Laboratorial Simulation for Assessing the Performance of Slates as Construction Materials in Cold Climates

Abstract

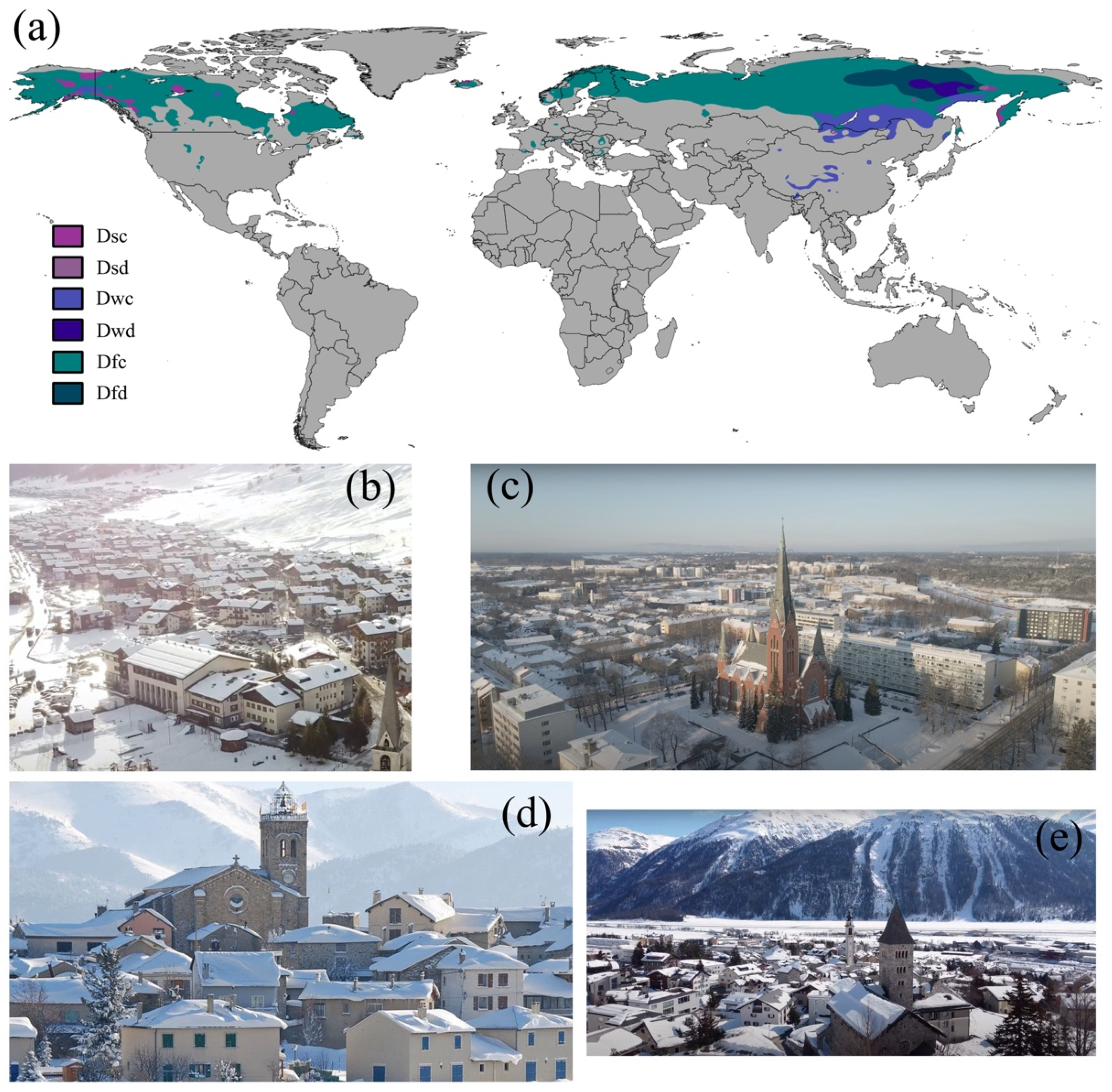

1. Introduction

Slate and Other Building Materials Performance at Low Temperatures

2. Slate Materials in European Building Sector

2.1. Slate Employment in Building Sector: Yesterday and Today

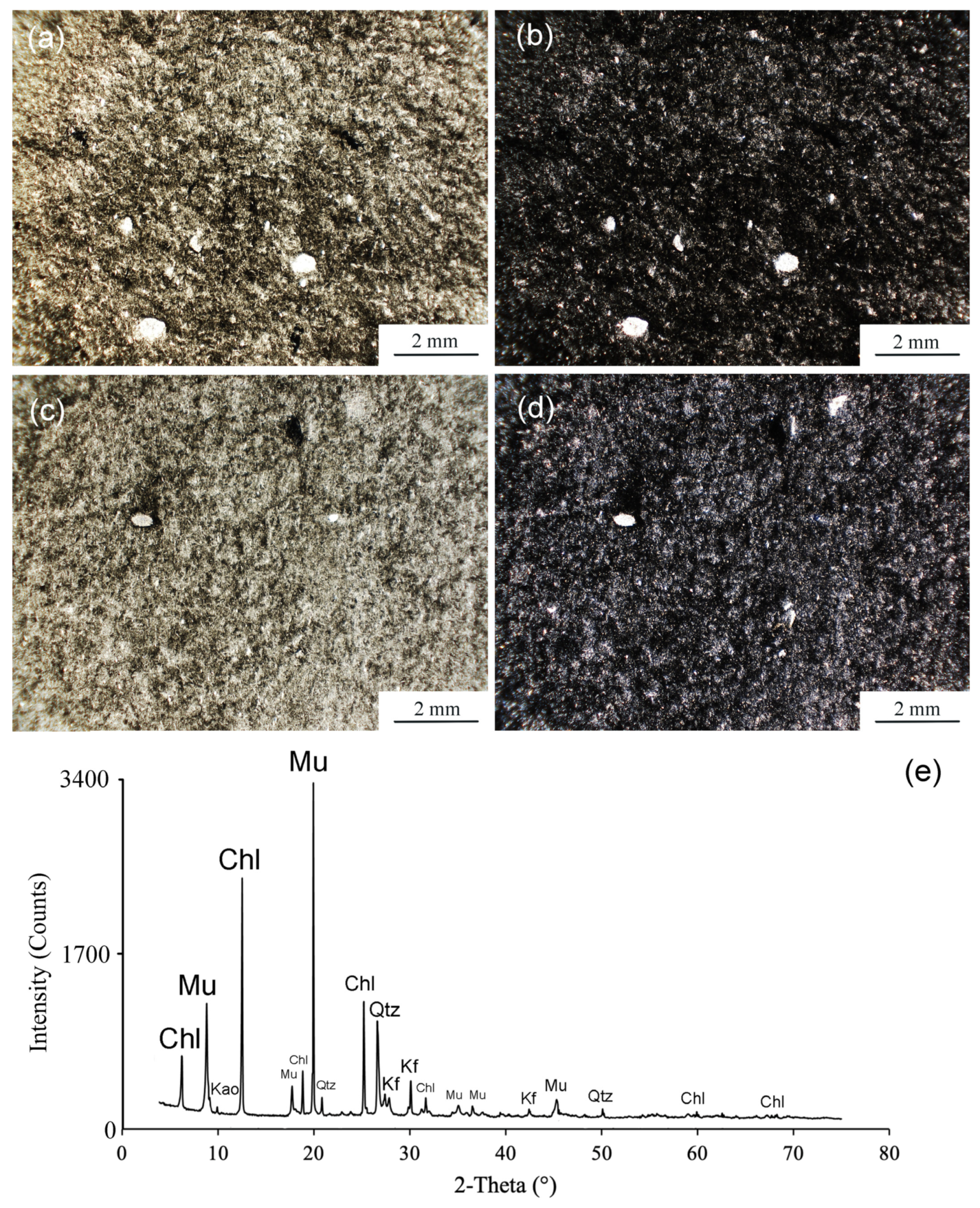

2.2. Petrographic Characteristics of Slate

3. Materials and Methods

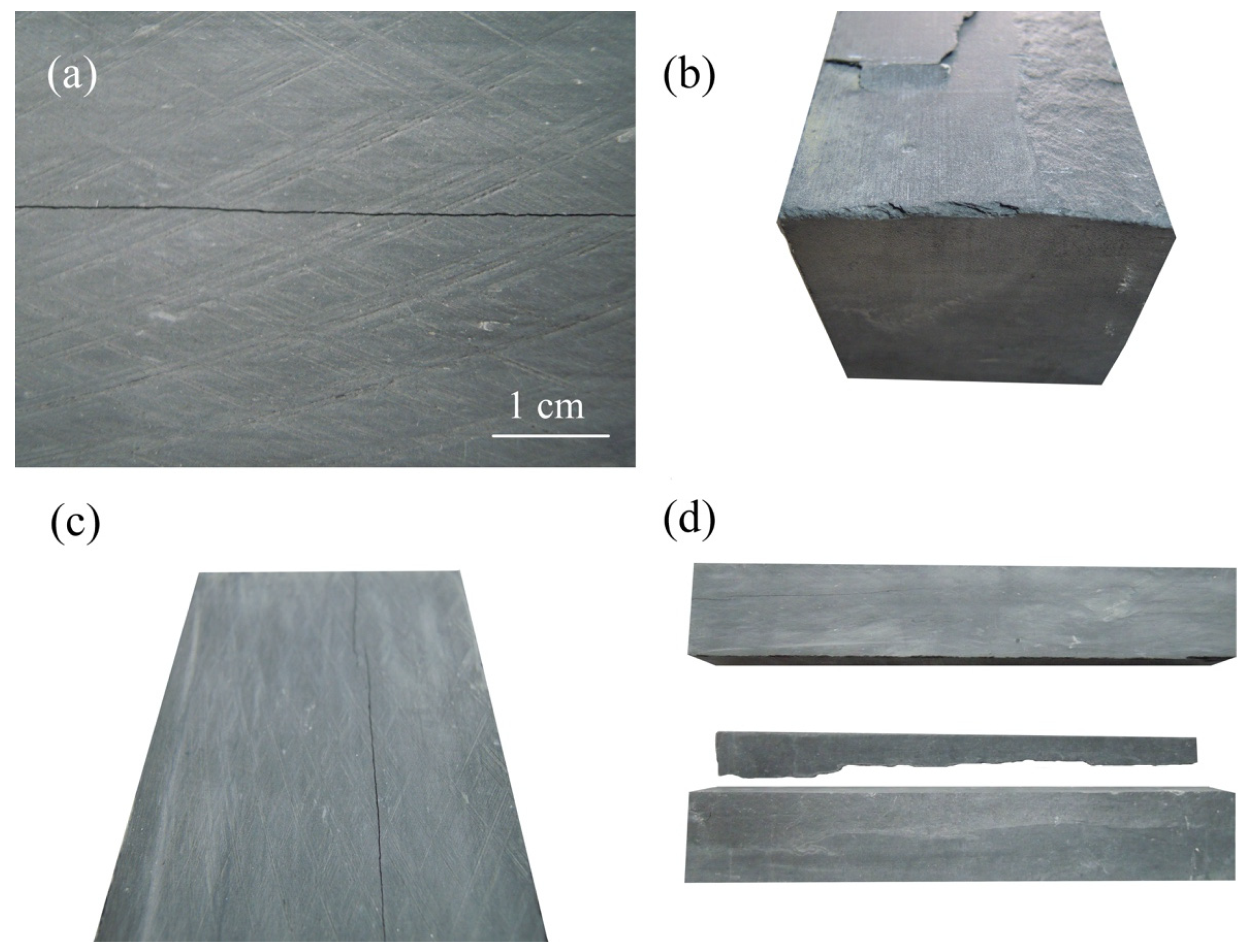

3.1. Materials

- (i)

- Prisms of 300 × 50 × 50 mm for flexural strength test (EN 12372, determination of flexure strength under concentrated load), measurement of sound propagation velocity (EN 14579, determination of sound speed propagation), and fundamental resonance frequency for the calculation of the elastic modulus (EN 14146, determination of dynamic elastic modulus);

- (ii)

- Cubes of 50 × 50 × 50 mm for apparent density and open porosity (EN 1936, determination of the real and apparent density and of the total and open porosity), water absorption test (EN 13755, determination of water absorption at atmospheric pressure), and uniaxial compression test (EN 1926, determination of uniaxial compressive strength);

- (iii)

- Slab-anchored specimens with stainless-steel metallic pins of 200 × 200 × 30 mm. In this last set, slabs had a 10 mm hole with 30 mm depth located in the center of each side in which the metallic anchor was fixed with CEM I 52.5 R according to EN 13364 (determination of the breaking load at dowel hole) standard test method requirements. Slate anisotropy was considered for specimens used in the flexural, compression, anchor rupture load, and capillary rising tests, and the specimens were oriented perpendicular to bedding planes;

- (iv)

- Prisms of 15 × 15 × 25 mm for the point load test (ASTM D 5731—determination of the point load strength index of rock);

- (v)

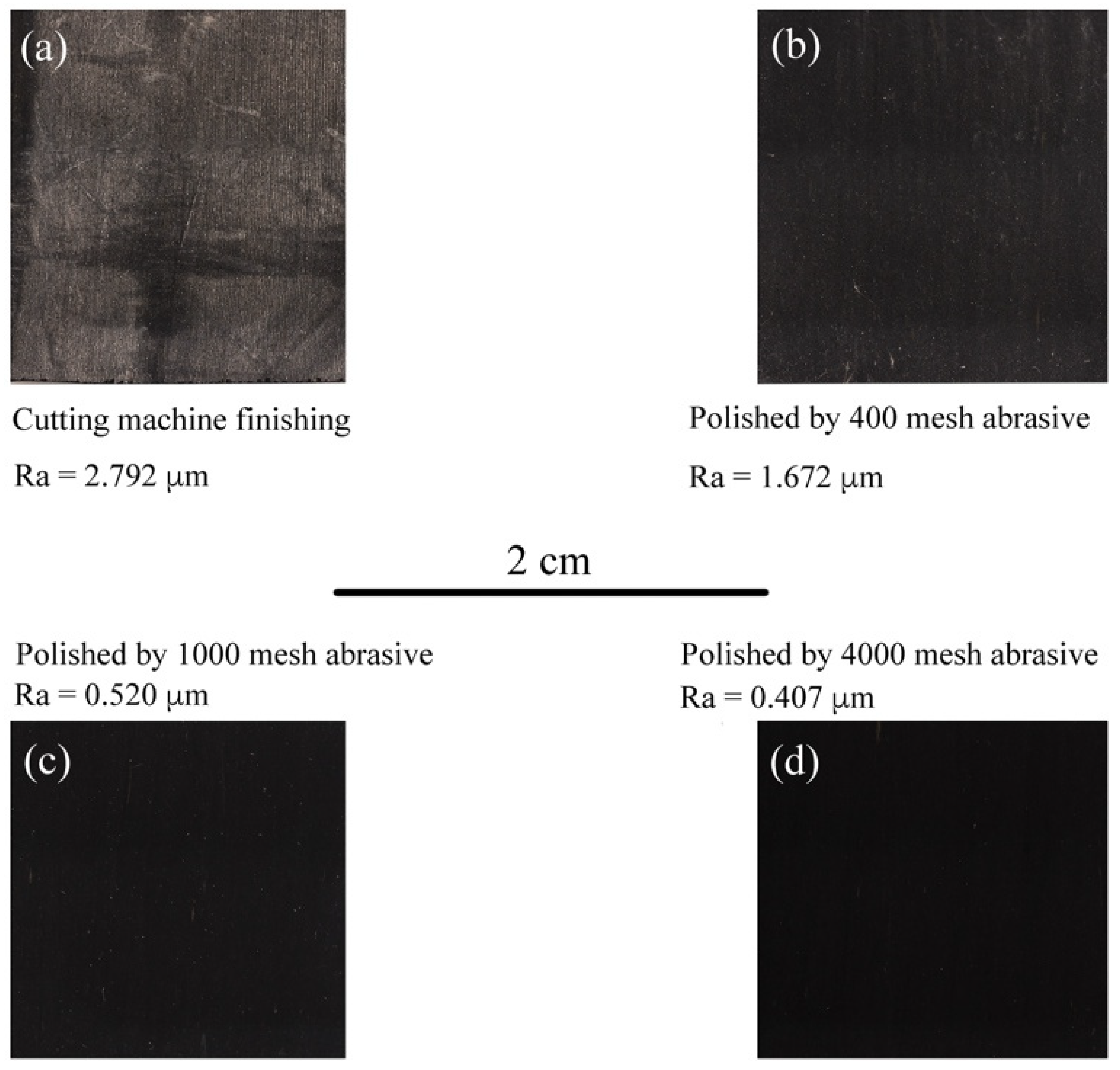

- Prisms of 20 × 20 × 8 mm for the accelerated aging from sunlight exposure in the SOLARBOX chamber.

3.2. Methods

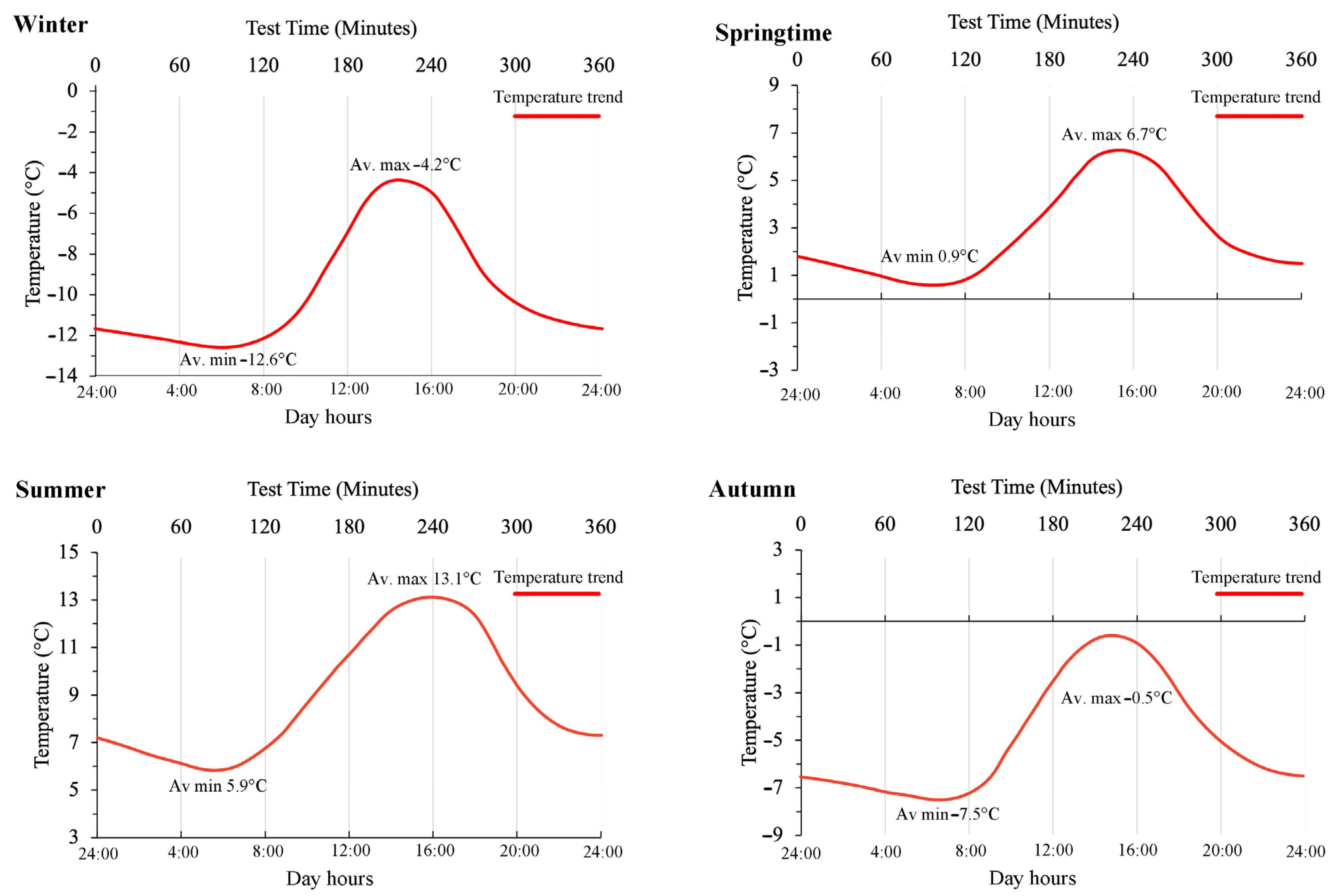

3.2.1. Artificial Climatic Cycles—FITOCLIMA Chamber Setting

3.2.2. Solar Radiation Simulation—SOLARBOX Chamber Setting

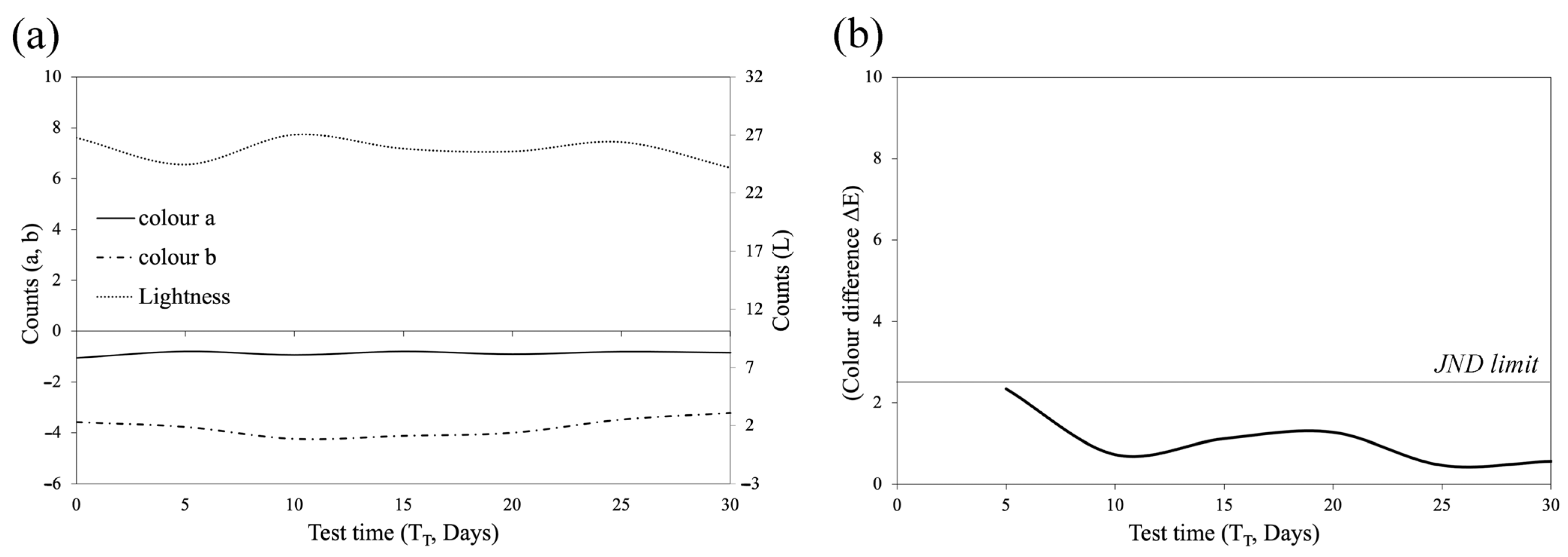

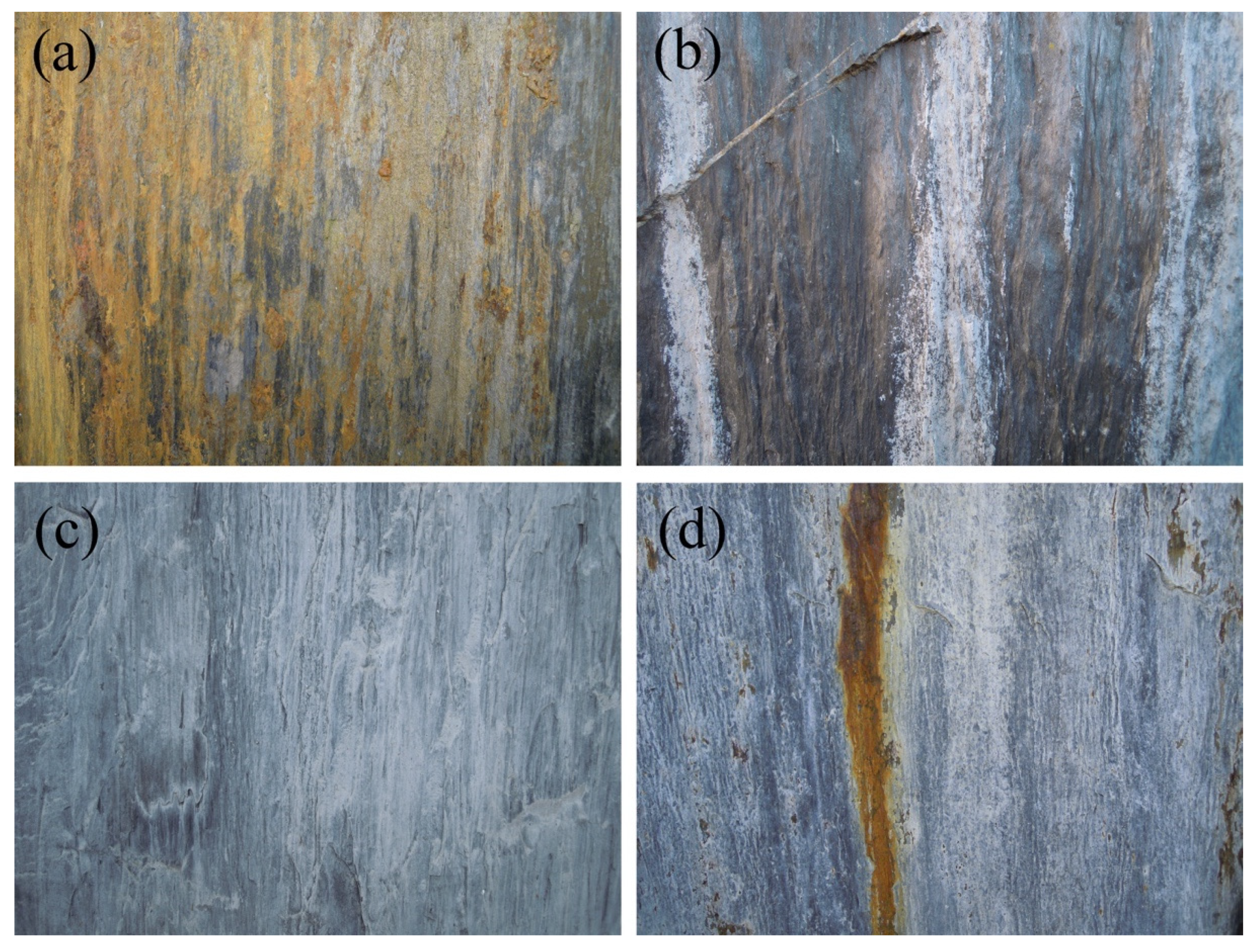

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geiger, R. Classificação Climática de Köppen- Geiger. Creat. Commons Attrib. Alike 3.0 Unported 1936. Available online: https://www.google.com/url?sa=i&rct=j&q=&esrc=s&source=web&cd=&ved=0CAQQw7AJahcKEwjIt8GisKT9AhUAAAAAHQAAAAAQAg&url=http%3A%2F%2Fwww.pha.poli.usp.br%2FLeArq.aspx%3Fid_arq%3D24064&psig=AOvVaw0Am1xDXGGkTQapStaHRXTo&ust=1676992005714690 (accessed on 10 February 2023).

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and Future Köppen-Geiger Climate Classification Maps at 1-Km Resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef] [PubMed]

- Pinna, M. L’atmosfera e Il Clima; UTET: Torino, Italy, 1978. [Google Scholar]

- Rubel, F.; Brugger, K.; Haslinger, K.; Auer, I. The Climate of the European Alps: Shift of Very High Resolution Köppen-Geiger Climate Zones 1800-2100. Meteorol. Z. 2017, 26, 115–125. [Google Scholar] [CrossRef]

- Stern, P. Critical Inuit Studies: An Anthology of Contemporary Arctic Ethnography; University of Nebraska: Lincoln, NE, USA, 2006; ISBN 9780803293489. [Google Scholar]

- Sitzia, F. Climate Change and Cultural Heritage: From Small- to Large-Scale Effects—The Case Study of Nora (Sardinia, Italy). Heritage 2022, 5, 3495–3514. [Google Scholar] [CrossRef]

- Columbu, S.; Palomba, M.; Sitzia, F.; Carcangiu, G.; Meloni, P. Pyroclastic Stones as Building Materials in Medieval Romanesque Architecture of Sardinia (Italy): Chemical-Physical Features of Rocks and Associated Alterations. Int. J. Archit. Herit. 2020, 16, 49–66. [Google Scholar] [CrossRef]

- García-Guinea, J.; Lombardero, M.; Roberts, B.; Taboada, J.; Peto, A. Mineralogy and Microstructure of Roofing Slate: Thermo-Optical Behaviour and Fissility. Mater. Constr. 1998, 48, 37–48. [Google Scholar] [CrossRef]

- Lisci, C.; Sitzia, F. Degrado, Danni e Difetti Delle Pietre Naturali e Dei Laterizi. Meccanismi Di Alterazione, Patologie, Tecniche Diagnostiche e Scehde Pratiche; Maggioli: Santarcangelo di Romagna, Italy, 2021; ISBN 8891650351. [Google Scholar]

- Martins, L.; Vasconcelos, G.; Lourenço, P.B.; Palha, C. Influence of the Freeze-Thaw Cycles on the Physical and Mechanical Properties of Granites. J. Mater. Civ. Eng. 2016, 28, 04015201. [Google Scholar] [CrossRef]

- Thomachot, C.; Jeannette, D. Evolution of the Petrophysical Properties of Two Types of Alsatian Sandstone Subjected to Simulated Freeze-Thaw Conditions. Geol. Soc. Spec. Publ. 2002, 205, 19–32. [Google Scholar] [CrossRef]

- Martínez-Martínez, J.; Benavente, D.; Gomez-Heras, M.; Marco-Castaño, L.; García-del-Cura, M.Á. Non-Linear Decay of Building Stones during Freeze–Thaw Weathering Processes. Constr. Build. Mater. 2013, 38, 443–454. [Google Scholar] [CrossRef]

- Laskaridis, K.; Arapakou, A.; Patronis, M.; Kouseris, I. Correlations between the Physical Mechanical Properties of Greek Dimension Stones. Mater. Proc. 2021, 5, 28. [Google Scholar]

- Park, K.; Kim, K.; Lee, K.; Kim, D. Analysis of Effects of Rock Physical Properties Changes from Freeze-Thaw Weathering in Ny-Ålesund Region: Part 1—Experimental Study. Appl. Sci. 2020, 10, 1707. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, X.; Hou, C.; He, J. Mechanical and Acoustic Emission Characteristics of Anhydrite Rock under Freeze-Thaw Cycles. J. Mt. Sci. 2023, 20, 227–241. [Google Scholar] [CrossRef]

- Abdolghanizadeh, K.; Hosseini, M.; Saghafiyazdi, M. Effect of Freezing Temperature and Number of Freeze–Thaw Cycles on Mode I and Mode II Fracture Toughness of Sandstone. Theor. Appl. Fract. Mech. 2020, 105, 102428. [Google Scholar] [CrossRef]

- Weng, L.; Wu, Z.; Taheri, A.; Liu, Q.; Lu, H. Deterioration of Dynamic Mechanical Properties of Granite Due to Freeze-Thaw Weathering: Considering the Effects of Moisture Conditions. Cold Reg. Sci. Technol. 2020, 176, 103092. [Google Scholar] [CrossRef]

- Navarro, R.; Catarino, L.; Pereira, D.; Paulo, F.; Campos, D.S. Effect of UV Radiation on Chromatic Parameters in Serpentinites Used as Dimension Stones. Bull. Eng. Geol. Environ. 2019, 78, 5345–5355. [Google Scholar] [CrossRef]

- Sitzia, F.; Lisci, C.; Mirão, J. Accelerate Ageing on Building Stone Materials by Simulating Daily, Seasonal Thermo-Hygrometric Conditions and Solar Radiation of Csa Mediterranean Climate. Constr. Build. Mater. 2021, 266, 121009. [Google Scholar] [CrossRef]

- Atalaya, M. Preventive Conservation Applied to the Mineralogical Collection of the National Museum of Natural History and Science of the University of Lisbon. Ph.D. Thesis, Universidade Nova de Lisboa, Lisboa, Portugal, 2020. [Google Scholar]

- Sitzia, F.; Lisci, C.; Mirão, J. Building Pathology and Environment: Weathering and Decay of Stone Construction Materials Subjected to a Csa Mediterranean Climate Laboratory Simulation. Constr. Build. Mater. 2021, 300, 124311. [Google Scholar] [CrossRef]

- Sitzia, F.; Lisci, C.; Mirão, J. The Interaction between Rainwater and Polished Building Stones for Flooring and Cladding—Implications in Architecture. J. Build. Eng. 2022, 52, 104495. [Google Scholar] [CrossRef]

- Labus, M.; Bochen, J. Sandstone Degradation: An Experimental Study of Accelerated Weathering. Environ. Earth Sci. 2012, 67, 2027–2042. [Google Scholar] [CrossRef]

- Pires, V.; Amaral, P.M.; Rosa, L.G.; Camposinhos, R.S. Slate Flexural and Anchorage Strength Considerations in Cladding Design. Constr. Build. Mater. 2011, 25, 3966–3971. [Google Scholar] [CrossRef]

- Taheri, B.M.; Ramezanianpour, A.M.; Sabokpa, S.; Gapele, M. Experimental Evaluation of Freeze-Thaw Durability of Pervious Concrete. J. Build. Eng. 2021, 33, 101617. [Google Scholar] [CrossRef]

- Sitzia, F.; Peters, M.J.H.; Lisci, C. Climate Change and Its Outcome on the Archaeological Areas and Their Building Materials. The Case Study of Tharros (Italy). Digit. Appl. Archaeol. Cult. Herit. 2022, 25, e00226. [Google Scholar] [CrossRef]

- Sitzia, F. The San Saturnino Basilica (Cagliari, Italy): An Up-Close Investigation about the Archaeological Stratigraphy of Mortars from the Roman to the Middle Ages. Heritage 2021, 4, 1836–1853. [Google Scholar] [CrossRef]

- Ruedrich, J.; Kirchner, D.; Siegesmund, S. Physical Weathering of Building Stones Induced by Freeze–Thaw Action: A Laboratory Long-Term Study. Environ. Earth Sci. 2011, 63, 1573–1586. [Google Scholar] [CrossRef]

- Lisci, C.; Pires, V.; Sitzia, F.; Mirão, J. Limestones Durability Study on Salt Crystallisation: An Integrated Approach. Case Stud. Constr. Mater. 2022, 17, e01572. [Google Scholar] [CrossRef]

- Pires, V.; Rosa, L.G.; Amaral, P.M.; Simão, J.A.R. The Susceptibility to Salt Fog Degradation of Stone Cladding Materials: A Laboratory Case Study on Two Limestones from Portugal. Heritage 2023, 6, 492–504. [Google Scholar] [CrossRef]

- Rivas, T.; Matías, J.M.; Taboada, J.; Argüelles, A. Application of Bayesian Networks to the Evaluation of Roofing Slate Quality. Eng. Geol. 2007, 94, 27–37. [Google Scholar] [CrossRef]

- Molina, E.; Cultrone, G.; Sebastián, E.; Alonso, F.J. Evaluation of Stone Durability Using a Combination of Ultrasound, Mechanical and Accelerated Aging Tests. J. Geophys. Eng. 2013, 10, 035003. [Google Scholar] [CrossRef]

- Amaral, P.M.; Fernandes, J.C.; Pires, V.; Rosa, L.G. Ornamental Stones. In Materials for Construction and Civil Engineering; Springer International Publishing: Cham, Switzerland, 2015; pp. 397–445. [Google Scholar]

- Savioli, L. Ardesia, Materia e Cultura; Sagep: Genova, Italy, 1988. [Google Scholar]

- Cardenes, V.; Cnudde, V.; Cnudde, J.P. Iberian Roofing Slate as a Global Heritage Stone Province Resource. Episodes 2015, 38, 97–105. [Google Scholar] [CrossRef]

- Kenneth, H. Building Materials; Longman Group: London, UK, 1972; ISBN 0-582-12791-2. [Google Scholar]

- Born, A. Blue Slate Quarrying in South Devon: An Ancient Industry. Ind. Archaeol. Rev. 2012. [Google Scholar] [CrossRef]

- Jope, E.M.; Dunning, G.C. The Use of Blue Slate for Roofing in Medieval England. Antiq. J. 1954, 34, 209–217. [Google Scholar] [CrossRef]

- Leite, A.; Guedes, C. Louseiras De Valongo 2022. Available online: https://repositorio-aberto.up.pt/bitstream/10216/141561/2/565602.pdf (accessed on 10 February 2023).

- Bartels, C.; Briggs, D.E.G.; Brassel, G. The Fossil Record of the Hunsrück Slate: Marine Life in the Devonian. Palaeontol. Electron. 1999. [Google Scholar]

- Hagen, A. Norges Oldtid; Cappelen: Oslo, Norway, 1967; ISBN 82-02-09067-9. [Google Scholar]

- Delgado, N.; Choffat, P. (Eds.) Carta Geológica de Portugal, Escala 1:500000; Direcção dos Trabalhos Geológicos: Lisbon, Portugal, 1908. [Google Scholar]

- EN 1926:2006—Natural Stone Test Methods—Determination of Uniaxial Compressive Strength. Available online: https://standards.iteh.ai/catalog/standards/cen/227bc05a-f18c-474f-8178-fd6f613fe740/en-1926-2006 (accessed on 9 August 2022).

- EN 12372:2006—Natural Stone Test Methods—Determination of Flexural Strength under Concentrated. Available online: https://standards.iteh.ai/catalog/standards/cen/304e13c4-a1ea-4a80-af45-ce1a644b5316/en-12372-2006 (accessed on 9 August 2022).

- EN 13364—Natural Stone Test Methods—Determination of the Breaking Load at Dowel Hole. Available online: https://standards.iteh.ai/catalog/standards/cen/8bee8e7b-e21e-4332-be71-58f161a74b6b/en-13364-2001 (accessed on 12 August 2022).

- ASTM D 5731; Standard Test Method for Determination of the Point Load Strength Index of Rock and Application to Rock Strength Classifications. American Society for Testing and Materials: West Conshohocken, PA, USA, 2008.

- EN 14579 Natural Stone Test Methods—Determination of Sound Speed Propagation—European Standards. Available online: https://www.en-standard.eu/une-en-14579-2005-natural-stone-test-methods-determination-of-sound-speed-propagation/ (accessed on 10 August 2022).

- EN 14146—Natural Stone Test Methods—Determination of the Dynamic Modulus of Elasticity (by Measuring the Fundamental Resonance Frequency). Available online: https://standards.globalspec.com/std/800632/EN14146 (accessed on 7 August 2022).

- Bansa, H. Accelerated Ageing of Paper: Some Ideas on Its Practical Benefit. Restaurator 2002, 23, 106–117. [Google Scholar] [CrossRef]

- Crewdson, M. Outdoor Weathering Must Verify Accelerated Testing. In Proceedings of the Annual Technical Conference—ANTEC, Newtown, CT, USA, 1–5 May 2011. [Google Scholar]

- Vergari, S. AM, Aeronautica Militare Italiana, La Radiazione Solare Globale e La Durata Del Soleggiamento in Italia Dal 1991 Al 2010; ENEA: Rome, Italy, 2018. [Google Scholar]

- EOTA TR 010, Exposure Procedure for Artificial Weathering, Technical Report. Available online: https://www.eota.eu/sites/default/files/uploads/Technical%20reports/tr010.pdf (accessed on 10 February 2023).

- ASTM D3424-11; Standard Practice for Evaluating the Relative Lightfastness and Weatherability of Printed Matter. ASTM International: West Conshohocken, PA, USA, 2001.

- Fookes, P.G.; Dearman, W.R.; Franklin, J.A. Some Engineering Aspects of Rock Weathering with Field Examples from Dartmoor and Elsewhere. Q. J. Eng. Geol. 1971, 4, 139–185. [Google Scholar] [CrossRef]

- Alves, C.; Figueiredo, C.A.M.; Sanjurjo-Sánchez, J.; Hernández, A.C. Effects of Water on Natural Stone in the Built Environment—A Review. Geosciences 2021, 11, 459. [Google Scholar] [CrossRef]

- Fahey, B.D. Frost Action and Hydration as Rock Weathering Mechanisms on Schist: A Laboratory Study. Earth Surf. Process. Landf. 1983, 8, 535–545. [Google Scholar] [CrossRef]

- Kahraman, S.; Ulker, U.; Delibalta, M.S. A Quality Classification of Building Stones from P-Wave Velocity and Its Application to Stone Cutting with Gang Saws. J. S. Afr. Inst. Min. Metall. 2007, 107, 427–430. [Google Scholar] [CrossRef]

- Amaral, P.M.; Fernandes, J.C.; Rosa, L.G. Weibull Statistical Analysis of Granite Bending Strength. Rock Mech. Rock Eng. 2008, 41, 917–928. [Google Scholar] [CrossRef]

- Amaral, P.M.; Guerra Rosa, L.; Cruz Fernandes, J. Assessment of Fracture Toughness in Ornamental Stones. Int. J. Rock Mech. Min. Sci. 2008, 45, 554–563. [Google Scholar] [CrossRef]

- Lo Monaco, A.; Marabelli, M.; Pelosi, C.; Picchio, R. Colour Measurements of Surfaces to Evaluate the Restoration Materials. In Proceedings of the O3A: Optics for Arts, Architecture, and Archaeology III, Munich, Germany, 25–26 May 2011. [Google Scholar]

- Lisci, C.; Sitzia, F.; Pires, V.; Mirão, J. Building Stones Durability by UVA Radiation, Moisture and Spray Accelerated Weathering. J. Build. Pathol. Rehabil. 2022, 7, 60. [Google Scholar] [CrossRef]

| Season | Average Min. Temperature (°C) | Average Max. Temperature (°C) | Average Rainfall Accumulation (mm) |

|---|---|---|---|

| Winter | −12.6 | −4.2 | 362 |

| Spring | 0.9 | 6.7 | 723 |

| Summer | 5.9 | 13.1 | 581 |

| Autumn | −7.5 | −0.5 | 417 |

| Conditioning | Step (i) | Step (ii) | Step (iii) | |

|---|---|---|---|---|

| Winter—repeated for 1 month | Soaking and rainfall for 1 h at 10 °C | 2 h|−12.6 °C | 1:30 h|−12.6 °C→−4.2 °C | 2:30 h|−4.2 °C→−12.6 °C |

| Spring—repeated for 1 month | 2 h|0.9 °C | 1:30 h|0.9 °C→−6.7 °C | 2:30 h|6.7 °C→0.9 °C | |

| Summer—repeated for 1 month | 2 h|5.9 °C | 1:30 h|5.9 °C→13.1 °C | 2:30 h|13.1 °C→5.9°C | |

| Fall—repeated for 1 month | 2 h|−7.5 °C | 1:30 h|−7.5 °C→−0.5 °C | 2:30 h|−0.5 °C→−7.5 °C |

| Physical and Mechanical Properties | No. of Tested Specimens | Before Aging | After Aging | Relative Difference (%) |

|---|---|---|---|---|

| Uniaxial compressive strength (MPa) | 10 | 175 ± 13 | 133 ± 14 | −24 |

| Flexural strength under concentrated load (MPa) | 10 | 30.4 ± 9.2 | 14.9 ± 3.8 | −50.9 |

| Anchor rupture load (N) | 12 × 4 | 3141 ± 221 | 2420 ± 275 | −22.9 |

| Point load strength index (MPa) | 10 | 13.1 ± 3.1 | 12.5 ± 2.4 | −4.5 |

| P-wave ultrasound speed (m/s) | 10 | 6120 ± 410 | 5566 ± 146 | −9 |

| Young’s modulus (GPa) | 10 | 88.5 ± 13.1 | 72.3 ± 6.9 | −18.3 |

| Apparent density (kg/m3) | 6 | 2833.5 ± 6.5 | 2813.4 ± 3.8 | −0.7 |

| Open porosity (%) | 6 | 0.87 ± 0.1 | 1.5 ± 0.2 | 72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sitzia, F.; Lisci, C.; Pires, V.; Alves, T.; Mirão, J. Laboratorial Simulation for Assessing the Performance of Slates as Construction Materials in Cold Climates. Appl. Sci. 2023, 13, 2761. https://doi.org/10.3390/app13052761

Sitzia F, Lisci C, Pires V, Alves T, Mirão J. Laboratorial Simulation for Assessing the Performance of Slates as Construction Materials in Cold Climates. Applied Sciences. 2023; 13(5):2761. https://doi.org/10.3390/app13052761

Chicago/Turabian StyleSitzia, Fabio, Carla Lisci, Vera Pires, Tiago Alves, and José Mirão. 2023. "Laboratorial Simulation for Assessing the Performance of Slates as Construction Materials in Cold Climates" Applied Sciences 13, no. 5: 2761. https://doi.org/10.3390/app13052761

APA StyleSitzia, F., Lisci, C., Pires, V., Alves, T., & Mirão, J. (2023). Laboratorial Simulation for Assessing the Performance of Slates as Construction Materials in Cold Climates. Applied Sciences, 13(5), 2761. https://doi.org/10.3390/app13052761