Design of a Quick-Pressing and Self-Locking Temporary Fastener for Easy Automatic Installation and Removal

Abstract

1. Introduction

2. Function and Principal Innovation

2.1. Function and Structure Innovation

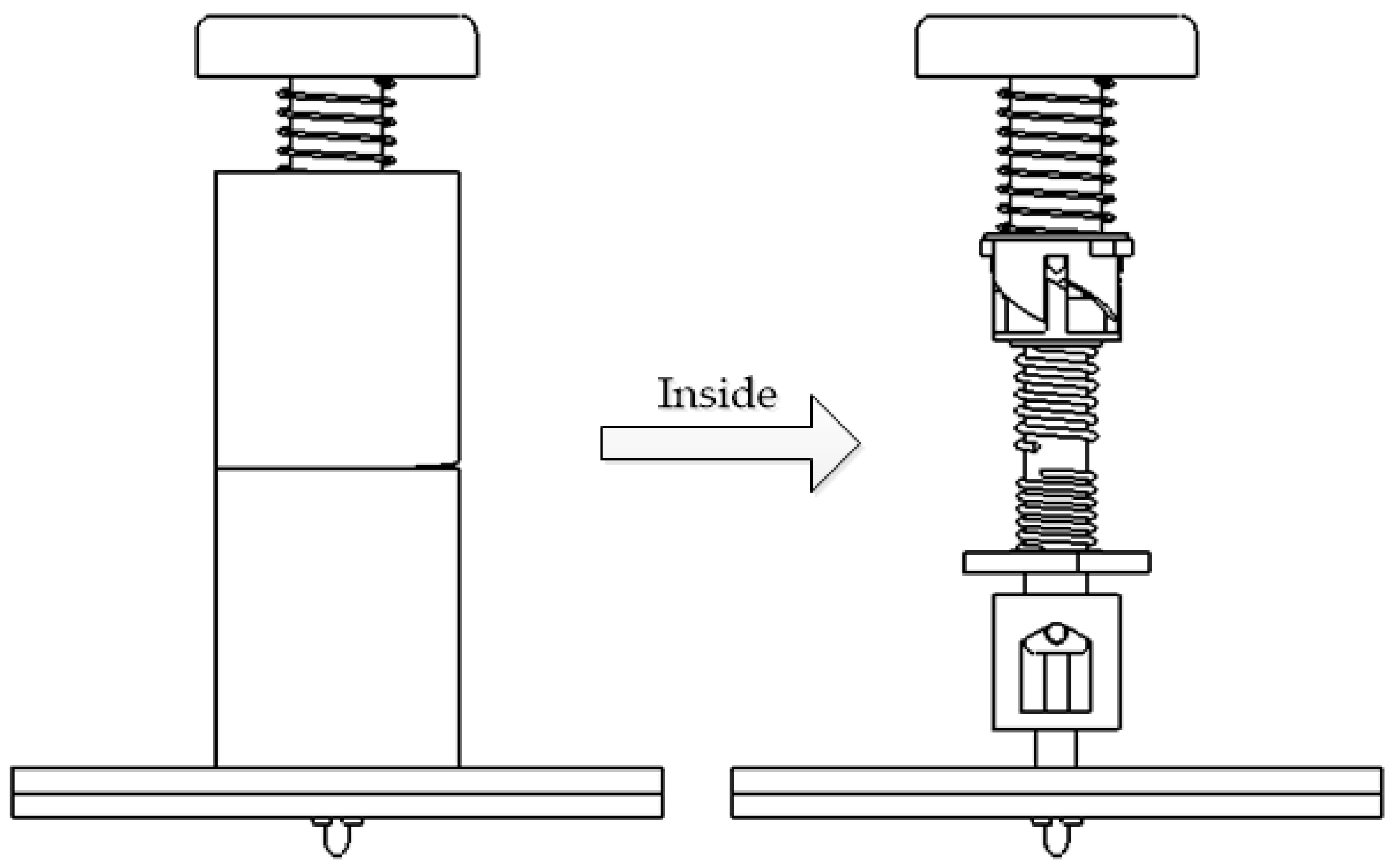

2.2. Working Principle of Fasteners and Steps of Loading and Unloading

2.2.1. Working Principle

2.2.2. Fast Installation and Removing Method of Fasteners

- (1)

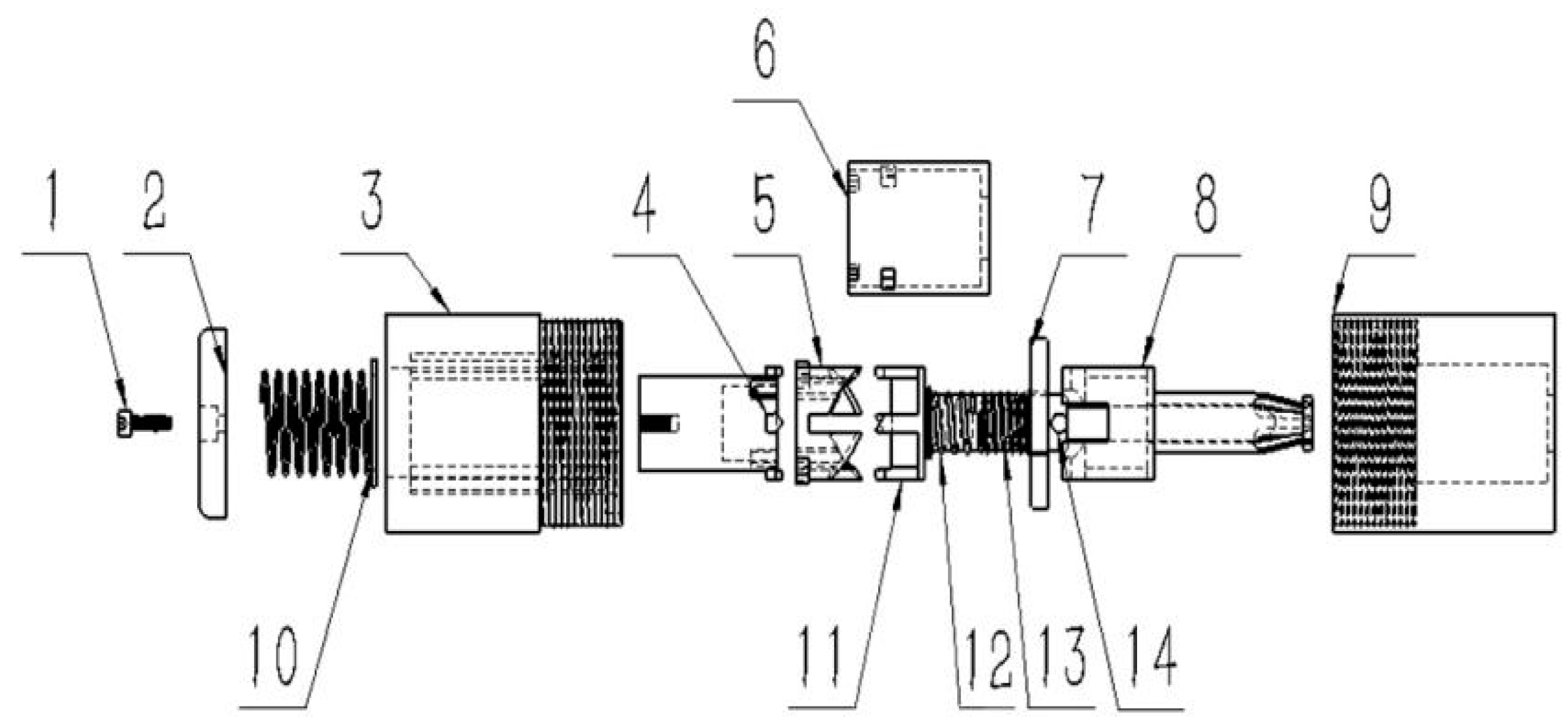

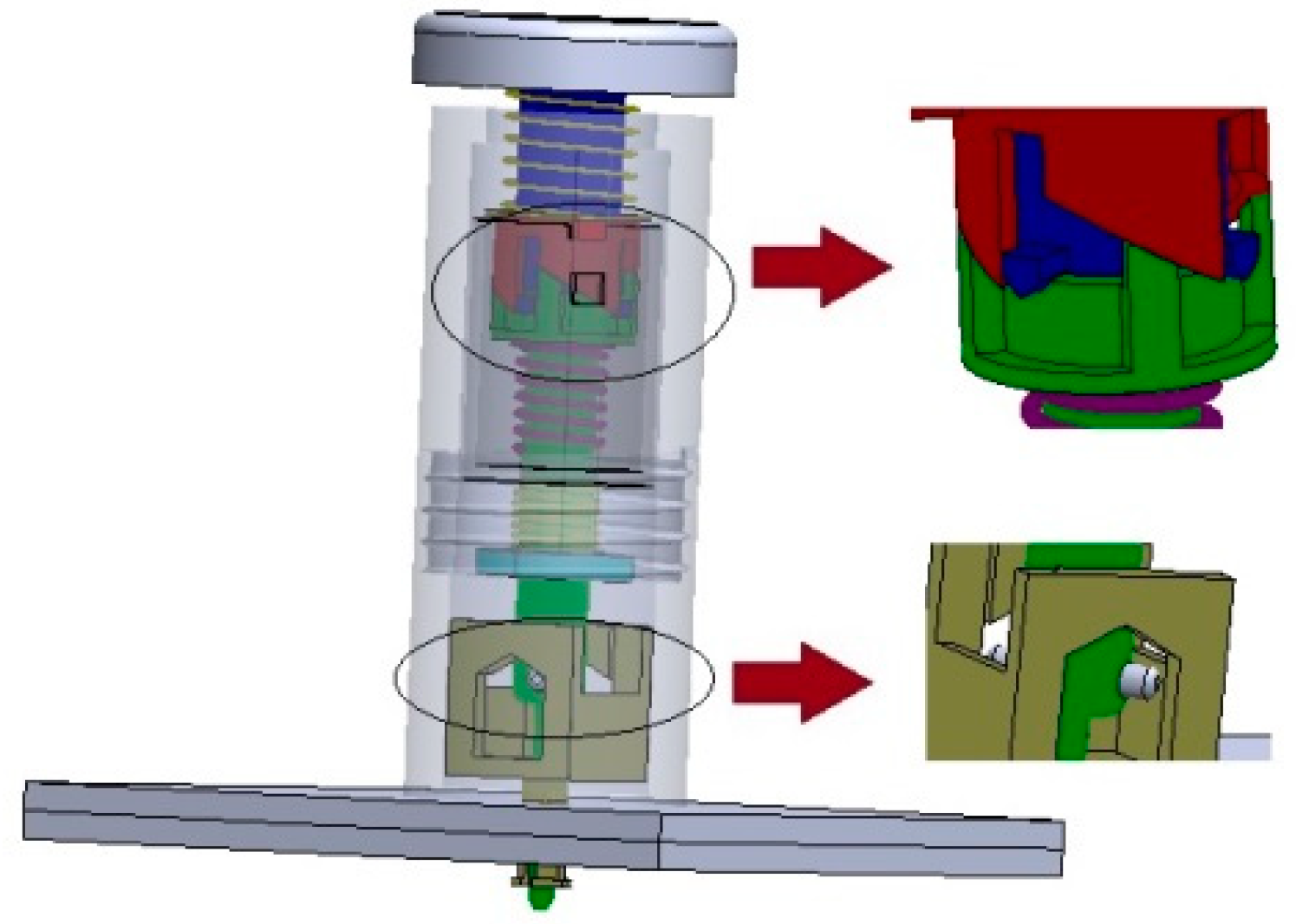

- As shown in Figure 3, insert a temporary fastener into the round hole and push the round button (2) forward. Then, the transmission assembly will slide forward at the same time, and the ejector spring (12) and the support spring (13) will be squeezed and compressed by the cylindrical top rod (11) and the inner sleeve (6), respectively. Afterwards, the mandrel retaining bar (14) will slide into the inside of the square groove of the clamping jaw (8).

- (2)

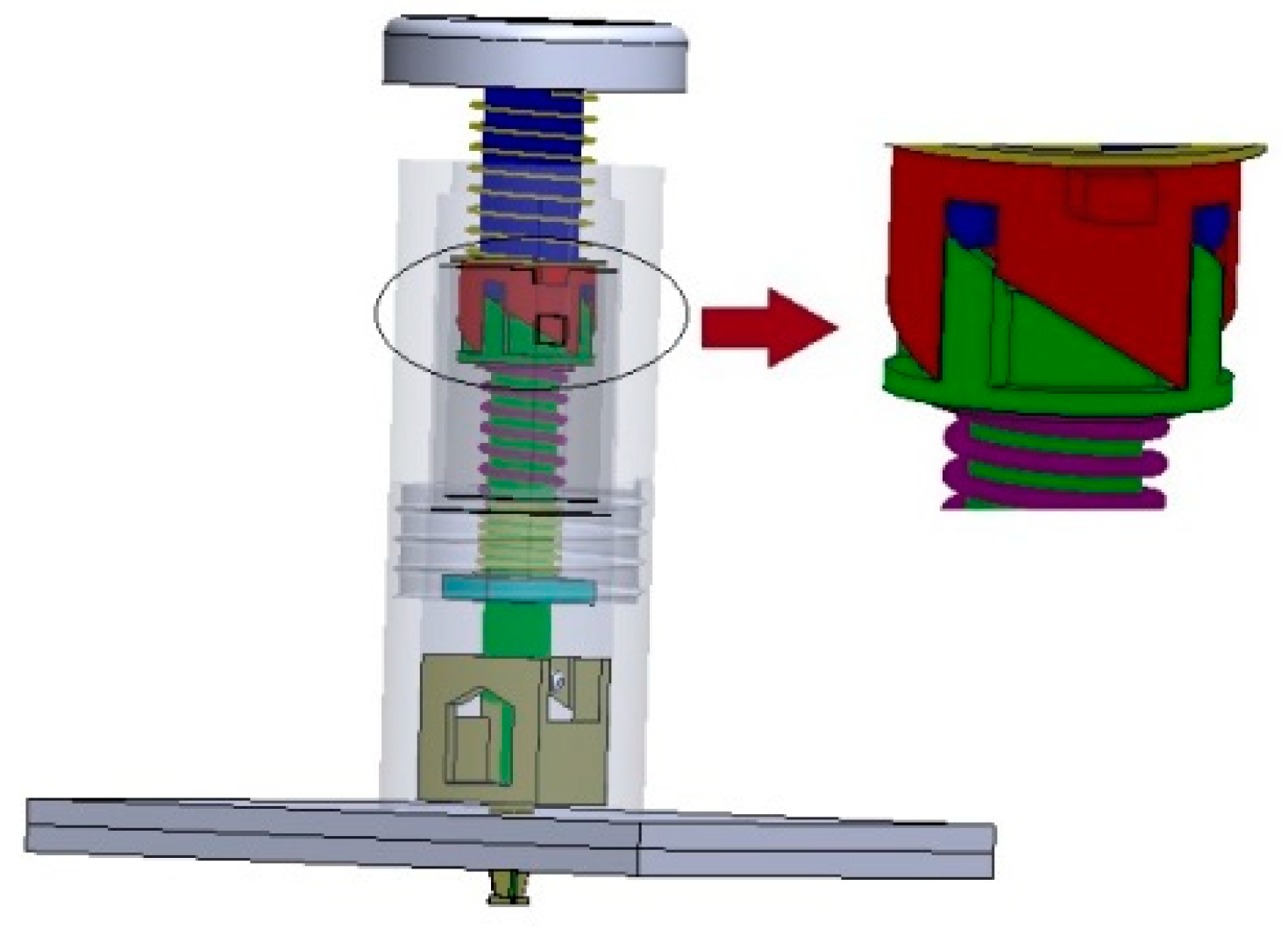

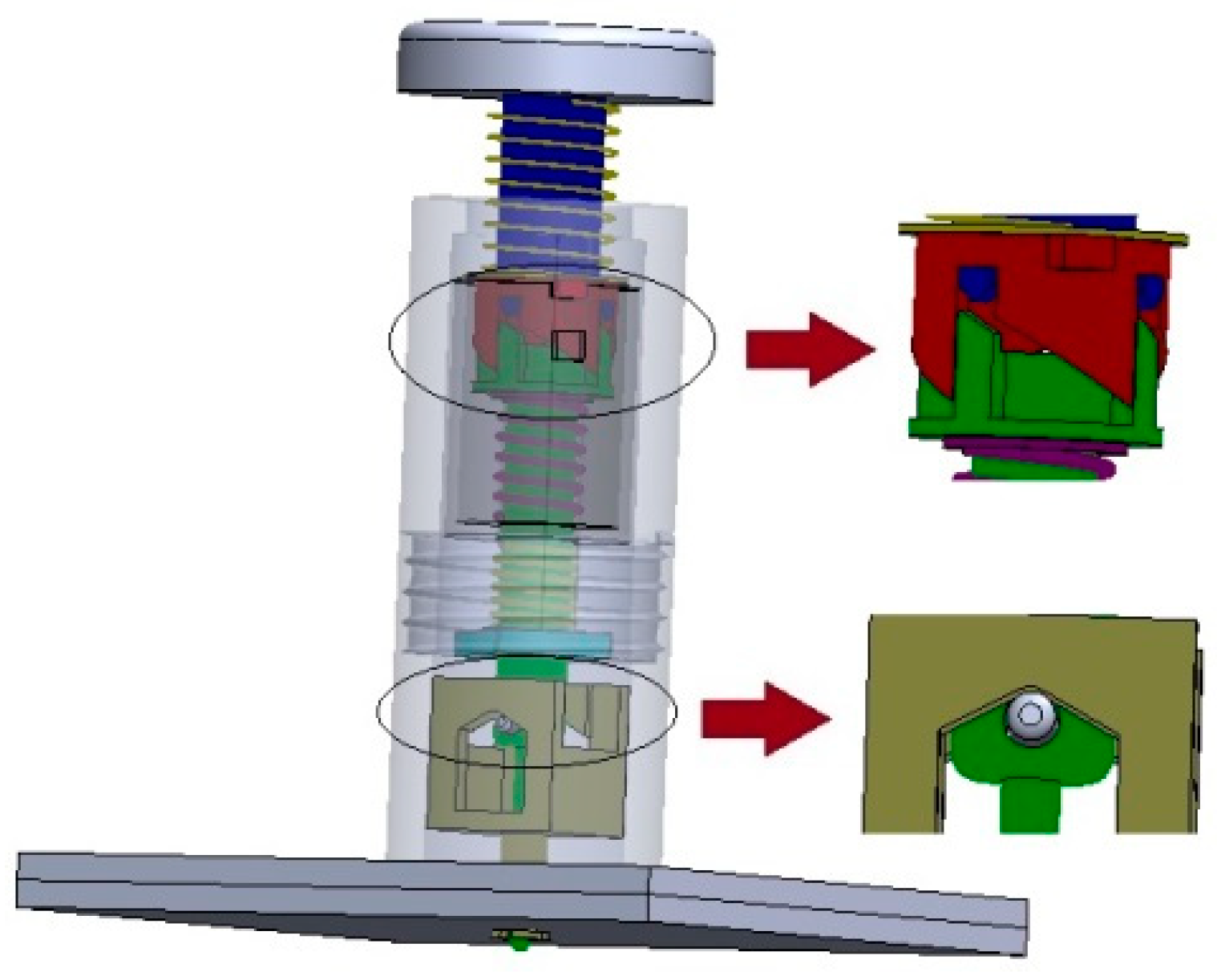

- Continue to push the round button (2) forward. The ejector spring (12) will begin to compress, the ratchet wheel (5) will be stationary relative to the inner sleeve, and the top of the cylindrical push rod (4) will be against the inclined surface of the cylinder top on the rod (11) and will move forward. The cylindrical top rod (11) will push out the four-petal claw structure with the taper barb of the clamping jaw to enlarge the taper section of the jaw. Its schematic is shown in Figure 4.

- (3)

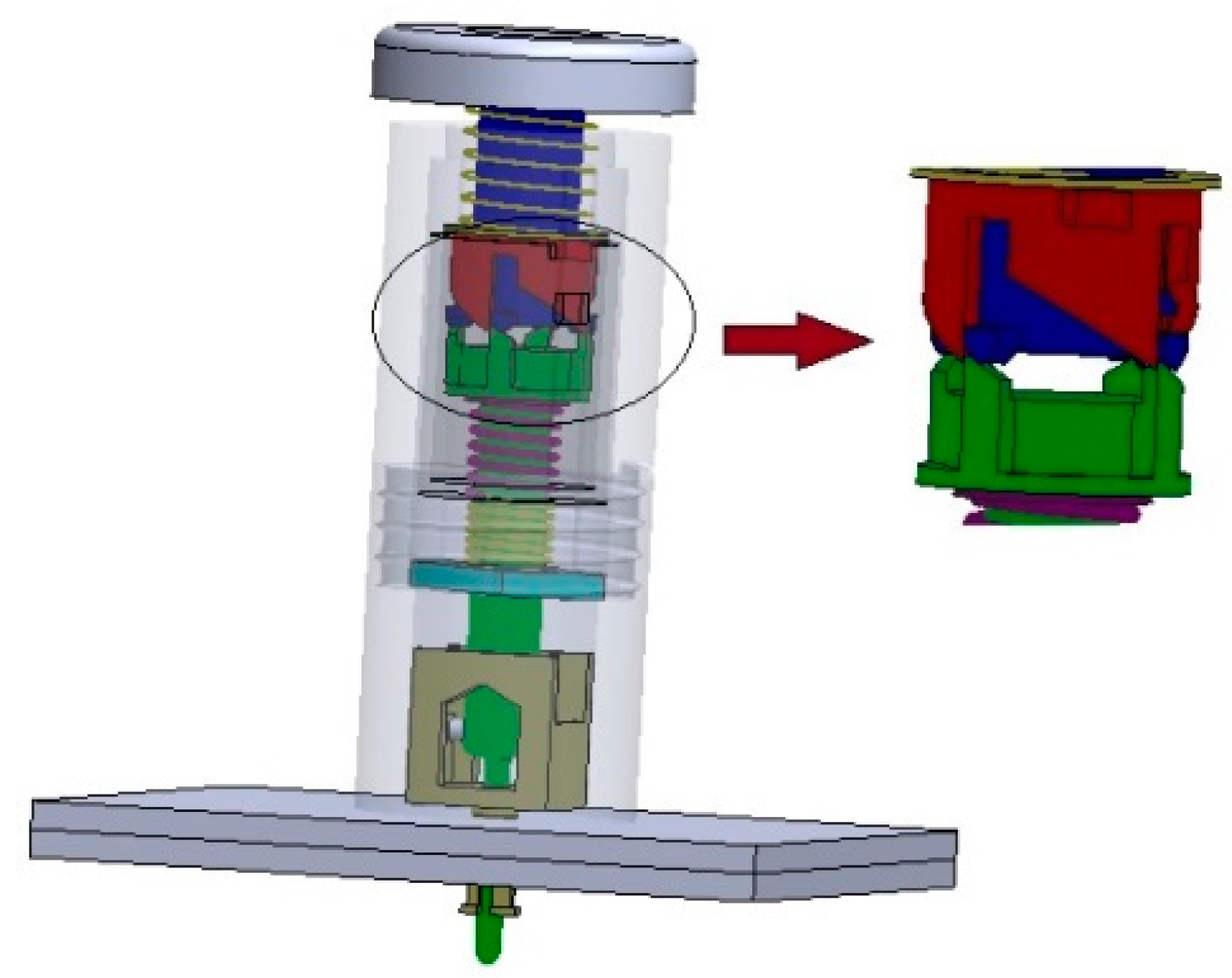

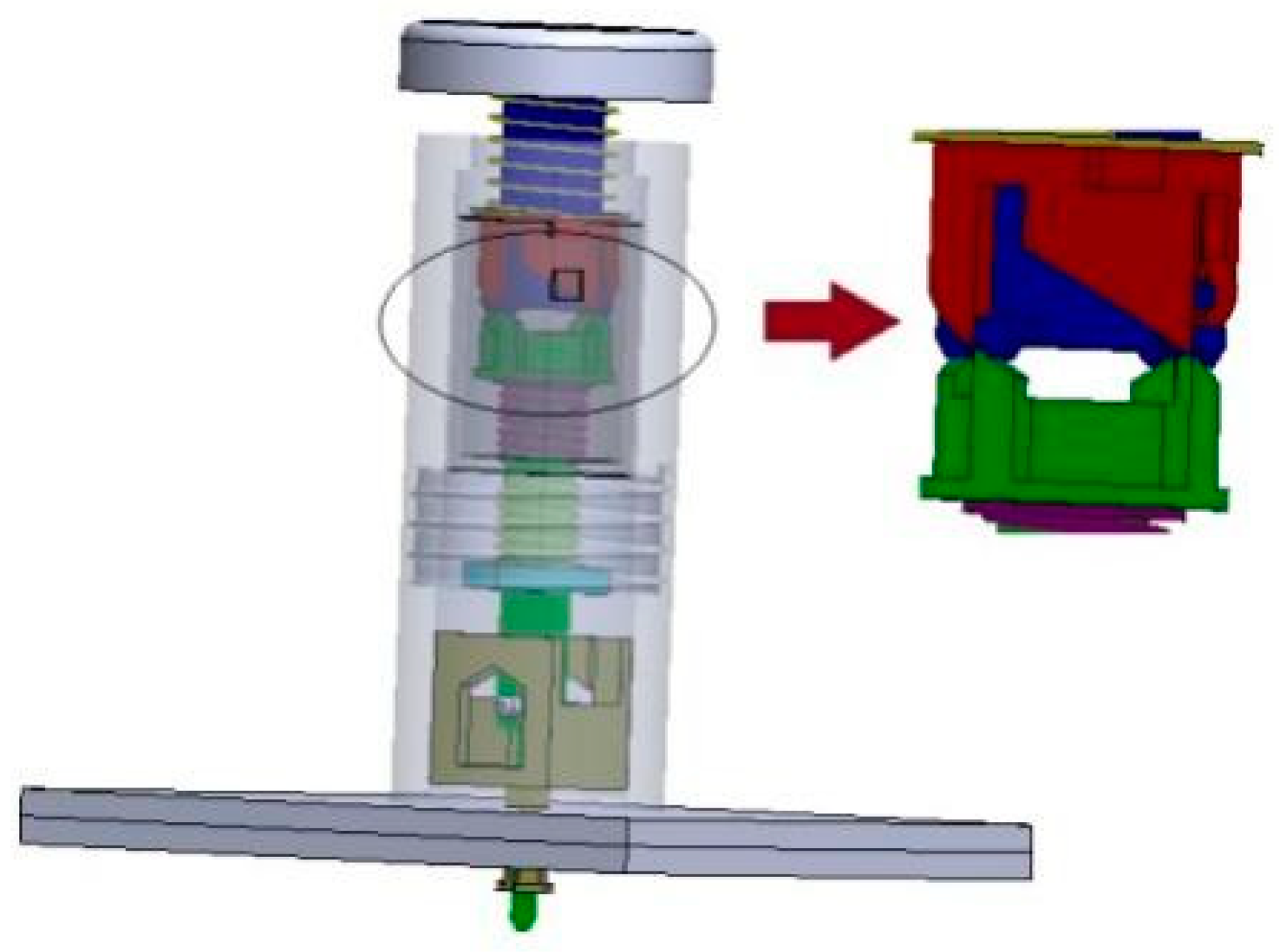

- As illustrated in Figure 5, when the cylindrical top rod (11) moves beyond the groove of the ratchet wheel (5), it will begin to revolve. Hereafter, under the response force of the mandrel spring (12), it will rotate along the slope of the ratchet wheel (5), and the mandrel retention bar (14) will hook the clamping jaws (8) in the square grooves of the clamping jaws by turning.

- (4)

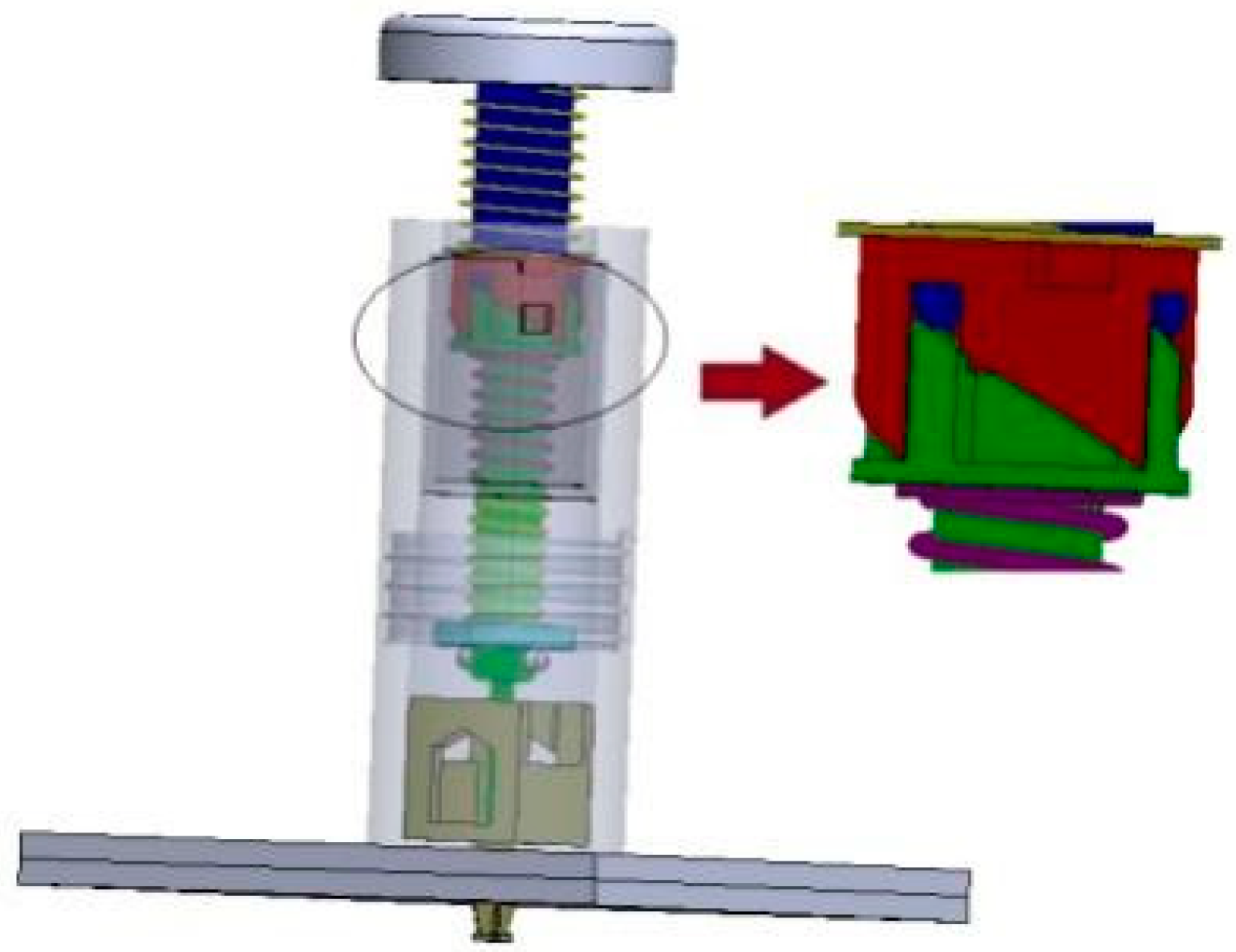

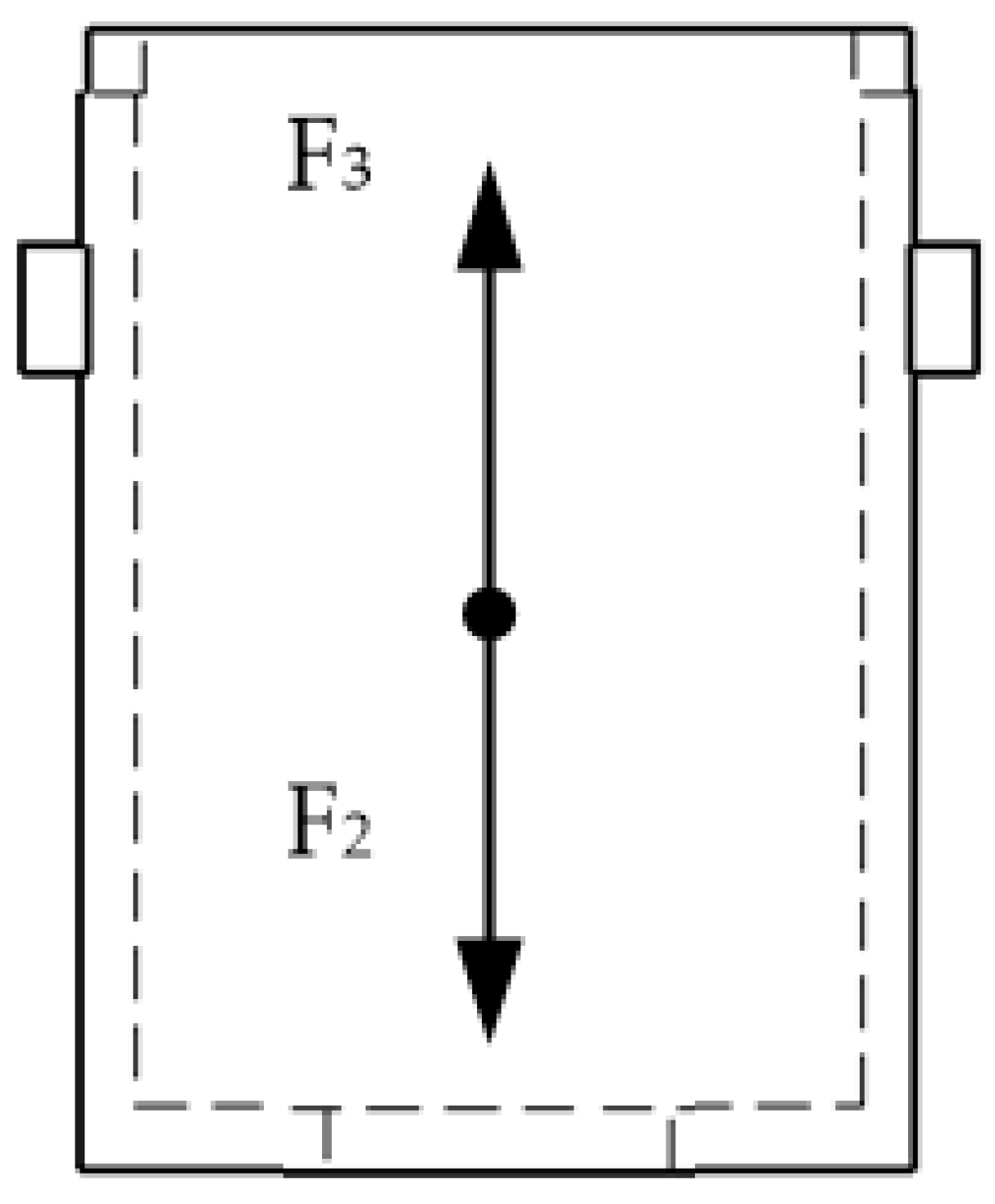

- As shown in Figure 6, release the round button (2), and the inner sleeve (6) will slide backwards and pass through the mandrel retaining bar (14) on the cylindrical push rod (11). Drive the clamping jaws to slide back axially so that the barbs on the four-petal jaws contact the connecting panels. The mandrel retaining bar will rotate 90°, and the connecting panels will be clamped.

- (5)

- When removing the temporary fasteners, press the round button (2) again, and the internal parts of the fasteners will repeat the previous installation movement procedure until the cylindrical plunger (11) rotates 90° to remove the mandrel holding bar (14) to depart from the jaws, as depicted in Figure 7.

- (6)

- When the spring response force is applied, the moving components will return to their original positions, the clamping claw structure will shrink back to its original shape, and the barb structure will loosen the connecting panels, as shown in Figure 8.

- (7)

- Repeat steps (1)–(6) for the installing and removing of other temporary fasteners.

3. Mechanical Relationship Analysis of Temporary Fasteners and Design of Key Parts

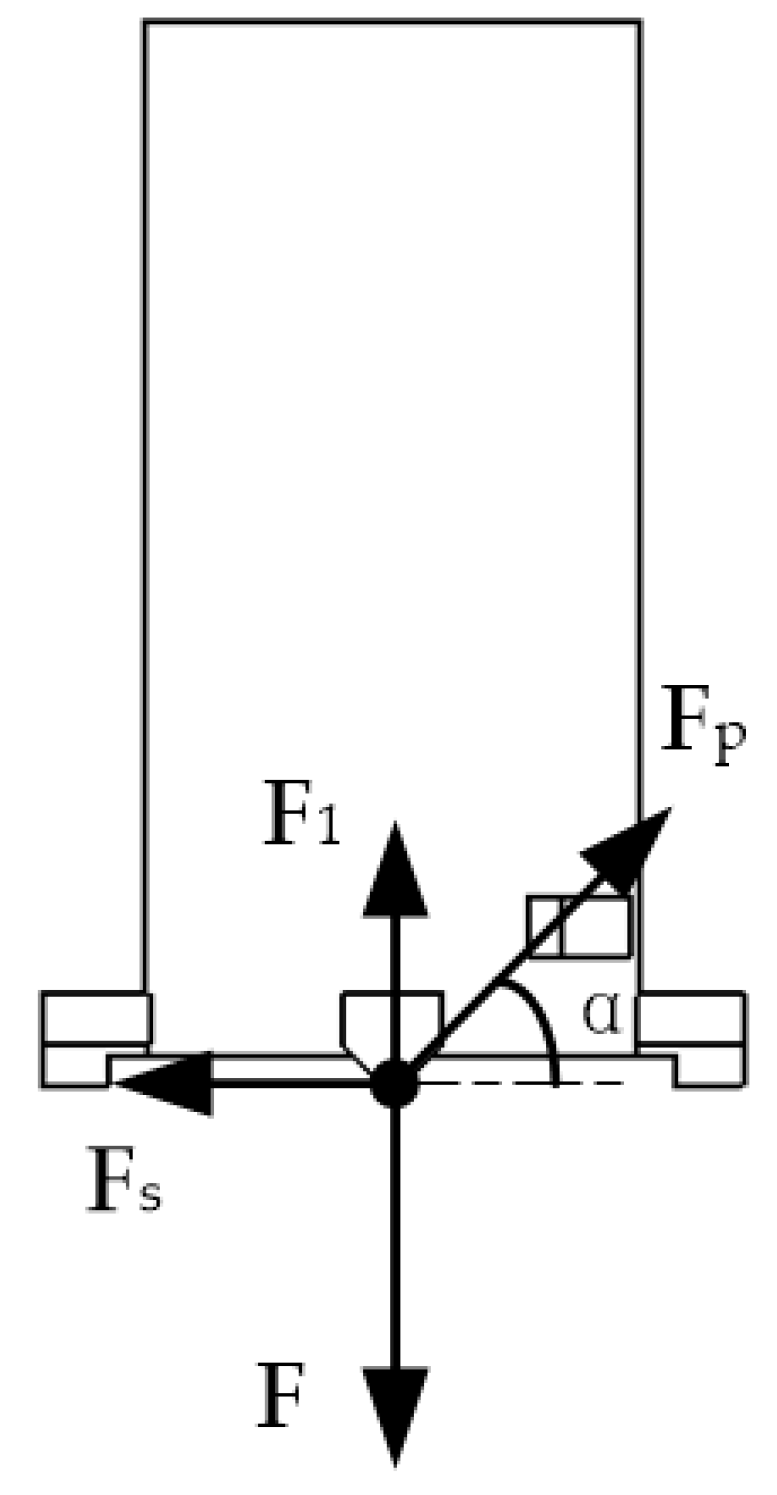

3.1. Critical State

- —Pressure force,

- —The restoring force of the return spring,

- —The tip of the cylindrical push rod receives the reaction force of the cylindrical top rod,

- —Reaction force from ratchet chute,

- —The angle formed by the cylindrical ejector pin’s reaction force and the horizontal plane.

- —The elastic force of the ejector spring,

- —The inclined surface of the cylindrical ejector rod receives the reaction force of the cylindrical push rod,

- —Ratchet chute reaction force,

- —The angle between the inclined plane of the top of the cylindrical top rod and the vertical plane.

- —The elastic force of the ejector spring,

- —The elastic force of the supporting spring,

- —The reaction force of the ratchet.

- —The restoring force of the return spring,

- —Supporting force of the inner sleeve,

- —Forces acting on the cylindrical push rod,

- —Reaction forces of the cylindrical top rod,

- —Supporting forces of the tail shell.

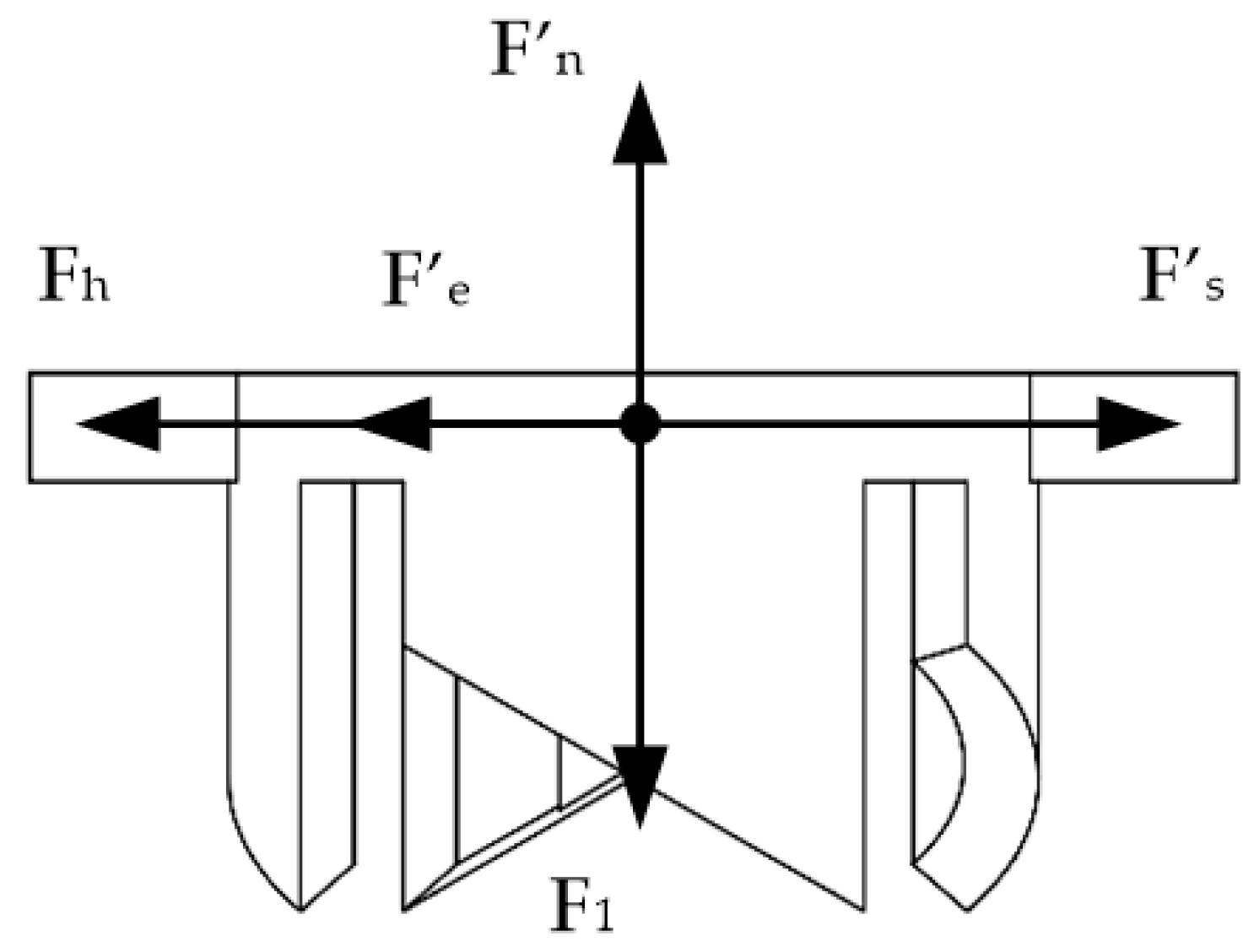

3.2. Clamping State

- —The elastic force of the ejector spring,

- —The clamping force of the connecting panels on the clamping jaw.

4. Example Verification

4.1. Experiment Materials and Device

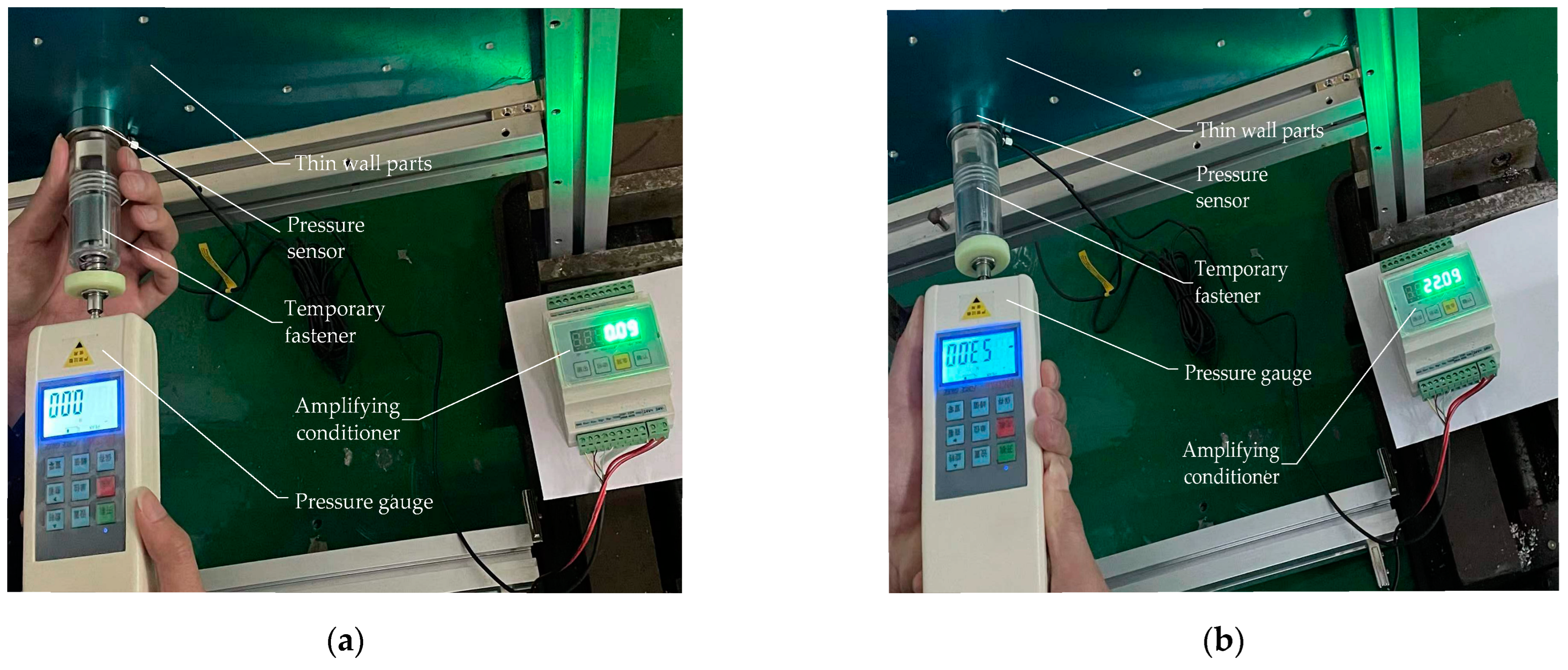

4.2. Experiment Procedure

- (1)

- Put the two aluminum plates to be overlapped into the chute of the support frame so that the round holes of the front and rear aluminum plates correspond one by one.

- (2)

- Install the pressure sensor and the amplifier conditioner according to the circuit diagram and provide the 24 V power supply.

- (3)

- Turn on the power switch and set the value on the amplifier conditioner to zero.

- (4)

- Assemble the quick-pressing self-locking temporary fasteners, set the pressure sensor on the hole surface of the aluminum plates, insert the clamping claw through the circular hole, and concentrically press the pressure gauge and the fastener. The maximum value of the pressure gauge is recorded before the clamping jaw rotates.

- (5)

- Let the temporary fastener’s head shell stay tightly attached to the pressure sensor’s surface and reach the self-locking stage. Make a note of the values on the pressure gauge and the amplifying conditioner. Perform the above experiment five times to obtain the average value.

4.3. Experiment Results and Analysis

4.3.1. Theoretical Calculation

4.3.2. Experimental Data Analysis and Discussion

5. Conclusions

- (1)

- This research has proposed a quick-pressing self-locking temporary fastener to address the issues of low work efficiency and the cumbersome installation of traditional bolts for panels. This fastener can not only carry out automatic bonding of thin-walled metal components, but it can also perform unilateral fastening and detaching.

- (2)

- The major components of this temporary fastener are theoretically calculated and statically analyzed. Aiming at the temporary connection of thin-walled plates with a large area, this temporary fastener is meant to achieve single-sided quick assembly and disassembly through the organic combination of a ratchet mechanism, clamping mechanism, and spring. After its analysis and verification, all parts satisfied work requirements under normal settings and proved the device’s practicality.

- (3)

- An experiment with a quick-pressing self-locking temporary fastener was performed. According to the results of the experiment, this temporary fastener had a high installation efficiency and could reach the required range of clamping force. Its movement status is essentially compatible with the established movement circumstances. The measured forces and the theoretical calculation values are both within a defined error range, with errors of 8.01% and 4.53%, respectively. The experiment results have shown that the temporary fastener could perform the tightening function, and its effect is close to the theoretical effect. Meanwhile, this fastener can perform unilateral operations, fast loading and unloading, recycling, and improving efficiency, which makes it suitable for large-scale application in automated panel manufacturing.

- (4)

- In addition to the assembly of thin-walled aircraft parts, this fastener can also be employed to assemble thin-walled vehicle parts. For example, after the sheet metal components have been positioned and clamped, fasteners are used to connect two or more sheet metal pieces in order to remove the gaps between or among the sheet metal parts, allowing the sheet metal parts to be welded.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jia, Z.; Bhatia, A.; Aronson, R.M.; Bourne, D.; Mason, M.T. A survey of automated threaded fastening. IEEE Trans. Autom. Sci. Eng. 2018, 16, 298–310. [Google Scholar] [CrossRef]

- Ranjan, B.S.C.; Vikranth, H.N.; Ghosal, A. A novel prevailing torque threaded fastener and its analysis. J. Mech. Des. 2013, 135, 101007. [Google Scholar] [CrossRef]

- Gong, H.; Ding, X.; Liu, J.; Feng, H. Review of research on loosening of threaded fasteners. Friction 2021, 10, 335–359. [Google Scholar] [CrossRef]

- Shan, Z.W.; Su, R.K.L. Behavior of shear connectors joined by direct fastening. Eng. Struct. 2019, 196, 109321. [Google Scholar] [CrossRef]

- Mourad, S. Behaviour of Blind Bolted Moment Connections for Square HSS Columns; McMaster University: Hamilton, ON, Canada, 1994. [Google Scholar]

- Sadri, S.M.; Plunkett, M.R.; Hicks, M.R. High Strength Blind Bolt with Uniform High Clamp over an Extended Grip Range. U.S. Patent US05603592A, 18 February 1997. [Google Scholar]

- Gang, L.; Tang, W.; Ke, Y.L.; Chen, Q.L.; Bi, Y.B. Modeling of fast pre-joining processes optimization for skin-stringer panels. Assem. Autom. 2014, 34, 323–332. [Google Scholar]

- Gang, L.; Tang, W.; Ke, Y.L.; Chen, Q.L.; Chen, X.M. Pre-joining process planning model for a batch of skin-stringer panels based on statistical clearances. Int. J. Adv. Manuf. Technol. 2015, 78, 41–51. [Google Scholar]

- Qu, W.W.; Tang, W.; Ke, Y.L. Pre-joining processes optimization method for panel orienting to the clearances suppression of units and the clearances flow among units. Int. J. Adv. Manuf. Technol. 2018, 94, 1357–1371. [Google Scholar] [CrossRef]

- Kim, C.; Bonjoon, G.; Moo, H.S.; Yi, S. Accurate Fastening of Blind Rivet Nuts: A Study. Trans. Mater. Process. 2020, 29, 331–337. [Google Scholar]

- Van de Velde, A.; Debruyne, D.; Maeyens, J.; Wevers, M.; Coppieters, S. Towards best practice in numerical simulation of blind rivet nut installation. Int. J. Mater. Form. 2021, 14, 1139–1155. [Google Scholar] [CrossRef]

- Klasztorny, M.; Nycz, D. Modelling and numerical study of blind rivet nut/bolt joints of composite shell segments. In Shell Structures: Theory and Application; CRC Press: Boca Raton, FL, USA, 2013; pp. 409–412. [Google Scholar]

- Studziński, R. Experimental investigation of the use of blind rivets in sandwich panels. J. Sandw. Struct. Mater. 2021, 23, 3669–3684. [Google Scholar] [CrossRef]

- Sun, L.; Liu, M.; Liu, Y.; Wang, P.; Zhao, H.; Sun, J.; Shang, Y. Studies on T-shaped one-side bolted connection to hollow section column under bending. J. Constr. Steel Res. 2020, 175, 106359. [Google Scholar] [CrossRef]

- Nikoukalam, M.T.; Mirghaderi, S.R.; Dolatshahi, K.M. Shear slotted bolted connection. Struct. Des. Tall Spec. Build. 2017, 26, e1313. [Google Scholar] [CrossRef]

- Nakajima, K.; Suzuki, H.; Kawabe, Y.; Fujii, K. Experimental Study on High Strength One-Side Bolted Joints; Taylor & Francis Group: London, UK, 2012. [Google Scholar]

- Vilela, P.M.L.; Carvalho, H.; Baião, O.T. Numerical simulation of bolted connections. Lat. Am. J. Solids Struct. 2018, 15, e94. [Google Scholar] [CrossRef]

- Ungermann, D.; Luebke, S. Innovative fastening of sandwich panels in one face sheet only. STAHLBAU 2012, 81, 912-U112. [Google Scholar] [CrossRef]

- Xu, F.; Cai, Y.; Chan, T.M.; Young, B. Tube wall deformation behaviour of tensile-loaded blind-bolted connections in octagonal hollow section tubes. Thin-Walled Struct. 2023, 184, 110447. [Google Scholar] [CrossRef]

- Tang, W.; Xie, X.; Ye, Y.K.; Qu, W.W. Design of a Fast Temporary Fastener with the Labor-Saving and Reversible Ability. Coatings 2021, 11, 1101. [Google Scholar] [CrossRef]

- Wang, W.; Hua, D.; Zhou, Q.; Li, S.; Eder, S.J.; Shi, J.; Wang, Z.; Wang, H.; Liu, W. Effect of a water film on the material removal behavior of Invar during chemical mechanical polishing. Appl. Surf. Sci. 2023, 616, 156490. [Google Scholar] [CrossRef]

- Ye, W.; Xie, M.; Huang, Z.; Wang, H.; Zhou, Q.; Wang, L.; Chen, B.; Wang, H.; Liu, W. Microstructure and tribological properties of in-situ carbide/CoCrFeNiMn high entropy alloy composites synthesized by flake powder metallurgy. Tribol. Int. 2023, 181, 108295. [Google Scholar] [CrossRef]

- Jia, Q.; He, W.; Hua, D.; Zhou, Q.; Du, Y.; Ren, Y.; Lu, Z.; Wang, H.; Zhou, F.; Wang, J. Effects of structure relaxation and surface oxidation on nanoscopic wear behaviors of metallic glass. Acta Mater. 2022, 232, 117934. [Google Scholar] [CrossRef]

- Rae, P.J.; Brown, E.N.; Orler, E.B. The mechanical properties of poly(ether-ether-ketone) (PEEK) with emphasis on the large compressive strain response. Polymer 2007, 48, 598–615. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, P. Effect of Tolerance in the Fitting of Rivets in the Holes of Double Lap Joints Subjected to Uniaxial Tension. In Key Engineering Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2014; Volume 607, pp. 49–54. [Google Scholar]

| Functional Innovation | Structure Innovation |

|---|---|

| Quick-press | The spring and cylindrical push rod closely cooperate with the ratchet. |

| Convenient for automated installation | The cylindrical-shape surface of the parts are the same. |

| Self-locking | Coordination between the mandrel retaining bar and the clamping jaw |

| Unilateral loading and unloading | Clamping jaws structure with elastic |

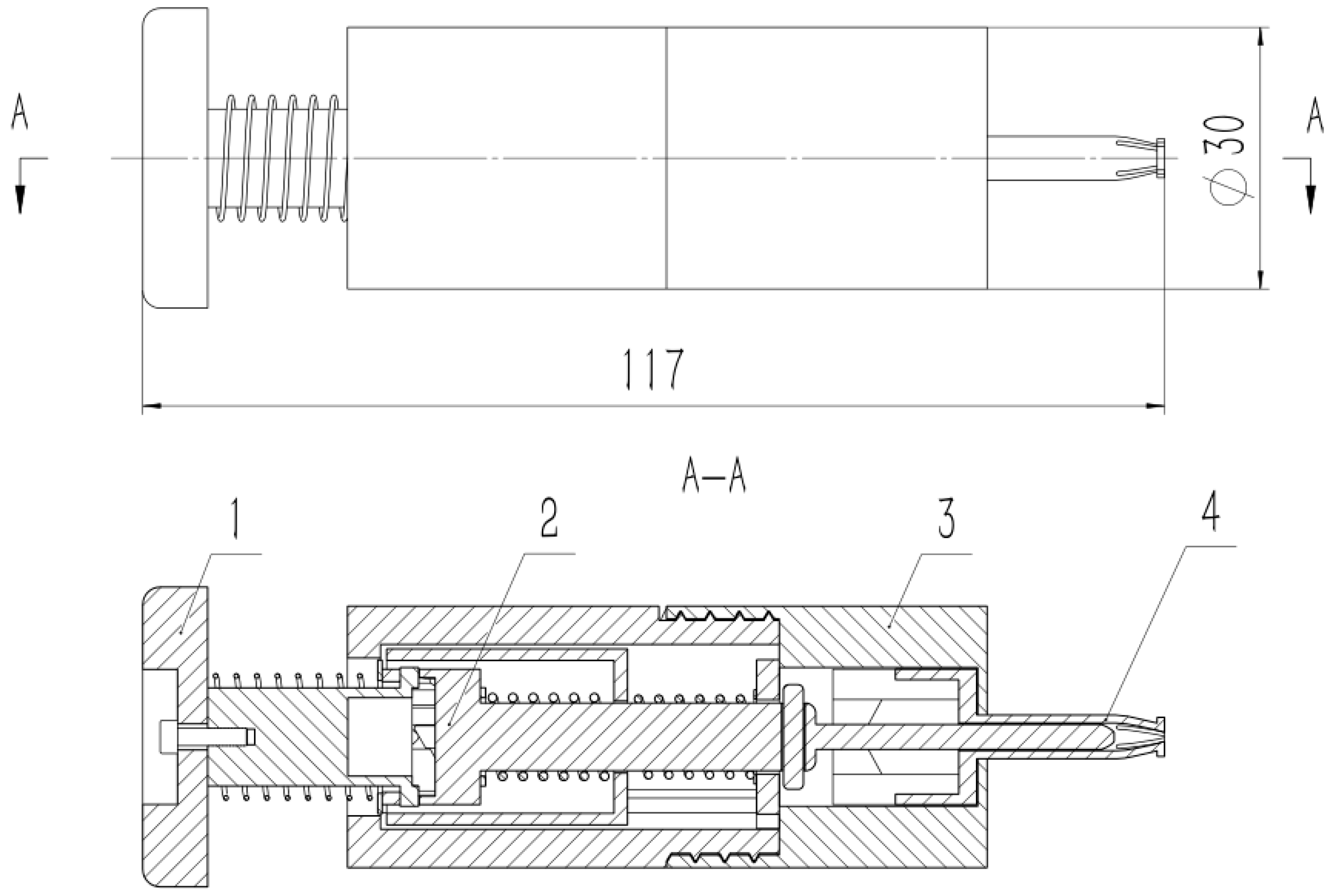

| Main Parts | Material | Related Size | ||||

|---|---|---|---|---|---|---|

| Thin wall parts | Aluminum alloy 7075 | length 800 mm | width 500 mm | thickness 2.5 mm | ||

| Cylindrical top rod | Stainless steel 316 L | length 80 mm | maximum diameter 15.52 mm | minimum diameter 2.85 mm | ||

| Supporting spring | Stainless steel 304 | external diameter 12 mm | internal diameter 9.2 mm | Free-height 15 mm | Effective laps 3 laps | |

| Spring of ejector rod | alloy steel 55CrSi | external diameter 12.5 mm | internal diameter 8.5 mm | Free-height 15 mm | Ultimate pressure 40.2 N | Ultimate compression rate 65% |

| Return spring | Spring steel | external diameter 16 mm | internal diameter 13.6 mm | Free-height 20 mm | Effective laps 3 laps | |

| Body of fastener | Resin r4600 | maximum length 115.5 mm | minimum length 109.4 mm | diameter 30 mm | ||

| Clamping claw | PEEK-450 G | length 15.5 mm | width 15.5 mm | height 38 mm | ||

| Forces | Measured Value/N | Theoretical Value/N | Error Rate |

|---|---|---|---|

| Pressure force | 53.00 | 48.75 | 8.01% |

| Clamping force | 22.09 | 21.09 | 4.53% |

| Reuse | Unilateral Operation | Self-Locking |

|---|---|---|

| Adopt a four-petals claw structure with elastic, which can be recycled. | Only need to press one button continuously to realize clamping and uninstalling. | Coordination among the spring, the clamping jaw and shell with buckle, to hold the claw firmly. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, W.; He, J.; Xiao, Y.; Qu, W.; Ye, J.; Long, H.; Liang, C. Design of a Quick-Pressing and Self-Locking Temporary Fastener for Easy Automatic Installation and Removal. Appl. Sci. 2023, 13, 3004. https://doi.org/10.3390/app13053004

Tang W, He J, Xiao Y, Qu W, Ye J, Long H, Liang C. Design of a Quick-Pressing and Self-Locking Temporary Fastener for Easy Automatic Installation and Removal. Applied Sciences. 2023; 13(5):3004. https://doi.org/10.3390/app13053004

Chicago/Turabian StyleTang, Wei, Jie He, Yunya Xiao, Weiwei Qu, Jiying Ye, Hui Long, and Chaolin Liang. 2023. "Design of a Quick-Pressing and Self-Locking Temporary Fastener for Easy Automatic Installation and Removal" Applied Sciences 13, no. 5: 3004. https://doi.org/10.3390/app13053004

APA StyleTang, W., He, J., Xiao, Y., Qu, W., Ye, J., Long, H., & Liang, C. (2023). Design of a Quick-Pressing and Self-Locking Temporary Fastener for Easy Automatic Installation and Removal. Applied Sciences, 13(5), 3004. https://doi.org/10.3390/app13053004