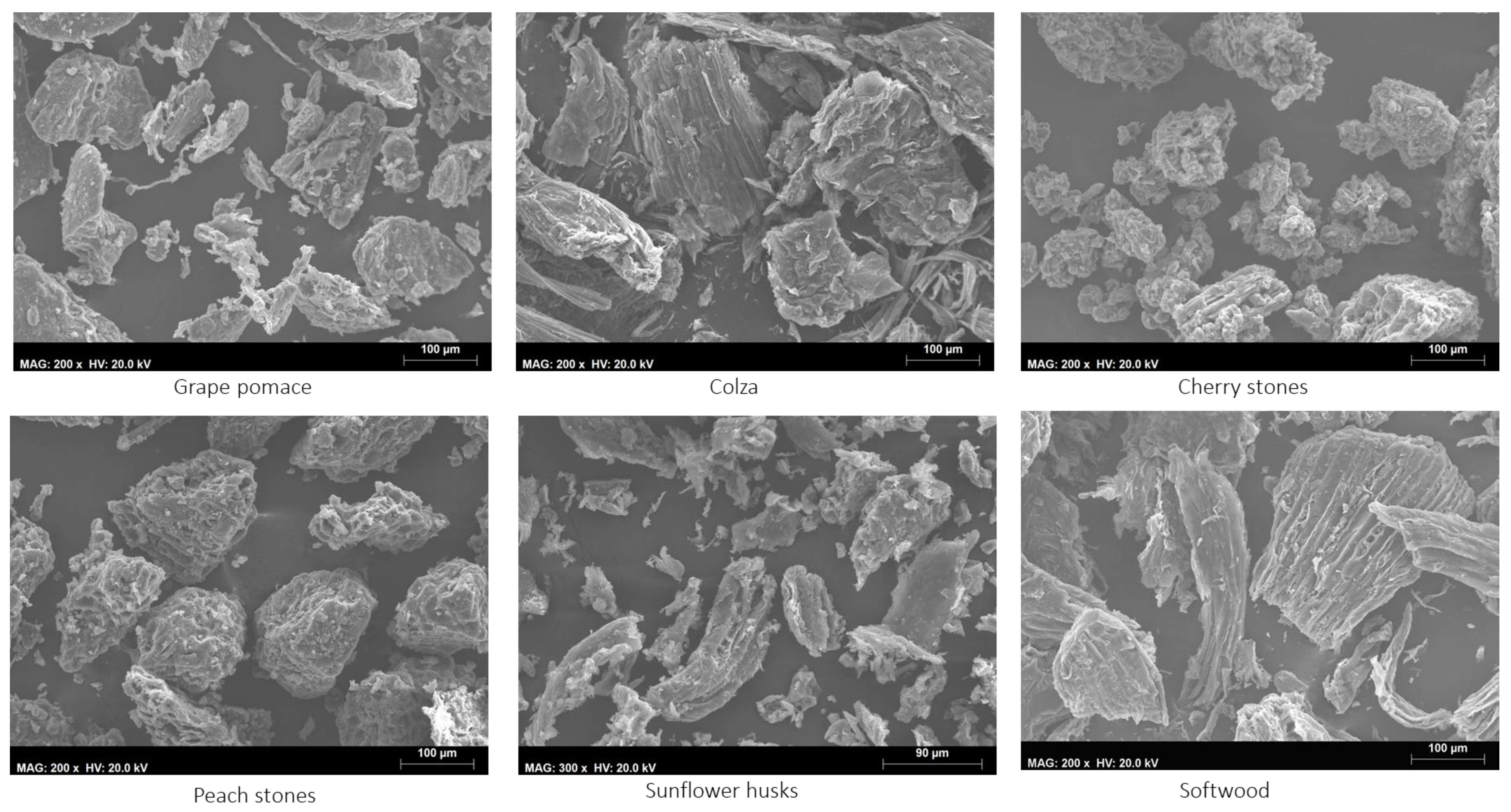

3.4. SEM and EDS Analysis

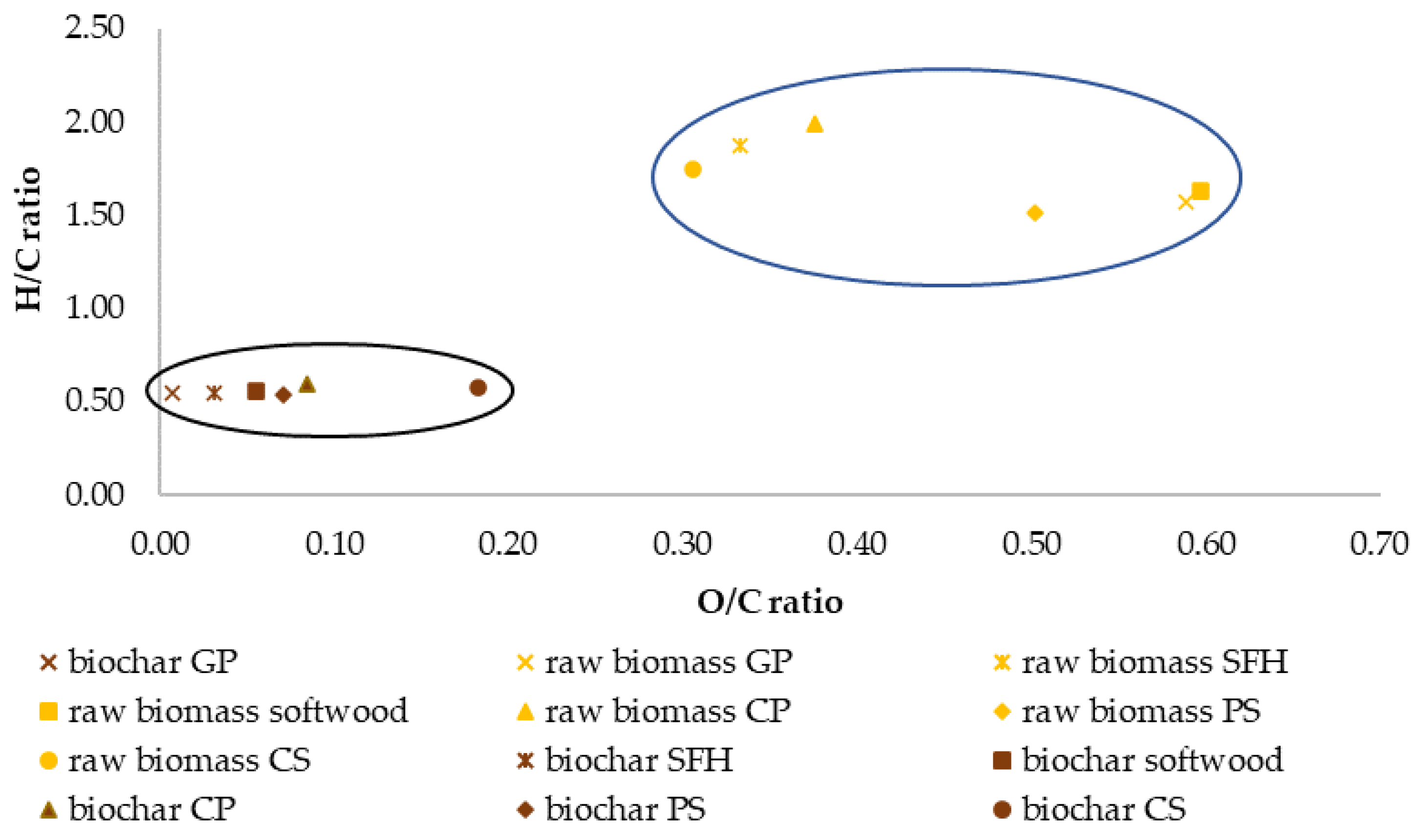

3.5. Biochar Characterization Using Proximate, Ultimate, Calorimetric, BET, and Combined pH/EC Analyses

3.6. Decision Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Naydenova, I.; Sandov, O.; Wesenauer, F.; Laminger, T.; Winter, F. Pollutants Formation during Single Particle Combustion of Biomass under Fluidized Bed Conditions: An Experimental Study. Fuel 2020, 278, 117958. [Google Scholar] [CrossRef]

- Petrova, T. Estimation of the Higher Heating Values for Lignocellulosic Biofuels. In Proceedings of the 2021 6th International Symposium on Environment-Friendly Energies and Applications (EFEA), Sofia, Bulgaria, 24–26 March 2021; pp. 14–18. [Google Scholar] [CrossRef]

- Ferreira, A.F.; Ribau, J.P.; Costa, M. A Decision Support Method for Biochars Characterization from Carbonization of Grape Pomace. Biomass Bioenergy 2021, 145, 105946. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A Review on Biomass as a Fuel for Boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Demirbaş, A. Relationships between Lignin Contents and Heating Values of Biomass. Energy Convers. Manag. 2001, 42, 183–188. [Google Scholar] [CrossRef]

- Valchev, I.; Yavorov, N.; Petrin, S. Topochemical Kinetic Mechanism of Cellulase Hydrolysis on Fast-Growing Tree Species. COST Action FP1105. Holzforschung 2016, 70, 1147–1153. [Google Scholar] [CrossRef]

- Housseinpour, R.; Latibari, A.J.; Farnood, R.; Fatehi, P.; Sepiddehdam, S.J. Fiber Morphology and Chemical Composition of Rape- Seed (Brassica Napus) Stems. IAWA J. 2010, 31, 457–464. [Google Scholar] [CrossRef]

- Burhenne, L.; Messmer, J.; Aicher, T.; Laborie, M.P. The Effect of the Biomass Components Lignin, Cellulose and Hemicellulose on TGA and Fixed Bed Pyrolysis. J. Anal. Appl. Pyrolysis 2013, 101, 177–184. [Google Scholar] [CrossRef]

- Ghai, H.; Sakhuja, D.; Yadav, S.; Solanki, P.; Putatunda, C.; Bhatia, R.K.; Bhatt, A.K.; Varjani, S.; Yang, Y.-H.; Bhatia, S.K.; et al. An Overview on Co-Pyrolysis of Biodegradable and Non-Biodegradable Wastes. Energies 2022, 15, 4168. [Google Scholar] [CrossRef]

- Mishra, S.; Upadhyay, R.K. Review on biomass gasification: Gasifiers, gasifying mediums, and operational parameters. Mater. Sci. Energy Technol. 2021, 4, 329–340. [Google Scholar] [CrossRef]

- Alsulami, R.A.; El-Sayed, S.A.; Eltaher, M.A.; Mohammad, A.; Almitani, K.H.; Mostafa, M.E. Thermal decomposition characterization and kinetic parameters estimation for date palm wastes and their blends using TGA. Fuel 2023, 334, 126600. [Google Scholar] [CrossRef]

- Choi, Y.-K.; Gurav, R.; Kim, H.J.; Yang, Y.-H.; Bhatia, S.K. Evaluation for Simultaneous Removal of Anionic and Cationic Dyes onto Maple Leaf-Derived Biochar Using Response Surface Methodology. Appl. Sci. 2020, 10, 2982. [Google Scholar] [CrossRef]

- Gurav, R.; Bhatia, S.K.; Choi, T.-R.; Choi, Y.-K.; Kim, H.J.; Song, H.-S.; Park, S.L.; Lee, H.S.; Lee, S.M.; Choi, K.-Y.; et al. Adsorptive removal of crude petroleum oil from water using floating pinewood biochar decorated with coconut oil-derived fatty acids. Sci. Total Environ. 2021, 781, 146636. [Google Scholar] [CrossRef]

- Obey, G.; Adelaide, M.; Ramaraj, R. Biochar derived from non-customized matamba fruit shell as an adsorbent for wastewater treatment. J. Bioresour. Bioprod. 2022, 7, 109–115. [Google Scholar] [CrossRef]

- Jjagwe, J.; Olupot, P.W.; Menya, E.; Kalibbala, H.M. Synthesis and Application of Granular Activated Carbon from Biomass Waste Materials for Water Treatment: A Review. J. Bioresour. Bioprod. 2021, 6, 292–322. [Google Scholar] [CrossRef]

- Corbin, K.R.; Hsieh, Y.S.Y.; Betts, N.S.; Byrt, C.S.; Henderson, M.; Stork, J.; DeBolt, S.; Fincher, G.B.; Burton, R.A. Grape Marc as a Source of Carbohydrates for Bioethanol: Chemical Composition, Pre-Treatment and Saccharification. Bioresour. Technol. 2015, 193, 76–83. [Google Scholar] [CrossRef] [PubMed]

- Chiou, B.S.; Valenzuela-Medina, D.; Bilbao-Sainz, C.; Klamczynski, A.K.; Avena-Bustillos, R.J.; Milczarek, R.R.; Du, W.X.; Glenn, G.M.; Orts, W.J. Torrefaction of Pomaces and Nut Shells. Bioresour. Technol. 2015, 177, 58–65. [Google Scholar] [CrossRef]

- Özsin, G.; Pütün, A.E. A Comparative Study on Co-Pyrolysis of Lignocellulosic Biomass with Polyethylene Terephthalate, Polystyrene, and Polyvinyl Chloride: Synergistic Effects and Product Characteristics. J. Clean. Prod. 2018, 205, 1127–1138. [Google Scholar] [CrossRef]

- Mohamed, A.R.; Mohammadi, M.; Darzi, G.N. Preparation of Carbon Molecular Sieve from Lignocellulosic Biomass: A Review. Renew. Sustain. Energy Rev. 2010, 14, 1591–1599. [Google Scholar] [CrossRef]

- Duman, G.; Okutucu, C.; Ucar, S.; Stahl, R.; Yanik, J. The Slow and Fast Pyrolysis of Cherry Seed. Bioresour. Technol. 2011, 102, 1869–1878. [Google Scholar] [CrossRef]

- González, J.F.; Encinar, J.M.; Canito, J.L.; Sabio, E.; Chacón, M. Pyrolysis of Cherry Stones: Energy Uses of the Different Fractions and Kinetic Study. J. Anal. Appl. Pyrolysis 2003, 67, 165–190. [Google Scholar] [CrossRef]

- Petrov, N.; Budinova, T.; Razvigorova, M.; Minkova, V.; Vigouroux, R.A.Z.; Bjornbom, E. Preparation of Activated Carbons from Cherry Stones, Apricot Stones and Grape Seeds for Removal of Metal Ions from Water. In Proceedings of the 2nd Olle Indstorm Symposium on Renewable Energy-Bioenergy, Stockholm, Sweden, 9–11 June 1999; pp. 46–50. [Google Scholar]

- Pedras, B.M.d.S. Valorization of Grape Pomace through Hot Compressed Water Extraction/Hydrolysis. Master’s Thesis, Universidade Nova, Lisbon, Portugal, 2015. Available online: https://run.unl.pt/handle/10362/16225 (accessed on 27 February 2023).

- Bhatia, S.K.; Palai, A.K.; Kumar, A.; Bhatia, R.K.; Patel, A.K.; Thakur, V.K.; Yang, Y.-H. Trends in renewable energy production employing biomass-based biochar. Bioresour. Technol. 2021, 340, 125644. [Google Scholar] [CrossRef]

- Novotný, M.; Marković, M.; Raček, J.; Šipka, M.; Chorazy, T.; Tošić, I.; Hlavínek, P. The use of biochar made from biomass and biosolids as a substrate for green infrastructure: A review. Sustain. Chem. Pharm. 2023, 32, 100999. [Google Scholar] [CrossRef]

- Qian, S.; Zhou, X.; Fu, Y.; Song, B.; Yan, H.; Chen, Z.; Sun, Q.; Ye, H.; Qin, L.; Lai, C. Biochar-compost as a new option for soil improvement: Application in various problem soils. Sci. Total Environ. 2023, 870, 162024. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Mohanty, S.; Sahu, G.; Rana, M.; Pilli, K. Biochar: A Sustainable Approach for Improving Soil Health and Environment. In Soil Erosion-Current Challenges and Future Perspectives in a Changing World; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, S.; Su, C. Impact of Biochar on the Bioremediation and Phytoremediation of Heavy Metal(loid)s in Soil. In Advances in Bioremediation and Phytoremediation; InTech: Rijeka, Croatia, 2018. [Google Scholar] [CrossRef]

- Sharma, G.K.; Jena, R.K.; Hota, S.; Kumar, A.; Ray, P.; Fagodiya, R.K.; Malav, L.C.; Yadav, K.K.; Gupta, D.K.; Khan, S.A.; et al. Recent Development in Bioremediation of Soil Pollutants through Biochar for Environmental Sustainability. In Biochar Applications in Agriculture and Environment Management; Singh, J., Singh, C., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Jung, S.; Kim, M.; Kim, Y.-H.; Lin, K.-Y.A.; Chen, W.-H.; Tsang, Y.F.; Kwon, E.E. Use of sewage sludge biochar as a catalyst in production of biodiesel through thermally induced transesterification. Biochar 2022, 4, 67. [Google Scholar] [CrossRef]

- Kumar, S.; Soomro, S.A.; Harijan, K.; Uqaili, M.A.; Kumar, L. Advancements of Biochar-Based Catalyst for Improved Production of Biodiesel: A Comprehensive Review. Energies 2023, 16, 644. [Google Scholar] [CrossRef]

- Arenas, C.; Sotres, A.; Alonso, R.M.; González-Arias, J.; Morán, A.; Gómez, X. Pyrolysed almond shells used as electrodes in microbial electrolysis cell. Biomass Convers. Biorefinery 2022, 12, 313–321. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, M.; Chen, X.; Yan, J.; Li, H.; Xu, X. Electricity production and pollutant removal performance of walnut shell biochar electrode in microbial fuel cell. Chin. J. Environ. Eng. 2022, 16, 3281–3290. [Google Scholar] [CrossRef]

- Piyo, N. Liquefaction of Sunflower Husks for Biochar Production. Master’s Thesis, North-West University, Vanderbijlpark, Portugal, 2014. Available online: https://repository.nwu.ac.za/bitstream/handle/10394/11942/Piyo_N.pdf?sequence=1 (accessed on 27 February 2023).

- Demirbaş, A. Calculation of Higher Heating Values of Biomass Fuels. Fuel 1997, 76, 431–434. [Google Scholar] [CrossRef]

- López-González, D.; Fernandez-Lopez, M.; Valverde, J.L.; Sanchez-Silva, L. Thermogravimetric-Mass Spectrometric Analysis on Combustion of Lignocellulosic Biomass. Bioresour. Technol. 2013, 143, 562–574. [Google Scholar] [CrossRef]

- Fan, F.; Zheng, Y.; Huang, Y.; Lu, Y.; Wang, Z.; Chen, B.; Zheng, Z. Combustion Kinetics of Biochar Prepared by Pyrolysis of Macadamia Shells. BioResources 2017, 12, 3918–3932. [Google Scholar] [CrossRef]

- Suman, S.; Gautam, S. Biochar Derived from Agricultural Waste Biomass Act as a Clean and Alternative Energy Source of Fossil Fuel Inputs. In Energy Systems and Environment; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Ferreira, A.F.; Soares Dias, A.P.; Silva, C.M.; Costa, M. Evaluation of Thermochemical Properties of Raw and Extracted Microalgae. Energy 2015, 92, 365–372. [Google Scholar] [CrossRef]

- No ISO 18134-3:2015; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Sample. ISO: London, UK, 2015.

- ISO 18122:2015; Solid Biofuels–Determination of Ash Content. ISO: London, UK, 2015.

- ISO 18123:2015; Solid Biofuels—Determination of the Content of Volatile Matter. ISO: London, UK, 2015.

- J.19P, S. EN 14918:2010; Solid Biofuels-Determination of Calorific Value. CSA: Singapore, 2010.

- Singh, B.; Dolk, M.M.; Shen, Q.; Camps-Arbestain, M. Biochar PH, Electrical Conductivity and Liming Potential. In Biochar: A Guide to Analytical Methods; CSIRO: Canberra, Australia, 2017; pp. 23–38. [Google Scholar]

- López-González, D.; Fernandez-Lopez, M.; Valverde, J.L.; Sanchez-Silva, L. Kinetic Analysis and Thermal Characterization of the Microalgae Combustion Process by Thermal Analysis Coupled to Mass Spectrometry. Appl. Energy 2014, 114, 227–237. [Google Scholar] [CrossRef]

- Liu, N.A.; Fan, W.; Dobashi, R.; Huang, L. Kinetic Modeling of Thermal Decomposition of Natural Cellulosic Materials in Air Atmosphere. J. Anal. Appl. Pyrolysis 2002, 63, 303–325. [Google Scholar] [CrossRef]

- Wang, X.; Zhai, M.; Wang, Z.; Dong, P.; Lv, W.; Liu, R. Carbonization and Combustion Characteristics of Palm Fiber. Fuel 2018, 227, 21–26. [Google Scholar] [CrossRef]

- Abdullah, H.; Wu, H. Biochar as a Fuel: 1. Properties and Grindability of Biochars Produced from the Pyrolysis of Mallee Wood under Slow-Heating Conditions. Energy Fuels 2009, 23, 4174–4181. [Google Scholar] [CrossRef]

- Lee, J.; Kim, K.H.; Kwon, E.E. Biochar as a Catalyst. Renew. Sustain. Energy Rev. 2017, 77, 70–79. [Google Scholar] [CrossRef]

- Cheng, F.; Li, X. Preparation and Application of Biochar-Based Catalysts for Biofuel Production. Catalysts 2018, 8, 346. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Liu, B.; Su, Z. A Critical Review on the Application and Recent Developments of Post-Modified Biochar in Supercapacitors. J. Clean. Prod. 2021, 310, 127428. [Google Scholar] [CrossRef]

- Deb, K. Multi-Objective Optimization Using Evolutionary Algorithms; Wiley Interscience Series in Systems and Optimization; John Wiley & Sons: New York, NY, USA, 2001; ISBN 978-0-471-87339-6. [Google Scholar]

- Gao, Y.; Wang, X.; Chen, Y.; Li, P.; Liu, H.; Chen, H. Pyrolysis of Rapeseed Stalk: Influence of Temperature on Product Characteristics and Economic Costs. Energy 2017, 122, 482–491. [Google Scholar] [CrossRef]

- Khiari, B.; Jeguirim, M. Pyrolysis of Grape Marc from Tunisian Wine Industry: Feedstock Characterization, Thermal Degradation and Kinetic Analysis. Energies 2018, 11, 730. [Google Scholar] [CrossRef]

- Ronsse, F.; van Hecke, S.; Dickinson, D.; Prins, W. Production and Characterization of Slow Pyrolysis Biochar: Influence of Feedstock Type and Pyrolysis Conditions. GCB Bioenergy 2012, 5, 104–115. [Google Scholar] [CrossRef]

- Wystalska, K.; Malińska, K.; Włodarczyk, R.; Chajczyk, O. Effects of Pyrolysis Parameters on the Yield and Properties of Biochar from Pelletized Sunflower Husk. E3S Web Conf. 2018, 44, 00197. [Google Scholar] [CrossRef]

- Zabaniotou, A.A.; Kantarelis, E.K.; Theodoropoulos, D.C. Sunflower Shells Utilization for Energetic Purposes in an Integrated Approach of Energy Crops: Laboratory Study Pyrolysis and Kinetics. Bioresour. Technol. 2008, 99, 3174–3181. [Google Scholar] [CrossRef] [PubMed]

- Anabel, F.; Celia, R.; Germán, M.; Rosa, R. Determination of Effective Moisture Diffusivity and Thermodynamic Properties Variation of Regional Wastes under Different Atmospheres. Case Stud. Therm. Eng. 2018, 12, 248–257. [Google Scholar] [CrossRef]

- Boukaous, N.; Abdelouahed, L.; Chikhi, M.; Meniai, A.H.; Mohabeer, C.; Bechara, T. Combustion of Flax Shives, Beech Wood, Pure Woody Pseudo-Components and Their Chars: A Thermal and Kinetic Study. Energies 2018, 11, 2146. [Google Scholar] [CrossRef]

- Fu, P.; Yi, W.; Bai, X.; Li, Z.; Hu, S.; Xiang, J. Effect of Temperature on Gas Composition and Char Structural Features of Pyrolyzed Agricultural Residues. Bioresour. Technol. 2011, 102, 8211–8219. [Google Scholar] [CrossRef] [PubMed]

- Botelho, T.; Costa, M.; Wilk, M.; Magdziarz, A. Evaluation of the Combustion Characteristics of Raw and Torrefied Grape Pomace in a Thermogravimetric Analyzer and in a Drop Tube Furnace. Fuel 2018, 212, 95–100. [Google Scholar] [CrossRef]

- Petrović, J.; Perišić, N.; Maksimović, J.D.; Maksimović, V.; Kragović, M.; Stojanović, M.; Laušević, M.; Mihajlović, M. Hydrothermal Conversion of Grape Pomace: Detailed Characterization of Obtained Hydrochar and Liquid Phase. J. Anal. Appl. Pyrolysis 2016, 118, 267–277. [Google Scholar] [CrossRef]

- Colantoni, A.; Evic, N.; Lord, R.; Retschitzegger, S.; Proto, A.R.; Gallucci, F.; Monarca, D. Characterization of Biochars Produced from Pyrolysis of Pelletized Agricultural Residues. Renew. Sustain. Energy Rev. 2016, 64, 187–194. [Google Scholar] [CrossRef]

- Van Krevelen, D.W.; Te Nijenhuis, K. Properties of Polymers: Their Correlation with Chemical Structure; Their Numerical Estimation and Prediction from Additive Group Contributions, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2009; ISBN 978-0-08-054819-7. [Google Scholar]

- Misse, S.E.; Brillard, A.; Mayandyshev, P.; Brilhac, J.F.; Obonou, M. Comparative Pyrolysis, Combustion, and Kinetic Modeling of Twelve Cameroonian Woody Biomass. Biomass Convers. Biorefinery 2022, 12, 3161–3181. [Google Scholar] [CrossRef]

- Oliveira, F.R.; Patel, A.K.; Jaisi, D.P.; Adhikari, S.; Lu, H.; Khanal, S.K. Environmental Application of Biochar: Current Status and Perspectives. Bioresour. Technol. 2017, 246, 110–122. [Google Scholar] [CrossRef] [PubMed]

- Waqas, M.; Aburiazaiza, A.S.; Miandad, R.; Rehan, M.; Barakat, M.A.; Nizami, A.S. Development of Biochar as Fuel and Catalyst in Energy Recovery Technologies. J. Clean. Prod. 2018, 188, 477–488. [Google Scholar] [CrossRef]

- Leng, L.; Huang, H.; Li, H.; Li, J.; Zhou, W. Biochar Stability Assessment Methods: A Review. Sci. Total Environ. 2019, 647, 210–222. [Google Scholar] [CrossRef]

- Crombie, K.; Mašek, O.; Sohi, S.P.; Brownsort, P.; Cross, A. The Effect of Pyrolysis Conditions on Biochar Stability as Determined by Three Methods. GCB Bioenergy 2013, 5, 122–131. [Google Scholar] [CrossRef]

- Pala, M.; Kantarli, I.C.; Buyukisik, H.B.; Yanik, J. Hydrothermal Carbonization and Torrefaction of Grape Pomace: A Comparative Evaluation. Bioresour. Technol. 2014, 161, 255–262. [Google Scholar] [CrossRef]

- Marczak, M.; Karczewski, M.; Makowska, D.; Burmistrz, P. Impact of the Temperature of Waste Biomass Pyrolysis on the Quality of the Obtained Biochar. Agric. Eng. 2016, 20, 115–124. [Google Scholar] [CrossRef]

- Yavorov, N.; Petrin, S.; Valchev, I.; Nenkova, S. Potential of Fast Growing Poplar, Willow and Paulownia for Bioenergy Production. Bulg. Chem. Commun. 2015, 47, 5–9. [Google Scholar]

- Dhyani, V.; Bhaskar, T. A Comprehensive Review on the Pyrolysis of Lignocellulosic Biomass. Renew. Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Angın, D. Effect of Pyrolysis Temperature and Heating Rate on Biochar Obtained from Pyrolysis of Safflower Seed Press Cake. Bioresour. Technol. 2013, 128, 593–597. [Google Scholar] [CrossRef]

- Nzediegwu, C.; Arshad, M.; Ulah, A.; Naeth, M.A.; Chang, S.X. Fuel, Thermal and Surface Properties of Microwave-Pyrolyzed Biochars Depend on Feedstock Type and Pyrolysis Temperature. Bioresour. Technol. 2021, 320, 124282. [Google Scholar] [CrossRef]

- Manyà, J.J.; González, B.; Azuara, M.; Arner, G. Ultra-Microporous Adsorbents Prepared from Vine Shoots-Derived Biochar with High CO2 Uptake and CO2/N2 Selectivity. Chem. Eng. J. 2018, 345, 631–639. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.C.; Li, W.Y.; Feng, J. Ash Contents and Ash-Forming Elements of Biomass and Their Significance for Solid Biofuel Combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical Properties of Solid Biofuels-Significance and Impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Anjum, M.; Miandad, R.; Waqas, M.; Tarar, A.I.; Alafif, Z.; Aburiazaiza, A.S.; Barakat, M.A.; Akhtar, T. Solid Waste Management in Saudi Arabia: A Review. J. Appl. Agric. Biotechnol. 2016, 1, 13–26. [Google Scholar]

- Mohamed, M.; Yusup, S.; Bustam, M.A. Synthesis of CaO-Based Sorbent from Biomass for CO2 Capture in Series of Calcination-Carbonation Cycle. Procedia Eng. 2016, 148, 78–85. [Google Scholar] [CrossRef]

- Conder, J.; Fic, K.; Ghimbeu, C.M. Supercapacitors (Electrochemical Capacitors). In Char and Carbon Materials Derived from Biomass: Production, Characterization and Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 383–427. [Google Scholar] [CrossRef]

- Brassard, P.; Godbout, S.; Lévesque, V.; Palacios, J.H.; Raghavan, V.; Ahmed, A.; Hogue, R.; Jeanne, T.; Verma, M. 4-Biochar for Soil Amendment. In Char and Carbon Materials Derived from Biomass: Production, Characterization and Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 109–146. ISBN 9780128148938. [Google Scholar] [CrossRef]

- EBC. European Biochar Certificate-Guidelines for a Sustainable Production of Biochar; Version 6.2E of 04th February 2016; Guidelines European Biochar Certificate for a Sustainable Production of Biochar 2; European Biochar Foundation (EBC): Arbaz, Switzerland, 2012; Available online: http://www.european-biochar.org/en/download (accessed on 27 February 2023). [CrossRef]

- Racioppi, M.; Tartaglia, M.; de la Rosa, J.M.; Marra, M.; Lopez-Capel, E.; Rocco, M. Response of Ancient and Modern Wheat Varieties to Biochar Application: Effect on Hormone and Gene Expression Involved in Germination and Growth. Agronomy 2020, 10, 5. [Google Scholar] [CrossRef]

| Biofuel (12 Variables) | Catalyst (6 Variables) | CO2 Sequestration and Soil Amendment (9 Variables) | Supercapacity (9 Variables) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Variable | Decision Goal | Best Value | Variable | Decision Goal | Best Value | Variable | Decision Goal | Best Value | Variable | Decision Goal | Best Value |

| Moisture (%) | lower | 4.49 | EDS/Content (%) of C, K, Ca, P | higher | 82.62%C, 10.05%K, 8.20%Ca, 2.27%P | EDS/Content (%) of C, K, Ca, P | higher | 82.62%C, 10.05%K, 8.20%Ca, 2.27%P | EDS/C, K, Ca, P Content (%) | higher | 82.62%C, 10.05%K, 8.20%Ca, 2.27%P |

| Ash (%, db) | lower | 1.29 | |||||||||

| HHV (MJ/kg) | lower | 33.34 | |||||||||

| Ashes (%) | higher | 1.36 | Ultimate analysis/Content (%) of C | higher | 82.35 | Ultimate analysis/Content (%) of C | higher | 82.35 | Ultimate analysis/Content (%) of C | higher | 82.35 |

| E (kJ/mol) stage 2—10, 20, 30, 40 °C | lower | 94.1, 99.71, 84.4, 80.2 | Specific surface area (m2/g) | higher | 331.62 | Specific surface area (m2/g) | higher | 331.62 | Specific surface area (m2/g) | higher | 331.62 |

| E (kJ/mol) stage 3—10, 20, 30, 40 °C | lower | 96.73, 100.34, 105.4, 99.5 | Bulk density (g/cm3) | higher | 0.4455 | Bulk density (g/cm3) | higher | 0.4455 | |||

| EC (μS/cm) | higher | 1960 | EC (μS/cm) | higher | 1960 | ||||||

| pH | higher | 11.08 | Salt content (ppm) | higher | 980 | ||||||

| Type of Biomass | Colza | Cherry Stones | Peach Stones | Grape Pomace | Softwood with Bark | Sunflower Husks |

|---|---|---|---|---|---|---|

| Biochar derived from different feedstock | ||||||

| Biomass (g) | 1.05 | 1.06 | 1.05 | 1.06 | 1.05 | 1.03 |

| Biochar (g) | 0.30 | 0.31 | 0.34 | 0.37 | 0.28 | 0.33 |

| Biochar yield (%), present work | 28.66 ± 0.14 | 29.24 ± 0.73 | 32.26 ± 1.32 | 35.07 ± 0.40 | 26.35 ± 1.09 | 31.48 ± 0.77 |

| Biochar yield (%), | 28–30 [36] | 27.50 [14] 27.00 [13] | 33.56 [11] | 39.68 [37] | 27.00 [38] | 31.59 [39] |

| EDS analysis | ||||||

| Carbon (%) | 78.67 | 76.71 | 76.17 | 73.94 | 82.62 | 65.42 |

| Oxygen (5) | 15.75 | 14.14 | 19.41 | 17.08 | 16.66 | 19.17 |

| Ash (%) | 5.58 | 9.14 | 13.32 | 8.99 | 0.73 | 15.41 |

| Descending order of ash component (%) | K (2.88) > Ca (2.35) > Na (0.16) > Mg (0.15) > S (0.03) > P (0.01) | K (4.30) > P (2.27) > Ca (1.58) > Mg (0.99) > Si (0.01) | K (10.05) > Si (1.52) > Ca (0.45) > Al (0.43) > Fe (0.40) > Mg, P (0.21) > S (0.04) > Na (0.02) | K (4.23) > Ca (2.97) > P (0.80) > Mg (0.32) > Si (0.28) > Al (0.16) | Si, K, Al (0.06) > Ca (0.55) | Ca (8.20) > K (6.27) > Mg (0.43) > S (0.42) > Na (0.05) > P (0.04) |

| Biochar | Colza | Cherry Stones | Peach Stones | Grape Pomace | Softwood | Sunflower Husks |

|---|---|---|---|---|---|---|

| Heating rate 10 °C/min | ||||||

| Stage 2 | ||||||

| E (kJ/mol) | 95.21 | 111.9 | 119.2 | 125.2 | 131.7 | 94.1 |

| A (1/s) | 1.44 × 105 | 2.69 × 106 | 6.06 × 106 | 1.19 × 108 | 8.92 × 107 | 9.1 × 104 |

| R2 | 0.9906 | 0.9934 | 0.9904 | 0.9900 | 0.9913 | 0.9848 |

| Stage 3 | ||||||

| E (kJ/mol) | 96.73 | 209.4 | 305.4 | 148.9 | 134.97 | 274.3 |

| A (1/s) | 2.69 × 106 | 1.21 × 1016 | 2.35 × 1019 | 5.40 × 108 | 3.7 × 107 | 1.42 × 1011 |

| R2 | 0.9782 | 0.9935 | 0.9868 | 0.9926 | 0.9543 | 0.9703 |

| Heating rate 20 °C/min | ||||||

| Stage 2 | ||||||

| E (kJ/mol) | 99.71 | 119.5 | 112.9 | 125.7 | 149.7 | 114.9 |

| A (1/s) | 1.20 × 106 | 1.79 × 107 | 2.31 × 106 | 7.62 × 107 | 5.86 × 109 | 2.62 × 107 |

| R2 | 0.9907 | 0.9826 | 0.9911 | 0.9944 | 0.9928 | 0.9914 |

| Stage 3 | ||||||

| E (kJ/mol) | 100.34 | 208.9 | 231.9 | 172.3 | 196.9 | 166.8 |

| A (1/s) | 2.514 × 105 | 2.76 × 1012 | 3.03 × 1013 | 8.47 × 109 | 9.92 × 1011 | 1.85 × 1010 |

| R2 | 0.9833 | 0.9645 | 0.9684 | 0.9909 | 0.9931 | 0.9674 |

| Heating rate 30 °C/min | ||||||

| Stage 2 | ||||||

| E (kJ/mol) | 86.3 | 110.6 | 84.4 | 91.6 | 160.9 | 96.9 |

| A (1/s) | 4.45 × 104 | 3.73 × 106 | 6.16 × 103 | 4.64 × 104 | 6.61 × 1010 | 3.32 × 105 |

| R2 | 0.9976 | 0.9948 | 0.9862 | 0.9953 | 0.9929 | 0.9831 |

| Stage 3 | ||||||

| E (kJ/mol) | 478.30 | 118.1 | 105.4 | 283.2 | 157.1 | 276.2 |

| A (1/s) | 7.26 × 1031 | 3.67 × 105 | 7.95 × 103 | 4.25 × 1016 | 9.3 × 108 | 4.33 × 1017 |

| R2 | 0.9925 | 0.9919 | 0.9828 | 0.9933 | 0.9901 | 0.9775 |

| Heating rate 40 °C/min | ||||||

| Stage 2 | ||||||

| E (kJ/mol) | 102.4 | 116.6 | 86.3 | 85.6 | 86.9 | 80.2 |

| A (1/s) | 4.39 × 106 | 1.62 × 107 | 7.14 × 103 | 1.97 × 104 | 1.32 × 104 | 1.08 × 104 |

| R2 | 0.9951 | 0.9915 | 0.9909 | 0.9943 | 0.988 | 0.9846 |

| Stage 3 | ||||||

| E (kJ/mol) | 112.6 | 109.4 | 463.5 | 99.5 | 562.9 | 429.9 |

| A (1/s) | 9.76 × 105 | 1.21 × 105 | 5.52 × 1026 | 9.87 × 103 | 1.12 × 1034 | 4.99 × 1026 |

| R2 | 0.9769 | 0.9934 | 0.9833 | 0.9935 | 0.9759 | 0.964 |

| Biochar | ||||||

|---|---|---|---|---|---|---|

| Colza | Cherry Stones | Peach Stones | Grape Pomace | Softwood | Sunflower Husks | |

| Proximate analysis (wt. %) | ||||||

| Moisture | 5.32 | 4.49 | 4.95 | 2.84 | 5.38 | 9.33 |

| Ashes (db) | 7.08 | 4.47 | 1.92 | 12.44 | 1.29 | 4.83 |

| Volatile matter (db) | 32.10 | 25.86 | 30.57 | 17.91 | 40.49 | 44.13 |

| Fixed carbon * (db) | 55.51 | 65.18 | 62.57 | 66.81 | 52.85 | 41.71 |

| Ultimate analysis (wt. %, db) | ||||||

| C | 73.52 | 67.01 | 81.56 | 77.61 | 82.35 | 76.76 |

| H | 3.66 | 3.22 | 3.61 | 3.52 | 3.78 | 3.50 |

| N | 1.97 | 4.28 | <0.10 | 2.64 | 0.97 | 2.24 |

| O* | 8.25 | 16.33 | 7.66 | 0.75 | 6.04 | 3.13 |

| S | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 |

| Cl | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 |

| HHV, MJ/kg | 24.94 | 28.62 | 33.34 | 28.11 | 30.88 | 31.05 |

| Specific surface area (m2/g), SBET | 252.30 | 265.74 | 306.72 | 293.27 | 331.62 | 278.25 |

| Bulk density (g/cm3) | 0.1585 | 0.4455 | 0.4301 | 0.3737 | 0.2028 | 0.2700 |

| pH | 9.70 | 9.55 | 9.10 | 11.08 | 8.38 | 9.93 |

| EC (μS/cm) | 1015 | 372 | 84 | 1960 | 56 | 897 |

| Salt content (ppm) | 508 | 186 | 42 | 980 | 28 | 448 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrova, T.; Naydenova, I.; Ribau, J.; Ferreira, A.F. Biochar from Agro-Forest Residue: Application Perspective Based on Decision Support Analysis. Appl. Sci. 2023, 13, 3240. https://doi.org/10.3390/app13053240

Petrova T, Naydenova I, Ribau J, Ferreira AF. Biochar from Agro-Forest Residue: Application Perspective Based on Decision Support Analysis. Applied Sciences. 2023; 13(5):3240. https://doi.org/10.3390/app13053240

Chicago/Turabian StylePetrova, Tsvetelina, Iliyana Naydenova, João Ribau, and Ana F. Ferreira. 2023. "Biochar from Agro-Forest Residue: Application Perspective Based on Decision Support Analysis" Applied Sciences 13, no. 5: 3240. https://doi.org/10.3390/app13053240

APA StylePetrova, T., Naydenova, I., Ribau, J., & Ferreira, A. F. (2023). Biochar from Agro-Forest Residue: Application Perspective Based on Decision Support Analysis. Applied Sciences, 13(5), 3240. https://doi.org/10.3390/app13053240