Development of Potato Mass Estimation System Based on Deep Learning

Abstract

1. Introduction

2. Materials and Methods

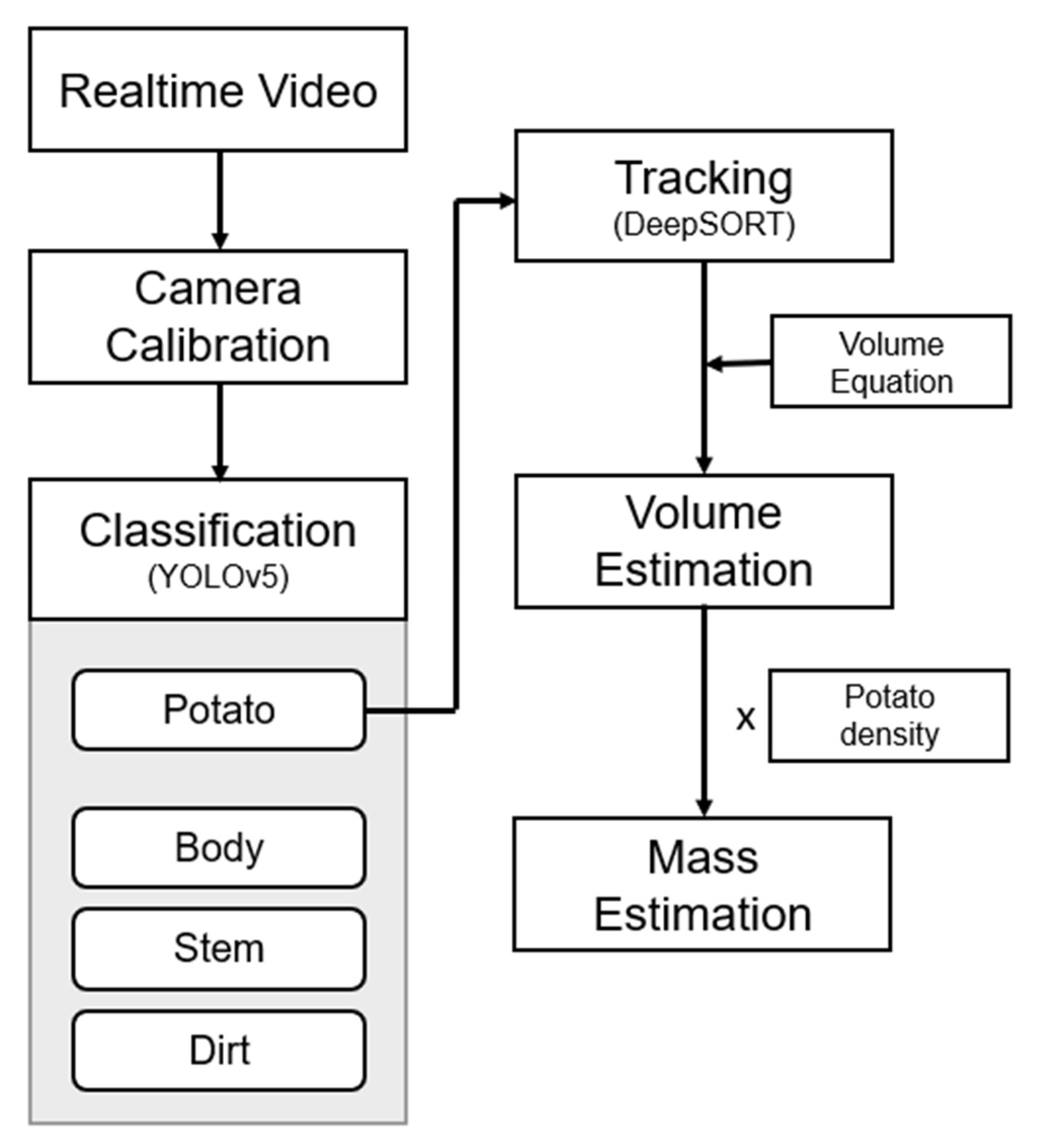

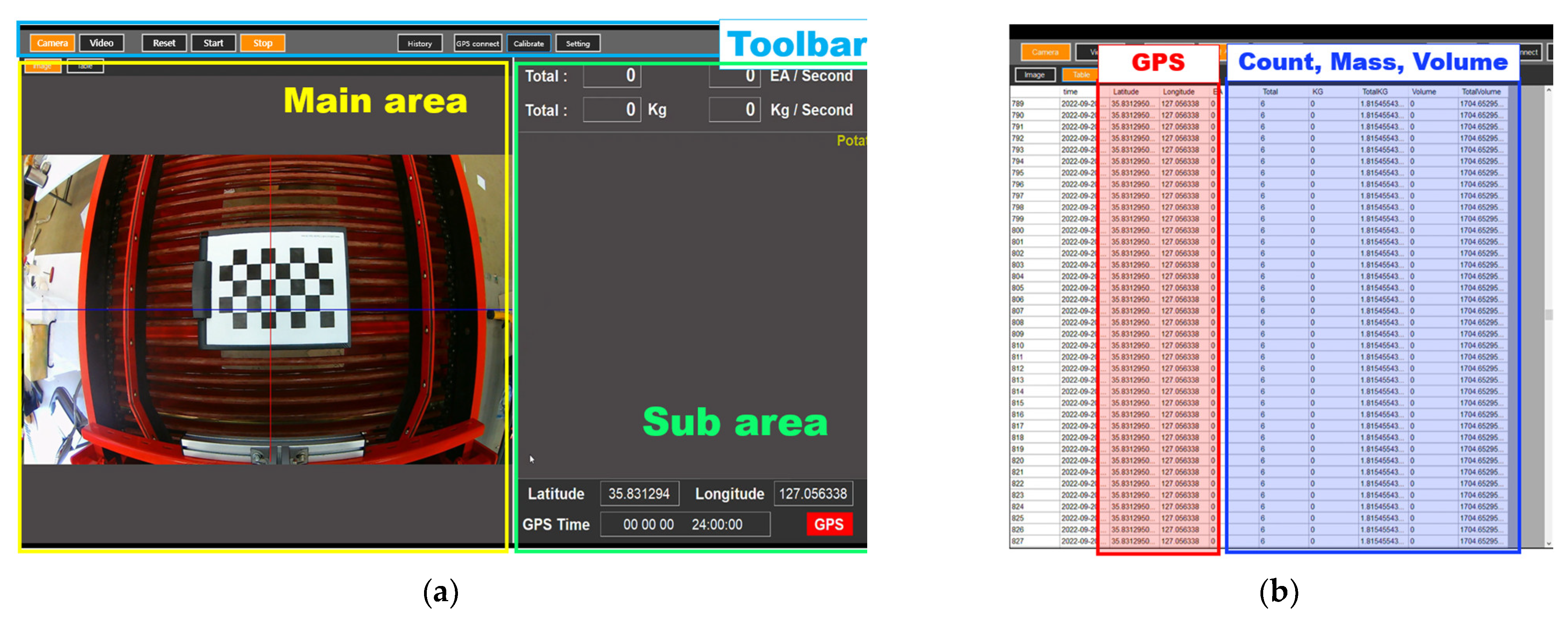

2.1. Potato Mass Estimation System

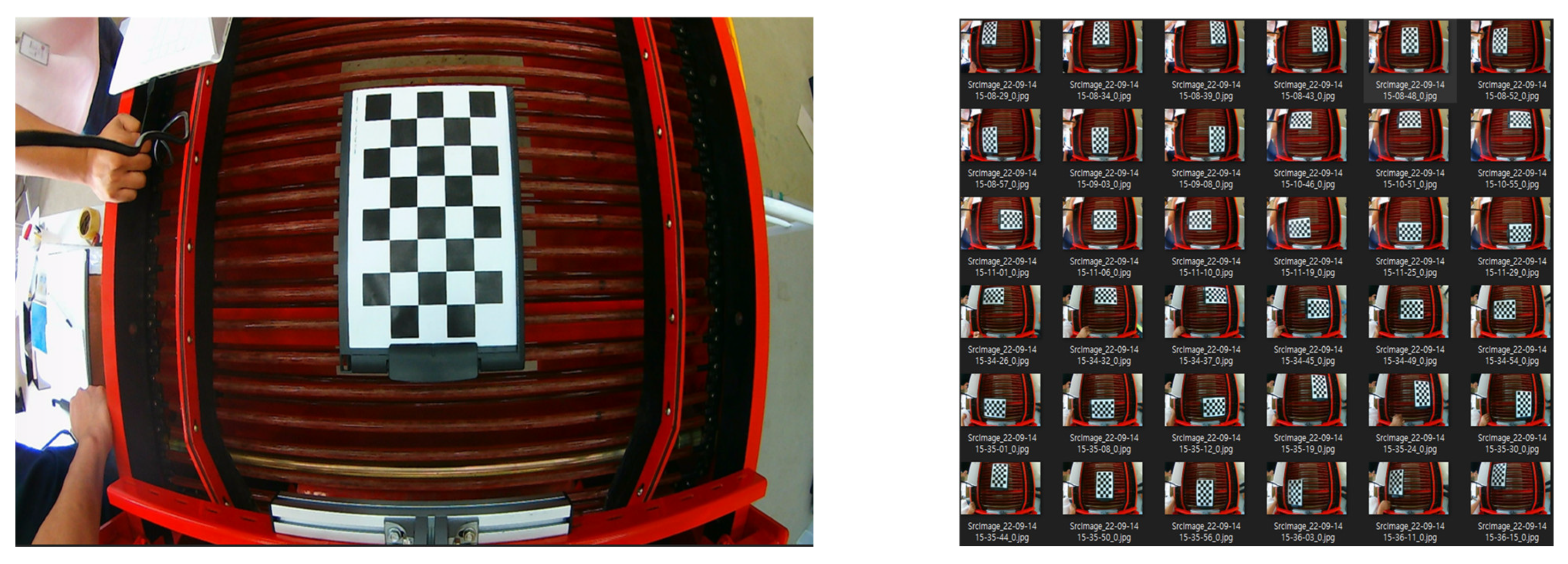

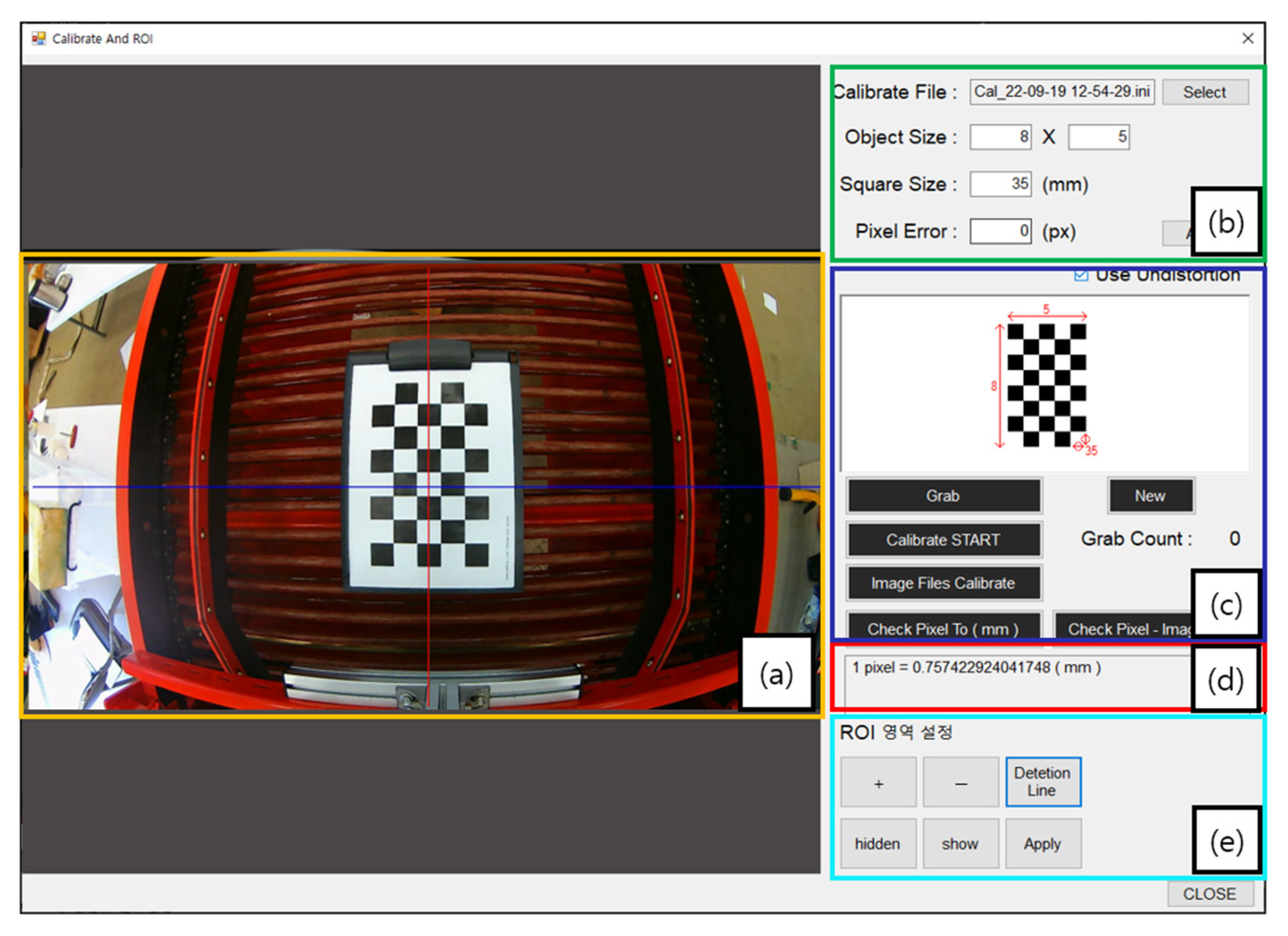

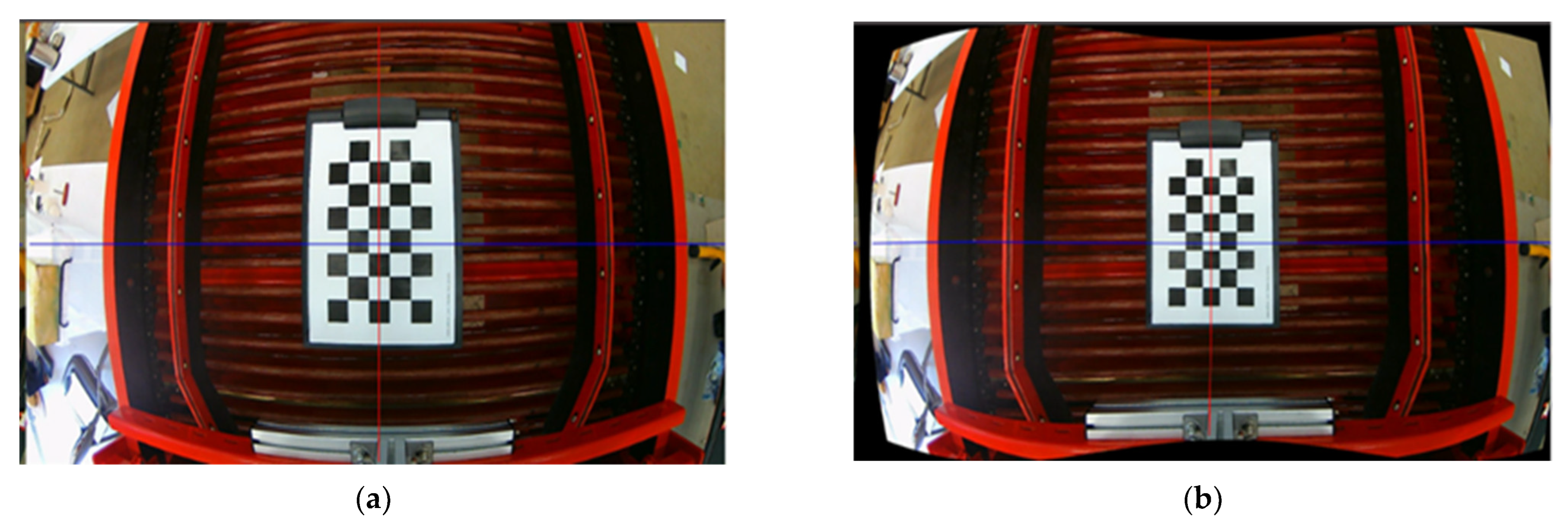

2.1.1. Camera Calibration

2.1.2. Classification

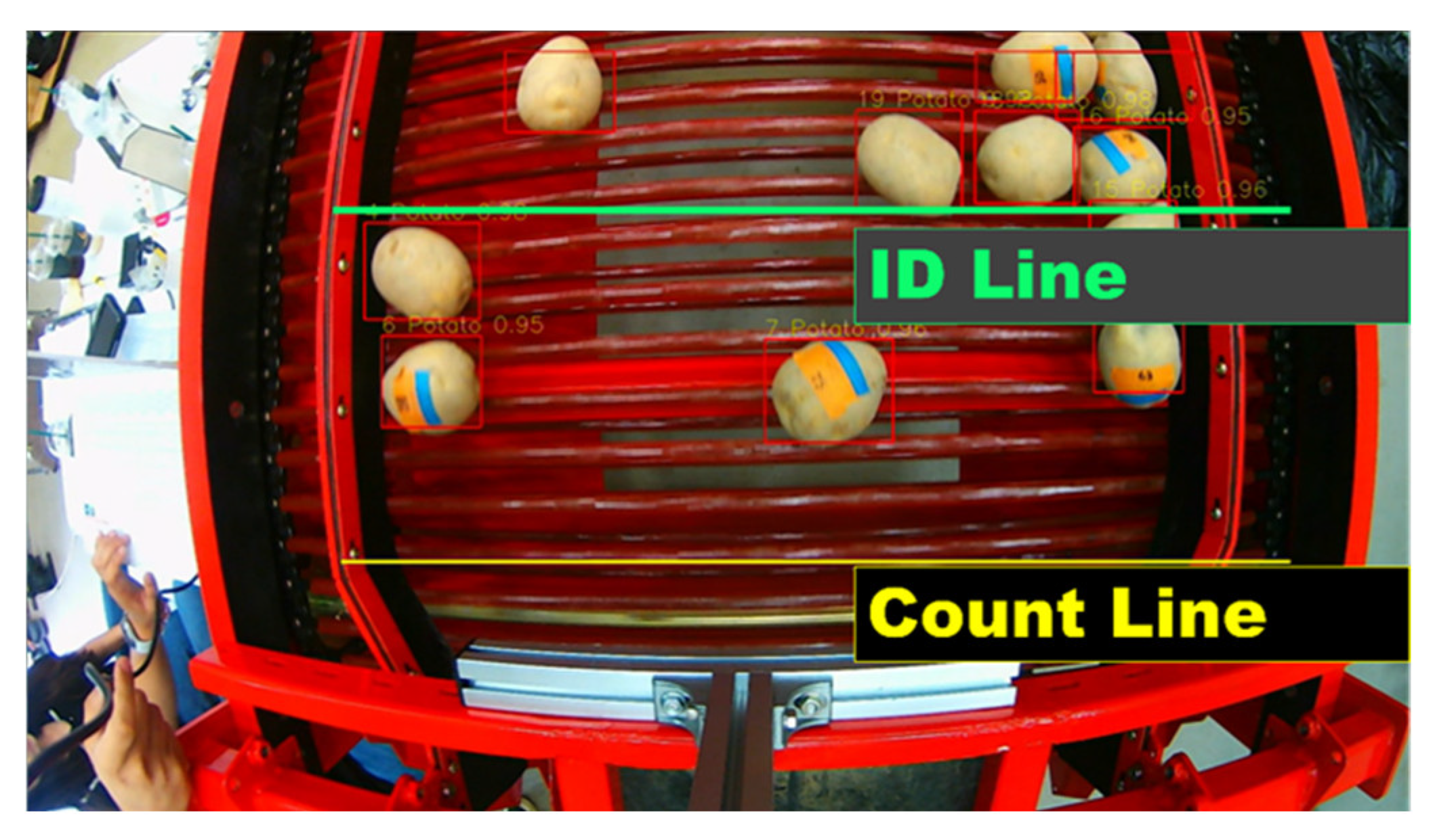

2.1.3. Tracking

2.2. Mass Estimation Equation

2.3. Potato Mass Estimation System Performance Analysis

3. Results and Discussion

3.1. Implement Results of Potato Mass Estimation System

3.2. Mass Estimation Equation

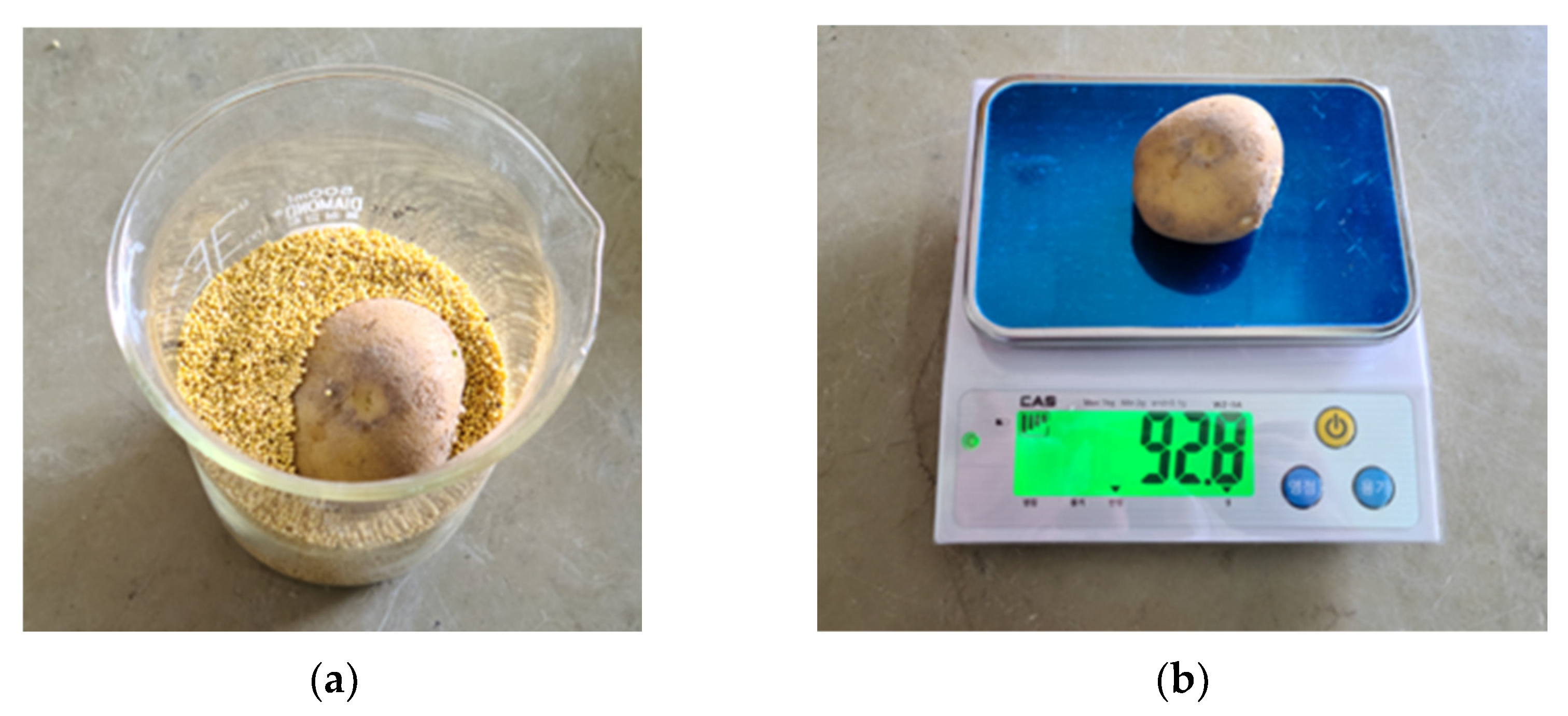

3.2.1. Physical Properties of Potatoes

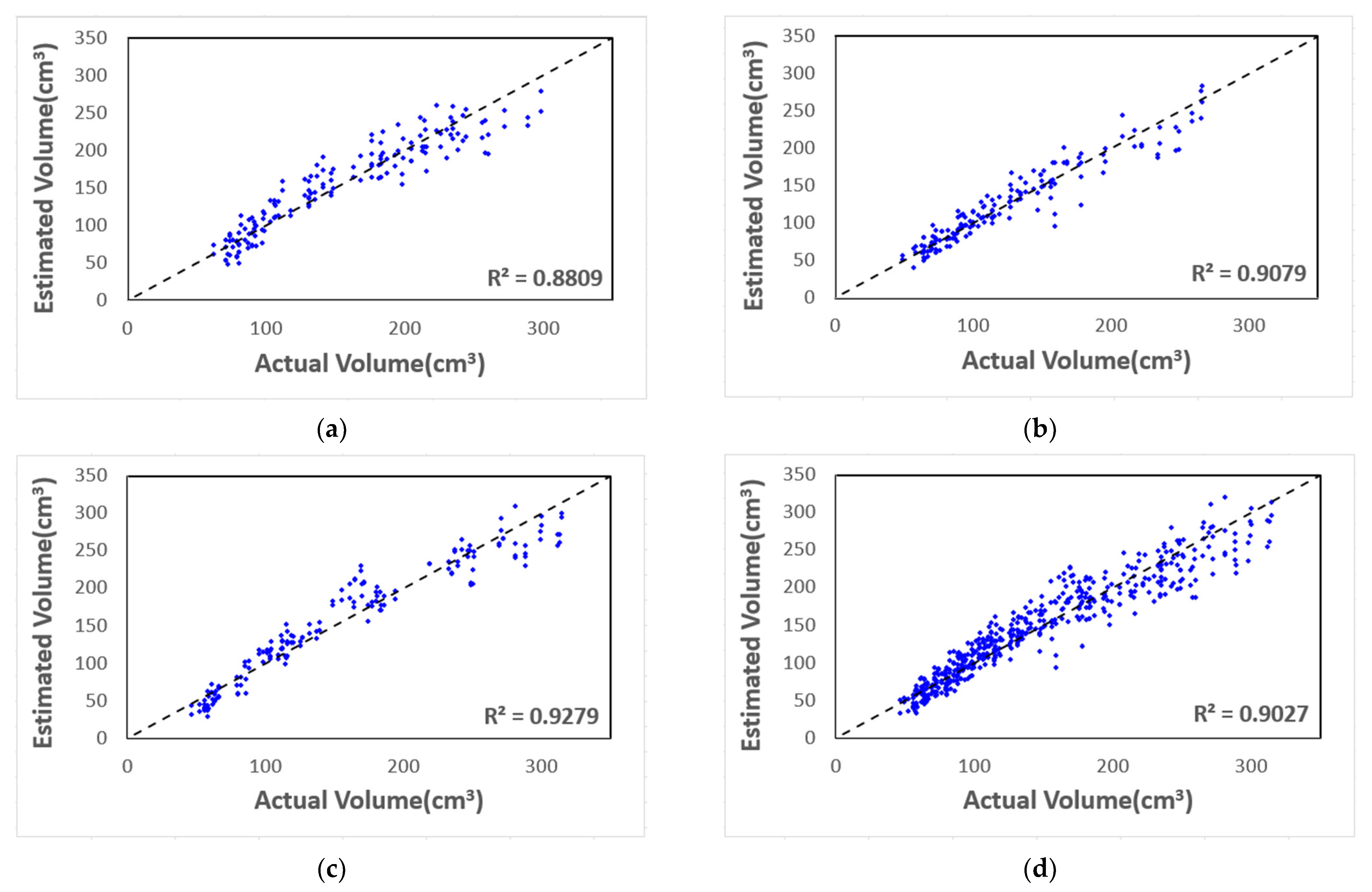

3.2.2. Volume Estimation Equation

3.2.3. Result of Mass Estimation

3.3. Performance Analysis Result of Potato Mass Estimation System

4. Conclusions

- (1)

- A system was developed that carries out potato object tracking and counting by applying YOLOv5, one of the deep learning algorithms, and DeepSORT, one of the object tracking algorithms, to the real-time image obtained by a camera installed on top of the potato harvester sorting unit, and this system estimates the mass of a detected potato by calculating its volume using the major axis and minor axis lengths of its bounding box and then multiplying this by the density.

- (2)

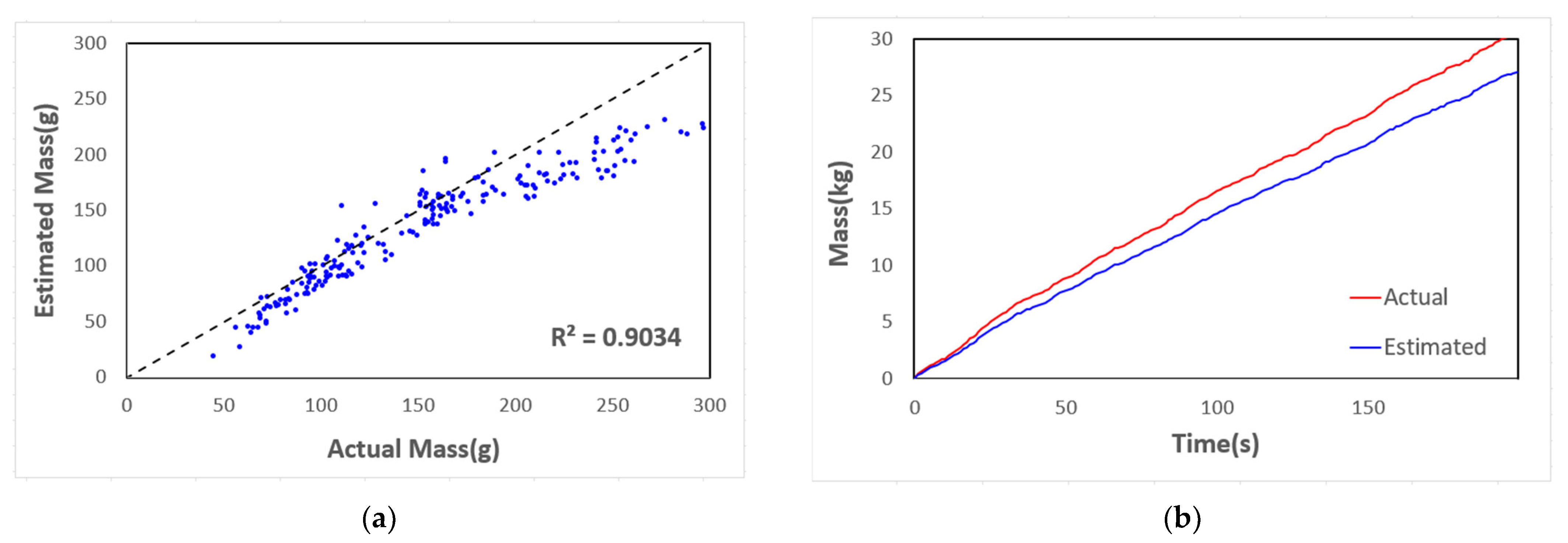

- As a result of estimating the mass of individual potatoes using the developed system, R2 was 0.9034 and the average error was found to be 13.09%. As a result of continuously putting in potatoes to match the actual harvesting speed, the potato object detection rate was found to be 95.2%, whereas the error of the total measured mass was 9%.

- (3)

- To improve the accuracy and reduce the error, a weighted value needs to be applied to the location of potato within the view angle of the camera. It is also necessary to improve the performance of the computer, and the phenomenon wherein potatoes are not counted due to frame drop must be prevented by widening the counting range to reduce the computation load. To reduce the error of the system, a regression model is required to be improved by dividing a dataset into calibration and validation.

- (4)

- The potato mass estimation system examined in the present study was developed and evaluated in a laboratory environment. The result of the evaluation indicates that the performance of the system and the algorithm used need to be improved. An additional study needs to be carried out in the future to apply an optimum algorithm and improve the problems found by conducting an actual field test, such as noise filtering caused by the vibration of the harvester and optimization of the integration time to improve the accuracy according to sunlight exposure.

- (5)

- An additional study needs to be carried out for the visualization of yield information within a lot by combining the yield information from the system and collecting GPS information to prepare a yield map, and it is judged that the yield monitoring of other underground crops such as onion would be possible by applying the same system used in the present study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO), Crops and Livestock Products. Available online: https://www.fao.org/ (accessed on 25 September 2022).

- Korea Statistical Information Service (KOSIS), Potatoes Production (Field). Available online: https://kosis.kr/ (accessed on 25 September 2022).

- Choi, M.K. An analysis for the changing trends of residential environment based on the change of residents in rural areas. J. Korean Inst. Rural. Archit. 2012, 14, 9–16. [Google Scholar]

- Bongiovanni, R.; Lowenberg-DeBoer, J. Precision agriculture and sustainability. Precis. Agric. 2004, 5, 359–387. [Google Scholar] [CrossRef]

- Linsley, C.M.; Bauer, F.C. Test Your Soil for Acidity; Circular, No. 346; University of Illinois, Agricultural Experiment Station: Urbana, IL, USA, 1929. [Google Scholar]

- Usery, E.L.; Pocknee, S.; Boydell, B. Precision farming data management using geographic information systems. Photogramm. Eng. Remote Sens. 1995, 61, 1383–1392. [Google Scholar]

- Chosa, T. Investigation of the deviation of the yield in a direct sowing paddy field. Jpn. J. Farm Work. Res. 1998, 33, 27–28. [Google Scholar]

- Kobayashi, T. Prototype yield monitoring combines (head feeding type). Jpn. J. Farm Work. Res. 1998, 33, 29–30. [Google Scholar]

- Reyns, P.; Missotten, B.; Ramon, H.; De Baerdemaeker, J. A review of combine sensors for precision farming. Precis. Agric. 2002, 3, 169–182. [Google Scholar] [CrossRef]

- Chinchuluun, R.; Lee, W. Machine vision-based citrus yield mapping system. In Proceedings of the Florida State Horticultural Society, Portland, OR, USA, 9–12 July 2006; pp. 142–147. [Google Scholar]

- Persson, D.; Eklundh, L.; Algerbo, P.-A. Evaluation of an optical sensor for tuber yield monitoring. Trans. ASAE 2004, 47, 1851. [Google Scholar] [CrossRef]

- Lee, Y.J. Development of Potato Yield Monitoring System Using Machine Vision. Master’s Thesis, Kangwon National University, Chuncheon-si, Republic of Korea, 2019. [Google Scholar]

- Larsson, K. Bildbehandlingsteknik för Sortering av Potatis; Jordbrukstekniska Institutet: Uppsala, Sweden, 1994. [Google Scholar]

- Hofstee, J.; Molema, G. Machine vision based yield mapping of potatoes. In Proceedings of the 2002 ASAE Annual Meeting, Chicago, IL, USA, 28–31 July 2002; p. 1. [Google Scholar]

- Long, Y.; Wang, Y.; Zhai, Z.; Wu, L.; Li, M.; Sun, H.; Su, Q. Potato volume measurement based on RGB-D camera. IFAC-Pap. 2018, 51, 515–520. [Google Scholar] [CrossRef]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You only look once: Unified, real-time object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, San Juan, PR, USA, 17–19 June 1997; pp. 779–788. [Google Scholar]

- Adarsh, P.; Rathi, P.; Kumar, M. YOLO v3-Tiny: Object Detection and Recognition using one stage improved model. In Proceedings of the 2020 6th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 6–7 March 2020; pp. 687–694. [Google Scholar]

- Jang, S.H.; Lee, S.H.; Choi, Y.; Kim, T.H.; Shin, S.Y. Design of a potato yield monitoring system using deep-learning. J. Korea Acad. Ind. 2022, 23, 217–224. [Google Scholar]

- Zhang, Z. A flexible new technique for camera calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1334. [Google Scholar] [CrossRef]

- Bewley, A.; Ge, Z.; Ott, L.; Ramos, F.; Upcroft, B. Simple online and realtime tracking. In Proceedings of the 2016 IEEE International Conference on Image Processing (ICIP), Phoenix, AZ, USA, 25–28 September 2016; pp. 3464–3468. [Google Scholar]

- Wojke, N.; Bewley, A.; Paulus, D. Simple online and realtime tracking with a deep association metric. In Proceedings of the 2017 IEEE International Conference on Image Processing (ICIP), Beijing, China, 17–20 September 2017; pp. 3645–3649. [Google Scholar]

- Yang, S.; Jung, I.; Kang, D.; Baek, H. Real-time multi-object tracking using mixture of SORT and DeepSORT. J. Korean Inst. Inf. Technol. 2021, 19, 1–9. [Google Scholar]

- Pitts, M.J.; Hyde, G.M.; Cavalieri, R.P. Modeling potato tuber mass with tuber dimensions. Trans. ASAE 1987, 30, 1154–1159. [Google Scholar] [CrossRef]

- Pyler, E. Physical and chemical test methods. Bak. Sci. Technol. 1979, 2, 891–895. [Google Scholar]

| Items | Specification |

|---|---|

| Width × height × depth (mm) | 46.5 × 96.4 × 24 |

| Power (W) | 5 |

| Weight (g) | 98 |

| Operation temperature (°C) | −25~85 |

| RTK accuracy | 0.010 m + 1 ppm CEP |

| RTK fix time (s) | 10~60 |

| GNSS TTFF (s) | Cold start: 25~28, aided start: 2 |

| Input port I/F | GNSS: MCx, DMB: SMA, LTE: MMCX |

| Output I/F | RS232 Serial (D-sub 9 pin) |

| Output type | NMEA-0183 |

| Variety | Position | Major Axis (mm) | Minor Axis (mm) | Volume (cm3) | Mass (g) | Density (kg m−3) |

|---|---|---|---|---|---|---|

| Superior | Top | 81.6 12.9 | 71.2 11.6 | 154.5 63.9 | 164.3 60.4 | 1085.3 81.7 |

| Side | 82.2 13.1 | 58.9 9.1 | ||||

| Atlantic | Top | 75.4 15.0 | 64.4 10.0 | 126.2 56.3 | 136.3 61.5 | 1080.7 68.7 |

| Side | 76.2 15.0 | 54.8 7.9 | ||||

| Jopung | Top | 87.1 20.9 | 70.6 13.4 | 157.9 80.4 | 166.1 86.9 | 1043.9 72.5 |

| Side | 88.7 22.1 | 55.9 9.5 |

| Variety | RMSE (cm3) | R2 |

|---|---|---|

| Superior | 22.11 | 0.88 |

| Atlantic | 17.15 | 0.90 |

| Jopung | 21.66 | 0.92 |

| Mixed | 21.50 | 0.90 |

| Variety | RMSD (g) | Error (%) | ||

|---|---|---|---|---|

| Max. | Min. | Ave. | ||

| Superior | 23.36 | 47.16 | 0.001 | 14.90 |

| Atlantic | 20.53 | 48.07 | 0.065 | 14.23 |

| Jopung | 20.48 | 51.22 | 0.104 | 12.67 |

| Mixed | 21.92 | 49.14 | 0.018 | 14.03 |

| Input | Estimation | Detection Ratio | Weight Estimation Error | ||

|---|---|---|---|---|---|

| (ea) | (kg) | (ea) | (kg) | (%) | (%) |

| 400 | 60.20 | 380.66 | 65.62 | 95.2 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, S.-H.; Moon, S.-P.; Kim, Y.-J.; Lee, S.-H. Development of Potato Mass Estimation System Based on Deep Learning. Appl. Sci. 2023, 13, 2614. https://doi.org/10.3390/app13042614

Jang S-H, Moon S-P, Kim Y-J, Lee S-H. Development of Potato Mass Estimation System Based on Deep Learning. Applied Sciences. 2023; 13(4):2614. https://doi.org/10.3390/app13042614

Chicago/Turabian StyleJang, Sung-Hyuk, Seok-Pyo Moon, Yong-Joo Kim, and Sang-Hee Lee. 2023. "Development of Potato Mass Estimation System Based on Deep Learning" Applied Sciences 13, no. 4: 2614. https://doi.org/10.3390/app13042614

APA StyleJang, S.-H., Moon, S.-P., Kim, Y.-J., & Lee, S.-H. (2023). Development of Potato Mass Estimation System Based on Deep Learning. Applied Sciences, 13(4), 2614. https://doi.org/10.3390/app13042614