Clogging Prevention of Slurry–Earth Pressure Balance Dual-Mode Shield in Composed Strata with Medium–Coarse Sand and Argillaceous Siltstone

Abstract

:1. Introduction

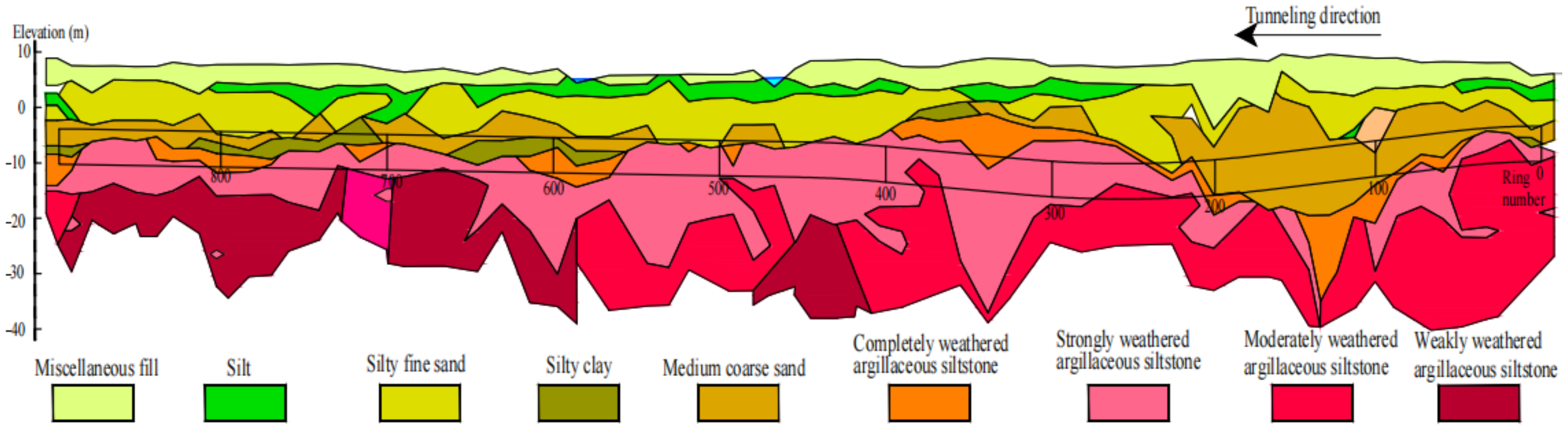

2. Project Description

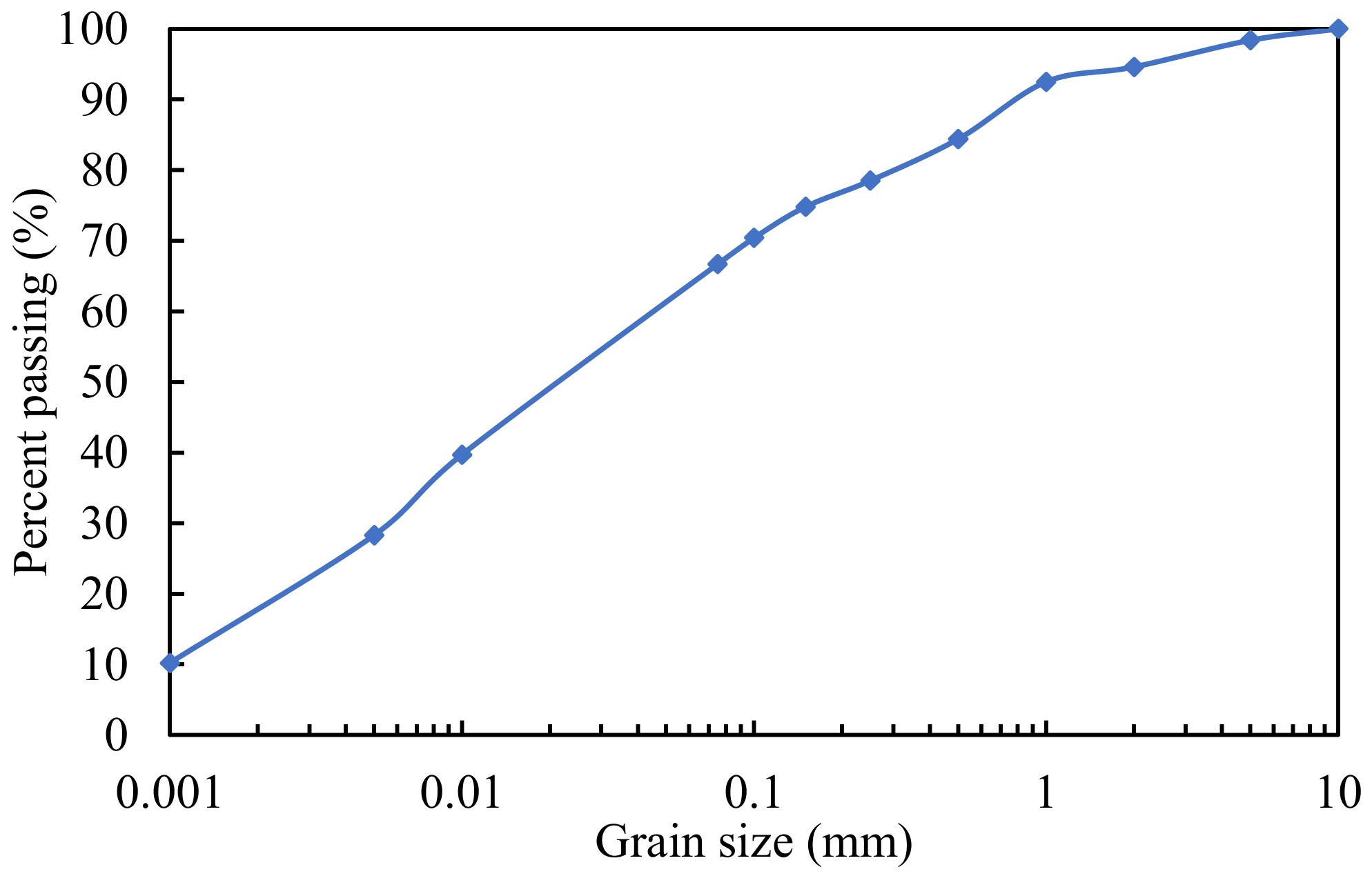

2.1. Engineering Geology and Hydrogeology

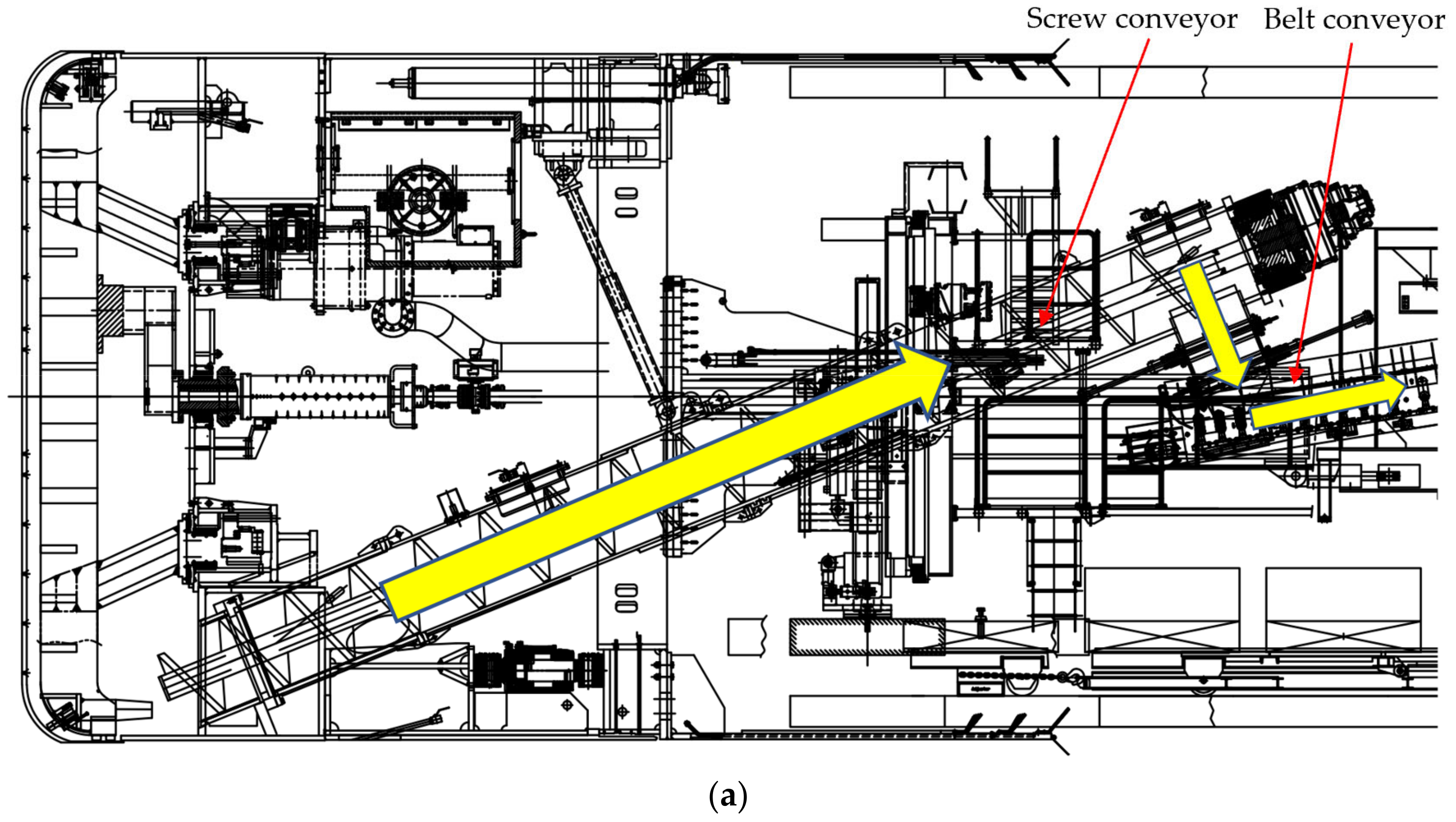

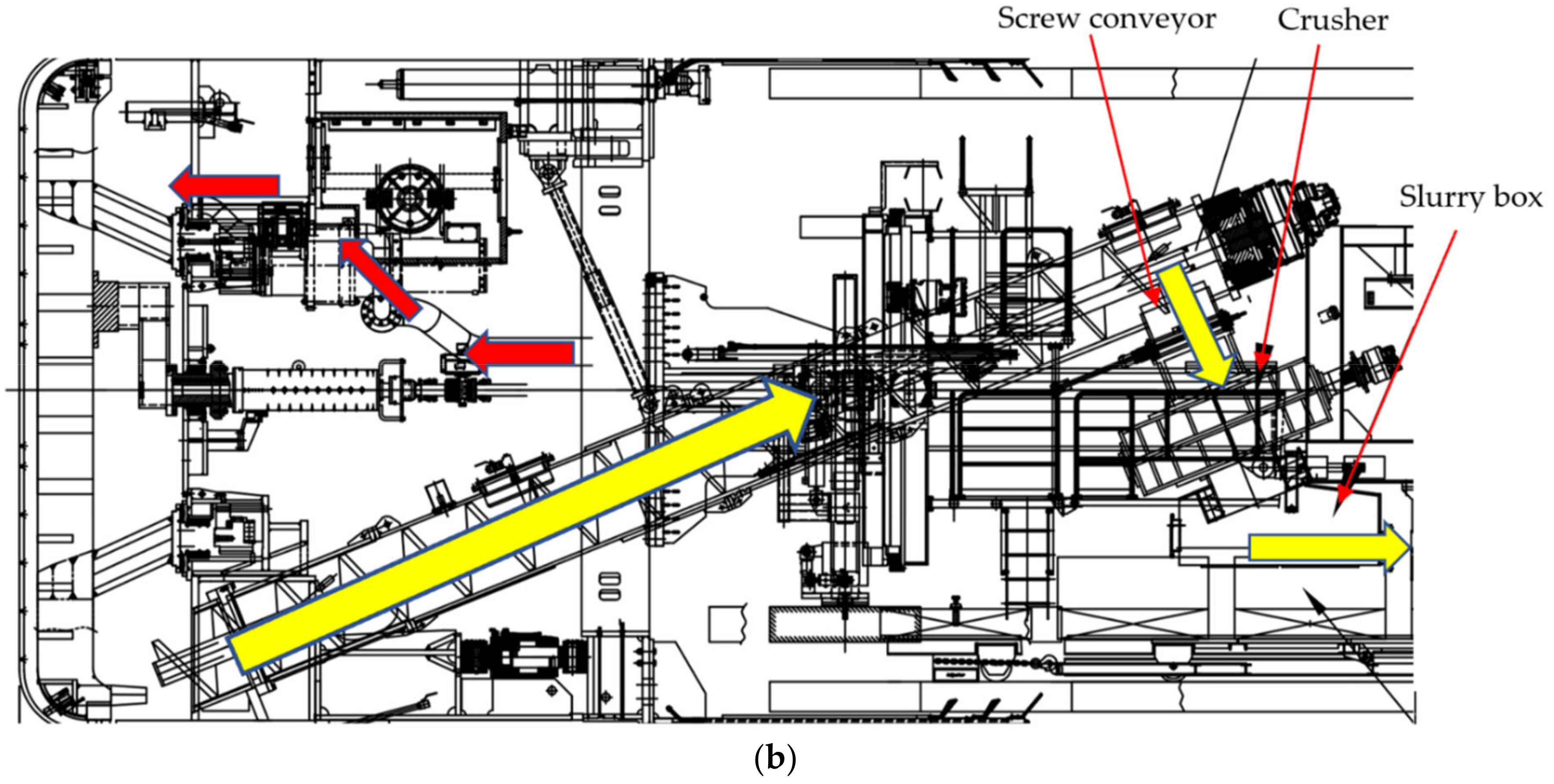

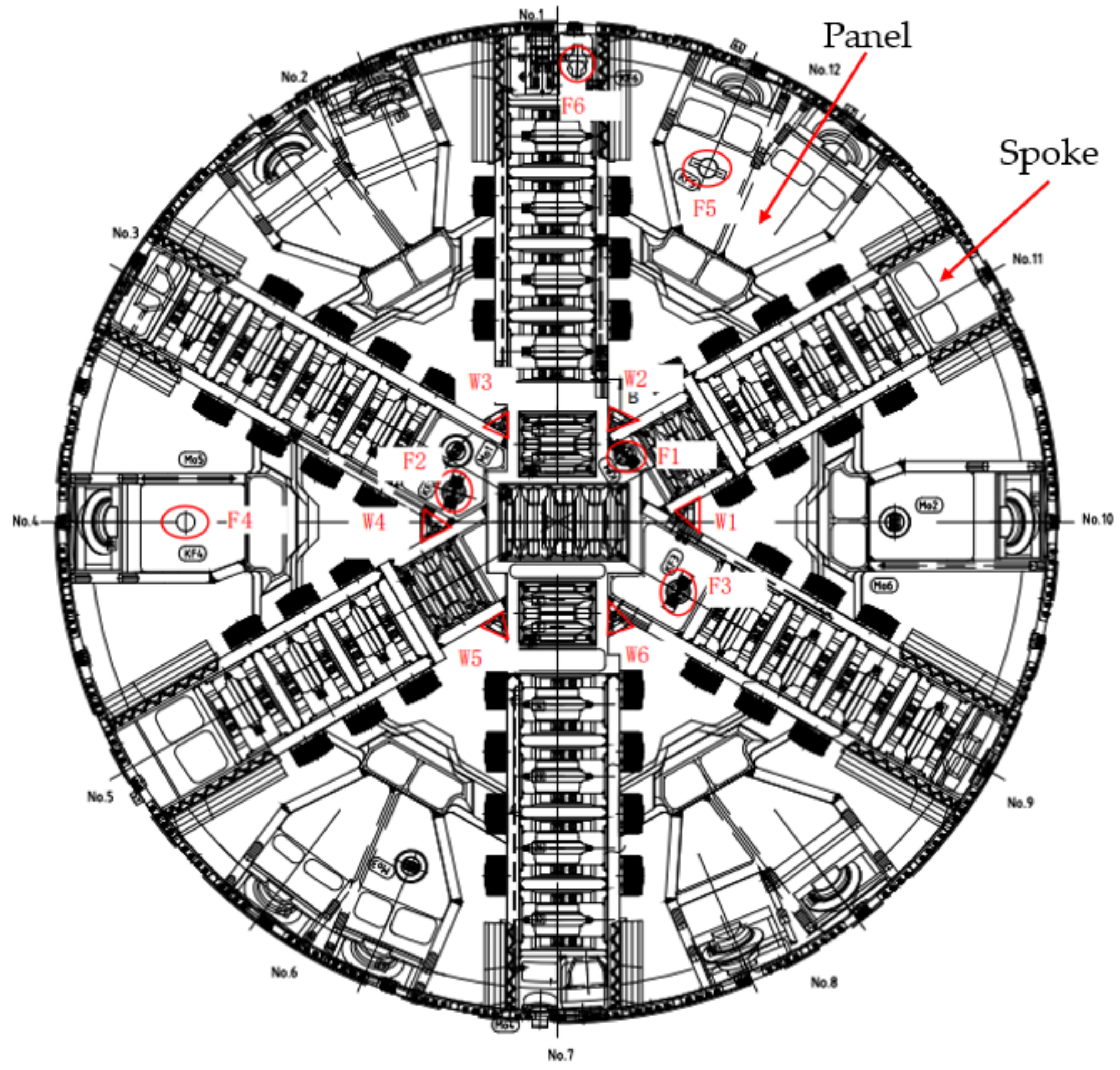

2.2. Description of the Shield Machine

3. Analysis of the Formation and Cause of Shield Clogging

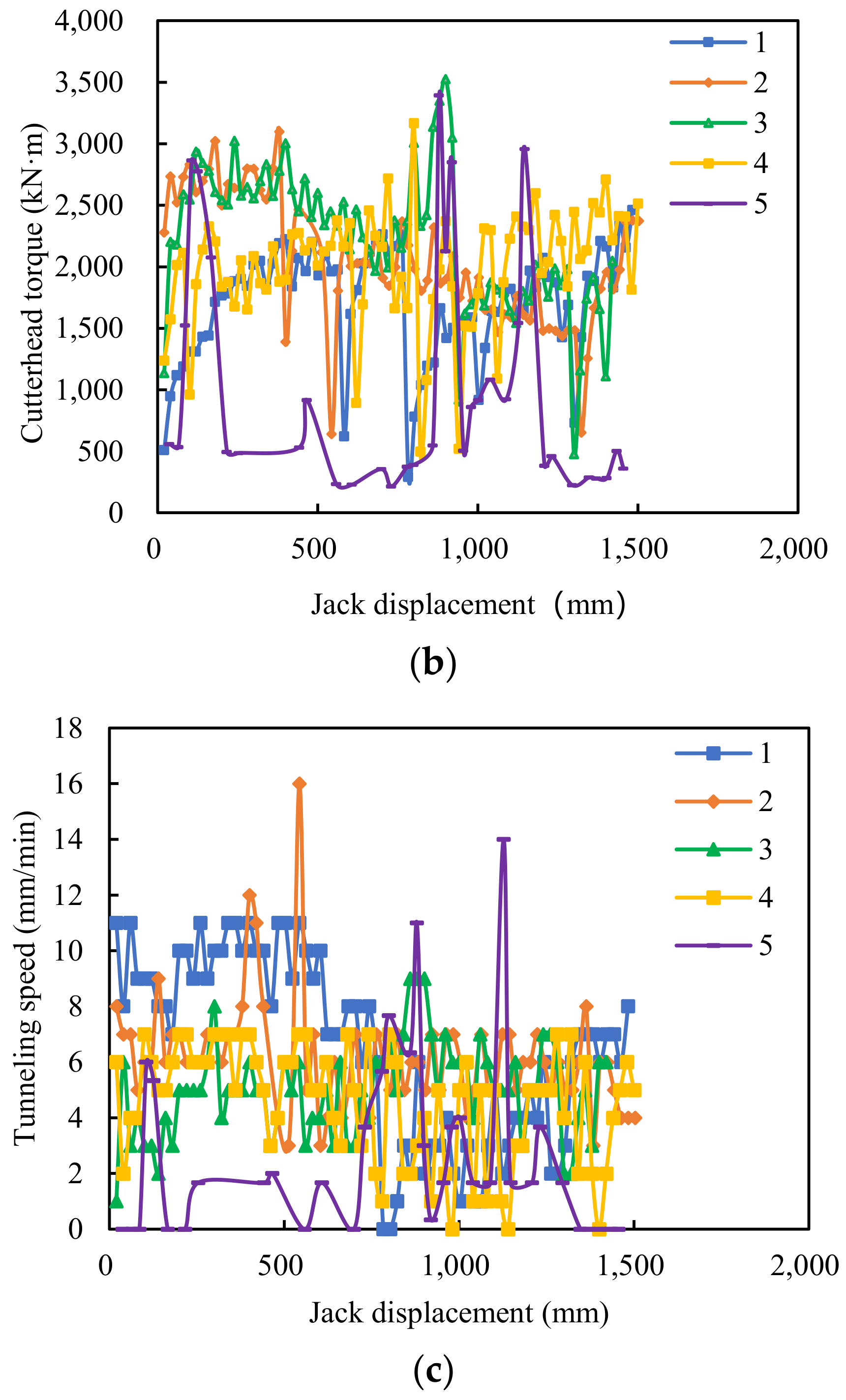

3.1. Variation in the Tunneling Parameters during the Formation of Shield Clogging

3.2. Causal Analysis of Shield Clogging

4. Ideal Soil Consistency Index for the Prevention of Shield Clogging

- (1)

- The specimen was placed into a shallow container with clean water. The water surface was approximately 20 mm higher than the specimen surface. Then, the mixture of the water and soil particles was stirred with a glass rod for 5 min to eliminate bubbles and covered for 24 h until complete wetting occurred.

- (2)

- The water on top of the specimen was poured out. A straw was used to remove the residual water from the specimen.

- (3)

- The specimen was spread in a pan. Then, the specimen was blown with warm air from a portable hair dryer and mixed continuously so that the water in the particle surface group evaporated to reach the estimated soil specimen state. The fine powder was not lost during the blowing.

- (4)

- The specimen was loosely placed into the test mold simultaneously. The upper and lower diameters of the conical test mold were 40 and 90 mm, respectively. The height was 75 mm. Then, the specimen was tamped 25 times with a tamping rod. The distance between the end of the tamping rod and the surface of the specimen should not exceed 10 mm so that it can fall freely. The mold opening was scraped after the tamping. It was unnecessary to refill the mold if a gap was present.

- (5)

- The test mold was lifted slowly in the vertical direction. If the specimen did not collapse, the soil specimen still contained surface water. Then, the soil was dried with warm air according to the above method until the specimen started to fall. If the specimen slumped too much after the test mold was lifted, then the specimen had been overly dried. At this time, the specimen was evenly sprinkled with approximately 5 mL of water, fully mixed, and placed in a covered container for 30 min. Then, it was tested according to the above method until it reached the required state. The required state was that one-third of the specimen slumped (Figure 9).

- (6)

- After the completion of the slump test, a specimen of not less than 20 g was immediately taken to determine its water content, that is, the water absorption of the specimen.

5. Soil Conditioning and Variation in the Tunneling Parameters

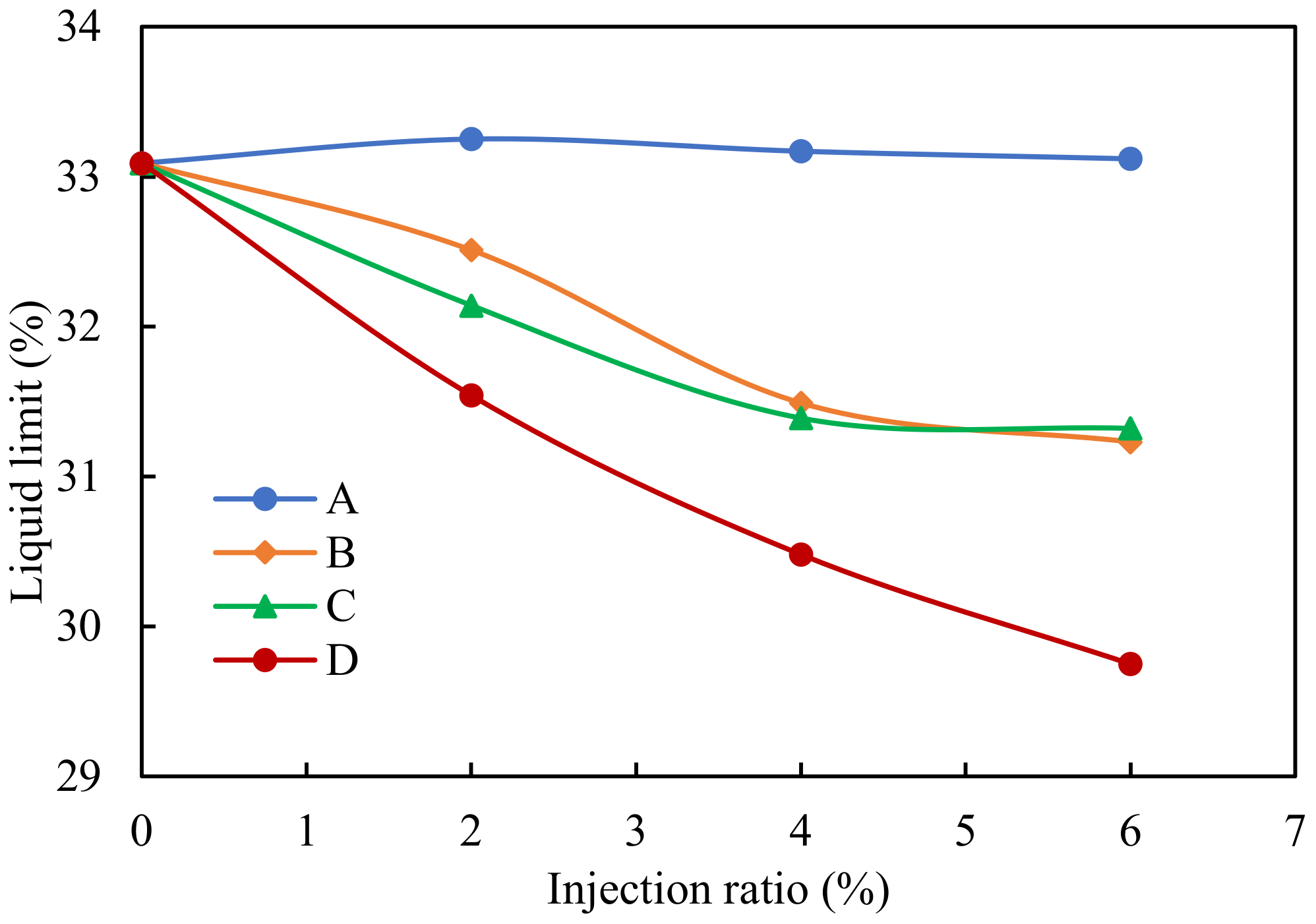

5.1. Determination of the Type of Soil Conditioner

- (1)

- Evaluation of the dispersant performance of soil conditioners

- (2)

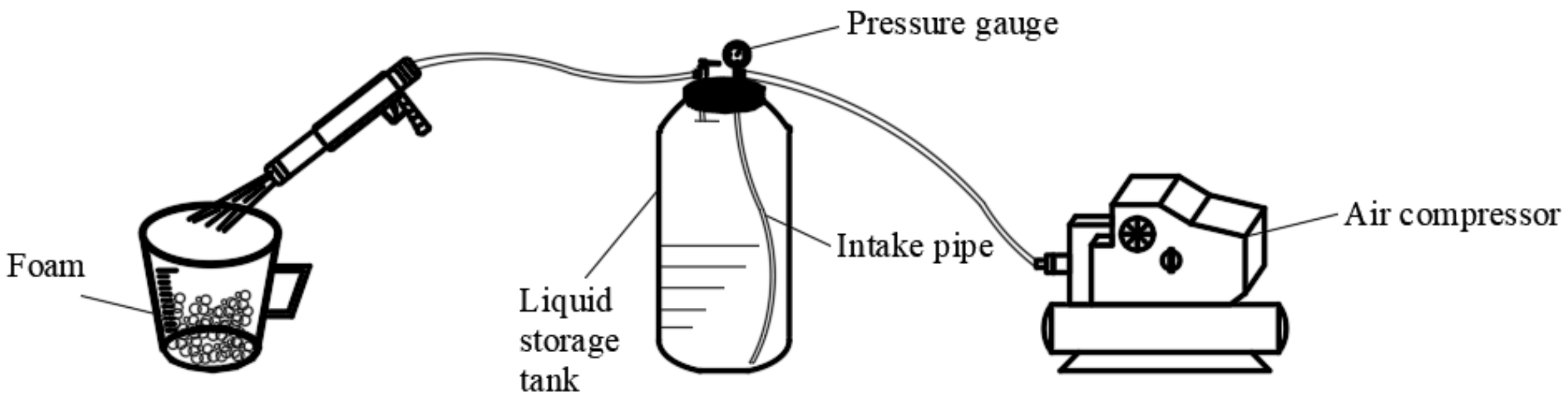

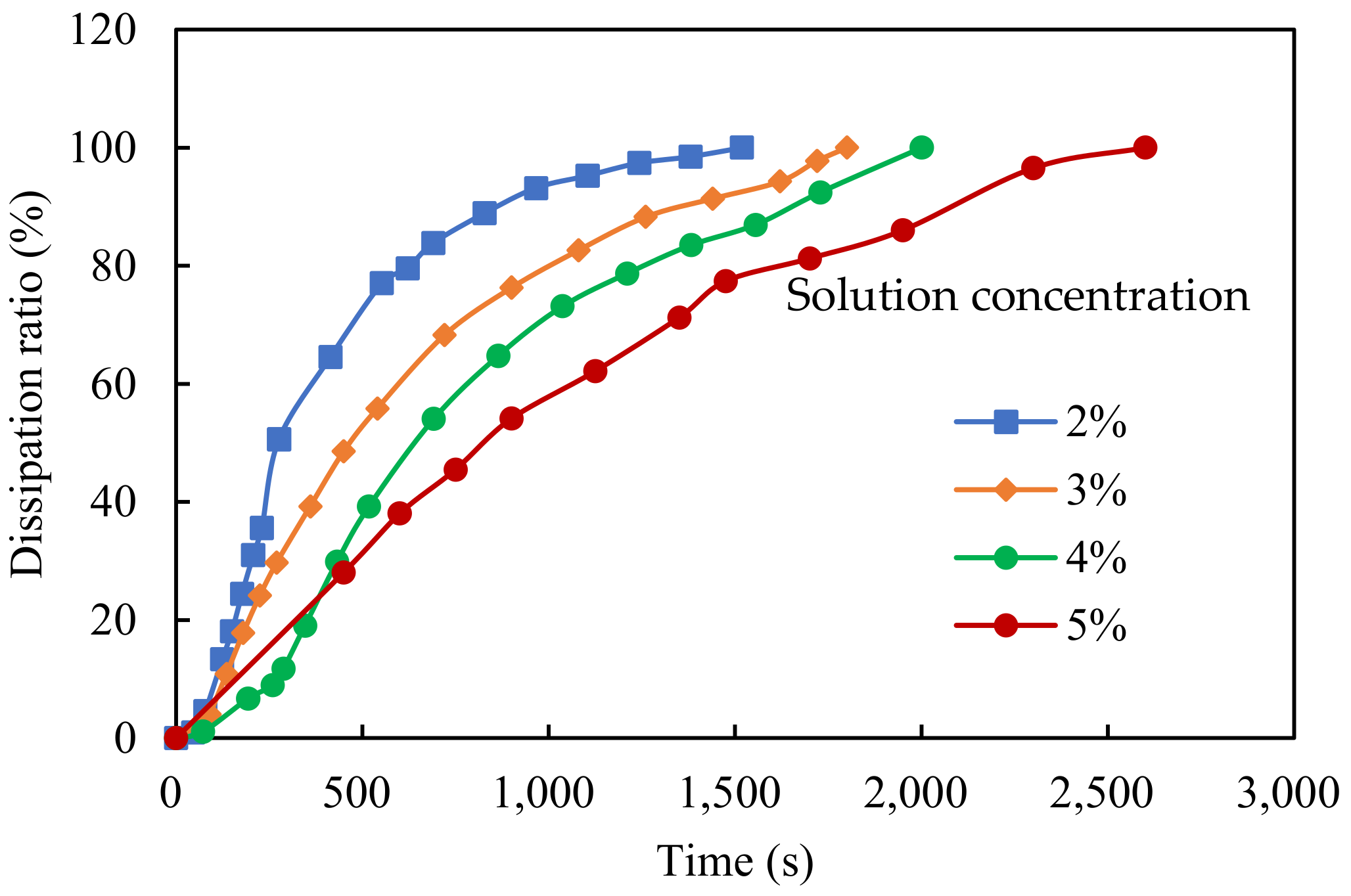

- Evaluation of the foaming performance of the foam agent

5.2. Engineering Application and Analysis of Soil Conditioning

- (1)

- Soil softness control

- (2)

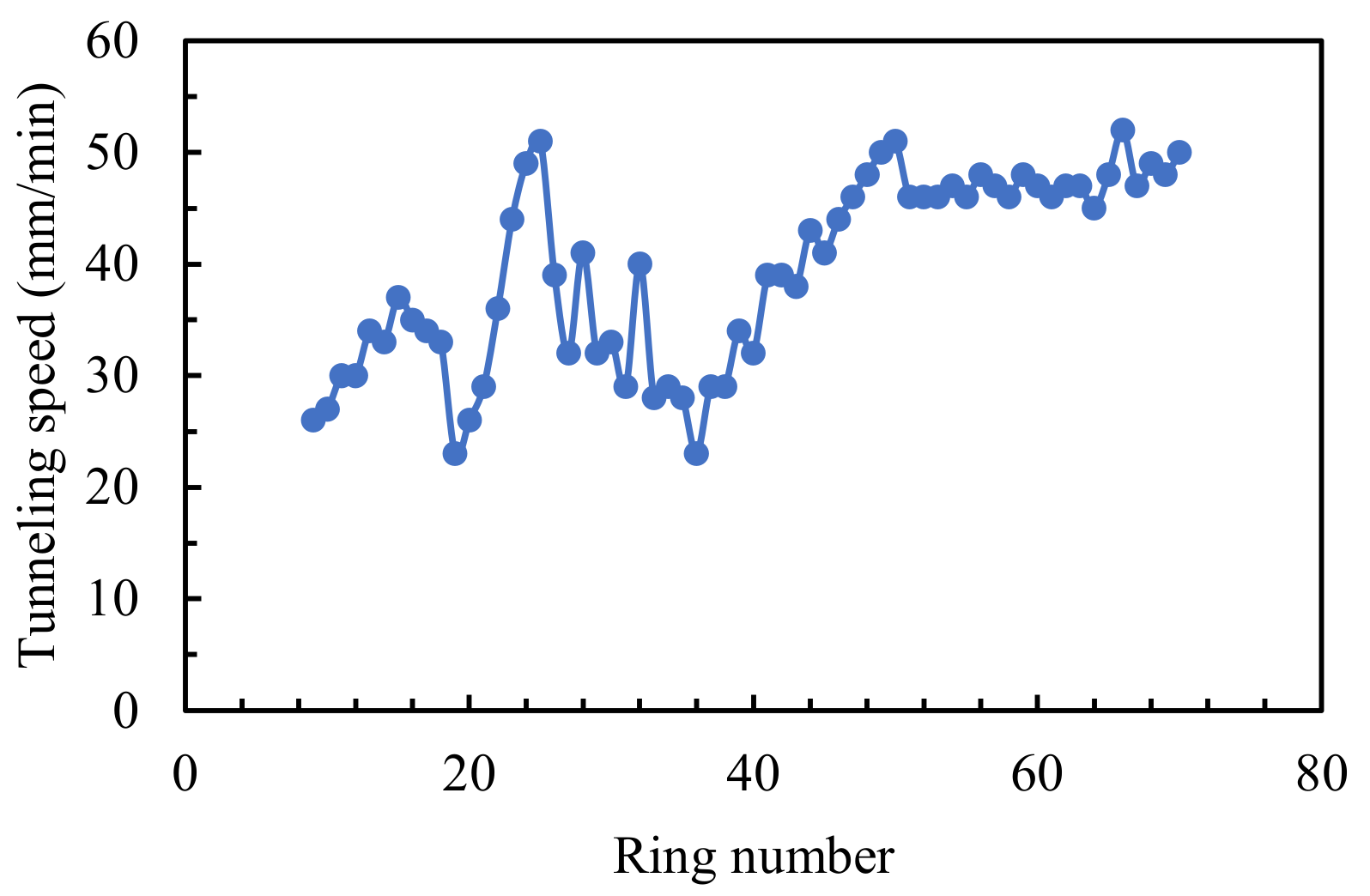

- Variation in the tunneling parameters

6. Conclusions

- (1)

- The slurry mode of the slurry–earth pressure balance dual-mode shield was not applicable to the composed stratum with medium–coarse sand and argillaceous siltstone. It was difficult to transport the adhesive soil from the chamber only by the slurry circulation. The excavated soil accumulated in the slurry chamber. The accumulated soil prevented the excavated soil from entering the slurry chamber. Finally, the excavated soil accumulated in the cutterhead, and the opening of the cutterhead was clogged.

- (2)

- The total thrust force of the shield increased significantly, the tunneling speed gradually decreased to 0, and the torque of the cutterhead increased slightly after the slurry–earth pressure dual-mode balance shield machine in the slurry mode was clogged. The fluctuations in the total thrust force, cutterhead torque, and tunneling speed also increased significantly.

- (3)

- The EPB mode is recommended for the composed strata with medium–coarse sand and argillaceous siltstone. The dispersible foam agent and water can be used to condition the soil. The type of dispersible foam agent was determined by measuring the effect of the soil conditioner on the liquid limit of the particles with sizes less than 0.15 mm in the soil. The concentration of the foam agent was determined by measuring the half-life and foam expansion ratio of the foam. The injection amount of the foam and water was determined according to the status of the mud discharged by the screw conveyor.

- (4)

- Water absorption can be used to characterize the water absorption capacity of particles larger than 0.15 mm. The ideal soil state was that the consistency index of the particles smaller than 0.15 mm was less than 0.5 to prevent the EPB shield from clogging. The water absorption of soil with a particle larger than 0.15 mm should be removed when calculating the consistency index.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, S.; Liu, P.; Gong, Z.; Yang, P. Auxiliary air pressure balance mode for EPB shield tunneling in water-rich gravelly sand strata: Feasibility and soil conditioning. Case Stud. Constr. Mater. 2021, 16, e00799. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Li, X.; Liu, H. Criteria for Cutting Head Clogging Occurrence during Slurry Shield Tunneling. Appl. Sci. 2022, 12, 1001. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, B.; Wei, G.; Yao, D.; Hu, C. Study for Longitudinal Deformation of Shield Tunnel in Side of Foundation Pit Based on Virtual Image Technique. Appl. Sci. 2022, 12, 8745. [Google Scholar] [CrossRef]

- Zumsteg, R.; Langmaack, L. Mechanized Tunneling in Soft Soils: Choice of Excavation Mode and Application of Soil-Conditioning Additives in Glacial Deposits. Engineering 2017, 3, 863–870. [Google Scholar] [CrossRef]

- EFNARC. Specification and Guidelines for the Use of Specialist Products for Soft Ground Tunnelling; European Federation for Specialist Construction Chemicals and Concrete Systems: Surry, UK, 2005. [Google Scholar]

- Wang, S.; Fu, J.; Zhang, C.; Yang, J. Shield Tunnel Engineering: From Theory to Practice; Central South University Press: Changsha, China, 2021. [Google Scholar]

- Maidl, B.; Herrenknecht, M.; Maidl, U.; Wehrmeyer, G. Mechanised Shield Tunnelling; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Thewes, M.; Hollmann, F. Assessment of clay soils and clay-rich rock for clogging of TBMs. Tunn. Undergr. Space Technol. 2016, 57, 122–128. [Google Scholar] [CrossRef]

- Ye, X.; Wang, S.; Yang, J.; Sheng, D.; Xiao, C. Soil Conditioning for EPB Shield Tunneling in Argillaceous Siltstone with High Content of Clay Minerals: Case Study. Int. J. Géomeéch. 2017, 17, 05016002. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, Z.; Liu, P.; Yang, Z.; Pan, Q.; Chen, W. On the critical particle size of soil with clogging potential in shield tunneling. J. Rock Mech. Geotech. Eng. 2022, in press. [Google Scholar] [CrossRef]

- Zumsteg, R.; Puzrin, A. Stickiness and adhesion of conditioned clay pastes. Tunn. Undergr. Space Technol. 2012, 31, 86–96. [Google Scholar] [CrossRef]

- Zumsteg, R.; Puzrin, A.; Anagnostou, G. Effects of slurry on stickiness of excavated clays and clogging of equipment in fluid supported excavations. Tunn. Undergr. Space Technol. 2016, 58, 197–208. [Google Scholar] [CrossRef]

- Oliveira, D.; Thewes, M.; Diederichs, M.S.; Langmaack, L. EPB tunnelling through clay-sand mixed soils: Pro-posed methodology for clogging evaluation. Geomech. Tunn. 2018, 11, 375–387. [Google Scholar] [CrossRef]

- Hollmann, F.S.; Thewes, M. Assessment method for clay clogging and disintegration of fines in mechanised tunnelling. Tunelling Undergr. Space Technol. 2013, 37, 96–106. [Google Scholar] [CrossRef]

- Liu, P.; Wang, S.; Shi, Y.; Yang, J.; Fu, J.; Yang, F. Tangential Adhesion Strength between Clay and Steel for Various Soil Softnesses. J. Mater. Civ. Eng. 2019, 31, 04019048. [Google Scholar] [CrossRef]

- Wang, S.; Liu, P.; Hu, Q.; Zhong, J. Effect of dispersant on the tangential adhesion strength between clay and metal for EPB shield tunnelling. Tunn. Undergr. Space Technol. 2020, 95, 103144. [Google Scholar] [CrossRef]

- GB/T 50123–2019; Standards for Geotechnical Test Methods. China Planning Press: Beijing, China, 2019. (In Chinese)

- ASTM D4318-10; Standard Test Method for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM C128-12; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2012.

- AASHTO T84-13; Standard Method of Test for Specific Gravity and Absorption of Fine Aggregate. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- JTG E42-2005; Test Method of Aggregate for Highway Engineering. China Communications Press: Beijing, China, 2005. (In Chinese)

- Liu, P.; Wang, S.; Ge, L.; Thewes, M.; Yang, J.; Xia, Y. Changes of Atterberg limits and electrochemical behaviors of clays with dispersants as conditioning agents for EPB shield tunnelling. Tunn. Undergr. Space Technol. 2018, 73, 244–251. [Google Scholar] [CrossRef]

- Quebaud, S.; Sibai, M.; Henry, J.-P. Use of chemical foam for improvements in drilling by earth-pressure balanced shields in granular soils. Tunn. Undergr. Space Technol. 1998, 13, 173–180. [Google Scholar] [CrossRef]

- Budach, C.; Thewes, M. Application ranges of EPB shields in coarse ground based on laboratory research. Tunn. Undergr. Space Technol. 2015, 50, 296–304. [Google Scholar] [CrossRef]

- Yan, X.; Gong, Q.; Jiang, H. Soil conditioning for Earth Pressure Balanced Shield Excavation in Sand Layer. Chin. J. Undergr. Space Eng. 2010, 6, 449–453. (In Chinese) [Google Scholar]

| Geotechnical Name | Natural Water Content (%) | Quick Shear | Content of Silty and Clay Particle (%) | Content of Sand (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Cohesion Force (kPa) | Internal Friction Angle (°) | 0.005~0.075 mm | <0.005 mm | 0.5~2 mm | 0.25~0.5 mm | 0.075~0.25 mm | ||

| Silty clay | 26.8 | 23 | 18 | 37.6 | 20.8 | 9.8 | 12.6 | 19.2 |

| Medium–coarse sand | 33.8 | / | 32.0 | 25.4 | 1.1 | 22.1 | 24.3 | 12.7 |

| Completely weathered argillaceous siltstone | 19.6 | 30.25 | 21.5 | 42.0 | 22.4 | 9.0 | 10.6 | 13.9 |

| Strongly weathered argillaceous siltstone | 17.0 | 36.5 | 24.0 | 42.2 | 20.5 | 10.1 | 12.8 | 12.9 |

| Moderately weathered argillaceous siltstone | / | 100 | 35 | / | / | / | / | / |

| Ring Number | Water Content (%) | Atterberg Limits of Soil Less than 0.15 mm (%) | Water Absorption (%) | Proportion of Different Particles (%) | Consistency Index of Soil Less than 0.15 mm | ||||

|---|---|---|---|---|---|---|---|---|---|

| Plastic Limit | Liquid Limit | 0.15~2 mm | >2 mm | <0.15 mm | 0.15~2 mm | >2 mm | |||

| 9 | 34.7 | 15.68 | 33.09 | 18.9 | 5.7 | 73.8 | 22.5 | 3.7 | 0.14 |

| 10 | 34.8 | 14.27 | 32.78 | 21.7 | 4.5 | 65.5 | 25.8 | 8.7 | 0.17 |

| 14 | 38.1 | 16.71 | 35.72 | 17.9 | 6.4 | 79.8 | 17.9 | 2.3 | 0.04 |

| 31 | 27.4 | 15.04 | 33.14 | 20.8 | 5.1 | 61.3 | 20.7 | 18 | 0.50 |

| 51 | 32.4 | 14.23 | 34.14 | 17.9 | 4.7 | 50.2 | 30.4 | 19.4 | 0.31 |

| 70 | 29.3 | 14.52 | 32.14 | 18.2 | 5.4 | 59.7 | 31.6 | 8.7 | 0.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Liu, P.; Chen, P.; Li, S.; Ji, F. Clogging Prevention of Slurry–Earth Pressure Balance Dual-Mode Shield in Composed Strata with Medium–Coarse Sand and Argillaceous Siltstone. Appl. Sci. 2023, 13, 2023. https://doi.org/10.3390/app13032023

Yang Z, Liu P, Chen P, Li S, Ji F. Clogging Prevention of Slurry–Earth Pressure Balance Dual-Mode Shield in Composed Strata with Medium–Coarse Sand and Argillaceous Siltstone. Applied Sciences. 2023; 13(3):2023. https://doi.org/10.3390/app13032023

Chicago/Turabian StyleYang, Zhao, Pengfei Liu, Peishuai Chen, Shuchen Li, and Fuquan Ji. 2023. "Clogging Prevention of Slurry–Earth Pressure Balance Dual-Mode Shield in Composed Strata with Medium–Coarse Sand and Argillaceous Siltstone" Applied Sciences 13, no. 3: 2023. https://doi.org/10.3390/app13032023

APA StyleYang, Z., Liu, P., Chen, P., Li, S., & Ji, F. (2023). Clogging Prevention of Slurry–Earth Pressure Balance Dual-Mode Shield in Composed Strata with Medium–Coarse Sand and Argillaceous Siltstone. Applied Sciences, 13(3), 2023. https://doi.org/10.3390/app13032023