Application of CNN Models to Detect and Classify Leakages in Water Pipelines Using Magnitude Spectra of Vibration Sound

Abstract

1. Introduction

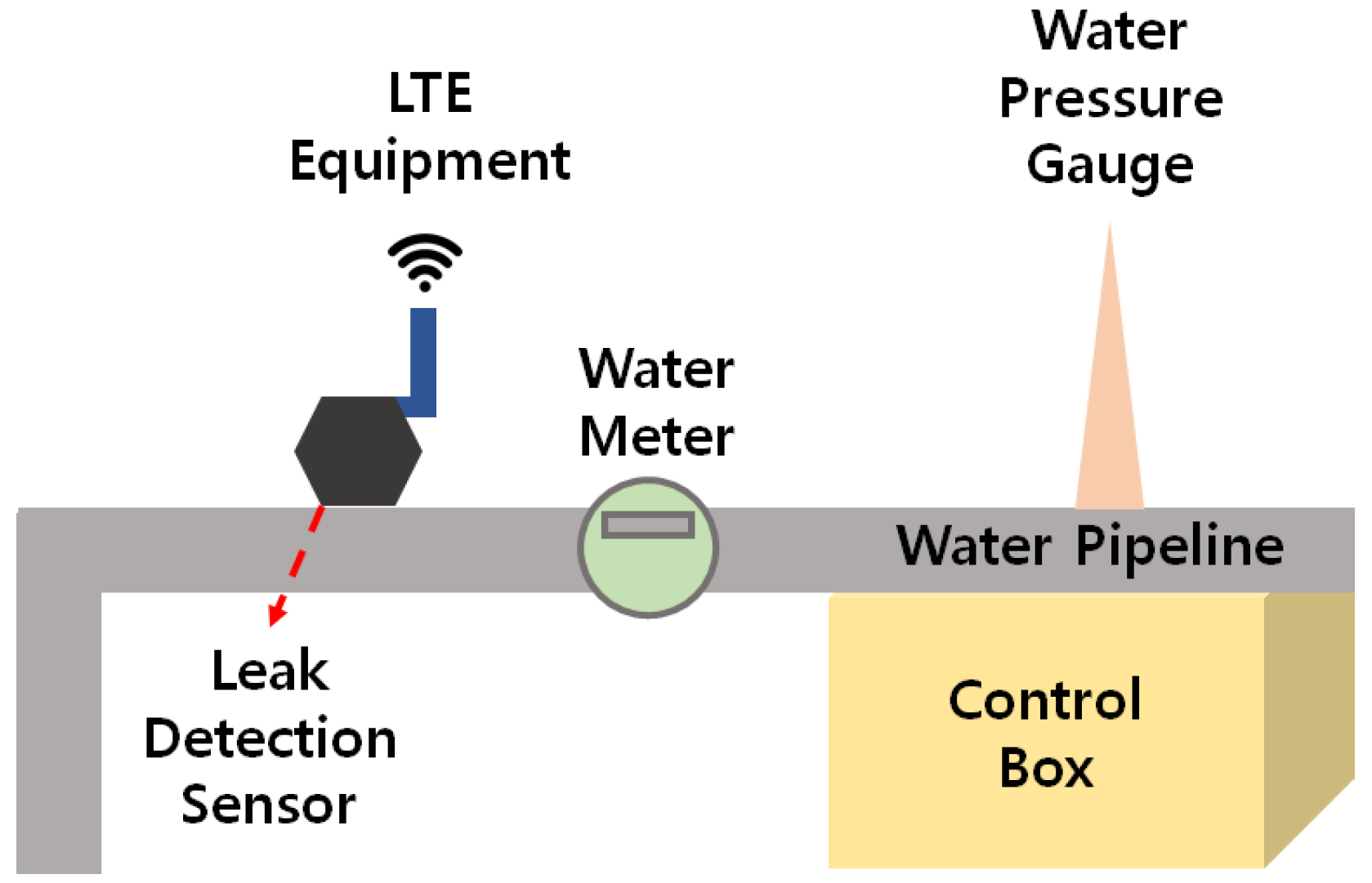

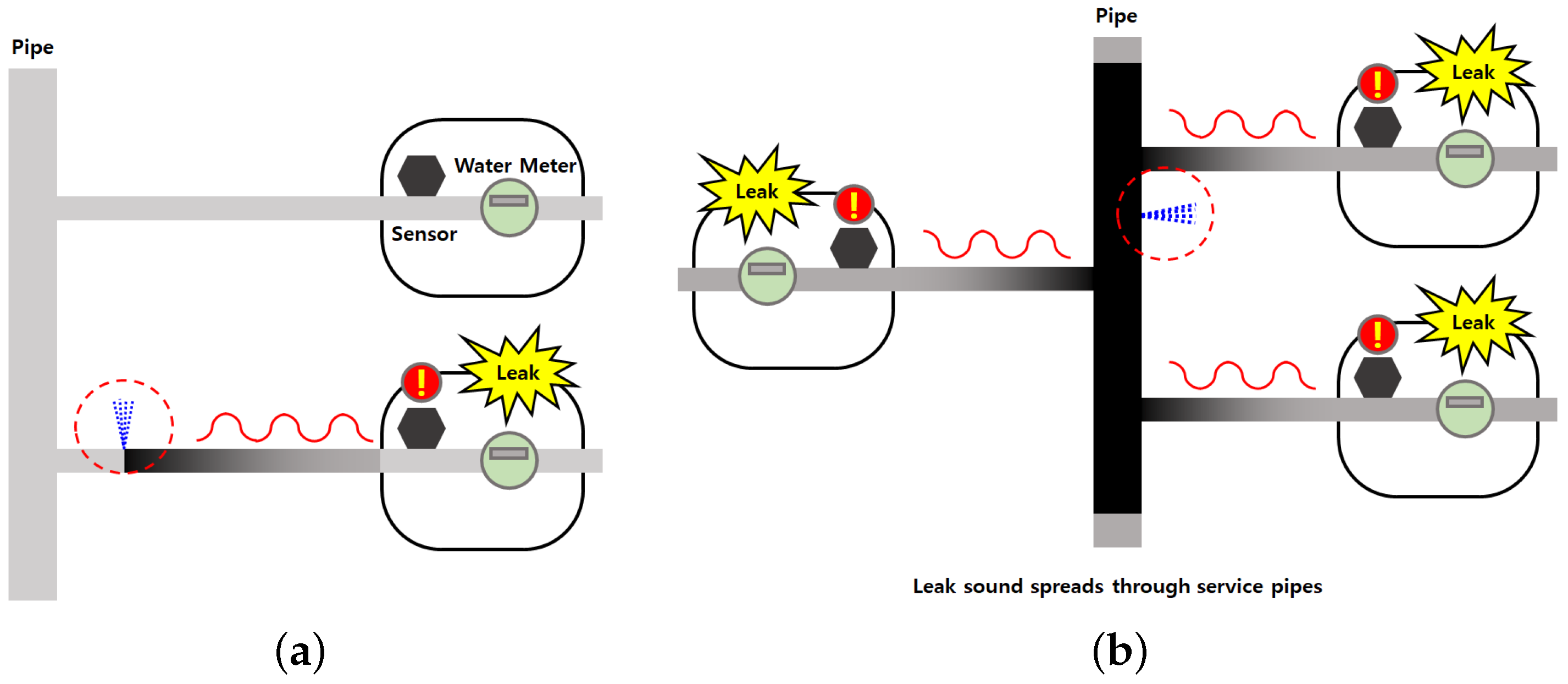

2. Data Description

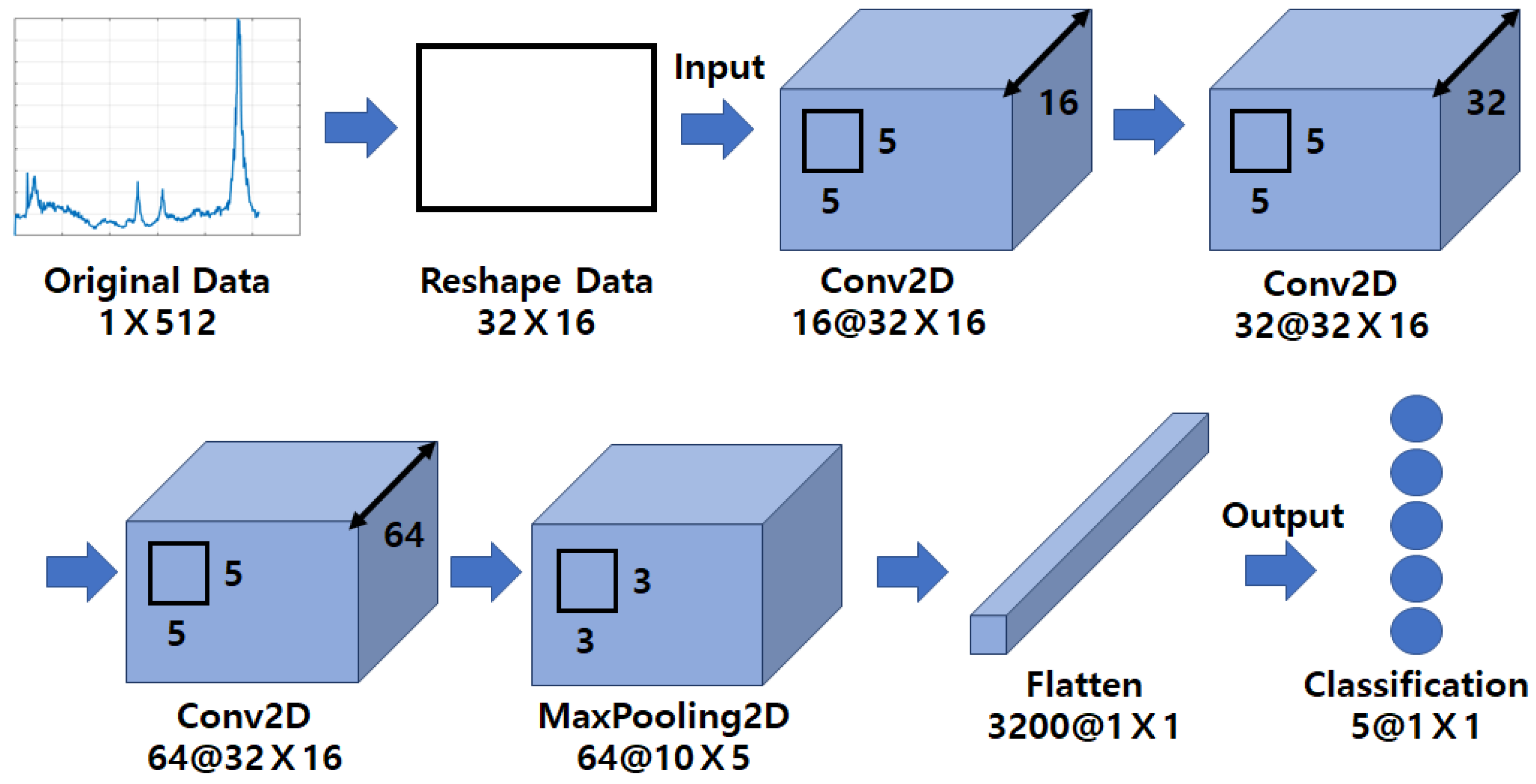

3. CNN Model

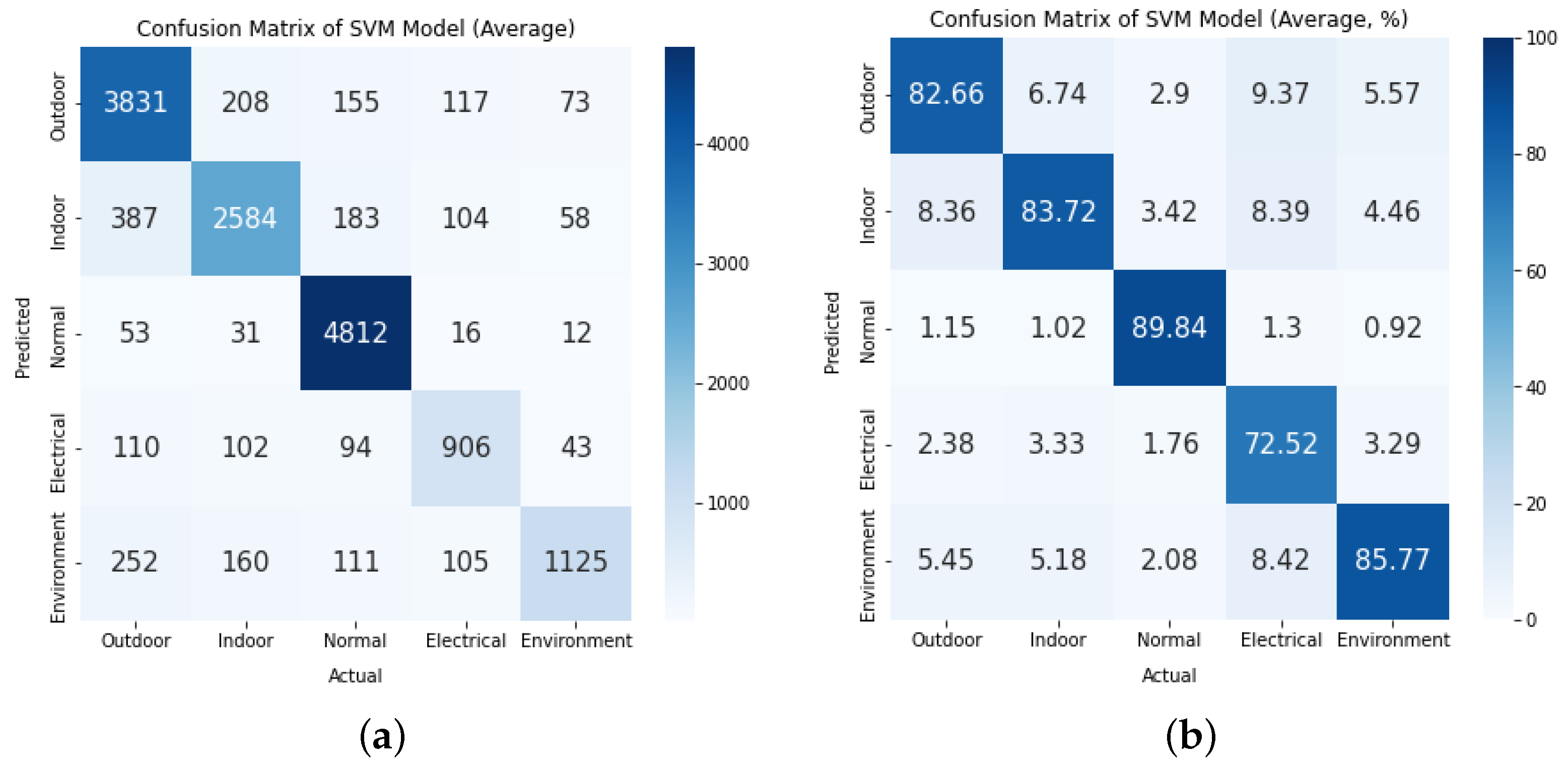

4. SVM Model

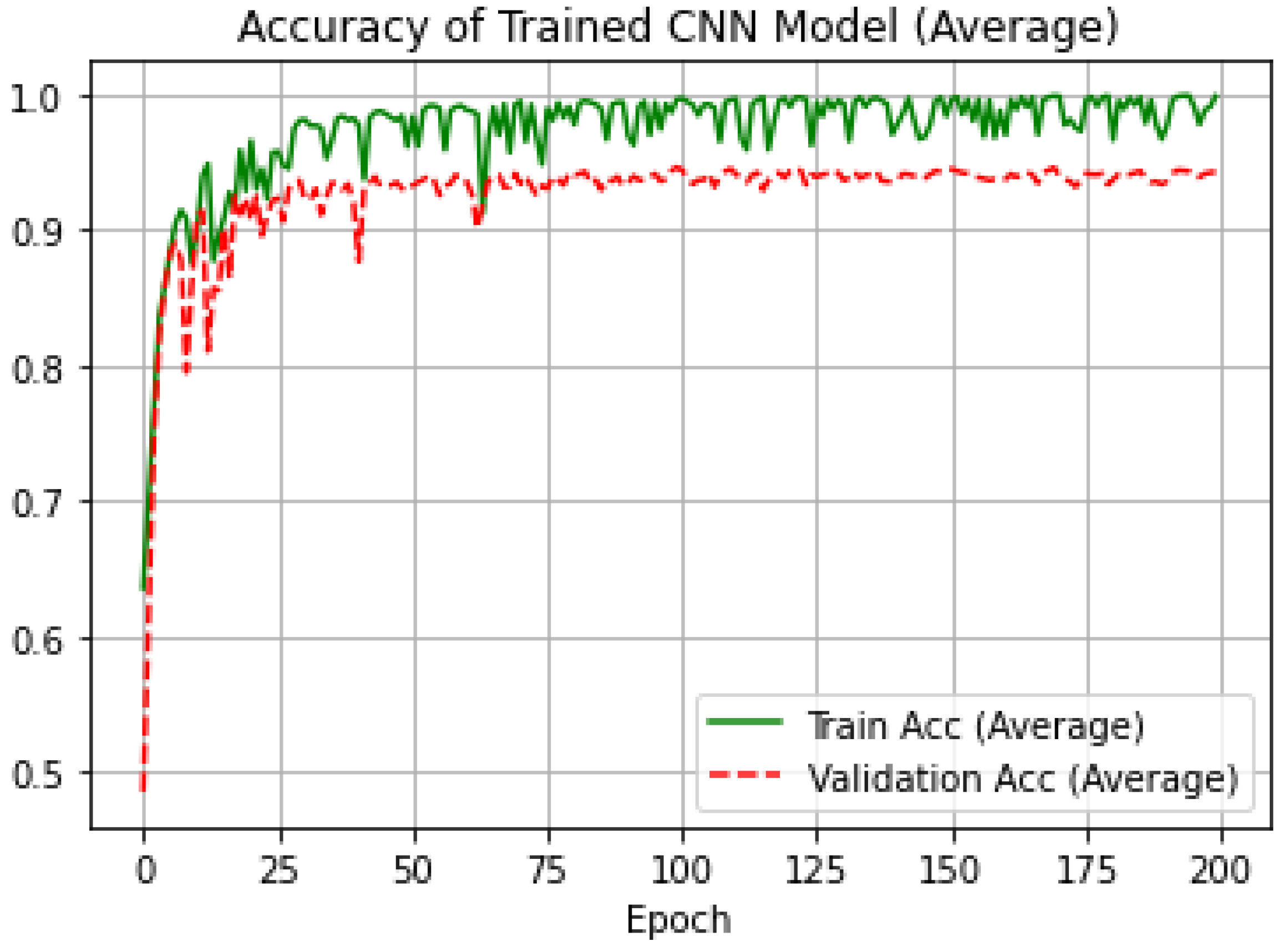

5. Experiment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choi, Y.H.; Kim, Y.R. Research Regard to Necessity of Smart Water Management Based on IoT Technology. J. Korea Ind. Inf. Syst. Res. 2017, 22, 11–18. [Google Scholar]

- Yoon, D.J.; Jeong, J.C.; Lee, Y.S. Leak detection of waterworks pipeline using acoustic emission and correlation method. In Proceedings of the KSME Conference, Busan, Korea, 23–25 April 2003; pp. 84–89. [Google Scholar]

- Colombo, A.F.; Karney, B.W. Energy and costs of leaky pipes: Toward comprehensive picture. J. Water Resour. Plan. Manag. 2002, 128, 441–450. [Google Scholar] [CrossRef]

- Xin, K.; Li, F.; Tao, T.; Xiang, N.; Yin, Z. Water losses investigation and evaluation in water distribution system—The case of SA city in China. Urban Water J. 2015, 12, 430–439. [Google Scholar] [CrossRef]

- Fuentes, H.; Mauricio, D. Smart water consumption measurement system for houses using IoT and cloud computing. Environ. Monit. Assess. 2020, 192, 1–16. [Google Scholar]

- Jan, F.; Min-Allah, N.; Saeed, S.; Iqbal, S.Z.; Ahmed, R. IoT-Based Solutions to Monitor Water Level, Leakage, and Motor Control for Smart Water Tanks. Water 2022, 14, 309. [Google Scholar]

- Rabeek, S.M.; Beibei, H.; Chai, K.T. Design of Wireless IoT Sensor Node & Platform for Water Pipeline Leak Detection. In Proceedings of the 2019 IEEE Asia-Pacific Microwave Conference (APMC), Singapore, 10–13 December 2019; IEEE: New York, NY, USA, 2019; pp. 1328–1330. [Google Scholar]

- Choi, S.H.; Eom, D.S. Wireless Water Leak Detection System Using Sensor Networks. J. Inst. Electron. Eng. Korea 2011, 48, 125–131. [Google Scholar]

- Choi, J.; Shin, J.; Song, C.; Han, S.; Park, D.I. Leak detection and location of water pipes using vibration sensors and modified ML prefilter. Sensors 2017, 17, 2104. [Google Scholar] [CrossRef]

- Chuang, W.Y.; Tsai, Y.L.; Wang, L.H. Leak detection in water distribution pipes based on CNN with mel frequency cepstral coefficients. In Proceedings of the 2019 3rd International Conference on Innovation in Artificial Intelligence, Suzhou, China, 15–18 March 2019; pp. 83–86. [Google Scholar]

- Choi, Y.; Cho, W. Research of Automatic Water Leak Detection Technology Used on Thermography and Deep Learning. J. Korean Inst. Inf. Technol. 2018, 16, 1–9. [Google Scholar]

- Ravichandran, T.; Gavahi, K.; Ponnambalam, K.; Burtea, V.; Mousavi, S.J. Ensemble-based machine learning approach for improved leak detection in water mains. J. Hydroinform. 2021, 23, 307–323. [Google Scholar] [CrossRef]

- Zhou, B.; Lau, V.; Wang, X. Machine-learning-based leakage-event identification for smart water supply systems. IEEE Internet Things J. 2019, 7, 2277–2292. [Google Scholar]

- Li, J.; Liu, Y.; Chai, Y.; He, H.; Gao, M. A Small Leakage Detection Approach for Gas Pipelines based on CNN. In Proceedings of the 2019 CAA Symposium on Fault Detection, Supervision and Safety for Technical Processes (SAFEPROCESS), Xiamen, China, 5–7 July 2019; IEEE: New York, NY, USA, 2019; pp. 390–394. [Google Scholar]

- Ning, F.; Cheng, Z.; Meng, D.; Duan, S.; Wei, J. Enhanced spectrum convolutional neural architecture: An intelligent leak detection method for gas pipeline. Process Saf. Environ. Prot. 2021, 146, 726–735. [Google Scholar]

- Ismail, M.I.M.; Dziyauddin, R.A.; Salleh, N.A.A.; Muhammad-Sukki, F.; Bani, N.A.; Izhar, M.A.M.; Latiff, L.A. A review of vibration detection methods using accelerometer sensors for water pipeline leakage. IEEE Access 2019, 7, 51965–51981. [Google Scholar] [CrossRef]

- Waleed, D.; Mustafa, S.H.; Mukhopadhyay, S.; Abdel-Hafez, M.F.; Jaradat, M.A.K.; Dias, K.R.; Arif, F.; Ahmed, J.I. An in-pipe leak detection robot with a neural-network-based leak verification system. IEEE Sens. J. 2018, 19, 1153–1165. [Google Scholar] [CrossRef]

- Ong, K.; Png, W.; Lin, H.; Pua, C.; Rahman, F. Acoustic vibration sensor based on macro-bend coated fiber for pipeline leakage detection. In Proceedings of the 2017 17th International Conference on Control, Automation and Systems (ICCAS), Jeju, Korea, 18–21 October 2017; IEEE: New York, NY, USA, 2017; pp. 167–171. [Google Scholar]

- Spandonidis, C.; Theodoropoulos, P.; Giannopoulos, F.; Galiatsatos, N.; Petsa, A. Evaluation of deep learning approaches for oil & gas pipeline leak detection using wireless sensor networks. Eng. Appl. Artif. Intell. 2022, 113, 104890. [Google Scholar]

- Spandonidis, C.; Theodoropoulos, P.; Giannopoulos, F. A Combined Semi-Supervised Deep Learning Method for Oil Leak Detection in Pipelines Using IIoT at the Edge. Sensors 2022, 22, 4105. [Google Scholar]

- Li, Q.; Shi, Y.; Lin, R.; Qiao, W.; Ba, W. A novel oil pipeline leakage detection method based on the sparrow search algorithm and CNN. Measurement 2022, 204, 112122. [Google Scholar]

- Yu, Y.; Samali, B.; Rashidi, M.; Mohammadi, M.; Nguyen, T.N.; Zhang, G. Vision-based concrete crack detection using a hybrid framework considering noise effect. J. Build. Eng. 2022, 61, 105246. [Google Scholar]

- Yu, Y.; Liang, S.; Samali, B.; Nguyen, T.N.; Zhai, C.; Li, J.; Xie, X. Torsional capacity evaluation of RC beams using an improved bird swarm algorithm optimised 2D convolutional neural network. Eng. Struct. 2022, 273, 115066. [Google Scholar]

- Zha, W.; Liu, Y.; Wan, Y.; Luo, R.; Li, D.; Yang, S.; Xu, Y. Forecasting monthly gas field production based on the CNN-LSTM model. Energy 2022, 260, 124889. [Google Scholar]

- Meniconi, S.; Capponi, C.; Frisinghelli, M.; Brunone, B. Leak detection in a real transmission main through transient tests: Deeds and misdeeds. Water Resour. Res. 2021, 57, e2020WR027838. [Google Scholar]

- Brunone, B.; Maietta, F.; Capponi, C.; Keramat, A.; Meniconi, S. A review of physical experiments for leak detection in water pipes through transient tests for addressing future research. J. Hydraul. Res. 2022, 60, 894–906. [Google Scholar] [CrossRef]

- Vapnik, V. An overview of statistical learning theory. IEEE Trans. Neural Netw. 1999, 10, 988–999. [Google Scholar] [CrossRef]

- Platt, J. Sequential Minimal Optimization: A Fast Algorithm for Training Support Vector Machines; Technical Report MSR-TR-98-14; Microsoft: Washington, DC, USA, 1998. [Google Scholar]

- Mandal, S.K.; Chan, F.T.; Tiwari, M. Leak detection of pipeline: An integrated approach of rough set theory and artificial bee colony trained SVM. Expert Syst. Appl. 2012, 39, 3071–3080. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, Q.; Wen, J.; Wang, F. Natural gas pipeline small leakage feature extraction and recognition based on LMD envelope spectrum entropy and SVM. Measurement 2014, 55, 434–443. [Google Scholar] [CrossRef]

- Gao, Y.; Brennan, M.; Joseph, P.; Muggleton, J.; Hunaidi, O. On the selection of acoustic/vibration sensors for leak detection in plastic water pipes. J. Sound Vib. 2005, 283, 927–941. [Google Scholar] [CrossRef]

- AI-Hub, Water and Sewage Data (Water Pipeline Leak Detection). Available online: https://www.aihub.or.kr/aihubdata/data/view.do?currMenu=115&topMenu=100&aihubDataSe=realm&dataSetSn=138 (accessed on 23 December 2022).

- LeCun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Han, S.; Qubo, C.; Meng, H. Parameter selection in SVM with RBF kernel function. In Proceedings of the World Automation Congress 2012, Puerto Vallarta, Mexico, 24–28 June 2012; IEEE: New York, NY, USA, 2012; pp. 1–4. [Google Scholar]

- Powers, D.M. Evaluation: From precision, recall and F-measure to ROC, informedness, markedness and correlation. arXiv 2020, arXiv:2010.16061. [Google Scholar]

- Grandini, M.; Bagli, E.; Visani, G. Metrics for Multi-Class Classification: An Overview. arXiv 2020, arXiv:2008.05756. [Google Scholar] [CrossRef]

- Jeni, L.A.; Cohn, J.F.; De La Torre, F. Facing imbalanced data–recommendations for the use of performance metrics. In Proceedings of the 2013 Humaine Association Conference on Affective Computing and Intelligent Interaction, Geneva, Switzerland, 2–5 September 2013; IEEE: New York, NY, USA, 2013; pp. 245–251. [Google Scholar]

- Gorodkin, J. Comparing two K-category assignments by a K-category correlation coefficient. Comput. Biol. Chem. 2004, 28, 367–374. [Google Scholar] [CrossRef]

- Chicco, D.; Jurman, G. The advantages of the Matthews correlation coefficient (MCC) over F1 score and accuracy in binary classification evaluation. BMC Genom. 2020, 21, 1–13. [Google Scholar] [CrossRef]

- Chicco, D.; Tötsch, N.; Jurman, G. The Matthews correlation coefficient (MCC) is more reliable than balanced accuracy, bookmaker informedness, and markedness in two-class confusion matrix evaluation. BioData Min. 2021, 14, 1–22. [Google Scholar] [CrossRef] [PubMed]

| Type | Label | Number |

|---|---|---|

| Normal | Normal | 24,628 |

| Anomaly | Outdoor Leakage | 21,923 |

| Indoor Leakage | 16,591 | |

| Noise | Electrical/Mechanical | 6288 |

| Environmental | 8774 | |

| Total | 78,204 |

| Layer | Type | Dimension | Kernel Size | Parameter # |

|---|---|---|---|---|

| 1 | Batch Normalization | 1@32 × 16 | 4 | |

| 2 | Convolution | 16@32 × 16 | 416 | |

| 3 | Batch Normalization | 16@32 × 16 | 5 × 5 | 64 |

| 4 | Convolution | 32@32 × 16 | 5 × 5 | 12,832 |

| 5 | Batch Normalization | 32@32 × 16 | 5 × 5 | 128 |

| 6 | Convolution | 64@32 × 16 | 5 × 5 | 51,264 |

| 7 | Maxpooling | 64@10 × 5 | 3 × 3 | - |

| 8 | Flatten | 3200@1 × 1 | - | - |

| 9 | Fully Connected | 5@1 × 1 | - | 16,005 |

| 10 | Output | 5@1 × 1 | - | - |

| Evaluation Metric | CNN | SVM |

|---|---|---|

| Precision | 0.9471 | 0.8295 |

| Recall | 0.9497 | 0.7984 |

| Accuracy | 0.9580 | 0.8478 |

| F1 score | 0.9482 | 0.8099 |

| MCC | 0.9447 | 0.7986 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.; Im, S. Application of CNN Models to Detect and Classify Leakages in Water Pipelines Using Magnitude Spectra of Vibration Sound. Appl. Sci. 2023, 13, 2845. https://doi.org/10.3390/app13052845

Choi J, Im S. Application of CNN Models to Detect and Classify Leakages in Water Pipelines Using Magnitude Spectra of Vibration Sound. Applied Sciences. 2023; 13(5):2845. https://doi.org/10.3390/app13052845

Chicago/Turabian StyleChoi, Jungyu, and Sungbin Im. 2023. "Application of CNN Models to Detect and Classify Leakages in Water Pipelines Using Magnitude Spectra of Vibration Sound" Applied Sciences 13, no. 5: 2845. https://doi.org/10.3390/app13052845

APA StyleChoi, J., & Im, S. (2023). Application of CNN Models to Detect and Classify Leakages in Water Pipelines Using Magnitude Spectra of Vibration Sound. Applied Sciences, 13(5), 2845. https://doi.org/10.3390/app13052845