4.1. Materials and Methods

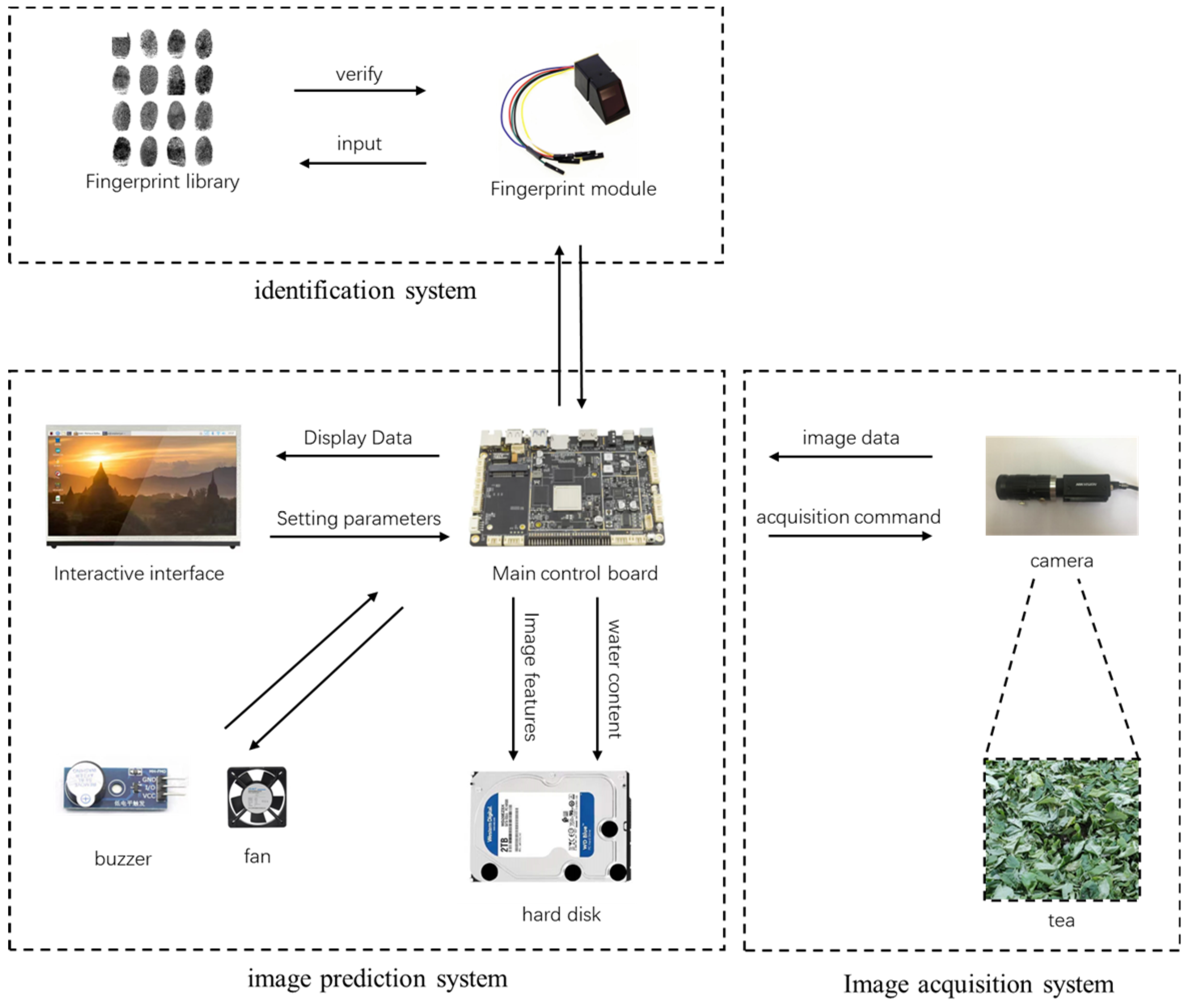

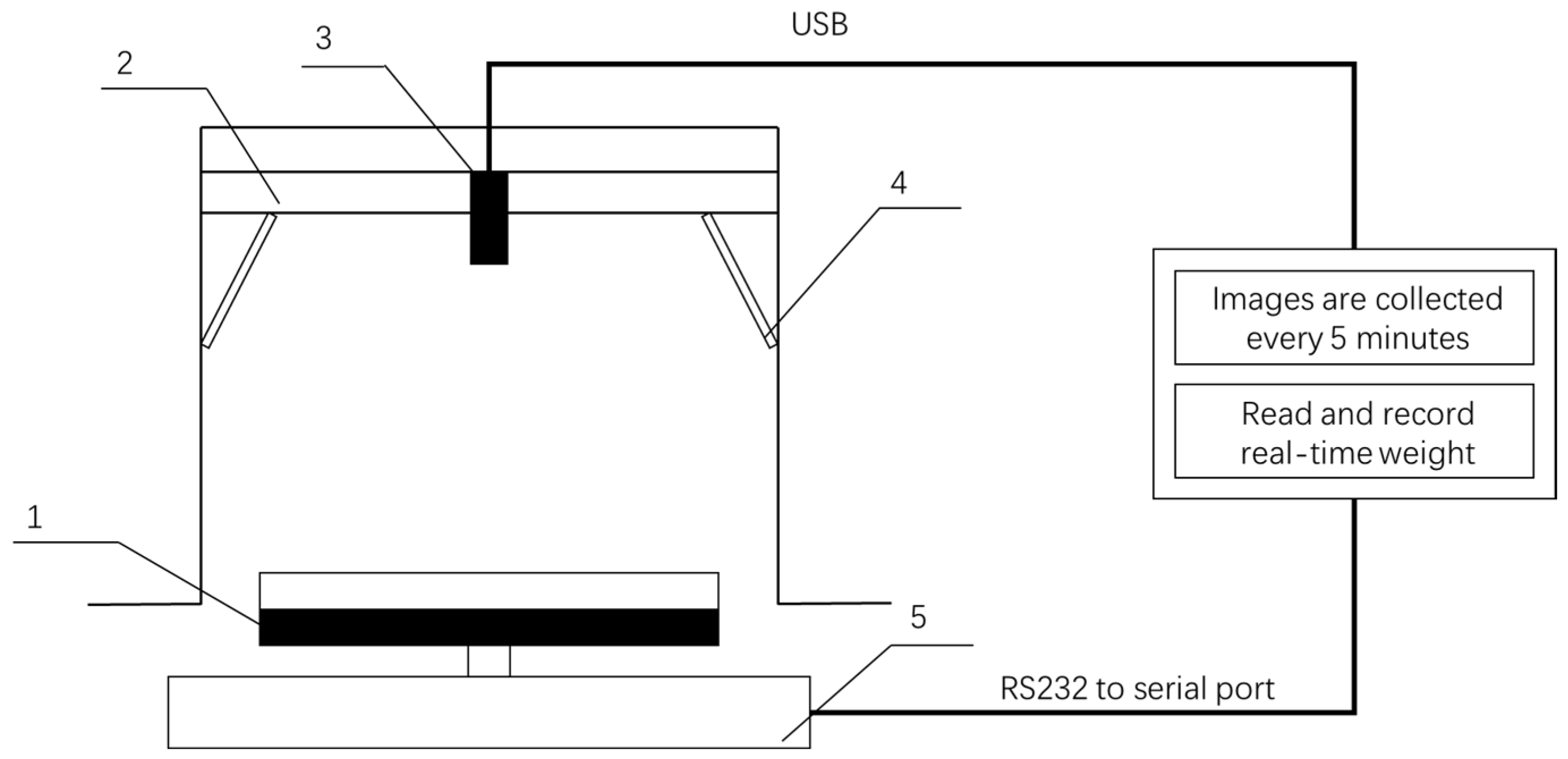

Taking the Yinghong No. 9 tea leaves moisture content detection device as the test platform, its composition is shown in

Figure 5. The platform consisted of a dark room, a control room, and an electronic scale of the model Leqi CN-LQC30001 (Kunshan City, Jiangsu Province, China, Youkeweit Electronic Technology Co., Ltd.), with an accuracy of 0.01 g. The dark box and control room are described in detail in

Section 3.

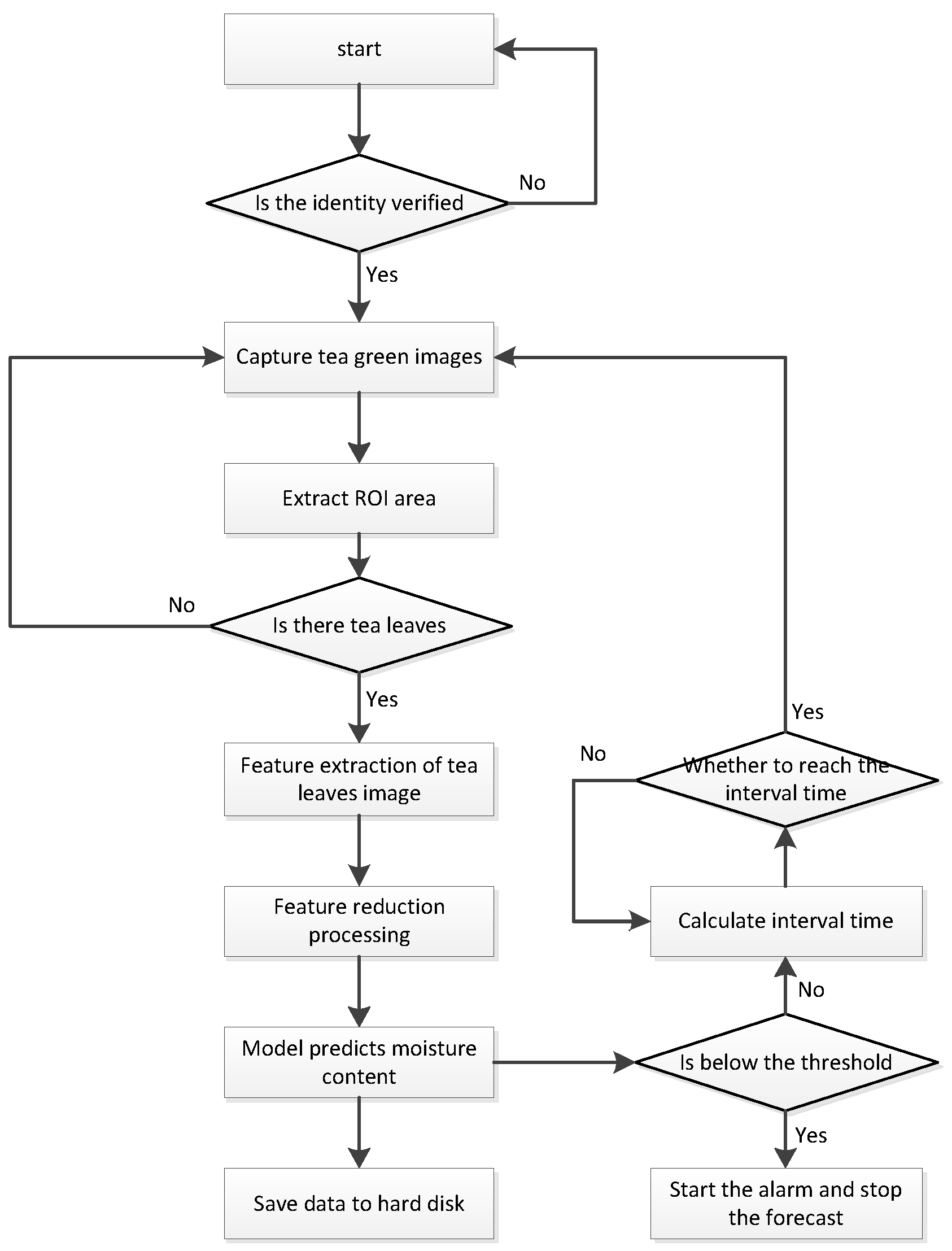

The test material was Yinghong No. 9 tea leaves, which were collected from the tea garden of Guangdong Yingjiu Manor Green Industry Development Co., Ltd., on November 6th and shipped back to South China Agricultural University. In order to ensure the quality of the tea leaves, the tea leaves harvested in the tea garden were placed in a fresh-keeping box, and approximately 5 kg of the wilted or damaged tea leaves was removed from the fresh-keeping box. The remaining tea leaves were divided into seven samples, each sample approximately 600 g, and the specific experimental steps were as follows:

Step 1: Place the electronic scale on the test bench for leveling.

Step 2: Place the iron frame on the electronic scale and perform a zero adjustment. After reading that the electronic scale is stable, click “tare”.

Step 3: Place and spread the tea leaves evenly on the iron plate until the electronic scale shows approximately 600 g.

Step 4: Fix the dark box above the tea leaves sample to ensure that the dark box does not contact the electronic scale and the iron plate and adjust the camera focus until the image is clear.

Step 5: Set the control room to collect the weight of the tea leaves and an image of the tea leaves every 5 min.

Step 6: After 10 h of moisture content loss, take out the tea leaves and put them into an aluminum box.

Step 7: Preheat the electric thermostatic drying oven to 102 degrees, and then put the aluminum box into the electric thermostatic drying oven. After 4 h, take it out, weigh it, and record the data. Then, put the aluminum box into the electric thermostatic drying oven for 1 h, and weigh it until the aluminum box reaches a constant weight state. Finally, calculate the dry weight of the tea leaves.

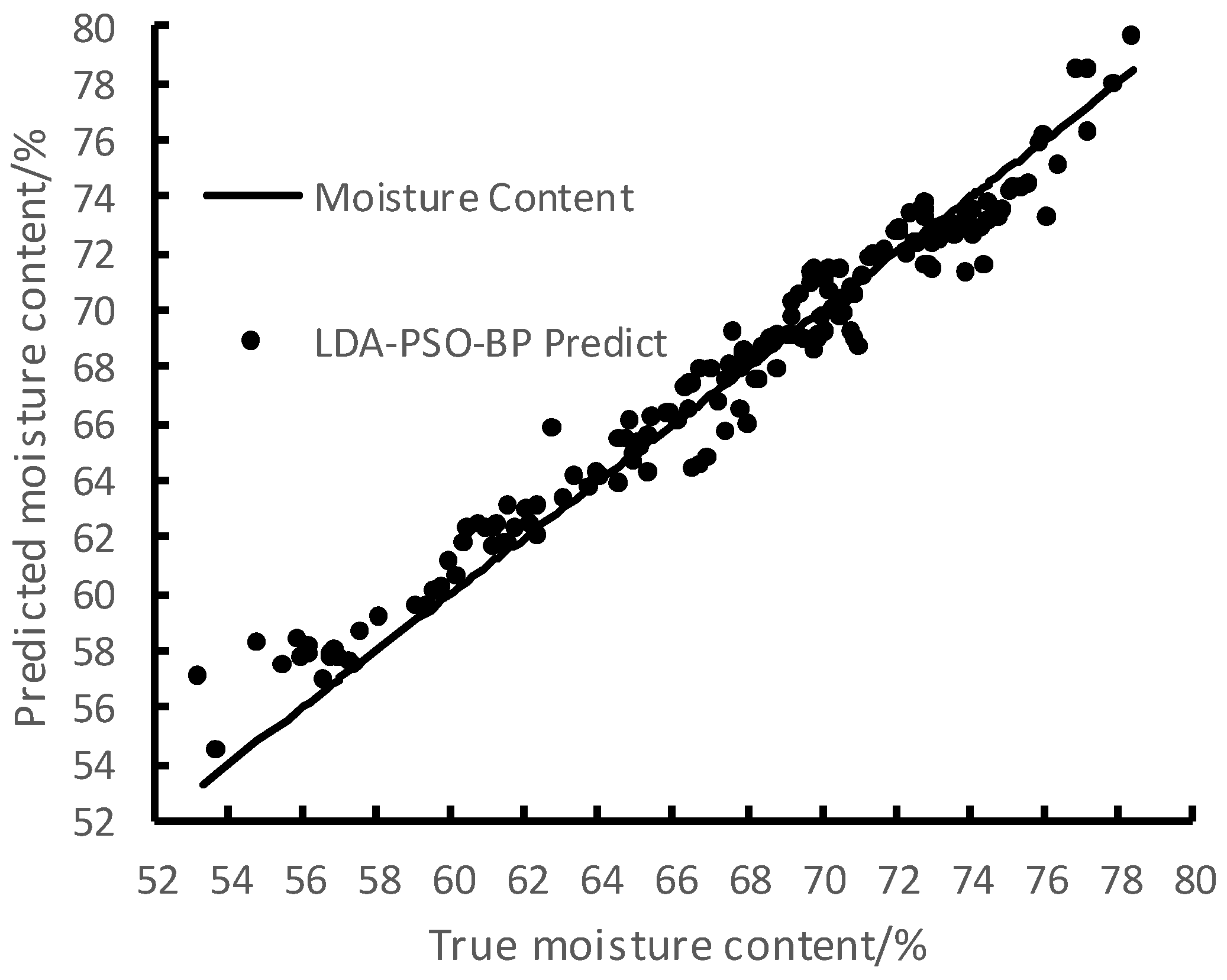

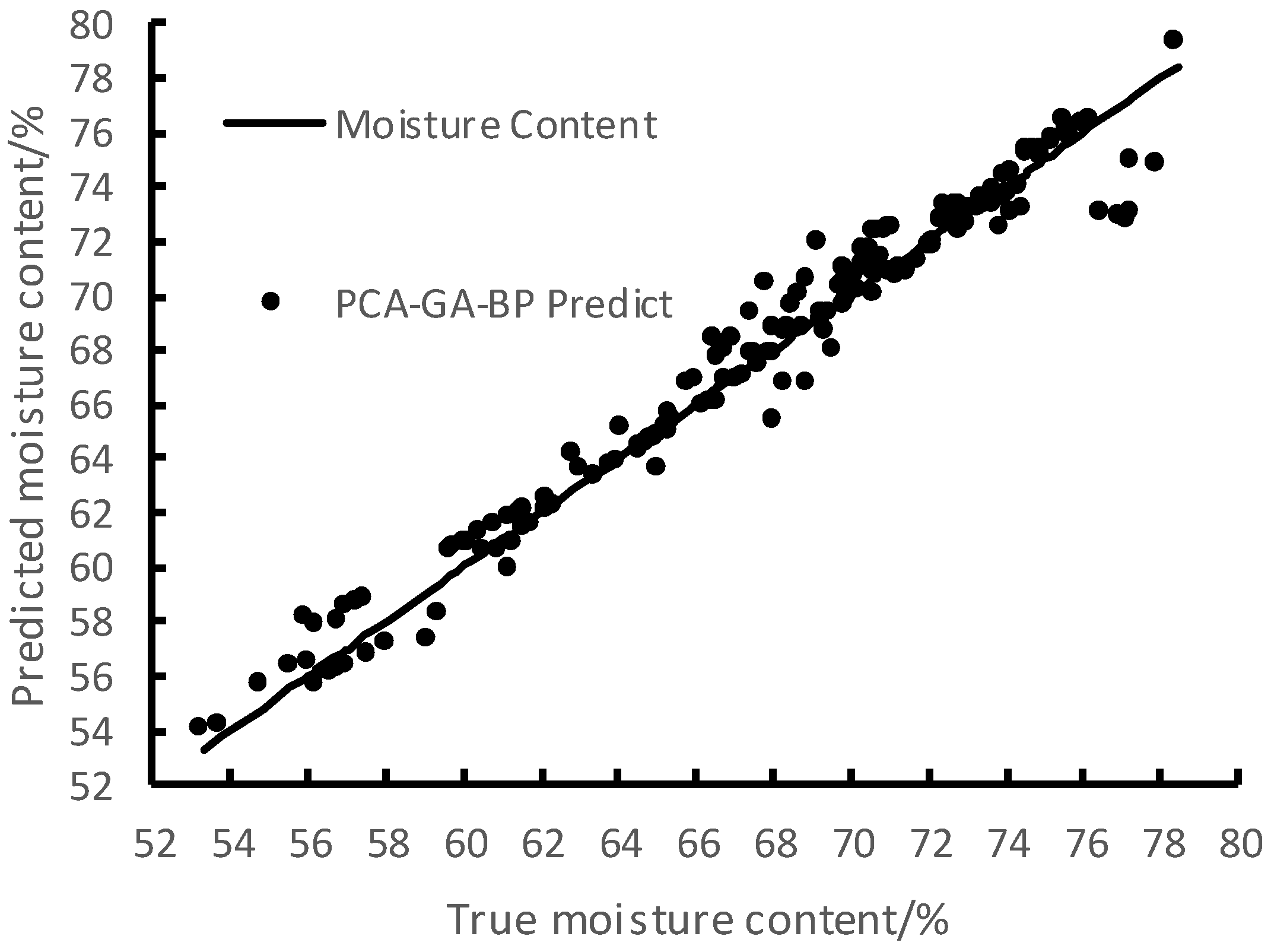

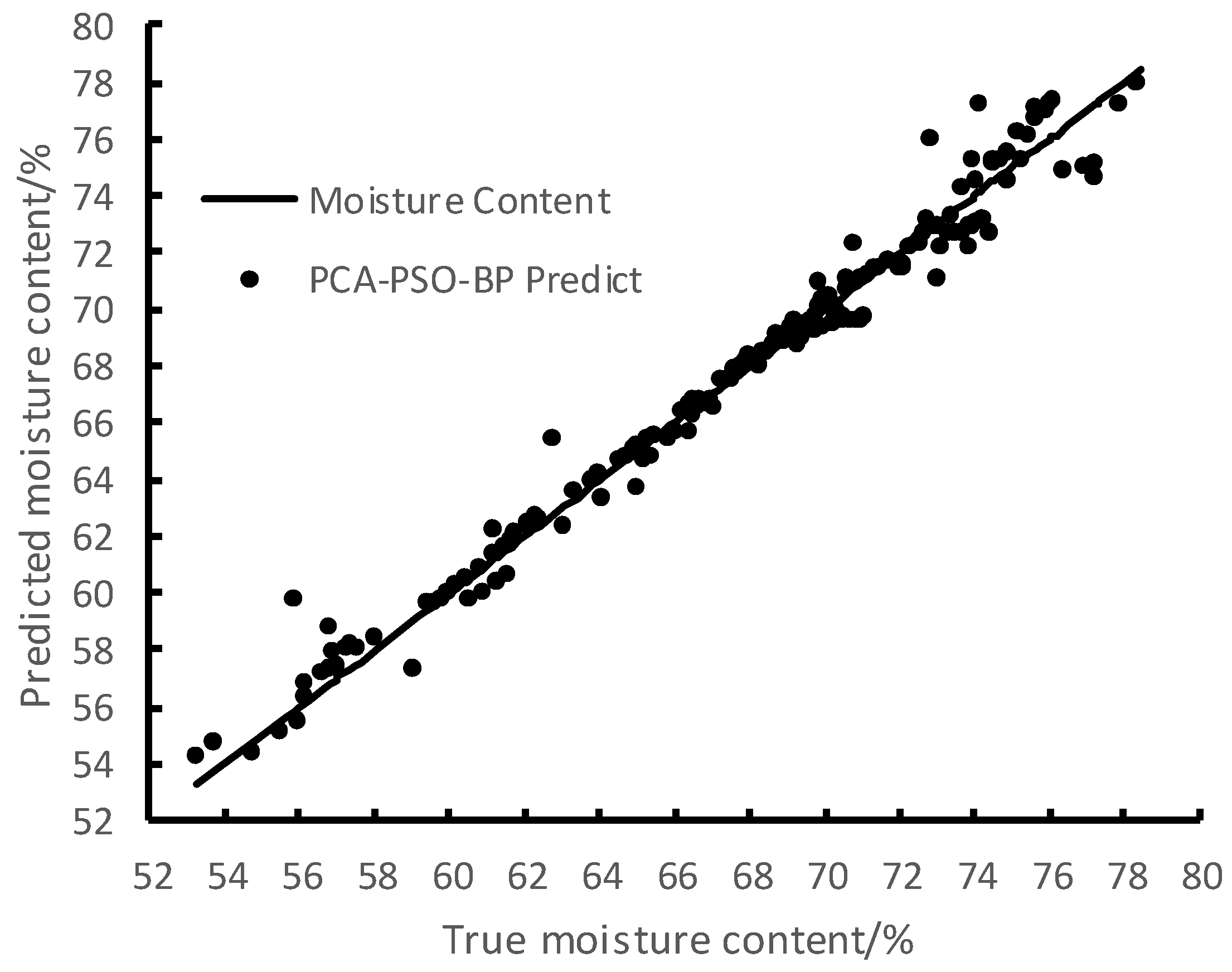

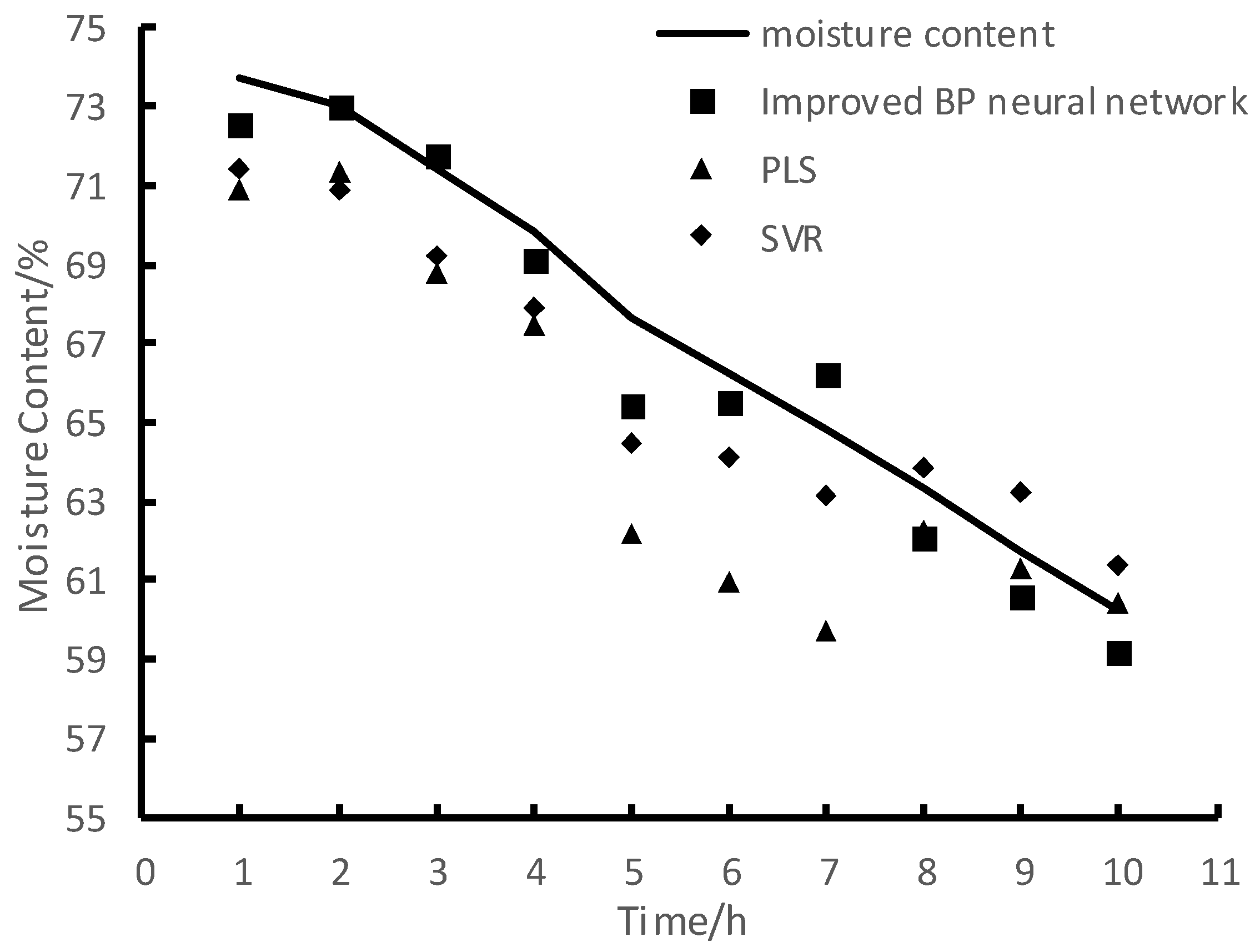

In each experiment, 120 groups of tea leaves images and tea leaves weights were collected, and a total of 840 groups of tea leaves images and tea leaves weights were obtained. For a certain time, t, referring to the GB/T 8304-2013 standard in Chinese to measure the moisture content of the tea leaves, the moisture content of the tea leaves was calculated using Equation (4). From the calculation, it was shown that the moisture content of the tea leaves dropped from 78.48% to 53.14%, and the average moisture content decreased by 0.09% every 5 min, which enriched the labeling range of the tea leaves images. The obtained images and moisture contents were divided into the training set and the test set at a ratio of 4:1.

Here, G1(t) is the weight of the fresh tea leaves at time t, G2 is the dry tea leaves weight, G3 is the aluminum box weight, and W(t) is the moisture content of the tea leaves at time t.

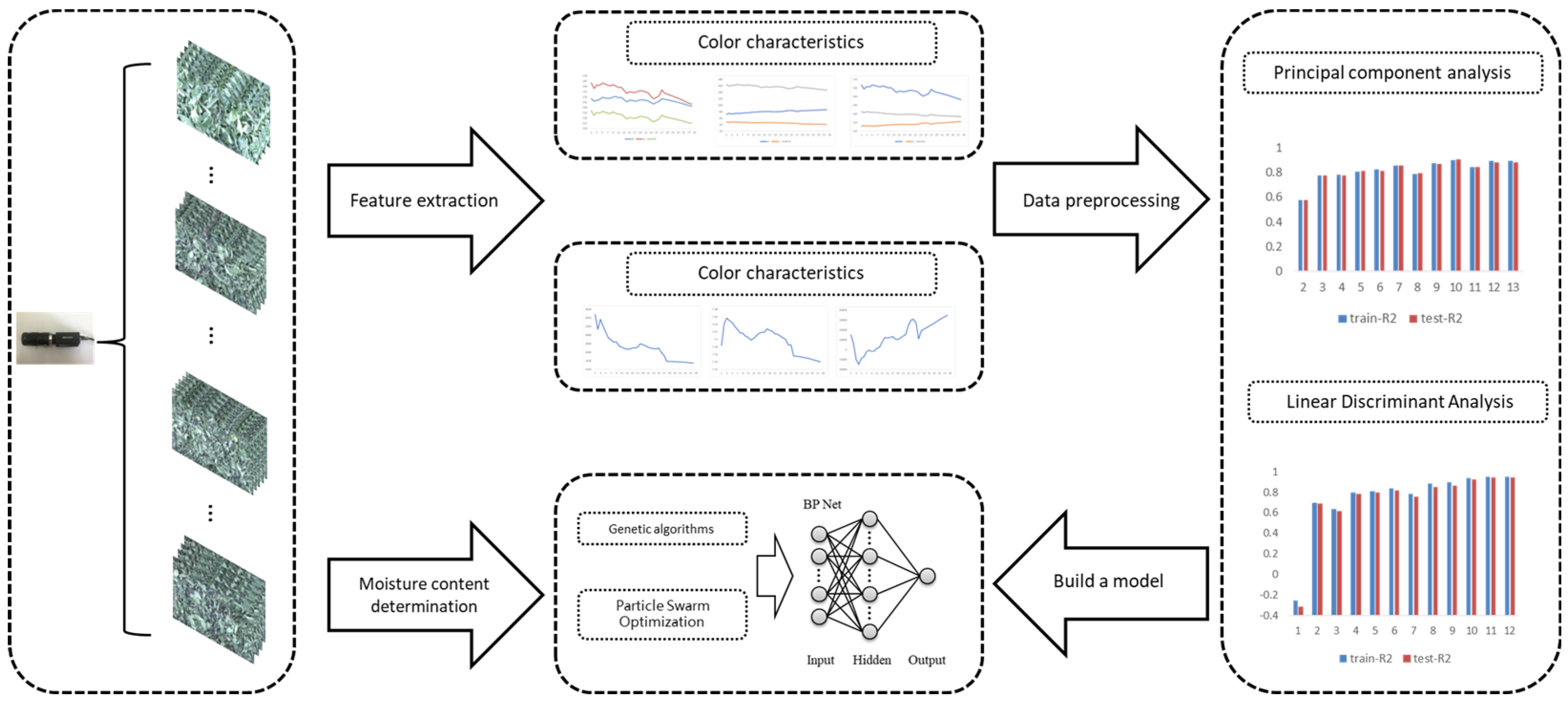

4.2. Image Preprocessing

Image preprocessing was divided into feature extraction and data standardization. In this paper, the characteristic information of the tea leaves was extracted from the two aspects of color and texture, and the Z-score standardization method was used to standardize the data, which can make the mean value that is characteristic of the tea leaves 0 and the standard deviation 1 [

17].

In terms of the color information, the collected tea leaves images were converted to RGB, LAB, and HSV color spaces for analysis. The RGB color mode is a color standard in the industry, which obtains various colors by changing the three color channels of red, green, and blue and superimposing them on each other; HSV is a color space created by Smith in 1978 based on the intuitive characteristics of colors, where H represents the hue of the color, S represents the saturation, and V represents the brightness; LAB is a color space formulated by CIE, which is insensitive to light noise and offsets the deficiencies of the RGB color space, where L is the pixel brightness, A represents the degree of red to green, and B represents a range from yellow to blue [

18].

The texture information was extracted based on the gray-level co-occurrence matrix (CCM). We used m (mean), u2 (second-order moment), u3 (third-order moment), U (consistency), and e (entropy) to describe the texture information of the tea leaves [

19]. The mean value describes the roughness of the tea leaves texture; the u2 and u3 describe the variance of the tea leaves’ pixels and reflect the local gray correlation of the tea leaves’ surface; the U refers to the uniformity of the tea leaves’ pixel distribution; and the entropy value describes the chaotic degree of the tea leaves image information and reflects the randomness of the pixels.

After extracting and standardizing the color features of the tea leaves images with different moisture contents, as shown in

Figure 6a, as the moisture content of the tea leaves decreases, the color feature parameters change significantly, and the three values of RGB show a downward trend, resulting in a decrease in the overall brightness of the tea leaves images. The V and L parameters representing the brightness decrease, and the saturation, S, decreases. In

Figure 6a, H and a gradually increased, while b gradually decreased, which means that the green component in the tea leaves image was decreasing, and the blue component was increasing. After the texture features were standardized, as shown in

Figure 6b, the e first increased and then decreased, and the u2 first decreased and then increased. This shows that the tea leaves had a clear texture and large differences in the early stage of the moisture content reduction. In the later stage, the tea leaves surface was relatively uniform and smooth, and an overall decline in the m and U was indicated. The u3 first decreased and then increased, the skewness of the tea leaves color increased, and the overall color depth increased.

4.4. Model Accuracy Evaluation Index

For this paper, we selected the root mean square error (RMSE), the mean absolute error (MAE), and the coefficient of determination (R

2) to evaluate the accuracy of the model, as shown in Equations (5)–(7). When the RMSE and MAE are smaller, the error between the predicted value of the model and the actual value is smaller. R

2 primarily shows the degree of correlation between the predicted value and the actual value, and the higher the correlation, the higher the prediction accuracy of the model [

23].

Here, is the model predicted sample moisture content, is the true moisture content of the sample, m is the number of samples, and is the sample mean.