Abstract

With the goal of introducing specialty beers with full flavor and effective processing, craft and functional beer have revived old assortments and established new assortments in countries throughout the world. These unique selections are produced utilizing various ingredient combinations or changes to the brewing process. Given the rise in celiac disease sufferers in recent years, research investigations on the use of buckwheat in brewing, particularly gluten-free beer, have intensified. In this study, malted and unmalted buckwheat were proposed for use in brewing, and the results were contrasted with those of beer made entirely of malted barley. Commercial enzymes were added to the technical mashing process in order to optimize it and increase output yield. It was simple to incorporate buckwheat in the technological process to produce a final product that, in many respects, resembled conventional beer, making buckwheat suitable for regular beer drinkers. In terms of original extract, apparent extract, alcohol content, and energy value, the beer obtained from 100% barley malt differs from the final beer, but only minor variations were found in color, pH, and bitterness value. Ethyl alcohol, a particularly significant distinguishing characteristic, was impacted by the use of buckwheat malt and unmalted buckwheat. The beer made from buckwheat was acceptable from a sensory perspective in terms of flavor, aroma, texture, bitterness, etc. The results demonstrate that the researched raw materials can be successfully used in the production of beer, both in malted and unmalted forms. For the latter option, it is recommended to use enzyme preparations to speed up the mashing and filtration of the wort.

1. Introduction

Beer production is a well-established sector with a long history. It is currently the third most consumed beverage worldwide, behind tea and water, and the most popular alcoholic beverage [1,2,3,4,5]. Consumers today seek out authentic, original products made from ingredients that give the completed product a distinct flavor and a touch of uniqueness [6,7,8]. The addition of new ingredients represents a constant challenge for the beer industry, through creativity and innovation, responds to the changing demands of consumers [4,9,10].

The traditional ingredients for beer are barley malt, water, hops, and yeast. Unmalted cereals, pseudocereals, and possibly exogenous enzymes may also be used [11,12,13].

The beer market is continually expanding, and producers use new raw materials in the both malted and unmalted forms to make new varieties of beer, such as other grains such as sorghum, corn, rice, and millet, as well as pseudocereals such as buckwheat, amaranth, and quinoa [8,14,15,16]. Every raw material is different, and its composition qualities can add a new sensory element and have both favorable and unfavorable effects on brewing. Currently, it is thought that between 85 and 90 percent of the world’s beer production uses locally sourced adjuncts, which, in addition to saving money, provide authentic goods of higher quality with distinct flavors and aromas [8,12,17,18].

In studies on the topic of the production of malts and gluten-free beers, as well as functional beers, buckwheat is one of the pseudocereals that is most frequently cited as a raw material because it has consistently demonstrated outstanding results in terms of productivity, enzymatic activity, and chemical composition of the final product [13,19,20]. For the production of biscuits, snacks, pasta, and other food items, as well as bakery, pastry, and confectionery products, buckwheat is frequently utilized in the food industry as flour or grits. Without gliadin and glutenin (gluten-generating proteins) in their composition, it is used as a source of protein for products designed for patients with celiac disease [9,13,19].

The method of brewing using unmalted and malted buckwheat has been the subject of several studies: Wijngaard et al. (2005, 2006) have published results of their own research on the optimization of the process of malting buckwheat and brewing from unmalted and malted buckwheat [20,21,22]. Phiarais et al. (2010) obtained a beer from 100% buckwheat malt with characteristics such as wheat beer in terms of pH, nitrogen content, degree of fermentation, and alcohol content [23]. Duliński et al. (2019, 2020, 2021) studied the use of different enzymes in the technology of buckwheat beer production [24,25,26]. Brasil et al. (2020) showed that unmalted buckwheat could be used as a beer adjunct in association with barley malt in proportion a 45–55% (m/m) [19]. According to Cela et al. (2022), brewing with 40% unmalted buckwheat created a final product with acceptable quality attributes [18]. It was discovered that the physico-chemical composition and sensory qualities of the final product are all impacted by the use of this raw material in brewing. Because of this, buckwheat contains a higher level of proteins and polyphenols of significant importance that can generate noticeable variations in the final beer [19,27,28].

Researchers who malted buckwheat came to the conclusion that the malt’s amylolytic activity was lower than that of barley malt [13]. The ability of amylolytic enzymes to hydrolyze non-fermentable starch into simple carbohydrates makes them essential for the brewing process [29]. Buckwheat malt also displayed a low percentage of fermentable carbohydrates in wort and a high friability when compared to barley malt. Exogenous enzymes may be used to promote starch breakdown and boost alcohol content to correct this issue [19,30]. On the other hand, malting requires a lot of energy. Thus brewing with a proportion of non-malting adjuncts has grown in appeal. As a result, the use of buckwheat as an unmalted adjunct in brewing has also been investigated in order to enable the creation of novel products with particularly desirable properties [31]. Since these enzyme systems are activated and generated during the malting process, the biggest disadvantage in terms of processability when including unmalted buckwheat is the decrease in enzyme activity (amylolytic, proteolytic, and cytolytic) [31].

The quality of beer made entirely from buckwheat malt has shown promise in research to date, but further research is required to optimize the malting and brewing processes. Additionally, the physicochemical and sensory characteristics of final buckwheat beer as well as buckwheat malt, have not been thoroughly studied [32]. The aim of our research was to use buckwheat grown in our country to produce a variety of gluten-free beers because making beer from unmalted and malted buckwheat is a novelty in Romania.

This study’s objective was to evaluate the effects of using unmalted and malted buckwheat on the physicochemical and sensory properties of wort and beer samples. The results were compared to those of beers made entirely with barley malt.

2. Materials and Methods

2.1. Raw Materials

Buckwheat (Fagoporium esculentum) grown in the NE part of Romania from the 2020 harvest and buckwheat malt from the Pennsylvania Craft Malt, USA, were used in the experiments. For the comparative study, barley from the 2020 harvest and Pilsner-type barley malt from Slovakia from the Osivo Company (Zvolen, Slovakia) were used.

Also, to obtain the beer in laboratory conditions, Amarillo Yachima Chief hops (Yakima, WA, USA), 2019 harvest, Fermentis brewer’s yeast type 74/30 (Marquette-lez-Lille, France), and enzyme preparation from the Novozyme Company (Bagsvaerd, Denmark), namely Termamyl Classic with thermostable α-amylase, were used.

The raw materials used in the manufacturing recipes were initially weighed, mixed, and then subjected to grinding.

2.2. Obtaining Beer in Laboratory Conditions

All the mash samples were obtained in Mash Bath R12 with PC connection (1-CUBE, Havlíckuv Brod, Czech Republic) according to EBC method 4.5.1. (Analytica EBC, European Brewery Convention, 2004) [33]. Physical and chemical analyses of wort produced by the Congress method (for samples of barley malt) and the modified Congress method (for samples of buckwheat malt) were used to determine the quality of the malt. The initial variants of the tested brewing recipes are depicted in Table 1, with variant 0 representing brewing with 100% buckwheat malt. The proportion of unmalted buckwheat used in these experiments ranged from 0 to 30%, while buckwheat malt made up the difference up to 100% (70–100%). The enzyme Termamyl Classic proportions from Table 1 were added based on recommendations from the specialized literature and industrial experience (the ideal amount of the enzyme used industrially when producing beer from unmalted and malted barley and barley is 2%). The enzyme was added at the beginning of the mashing at a temperature of 35 °C.

Table 1.

Variant mashing recipes used in experiments.

The variants shown in Table 2 were suggested for the manufacturing of beer based on the preliminary findings obtained for the mashing recipes described in Table 1.

Table 2.

Experimental variants of obtaining beer in laboratory conditions.

The proposed brewing recipes were developed using knowledge from both the specialized literature and the author’s own experimental brewing results. These buckwheat beers (B1, B2, B3, B4) obtained were compared with beer obtained exclusively from 100% barley malt (CS).

All laboratory experiments, both for mashing variants and for beer production, had been repeated at least three times.

2.2.1. Mashing

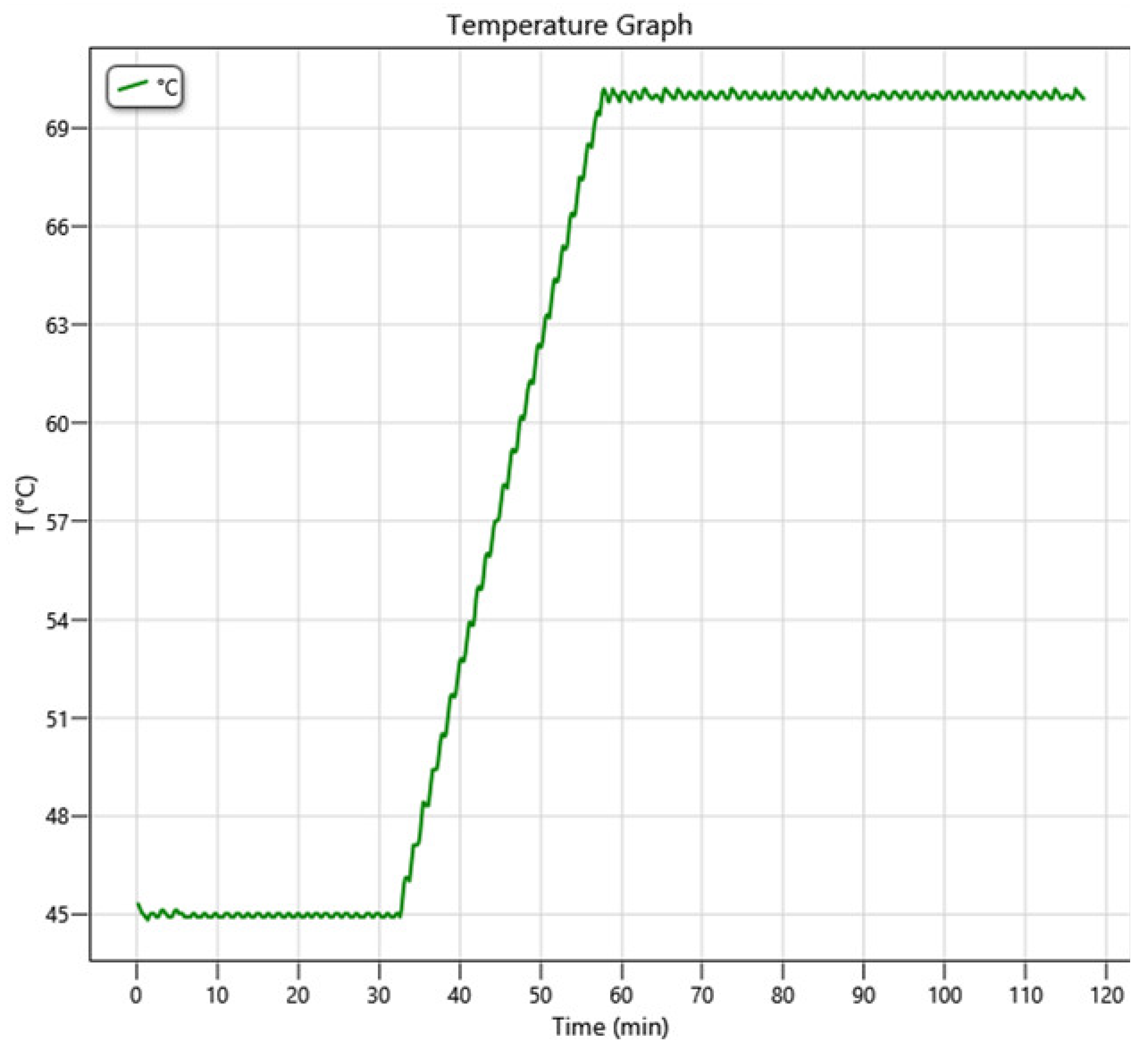

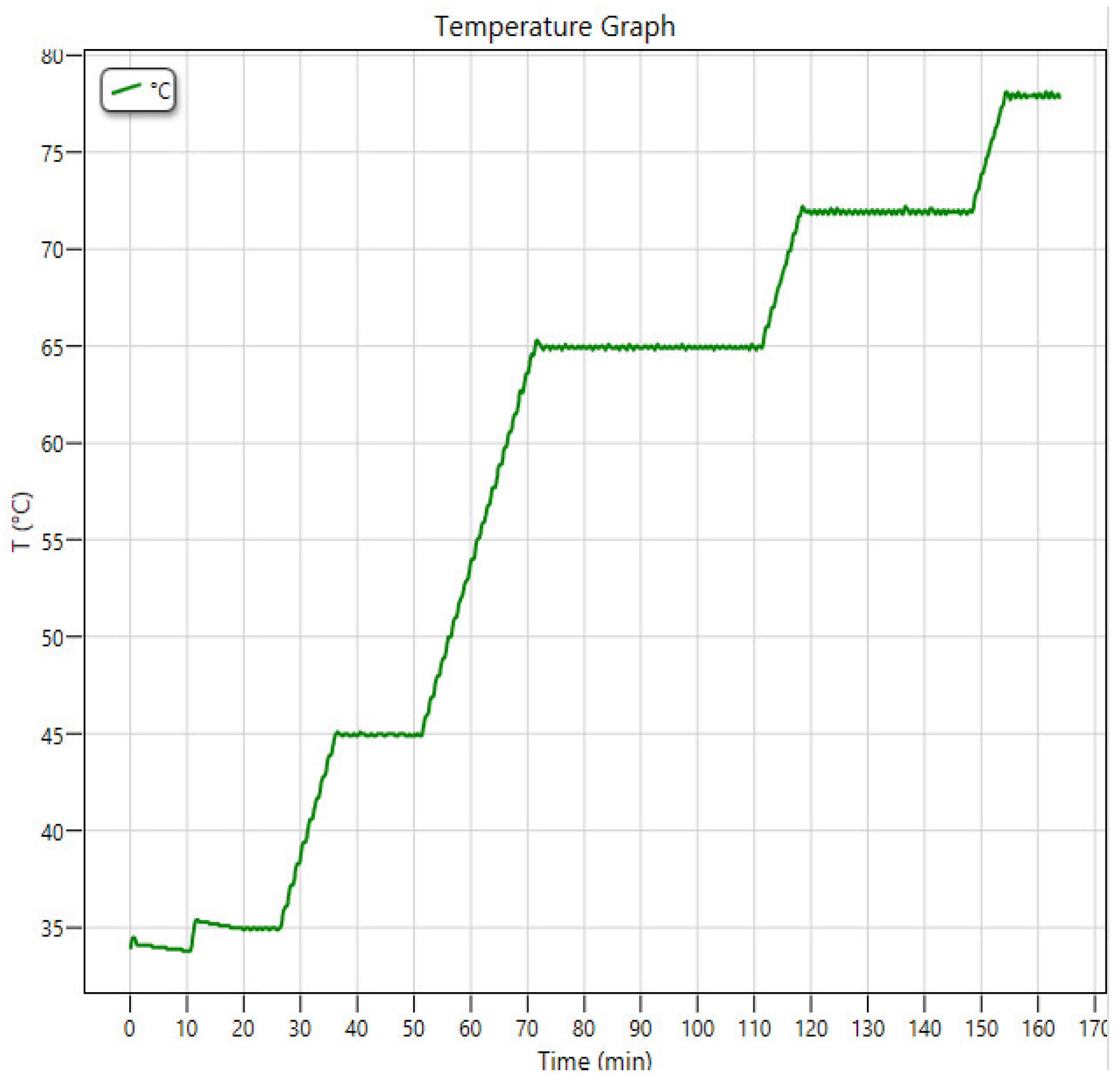

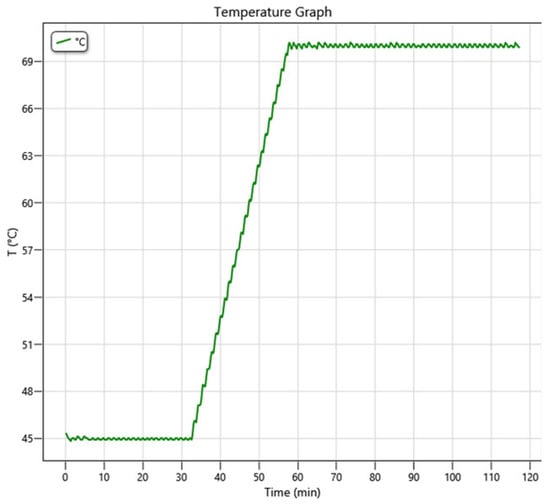

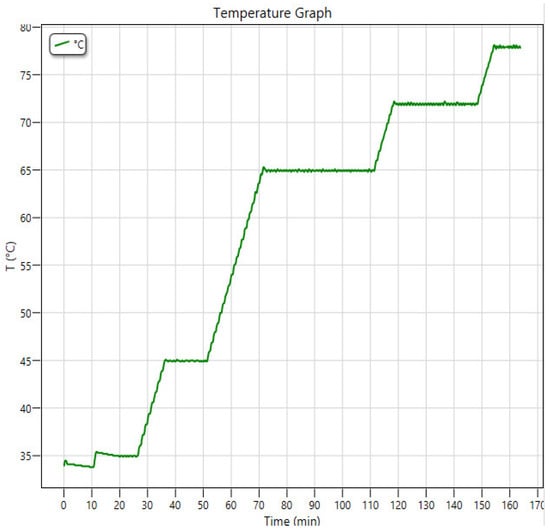

The malt and buckwheat samples were subjected to milling with a laboratory disc mill (the gap between the grinding discs 0.20 mm) type Perten LM 3310 (Cheltenham, UK). The Congress method was applied to the barley malt (EBC method 4.5.1) (Figure 1) [33]. The modified Congress method, shown in Figure 2, has been used with buckwheat malt and buckwheat as an unmalted ingredient [22].

Figure 1.

Congress mashing.

Figure 2.

Modified Congress mashing.

The saccharification rate was determined with a negative iodine test—a yellow color is produced with iodine rather than a violet color. After keeping variant 0 at 72 °C for 60 min, the sample with 100% buckwheat malt did not become saccharified.

This experiment’s findings suggest that using enzyme preparations to shorten the duration of saccharification of mash should be tried. Finding the right amount of enzyme for brewing needed more investigation.

2.2.2. Mash Filtration

After mashing, the contents of each mash beaker were brought to 450 g with distilled water, followed by homogenization and separate filtration through a folded filter (Sartorius with diameter 290 mm, 1602 N grade). The first 100 mL of wort was returned to the filter to give a high clarity of the obtained Congress wort. Before boiling, the quality characteristics of the wort were separately determined.

2.2.3. Wort Boiling

The obtained Congress wort from three mash beakers (2–2.2 L) was boiled with hops (1.52–1.54 g Amarillo hops with 7.8% alpha bitter acids) in Erlenmeyer flasks for 1 h. The aimed wort bitterness was 20 IBU. After boiling, the wort (1.5–1.7 L) was cooled to 20 °C and left to rest for 30 min in order to allow sedimentation of the hot tub and decanted into glass fermentation vessels with a capacity of 2 L equipped with CO2 exhaust valves. Before inoculation with yeast, the wort was analyzed.

2.2.4. Fermentation

After cooling to 12 °C, the wort (1.5 L) was inoculated with 25 g of yeast type 74/30 Fermentis, the quality of which was previously determined using the Nucleocounter YC-100 (ChemoMetec A/S, Allerod, Denmark), the number of total cells being 24 × 108/mL biomass, of which dead cells 1.42%. The primary fermentation took place in glass fermentation vessels type Erlenmayer (Brand with 2 L volume) to 12 °C for 6 days, in an industrial refrigerator with the possibility of digital regulation, after which the young beer was bottled and subjected to secondary fermentation and maturation for 30 days at 4 °C in the same refrigerator industrial. Each beer recipe was repeated three times.

2.3. Methods of Analysis

2.3.1. Analysis of Raw Materials and Wort

The raw materials and wort properties were determined for the barley and buckwheat samples according to the standard procedures of the latest versions of Analytica EBC by the European Brewery Convention. The moisture (EBC 4.2) [34], foreign matters (EBC 4.22) [35], saccharification rate and filtration speed (EBC 4.5.1) [33], the color of wort (EBC 4.7.1) [36] and free amino nitrogen in wort (FAN, EBC 8.10.1) [37] with spectrophotometer Hach Lange DM 6000 (Hach Lange GmbH, Düsseldorf, Germany); pH of wort (EBC 8.17) WTW Inolab 720 table pH meter (Xylem Analytics, Ingolstadt, Germany) [38], original extract (EBC 8.3) [39], extract of malt, Congress mash (EBC 8.2.1) [40], fermentability, final attenuation of laboratory wort from malt (EBC 4.11.2) [41] with Anton Paar Alex (Anton Paar Austria 158 GmbH, Graz, Austria); Total nitrogen of malt (EBC 4.3.1) [42], soluble nitrogen of malt (EBC 4.9.1) [43], with Velp Scientifica UDK129 (Velp Scientifica Srl, Usmate, Italy).

Each mashing, a beaker was made for analytical determination, and the result presents the mean and standard deviation. The determinations from the same sample were performed in triplicate for analysis, and the mean values were used in this report.

2.3.2. Analysis of Beer

For the final beer, the following physico-chemical analyses were performed according to the standard procedures of the latest versions of Analytica EBC by the European Brewery Convention: the original extract and density (EBC 9.43.2) [44], the alcohol content (% v/v, % m/m; EBC 9.2.1) [45], turbidity, turbidity S25/S0, turbidity S90/S0; EBC 9.29) [46], pH (EBC 9.35) [47], CO2 content (EBC 9.28.3) [48], O2 content (EBC 9.37.1) [49], calories kJ/100 mL (EBC 9.45) [50] Anton Paar modular DMA meter (Anton Paar Austria 158 GmbH, Graz, Austria), color (EBC 9.6) [51] and bitterness (EBC 9.8) [52] with spectrophotometer Hach Lange DM 6000 (Hach Lange GmbH, Düsseldorf, Germany).

Three determinations from the same sample were performed in parallel for analysis, and the mean value was used in this study.

2.3.3. Sensory Analysis

The sensory analysis of the beer samples was conducted with the help of a semi-trained panel of 54 evaluators. A 9-point hedonic scale was used to evaluate the beer samples from 1 to 9, where: 1—dislikes extremely, 5—neither like nor dislike, and 9—like extremely. Nine attributes were evaluated for each beer sample as follows: appearance, color, aroma, general taste, bitterness, carbonation, body, mouthfeel, and general acceptability. The test was performed in the Sensory Analysis Laboratory of the Stefan cel Mare University of Suceava, Faculty of Food Engineering. Approximately 70 mL of beer samples coded with three-digit numbers were served to the panelists in random order at 8 °C in glass cups. Between samples, the panelists used unsalted crackers and water to cleanse their mouths to reduce taste transfer from one sample to another. The tasting area and equipment were in concordance with EBC 13.2 [53].

2.3.4. Statistical Analysis

The results were the mean of three values ± standard deviation. For the statistical evaluation of the data, we performed a one-way analysis of variance (ANOVA) and Tukey’s HSD test for multiple comparisons. The differences between the means were considered statistically significant for p values ≤ 0.01. The data showing the variation of beer parameters according to the various levels of buckwheat flour and buckwheat malted flour were plotted using the design of experiment software (DOE) (Design Expert, trial version, Stat-Ease, Inc., Minneapolis, MN, USA). Using Microsoft Excel, the evaluators’ mean value of the sensory data was graphically represented (Microsoft, Redmond, WA, USA). Principal component analysis (PCA) was performed using the software XLSTAT (version 2020.3.1., Addinsoft, Paris, France) to underline the correlations and differences between sensory and physicochemical characteristics of beers and their variability according to these variables.

3. Results and Discussion

3.1. Evaluation of the Quality of Buckwheat and Buckwheat Malt

The first step in assessing the potential of buckwheat as an unmalted raw material and buckwheat malt in brewing was their analysis. In Table 3, the raw materials, unmalted buckwheat, and unmalted barley, are compared in terms of their quality attributes.

Table 3.

Results of the physico-chemical evaluation of the unmalted barley and buckwheat samples used in the experiments.

It is seen that the moisture content of buckwheat grains (10.63%) is lower than the moisture content of barley grains (11%). This is a small difference and may be due to transport and storage conditions. The content of foreign matter is double in buckwheat compared to barley, which can be explained by the fact that the buckwheat came from a small producer who did not have the equipment to clean it, but this does not mean that if controlled quality buckwheat from a large producer is used, the losses will be of this magnitude.

The starch content is higher in buckwheat (67%) compared to barley (62%), which will contribute to obtaining a malt with a higher extract content. In the specialized literature, the content of starch varies between 62–91%; and the content in starch for barley varies between 52.10–69.08%. The low used buckwheat content of starch can be explained by the fact that the starch content is influenced by variety, production area, and crop year [13,14,16]. Correlated with the high content of starch, the two raw materials have a lower content of protein substances, namely barley 10.8%, and buckwheat 11.3%, which will be beneficial to the malting process. The results obtained for buckwheat are consistent with those of the studies conducted by Bobkov, S. (2016), Pirzadah et al. (2020), and Huda et al. (2021) [54,55,56]. Table 4 summarizes the quality characteristics of buckwheat malt and barley malt used in the study.

Table 4.

Physico-chemical characteristics for barley malt and buckwheat malt.

A traditional malt analysis can be subdivided into five key groups: starch conversion, carbohydrate conversion, extract content, color, and enzyme potential. Malt analysis guides the brewer in many ways by advising them on how to adjust the mashing or grinding conditions in order to prevent challenges in the technological process [57]. The obtained buckwheat malt presents comparative values with barley malt in terms of moisture and pH of the wort, with lower values being recorded for the content in the extract and the Kolbach Index. Given that the durations of saccharification and filtration were substantially longer than they were in the case of barley malt, it was suggested that enzyme preparations be used in the experiments in order to shorten these durations. Wijngaard et al. (2005) explained that due to the botanical differences between barley and buckwheat, enzyme production and, therefore, the malting process would differ, and the finished malt product would have some different physicochemical characteristics [20]. It is well known that barley is a monocotyledonous plant, and buckwheat is a dicotyledonous plant. The levels of amylolytic activity and, therefore, the yield in the extract is low compared to barley malt, but the brewing process can be optimized by adding commercial enzyme preparations [19,54]. For example, Nic Phiarais et al. (2006) showed that the addition of commercial enzyme preparations improved the filtration process and the quality of buckwheat beer by increasing extract content, yield, and total fermentable extract [58]. These effects were also obtained by Wijngaard & Arendt (2006), who developed a mashing diagram for 100% buckwheat malt by perfecting the two important parameters, temperature, and mashing time [13,22]. Myncke E. et al. (2022) investigated additionally, 40% of unmalted buckwheat mashes’ lautering was enhanced by grinding the unmalted buckwheat more finely or by adding brewing enzymes, which contain α-amylase, protease, and β-glucanase. Finally, the small-scale lautering of 40% unmalted buckwheat mashes was enhanced by the addition of other enzyme solutions (β-amylase and β-glucanase). The mash filtration was unaffected by protease, in contrast [59].

3.2. Experimental Brewing with Buckwheat Malt and Buckwheat

At the start of brewing, the ground ingredients were mixed with water to form the mash. During the gradual increase in temperature (infusion mash), the enzymes in the malt and those added according to the recipe broke down the complex compounds into smaller molecules [60]. The saccharification rate indicator is a general measure of malt starch degradation, dependent on the activity of amylolytic enzymes in the mash. It is known that a particularly important factor in starch decomposition is its gelatinization temperature [60]. Giménez-Bastida et al. (2015) reported that gelatinization temperatures of buckwheat malts ranged from 65.76–67.12 °C [61].

The values of the determinations made on the resulting wort for all eight variants of brewing recipes studied are summarized in Table 5. Variant 0 is missing from Table 5 because the parameters are presented in Table 4 under the name of buckwheat malt.

Table 5.

Physico-chemical properties of Congress wort for mashing variants.

The duration of saccharification for each of the versions examined, independent of the amount of buckwheat malt used, was found to be 5 min during the experiment, with the exception of variant 8 (utilizing 100% buckwheat malt and 2% Termamyl enzyme), for which the duration of saccharification was 10 min. Following the mashing, the EBC method called for cooling the mash to 20 °C and adding water up to a weight of 450 g. The duration of filtration depends on the composition of the raw material, the content of β-glucans, other fibers, high molecular weight proteins, starches, and the viscosity of the mash. In studies of unconventional brewing raw materials or adjunct additives, a significant increase in the viscosity of the wort was seen, resulting in a longer filtration than when using barley malt or wheat malt [30,62]. Also, β-glucans can decrease the yield in the extract and lead to an increase in the risk of turbidity of the finished beer [30]. In this case, the specialized literature recommends the use of exogenous enzymes (β-glucanase) that allow the decomposition of β-glucans [18,63]. Recent studies showed very low levels of β-glucans for alternative cereals and pseudocereals [16,59]. The most important indicator of malt, which affects the efficiency of beer production, is the extract yield. The obtained results showed that buckwheat malt and unmalted buckwheat could be used to obtain beer. In other studies, for buckwheat malt, the mean extract yield levels were around 65% compared to 80% for the control sample (barley malt) [22]. Comparable results were obtained by Phiarais et al. (2006), who obtained an extract yield between 61.8% and 69.2% [58]. Moreover, the research conducted emphasizes the fact that the wort obtained from buckwheat and buckwheat malt presented low fermentability values and high levels of viscosity compared to the wort obtained from barley malt [22,23,64]. The color of the wort presented close values for all eight variants; the lowest value was recorded for variant 1 (7.54 EBC), and the highest value was presented by variant 5 (8.36 EBC). All variants showed higher values for color than barley malt (3.1 EBC, shown in Table 4). The pH for all variants studied showed close values in the range of 6.07–6.16, while the pH of barley Congress wort varies from 6.00–6.10, which shows that pH does not seem to have an important influence on beer quality. Lowering the pH of the wort is beneficial because many processes occur faster and better at lower pH [60]. For instance, the pH level affects the mash’s viscosity, enzymatic decomposition processes, the solubilization of proteins, bitter hop compounds, and the color of the boiling wort. The pH of the wort and that of the beer produced from it are correlated. Beers with high pH values are exposed to physico-chemical disturbances due to insufficient protein coagulation during boiling. Although variant 8 showed higher values for saccharification rate and filtration speed, no considerable differences were observed for the other parameters at variants 2–7. We considered that increasing the percentage of the enzyme (3–5%) will not lead to a significant increase in extract, so from an economic point of view does not make sense. For this reason, we chose the beer recipes presented in Table 2. because we wanted to see how the mixtures of unmalted buckwheat and buckwheat malt would behave by adding only 2% Termamyl enzyme.

3.3. Study on the Production of Beer from Buckwheat and Buckwheat Malt under Laboratory Conditions

The physico-chemical parameters of beer wort in all experimental variants are summarized in Table 6.

Table 6.

Physico-chemical properties of wort for the second experiment.

It is seen that, compared to the control sample (CS), the four experimental samples have close values in terms of wort pH, total nitrogen, and apparent degree of fermentation. Significant differences were obtained in saccharification rate, filtration speed, extract content, wort color, extract yield, soluble nitrogen, Kolbach index, and FAN. Between the variants, the saccharification rate, pH, and total nitrogen content are not had significant differences (at p < 0.01 level). The filtration speed is the best in B4 (1:1, unmalted buckwheat:buckwheat malt with 2% Termamyl enzyme). These data show that unmalted buckwheat has a positive effect on speed filtration. This variant shows smaller extract and extract yield, FAN content, and apparent degree of fermentation. Cela et al. (2022) showed that the yield in the extract depends on the chemical composition of the raw materials, mainly on the content of sugars and dextrin, and also on the content of nitrogenous compounds [18]. Comparing buckwheat malt to other gluten-free malts, Buiatti et al. (2018) found that buckwheat malt produced the highest extract yields for beer (40%) [65]. For this parameter, we achieved higher values between 61.53% and 64.33%. The latter is an important source of nutrition for yeast during fermentation and influence the physical and sensory properties of beer, such as colloidal stability, foam stability, and flavor profile [66]. The total nitrogen content of the wort will depend on both the raw materials used during brewing and the parameters of the brewing process [67]. The results obtained are consistent with those highlighted in other research carried out on unmalted buckwheat and buckwheat malt as raw materials in the beer industry [18,65,68]. The wort obtained was subjected to the boiling process with hops. The physico-chemical characteristics of wort after boiling with hops are summarized in Table 7.

Table 7.

Physico-chemical properties of wort after boiling.

After 60 min of boiling the samples with hops, a slight decrease in pH was observed compared to the same samples before boiling. The extracted content increased in B1, B2, B3, and B4 samples as a result of the boiling operation due to water evaporation. Compared to the wort obtained from barley malt, where the content in the extract increased after boiling to the value of 11°P, all four wort samples had the content in the extract lower, between 11 and 12°P. To improve the extracted content of wort, Cela et al. (2022) propose the gelatinization of unmalted raw materials during brewing [18]. Boiling led to an increase in color of all tested buckwheat samples from about 7–8 EBC to 11–12 EBC. After cooling to 12 °C, the wort was inoculated with yeast. The primary fermentation lasted 6 days, after which the young beer was bottled and subjected to secondary fermentation and maturation for 30 days. The final beer presented the physico-chemical characteristics displayed in Table 8.

Table 8.

Physico-chemical characteristics of beer final product.

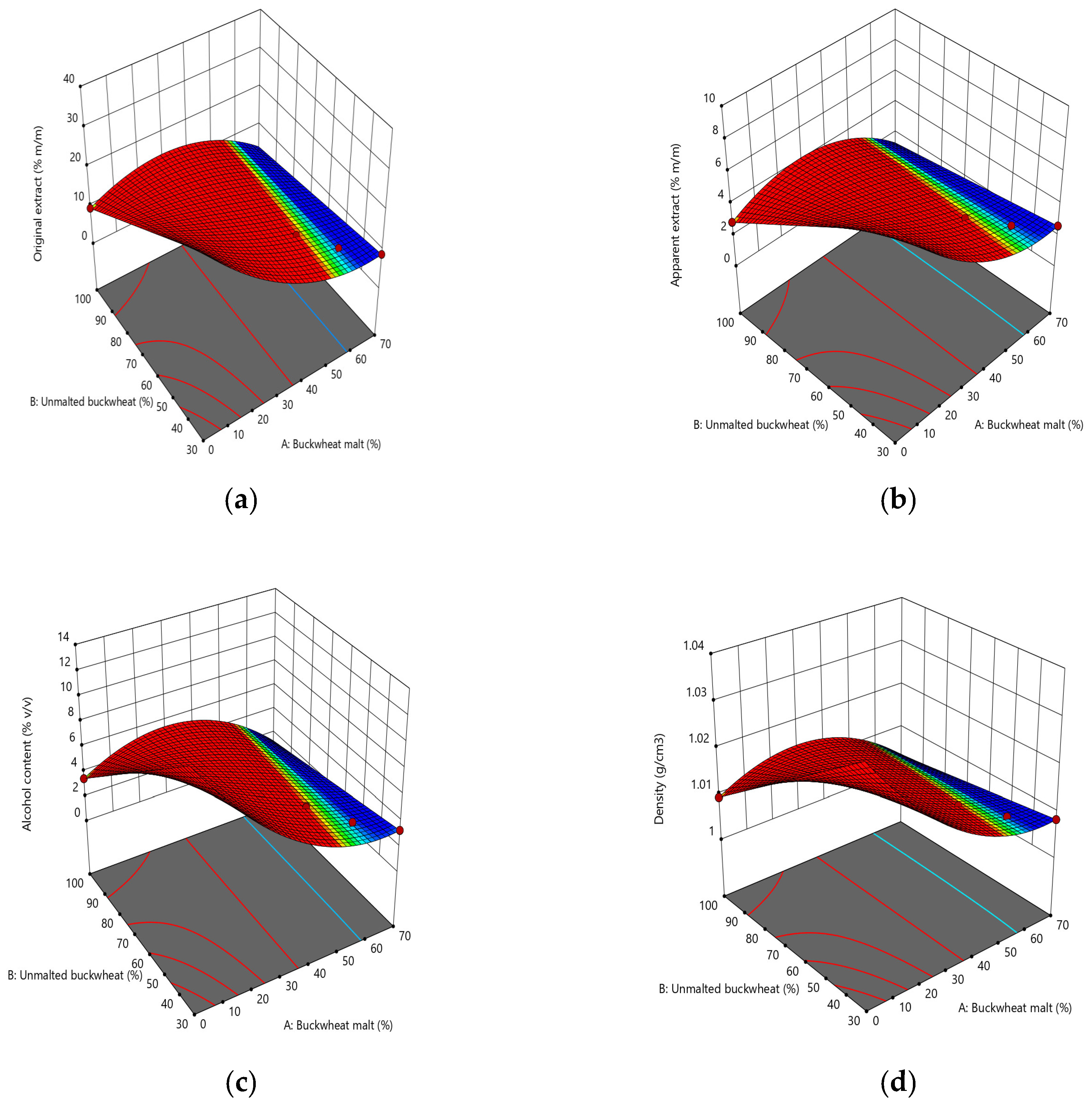

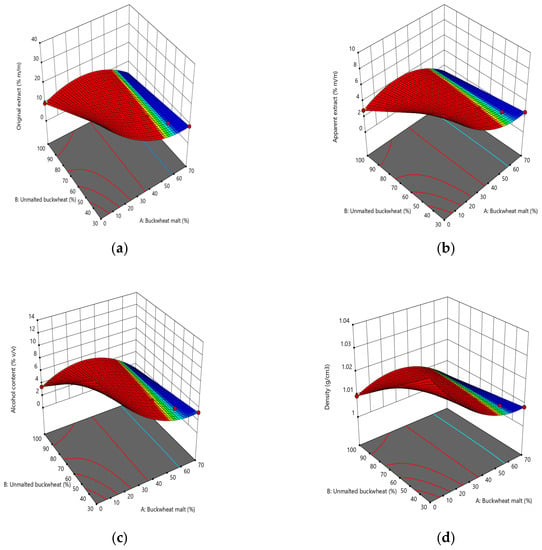

Insignificant differences were found in color, pH, and bitterness value. However, the beers obtained by the four variants differ from the control sample in terms of original extract, apparent extract, alcohol content, and energy value. The amount of ethyl alcohol, a crucial distinguishing factor, was influenced by utilizing buckwheat malt and unmalted buckwheat. Beer color is a consequence, among others, of products resulting from the Maillard reaction between FAN compounds and reducing carbohydrates [60]. In the study conducted by Steiner et al. (2012), a higher FAN content in 100% barley malt caused an increase in beer color due to the Maillard reaction [69]. The results obtained are in accordance with those obtained by Agu et al. (2012) and Deng et al. (2019) in their works [66,70]. For example, a study realized by Deng et al. (2019) concluded that doubling the amount of buckwheat malt as a brewing adjunct (from 20% to 40%) led to a further increase in beer color to approximately 5.1 EBC [66]. The bitter value of buckwheat beer decreased slightly compared to that of 100% barley malt beer. These differences may be due to evaporation losses when boiling the wort with hops. Because the same hopping regime was used, the isohumulone content was similar among the four varieties. The estimated global overall influence of unmalted buckwheat and buckwheat malt on the original extract, apparent extract, alcohol content, and density of the beer is shown in Figure 3.

Figure 3.

The graphical representations of the original extract (a), apparent extract (b), alcohol content (c), and density (d) as affected by the levels of unmalted buckwheat and buckwheat malt used in the beer recipe.

When the amount of unmalted buckwheat in the beer recipe is increased, the original and apparent extract of the beer rises; however, when buckwheat malt is added in large quantities, it falls. The beer’s extract concentration is a significant qualitative indicator of it. Nitrogenous substances and carbohydrates make up the majority of their composition. The data obtained regarding the content in the extract are unexpected, and we believe that this aspect is due exclusively to the enzyme used in the mashing process (Termamyl classic). Besides these, the beer extract also contains glycerine, mineral substances, bitter substances, tannins, dyes, and organic acids. During the fermentation of wort, the alcoholic fermentation of carbohydrates takes place with the formation of ethyl alcohol and carbon dioxide. By transforming the sugars into alcohol, the density of the wort decreases, and that way, the dynamics of the fermentation can be checked by measuring the concentration of the wort extract.

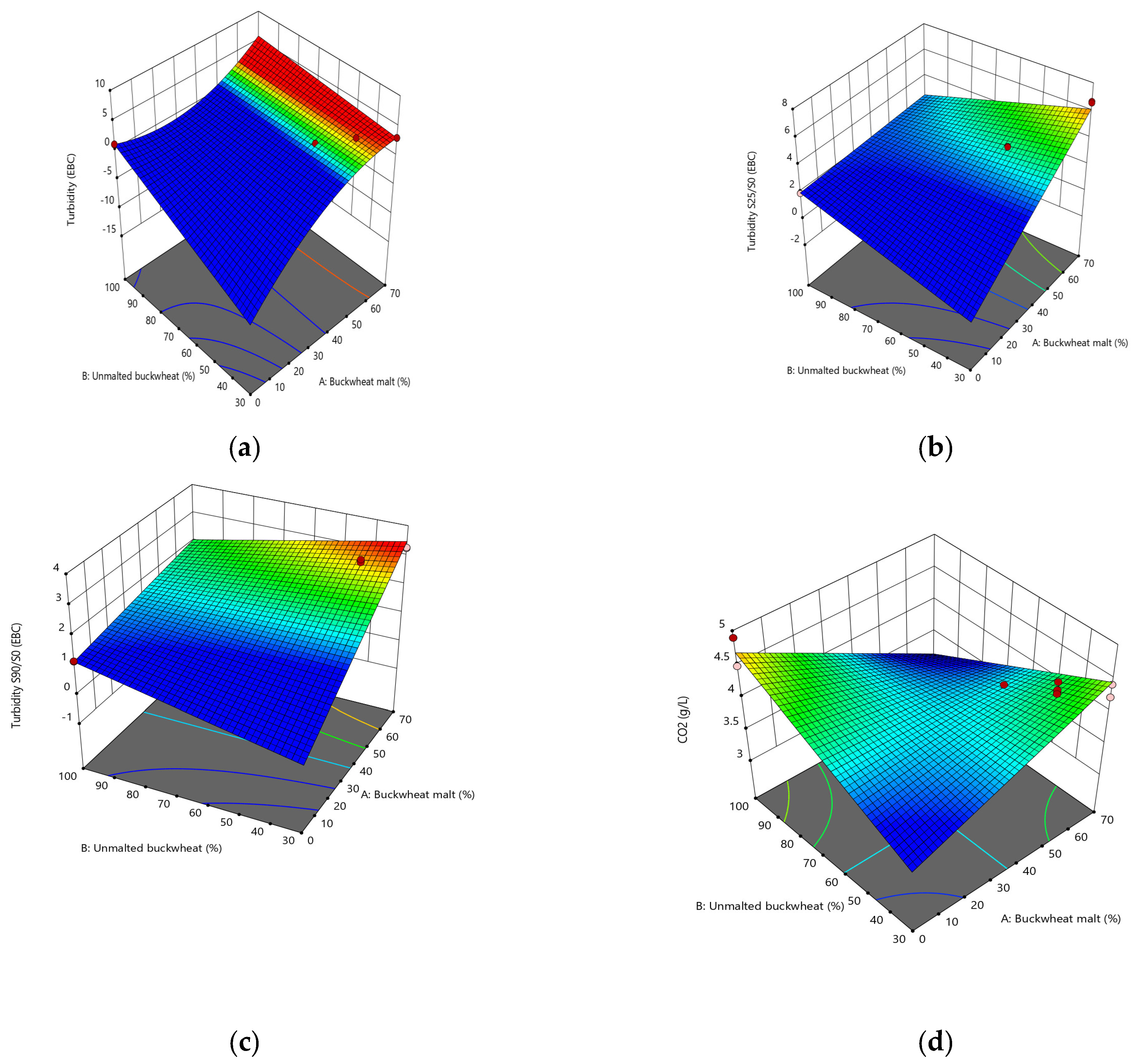

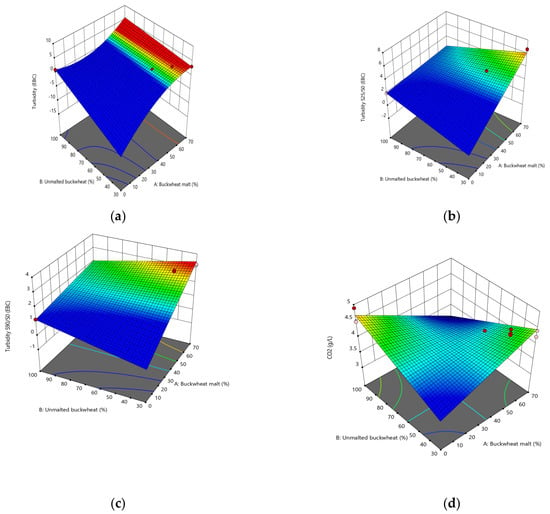

A graphical representation of the beer turbidity and carbon dioxide levels is shown in Figure 4.

Figure 4.

The graphical representations of the beer turbidity (a), turbidity S25/S0 (b), turbidity S90/S0 (c), and carbon dioxide (d) as affected by the levels of unmalted buckwheat and buckwheat malt used in a beer recipe.

All turbidity readings followed a similar trend, with values falling as unmalted buckwheat malt addition levels increased. This may be explained by the fact that unmalted buckwheat contains more soluble nitrogen and polyphenolic tannins than malted buckwheat and is, therefore, more protein-rich, favoring the appearance of a beer with a higher turbidity value [71]. Proteins and other particles smaller than 1 μm, which are measured under 90° and shown in Figure 4c, scatter light predominantly. The majority of forward-scattered light is caused by particles larger than 1 μm, such as diatomaceous earth and yeast, which are measured under 25° and are shown in Figure 4b. Since our samples were analyzed in an unfiltered form, the greater turbidity S25/S0 values can be explained. Brewing with raw materials with a high Kolbach Index (which is higher for wort with high levels of unmalted buckwheat than for those with a high level of buckwheat malt), causes an increase in turbidity of the beer [18]. The absence of a malting process for buckwheat will lead to a decrease in its proteolytic activity. Therefore, when unmalted buckwheat is used in brewing as a partial replacement for buckwheat malt, there is a decrease in low-molecular nitrogen compounds and protein content, preventing haze formation. The carbon dioxide content of the beer samples varies between 4.36–4.49 g/L, while the control sample (CS) had 5.12 g/L. The absorption capacity of carbon dioxide in beer is influenced by its composition, especially by the colloid’s distribution with a high contact surface [72]. For instance, some protein macromolecules may be important in stabilizing carbon dioxide, which appears to occur more frequently in malted flours [73].

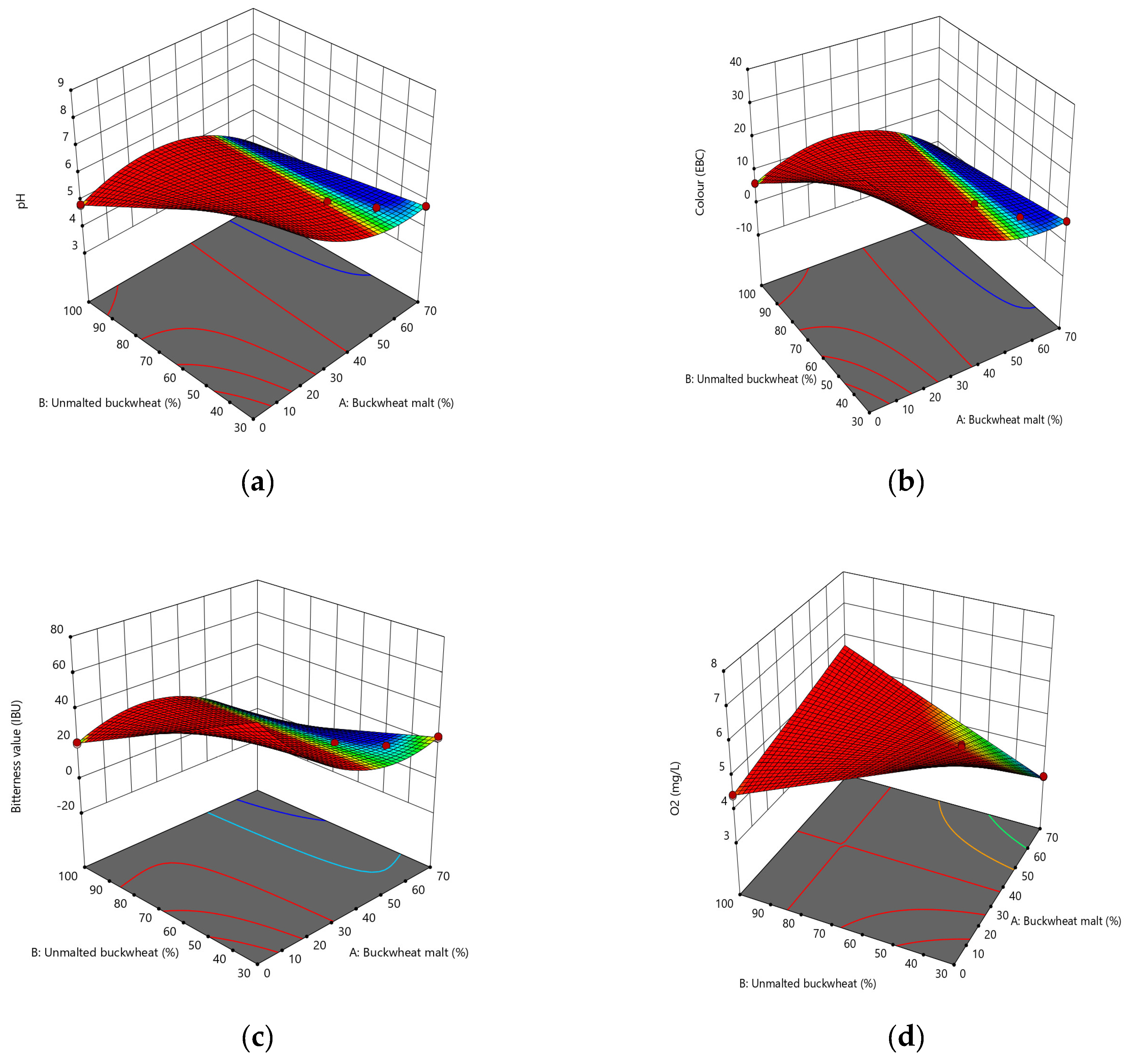

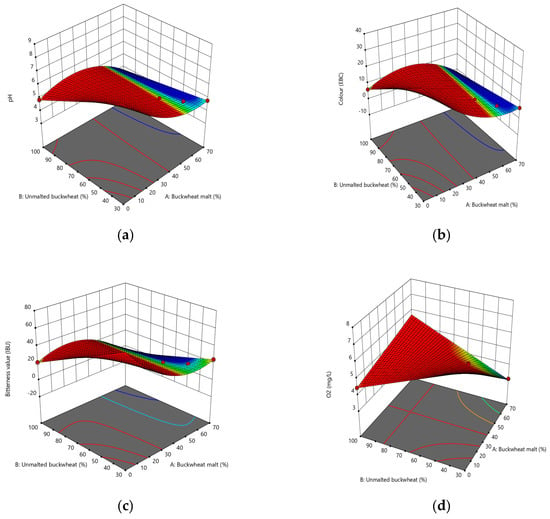

Figure 5 shows the values of pH, color, bitterness, and oxygen content according to the various proportions of unmalted and malted buckwheat used in the beer recipe. There is no conclusive trend in color, pH, bitterness, and oxygen values depending on the dose of malted or unmalted buckwheat used. Bitterness is a cause of α-acids isomerization from hops during boiling. No definite trend based on the brewing recipe was seen because the identical hopping regime was followed for the manufacture of all beers. Similar findings were also reported by Phiarais et al. (2010), who came to the conclusion that the color of the beer made from buckwheat malt was likely similar to that of beers made from natural grains because no significant changes between malted and unmalted buckwheat grain were seen [23]. Since all laboratory-scale productions employed the same brewing regime, the pH and oxygen content readings were comparable across beers.

Figure 5.

The graphical representations of the beer pH (a), color (b), bitterness (c), and oxygen (d) as affected by the levels of unmalted buckwheat and buckwheat malt used in the beer recipe.

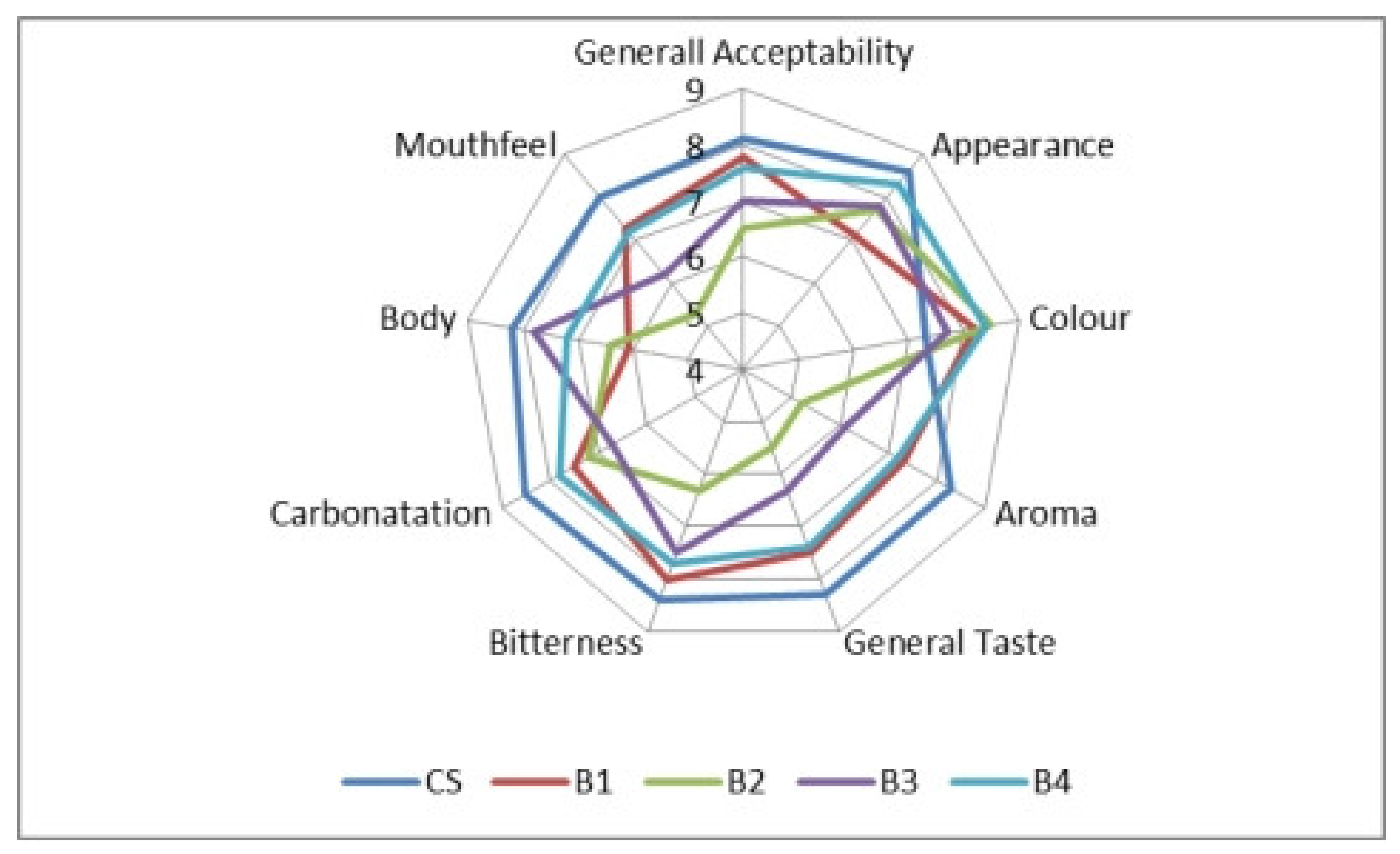

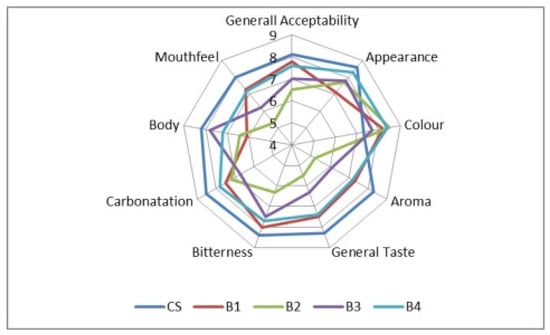

When creating products that live up to consumer expectations, sensory analysis plays a key role. As a result, studies exploring the addition of nutritious functional ingredients such as buckwheat to conventional recipes are frequently supplemented by evaluations of overall quality, appearance, scent, taste, and texture using standardized techniques involving professional judges or consumer panels. The sensory evaluation of flavor is frequently accompanied by analytical workflows aimed at isolating and determining the concentration of volatile compounds in food and determining the impact of food components on overall flavor intensity and/or final product perception. Flavor is of particular importance in influencing consumer preferences [74,75]. The sensory analysis data are shown in Figure 6.

Figure 6.

Sensory characteristics of the beer samples.

The CS sample earned the greatest for overall acceptability, whereas the B2 sample scored the lowest, according to the data collected. All of the beer samples were enjoyed to a certain extent by the panelists. The CS, B1, and B4 samples obtained a like very much score of 8.1, 7.8, and 7.6, respectively, whereas the B3 and B2 samples obtained a mean like moderate score of 7.0 and 6.6, respectively. These results are consistent with those found by Sebestyén et al. (2013), who determined in the sensory analysis that the buckwheat beer had the aroma of roasted sunflower seeds and a chestnut-like aroma and was positively evaluated by the tasters [76]. Also, Phiarais et al. (2005) have reported that buckwheat beers were acceptable regarding taste purity, odor, mouthfeel, bitterness, and tingling [77]. The sensory characteristics that contributed to the general acceptability varied depending on the recipe for beer making. The best sensory results were obtained for the CS sample. However, for the color parameter, gluten-free beer samples obtained better sensory results. These data were in disagreement with those obtained by Brasil et al. (2020) who reported a paler beer with an increased level of buckwheat malt addition in the beer recipe [19]. From non-gluten beer samples, the highest acceptability was recorded for B1 samples which contained the highest level of buckwheat malt in its recipe. These data were in agreement with those reported by Dezelak et al. (2014), who concluded that beer from buckwheat malt has high scores from the sensory point of view [78].

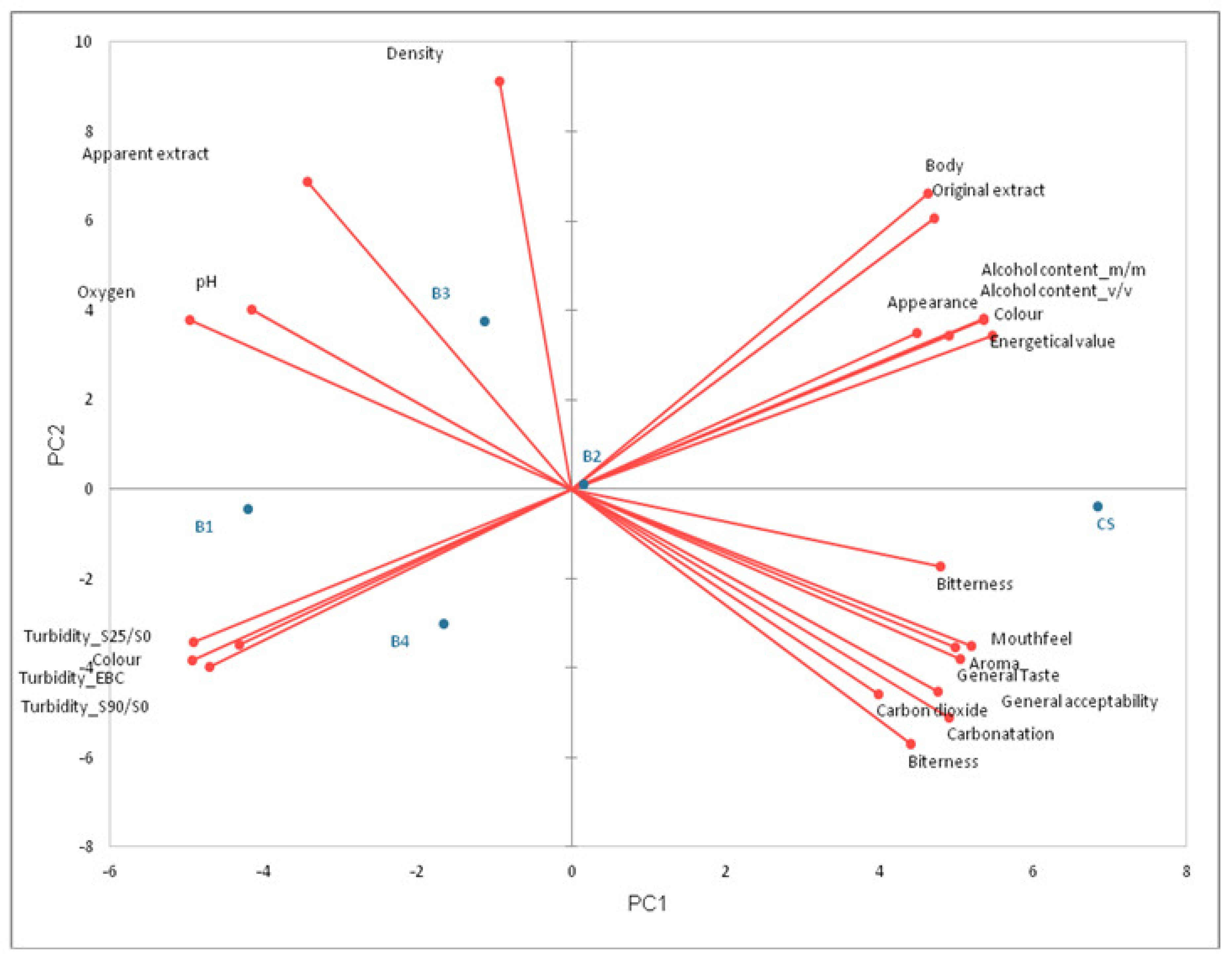

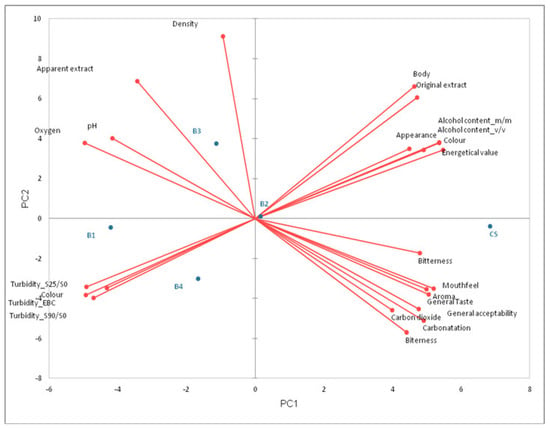

3.4. Principal Component Analysis of the Physico-Chemical and Sensory Characteristics of the Beer Samples

Principal Component Analysis (Figure 7) highlighted the correlation between physicochemical data and sensory characteristics of the beer samples. The first two principal components explain 69.47% of the total variance (PC1 = 37.82% and PC2 = 31.65%). The PCA graph shows a clear distinction between the beer samples in terms of their physiochemical and sensory properties. Beer made from malted barley (CS) is positioned on the graph’s right side among the sensory qualities, indicating that these qualities are crucial to understanding how to appreciate it. These characteristics have a high association with this sample since, based on previously collected data, this beer was the one that consumers liked the most. These samples had a similar score for overall acceptability from consumers and were the most well-liked non-gluten beer. Due to the fact that all of the B1, B4, and CS samples are alongside the PC2 component on the PCA graph, these samples were also the closest to a malted barley beer from a sensory and physico-chemical perspective. The placement of B2 beer in the primary component area indicates that it is the most distinctive from the other beers, with this sample receiving the lowest consumer approval.

Figure 7.

Principal component analysis of the physicochemical and sensory characteristics of the beer samples.

B2 and B3 are both samples that are most closely related to the PC2 component of the PCA graph, and both are located near the top of the graph. This result is consistent with the observation that both the B3 and B2 samples received similar levels of consumer appreciation based on our prior research. Relationships between physico-chemical and sensory values of beer samples show that is a good correlation between original extract and alcohol content with an r = 0.962, between body and original extract with an r = 0.968 between appearance and color (r = 0.877), between alcohol content and energy value (r = 0.999) for a level of 0.01. The original extract is one of the most important parameters from a financial point of view. This serves as an indicator of the amount of dry matter in the wort used to make the examined beer. This will have an impact on the beer’s body, which consumers will feel as being heavier or denser on the tongue [18]. Also, with respect to the first principal component PC2, it may be seen direct positive correlations between body and density (r = 0.625), original extract (r = 0.968), and alcohol content (r = 0.917). During alcohol fermentation, chemical reactions take place, which transforms fermentable sugars into alcohol and carbon dioxide. Therefore, the higher the quantity of real extract is, the higher the alcohol content is. The highly significant correlation between energy value, alcohol content (r = 0.999), and original extract (r = 0.949) may be explained by the fact that the energetical value of a beer is calculated according to its alcohol content and original extract value [79]. The two plots underline a close association between the physico-chemical trait carbon dioxide and sensory carbonatation (r = 0.942) which was explainable given that beer carbonatation is experienced as a burning and stinging sensation on the tongue, being influenced by the amount of carbon dioxide and the size of the bubbles [18]. Other notable correlations were found between sensory characteristics such as general acceptability, general taste, aroma, mouthfeel, and bitterness, as well as between the measured sensory bitterness and the analytically determined bitterness characteristics (r = 0.884). In evaluating the sensory quality of beer, the highest rating was the taste and its impact on the consumers [80]. The sensory quality of beer taste is correlated to some extent with all the elements strongly associated with general acceptance (aroma, mouthfeel, bitterness).

4. Conclusions

The technological method of making beer from buckwheat and buckwheat malt is effortless, and the final product is essentially equivalent to a standard beer in many ways, making buckwheat a potential raw material for habitual beer drinkers who are looking for new sensory experiences.

The different fermentation profile for buckwheat beer with a higher first concentration of glucose is crucial for alcohol and other fermentation products, positively changing its aroma and taste. However, its high content of polyphenolic compounds can cause a slightly astringent taste and a spicy and sweet aroma appreciated by tasters.

The beer made with 50% unmalted buckwheat and 50% buckwheat malt with 2% Termamyl Classic enzyme had the best results out of all the studied recipes in terms of the key physico-chemical traits: original extract was 10.65%, apparent extract was 3.13%, alcohol content was 3.97% (v/v), and turbidity was 1.98 EBC. The sample made entirely of unmalted buckwheat with 2% Termamyl Classic enzyme was the most well-liked from a sensory perspective. We achieved our research objective to create a final beer that had good physico-chemical properties, was well-liked by consumers, and was produced at the lowest cost.

As a result of the findings, it is suggested that in subsequent experiments, beer only be produced from unmalted buckwheat with enzyme addition, which is much more advantageous from an economic and technological standpoint. This is because it is possible to produce beer from buckwheat without it being malted by simply adding enzyme preparations to the brewing process.

Author Contributions

Conceptualization, M.E.C., A.D., R.V.S. and G.G.C.; Methodology, A.C., R.V.S. and Á.A.; Formal Analysis, A.C. and A.D.; Investigation, M.E.C., R.V.S. and Á.A.; Resources, G.G.C.; Writing—Original Draft Preparation, A.D., R.V.S., G.G.C. and M.E.C.; Writing—Review and Editing, A.C. and A.D. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Ministry of Research, Innovation, and Digitalization within Program 1—Development of national research and development system, Subprogram 1.2—Institutional Performance—RDI excellence funding projects, under contract no. 10PFE/2021.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Betancur, M.I.; Motoki, K.; Spence, C.; Velasco, C. Factors influencing the choice of beer: A review. Food Res. Int. 2020, 137, 109367. [Google Scholar] [CrossRef] [PubMed]

- Chetrariu, A.; Dabija, A. Pre-treatments used for the recovery of brewer’s spent grain—A minireview. J. Agroaliment. Process. Technol 2020, 26, 304–312. [Google Scholar]

- Parés Viader, R.; Yde, M.S.H.; Hartvig, J.W.; Pagenstecher, M.; Carlsen, J.B.; Christensen, T.B.; Andersen, M.L. Optimization of Beer Brewing by Monitoring α-Amylase and β-Amylase Activities during Mashing. Beverages 2021, 7, 13. [Google Scholar] [CrossRef]

- Piva, R.C.; Verdan, M.H.; Mascarenhas Santos, M.D.S.; Batistote, M.; Cardoso, C.A.L. Manufacturing and characterization of craft beers with leaves from Ocimum selloi Benth. J. Food Sci. Technol. 2021, 58, 4403–4410. [Google Scholar] [CrossRef]

- Díaz, A.B.; Durán-Guerrero, E.; Lasanta, C.; Castro, R. From the Raw Materials to the Bottled Product: Influence of the Entire Production Process on the Organoleptic Profile of Industrial Beers. Foods 2022, 11, 3215. [Google Scholar] [CrossRef]

- Ciocan, M.; Dabija, A.; Codină, G.G. Effect of some unconventional ingredients on the production of black beer. Ukr. Food J. 2020, 9, 322–331. [Google Scholar] [CrossRef]

- Muscolo, A.; Marra, F.; Salafia, F.; Andronaco, P.; Di Sanzo, R.; Carabetta, S.; Russo, M. Bergamot and olive extracts as beer ingredients: Their influence on nutraceutical and sensory properties. Eur. Food Res. Technol. 2022, 248, 1–11. [Google Scholar] [CrossRef]

- Villacreces, S.; Blanco, C.A.; Caballero, I. Developments and characteristics of craft beer production processes. Food Biosci. 2022, 45, 101495. [Google Scholar] [CrossRef]

- Orhotohwo, O.L.; Czipa, N.; Kovács, B.; Alexa, L. Impact of the use of gluten-free cereals and spices on the quality parameters of beer. J. Microbiol. Biotechnol. Food Sci. 2021, 11, e3838. [Google Scholar] [CrossRef]

- Paiva, R.A.; Mutz, Y.S.; Conte-Junior, C.A. A Review on the Obtaining of Functional Beers by Addition of Non-Cereal Adjuncts Rich in Antioxidant Compounds. Antioxidants 2021, 10, 1332. [Google Scholar] [CrossRef]

- Cela, N.; Condelli, N.; Caruso, M.C.; Perretti, G.; Di Cairano, M.; Tolve, R.; Galgano, F. Gluten-free brewing: Issues and perspectives. Fermentation 2020, 6, 53. [Google Scholar] [CrossRef]

- Castro Marin, A.; Baris, F.; Romanini, E.; Lambri, M.; Montevecchi, G.; Chinnici, F. Physico-chemical and sensory characterization of a fruit beer obtained with the addition of cv. Lambrusco grapes must. Beverages 2021, 7, 34. [Google Scholar] [CrossRef]

- Dabija, A.; Ciocan, M.E.; Chetrariu, A.; Codină, G.G. Buckwheat and Amaranth as Raw Materials for Brewing, a Review. Plants 2022, 11, 756. [Google Scholar] [CrossRef]

- Dabija, A.; Ciocan, M.E.; Chetrariu, A.; Codină, G.G. Maize and sorghum as raw materials for brewing, a review. Appl. Sci. 2021, 11, 3139. [Google Scholar] [CrossRef]

- Trummer, J.; Watson, H.; De Clippeleer, J.; Poreda, A. Brewing with 10% and 20% Malted Lentils—Trials on Laboratory and Pilot Scales. Appl. Sci. 2021, 11, 9817. [Google Scholar] [CrossRef]

- Baillière, J.; Laureys, D.; Vermeir, P.; Van Opstaele, F.; De Rouck, G.; De Cooman, L.; De Clippeleer, J. 10 unmalted alternative cereals and pseudocereals: A comparative analysis of their characteristics relevant to the brewing process. J. Cereal Sci. 2022, 106, 103482. [Google Scholar] [CrossRef]

- Habschied, K.; Živković, A.; Krstanović, V.; Mastanjević, K. Functional beer—A review on possibilities. Beverages 2020, 6, 51. [Google Scholar] [CrossRef]

- Cela, N.; Galgano, F.; Perretti, G.; Di Cairano, M.; Tolve, R.; Condelli, N. Assessment of brewing attitude of unmalted cereals and pseudocereals for gluten free beer production. Food Chem. 2022, 384, 132621. [Google Scholar] [CrossRef]

- Brasil, V.C.B.; Guimarães, B.P.; Evaristo, R.B.W.; Carmo, T.S.; Ghesti, G.F. Buckwheat (Fagopyrum esculentum Moench) characterization as adjunct in beer brewing. Food Sci. Technol. 2020, 41, 265–272. [Google Scholar] [CrossRef]

- Wijngaard, H.H.; Ulmer, H.M.; Neumann, M.; Arendt, E.K. The effect of steeping time on the final malt quality of buckwheat. J. Inst. Brew. 2005, 111, 275–281. [Google Scholar] [CrossRef]

- Wijngaard, H.H.; Ulmer, H.M.; Arendt, E.K. The effect of germination time on the final malt quality of buckwheat. J. Am. Soc. Brew. Chem. 2006, 64, 214–221. [Google Scholar] [CrossRef]

- Wijngaard, H.H.; Arendt, E.K. Optimisation of a mashing program for 100% malted buckwheat. J. Inst. Brew. 2006, 112, 57–65. [Google Scholar] [CrossRef]

- Phiarais, B.P.N.; Mauch, A.; Schehl, B.D.; Zarnkow, M.; Gastl, M.; Herrmann, M.; Arendt, E.K. Processing of a top fermented beer brewed from 100% buckwheat malt with sensory and analytical characterisation. J. Inst. Brew. 2010, 116, 265–274. [Google Scholar] [CrossRef]

- Duliński, R.; Zdaniewicz, M.; Pater, A.; Żyła, K. Impact of Two Commercial Enzymes on the Release of Inositols, Fermentable Sugars, and Peptides in the Technology of Buckwheat Beer. J. Am. Soc. Brew. Chem. 2019, 77, 119–125. [Google Scholar] [CrossRef]

- Duliński, R.; Zdaniewicz, M.; Pater, A.; Poniewska, D.; Żyła, K. The impact of phytases on the release of bioactive inositols, the profile of inositol phosphates, and the release of selected minerals in the technology of buckwheat beer production. Biomolecules 2020, 10, 166. [Google Scholar] [CrossRef]

- Duliński, R.; Zdaniewicz, M.; Pater, A. Effect of Phytase Addition to Buckwheat Wort on the Selected Fermentable Sugars, Polypeptide Profile and Nitrogen Content from Free Aminoacids. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca. Food Sci. Technol. 2021, 78, 33–40. [Google Scholar] [CrossRef]

- Kowalska, E.; Ziarno, M. Characterization of Buckwheat Beverages Fermented with Lactic Acid Bacterial Cultures and Bifidobacteria. Foods 2020, 9, 1771. [Google Scholar] [CrossRef]

- Streimikyte, P.; Balciunaitiene, A.; Liapman, T.D.; Streimikyte-Mockeliune, Z.; Puzeryte, V.; Borkertas, S.; Viskelis, J. Enzymatically Hydrolysed Common Buckwheat (Fagopyrum esculentum M.) as a Fermentable Source of Oligosaccharides and Sugars. Appl. Sci. 2022, 12, 8210. [Google Scholar] [CrossRef]

- Koller, H.; Perkins, L.B. Brewing and the Chemical Composition of Amine-Containing Compounds in Beer: A Review. Foods 2022, 11, 257. [Google Scholar] [CrossRef]

- Blšáková, L.; Gregor, T.; Mešťánek, M.; Hřivna, L.; Kumbár, V. The Use of Unconventional Malts in Beer Production and Their Effect on the Wort Viscosity. Foods 2021, 11, 31. [Google Scholar] [CrossRef]

- Yorke, J.; Cook, D.; Ford, R. Brewing with unmalted cereal adjuncts: Sensory and analytical impacts on beer quality. Beverages 2021, 7, 4. [Google Scholar] [CrossRef]

- Dabija, A.; Ciocan, M.E.; Chetrariu, A.; Mîrzan, D. Comparative evaluation of the physico-chemical characteristics of buckwhweat malt and barley malt. Int. Multidiscip. Sci. GeoConference SGEM 2021, 21, 51–58. [Google Scholar]

- EBC Analytica, 4.5.1—Extract of Malt: Congress Mash (IM), 2004. 22 October 2018. Available online: https://brewup.eu/ebc-analytica/malt/extract-of-malt-congress-mash/4.5.1 (accessed on 10 February 2022).

- EBC Analytica, 4.2—Moisture content of malt, 2000. 22 October 2018. Available online: https://brewup.eu/ebc-analytica/malt/moisture-content-of-malt/4.2 (accessed on 10 February 2022).

- EBC Analytica, 4.22—Sieving Test for Malt, 2005. 22 October 2018. Available online: https://brewup.eu/ebc-analytica/malt/sieving-test-for-malt/4.22 (accessed on 10 February 2022).

- EBC Analytica, 4.7.1—Colour of Wort: Spectrophotometric Method (RM), 2000. 22 October 2018. Available online: https://brewup.eu/ebc-analytica/malt/colour-of-malt-sepctrophotometric-method-rm/4.7.1 (accessed on 10 February 2022).

- EBC Analytica, 8.10.1—Free Amino Nitrogen in Wort (FAN), 2015. 23 October 2018. Available online: https://brewup.eu/ebc-analytica/wort/free-amino-nitrogen-in-wort-by-spectrophotometry-manual-method-im/8.10.1 (accessed on 10 February 2022).

- EBC Analytica, 8.17—pH of Wort, 1999. 23 October 2018. Available online: https://brewup.eu/ebc-analytica/wort/ph-of-wort/8.17 (accessed on 10 February 2022).

- EBC Analytica, 8.3—Extract of Wort, 2004. 23 October 2018. Available online: https://brewup.eu/ebc-analytica/wort/extract-of-wort/8.3 (accessed on 10 February 2022).

- EBC Analytica, 8.2.1—Determination of the Specific Gravity of the Wort, 2004. 22 October 2018. Available online: https://brewup.eu/ebc-analytica/wort/specific-gravity-of-wort-using-a-pyknometer/8.2.1 (accessed on 10 February 2022).

- EBC Analytica, 4.11.2—Fermentability, Final Attenuation of Laboratory Wort from Malt: Rapid, 1999. 22 October 2018. Available online: https://brewup.eu/ebc-analytica/malt/fermentability-final-attenuation-of-laboratory-wort-from-malt-rapid-242/4.11.2 (accessed on 10 February 2022).

- EBC Analytica, 4.3.1.—Total Nitrogen of Malt: Kjeldahl Method (IM), 2004. 22 October 2018. Available online: https://brewup.eu/ebc-analytica/malt/total-nitrogen-of-malt-kjeldahl-method-im/4.3.1 (accessed on 10 February 2022).

- EBC Analytica, 4.9.1.—Soluble Nitrogen of Malt: Kjeldahl Method, 1997. 22 October 2018. Available online: https://brewup.eu/ebc-analytica/malt/soluble-nitrogen-of-malt-kjeldahl-method/4.9.1 (accessed on 10 February 2022).

- EBC Analytica, 9.43.2—Specific-Gravity-of-Beer-Using-a-Density-Meter, 2004. 23 October 2018. Available online: https://brewup.eu/ebc-analytica/beer/specific-gravity-of-beer-using-a-density-meter/9.43.2 (accessed on 10 February 2022).

- EBC Analytica, 9.2.1—Alcohol-in-Beer-by-Distillation, 2008. 23 October 2018. Available online: https://brewup.eu/ebc-analytica/beer/alcohol-in-beer-by-distillation/9.2.1 (accessed on 10 February 2022).

- EBC Analytica, 9.29—Haze in Beer 2015. 23 October 2018. Available online: https://brewup.eu/ebc-analytica/beer/haze-in-beer-calibration-of-haze-meters/9.29 (accessed on 10 February 2022).

- EBC Analytica, 9.35—pH of Beer (Formerly Published as IOB Method 9.42) 2004. 23 October 2018. Available online: https://brewup.eu/ebc-analytica/beer/ph-of-beer-formerly-published-as-iob-method-9-42/9.35 (accessed on 10 February 2021).

- EBC Analytica, 9.28.3—Carbon Dioxide in Beer: Pressure Method, 2007. 23 November 2018. Available online: https://brewup.eu/ebc-analytica/beer/carbon-dioxide-in-beer-pressure-method/9.28.3 (accessed on 10 February 2022).

- EBC Analytica, 9.37.1—Measurement of Dissolved Oxygen by Optical Sensors, 2015. 23 November 2018. Available online: https://brewup.eu/ebc-analytica/beer/measurement-of-dissolved-oxygen-by-optical-sensors/9.37.1 (accessed on 10 February 2022).

- EBC Analytica, 9.45—Energy Value of Beer by Calculation, 2015. 23 November 2018. Available online: https://brewup.eu/ebc-analytica/beer/energy-value-of-beer-by-calculation/9.45 (accessed on 10 February 2022).

- EBC Analytica, 9.6—Colour of Beer: Spectrophotometric Method (IM), 2004. 23 October 2018. Available online: https://brewup.eu/ebc-analytica/beer/colour-of-beer-spectrophotometric-method-im/9.6 (accessed on 10 February 2022).

- EBC Analytica, 9.8—Bitterness of Beer (IM), 2004. 23 November 2020. Available online: https://brewup.eu/ebc-analytica/beer/bitterness-of-beer-im/9.8 (accessed on 10 February 2022).

- EBC Analytica, 13.2—Sensory Analysis Tasting Area Equipment Conduct of Test, 2010. 24 October 2018. Available online: https://brewup.eu/ebc-analytica/sensory/sensory-analysis-tasting-area-equipment-conduct-of-test/13.2 (accessed on 10 February 2022).

- Bobkov, S. Biochemical and technological properties of buckwheat grains. In Molecular Breeding and Nutritional Aspects of Buckwheat, 1st ed.; Zhou, M., Kreft, I., Woo, S.H., Chrungoo, N., Wieslander, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 423–440. [Google Scholar]

- Pirzadah, T.B.; Malik, B.; Tahir, I.; Ul Rehman, R. Buckwheat journey to functional food sector. Curr. Nutr. Food Sci. 2020, 16, 134–141. [Google Scholar] [CrossRef]

- Huda, M.N.; Lu, S.; Jahan, T.; Ding, M.; Jha, R.; Zhang, K.; Zhou, M. Treasure from garden: Bioactive compounds of buckwheat. Food Chem. 2021, 335, 127653. [Google Scholar] [CrossRef]

- Kellershohn, J. Brewing Materials and Processes: A Practical Approach to Beer Excellence, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Phiarais, B.P.N.; Schehl, B.D.; Oliveira, J.C.; Arendt, E.K. Use of response surface methodology to investigate the effectiveness of commercial enzymes on buckwheat malt for brewing purposes. J. Inst. Brew. 2006, 112, 324–332. [Google Scholar] [CrossRef]

- Myncke, E.; Laureys, D.; Baillière, J.; Vanderputten, D.; De Clippeleer, J. Use of unmalted buckwheat for innovative beer production. In Proceedings of the Brewers Forum/38th EBC Congress, Madrid, Spain, 29 May–1 June 2022. [Google Scholar]

- Zdaniewicz, M.; Pater, A.; Hrabia, O.; Duliński, R.; Cioch-Skoneczny, M. Tritordeum malt: An innovative raw material for beer production. J. Cereal Sci. 2020, 96, 103095. [Google Scholar] [CrossRef]

- Giménez-Bastida, J.A.; Piskuła, M.; Zieliński, H. Recent advances in development of gluten-free buckwheat products. Trends Food Sci. Technol. 2015, 44, 58–65. [Google Scholar] [CrossRef]

- Zhuang, S.; Shetty, R.; Hansen, M.; Fromberg, A.; Hansen, P.B.; Hobley, T.J. Brewing with 100% unmalted grains: Barley, wheat, oat and rye. Eur. Food Res. Technol. 2017, 243, 447–454. [Google Scholar] [CrossRef]

- Byeon, Y.S.; Lim, S.T.; Kim, H.J.; Kwak, H.S.; Kim, S.S. Quality characteristics of wheat malts with different country of origin and their effect on beer brewing. J. Food Qual. 2021, 2021, 2146620. [Google Scholar] [CrossRef]

- Arendt, E.; Dal Bello, F. Gluten-Free Cereal Products and Beverages, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Buiatti, S.; Bertoli, S.; Passaghe, P. Influence of gluten-free adjuncts on beer colloidal stability. Eur. Food Res. Technol. 2018, 244, 903–912. [Google Scholar] [CrossRef]

- Deng, Y.; Lim, J.; Lee, G.H.; Nguyen, T.T.H.; Xiao, Y.; Piao, M.; Kim, D. Brewing rutin-enriched lager beer with buckwheat malt as adjuncts. J. Microbiol. Biotechnol. 2019, 29, 877–886. [Google Scholar] [CrossRef] [PubMed]

- Bamforth, C.W. Flavorsome components of beer. In Brewing Materials and Processes, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 151–155. [Google Scholar]

- Gallagher, E. (Ed.) Gluten-Free Food Science and Technology, 1st ed.; John Wiley & Sons: Oxford, UK, 2009. [Google Scholar]

- Steiner, E.; Auer, A.; Becker, T.; Gastl, M. Comparison of beer quality attributes between beers brewed with 100% barley malt and 100% barley raw material. J. Sci. Food Agric. 2012, 92, 803–813. [Google Scholar] [CrossRef] [PubMed]

- Agu, R.C.; Chiba, Y.; Goodfellow, V.; Mackinlay, J.; Brosnan, J.M.; Bringhurst, T.A.; Bryce, J.H. Effect of germination temperatures on proteolysis of the gluten-free grains rice and buckwheat during malting and mashing. J. Agric. Food Chem. 2012, 60, 10147–10154. [Google Scholar] [CrossRef]

- Cadenas, R.; Caballero, I.; Nimubona, D.; Blanco, C.A. Brewing with starchy adjuncts: Its influence on the sensory and nutritional properties of beer. Foods 2021, 10, 1726. [Google Scholar] [CrossRef] [PubMed]

- Salamon, R.V.; Dabija, A.; Ferencz, Á.; Tankó, G.; Ciocan, M.E.; Codină, G.G. The Effect of Dry Hopping Efficiency on β-Myrcene Dissolution into Beer. Plants 2022, 11, 1043. [Google Scholar] [CrossRef]

- Gribkova, I.N.; Eliseev, M.N.; Belkin, Y.D.; Zakharov, M.A.; Kosareva, O.A. The Influence of Biomolecule Composition on Colloidal Beer Structure. Biomolecules 2021, 12, 24. [Google Scholar] [CrossRef]

- Gorzelany, J.; Patyna, M.; Pluta, S.; Kapusta, I.; Balawejder, M.; Belcar, J. The Effect of the Addition of Ozonated and Non-Ozonated Fruits of the Saskatoon Berry (Amelanchier alnifolia Nutt.) on the Quality and Pro-Healthy Profile of Craft Wheat Beers. Molecules 2022, 27, 4544. [Google Scholar] [CrossRef]

- Habschied, K.; Krstanović, V.; Mastanjević, K. Beer Quality Evaluation—A Sensory Aspect. Beverages 2022, 8, 15. [Google Scholar] [CrossRef]

- Sebestyén, A.; Kiss, Z.; Vecseri-Hegyes, B.; Kun-Farkas, G.; Hoschke, Á. Experiences with laboratory and pilot plant preparation of millet and buckwheat beer. Acta Aliment. 2013, 42, 81–89. [Google Scholar] [CrossRef]

- Phiarais, B.P.N.; Wijngaard, H.H.; Arendt, E.K. The impact of kilning on enzymatic activity of buckwheat malt. J. Inst. Brew. 2005, 111, 290–298. [Google Scholar] [CrossRef]

- Deželak, M.; Zarnkow, M.; Becker, T.; Košir, I.J. Processing of bottom-fermented gluten-free beer-like beverages based on buckwheat and quinoa malt with chemical and sensory characterization. J. Inst. Brew. 2014, 120, 360–370. [Google Scholar] [CrossRef]

- Salanță, L.C.; Coldea, T.E.; Ignat, M.V.; Pop, C.R.; Tofană, M.; Mudura, E.; Zhao, H. Functionality of special beer processes and potential health benefits. Processes 2020, 8, 1613. [Google Scholar] [CrossRef]

- Viejo, C.G.; Fuentes, S.; Howell, K.; Torrico, D.D.; Dunshea, F.R. Integration of non-invasive biometrics with sensory analysis techniques to assess acceptability of beer by consumers. Physiol. Behav. 2019, 200, 139–147. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).