Impact of Interdependencies: Multi-Component System Perspective toward Predictive Maintenance Based on Machine Learning and XAI

Abstract

1. Introduction

2. Background

2.1. Predictive Maintenance

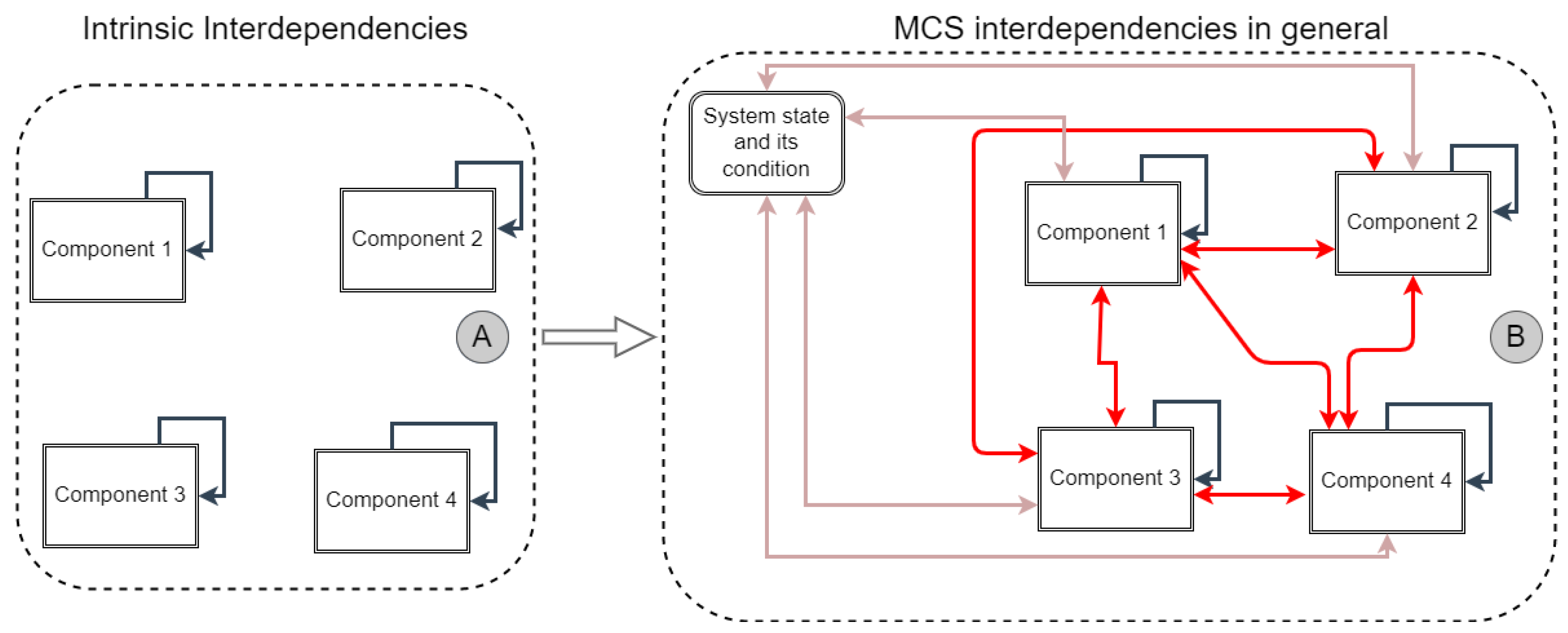

2.2. Multi Component Systems

2.3. Visual Analytics and XAI

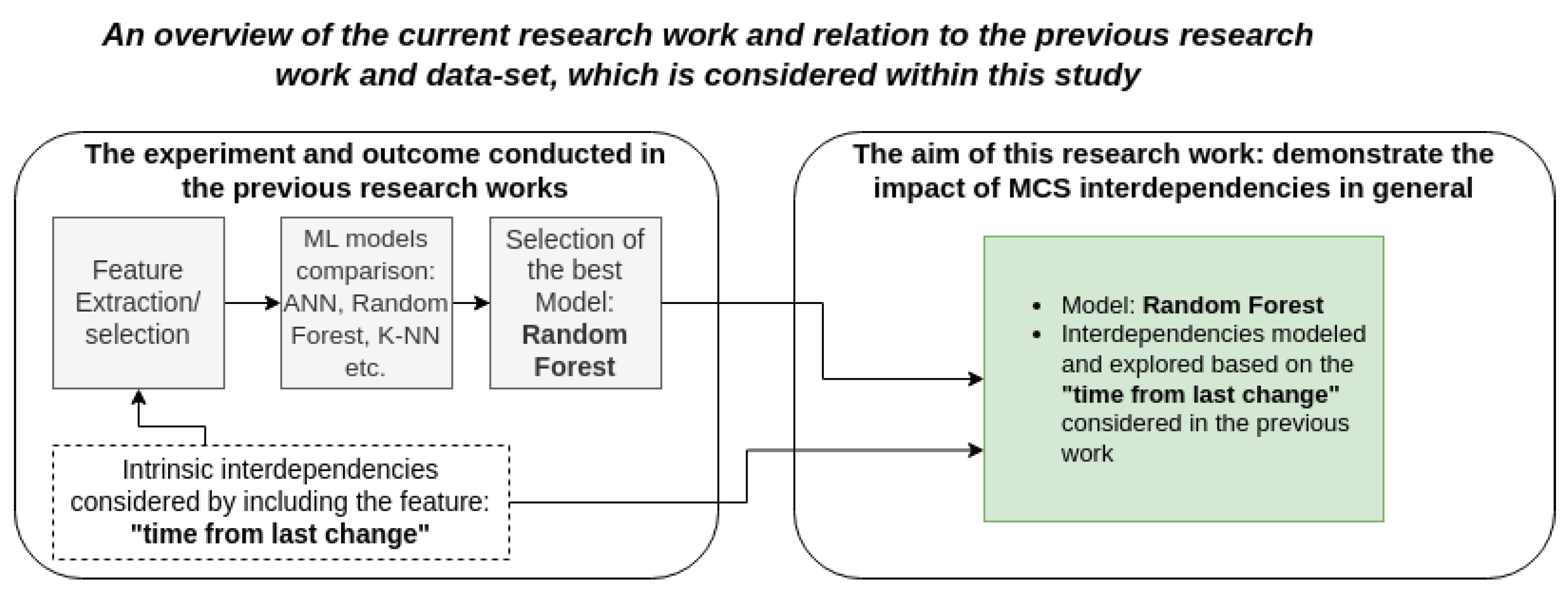

3. Materials and Methods

3.1. Data Set and Problem Definition

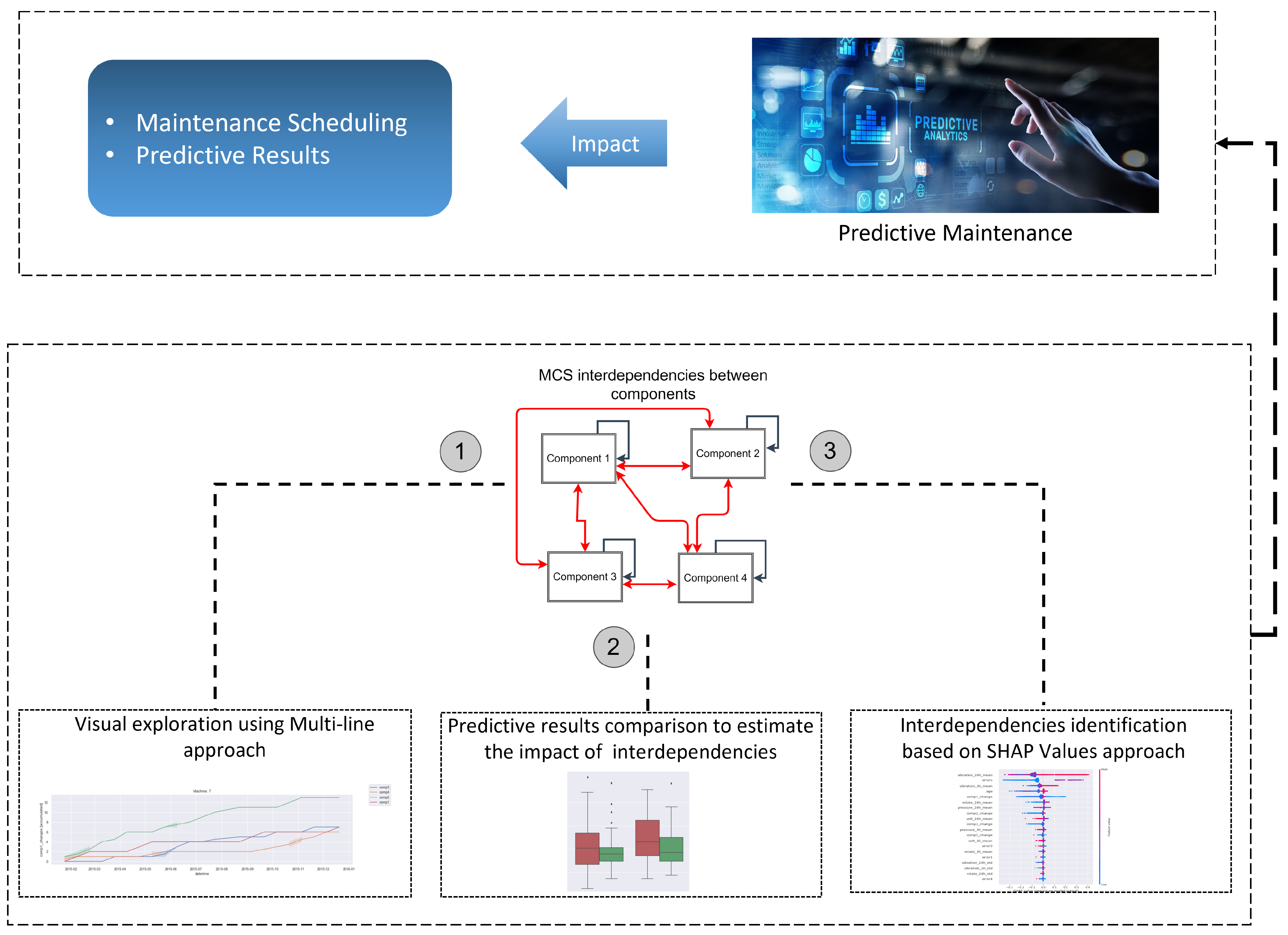

3.2. Proposed Framework

4. Experimental Results

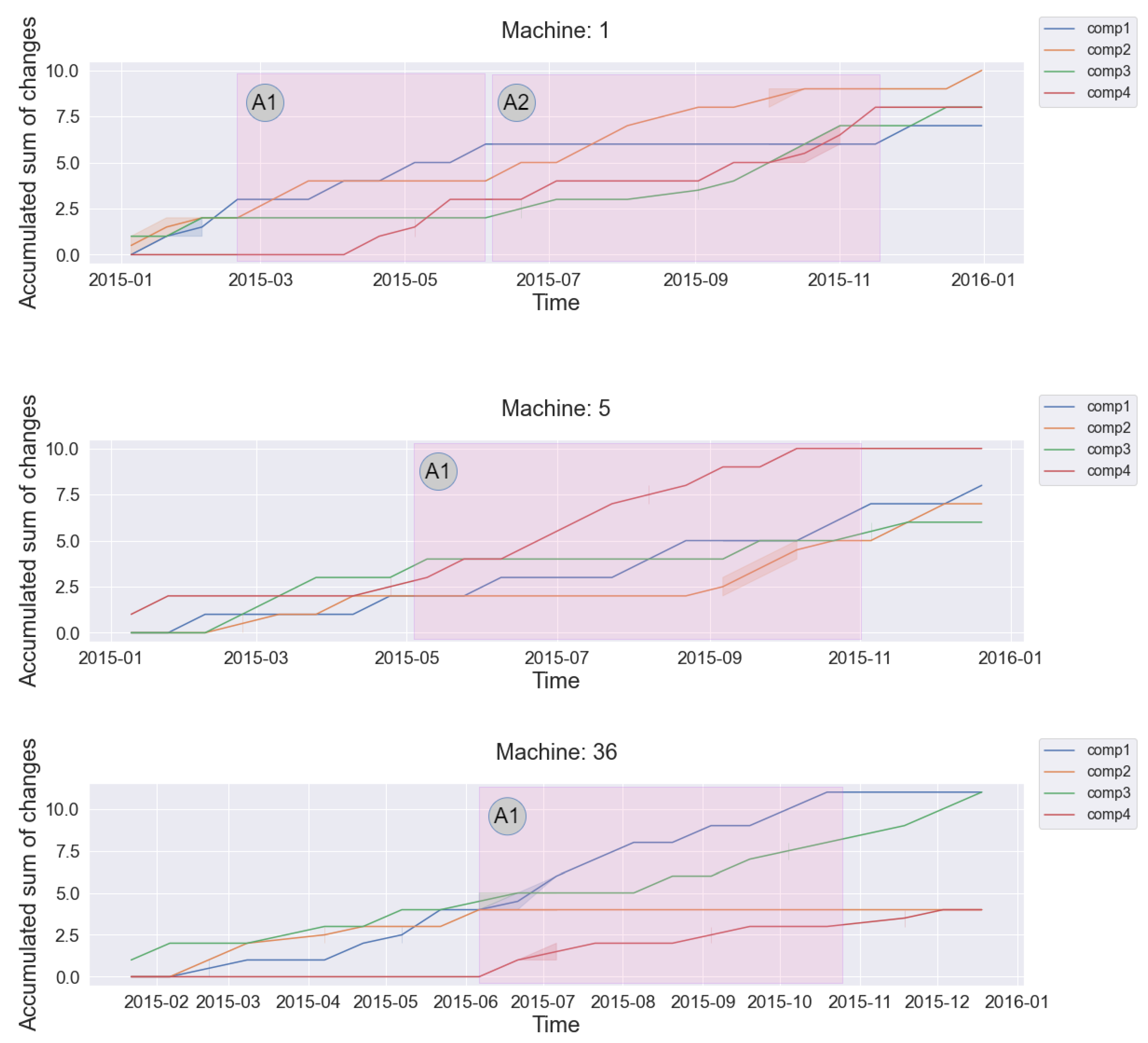

4.1. Visual Exploration of Interdependencies

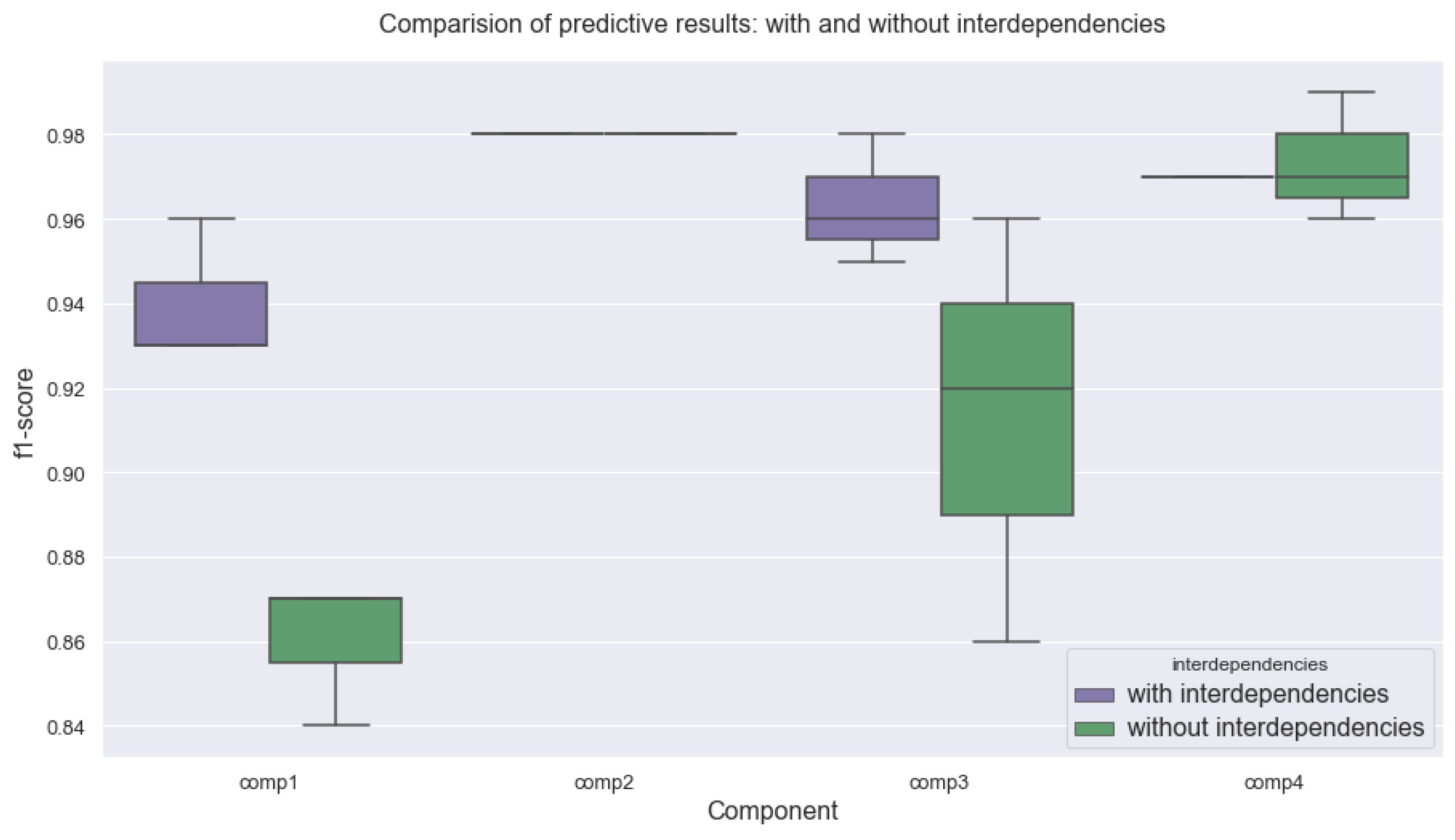

4.2. Interdependencies Impact on Predictive Results

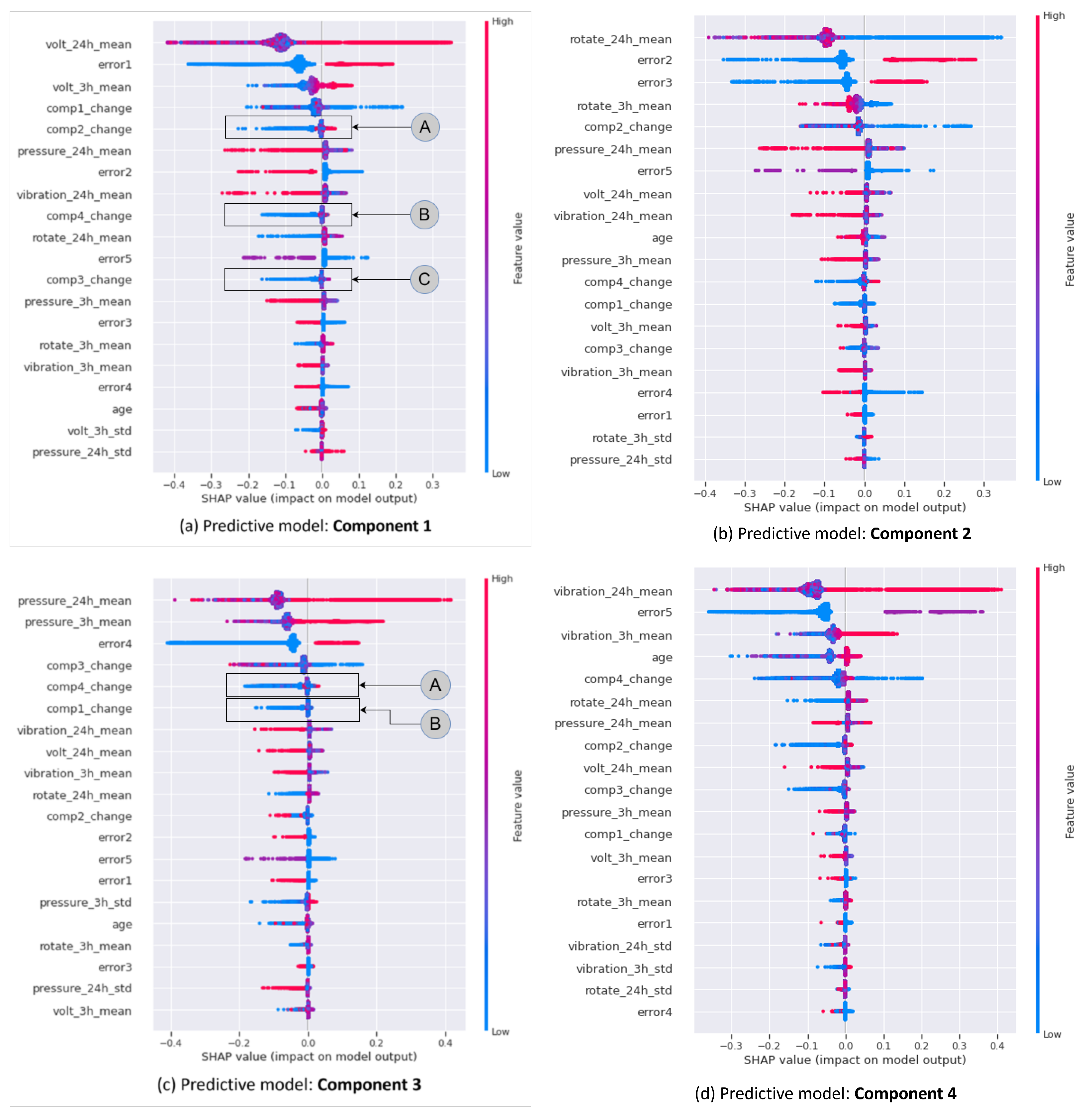

4.3. Interdependencies Exploration Using SHAP

5. Discussion

5.1. Theoretical Contributions

5.2. Implications for Practice

5.3. Limitations and Future Research Direction

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thalmann, S.; Fessl, A.; Pammer-Schindler, V. How large manufacturing firms understand the impact of digitization: A Learning Perspective. In Proceedings of the 53rd Hawaii International Conference on System Sciences, Maui, HI, USA, 7–10 January 2020. [Google Scholar]

- Assaf, R.; Do, P.; Scarf, P.; Nefti-Meziani, S. Wear rate-state interaction modelling for a multi-component system: Models and an experimental platform. IFAC-PapersOnLine 2016, 49, 232–237. [Google Scholar] [CrossRef]

- Bian, L.; Gebraeel, N. Stochastic framework for partially degradation systems with continuous component degradation-rate-interactions. Nav. Res. Logist. (NRL) 2014, 61, 286–303. [Google Scholar] [CrossRef]

- Gashi, M.; Thalmann, S. Taking Complexity into Account: A Structured Literature Review on Multi-component Systems in the Context of Predictive Maintenance. In Proceedings of the Information Systems-16th European, Mediterranean, and Middle Eastern Conference, EMCIS 2019, Dubai, United Arab Emirates, 9–10 December 2019; Springer: Cham, Switzerland, 2020; pp. 31–44. [Google Scholar]

- Van Horenbeek, A.; Pintelon, L. A dynamic predictive maintenance policy for complex multi-component systems. Reliab. Eng. Syst. Saf. 2013, 120, 39–50. [Google Scholar] [CrossRef]

- Kaiser, R.; Thalmann, S.; Pammer-Schindler, V. An investigation of knowledge protection practices in inter-organisational collaboration: Protecting specialised engineering knowledge with a practice based on grey-box modelling. VINE J. Inf. Knowl. Manag. Syst. 2020, 51, 713–731. [Google Scholar] [CrossRef]

- Thalmann, S.; Gursch, H.G.; Suschnigg, J.; Gashi, M.; Ennsbrunner, H.; Fuchs, A.K.; Schreck, T.; Mutlu, B.; Mangler, J.; Kappl, G.; et al. Cognitive decision support for industrial product life cycles: A position paper. In Proceedings of the 11 th International Conference on Advanced Cognitive Technologies and Applications, Venice, Italy, 5–9 May 2019; pp. 3–9. [Google Scholar]

- Gashi, M.; Ofner, P.; Ennsbrunner, H.; Thalmann, S. Dealing with missing usage data in defect prediction: A case study of a welding supplier. Comput. Ind. 2021, 132, 103505. [Google Scholar] [CrossRef]

- Gashi, M.; Mutlu, B.; Lindstaedt, S.; Thalmann, S. Decision support for multi-component systems: Visualizing interdependencies for predictive maintenance. In Proceedings of the 55rd Hawaii International Conference on System Sciences, Maui, HI, USA, 4–7 January 2022. [Google Scholar]

- Cardoso, D.; Ferreira, L. Application of Predictive Maintenance Concepts Using Artificial Intelligence Tools. Appl. Sci. 2021, 11, 18. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, D.; Wang, H. Data-driven methods for predictive maintenance of industrial equipment: A survey. IEEE Syst. J. 2019, 13, 2213–2227. [Google Scholar] [CrossRef]

- Susto, G.A.; Schirru, A.; Pampuri, S.; McLoone, S.; Beghi, A. Machine learning for predictive maintenance: A multiple classifier approach. IEEE Trans. Ind. Inform. 2014, 11, 812–820. [Google Scholar] [CrossRef]

- Selcuk, S. Predictive maintenance, its implementation and latest trends. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1670–1679. [Google Scholar] [CrossRef]

- Thalmann, S.; Mangler, J.; Schreck, T.; Huemer, C.; Streit, M.; Pauker, F.; Weichhart, G.; Schulte, S.; Kittl, C.; Pollak, C.; et al. Data analytics for industrial process improvement a vision paper. In Proceedings of the 2018 IEEE 20th Conference on Business Informatics (CBI), Vienna, Austria, 11–13 July 2018; IEEE: Piscataway, NJ, USA, 2018; Volume 2, pp. 92–96. [Google Scholar]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive Maintenance and Intelligent Sensors in Smart Factory. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef] [PubMed]

- King, R.; Curran, K. Predictive Maintenance for Vibration-Related failures in the Semi-Conductor Industry. J. Comput. Eng. Inf. Technol. 2019, 8, 1. [Google Scholar]

- Dogan, A.; Birant, D. Machine learning and data mining in manufacturing. Expert Syst. Appl. 2020, 166, 114060. [Google Scholar] [CrossRef]

- Durbhaka, G.K.; Selvaraj, B. Predictive maintenance for wind turbine diagnostics using vibration signal analysis based on collaborative recommendation approach. In Proceedings of the 2016 International Conference on Advances in Computing, Communications and Informatics (ICACCI), Jaipur, India, 21–24 September 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1839–1842. [Google Scholar]

- Sipos, R.; Fradkin, D.; Moerchen, F.; Wang, Z. Log-based predictive maintenance. In Proceedings of the 20th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, New York, NY, USA, 24–27 August 2014; pp. 1867–1876. [Google Scholar]

- Gashi, M.; Gursch, H.; Hinterbichler, H.; Pichler, S.; Lindstaedt, S.; Thalmann, S. MEDEP: Maintenance Event Detection for Multivariate Time Series Based on the PELT Approach. Sensors 2022, 22, 2837. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, K.T.; Medjaher, K. A new dynamic predictive maintenance framework using deep learning for failure prognostics. Reliab. Eng. Syst. Saf. 2019, 188, 251–262. [Google Scholar] [CrossRef]

- Chen, C.; Wang, C.; Lu, N.; Jiang, B.; Xing, Y. A data-driven predictive maintenance strategy based on accurate failure prognostics. Eksploat. I Niezawodn. 2021, 23, 387–394. [Google Scholar] [CrossRef]

- Sun, Y.; Ma, L.; Mathew, J.; Wang, W.; Zhang, S. Mechanical systems hazard estimation using condition monitoring. Mech. Syst. Signal Process. 2006, 20, 1189–1201. [Google Scholar] [CrossRef]

- Lindley, D.V.; Singpurwalla, N.D. Multivariate distributions for the life lengths of components of a system sharing a common environment. J. Appl. Probab. 1986, 23, 418–431. [Google Scholar] [CrossRef]

- Bektas, O.; Jones, J.A.; Sankararaman, S.; Roychoudhury, I.; Goebel, K. A neural network filtering approach for similarity-based remaining useful life estimation. Int. J. Adv. Manuf. Technol. 2019, 101, 87–103. [Google Scholar] [CrossRef]

- Feng, Q.; Jiang, L.; Coit, D.W. Reliability analysis and condition-based maintenance of systems with dependent degrading components based on thermodynamic physics-of-failure. Int. J. Adv. Manuf. Technol. 2016, 86, 913–923. [Google Scholar] [CrossRef]

- Nguyen, K.A.; Do, P.; Grall, A. Multi-level predictive maintenance for multi-component systems. Reliab. Eng. Syst. Saf. 2015, 144, 83–94. [Google Scholar] [CrossRef]

- Nicolai, R.P.; Dekker, R. Optimal maintenance of multi-component systems: A review. In Complex System Maintenance Handbook; Springer: London, UK, 2008; pp. 263–286. [Google Scholar]

- Alaswad, S.; Xiang, Y. A review on condition-based maintenance optimization models for stochastically deteriorating system. Reliab. Eng. Syst. Saf. 2017, 157, 54–63. [Google Scholar] [CrossRef]

- Keizer, M.C.O.; Flapper, S.D.P.; Teunter, R.H. Condition-based maintenance policies for systems with multiple dependent components: A review. Eur. J. Oper. Res. 2017, 261, 405–420. [Google Scholar] [CrossRef]

- Yin, S.; Ding, S.X.; Zhou, D. Diagnosis and prognosis for complicated industrial systems—Part I. IEEE Trans. Ind. Electron. 2016, 63, 2501–2505. [Google Scholar] [CrossRef]

- Zhou, F.; Lin, X.; Liu, C.; Zhao, Y.; Xu, P.; Ren, L.; Xue, T.; Ren, L. A survey of visualization for smart manufacturing. J. Vis. 2019, 22, 419–435. [Google Scholar] [CrossRef]

- Liu, S.; Cui, W.; Wu, Y.; Liu, M. A survey on information visualization: Recent advances and challenges. Vis. Comput. 2014, 30, 1373–1393. [Google Scholar] [CrossRef]

- Gashi, M.; Mutlu, B.; Suschnigg, J.; Ofner, P.; Pichler, S.; Schreck, T. Interactive Visual Exploration of defect prediction in industrial setting through explainable models based on SHAP values. In Proceedings of the IEEE VIS 2020, Salt Lake City, UT, USA, 25–30 October 2020. [Google Scholar]

- Van Lent, M.; Fisher, W.; Mancuso, M. An explainable artificial intelligence system for small-unit tactical behavior. In Proceedings of the National Conference on Artificial Intelligence, San Jose, CA, USA, 25–29 July 2004; AAAI Press: Menlo Park, CA, USA; MIT Press: Cambridge, MA, USA; London, UK, 1999; pp. 900–907. [Google Scholar]

- Adadi, A.; Berrada, M. Peeking inside the black-box: A survey on explainable artificial intelligence (XAI). IEEE Access 2018, 6, 52138–52160. [Google Scholar] [CrossRef]

- Caruana, R.; Lou, Y.; Gehrke, J.; Koch, P.; Sturm, M.; Elhadad, N. Intelligible models for healthcare: Predicting pneumonia risk and hospital 30-day readmission. In Proceedings of the 21th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Sydney, Australia, 10–13 August 2015; pp. 1721–1730. [Google Scholar]

- Holzinger, A.; Biemann, C.; Pattichis, C.S.; Kell, D.B. What do we need to build explainable AI systems for the medical domain? arXiv 2017, arXiv:1712.09923. [Google Scholar]

- Tan, S.; Caruana, R.; Hooker, G.; Lou, Y. Detecting bias in black-box models using transparent model distillation. arXiv 2017, arXiv:1710.06169. [Google Scholar]

- Jiarpakdee, J.; Tantithamthavorn, C.; Dam, H.K.; Grundy, J. An empirical study of model-agnostic techniques for defect prediction models. IEEE Trans. Softw. Eng. 2020, 48, 166–185. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.I. A unified approach to interpreting model predictions. In Proceedings of the 31st International Conference on Neural Information Processing Systems, Long Beach, CA, USA, 4–9 December 2017; pp. 4768–4777. [Google Scholar]

- Shapley, L.S.; Kuhn, H.; Tucker, A. Contributions to the Theory of Games. Ann. Math. Stud. 1953, 28, 307–317. [Google Scholar]

- Lundberg, S.M.; Erion, G.G.; Lee, S.I. Consistent individualized feature attribution for tree ensembles. arXiv 2018, arXiv:1802.03888. [Google Scholar]

- Predictive Maintenance Modelling Guide Data Sets. Available online: https://gallery.azure.ai/Experiment/Predictive-Maintenance-Implementation-Guide-Data-Sets-1 (accessed on 12 August 2021).

- Batista, G.E.; Bazzan, A.L.; Monard, M.C. Balancing Training Data for Automated Annotation of Keywords: A Case Study. In Proceedings of the WOB, Macaé, RJ, Brazil, 3–5 December 2003; pp. 10–18. [Google Scholar]

- Chawla, N.V.; Bowyer, K.W.; Hall, L.O.; Kegelmeyer, W.P. SMOTE: Synthetic minority over-sampling technique. J. Artif. Intell. Res. 2002, 16, 321–357. [Google Scholar] [CrossRef]

- Wilson, D.L. Asymptotic properties of nearest neighbor rules using edited data. IEEE Trans. Syst. Man Cybern. 1972, SMC-2, 408–421. [Google Scholar] [CrossRef]

- Buitinck, L.; Louppe, G.; Blondel, M.; Pedregosa, F.; Mueller, A.; Grisel, O.; Niculae, V.; Prettenhofer, P.; Gramfort, A.; Grobler, J.; et al. API design for machine learning software: Experiences from the scikit-learn project. In Proceedings of the ECML PKDD Workshop: Languages for Data Mining and Machine Learning, Prague, Czech Republic, 23–27 September 2013; pp. 108–122. [Google Scholar]

- Keim, D.A.; Mansmann, F.; Stoffel, A.; Ziegler, H. Visual analytics. In Encyclopedia of Database Systems; Springer: Berlin/Heidelberg, Germany, 2009; pp. 3341–3346. [Google Scholar]

- Tallarida, R.J.; Murray, R.B. Chi-square test. In Manual of Pharmacologic Calculations; Springer: Berlin/Heidelberg, Germany, 1987; pp. 140–142. [Google Scholar]

- Leevy, J.L.; Khoshgoftaar, T.M.; Bauder, R.A.; Seliya, N. A survey on addressing high-class imbalance in big data. J. Big Data 2018, 5, 1–30. [Google Scholar] [CrossRef]

- Kumar, A.; Shankar, R.; Choudhary, A.; Thakur, L.S. A big data MapReduce framework for fault diagnosis in cloud-based manufacturing. Int. J. Prod. Res. 2016, 54, 7060–7073. [Google Scholar] [CrossRef]

- Vukovic, M.; Thalmann, S. Causal discovery in manufacturing: A structured literature review. J. Manuf. Mater. Process. 2022, 6, 10. [Google Scholar] [CrossRef]

| Datetime | machineID | Volt | Rotate | Pressure | Vibration |

|---|---|---|---|---|---|

| 1 January 2015 06:00 | 1 | 176.22 | 418.5 | 113.08 | 45.09 |

| 1 January 2015 07:00 | 1 | 162.88 | 402.75 | 95.46 | 43.41 |

| 1 January 2015 08:00 | 1 | 170.99 | 527.35 | 75.24 | 34.18 |

| Data Types | Nr. of Records | Features |

|---|---|---|

| Machine conditions and | ||

| usage data | 8761 | datetime, voltage, rotation, pressure, vibration |

| failure logs | 761 | datetime, machineID, failure |

| error logs | 3919 | datetime, machineID, errorID |

| maintenance logs | 3286 | datetime, machineID, comp |

| machine metadata | 100 | machineID, Model, Age |

| Random Forest Classifier | ||||

|---|---|---|---|---|

| Failure | Precision | Recall | F1-Score | Support |

| None | 1.00 | 1.00 | 1.00 | 47,997 |

| comp1 | 0.96 | 0.89 | 0.93 | 238 |

| comp2 | 1.00 | 0.94 | 0.97 | 381 |

| comp3 | 0.98 | 0.92 | 0.95 | 167 |

| comp4 | 1.00 | 0.93 | 0.96 | 227 |

| macro avg | 0.99 | 0.94 | 0.96 | 49,010 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gashi, M.; Mutlu, B.; Thalmann, S. Impact of Interdependencies: Multi-Component System Perspective toward Predictive Maintenance Based on Machine Learning and XAI. Appl. Sci. 2023, 13, 3088. https://doi.org/10.3390/app13053088

Gashi M, Mutlu B, Thalmann S. Impact of Interdependencies: Multi-Component System Perspective toward Predictive Maintenance Based on Machine Learning and XAI. Applied Sciences. 2023; 13(5):3088. https://doi.org/10.3390/app13053088

Chicago/Turabian StyleGashi, Milot, Belgin Mutlu, and Stefan Thalmann. 2023. "Impact of Interdependencies: Multi-Component System Perspective toward Predictive Maintenance Based on Machine Learning and XAI" Applied Sciences 13, no. 5: 3088. https://doi.org/10.3390/app13053088

APA StyleGashi, M., Mutlu, B., & Thalmann, S. (2023). Impact of Interdependencies: Multi-Component System Perspective toward Predictive Maintenance Based on Machine Learning and XAI. Applied Sciences, 13(5), 3088. https://doi.org/10.3390/app13053088