Detecting Cracks in Aerated Concrete Samples Using a Convolutional Neural Network

Abstract

:1. Introduction

- −

- −

- optimization of the parameters of the intellectual model based on the convolutional neural network YOLOv4 for its further use in production to track defective products in real time.

- −

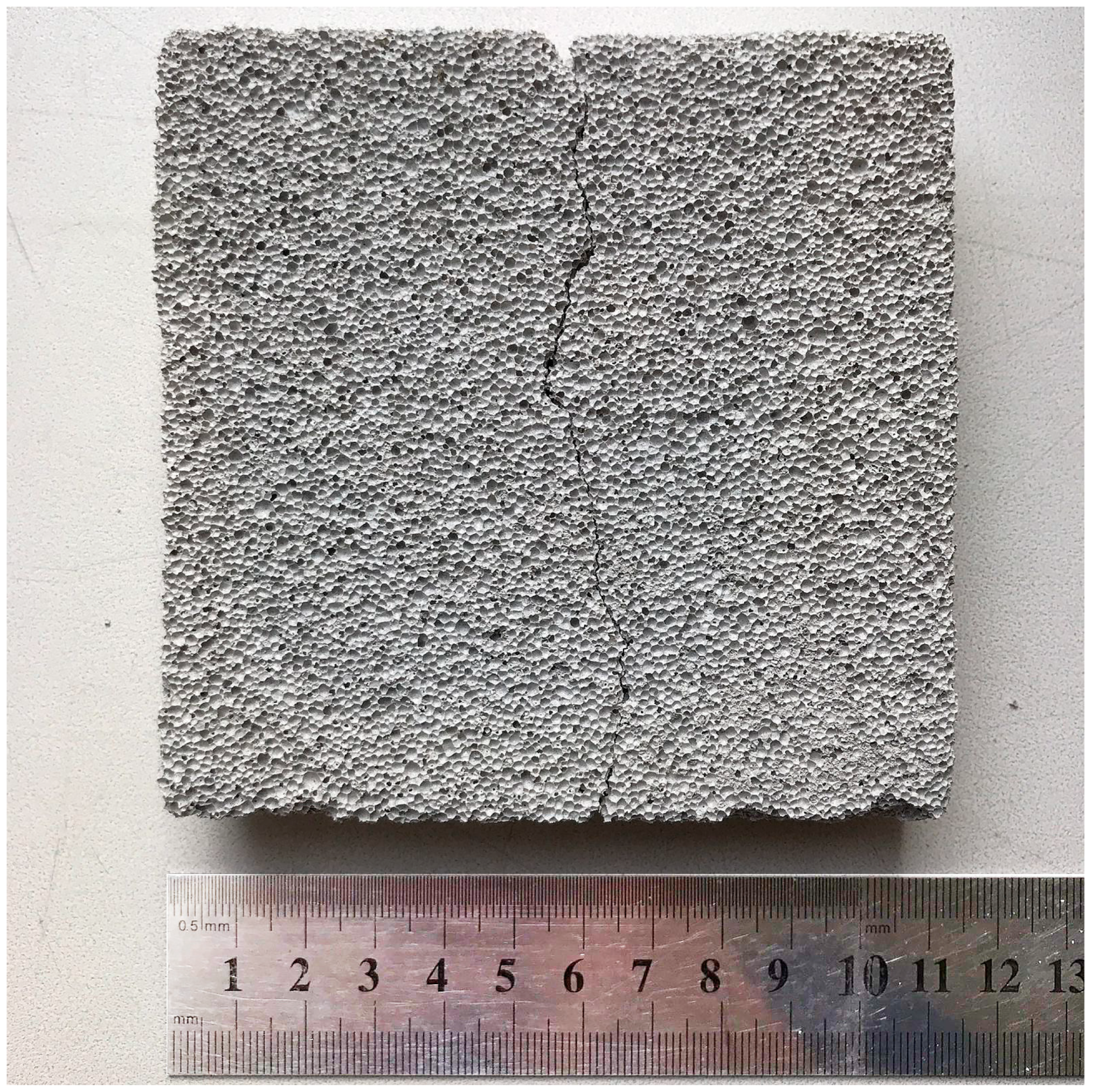

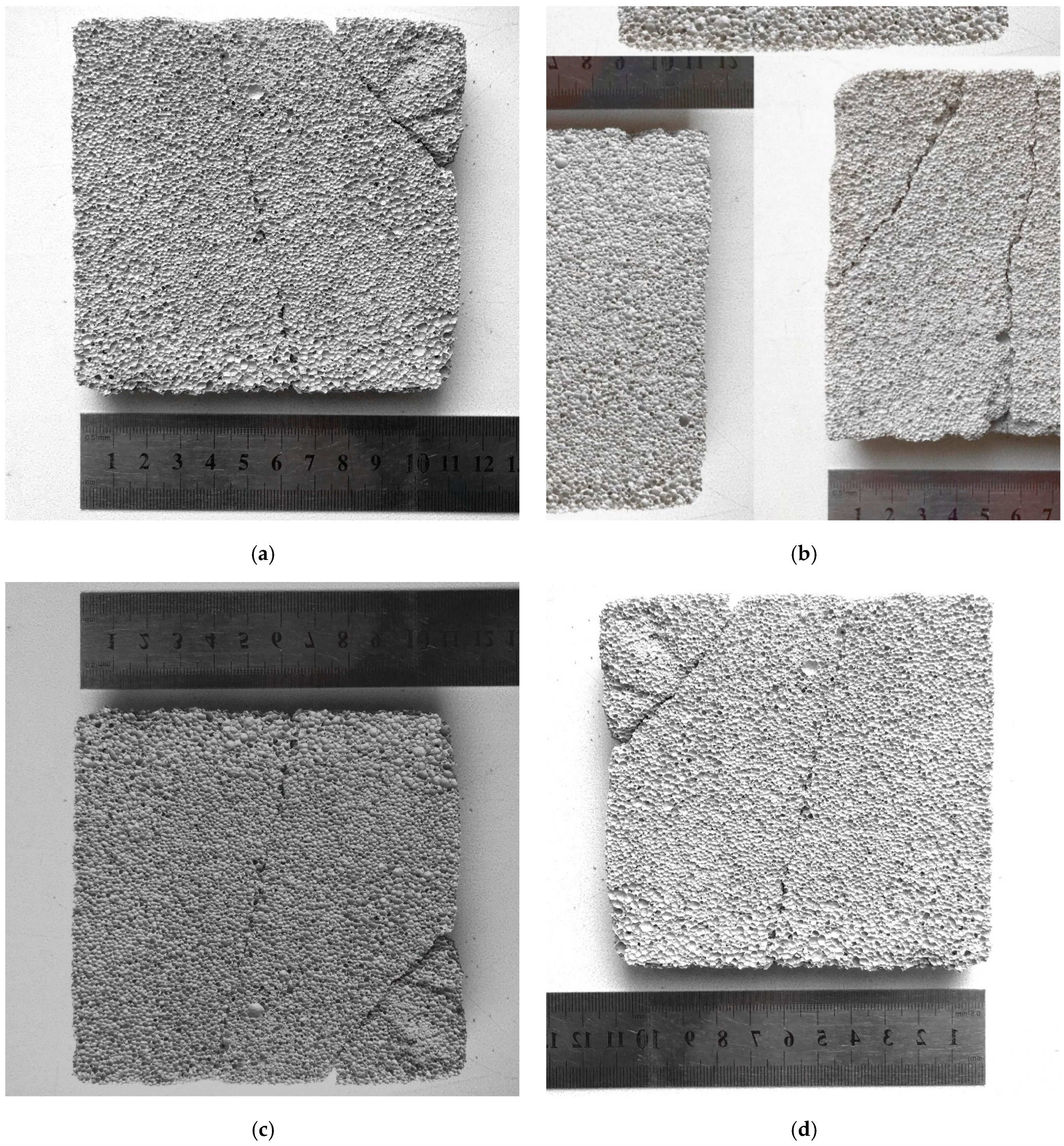

- collection of an empirical database of images of aerated concrete samples;

- −

- substantiation of the chosen detection method;

- −

- conducting the augmentation process to expand the sample;

- −

- implementation and optimization of the algorithm using the convolutional neural network YOLOv4.

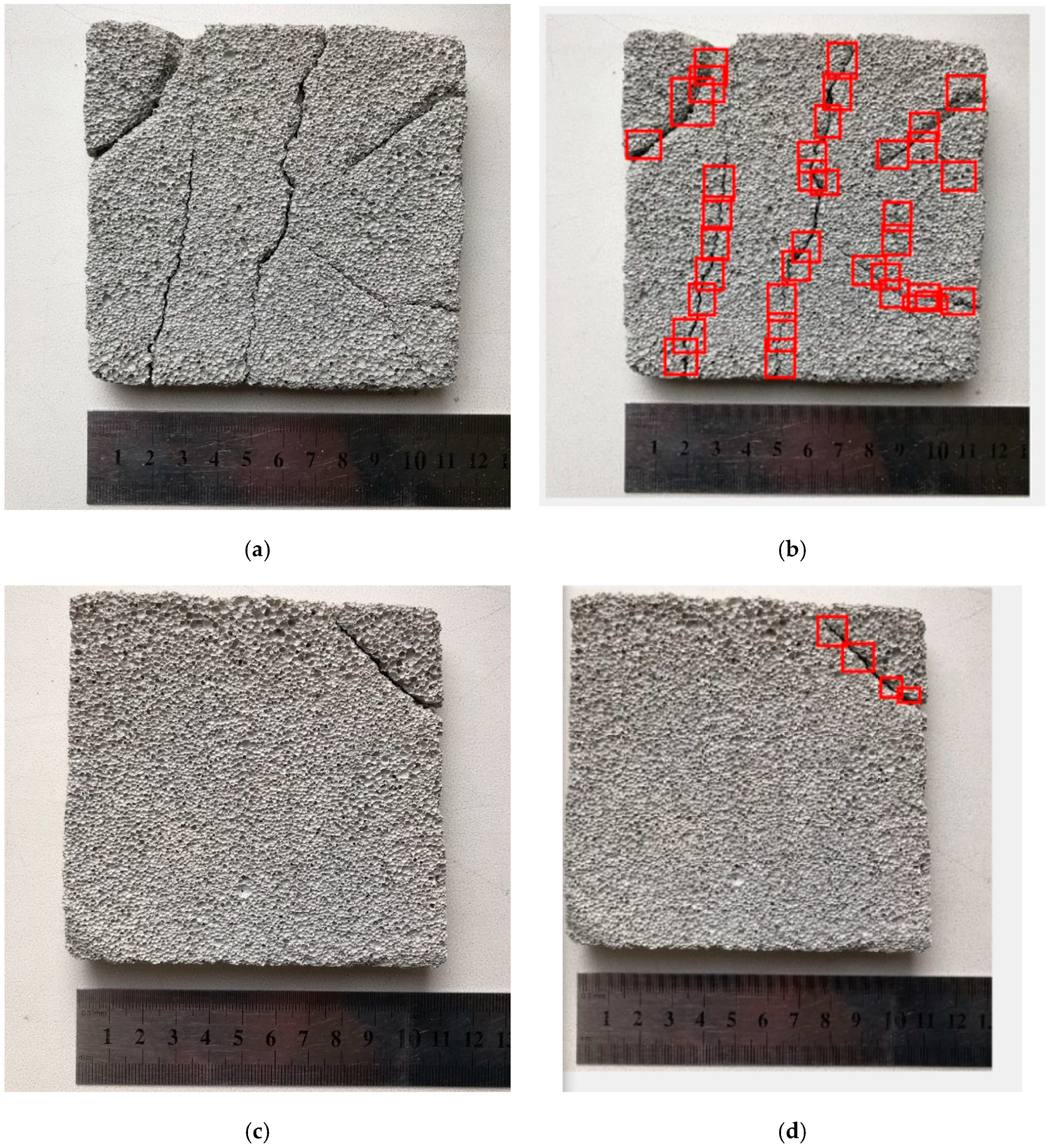

2. Materials and Methods

2.1. Characteristics of the Analyzed Building Material

2.2. Augmentation and Data Markup

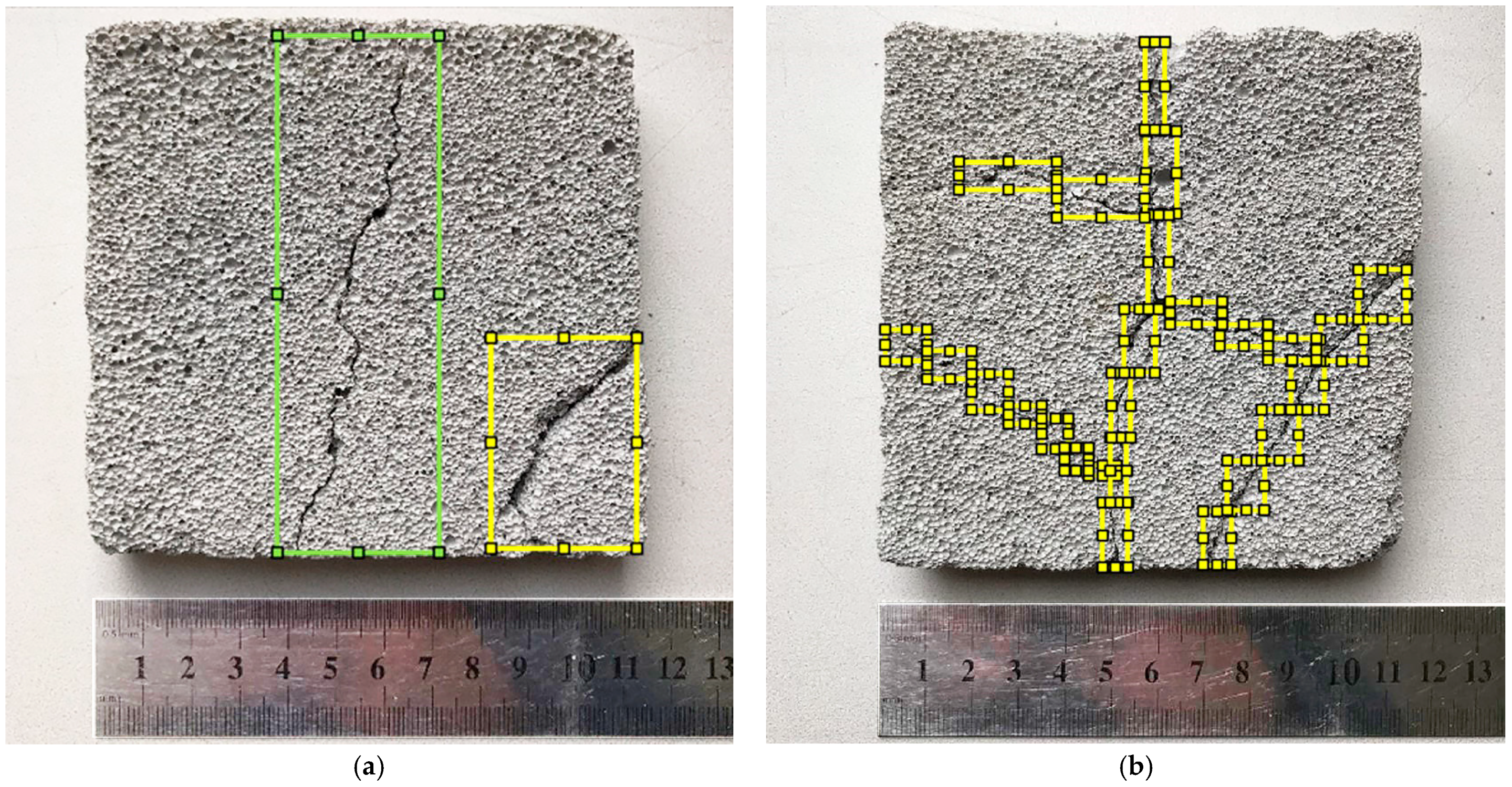

2.2.1. Image Markup

2.2.2. Image Augmentation

- Original photo addition without changes to the training set.

- Display (vertical and/or horizontal).

- Random image shift along the Ox and Oy axes.

- Image rotation 90°, 180°, 270°.

- Change brightness, contrast, and saturation.

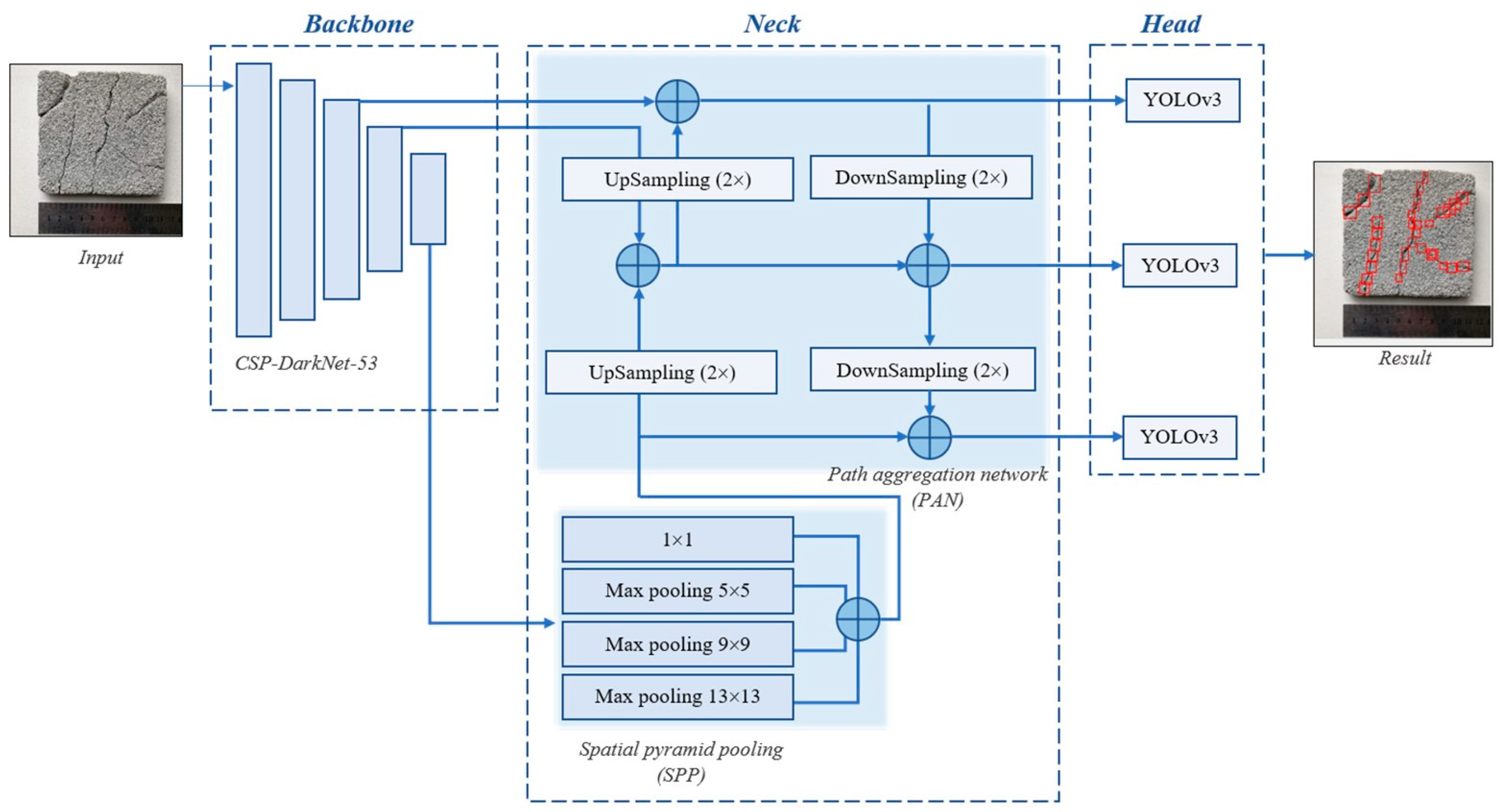

2.3. Development of an Intelligent Algorithm Based on the YOLOv4 Convolutional Neural Network

- Input, represented as our set of training images that will be fed into the network.

- Backbone and Neck, which perform feature extraction and aggregation. The Backbone is based on a pre-trained deep learning network built using CSP-DarkNet-53 as the base network.

- 3.

- In the YOLOv4 network, single-stage object detectors, such as in YOLOv3, are used as detection heads.

- 4.

- Result, which is an image with the specified bounding box coordinates.

3. Results and Discussion

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rehman, Z.; Khalid, U.; Ijaz, N.; Mujtaba, H.; Haider, A.; Farooq, K.; Ijaz, Z. Machine learning-based intelligent modeling of hydraulic conductivity of sandy soils considering a wide range of grain sizes. Eng. Geol. 2022, 311, 106899. [Google Scholar] [CrossRef]

- Dais, D.; Bal, E.; Smyrou, E.; Sarhosis, V. Automatic crack classification and segmentation on masonry surfaces using convolutional neural networks and transfer learning. Autom. Constr. 2021, 125, 103606. [Google Scholar] [CrossRef]

- Beskopylny, A.; Lyapin, A.; Anysz, H.; Meskhi, B.; Veremeenko, A.; Mozgovoy, A. Artificial Neural Networks in Classification of Steel Grades Based on Non-Destructive Tests. Materials 2020, 13, 2445. [Google Scholar] [CrossRef] [PubMed]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Kozhakin, A.; Beskopylny, N. Prediction of Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete Based on Deep Neural Network and Ensemble Regression Trees Methods. Materials 2022, 15, 6740. [Google Scholar] [CrossRef] [PubMed]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Chernil’nik, A.; Beskopylny, N. Concrete Strength Prediction Using Machine Learning Methods CatBoost, k-Nearest Neighbors, Support Vector Regression. Appl. Sci. 2022, 12, 10864. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Mailyan, L.R.; Stel’makh, S.A.; Shcherban’, E.M.; Razveeva, I.F.; Beskopylny, N.A.; Dotsenko, N.A.; El’shaeva, D.M. The Program for Determining the Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete based on Artificial Intelligence Methods. Russian Federation Computer Program 2022668999. 14 October 2022. Available online: https://www.fips.ru/registers-doc-view/fips_servlet?DB=EVM&DocNumber=2022668999&TypeFile=html (accessed on 7 January 2023).

- Romanevich, K.; Lebedev, M.; Andrianov, S.; Mulev, S. Integrated Interpretation of the Results of Long-Term Geotechnical Monitoring in Underground Tunnels Using the Electromagnetic Radiation Method. Foundations 2022, 2, 3. [Google Scholar] [CrossRef]

- Sztubecki, J.; Topoliński, S.; Mrówczyńska, M.; Bağrıaçık, B.; Beycioğlu, A. Experimental Research of the Structure Condition Using Geodetic Methods and Crackmeter. Appl. Sci. 2022, 12, 13. [Google Scholar] [CrossRef]

- Amaya, A.; Sierra-Pérez, J. Toward a Structural Health Monitoring Methodology for Concrete Structures under Dynamic Loads Using Embedded FBG Sensors and Strain Mapping Techniques. Sensors 2022, 22, 12. [Google Scholar] [CrossRef]

- Chakraborty, J.; Wang, X.; Stolinski, M. Damage Detection in Multiple RC Structures Based on Embedded Ultrasonic Sensors and Wavelet Transform. Buildings 2021, 11, 2. [Google Scholar] [CrossRef]

- Bońkowski, P.; Bobra, P.; Zembaty, Z.; Jędraszak, B. Application of Rotation Rate Sensors in Modal and Vibration Analyses of Reinforced Concrete Beams. Sensors 2020, 20, 17. [Google Scholar] [CrossRef]

- Strangfeld, C.; Johann, S.; Bartholmai, M. Smart RFID Sensors Embedded in Building Structures for Early Damage Detection and Long-Term Monitoring. Sensors 2019, 19, 24. [Google Scholar] [CrossRef]

- Gkantou, M.; Muradov, M.; Kamaris, G.; Hashim, K.; Atherton, W.; Kot, P. Novel Electromagnetic Sensors Embedded in Reinforced Concrete Beams for Crack Detection. Sensors 2019, 19, 23. [Google Scholar] [CrossRef]

- Liu, S.; Sun, W.; Jing, H.; Dong, Z. Debonding Detection and Monitoring for CFRP Reinforced Concrete Beams Using Pizeoceramic Sensors. Materials 2019, 12, 13. [Google Scholar] [CrossRef]

- Hu, X.; Zhu, H.; Wang, D. A Study of Concrete Slab Damage Detection Based on the Electromechanical Impedance Method. Sensors 2014, 14, 10. [Google Scholar] [CrossRef]

- Chalioris, C.; Kytinou, V.; Voutetaki, M.; Karayannis, C. Flexural Damage Diagnosis in Reinforced Concrete Beams Using a Wireless Admittance Monitoring System—Tests and Finite Element Analysis. Sensors 2021, 21, 3. [Google Scholar] [CrossRef]

- Pang, L.; Liu, J.; Harkin, J.; Martin, G.; McElholm, M.; Javed, A.; McDaid, L. Case Study—Spiking Neural Network Hardware System for Structural Health Monitoring. Sensors 2020, 20, 18. [Google Scholar] [CrossRef]

- Mandal, D.; Bentahar, M.; Mahi, A.; Brouste, A.; Guerjouma, R.; Montresor, S.; Cartiaux, F. Acoustic Emission Monitoring of Progressive Damage of Reinforced Concrete T-Beams under Four-Point Bending. Materials 2022, 15, 10. [Google Scholar] [CrossRef]

- Eid, R.; Muravin, B.; Kovler, K. Acoustic Emission Monitoring of High-Strength Concrete Columns Subjected to Compressive Axial Loading. Materials 2020, 13, 14. [Google Scholar] [CrossRef]

- Sengsri, P.; Ngamkhanong, C.; Melo, A.; Papaelias, M.; Kaewunruen, S. Damage Detection in Fiber-Reinforced Foamed Urethane Composite Railway Bearers Using Acoustic Emissions. Infrastructures 2020, 5, 6. [Google Scholar] [CrossRef]

- Lee, K.; Lee, S.; Kim, H. Accelerating multi-class defect detection of building façades using knowledge distillation of DCNN-based model. Gen. Artic. 2021, 12, 2. [Google Scholar] [CrossRef]

- Lee, K.; Hong, G.; Sael, L.; Lee, S.; Kim, H. MultiDefectNet: Multi-Class Defect Detection of Building Façade Based on Deep Convolutional Neural Network. Sustainability 2020, 12, 22. [Google Scholar] [CrossRef]

- Kalantar, B.; Ueda, N.; Al-Najjar, H.; Halin, A. Assessment of Convolutional Neural Network Architectures for Earthquake-Induced Building Damage Detection based on Pre-and Post-Event Orthophoto Images. Remote Sens. 2020, 12, 21. [Google Scholar] [CrossRef]

- Ji, M.; Liu, L.; Buchroithner, M. Identifying Collapsed Buildings Using Post-Earthquake Satellite Imagery and Convolutional Neural Networks: A Case Study of the 2010 Haiti Earthquake. Remote Sens. 2018, 10, 11. [Google Scholar] [CrossRef]

- Alva, R.; Pujades, L.; González-Drigo, R.; Luzi, G.; Caselles, O.; Pinzón, L. Dynamic Monitoring of a Mid-Rise Building by Real-Aperture Radar Interferometer: Advantages and Limitations. Remote Sens. 2020, 12, 6. [Google Scholar] [CrossRef]

- Hajializadeh, D. Deep-Learning-Based Drive-by Damage Detection System for Railway Bridges. Infrastructures 2022, 7, 6. [Google Scholar] [CrossRef]

- Cornaggia, A.; Ferrari, R.; Zola, M.; Rizzi, E.; Gentile, C. Signal Processing Methodology of Response Data from a Historical Arch Bridge toward Reliable Modal Identification. Infrastructures 2022, 7, 5. [Google Scholar] [CrossRef]

- Tran, T.; Ozer, E. Automated and Model-Free Bridge Damage Indicators with Simultaneous Multiparameter Modal Anomaly Detection. Sensors 2020, 20, 17. [Google Scholar] [CrossRef]

- Li, Z.; Jin, Z.; Zhao, T.; Wang, P.; Zhao, L.; Xiong, C.; Kang, Y. Service Life Prediction of Reinforced Concrete in a Sea-Crossing Railway Bridge in Jiaozhou Bay: A Case Study. Appl. Sci. 2019, 9, 17. [Google Scholar] [CrossRef]

- Dorofeev, N.; Grecheneva, A.; Pankinac, E. The algorithm for early detection of defects at construction objects. AIP Conf. Proc. 2022, 2467, 060044. [Google Scholar] [CrossRef]

- Ansari, M.; Crampton, A.; Parkinson, S. A Layer-Wise Surface Deformation Defect Detection by Convolutional Neural Networks in Laser Powder-Bed Fusion Images. Materials 2022, 15, 20. [Google Scholar] [CrossRef]

- Vrochidou, E.; Sidiropoulos, G.; Ouzounis, A.; Lampoglou, A.; Tsimperidis, I.; Papakostas, G.; Sarafis, I.; Kalpakis, V.; Stamkos, A. Towards Robotic Marble Resin Application: Crack Detection on Marble Using Deep Learning. Electronics 2022, 11, 20. [Google Scholar] [CrossRef]

- Park, S.; Lee, K.; Park, J.; Shin, Y. Deep Learning-Based Defect Detection for Sustainable Smart Manufacturing. Sustainability 2022, 14, 5. [Google Scholar] [CrossRef]

- Shin, H.; Ahn, Y.; Tae, S.; Gil, H.; Song, M.; Lee, S. Enhancement of Multi-Class Structural Defect Recognition Using Generative Adversarial Network. Sustainability 2021, 13, 22. [Google Scholar] [CrossRef]

- Ramli, J.; Coulson, J.; Martin, J.; Nagaratnam, D.; Poologanathan, K.; Cheung, W. Crack Detection and Localisation in Steel-Fibre-Reinforced Self-Compacting Concrete Using Triaxial Accelerometers. Sensors 2021, 21, 6. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, Y.; Xu, J.; Ni, L.; Li, H. Structural Crack Detection Using DPP-BOTDA and Crack-Induced Features of the Brillouin Gain Spectrum. Sensors 2020, 20, 23. [Google Scholar] [CrossRef]

- Wu, Z.; Wei, J.; Dong, R.; Chen, H. Epoxy Composites with Reduced Graphene Oxide–Cellulose Nanofiber Hybrid Filler and Their Application in Concrete Strain and Crack Monitoring. Sensors 2019, 19, 18. [Google Scholar] [CrossRef]

- Kim, I.; Jeon, H.; Baek, S.; Hong, W.; Jung, H. Application of Crack Identification Techniques for an Aging Concrete Bridge Inspection Using an Unmanned Aerial Vehicle. Sensors 2018, 18, 6. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.; Ahn, E.; Cho, S.; Shin, M.; Sim, S. Concrete Crack Identification Using a UAV Incorporating Hybrid Image Processing. Sensors 2017, 17, 9. [Google Scholar] [CrossRef]

- Perez, H.; Tah, J.; Mosavi, A. Deep Learning for Detecting Building Defects Using Convolutional Neural Networks. Sensors 2019, 19, 16. [Google Scholar] [CrossRef]

- Liu, J.; Li, K. Intelligent Metal Welding Defect Detection Model on Improved FAST-PNN. Coatings 2022, 12, 10. [Google Scholar] [CrossRef]

- Buongiorno, D.; Prunella, M.; Grossi, S.; Hussain, S.; Rennola, A.; Longo, N.; Stefano, G.; Bevilacqua, V.; Brunetti, A. Inline Defective Laser Weld Identification by Processing Thermal Image Sequences with Machine and Deep Learning Techniques. Appl. Sci. 2022, 12, 13. [Google Scholar] [CrossRef]

- Nele, L.; Mattera, G.; Vozza, M. Deep Neural Networks for Defects Detection in Gas Metal Arc Welding. Appl. Sci. 2022, 12, 7. [Google Scholar] [CrossRef]

- Mustafaev, B.; Tursunov, A.; Kim, S.; Kim, E. A Novel Method to Inspect 3D Ball Joint Socket Products Using 2D Convolutional Neural Network with Spatial and Channel Attention. Sensors 2022, 22, 11. [Google Scholar] [CrossRef] [PubMed]

- Perez, H.; Tah, J. Deep learning smartphone application for real-time detection of defects in buildings. Struct. Control. Health Monit. 2021, 28, 7. [Google Scholar] [CrossRef]

- Wang, W.; Su, C.; Fu, D. Automatic detection of defects in concrete structures based on deep learning. Structures 2022, 43, 192–199. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Mailyan, L.R.; Stel’makh, S.A.; Shcherban’, E.M.; Razveeva, I.F.; Kozhakin, A.N.; Beskopylny, N.A.; El’shaeva, D.M.; Tyutina, A.D.; Onore, G.S. Photographic Images of the Structure of Aerated Concrete. Russian Federation Database 2022623622. 22 December 2022. Available online: https://www.fips.ru/registers-doc-view/fips_servlet?DB=DB&DocNumber=2022623622&TypeFile=html (accessed on 7 January 2023).

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Razveeva, I.F.; Kozhakin, A.N.; Beskopylny, N.A.; Onore, G.S. Image Augmentation Program. Russian Federation Computer Program 2022685192. 21 December 2022. Available online: https://www.fips.ru/registers-doc-view/fips_servlet?DB=EVM&DocNumber=2022685192&TypeFile=html (accessed on 7 January 2023).

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; Dotsenko, N.; Kotenko, M. Influence of Recipe Factors on the Structure and Properties of Non-Autoclaved Aerated Concrete of Increased Strength. Appl. Sci. 2022, 12, 6984. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Shuyskiy, A.; Beskopylny, N.; Dotsenko, N. Mathematical Modeling and Experimental Substantiation of the Gas Release Process in the Production of Non-Autoclaved Aerated Concrete. Materials 2022, 15, 2642. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Mark Liao, H.-Y.; Wu, Y.-H.; Chen, P.-Y.; Hsieh, J.-W.; Yeh, I.-H. "CSPNet: A New Backbone that can Enhance Learning Capability of CNN. In Proceedings of the 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops (CVPRW), Seattle, WA, USA, 14–19 June 2020; pp. 1571–1580. [Google Scholar] [CrossRef]

- Fu, H.; Song, G.; Wang, Y. Improved YOLOv4 Marine Target Detection Combined with CBAM. Symmetry 2021, 13, 623. [Google Scholar] [CrossRef]

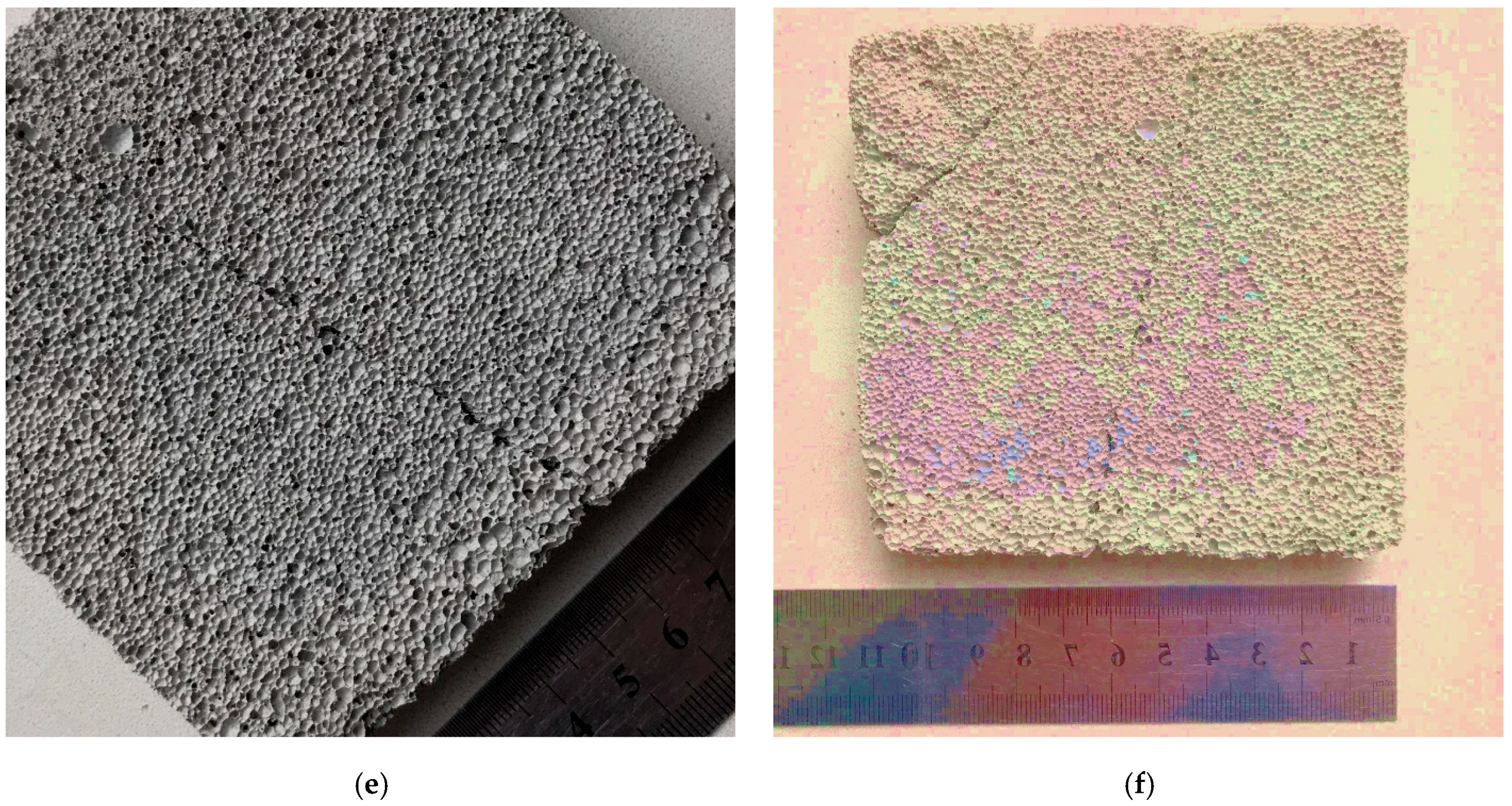

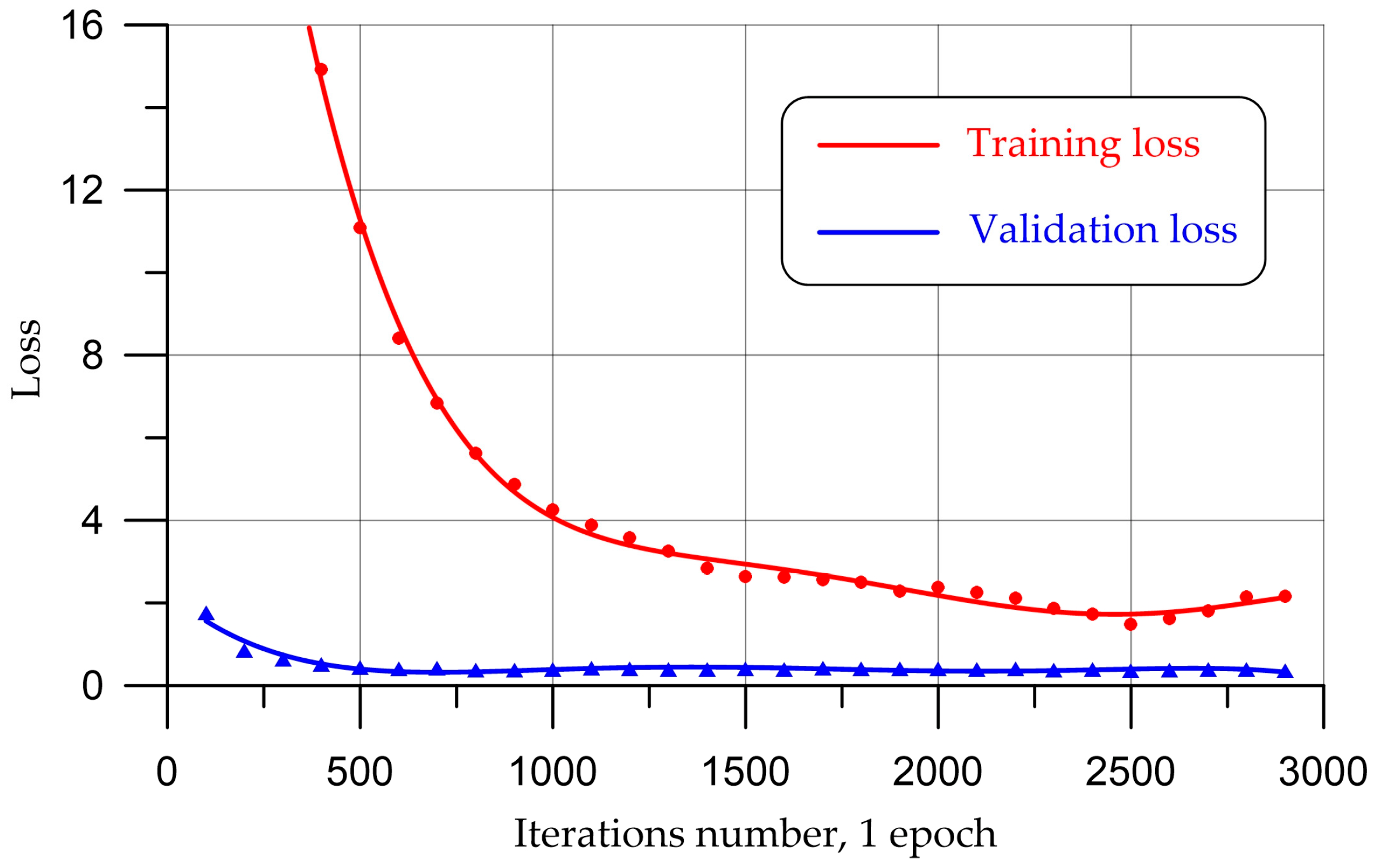

| Num | Parameter | Value |

|---|---|---|

| 1 | Number of photos in the training set | 2800 (70%) |

| 2 | Number of photos in the validation set | 800 (20%) |

| 3 | Number of photos in the test set | 400 (10%) |

| 4 | MiniBatchSize | 28 |

| 5 | Number of epochs | 30 |

| 6 | Number of iterations | 3000 |

| 7 | Learning rate | 0.001 |

| 8 | Solver | Adam solver |

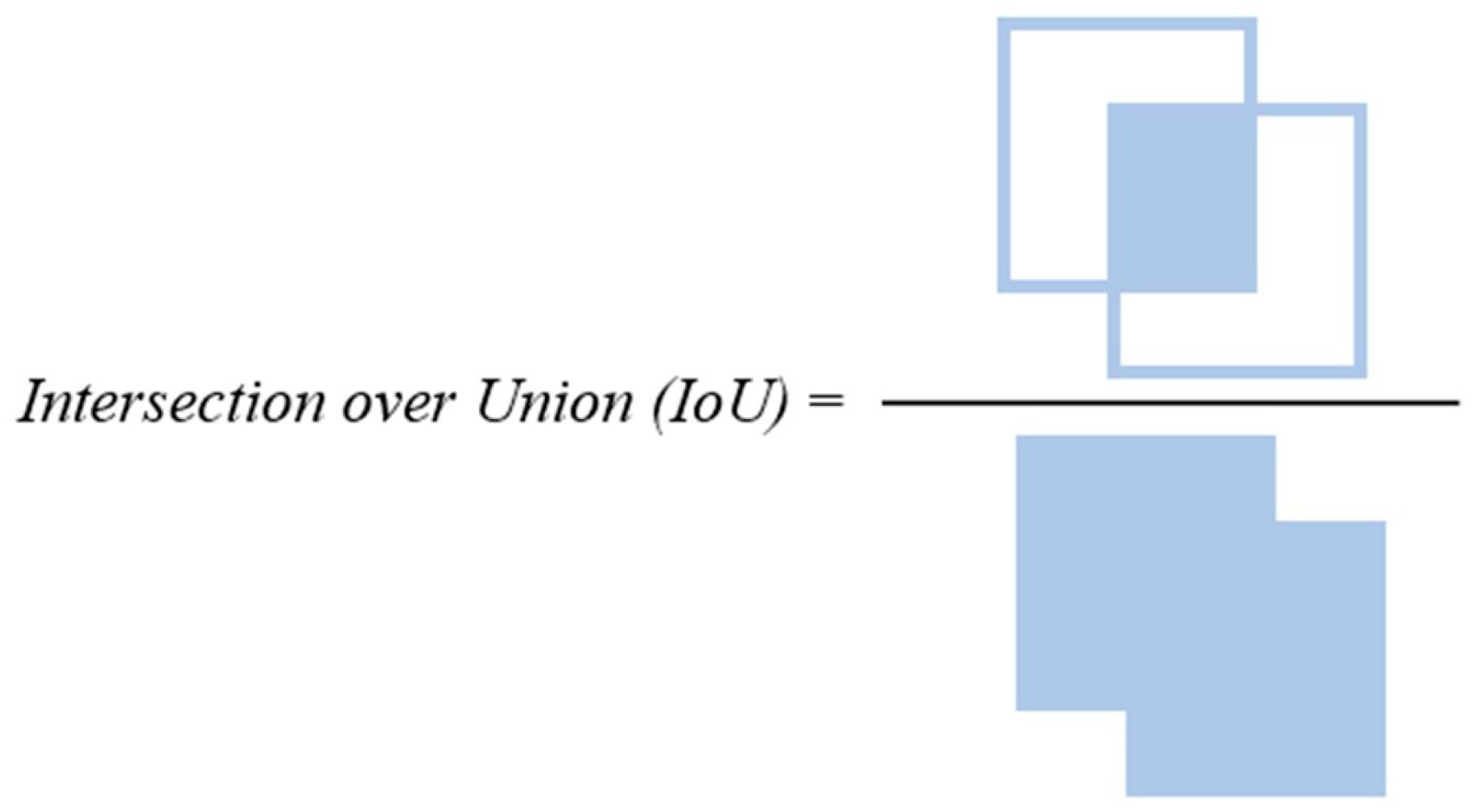

| Number | Parameter | IoU = 0.50 | IoU = 0.75 |

|---|---|---|---|

| 1 | Precision | 88% | 71% |

| 2 | Recall | 70% | 61% |

| 3 | AP | 85% | 68% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Kozhakin, A.; El’shaeva, D.; Beskopylny, N.; Onore, G. Detecting Cracks in Aerated Concrete Samples Using a Convolutional Neural Network. Appl. Sci. 2023, 13, 1904. https://doi.org/10.3390/app13031904

Beskopylny AN, Shcherban’ EM, Stel’makh SA, Mailyan LR, Meskhi B, Razveeva I, Kozhakin A, El’shaeva D, Beskopylny N, Onore G. Detecting Cracks in Aerated Concrete Samples Using a Convolutional Neural Network. Applied Sciences. 2023; 13(3):1904. https://doi.org/10.3390/app13031904

Chicago/Turabian StyleBeskopylny, Alexey N., Evgenii M. Shcherban’, Sergey A. Stel’makh, Levon R. Mailyan, Besarion Meskhi, Irina Razveeva, Alexey Kozhakin, Diana El’shaeva, Nikita Beskopylny, and Gleb Onore. 2023. "Detecting Cracks in Aerated Concrete Samples Using a Convolutional Neural Network" Applied Sciences 13, no. 3: 1904. https://doi.org/10.3390/app13031904

APA StyleBeskopylny, A. N., Shcherban’, E. M., Stel’makh, S. A., Mailyan, L. R., Meskhi, B., Razveeva, I., Kozhakin, A., El’shaeva, D., Beskopylny, N., & Onore, G. (2023). Detecting Cracks in Aerated Concrete Samples Using a Convolutional Neural Network. Applied Sciences, 13(3), 1904. https://doi.org/10.3390/app13031904