Abstract

This study focuses on a comparative analysis of mechanical behavior and microstructural characteristics of Cu matrix (C87600) based hybrid composites reinforced with SiC-Grp and WC-Grp fabricated by the stir casting process. The graphite particle percentage was kept constant, whereas the content of SiC and WC in the respective composites was varied to analyze the mechanical properties of the fabricated composites. The morphological observation was carried out by field emission scanning electron microscope (FESEM), which revealed uniform dispersion of the reinforced particles in the hybrid composites. Clear phases of SiC and WC along with the Cu alloy were identified by the x-ray diffractometer (XRD). Further, a comparative study was conducted to analyze the mechanical behavior of the Cu-SiC-Gr and Cu-WC-Gr hybrid composites. With the addition of the hard ceramic materials, the tensile behavior and microhardness of both the Cu-based MMCs were improved. The WC-Gr reinforced composites exhibited higher mechanical properties than the SiC-Gr reinforced hybrid composites. Further, the fracture surfaces were also characterized to study the tensile behavior of the fabricated copper-based hybrid composites, which shows that ductile fracture was mainly associated with both hybrid composites.

1. Introduction

Metal matrix composites (MMCs) are the most promising materials and find their usage in a wide range of industrial applications such as automotive, aerospace, defense, marine, electronics, etc. Moreover, MMCs do not lose their basic behavior even in critical environmental conditions. Further, MMCs exhibit superior properties over monolithic materials in terms of higher stiffness, strength, specific weight, excellent wear and corrosion resistance, etc. [1,2,3]. Still, issues and the possibility of amalgamation of several matrices and reinforcements are present in the development of MMCs. Copper alloy matrix-based composites are widely utilized in different automobile and electronics components owing to their exceptional corrosion and wear resistance, high weldability, high thermal conductivity, etc. [4,5]. Xiao et al. [6] studied the tensile and tribological properties of Cu matrix composites as brake pad materials for high-speed trains, in which the copper composites exhibited excellent mechanical and frictional behavior.

The characteristics of various copper composites can be enhanced with proper consideration of the ceramic reinforcement particles. Wang et al. [7] reported the usage of Al2O3 particulates as reinforcement in the Cu-based composite, where grain refinement strengthening was found to be superior to particle dispersion strengthening. Similarly, Ramesh et al. [8] examined the mechanical characteristics of Cu-based hybrid composites. The tensile properties and hardness of the hybrid composites were enhanced due to the synergistic effect of the reinforcement particulates along with their interfacial bonding with the matrix alloy. Singh et al. [9] reported the mechanical properties of pure copper matrix composites incorporated with WC-Al2O3-Cr and WC-ZrO2-Cr reinforcements using the stir-casting process. They reported that the alumina particulate reinforced composites exhibited enhanced properties than zirconia owing to the load transfer effect and particle strengthening. Similarly, Liang et al. [10] fabricated copper matrix-based composites with TiB2 particles and TiB whiskers as reinforcements using in-situ casting followed by rolling and annealing. With the combined influence of whiskers and particles, the hybrid composites exhibited enhanced strength. Further, Zhang et al. [11] investigated the mechanical and microstructural characterization of Cu alloy composites reinforced with ZrB2 by the in-situ synthesis process. The effects of cryo-rolling and aging treatment resulted in an increment in the tensile properties with the help of precipitation and dislocation strengthening mechanisms. Sap et al. [12] produced Cu-SiC-Ti-B hybrid composites following the powder metallurgy method, where the homogenous interface with the matrix was observed. Further, the bending and tensile strength were also improved by incorporating hybrid reinforcements.

Furthermore, Yin et al. [13] reported the mechanical characteristics of Cu-TiB2-TiN hybrid composites prepared by high-temperature self-propagating reaction synthesis followed by the hot pressing process. The strengthening effect resulted from the higher load-carrying ability of the ceramic particulates yielded better tensile strength of the copper composites. Nageswaran et al. [14] investigated the tensile behavior of the copper hybrid composites reinforced with titanium dioxide and graphite particles synthesized by the stir casting method. Homogenous dispersion along with a reduction in grain size gave rise to refinement in the copper phase, which in turn strengthened the copper-based composites. Singh et al. [15] studied the mechanical characteristics of Copper/WC hybrid composites with highly strained stainless steel chips fabricated through the liquid metallurgy process. The ultimate tensile strength and micro-hardness of the MMCs were enhanced considerably along with the corrosion resistance as related to the base copper alloy. Further, TiC-reinforced copper alloy composites were produced by the in-situ reaction method, where the mechanical behavior of the composites was enhanced considerably with a decline in electrical conductivity [16].

It can be evident from the literature that most of the studies related to copper-based metal matrix composites utilize pure copper as the matrix phase. Further, very few works have been reported on Cu-based hybrid composites where the Silicon brass alloy has not yet been used as a matrix material. In this research, an effort is made to fabricate the silicon brass copper alloy (C87600) hybrid composites by using a low-cost stir-casting process. Furthermore, an attempt is made to study a comparative analysis of the mechanical behavior between SiC-Gr and WC-Gr particulate-reinforced composites. The comparative analysis was formulated in terms of tensile strength and hardness, along with the tensile fractography behavior of the hybrid composites.

2. Materials and Methodology

In this study, commercially available silicon-brass Copper alloy, also termed C87600 alloy was considered as the matrix phase for the composites, where zinc and silicon are the primary alloying element with traces of iron and magnesium. The elemental composition of the C87600 alloy (as received) is presented in Table 1. This alloy exhibits high wear and corrosion resistance behavior along with excellent conductivity. The copper alloy C87600 does not respond to heat treatment. It is usually used in marine shafting, architectural appliances, etc., due to its exceptional wear resistance, corrosion resistance, and electrical conductivity. Table 2 presents the physical properties of the C87600 alloy. To fabricate the hybrid composites, SiC, WC, and Gr micro-particulates with 99% purity were bought from Vision Casting Pvt. Ltd., Hyderabad. Besides the base matrix alloy, two sets of copper hybrid composites were fabricated considering SiC-Gr and WC-Gr composites. The graphite particle being considered as secondary reinforcement, its content in the hybrid composites was kept constant at 1 wt.%, whereas the weight percentages of SiC and WC varied at 3 wt.%, 6 wt.%, and 9 wt.%, respectively. These hard ceramic constituents were selected as the reinforcing phase as these materials tend to enhance the physical characteristics to a significant extent [17,18]. The copper-based hybrid composite materials were fabricated through the stir casting process due to their cost-effectiveness and favorable for mass production [19].

Table 1.

Elemental composition of silicon-brass Copper (C87600) alloy.

Table 2.

Physical properties of C87600 alloy.

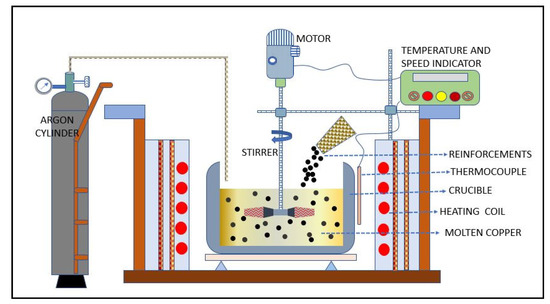

Firstly, the copper alloy (C87600) ingots were kept in a high-temperature sustaining graphite crucible and heated in an electric furnace at a temperature of 1200 °C, which is above its melting limit. After the ingots reached a fully molten state, the pre-heated reinforcements (heated at a temperature of 600 °C for 1 h) were introduced to the copper melt for the manufacture of the composites. Pre-heating the reinforcement is necessary to remove any moisture content. In this stage, the reinforcements were either SiC or WC particles as per the compositions. The mechanical stirrer was attached to the furnace, which was uninterruptedly stirred at 400 rpm for 15 min to obtain the homogenous distribution of the reinforcement particles. Thereafter, the graphite particles of 1 wt.% content were introduced to the copper melt for the development of hybrid MMCs. The stirring action was continued for another 15 min with the same speed to effectively distribute the reinforcements in the molten copper alloy. The complete process was conducted with argon gas shielding to evade any contamination of the molten metals with atmospheric gases. Further, the degasser (C2Cl6) was added to the molten alloy to get rid of any dissolved hydrogen gas existing in it. After removing the slag from the surface, the molten metals were poured into a metallic split die, which was preheated at a temperature of 600 °C. Pre-heating the die was necessary to minimize the temperature gradient and shun the chilling effect while pouring the molten metals. Moreover, the pre-heating process also removes the moisture and oil present on the exposed faces, thus avoiding any surface porosity defects. Figure 1 represents the schematic representation of the stir casting setup used for the manufacturing of the copper-based hybrid MMCs. Different compositions of the fabricated copper MMC are presented in Table 3.

Figure 1.

Schematic representation of the stir casting setup for composite synthesis.

Table 3.

Compositions of the fabricated MMC.

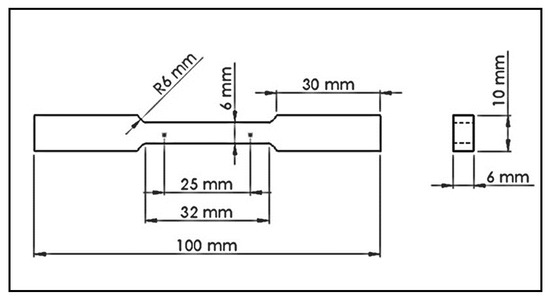

The fabricated copper composites were analyzed using FESEM and XRD to analyze the microstructural and phase behavior. The specimen for microstructural examination were cut with 10 mm × 10 mm dimension from the as-casted composites, and the surface irregularities were removed by the dry belt grinding machine. The specimens were polished with several grades of emery paper (up to 1500 grade) followed by velvet cloths polishing by aerosol and diamond suspension. Further, a chemical etchant consisting of 50 mL Nitric acid and 50 mL distilled water was used for the etching process to reveal the microstructure of the copper alloy composites. The compositional details along with morphological analysis of the hybrid composites were obtained using a field emission scanning electron microscope (FESEM) coupled with an EDX detector (ZEISS Merlin Compact Gemini). X-ray diffractometer (BRUKER D8 ADVANCE) was utilized to characterize the phase structure analysis of the hybrid composites, which was carried out in the 2θ incident angle range of 20°–90° [20]. In the diffraction process, Cu Kα radiation with a wavelength of 1.54 Å was generally used. An automatic Vickers hardness testing apparatus (Zwick Roell Indentec) was employed to evaluate the micro-hardness of the copper composites, where the experiments were conducted at an indentation load of 500 gf with a 10 sec dwell time. Five sets of hardness values were measured at five different locations of the specimen, and the average value along with the standard deviation was reported as the ultimate hardness value of the composites. To evaluate the tensile strength of the fabricated composites, the samples were machined by a wire-EDM machine from the as-casted composites according to ASTM E8M standards which have gauge lengths of 25 mm and width of 6 mm. The schematic diagram of the tensile sample is shown in Figure 2. The tensile tests were conducted in a computerized universal testing machine (TUE-C-400) at room temperature with an extension speed of 1 mm/min. Three experiments were performed for each composition of the composite to have the average tensile strength value along with the standard deviation presented. The tensile fractography was also analyzed by the FESEM to examine the fracture behavior of the composites. The experimental process followed for the current study is shown in Figure 3.

Figure 2.

Schematic of the tensile test specimen.

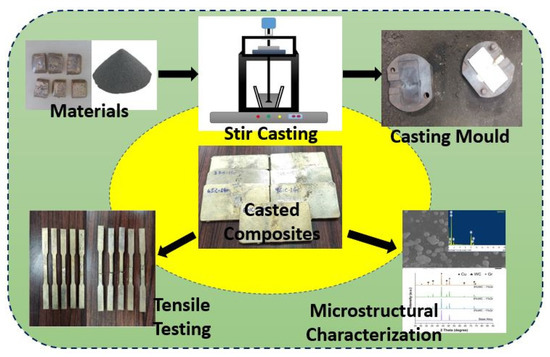

Figure 3.

Process flow chat for the current research.

3. Results and Discussion

3.1. Microstructural Characterization

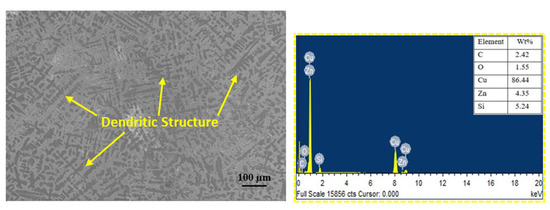

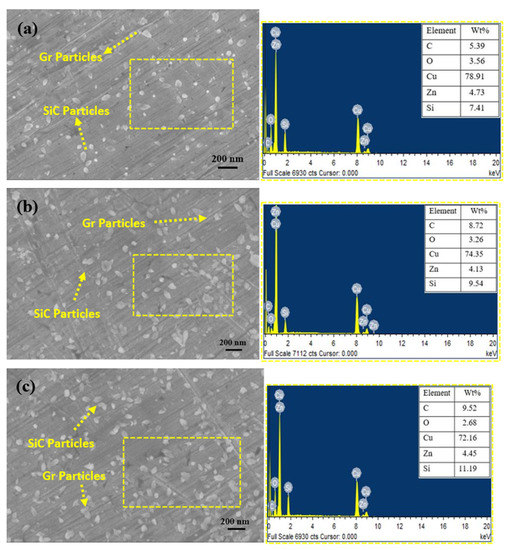

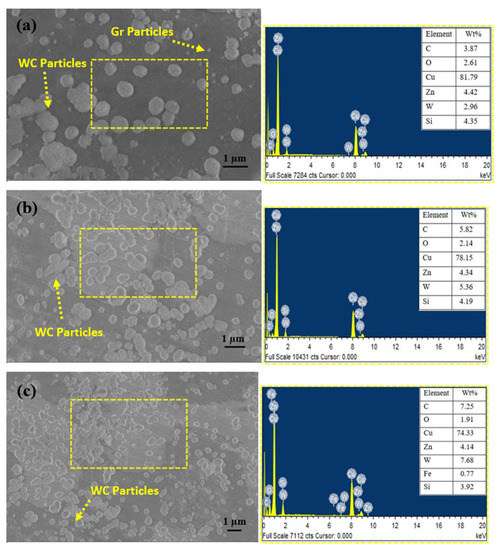

The microstructure of the as-received base copper alloy is shown in Figure 4. It can be observed from the micrograph that the dendritic structure of the silicon brass alloy is clearly visible. Similarly, the composition of the copper alloy can also be confirmed from the EDX images, which shows the zinc and silicon element in the alloy. The FESEM microstructure of the Cu-SiC-Gr and Cu-WC-Gr hybrid composites are shown in Figure 5 and Figure 6, respectively. The homogenous distribution of the reinforcement particulates could be visible from the SEM micrographs, which was the result of the optimum stirring action throughout the casting process. Moreover, the vortex formation due to the mechanical stirring within the melt resulted in the uniform dispersion of the reinforcement phases during the stir-casting process [21]. When the FESEM images were examined, it could be said that there were no signs of agglomeration of the particles for both the hybrid composites. Pointed and irregularly formed SiC could be easily observed from the microstructures, whereas the spherical (round) shaped WC was observed for the respective composites. Moreover, there were no shrinkage porosity defects which also demonstrates an effective stir-casting process. Similarly, the intensity of the alloying elements as well as the reinforcing elements was also observed in the regional EDX analysis. Several elements like Zn, Si, C, O, and W existed along with the copper matrix that established the development of the composites. The micrographs also revealed that the concentration of the elements in the base alloy was different from that of the composites, which corresponds to the different content of the reinforcements. Further, the very low oxygen content, as shown in the EDX spectrum, revealed that substantially minimum oxidation happened during the fabrication as the whole process was carried out under the argon atmosphere. This restricted any possible contamination with the outside oxide environment, which could have deteriorated the quality of the casting.

Figure 4.

FESEM micrograph and EDX analysis of Cu alloy matrix.

Figure 5.

FESEM micrograph and EDX analysis of Cu-SiC-Gr hybrid composites with SiC variation of (a) 3, (b) 6, and (c) 9 wt.%.

Figure 6.

FESEM micrograph and EDX analysis of Cu-SiC-Gr hybrid composites with WC variation of (a) 3, (b) 6, and (c) 9 wt.%.

3.2. XRD Analysis

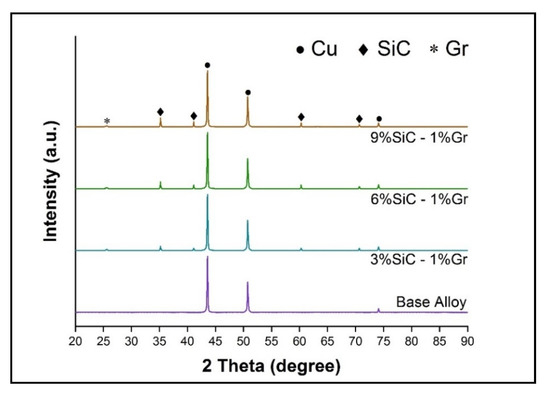

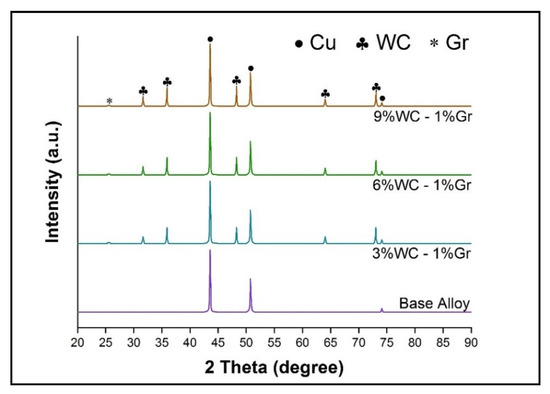

The XRD spectrum of the fabricated Cu-SiC-Gr and Cu-WC-Gr hybrid composites are shown in Figure 7 and Figure 8, respectively. The phase structure examination of the hybrid composites was conducted at a diffraction angle of 20° to 90° by the x-ray diffraction. Major diffraction peaks of Cu were found in the base alloy as well as the composites. The peaks corresponding to the 2θ angle of 34.4°, 50.5°, and 74.1° refer to the copper peaks, and the lattice planes are (1 1 1), (2 0 0), and (2 2 0), respectively. Similarly, clean peaks of SiC were found in Figure 5, whereas the peaks of WC can also be observed in Figure 6. The very small peak of graphite can be visible in both the hybrid composites due to the small intensity as compared with the Cu peaks. The XRD pattern shows that there are no intermediate reactions between Cu with SiC or WC and graphite that can be confirmed from the spectrum, which shows a successful casting process. The absence of any undesirable intermetallic reaction products in the composites was a good sign for the hybrid composites, which otherwise would have adversely affected the properties. Sadeghi et al. [22] fabricated nano-MMCs of Cu-reinforced in-situ TiC and carbon particles, and they reported only diffraction peaks related to TiC and Cu without any other intermetallic compounds. Moreover, the careful analysis revealed that the intensity of the peaks in the case of the composites was changed with respect to the base alloy, which can be associated with the reinforcement content for both the hybrid composites. Further, the major diffraction peaks of the copper elements in the hybrid composites were shifted towards a higher two-theta angle compared to that of the base matrix, which also facilitated the incorporation of the ceramic reinforcements.

Figure 7.

XRD phase analysis of Cu alloy and Cu-(3, 6, 9) wt.% SiC-Gr hybrid composites.

Figure 8.

XRD phase analysis of Cu alloy and Cu-(3, 6, 9) wt.% WC-Gr hybrid composites.

3.3. Micro-Hardness Evaluation

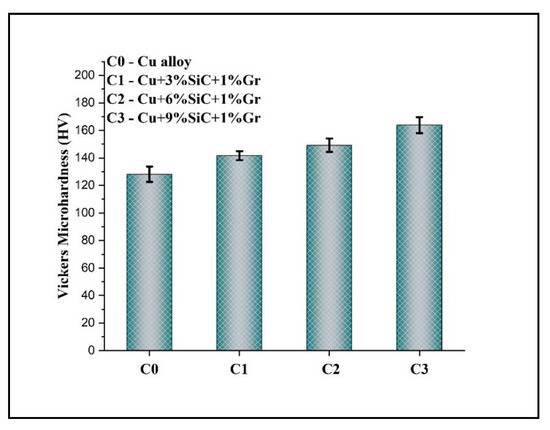

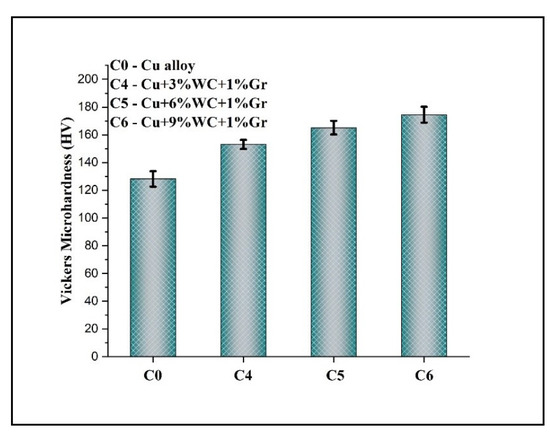

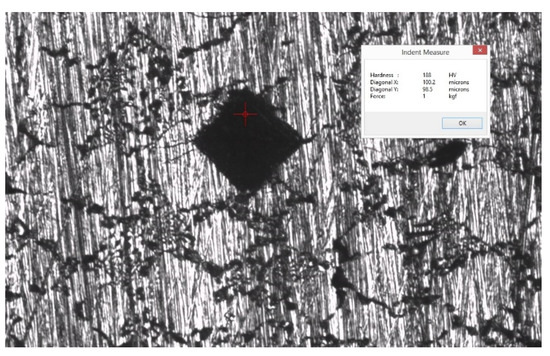

The micro-hardness values of behaviors of the Cu-SiC-Gr and Cu-WC-Gr hybrid composites in comparison to the base copper matrix are summarized in Figure 9 and Figure 10, respectively. It was found that the addition of hard and stiff reinforcements contributed to the improvement of the hardness of the copper composites. The microhardness value of the base alloy was found to be 128 HV. It is important to note that the maximum hardness value was observed in the case of 9 wt.% SiC-Gr and 9 wt.% WC-Gr composites in comparison to the base matrix. However, WC-Gr reinforced hybrid composites had more hardness value than the SiC-Gr composites. The Cu-9%SiC-1%Gr composites witnessed a microhardness value of 164 HV, whereas the Cu-9%WC%-1%Gr composites exhibited a value of 174 HV. Further, the Cu-9%SiC-1%Gr composites revealed an increment of 28% in comparison to the base alloy, whereas the Cu-9%WC-1%Gr had shown a 36% increase in hardness property. Both SiC and WC are considered to be hard constituents, and their further addition led to a significant enhancement of the hardness of the composites. Various factors resulted in the strengthening of the hybrid composites. Primarily, it is associated with the uniform distribution of the ceramics particulates in the soft copper matrix. Similarly, the hard reinforcements caused resistance to deformation during the indentation. Moreover, the interfacial strength of the SiC and WC with copper matrix improved the hardness properties of the composites by transferring the load to the reinforcement particles. The well-dispersed SiC and WC particles occupied the interstitial position in the copper alloy, therefore, restricting the local deformation and crack growth in the composites. A sample image of the indentation during the Vickers micro-hardness testing is presented in Figure 11. Several previous works of literature also reported similar results. Nageswaran et al. [14] examined the mechanical characteristics of the Copper hybrid composites reinforced with titanium dioxide and graphite produced through stir casting, which resulted in the enhancement of the hardness. Similarly, the Cu matrix reinforced with TiB2 particulates exhibited higher hardness due to the homogeneity in distribution with less porosity in the composites [23]. Moreover, the 10 wt.% silicon carbide reinforced Cu-Sn alloy composites witnessed the maximum enhancement of 50% (approx.) in the hardness behavior due to the Orowan strengthening and particle strengthening mechanism [24]. The Orowan mechanism is applicable in the case of the MMCs, where the reinforcements are nano and sub-micron levels. Similarly, Meher et al. [25] investigated the hardness properties of copper hybrid composites by powder metallurgy route. They reported that the Orowan mechanism had contributed more to the increase in the hardness behavior of the composites due to the less inter-particle spacing for the fine reinforcement particles.

Figure 9.

Variation of Vickers micro-hardness Cu alloy and Cu-(3, 6, 9) wt.% SiC-Gr hybrid composites.

Figure 10.

Variation of Vickers micro-hardness Cu alloy and Cu-(3, 6, 9) wt.% WC-Gr hybrid composites.

Figure 11.

Pyramid indentation during Vickers micro-hardness test.

3.4. Tensile Strength Analysis

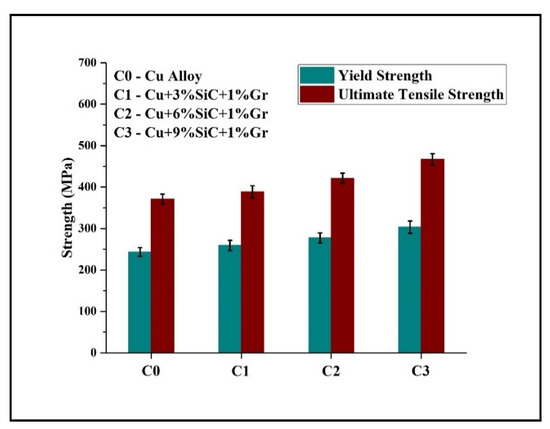

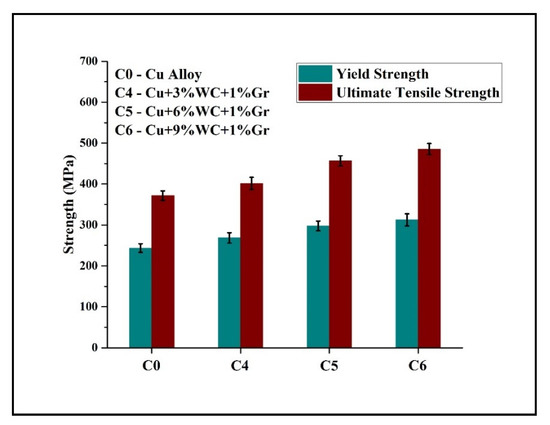

The effect of different reinforcements on copper alloy-based hybrid metal matrix composite on tensile stress-strain behavior is analyzed under ambient conditions. The tensile properties of the developed hybrid composites are analyzed in comparison with the base copper C87600 alloy matrix. The typical image of the tensile specimens before and after their fracture is presented in Figure 12. The variation of tensile strength of the Copper hybrid composite with the content of reinforcement is presented in Figure 13 and Figure 14. Both the ultimate tensile strength (UTS) and yield strength of the hybrid composites were measured and observed to be increased with an increase in the reinforcement content. The physical and mechanical properties of the reinforcement materials significantly influence the tensile strength of the developed material. The graph shows that the ultimate tensile and yield strength of the copper C87600 alloy is 371.5 MPa and 243.6 MPa, respectively. The addition of SiC ceramic particulate by 3, 6, and 9 wt.% along with 1 wt.% graphite increased the yield strength by 6.5, 13.7, and 24%. In contrast, the ultimate tensile strength is increased by 4.5, 13.4, and 26%, respectively, compared with the base copper C87600 alloy. It was found that the Cu-9%SiC-1%Gr hybrid composite displayed maximum yield strength of 303 MPa and ultimate tensile strength of 467 MPa. The ultimate tensile strength and yield strength of the Cu-9%SiC-1%Gr hybrid composites are increased by 26% and 24%, respectively, in comparison to the base copper alloy.

Figure 12.

Tensile specimen before and after tensile test.

Figure 13.

Variation of yield strength and ultimate tensile strength of Cu alloy and Cu-(3, 6, 9) wt.% SiC-Gr hybrid composites.

Figure 14.

Variation of yield strength and ultimate tensile strength of Cu alloy and Cu-(3, 6, 9) wt.% WC-Gr hybrid composites.

In the present study, Cu-9%WC-1%Gr showed the highest tensile strength among the developed composites. It is important to note that the tensile strength of WC-reinforced composites had shown relatively higher strength than the SiC-reinforced hybrid composites may be due to the better mechanical properties of the reinforcement used [26]. The ultimate tensile strength and yield strength of the materials increased by 30% and 28%, respectively, for the Cu-9%WC-1%Gr hybrid composites. Similarly, Cu-6%WC-1%Gr hybrid composites exhibited a 24% and 22% increment in the UTS, and yield strength was observed as compared with the base alloy. This improved mechanical strength of the hybrid composites is associated with excellent plastic strain-sustaining capability, which is increased by the higher interfacial bonding between the materials. Furthermore, adding these reinforcements hampers the dislocation motion by repulsive or attractive interactions, which is linked to strain hardening [27]. The mechanical properties of the copper hybrid composites consist of different concentrations of reinforcement, which are presented in Table 4. From these mechanical results, it could be concluded that adding the silicon carbide and tungsten carbide along with graphite particulates into the copper matrix alloy holds promise for improved tensile properties. The improvement in the tensile properties also indicates that the reinforcement particles exhibited great wettability with the molten copper alloy.

Table 4.

Mechanical Properties of Copper hybrid composites.

A significant increase in the strength of the materials is observed due to the transfer of tensile load from the ceramic reinforcement (SiC and WC) to the copper C87600 alloy matrix. Based on the continuum mechanics, the excellent bonding between the reinforcement and the matrix helps to enhance the tensile behavior of the materials. The yield strength of the materials is enhanced due to the discontinuously reinforced ceramic particulate based on the shear-lag model [28]. The theoretical yield strength of the developed composite () can be determined based on the theoretical strength of the matrix (), the volume fraction of the reinforcement () and aspect ratio of the ceramic particulate () shear-lag model, as shown in Equation (1) [29].

The yield strength and UTS of the composite materials also increased due to the presence of ceramic reinforcement acting as a resistance to plastic deformation and crack propagation [30]. An earlier study by Fenghong et al. [26] indicated that adding 10 wt.% SiC and 10 wt.% WC in the soft aluminum 6061 alloy matrix enhances the yield strength and UTS by 30.76% and 38%, respectively, with the reduction of maximum ductility by 86%. In the present study, it was experienced that the addition of 9 wt.% of SiC along with 1 wt.% of graphite enhanced the ultimate tensile strength by 26%, and the addition of 9 wt.% of WC along with 1 wt.% of graphite enhanced the ultimate tensile strength by 30%. Moreover, the thermal mismatch between the copper matrix and the ceramics reinforcements would probably be another reason for improving the tensile properties. The mismatch among the coefficients of thermal expansion (CTE) generates a rise in the dislocation density in the composites. Therefore, it resulted in prismatic punching of the dislocations at the interface, which led to the work-hardening of the composites [31]. The formation of these dislocation densities is proportional to the surface area of the reinforcement. The homogenous dispersion of the reinforcements tends to increase the surface area, resulting in higher work hardening in the fabricated composites.

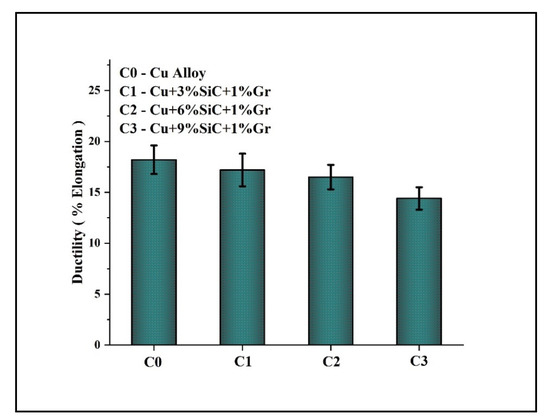

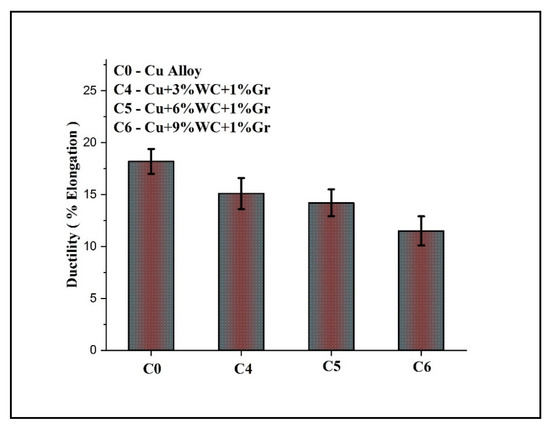

The introduction of ceramic reinforcement like SiC and WC in the copper C87600 alloy matrix enhanced the tensile properties of the materials; however, the ductility of the materials was reduced. The effect of ceramic reinforcement on the percentage elongation of the developed copper-based hybrid metal matrix composites is shown in Figure 15 and Figure 16. The base copper C87600 alloy showed a percentage elongation of 18.2%; however, by adding 9 wt.% SiC and 1 wt.% graphite to the copper matrix, the ductility of the materials is reduced to 14.4%. Similarly, the ductility of the materials is decreased to 11.5% for Cu-9%WC-1%Gr composites in comparison with the base copper alloy. The 9%SiC-1%Gr reinforced copper composites had witnessed a 21% reduction in the elongation percentage in comparison to the base alloy, whereas the decrease in the percentage elongation was found to be 36% for the Cu-9%WC-1%Gr composites. The addition of these hard and stiff particulates resulted in the increment of brittleness that subjected to the decline in the ductility of the composite. A higher decrease in ductility was observed by the addition of WC particulate as compared to SiC particulates. Similar results were also reported by Mengqi et al. [32], where the elongation percentage of the copper hybrid MMCs was linearly reduced with the higher reinforcement.

Figure 15.

Variation % elongation of Cu alloy and Cu-(3, 6, 9) wt.% SiC-Gr hybrid composites.

Figure 16.

Variation % elongation of Cu alloy and Cu-(3, 6, 9) wt.% WC-Gr hybrid composites.

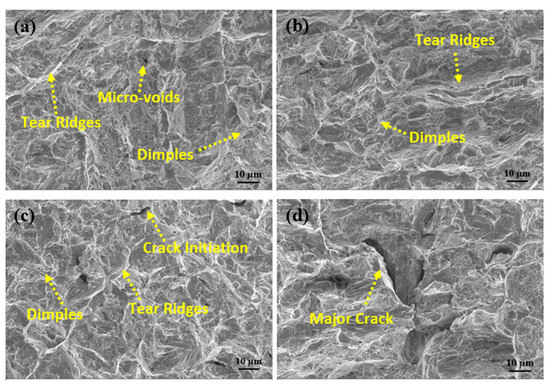

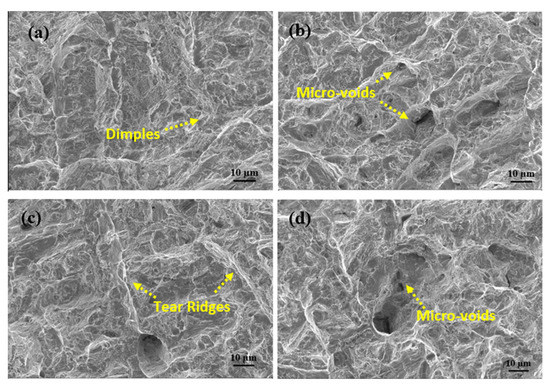

To characterize the tensile behavior, the fractured tensile surfaces of the Cu-SiC-Gr and Cu-WC-Gr hybrid composites were also analyzed through FESEM micrographs and are presented in Figure 17 and Figure 18, respectively. Generally, the ductile mode of fracture is characterized by the cup and cone structure, whereas a flat surface mechanism is associated with the brittle mode of fracture. Most fractography in this study shows small-sized dimples and micro-voids, indicating that the composites retained their ductile behavior up to a significant extent [33,34]. The micro-voids were the primary reason for the tensile failure as these became the crack initiation site during the testing. Moreover, the micro-voids were formed as a result of the higher reinforcement content, which became stress-intensity sites. As the tensile load gradually increased, these sites further experienced coalescence and growth, resulting in the propagation of cracks. This might have happened due to the lack of sites to release the strain energy. Moreover, there were not any signs of particle fracture as observed in the micrographs. The hybrid composites didn’t exhibit any form of cleavage facets that showed no or minimum quantity of brittle fracture.

Figure 17.

FESEM of tensile fractography surface of Cu alloy and Cu-(3, 6, 9) wt.% SiC-Gr hybrid composites.

Figure 18.

FESEM of tensile fractography surface of Cu alloy and Cu-(3, 6, 9) wt.% WC-Gr hybrid composites.

4. Conclusions

Copper alloy (C87600) matrix hybrid composites were successfully fabricated by stir casting using SiC-Gr and WC-Gr particles, from which the following conclusions are made:

- i.

- Homogenously dispersion of the reinforcement particulates was observed with the help of the optimum stirring action during the casting. Moreover, the elemental composition of the hybrid composites was also analyzed through EDX analysis.

- ii.

- Clear peaks of the SiC and WC were found along with the copper matrix from the XRD spectrum, which also indicated the successfulness of the casting process. Moreover, there were no intermetallic products observed between the copper and ceramic reinforcements.

- iii.

- The micro-hardness and tensile strength of copper hybrid MMCs were improved significantly with the incorporation of the SiC and WC particles along with graphite, which shows better interfacial bonding and wettability of the ceramic particulates with molten alloy.

- iv.

- The hybrid composites reinforced with WC particulates exhibited higher strength compared to SiC-reinforced composites.

- v.

- The tensile fractography was also characterized in the form of micro-dimples and tear-ridges, which shows that the hybrid composites retained their ductility to a significant extent.

Author Contributions

Conceptualization, P.S., H.T. and P.R.V.; methodology, P.S., H.T., A.M. and P.R.V.; formal analysis, P.S., H.T. and A.M.; investigation, P.S., H.T. and P.R.V.; resources, B.S. and P.R.V.; data curation, P.S. and H.T.; writing—original draft preparation, P.S., H.T. and A.M.; writing—review and editing, B.S. and P.R.V.; supervision, P.R.V.; project administration, P.R.V.; funding acquisition, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

The authors would like to express their great appreciation to the Head of the School of Mechanical Sciences, IIT Bhubaneswar for providing the experimental facility for the completion of this research work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Singh, N.; Belokar, R.M.; Walia, R.S. A Critical Review on Advanced Reinforcements and Base Materials on Hybrid Metal Matrix Composites. Silicon 2020, 14, 335–358. [Google Scholar] [CrossRef]

- Meher, A.; Mahapatra, M.M.; Samal, P.; Vundavilli, P.R. A review on manufacturability of magnesium matrix composites: Processing, tribology, joining, and machining. CIRP J. Manuf. Sci. Technol. 2022, 39, 134–158. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Mahato, A.; Mondal, S. Fabrication and Microstructure of Micro and Nano Silicon Carbide Reinforced Copper Metal Matrix Composites/Nanocomposites. Silicon 2020, 13, 1097–1105. [Google Scholar] [CrossRef]

- Jamwal, A.; Seth, P.P.; Kumar, D.; Agrawal, R.; Sadasivuni, K.K.; Gupta, P. Microstructural, tribological and compression behaviour of Copper matrix reinforced with Graphite-SiC hybrid composites. Mater. Chem. Phys. 2020, 251, 123090. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, Z.; Yao, P.; Fan, K.; Zhou, H.; Gong, T.; Zhao, L.; Deng, M. Mechanical and tribological behaviors of copper metal matrix composites for brake pads used in high-speed trains. Tribol. Int. 2018, 119, 585–592. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Su, Y.; Qu, Z. Synergetic strengthening effects on copper matrix induced by Al2O3 particle revealed from micro-scale mechanical deformation and microstructure evolutions. Ceram. Int. 2019, 45, 14889–14895. [Google Scholar] [CrossRef]

- Ramesh, C.; Ahmed, R.N.; Mujeebu, M.; Abdullah, M. Development and performance analysis of novel cast copper–SiC–Gr hybrid composites. Mater. Des. 2009, 30, 1957–1965. [Google Scholar] [CrossRef]

- Singh, M.K.; Gautam, R.K. Synthesis of Copper Metal Matrix Hybrid Composites Using Stir Casting Technique and Its Mechanical, Optical and Electrical Behaviours. Trans. Indian Inst. Met. 2017, 70, 2415–2428. [Google Scholar] [CrossRef]

- Liang, S.; Li, W.; Jiang, Y.; Cao, F.; Dong, G.; Xiao, P. Microstructures and properties of hybrid copper matrix composites reinforced by TiB whiskers and TiB2 particles. J. Alloy Compd. 2019, 797, 589–594. [Google Scholar] [CrossRef]

- Zhang, S.; Kang, H.; Li, R.; Zou, C.; Guo, E.; Chen, Z.; Wang, T. Microstructure evolution, electrical conductivity and mechanical properties of dual-scale Cu5Zr/ZrB2 particulate reinforced copper matrix composites. Mater. Sci. Eng. A 2019, 762, 138108. [Google Scholar] [CrossRef]

- Şap, S.; Turgut, A.; Uzun, M. Investigation of microstructure and mechanical properties of Cu/Ti–B–SiCp hybrid composites. Ceram. Int. 2021, 47, 29919–29929. [Google Scholar] [CrossRef]

- Yin, J.; Zhou, P.; Liang, H.; Yao, D.; Xia, Y.; Zuo, K.; Zeng, Y. Microstructure and Mechanical Properties of Cu Matrix Composites Reinforced by TiB2/TiN Ceramic Reinforcements. Acta Met. Sin. (Engl. Lett.) 2020, 33, 1609–1617. [Google Scholar] [CrossRef]

- Nageswaran, G.; Natarajan, S.; Ramkumar, K. Synthesis, structural characterization, mechanical and wear behaviour of Cu-TiO2-Gr hybrid composite through stir casting technique. J. Alloy Compd. 2018, 768, 733–741. [Google Scholar] [CrossRef]

- Singh, M.K.; Gautam, R.K.; Ji, G. Mechanical properties and corrosion behavior of copper based hybrid composites synthesized by stir casting. Results Phys. 2019, 13, 102319. [Google Scholar] [CrossRef]

- Bagheri, G. The effect of reinforcement percentages on properties of copper matrix composites reinforced with TiC particles. J. Alloy Compd. 2016, 676, 120–126. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H.; Dora, T.L. A review on fabrication methods, reinforcements and mechanical properties of aluminum matrix composites. J. Manuf. Process. 2020, 56, 1059–1074. [Google Scholar] [CrossRef]

- Bhoi, N.K.; Singh, H.; Pratap, S. Developments in the aluminum metal matrix composites reinforced by micro/nano particles—A review. J. Compos. Mater. 2019, 54, 813–833. [Google Scholar] [CrossRef]

- Jamwal, A.; Mittal, P.; Agrawal, R.; Gupta, S.; Kumar, D.; Sadasivuni, K.K.; Gupta, P. Towards sustainable copper matrix composites: Manufacturing routes with structural, mechanical, electrical and corrosion behaviour. J. Compos. Mater. 2020, 54, 2635–2649. [Google Scholar] [CrossRef]

- Samal, P.; Surekha, B.; Vundavilli, P.R. Experimental Investigations on Microstructure, Mechanical Behavior and Tribological analysis of AA5154/SiC Composites by Stir Casting. Silicon 2021, 14, 3317–3328. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Reinforcing effect of multi-walled carbon nanotubes on microstructure and mechanical behavior of AA5052 composites assisted by in-situ TiC particles. Ceram. Int. 2021, 48, 8245–8257. [Google Scholar] [CrossRef]

- Sadeghi, N.; Aghajani, H.; Akbarpour, M. Microstructure and tribological properties of in-situ TiC-C/Cu nanocomposites synthesized using different carbon sources (graphite, carbon nanotube and graphene) in the Cu-Ti-C system. Ceram. Int. 2018, 44, 22059–22067. [Google Scholar] [CrossRef]

- Ziemnicka-Sylwester, M. The Cu matrix cermets remarkably strengthened by TiB2 “in situ” synthesized via self-propagating high temperature synthesis. Mater. Des. 2014, 53, 758–765. [Google Scholar] [CrossRef]

- Radhika, N.; Karthik, R.; Gowtham, S.; Ramkumar, S. Synthesis of Cu-10Sn/SiC Metal Matrix Composites and Experimental Investigation of its Adhesive Wear Behaviour. Silicon 2018, 11, 345–354. [Google Scholar] [CrossRef]

- Meher, A.; Chaira, D. Effect of Graphite and SiC Addition into Cu and SiC Particle Size Effect on Fabrication of Cu–Graphite–SiC MMC by Powder Metallurgy. Trans. Indian Inst. Met. 2017, 70, 2047–2057. [Google Scholar] [CrossRef]

- Fenghong, C.; Chang, C.; Zhenyu, W.; Muthuramalingam, T.; Anbuchezhiyan, G. Effects of Silicon Carbide and Tungsten Carbide in Aluminium Metal Matrix Composites. Silicon 2019, 11, 2625–2632. [Google Scholar] [CrossRef]

- Sivasankaran, S.; Ramkumar, K.R.; Alaboodi, A. Strengthening Mechanisms on (Cu–10Zn)100−x–x wt.% Al2O3 (x = 0, 3, 6, 9 and 12) Nanocomposites Prepared by Mechanical Alloying and Vacuum Hot Pressing: Influence of Reinforcement Content. Trans. Indian Inst. Met. 2017, 70, 791–800. [Google Scholar] [CrossRef]

- Han, L.; Wang, J.; Chen, Y.; Huang, Y.; Liu, Y.; Wang, Z. Fabrication and mechanical properties of WC nanoparticle dispersion-strengthened copper. Mater. Sci. Eng. A 2021, 817, 141274. [Google Scholar] [CrossRef]

- Chen, F.; Chen, Z.; Mao, F.; Wang, T.; Cao, Z. TiB2 reinforced aluminum based in situ composites fabricated by stir casting. Mater. Sci. Eng. A 2015, 625, 357–368. [Google Scholar] [CrossRef]

- Meher, A.; Mahapatra, M.M.; Samal, P.; Vundavilli, P.R. Abrasive Wear Behaviour of TiB2 Reinforced In-Situ Synthesized Magnesium RZ5 Alloy based Metal Matrix Composites. Met. Mater. Int. 2020, 27, 3652–3665. [Google Scholar] [CrossRef]

- Akbarpour, M.; Salahi, E.; Hesari, F.A.; Simchi, A.; Kim, H. Fabrication, characterization and mechanical properties of hybrid composites of copper using the nanoparticulates of SiC and carbon nanotubes. Mater. Sci. Eng. A 2013, 572, 83–90. [Google Scholar] [CrossRef]

- Li, M.; Zhai, H.; Huang, Z.; Liu, X.; Zhou, Y.; Li, S.; Li, C. Tensile behavior and strengthening mechanism in ultrafine TiC0.5 particle reinforced Cu–Al matrix composites. J. Alloy Compd. 2015, 628, 186–194. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Influence of TiC on dry sliding wear and mechanical properties of in situ synthesized AA5052 metal matrix composites. J. Compos. Mater. 2019, 53, 4323–4336. [Google Scholar] [CrossRef]

- Feng, J.; Tao, J.; Liu, Y.; Bao, R.; Li, F.; Fang, D.; Li, C.; Yi, J. Optimization of the mechanical properties of CNTs/Cu composite by regulating the size of interfacial TiC. Ceram. Int. 2022, 48, 26716–26724. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).