An Analysis of the Process of Applying Technical Lubricating Coatings

Abstract

1. Introduction

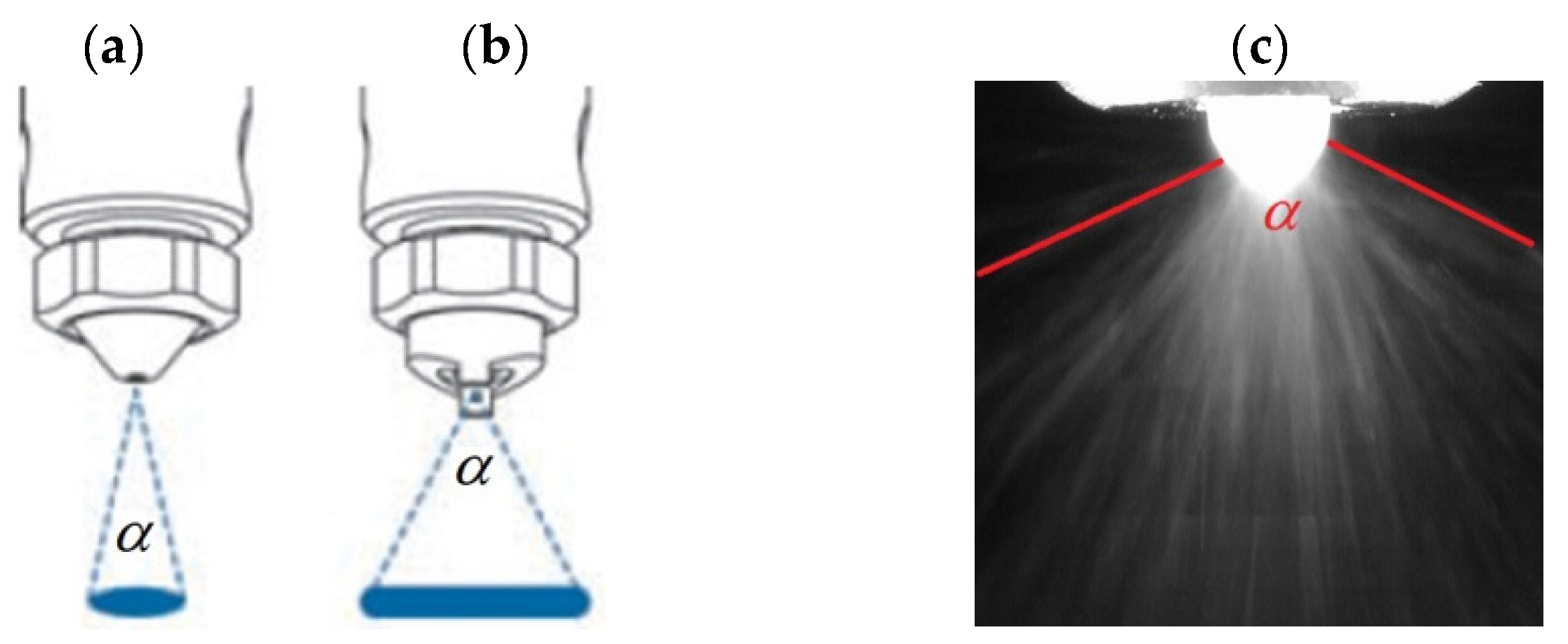

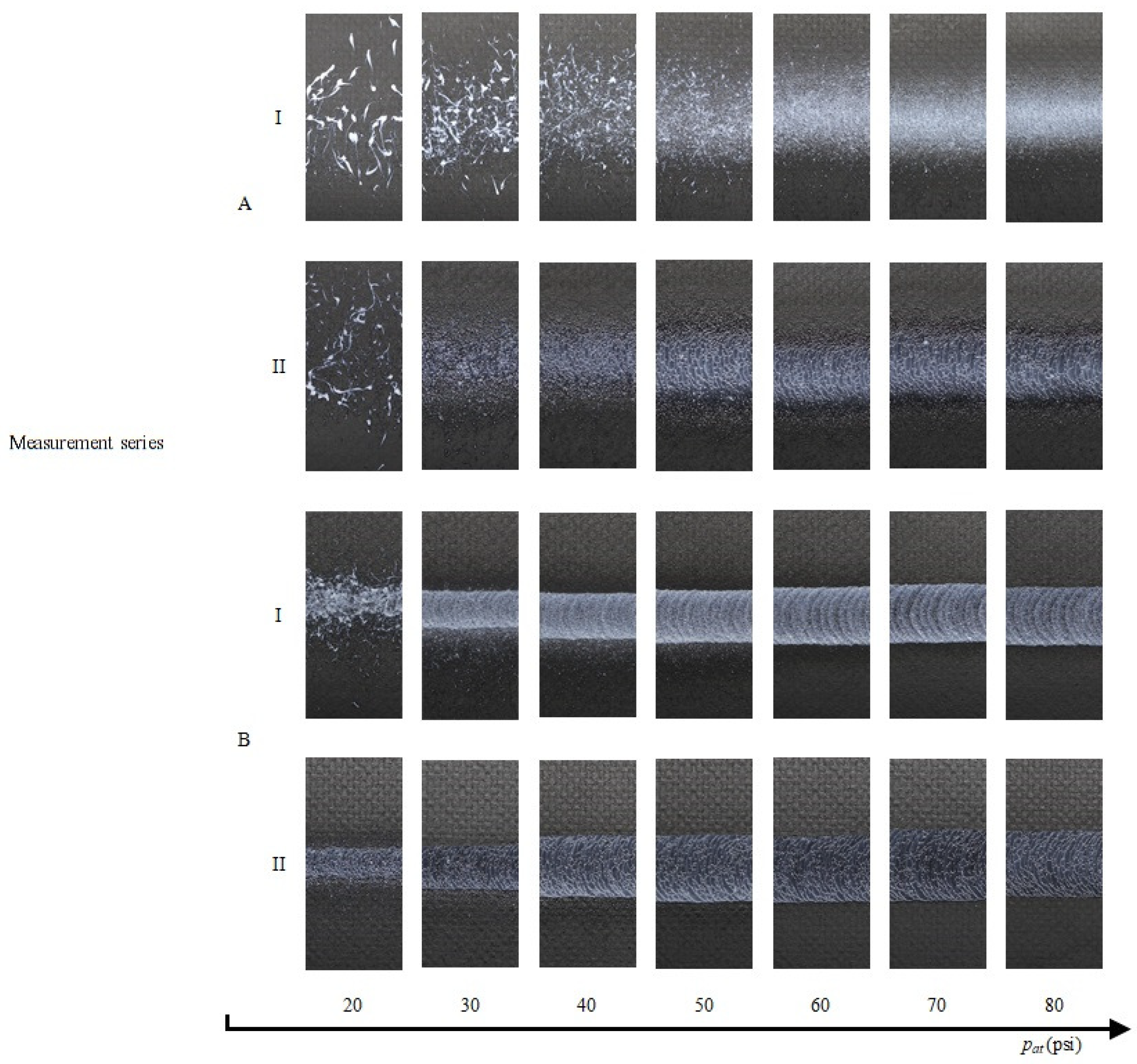

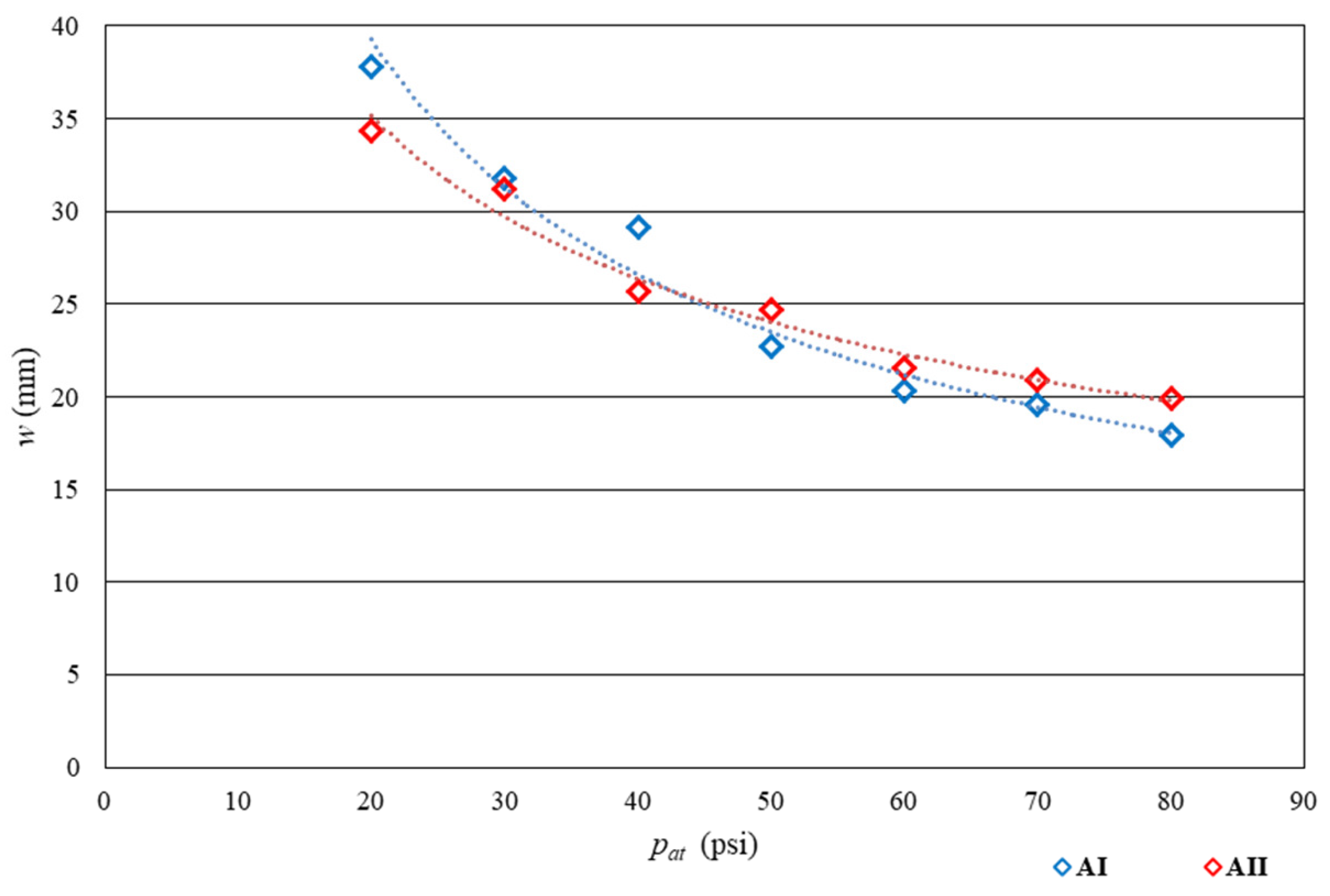

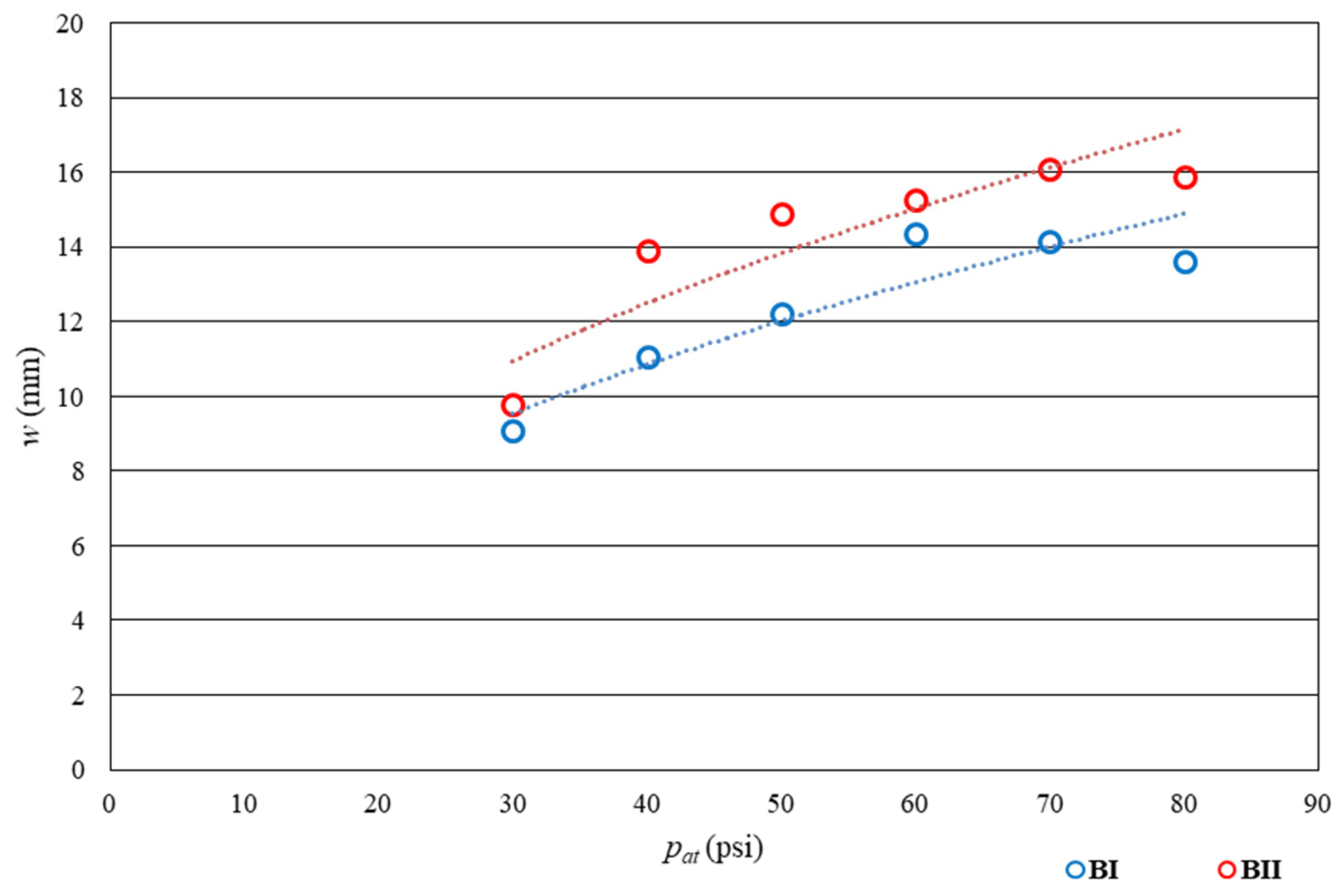

2. Materials and Methods

2.1. Experimental Set-Up and Materials

2.2. Methods

- –

- Setting constant process parameters;

- –

- Modifying the material flow as needed by adjusting the degree of valve opening, i.e., needle lift, by adjusting (microadjust);

- –

- Re-regulating the material flow by changing the material pressure from 4 bar to 4.4 bar;

- –

- Dosing material into a controlled vessel for 10 s;

- –

- Measuring the weight of the dosed material;

- –

- Performing calculations to check the flow in 60 s.

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gateman, S.A.; Alidokht, S.A.; Mena-Morcillo, E.; Schulz, R.; Chromik, R.R.; Kietzig, A.-M.; Parkin, I.P.; Mauzeroll, J. Wear resistant solid lubricating coatings via compression molding and thermal spraying technologies. Surf. Coat. Technol. 2021, 426, 127790. [Google Scholar] [CrossRef]

- Lee, S.W.; Hong, J.W.; Wye, M.Y.; Kim, J.H.; Kang, H.J.; Lee, Y.S. Surface modification and adhesion improvement of PTFE film by ion beam irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms. 2004, 219–220, 963–967. [Google Scholar] [CrossRef]

- Tie, L.; Li, J.; Liu, M.; Guo, Z.; Liang, Y.; Liu, W. Facile Fabrication of Superhydrophobic and Underwater Superoleophobic Coatings. ACS Appl. Nano Mater. 2018, 1, 4894–4899. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, F. Tribological properties of transfer films of PTFE-based composites. Wear 2006, 261, 1359–1366. [Google Scholar] [CrossRef]

- Burmistrov, D.E.; Serov, D.A.; Simakin, A.V.; Baimler, I.V.; Uvarov, O.V.; Gudkov, S.V. A Polytetrafluoroethylene (PTFE) and Nano-Al2O3 Based Composite Coating with a Bacteriostatic Effect against E. coli and Low Cytotoxicity. Polymers 2022, 14, 4764. [Google Scholar] [CrossRef] [PubMed]

- Maghsoudi, K.; Momen, G.; Jafari, R.; Farzaneh, M. Direct replication of micro-nanostructures in the fabrication of superhydrophobic silicone rubber surfaces by compression molding. Appl. Surf. Sci. 2018, 458, 619–628. [Google Scholar] [CrossRef]

- Demian, C.; Liao, H.; Lachat, R.; Costil, S. Investigation of surface properties and mechanical and tribological behaviors of polyimide based composite coatings. Surf. Coat. Technol. 2013, 235, 603–610. [Google Scholar] [CrossRef]

- Xu, B.; Zhu, Z.; Ma, S.; Zhang, W.; Liu, W. Sliding wear behavior of Fe–Al and Fe–Al/WC coatings prepared by high velocity arc spraying. Wear 2004, 257, 1089–1095. [Google Scholar] [CrossRef]

- Guilemany, J.; Dosta, S.; Miguel, J. The enhancement of the properties of WC-Co HVOF coatings through the use of nanostructured and microstructured feedstock powders. Surf. Coat. Technol. 2006, 201, 1180–1190. [Google Scholar] [CrossRef]

- Chen, X.; Gong, Y.; Suo, X.; Huang, J.; Liu, Y.; Li, H. Construction of mechanically durable superhydrophobic surfaces by thermal spray deposition and further surface modification. Appl. Surf. Sci. 2015, 356, 639–644. [Google Scholar] [CrossRef]

- Kałdońki, T.J.; Gryglewicz, Ł.; Stańczyk, M.; Kałdoński, T. Investigations on lubricity and surface properties of selected perfluoropolyether oils. J. KONES Powertrain Transp. 2011, 18, 199–212. [Google Scholar]

- Perfluoropolyethers a Unique Source for High Performance Pfpe Lubricants. Available online: www.solvaysolexis.com/static/wma/pdf/6/9/9/2/Perfluoropolyethers.pdf (accessed on 25 April 2022).

- Fomblin PFPE Lubricants. Solvay Solexis, Manufacturer’s. Available online: www.solvaysolexis.com/static/wma/pdf/1/1/7/3/0/fom_lube.pdf (accessed on 10 January 2023).

- Tyndall, G.; Leezenberg, P.; Waltman, R.; Castenada, J. Interfacial interactions of perfluoropolyether lubricants with magnetic recording media. Tribol. Lett. 1998, 4, 103–108. [Google Scholar] [CrossRef]

- Grechin, A.; Schott, V.; Kling, R. PFPE-Greases: Modern Trends and Perspectives. Conference ELGI AGM, London. April 2018, pp. 1–11. Available online: https://www.researchgate.net/publication/324830711_PFPE-Greases_modern_trends_and_perspectives (accessed on 10 January 2023).

- Von Krusenstierna, A. Grease-Oil Compatibility in Tribological Applications—Supergrease. Master’s Thesis, Faculty of Engineering, Lund University, Lund, Sweden, 2016. [Google Scholar]

- Fluid Solutions, Inc. Available online: https://fluidsolutions.com.ph (accessed on 5 January 2023).

- Caporiccio, G.; Soldini, S.; Strepparola, E. Process for Preparng Lubricating Greases Based on Polytetrafluoroethylene and Perfluoropolyethers. US Patent No 4472290, 18 September 1984. [Google Scholar]

- Krawiec, S. The Compositions of Plastic and Solid Lubricants in the Friction Process of Steel Machine Components; Publishing House of Wrocław University of Technology: Wroclaw, Poland, 2011. [Google Scholar]

- Scharf, T.W.; Prasad, S.V. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Czarny, R. Plastic Lubricants; WNT Publishers, reprinted by PWN Scientific Publishers: Warsaw, Poland, 2018. [Google Scholar]

- Kozdrach, R. The effect of the type of dispersing phase on the tribological properties of plastic lubricants. Tribology 2012, 6, 85–97. [Google Scholar]

- Gow, G. Lubricating grease. In Chemistry and Technology of Lubricants; Mortier, R.M., Orszulik, S.T., Eds.; Springer: Boston, MA, USA, 1992. [Google Scholar] [CrossRef]

- Drabik, J. Impact of additives on tribological characteristics of plastic lubricants. Tribologia 2015, 5, 17–28. [Google Scholar]

- Parfenov, A.S.; Berezina, E.V.; Smirnova, A.I.; Gvozdev, A.A.; Shilov, M.A.; Dyachkova, T.; Rozhkova, N.N.; Savilov, S.V.; Usol’Tseva, N.V. Tribological Properties of Plastic Lubricants in Compositions with Various Carbon Nanostructures. J. Frict. Wear 2019, 40, 453–460. [Google Scholar] [CrossRef]

- Pawelec, E.; Siwiec, E. The effect of lubricant additives on selected rheological properties. Tribology 2012, 6, 129–138. [Google Scholar]

- Kamel, B.M.; El-Kashif, E.; Hoziefa, W.; Shiba, M.S.; Elshalakany, A.B. The effect of MWCNTs/GNs hybrid addition on the tribological and rheological properties of lubricating engine oil. J. Dispers. Sci. Technol. 2021, 42, 1811–1819. [Google Scholar] [CrossRef]

- Ukomski, A. Oils, lubricants, tribology. Des. Eng. Constr. 2020, 4, 14–21. [Google Scholar]

- Bajer, J. Characteristic properties of low temperature resistant plastic grease. Tribology 2006, 5, 97–110. [Google Scholar]

- Tiwari, S.; Christy, J.V. Tribological Analysis of Thermal Spray Coatings of Ni and Al2O3 with Dispersion of Solid Lubricants in Erosive Wear Modes. Procedia Technol. 2016, 23, 150–155. [Google Scholar] [CrossRef]

- Ganvir, A.; Jahagirdar, A.R.; Mulone, A.; Örnfeldt, L.; Björklund, S.; Klement, U.; Joshi, S. Novel utilization of liquid feedstock in high velocity air fuel (HVAF) spraying to deposit solid lubricant reinforced wear resistant coatings. J. Mater. Process. Technol. 2021, 295, 117203. [Google Scholar] [CrossRef]

- Accurately Spray Coatings and Lubricants Using Spray Technology. Available online: https://engineeringnews.co.nz/2017/08/23/accurately-spray-coatings-and-lubricants-using-spray-technology/ (accessed on 20 February 2023).

- Grützmacher, P.G.; Schranz, M.; Hsu, C.-J.; Bernardi, J.; Steiger-Thirsfeld, A.; Hensgen, L.; Ripoll, M.R.; Gachot, C. Solid lubricity of WS2 and Bi2S3 coatings deposited by plasma spraying and air spraying. Surf. Coat. Technol. 2022, 446, 128772. [Google Scholar] [CrossRef]

- Nordson EFD. Game Changing Dispensing Solutions. In Engineered Fluid Dispensing, 9th ed.; Nordson EFD: Vestlejk, OH, USA, 2019. [Google Scholar]

- Technical Data Sheet for PFPE Lubricants. 2022.

- Molenda, J.; Wójcicki, T.; Pawelec, E. Application of a computer image analysis for quantitative description of adhesive interactions between grease and steel surface. Nafta Gaz 2011, 67, 361–366. [Google Scholar]

| NLGI Consistency Class (DIN 51 818) | Penetration According to PN/C-96-04095 (0.1 mm) | Consistency | Basic Application |

|---|---|---|---|

| 000 | 440–480 | liquid | Mechanical transmissions, central lubrication systems |

| 00 | 395–435 | semi-liquid | |

| 0 | 350–390 | semi-liquid | |

| 1 | 305–345 | very soft | Rolling and sliding bearings, central lubrication systems |

| 2 | 260–300 | soft | |

| 3 | 215–255 | medium | |

| 4 | 170–210 | thick | Other uses; most commonly used as a sealant for fittings |

| 5 | 125–165 | very thick | |

| 6 | 80–120 (penetration in a resting state) | hard |

| Characteristics | Lubricant No. 1 | Lubricant No. 2 |

|---|---|---|

| Base oil | PFPE | PFPE |

| Viscosity of oil at 40 °C (mm2/s) | 8 | 8 |

| Thickener | PTFE | PTFE |

| Density (kg/dm3) | 1.93 | 1.93 |

| Penetration × 0.1 mm | 265–295 | 355–385 |

| NLGI class | 2 | 0 |

| Vapor pressure at 70° C (Torr) | 10−3 | <10−2 |

| Operating temperature range (°C) | −70–200 | −70–200 |

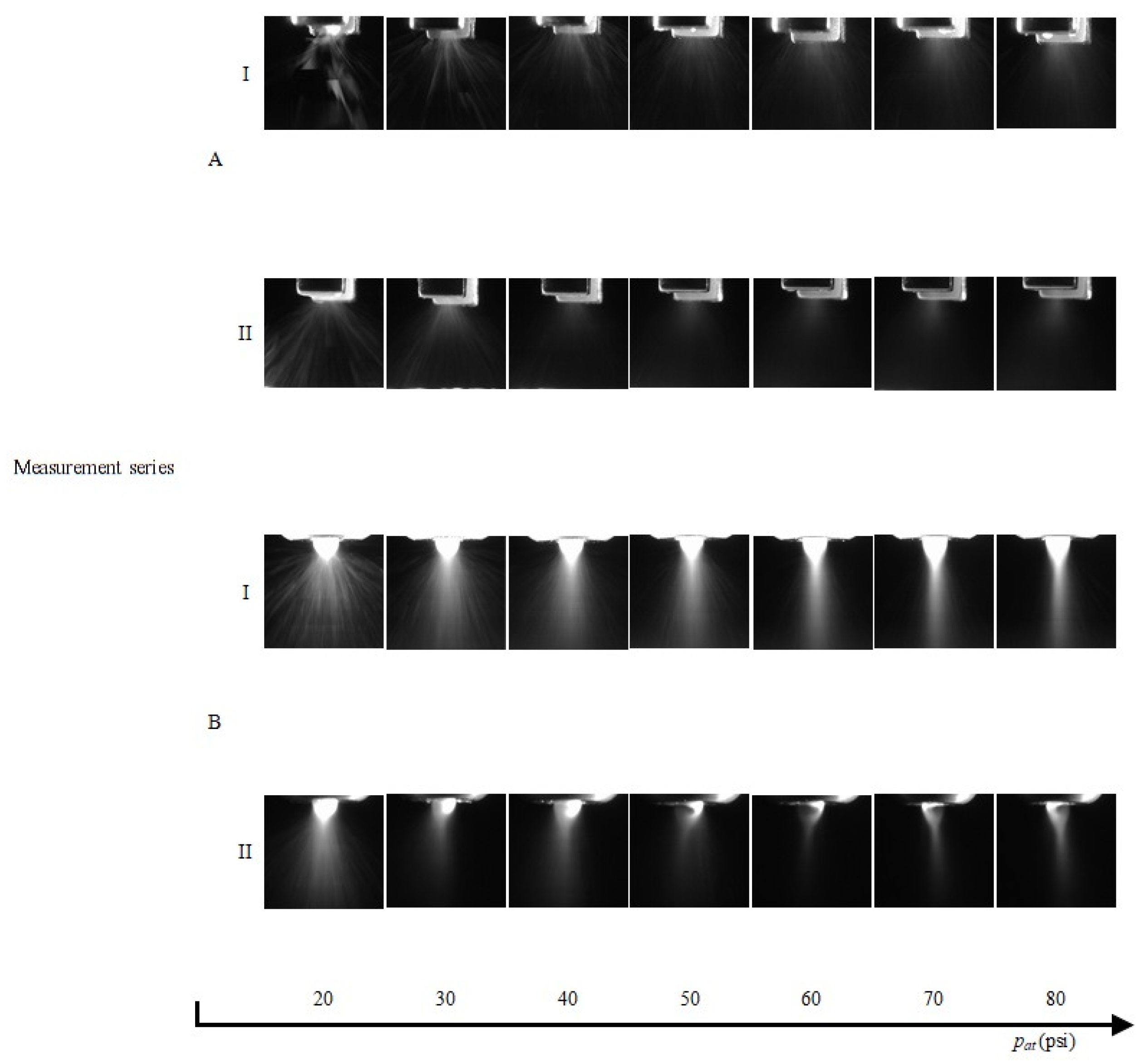

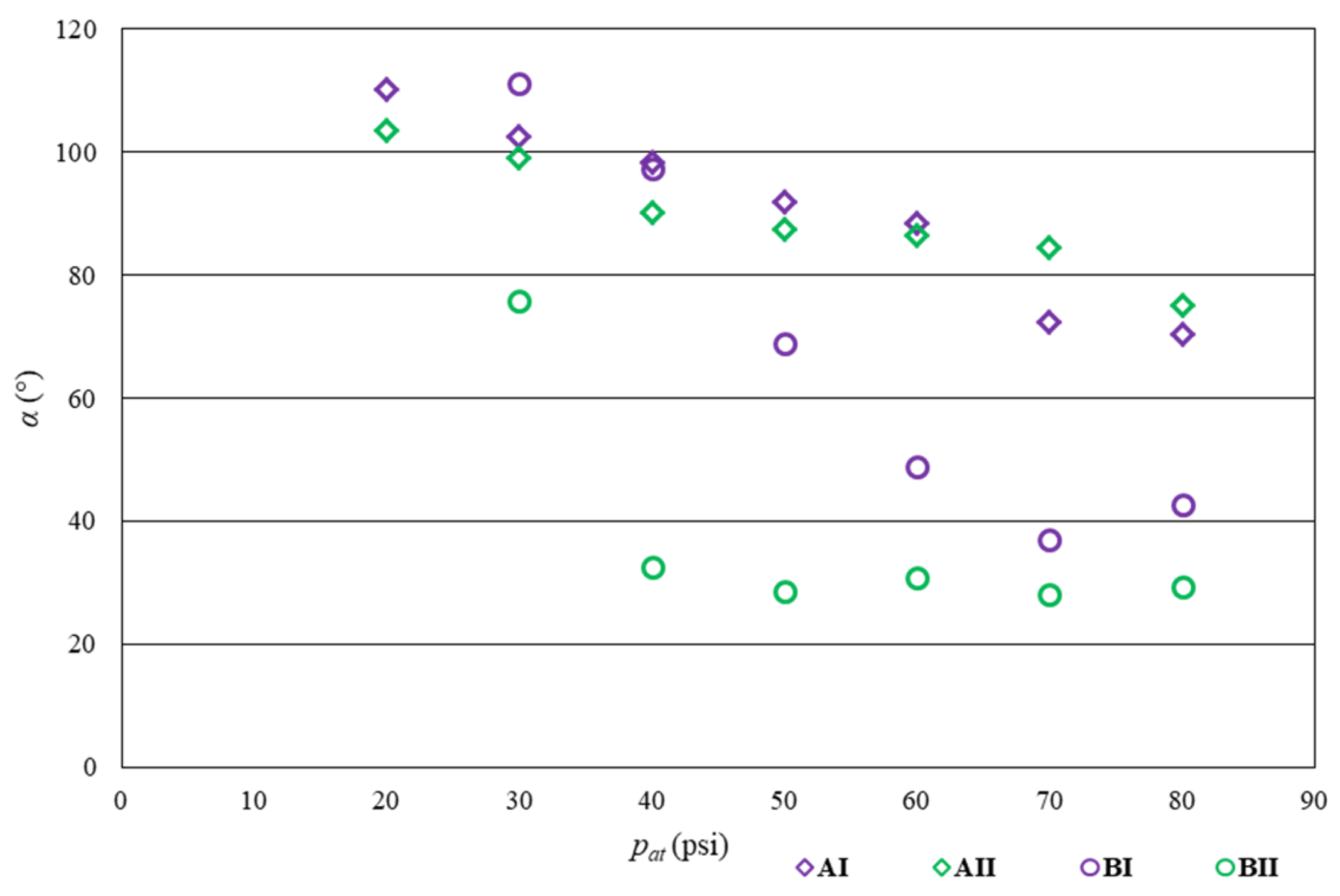

| Designation | Nozzle | Lubricant | Temperature of Air (°C) | Humidity of Air (%) | Pressure of Lubricant (psi) |

|---|---|---|---|---|---|

| AI | Nordson EFD 7856F–46SS 0.046″ | No I | 20.9 | 38.6 | 40.0 |

| AII | No II | 21.0 | 38.3 | 14.5 | |

| BI | Nordson EFD 7856–46SS 0.046″ | No I | 20.8 | 33.9 | 15.05 |

| BII | No II | 20.8 | 34.4 | 14.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ochowiak, M.; Werowska, K.; Krupińska, A.; Matuszak, M.; Włodarczak, S.; Bielecki, Z. An Analysis of the Process of Applying Technical Lubricating Coatings. Appl. Sci. 2023, 13, 2983. https://doi.org/10.3390/app13052983

Ochowiak M, Werowska K, Krupińska A, Matuszak M, Włodarczak S, Bielecki Z. An Analysis of the Process of Applying Technical Lubricating Coatings. Applied Sciences. 2023; 13(5):2983. https://doi.org/10.3390/app13052983

Chicago/Turabian StyleOchowiak, Marek, Klaudia Werowska, Andżelika Krupińska, Magdalena Matuszak, Sylwia Włodarczak, and Zdzisław Bielecki. 2023. "An Analysis of the Process of Applying Technical Lubricating Coatings" Applied Sciences 13, no. 5: 2983. https://doi.org/10.3390/app13052983

APA StyleOchowiak, M., Werowska, K., Krupińska, A., Matuszak, M., Włodarczak, S., & Bielecki, Z. (2023). An Analysis of the Process of Applying Technical Lubricating Coatings. Applied Sciences, 13(5), 2983. https://doi.org/10.3390/app13052983